Walrus Pump TQCN200, TQCN800, TQCN400, TQCN1500, TQCN2200 Instruction Manual

ISO 9001 Certied

50Hz

Walrus Pump Co., Ltd.

TQCN Series

Instruction Manual

HOT WATER PUMP

TQCN Series

EC Declaration of Conformity

Manufacturer:

Walrus Pump Co., Ltd.

Address:

No.83-14, Dapiantou, Sanzhi Dist., New Taipei City 252, Taiwan

Declare that the machinery described:

Name : Water Pump

Model : TQCN Series

Conform to the following directive:

2006/42/EC—Machinery directive

2006/95/EC—Low voltage directive

2004/108/EC—EMC (Electromagnetic compatibility) directive

Refer to the following standards:

EN ISO 12100:2010 EN ISO 13857:2008

EN 809:1998+A1:2009

EN 60335-1:2012 EN 60335-2-41:2003

EN 61000-6-2:2005 EN 61000-6-3:2007

R&D department manager: Kao Tien-chuan

Manager:

~ 1 ~

TQCN Series Instruction Manual

Before beginning installation procedures, these

installation and operating instructions should be

read carefully.

I. Applications:

This TQCN Series are designed for hot water

supply (up to +90°C) and pressure boosting in

residential and commercial applications.

They are suitable for solar energy hot water

system or other types of hot water systems.

II. Operating conditions:

1. Ambient temperature: Max. +40°C

2. Liquid temperature: +4°C ~ +90°C

3. Relief pressure value automatically : 5kg/cm²

4. Relative humidity: Max. 85% (RH)

III. Installation

1.The pump foundation should be rigid enough

to absorb any vibration from the motor, and

the pump should be securely bolted to the

foundation.

2. It is recommended that the plumber/installer

provides an adequate draining system to

avoid damage in case of leakage, particularly when installed indoors. When it is

installed outside, it should be covered by a

weather-proof housing, well ventilated to

allow motor heat to escape.

3. The pump should be installed as close as

possible to the liquid source.

4. When use with water heaters, a check valve

should be installed between pump

(discharge) pipeline and water heater

(suction) to avoid high-pressure steam

backflow.

5. It is recommended to shut off the pump

when the liquid source is unavailable;

although it has the dry run cut off function.

6. The pump has a built-in check valve. Please

do not install any other valve on the suction.

7. TO avoid your furniture damage, do not

install the pump on ceiling, carpet or any

place close to electrical appliance, outdoor

installation must covered by tent.

IV. Piping

1. The suction line should be installed as short

and straight as possible, with a minimum of

bends. The internal diameter of the suction

pipe must be equal to, or greater than the

ports of the pump.

2. The connection between the suction line and

pump must be airtight, and the suction pipe

must be positioned so it has an upward

slope to the pump (thus avoiding the

formation of air pockets).

3. When used on a suction lift, a foot valve

should be fitted on the suction line, below

the liquid level.

4. If hose is used as the suction pipe, it must

be non-collapsible.

5. To minimize pressure drop, the discharge

pipe should be at least the same size as the

discharge port of the pump.

6. For long suction pipes or high suction lifts

over 13 ft, the suction pipe should be of

greater diameter than the suction port.

7. Ensure all connections are completely

sealed using thread tape only.

V. Electrical connection

This mark located outside the

connection box is a warning for an

electrical hazard.

1. Ensure the mains voltage is the same as the

value shown on the motor plate and that the

pump is safely connected to ground/earth.

2. The single phase models are supplied with

plug and lead and can be connected directly

to the mains supply. The 3 phase models

should hook up with a circuit breaker.

VI. Wiring diagram

WARNING:

Risk of Electric Shock - This pump is

supplied with a grounding conductor and

grounding-type attachment plug. To reduce

the risk of electric shock, be certain that it

is connected only to a properly grounded,

grounding-type receptacle".

Before operation, please ensure the voltage is

correct and the circuit breaker and grounding

connectors are all connected in accordance

with local regulations.

