Wallstar HRM Handbook

20/2415/1912/14

SYSTEMSTANDARD

24/18

COMBI

Your Boiler Serial Number is:

to be found on the Burner Cover.

WALLSTAR

CONDENSING

HANDBOOK AND SERVICE LOG

The code of practice for the

installation, commissioning, and

servicing of oil central heating

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

1

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

DESCRIPTION

PAGE

Householder Information

Warranty Registration Document End Of Manual

Warranty 3

Extended Warranty 3

After Sales Service 3

Boiler Controls: Wallstar 4

System Wallstar 5

Wallstar Combi 6-7

Burner Lockout 8

Technical Specifications

Boiler Dimensions: Wallstar 9

Boiler Dimensions: System Wallstar 10

Boiler Dimensions: Wallstar Combi 11

Technical Specifications 12

Burner Settings 13

Boiler Installation

Regulations 14

Boiler Sizing 14

Refurbishing An Old System 14

System Protection 14

Boiler Location 15

Wall Construction 15

Flue Terminating Positions 16

Fuel Supply System 17

Oil Supply 17

Installation Procedure

Wallstar 18-23

System Wallstar 24-31

Wallstar Combi 32-40

Condensate Drain 41

Wiring Diagrams

Wallstar 42

System Wallstar 42

Wallstar Combi 43

Boiler Maintenance

Baffle Removal 44

Fault Diagnosis

Wallstar Combi 45

Wallstar Combi Components 46

Contacts

Tel No: 01953 455400

Fax No: 01953 454483

Email: info@hrmboilers.co.uk

or technical@hrmboilers.co.uk

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

32

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Introduction

Dear Householder

Thank you, for selecting a boiler from HRM. Your boiler is the culmination of years of experience in the development,

testing, and manufacture of oil fired equipment.

Our boilers are independently tested and comply with the latest European Boiler Efficiency Directive. Our quality

assurance procedures are also approved and comply with the International Standard, ISO9001.

Each boiler is assembled and tested with care by a member of our production team, you will find their name inside the

boiler casing.

Your boiler will provide you with a long and trouble free service life providing that a few essential steps are addressed.

Please take time to read the “Householder Information” section of this handbook.

In the unlikely event of a fault, please contact your installer who should be able to identify the cause of the problem, if

appropriate your installer will contact us.

HMickleburgh

Hedley Mickleburgh

Chairman

Simon Eastwell

Managing Director

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty.

- Ensure the boiler has been installed correctly and avoid premature failure.

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook.

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM.

- The warranty engineer must have direct access to all the indoor components of the boiler and any

outdoor components of the boiler must be no more than 3 meters above ground level or a safe

working platform.

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual.

- This warranty is in addition to your statutory and other legal rights.

After Sales Service

- If your boiler fails during the warranty period contact your installer who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances

should “in warranty” work be undertaken without authorisation from the HRM

service department.

- If you are unable to contact your installer please contact our service department, quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

If your boiler fails during the warranty period contact your installer who will be able to identify the

cause of the problem and refer to HRM for any warranty work instruction.

