Walrus TQ200, TQ400, TQ800, TQ1500, TQ3700 Instruction Manual

...

Walrus America Inc

TQ Series

TQ Series

Instruction Manual

Electronic Control Pump

TQ Series

TQ Series

ISO 9001 Certified

®

234867

9808 Whithorn Drive, Houston, TX 77095

Web: www.walruspumps.com

Limited Warranty

Products manufactured by Walrus Pumps Co (Walrus) are warranted to the first user only

to be free of defects in material and workmanship for a period of 12 months from date of

installation, but no more than 24 months from date of shipment. Walrus' liability under this

warranty shall be limited to repairing or replacing at our election, without charge, FOB

Walrus' distribution center or authorized service agent. Walrus will not be liable for any

cost of removal, installation, transportation or any other charges that may arise in

connection with warranty claim.

The warranty period commences on the date of original purchase of the equipment. Proof

of purchase and installation date, failure date, and supporting installation data must be

provided when claiming repairs under warranty.

This warranty is subject to due compliance by the original purchaser with all directions and

conditions set out in the installation and operating instructions. Failure to comply with

these instructions, damage or breakdown caused by fair wear and tear, negligence, misuse,

incorrect installation, inappropriate chemicals or additives in the water, inadequate

protection against freezing, rain or other adverse weather conditions, corrosive or abrasive

water, lightning or high voltage spikes or through unauthorized persons attempting repairs

are not covered under warranty.

Walrus will not be liable for any incidental or consequential damages, losses, or expenses,

arising from installation, use, or any other causes. There are no express or implied

warranties, including merchantability or fitness for a particular purpose, which extend

beyond those warranties described or referred to above.

Certain states do not permit the exclusion or limitation of incidental or consequential

damages or the placing of limitations on the duration of an implied warranty, therefore, the

limitations or exclusions herein may not apply. This warranty sets forth specific legal rights

and obligations, however, additional rights may exist, which may vary from state to state.

Supersedes all previous publications

Walrus America Inc

P099C019U200-01

®

G2

EC Declaration of Conformity

Manufacturer:

Walrus Pump Co., Ltd.

Address:

No. 83 -14, Dapiantou, Sanjhih Township, Taipei County 252,

Taiwan

Declare that the machinery described:

Name : Water Pump

Model : TQ Series

Conform to the following directive:

98/37/EC-----Machinery directive

2006/95/EC—Low voltage directive

2004/108/EC----EMC (Electromagnetic compatibility) directive

Refer to the following standards:

EN ISO 12100-1:2003 EN ISO 12100-2:2003

EN1050:1996

EN60335-1:2001 EN 809:1998

EN60335-2-41:2001

EN61000-6-2 EN61000-6-3

R&D department manager: Kao Tien-chuan

Manager:

~ 1 ~

TQ Series Instruction Manual

Please read all instructions carefully before

installing your new systems, as failures caused

by incorrect installation or operation are not

covered by the warranty.

I. Product

The TQ series are designed for the pumping of

non-aggressive water, or water not containing

solid particles.

II. Operating conditions:

1. Ambient temp. : Max. +104ºF (40ºC)

2. Liquid temp. : +39ºF(4ºC) ~ +104ºF(40ºC)Max.

3. System pressure: Max. 120 PSI

4. Relative humidity: Max. 85%(RH)

III. Installation

1.The pump foundation should be rigid enough

to absorb any vibration from the motor, and

the pump should be securely bolted to the

foundation.

2. It is recommended that the plumber/installer

provides an adequate draining system to

avoid damage in case of leakage, particularly when installed indoors. When it is

installed outside, it should be covered by a

weather-proof housing, well ventilated to

allow motor heat to escape.

3. The pump should be installed with horizontal

suction port and vertical discharge port; and

as close as possible to the liquid source.

4. When use with water heaters, a check valve

should be installed between pump

(discharge) pipeline and water heater

(suction) to avoid high-pressure steam

backflow.

5. It is required to shut off the pump when the

liquid source is unavailable; although it has

the dry run cut off function.

6. The pump has a built-in check valve. Please

do not install any other valve on the suction.

7. For TQ1500/2200/3700, Please cut out the

center of the rubber gasket inside the inlet

and outlet flanges as it will block the water

flow.

