Walrus TPRK 1T 60Hz Series, TPRK 1T 50Hz Series, TPRK 3T 50Hz Series, TPRK 5T 50Hz Series, TPRK1T 17-17 Instruction Manual

...

TPRK Series

Immersible Pump

Instruction Manual

ISO 9001 Certified

Walrus Pump Co., Ltd.

EC Declaration of Conformity

Manufacturer:

Walrus Pump Co., Ltd.

Address:

No.83-14, Dapiantou, Sanzhi Dist., New Taipei City 252, Taiwan

Declare that the machinery described:

Name : Water Pump

Model : TPRK Series

Conform to the following directive:

2006/42/EC—Machinery directive

2014/35/EU—Low voltage directive

2014/30/EU—EMC (Electromagnetic compatibility) directive

Refer to the following standards:

EN ISO 12100:2010 EN ISO 13857:2008

EN 809:1998+A1:2009 EN 60204-1:2006

EN 60335-1:2002 EN 60335-2-41:2003+A2:2012

EN 61000-6-2:2005 EN 61000-6-3:2007

R&D department manager: Kao Tien-chuan

Manager:

~ 2 ~

Please read this installation and

operating instructions carefully

before beginning installation and

operation.

1. Application

1.1 The TPRK Series is multi-stage centrifugal

pump designed for transf erring liquid

used in machine tools.

1.2 The pump can not be used to transfer

explosive liquids,such as gasoline,

diesel oil and other similar liquids.

It is only suitable for water diluted,

low viscosity, uncorrosive cooling or

lubricant liquids.

2. Model Explanation

The pump models are coded based on the

number of pump stages. Standard stages

consist of both diusers and impellers,

and null stages, for special installation

considerations, contain diuser chamber

only. The pump model is shown on the pump

nameplate.

TPRK 1T 23 - 23

E

Drain back tank structure

Number of Impellers

Number of diffuser

Standard capacity m

Model code

3

/h

3. Technical Data

1. Liquid Temperature : +0°C~+90°C

2. Ambient Temperature : Max.+40°C

3. Enclosure Class: IP54

4. Discharge Pressure: Max. 25kg/cm²

5. Submerged depth : Min. 40mm

6. Stainer Diameter: Ø2mm

7. Particle Size: 2mm

8. Liquids(maximum content of solid

particles in suspension 50g/m³)

9. Kinematical Viscosity: 32 cst (mm²/s)

10. Head: 50Hz : Up to 240M

60Hz : Up to 240M

4. Installation

The pump has hot surface on the

motor. It must be installed so that

persons cannot accidentally come

into contact the hot surface.

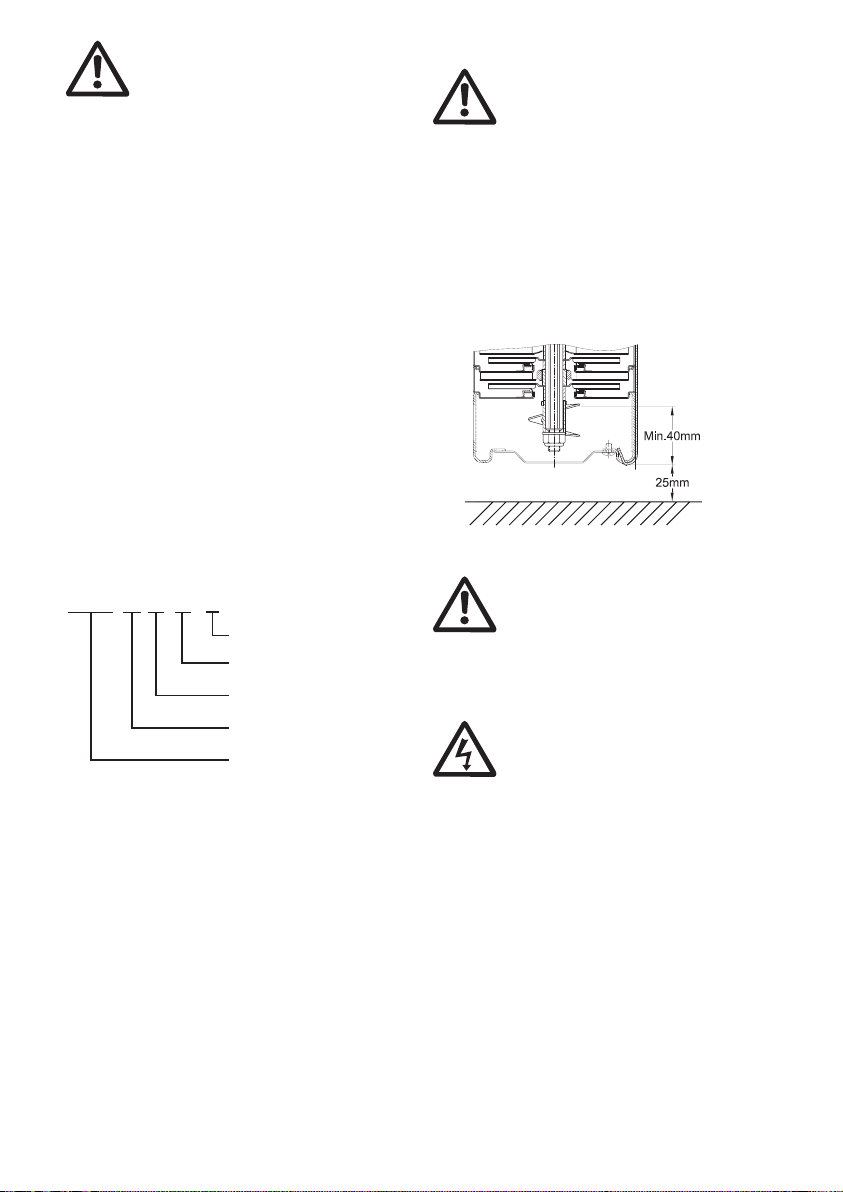

4.1. Submerged Depth

To avoid dry running and damage the pump

during operation, the minimum pump

submerged depth is 40mm as shown in Fig 1.

In addition, the bottom of the pump suction

inlet must be at least 25 mm above the

bottom of the tank.

Fig.1

5. Electrical Connection

5.1 The electrical connection should

be carried out in accordance

with local regulations. Never

make any connections unless

the electricity supply has been

switched o .

5.2. The electrical hazard warning

mark is placed outside the

connection box. Be careful.

5.3. Electrical data (voltage and frequency)

are shown on the pump nameplate.

Ver ify if these data match your

electricity supply. A Residual current

device (RCD, 30mA) should be installed

and the grounding be properly

connected for your safety.

5.4. Motors must be connected to a motor-

protective circuit breaker which can be

manually reset. Set the motor-protective

circuit breaker according to the rated

current of the motor. See nameplate.

5.5. Make electrical connection in accordance

~ 3 ~

Loading...

Loading...