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

54

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

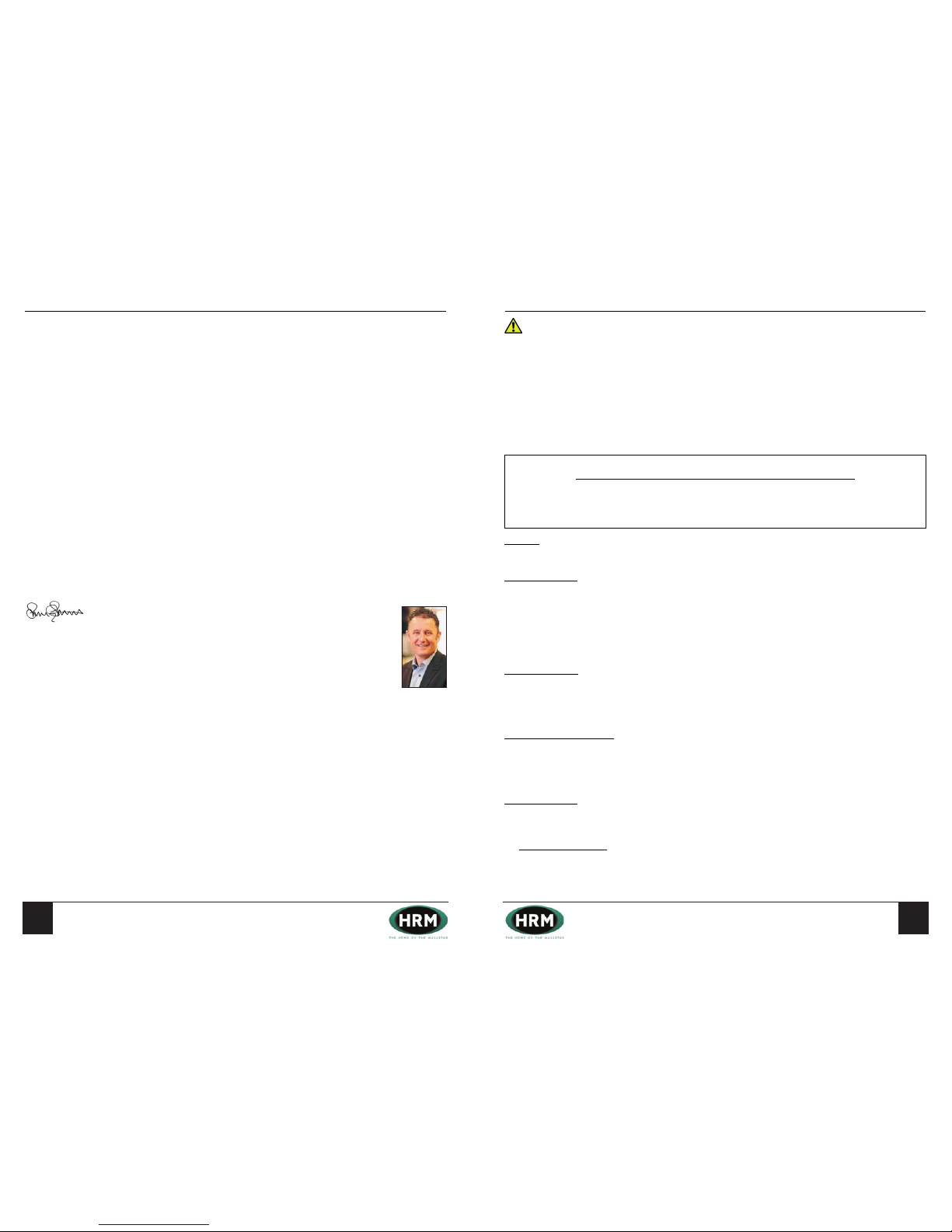

Boiler Controls – Standard Wallstar

Control Panel

Temperature Control Thermostat

The control thermostat regulates the temperature of the water within the boiler.

The recommended settings, governed by the control knob, are maximum for heating and hot water, and minimum for

hot water only.

Boiler Overheat (Limit) Thermostat

In the unlikely event the boiler overheats, the reset button will trip and cut the power supply to the boiler. Allow the

boiler to cool then press the reset button to reset the thermostat.

IMPORTANT - If overheating occurs regularly, consult your installation engineer. There may be a fault with the

central heating system.

Power Neon Lamp

The lamp is illuminated when there is power to the control thermostat and the control system (time clock) is

requesting heat.

Limit Neon Lamp

The lamp is illuminated when there is power to the controls, but the boiler has overheated. When the limit reset is

pressed this lamp should extinguish.

Lockout Reset Lamp

The lamp is illuminated when there is power to the controls, but the burner has not fired correctly. When the lockout

reset is pressed this lamp should extinguish. This lamp is also a reset button which provides an alternative to pressing

the reset on the burner itself.

