Walrus TPH2T5K, TPH 2T2K, TPH4T2K, TPH2T4K, TPH4T3K Instruction Manual

...

TPH Series

MULTISTAGE CENTRIFUGAL PUMP

Instruction Manual

ISO 9001 Certied

WALRUS PUMP CO., LTD.

NSF/ANSI 372

~ 2 ~

EC Declaration of Conformity

Manufacturer:

Walrus Pump Co., Ltd.

Address:

No.83-14, Dapiantou, Sanzhi Dist., New Taipei City 252, Taiwan

Declare that the machinery described:

Name : Water Pump

Model : TPH Series

Conform to the following directive:

2006/42/EC—Machinery directive

2014/35/EU—Low voltage directive

2014/30/EU—EMC (Electromagnetic compatibility) directive

Refer to the following standards:

EN ISO 12100:2010 EN ISO 13857:2008

EN 809:1998+A1:2009 EN 60204-1:2006

EN 60335-1:2012 EN 60335-2-41:2003

EN 61000-6-2:2005 EN 61000-6-3:2007

R&D department manager: Kao Tien-chuan

Manager:

~ 3 ~

TPH Instruction Manual

Please study all instructions carefully before

installing your new system, as failures caused

by incorrect installation and operation are not

covered by the warranty.

1. General Data:

1.1 Applications

The TPH Series are modernly designed with quiet and

high ecient operation pumps, suitable for dependable

water transfer, circulating or booster service. It works for

clean or other liquids without abrasive matters.

-Industrial circulation system

-Washing/cleaning system

-Pressure boosting system

-Water/liquid transfer

-Agricultural irrigation

-Air-conditioning

1.2 Pump Construction:

Horizontal multi-stage centrifugal pump, non selfpriming, co-axial pump/motor design, impellers

mounted on extended motor shaft. All parts in

contact with the pumped liquid are made of

stainless steel.

1.3 Operation conditions:

1. Ambient temperature: Max. 40°C

2. Liquid temperature range: 0°C to 90°C

3. Operating pressure: Max. 10 kg/cm²

4. Inlet pressure: Max. 6 kg/cm²

5. Head: 50Hz : Up to 70M

60Hz : Up to 80M

1.4 Applications

TPH pumps are horizontal, multistage centrifugal pumps

for the pumping of clean, thin and non-explosive liquids,

not containing solid particles or fibres that may attack

the pump mechanically or chemically.

The pump must not be used for the transfer of ammable

or toxic liquids.

2. Installation and piping

2.1 Installation site

2.1.1 For secure operation, please mount and bolt

the pump base to the foundation.

2.1.2 Select a dry and good ventilated site and

provide accessible space around the pump

for future maintenance and service.

2.1.3 Make sure the ambient temperature is

below 40°C(104°F) and the flowing liquid

temperature does not exceed 90°C(194°F) .

2.1.4 Do not operate the pump under explosive

environment.

2.1.5 Horizontal installation is recommended.

When it is installed in other positions, please

provide drain holes to allow drainage of the

pump.

2.1.6 Indoor: TO avoid your furniture damage, do

not install the pump on ceiling, carpet or any

place close to electrical appliance, and also

must provide drain hole.

2.1.7 Outdoor: When the pump is installed outside,

please provide a suitable cover to protect it

from weather and frost. Please do not allow

any foreign objects fall into the motor fan

cover.

2.2 Electrical connection

2.2.1

This mark located outside the connection

box is a warning for an electrical hazard.

2.2.2 The electrical connection should be carried

out in accordance with local regulations. The

operating voltage and frequency are marked

on the nameplate. Please make sure that

these data match with your job requirement.

For your safety, be sure the Residual current

device (RCD, 30mA) is in your system and

grounding is properly connected to prevent

from electric shock.

2.2.3 Motors must be connected to a motorprotective circuit breaker which can be

manually reset. Set the motor-protective

circuit breaker according to the rated current

of the motor. See nameplate.

2.2.4 Three phase motors must be connected to

a motor starter for protection of overload

and single phase running. Please be sure if

the direction of rotation is correct. For three

phase motor you can reverse the direction

of rotation by interchanging any two of

the incoming supply wires. Before your

first operation, please place a allen wrench

against the shaft at motor end and turn by

the direction of rotation to see if rotor spins

freely.

