Walrus TP8-P Series, TP825P, TP820P, TP820PT, TP825PT Instruction Manual

WALRUS PUMP CO., LTD.

Instruction Manual

Automatic Booster Pump

TP8-P Series

TP8-P Series

ISO 9001 Certied

Operation Conditions:

1. Ambient temperature: Max. +40°C

2. Liquid temperature: +4°C ~ +40°C

3. Inlet pressure: Lower than the pressure

switch ON setting. ( See Specication )

4. Operating pressure: Max. 6 kg/cm²

OPERATION

1. Make sure connect the correct voltage.

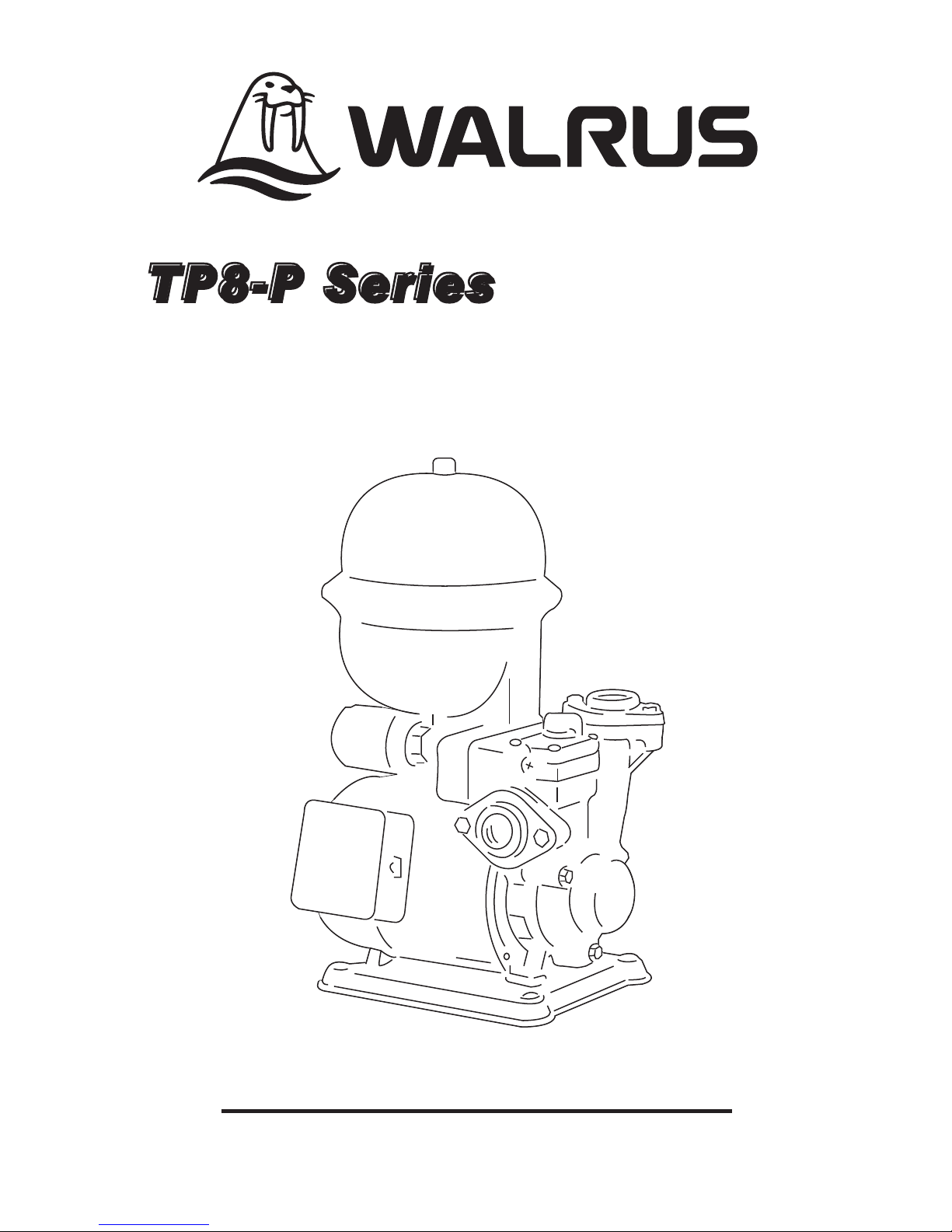

2. Remove the water plug and pour water into

the pump and suction piping ,then secure

the plug.( FIG.1 )