Boiler Controls – System Wallstar

Control Panel

Temperature Control Thermostat

The control thermostat regulates the temperature of the water within the boiler.

The recommended settings, governed by the control knob, are maximum for heating and hot water and minimum for

hot water only.

Boiler Overheat (Limit) Thermostat

In the unlikely event the boiler overheats, the reset button will trip and cut the power supply to the boiler. Allow the

boiler to cool then press the reset button to reset the thermostat.

IMPORTANT - If overheating occurs regularly, consult your installation engineer. There may be a fault with the

central heating system.

Power Neon Lamp

The lamp is illuminated when there is power to the control thermostat and the control system (time clock) is

requesting heat.

Limit Neon Lamp

The lamp is illuminated when there is power to the controls, but the boiler has overheated. When the limit reset is

pressed this lamp should extinguish.

Lockout Reset Lamp

The lamp is illuminated when there is power to the controls, but the burner has not fired correctly. When the lockout

reset is pressed this lamp should extinguish. This lamp is also a reset button which provides an alternative to pressing

the reset on the burner itself.

Pressure Gauge

The heating system should be pressurised to approximately 1 bar when cold. Check the pressure occasionally, as

loss of pressure may cause the boiler to overheat. Please refer to note 10 (Page 28) in the installation procedure

section for instructions on pressurising the system.