~ 2 ~

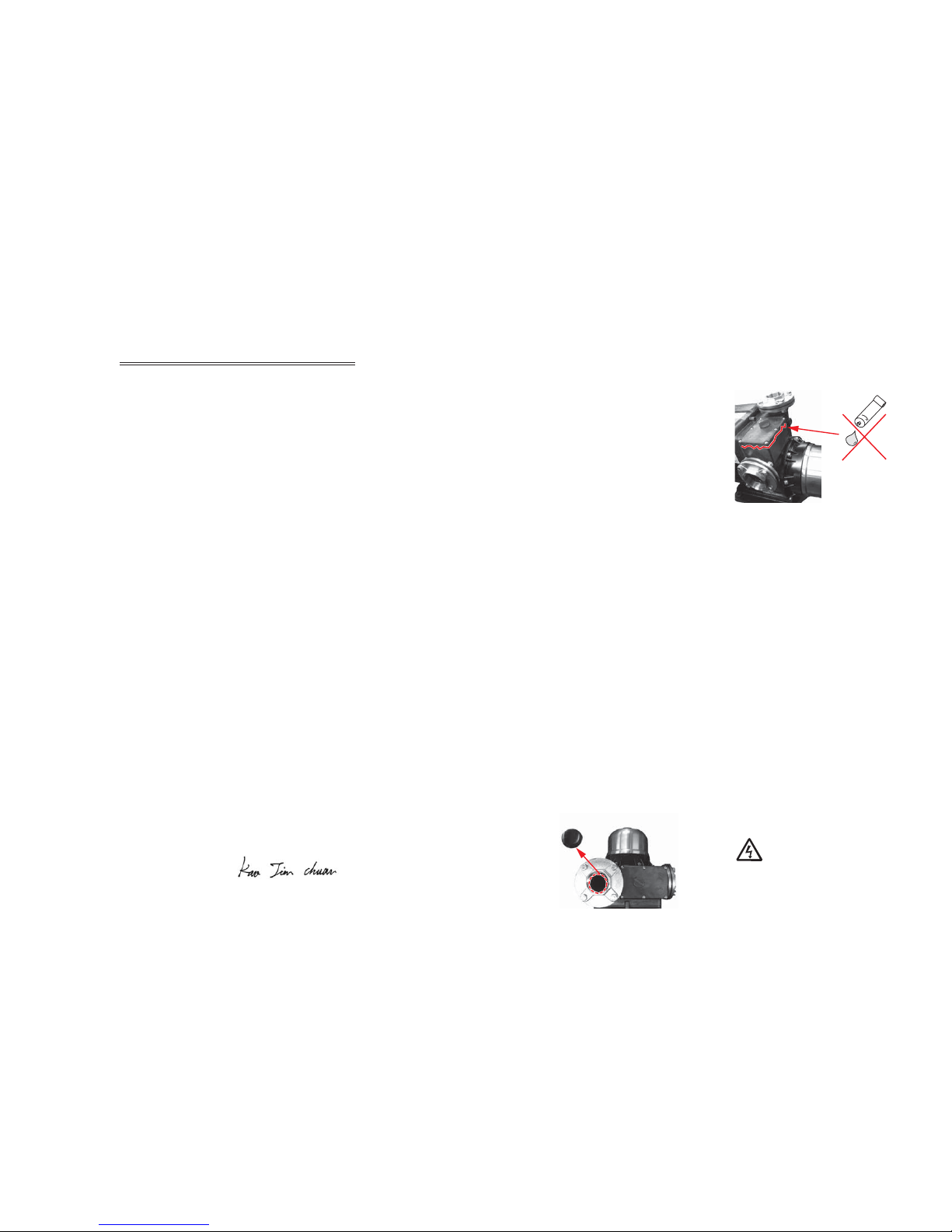

8. When performing regular maintenance, the

prime cover has to open in order to check

the condition of the check valve. DO NOT

apply any bonded material (such as silicon,

glue etc) to seal the chamber cover (see

drawing below).

IV. Piping

1. The suction line should be installed as short

and straight as possible, with a minimum of

bends. The internal diameter of the suction

pipe must be equal to, or greater than the

ports of the pump.

2. The connection between the suction line and

pump must be airtight, and the suction pipe

must be positioned so it has an upward

slope to the pump (thus avoiding the

formation of air pockets).

3. When used on a suction lift, a foot valve

should be fitted on the suction line, below

the liquid level.

4. If hose is used as the suction pipe, it must

be non-collapsible.

5. To minimize pressure drop, the discharge

pipe should be at least the same size as the

discharge port of the pump.

6. For long suction pipes or high suction lifts

over 13 ft, the suction pipe should be of

greater diameter than the suction port.

7. Ensure all connections are completely

sealed using thread tape only.

V. Electrical connection

This mark located outside the

connection box is a warning for an

electrical hazard.

1. Ensure the mains voltage is the same as the

value shown on the motor plate and that the

pump is safely connected to ground/earth.

Loading...

Loading...