In suction lift application, please follow below

instruction ll up water to the chamber

1. Remove 4 screws and water cover

2. Remove check valve

3. Fill up water

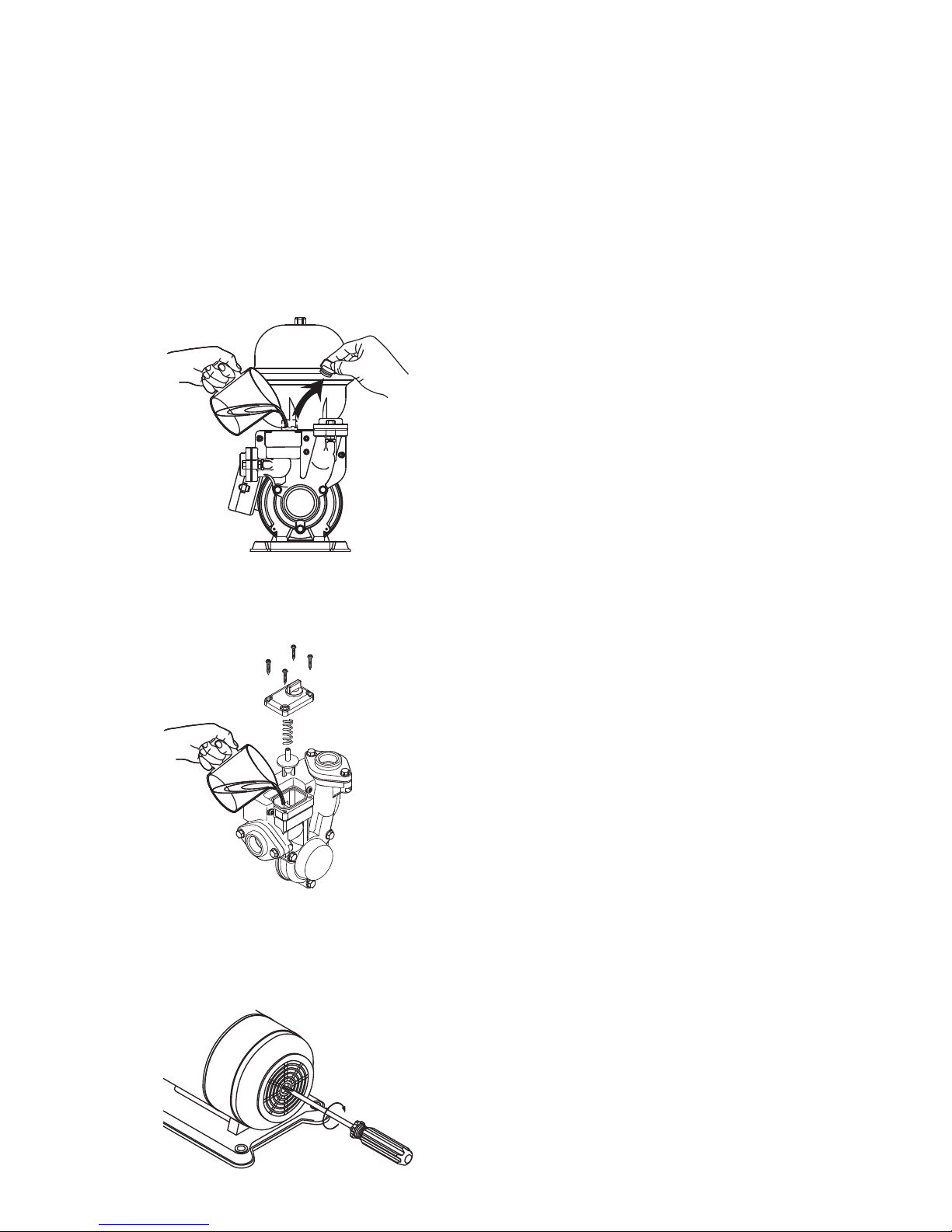

3. Insert a screw driver cross into the shaft slot ,

and turns the shaft 2-3 rounds to check if the

pump runs normally , then open one faucet

on the delivery side , the turn the power

switch ON.( FIG.3 )

4. After the power switch on, the motor

should turn immediately . After a few

seconds, the water should be delivered .

5. If the water does not be delivered immediately turn the power OFF. Repeat step 2 and

set power ON/OFF continuously to make

the suction piping be lled with water.

6. Once the water is pumped out, close the

faucets on the delivery side to check the

automatic stopping and pumping operation.

IMPORTANT NOTE

1. Use the correct voltage and wiring by the

connecting diagram. Motor must be

grounded in compliance with applicable

electrical code to avoid accident.

2. please use a sturdy foundation and bolt the

pump to it securely.

3. Be sure to arrange earthling or circuit

breaker against electric leakage.

4. The pump should be installed as close as to

the reservoir or well to avoid the low

eciency due to the long suction pipe.

5. The location must be dry with good ventila-

tion and adequate space.

6. Do not run without water actually pump-

ing. Do not operate hot water (more than

60 °C ), or the other liquid except normal

water.

7. Be careful not to allow the foreign matter

(chips, dirt, sand, glue, etc) into the pump,

or the will damage and shorten the life of

pump.

8. Piping joints should be tted carefully to

prevent leakage.

a. Leakage in the suction piping will cause

the pump does not function well.

b. Leakage in the discharge piping will

cause a high frequency ON /OFF motor

operation while all the faucet and valves

are closed.

9. Keep the faucets opened fully to get more

ecient operation. Never keep continuous

operation under the condition of half open.

10. TO avoid your furniture damage, do not

install the pump on ceiling, carpet or any

place close to electrical appliance, outdoor

installation must covered by tent.

FIG.2

FIG.1

FIG.3

Loading...

Loading...