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

76

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

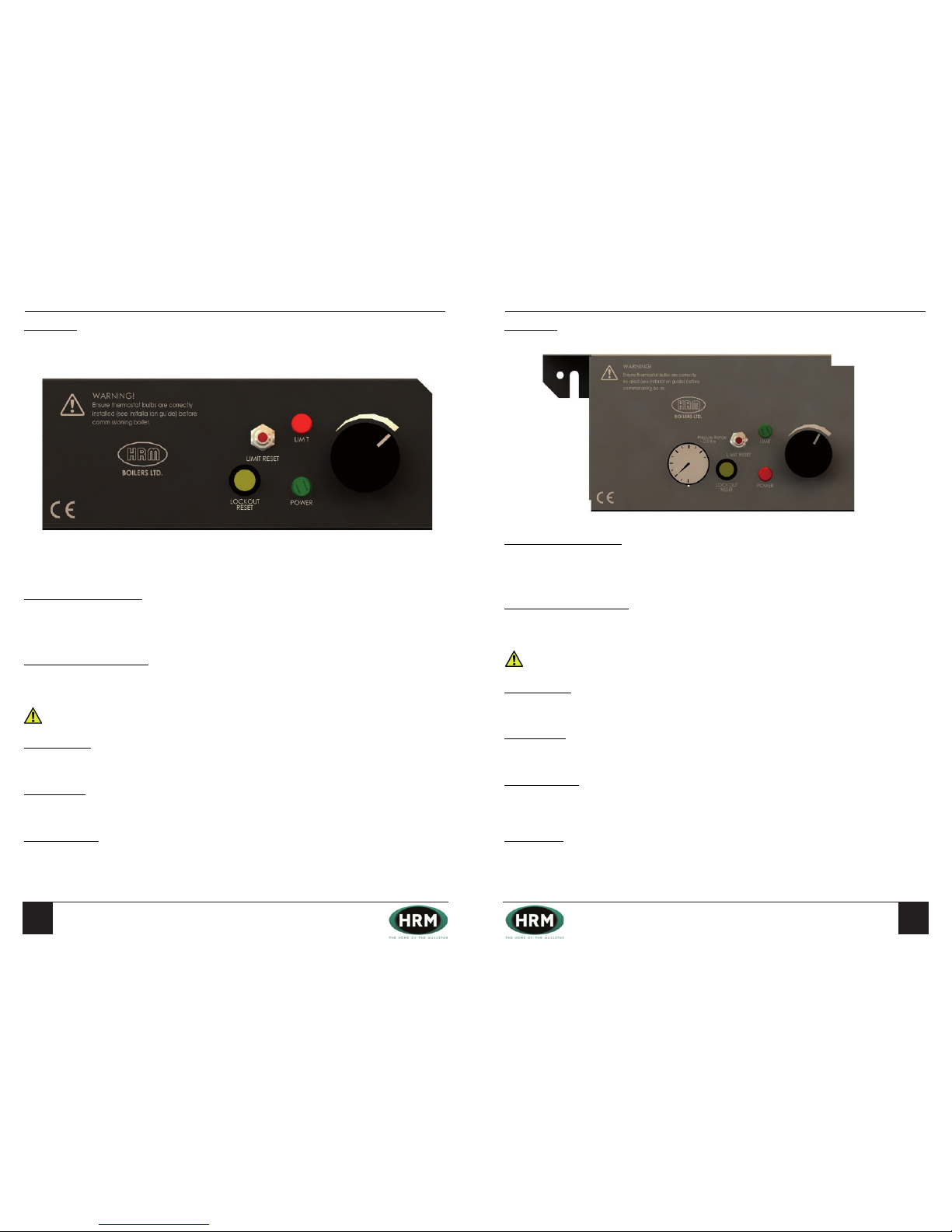

Boiler Controls – Wallstar Combi

Control Panel

Mixing Valve

The mixing valve can be adjusted to set the maximum temperature of hot water produced. The valve is graduated

between 1 to 5, the greater the number the hotter the water.

IMPORTANT - Too high a setting may cause scalding!

Auxiliary Thermostat

This thermostat maintains the temperature of the boiler for the production of hot water. For best hot water

Boiler Controls – Wallstar Combi

Control Panel

Mixing Valve

The mixing valve can be adjusted to set the maximum temperature of hot water produced. The valve is graduated

between 1 to 5, the greater the number the hotter the water.

IMPORTANT - Too high a setting may cause scalding!

Auxiliary Thermostat

This thermostat maintains the temperature of the boiler for the production of hot water. For best hot water

performance leave the knob set in its maximum position.

Heating Thermostat

The heating thermostat regulates the temperature of the water supplied to the central heating system. To achieve the

Boiler Controls – Wallstar Combi

Control Panel

Mixing Valve

The mixing valve can be adjusted to set the maximum temperature of hot water produced. The valve is graduated

between 1 to 5, the greater the number the hotter the water.

