Walrus Pump Co., Ltd. HQ Series, HQ200, HQ400, HQ800, HQ800H Instruction Manual

HQ Series

Electronic Control Pump

Instruction Manual

“Original Instructions”

HQ Series

ISO 9001 Certified

WALRUS PUMP CO., LTD.

EC Declaration of Conformity

Manufacturer:

Walrus Pump Co., Ltd.

Address:

No.83-14, Dapiantou, Sanzhi Dist., New Taipei City 252, Taiwan

Declare that the machinery described:

Name : Water Pump

Model : HQ Series

Conform to the following directive:

2006/42/EC—Machinery directive

2014/35/EU —Low voltage directive

2014/30/EU—EMC (Electromagnetic compatibility) directive

Refer to the following standards:

EN ISO 12100:2010 EN ISO 13857:2008

EN 809:1998+A1:2009

EN 60335-1:2012 EN 60335-2-41:2003

EN 61000-6-2:2005 EN 61000-6-3:2007

R&D department manager: Kao Tien-chuan

Manager:

~ 1 ~

HQ Series Instruction Manual

Please read all instructions carefully before installing your new systems, as failures caused by

incorrect installation or operation are not covered by the warranty.

I. Product

The HQ series are designed for the pumping of non-aggressive water, or water not containing solid

particles.

II. Operating conditions:

1. Ambient temp. : Max. +40ºC (104ºF)

2. Liquid temp. : +4ºC(39ºF) ~ +40ºC(104ºF)Max.

3. System pressure: Max. 8.5kg/cm² (121 PSI)

4. Relative humidity: Max. 85%(RH)

5. Indoor Use Only

6. The max head :

III. Installation

1.The pump foundation should be rigid enough to absorb any vibration from the motor, and the

pump should be securely bolted to the foundation.

2. It is recommended that the plumber/installer provides an adequate draining system to avoid

damage in case of leakage, particularly when installed indoors. When it is installed outside, it

should be covered by a weather-proof housing, well ventilated to allow motor heat to escape.

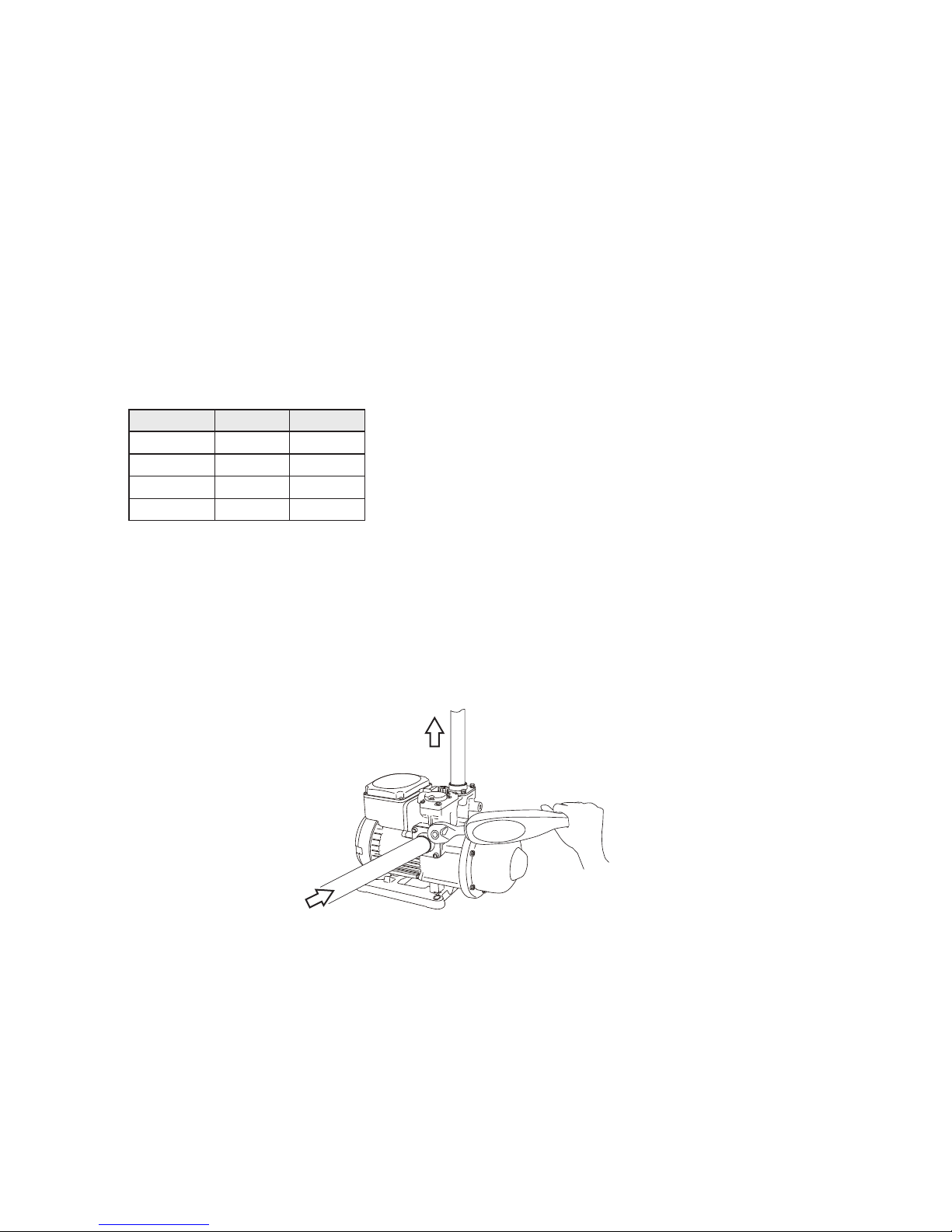

3. Connect the suction pipe to the side and discharge pipe on the top.( See Fig 1 )

4. When it is installed with water heater, a check valve should be installed between pump

(discharge) pipeline and water heater (suction) to avoid high-pressure steam backflow.

5. It is required to shut off the pump when the liquid source is unavailable; although it has the dry

run cut off function.

6. To avoid your furniture damage, do not install the pump on ceiling, carpet or any place close to

electrical appliance, outdoor installation must covered by tent.

7. The electrical connection should be carried out in accordance with local regulations. The

operating voltage and frequency are marked on the nameplate. Please make sure that these data

match with your job requirement. For your safety, be sure the Residual current device (RCD,

30mA) is in your system and grounding is properly connected to prevent from electric shock.

~ 2 ~

60Hz

23m

26m

27m

45m

50Hz

24m

31m

33m

-

Model

HQ200

HQ400

HQ800

HQ800H

Fig. 1

Discharge

Flange Bolt Torque :

20~25 kgf-cm

25

kg-cm

Suction

Loading...

Loading...