~ 2 ~

L2

Input power

Grounding

L1

L2

Input power

Grounding

L3

L1

Single-phase power supply

3-phase power supply (check if rotation is correct)

Fig. 1

VII. Starting

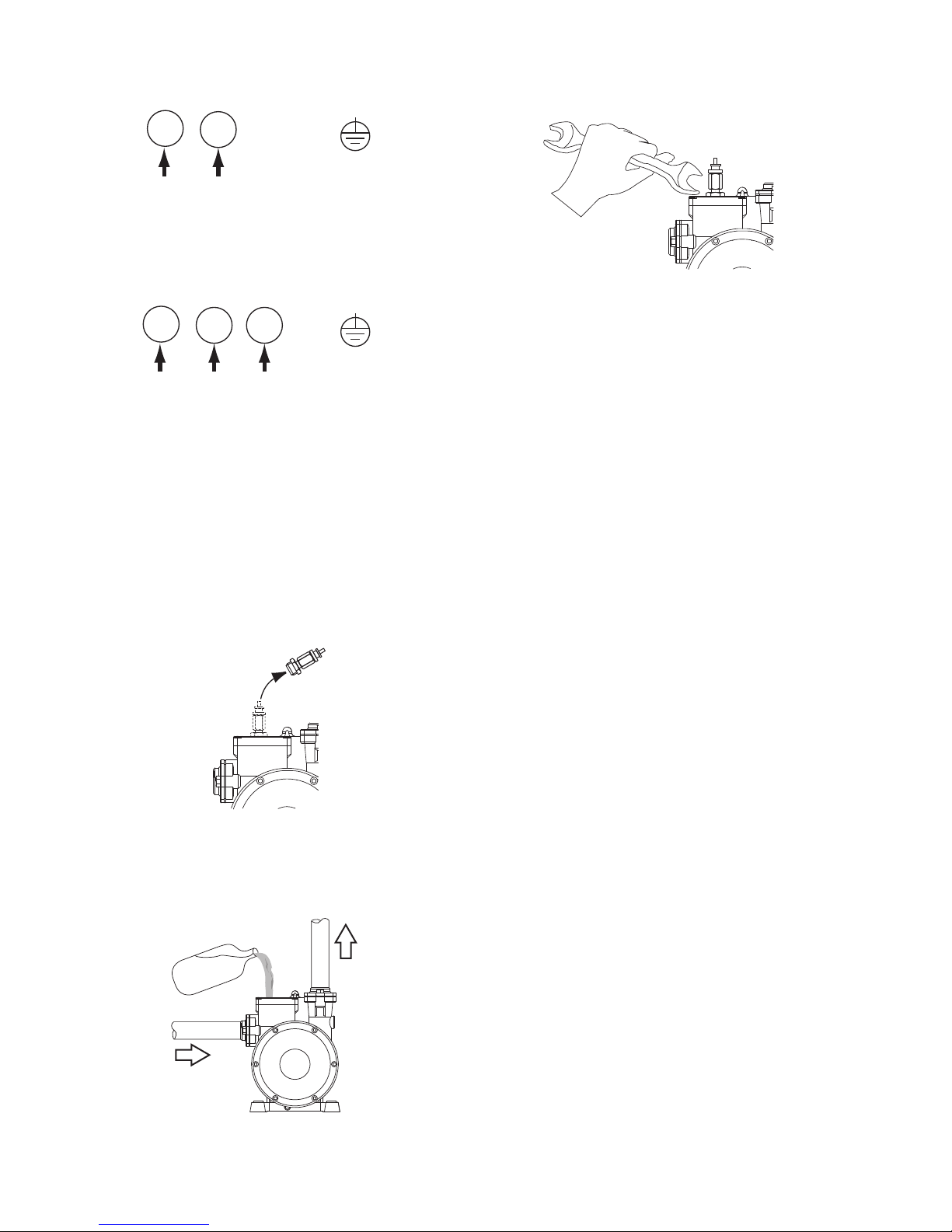

1. Before starting, the pump must be primed.

Please follow the procedure as shown in Fig 2.

a. Remove the filling plug

b. Fill water in chamber

Water

c. Replace the filling plug

Fig. 2

2. Installation where the pump inlet is below

the water supply, remove the priming plug

and allow the water to flow into the priming

chamber until all air is expelled.

3. The priming procedure should be repeated

until all air is expelled and the pump delivers

a full stream of water without air bubbles.

4. The pump must always be checked for

prime if not used for a prolonged period. It is

imperative to fill the pump with liquid before

operation as dry running causes irreparable

damage to the mechanical seal.

5. When 3-phase motor is supplied, please

ensure if the rotation is correct. You can

switch any of the 2 wires to get your desired

rotation.

VIII. Precautions

1. The pump should be shut down and the

trouble corrected if the pump is running at

speed and found to have any of the following

problems:

- No liquid discharged - Not enough liquid

discharged

- Excessive vibration - Motor runs hot

2. Do not allow the pump to continually start

and stop (cycling) as this will reduce the

motor life.

3. Cycling can occur on pressure units when

the pressure tank pre-charge drops, or

where there is a leak in the discharge

plumbing.

~ 3 ~

Suction

Discharge

Loading...

Loading...