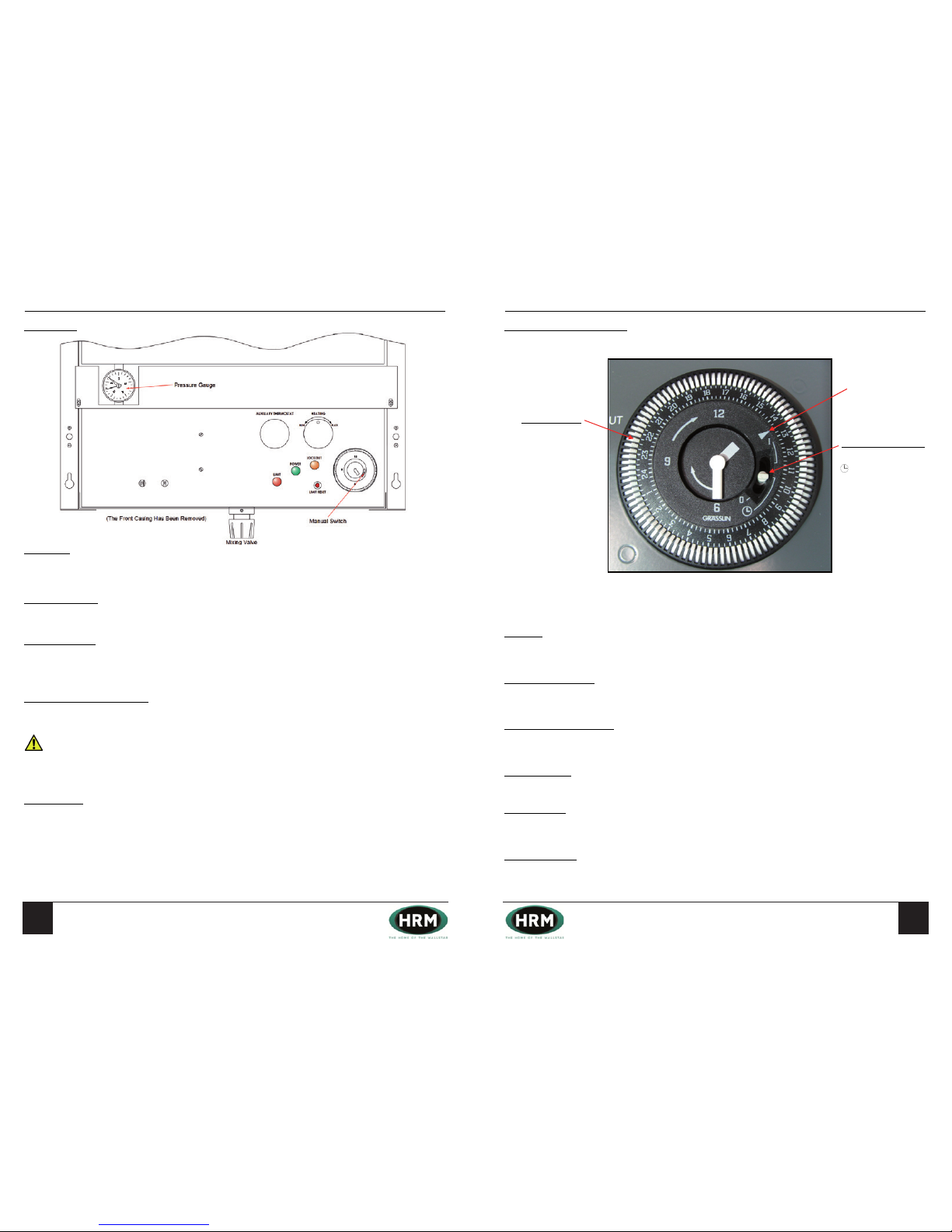

Boiler Controls – Wallstar Combi Continued

Time Clock Programming Guide

Setting Up

The outer dial should be set to the current time. Rotate the dial slowly in a clockwise direction, until the correct hour is

approaching the arrow printed on the dial.

Manual Switch Operation

The manual switch will provide On / Timed / Off control, thereby allowing manual control of the heating without

disrupting the timed (tappet) settings.

Programming Switching Times

One tappet is equal to 15 minutes. Set the number of tappets to the outer edge of the dial, equal to the duration of

time the heating is required to be switched on.

Power Neon Lamp

The lamp is illuminated when the mains supply to the boiler is switched on.

Limit Neon Lamp

The lamp is illuminated when there is power to the controls, but the boiler has overheated. When the limit reset is

pressed this lamp should extinguish.

Lockout Neon Lamp

The lamp is illuminated when there is power to the controls, but the burner has not fired correctly.

Arrow

Manual Switch Position

I = On (top position)

= Timed (centre position)

0 = Off (bottom position)

Tappets Position

In = Off

Out = On

Boiler Controls – Wallstar Combi

Control Panel

Mixing Valve

The mixing valve can be adjusted to set the maximum temperature of hot water produced. The valve is graduated

between 1 to 5, the greater the number the hotter the water.

IMPORTANT - Too high a setting may cause scalding!

Auxiliary Thermostat

This thermostat maintains the temperature of the boiler for the production of hot water. For best hot water

performance leave the knob set in its maximum position.

Heating Thermostat

The heating thermostat regulates the temperature of the water supplied to the central heating system. To achieve the

heating system performance indicated by the ‘max’ setting, the auxiliary thermostat should also be set to its maximum

position.

Note: The heating function is interrupted whenever there is a demand for domestic hot water.