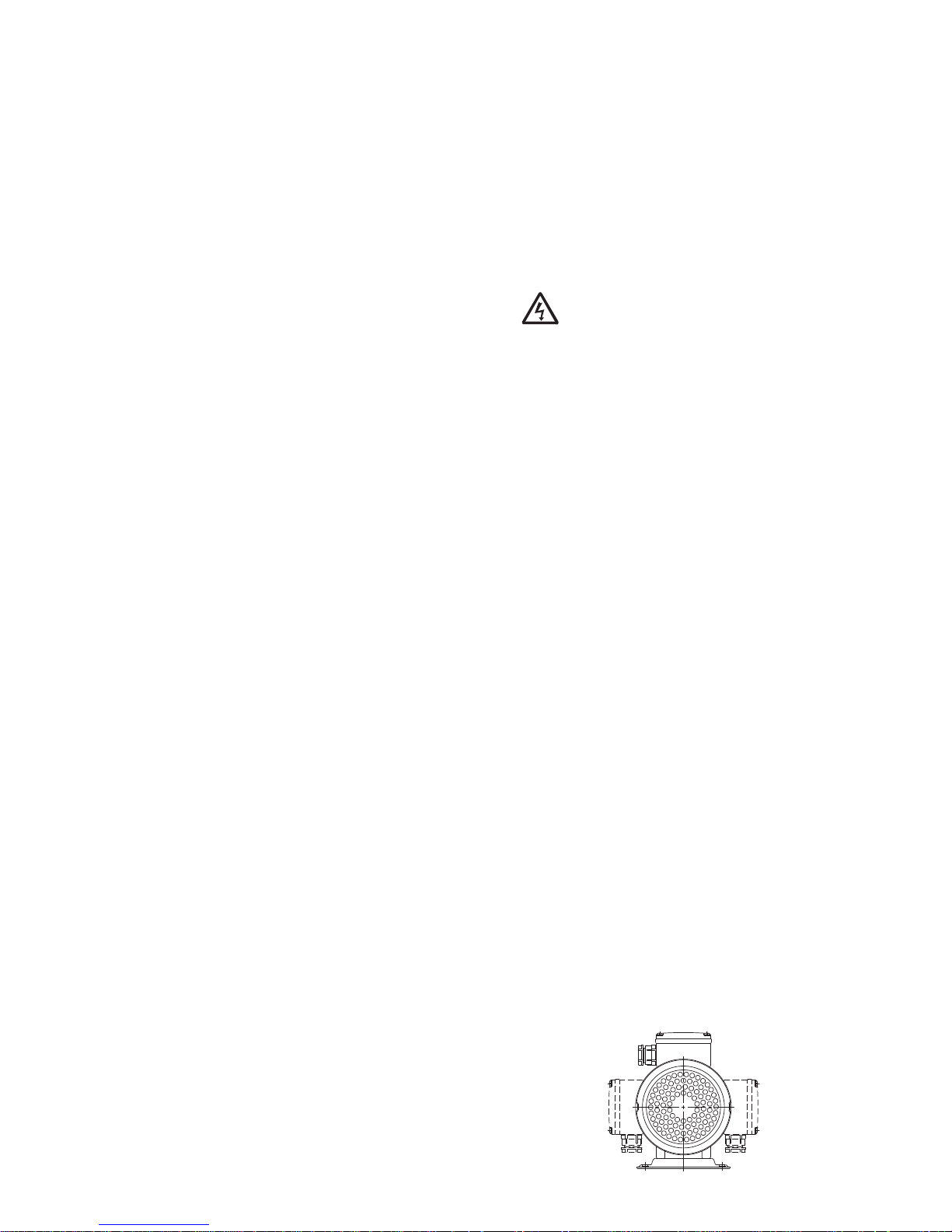

2.2.5 The position of the connection box is

adjustable. It can be turned either side before

the pump is installed. The preset position

from the factory is on the top of the motor.

To change the position of the connection

box, please remove the bolts on the motor

frame (4 bolts which are bolted into the

chamber) and turn the stator housing to the

required position. Replace the screws and

tighten securely.

Fig.1

Loading...

Loading...