Boiler Overheat (Limit) Thermostat

In the unlikely event the boiler overheats, the reset button will trip and cut the power supply to the boiler. Allow the

boiler to cool then press the reset button to reset the thermostat.

IMPORTANT - If overheating occurs regularly, consult your installation engineer. There may be a fault with the

central heating system.

Note: Loss of system pressure may cause the overheat (limit) thermostat to trip; refer to the pressure gauge section

below.

Pressure Gauge

The heating system should be pressurised to approximately 1 bar when cold. Check the pressure occasionally, as

loss of pressure may cause the boiler to overheat. Please refer to the combi fault diagnosis page for instructions

on pressurising the system.

This thermostat maintains the temperature of the boiler for the production of hot water. Pre-set at maximum position.

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

98

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Burner Lockout

The burner is equipped with a flame failure device. When activated the reset button on the burner control box is

illuminated. Refer to the fault finding section of the handbook to identify possible causes.

The test switch is provided for the service engineer, in normal operation the switch should be left in the “PROG”

position for Wallstar and System Wallstar boilers and in the “NORMAL” position for the Wallstar Combi.

Switching The Boiler On

- Turn on the oil supply

- Switch on the mains supply

- Set the timer control to “on”

- Set the boiler control thermostat to the required setting

Switching The Boiler Off For Long Periods

- Have the boiler serviced

- Switch off the mains supply

- Turn off the oil at the tank

Pump Priming

If the burner fails to lift oil, the pump may be dry and require priming. To prime the burner, fill a suitable container,

such as a jar, with heating oil, disconnect the flexible oil line at the isolating valve and place the end into the container.

Hold the container above the height of the burner and press the lockout reset button, once the pump has pulled the oil

from the container through, it is primed and can be reconnected to the main supply.

Oil Delivery

Switch the boiler off during an oil delivery, wait for a short period before switching the boiler back on to allow sediment

in the bottom of the oil supply tank to settle.

Maintenance

Your boiler should be serviced annually. Failure to have this done will invalidate your warranty and may also lead to

inconvenient breakdowns. A “Benchmark” service log can be found at the back of this manual.

If you have difficulty in locating a service engineer, please contact our service department who may be able to provide

you with the name of an engineer in your area.

Additional Burner Information

Further information on burner settings can be found within the burner instruction manual which will have been

included with the boiler. If you have misplaced this manual or simply require additional copies, please contact our

service team.

Burner Spares

Please contact our sales department for further information on burner spares.

Burner Lockout

The burner is equipped with a flame failure device. When activated the reset button on the burner control box is

illuminated. Refer to the fault finding section of the handbook to identify possible causes.

The test switch is provided for the service engineer, in normal operation the switch should be left in the “PROG”

position for Wallstar and System Wallstar boilers and in the “NORMAL” position for the Wallstar Combi.

Switching The Boiler On

- Turn on the oil supply

- Switch on the mains supply

- Set the timer control to “on”

- Set the boiler control thermostat to the required setting

Switching The Boiler Off For Long Periods

- Have the boiler serviced

- Switch off the mains supply

- Turn off the oil at the tank

Pump Priming

If the burner fails to lift oil, the pump may be dry and require priming. To prime the burner, fill a suitable container,

such as a jar, with heating oil, disconnect the flexible oil line at the isolating valve and place the end into the container.

Hold the container above the height of the burner and press the lockout reset button, once the pump has pulled the oil

from the container through, it is primed and can be reconnected to the main supply.

Oil Delivery

Switch the boiler off during an oil delivery, wait for a short period before switching the boiler back on to allow sediment

in the bottom of the oil supply tank to settle.

Maintenance

Your boiler should be serviced annually. Failure to have this done will invalidate your warranty and may also lead to

inconvenient breakdowns. A “Benchmark” service log can be found at the back of this manual.

If you have difficulty in locating a service engineer, please contact our service department who may be able to provide

you with the name of an engineer in your area.

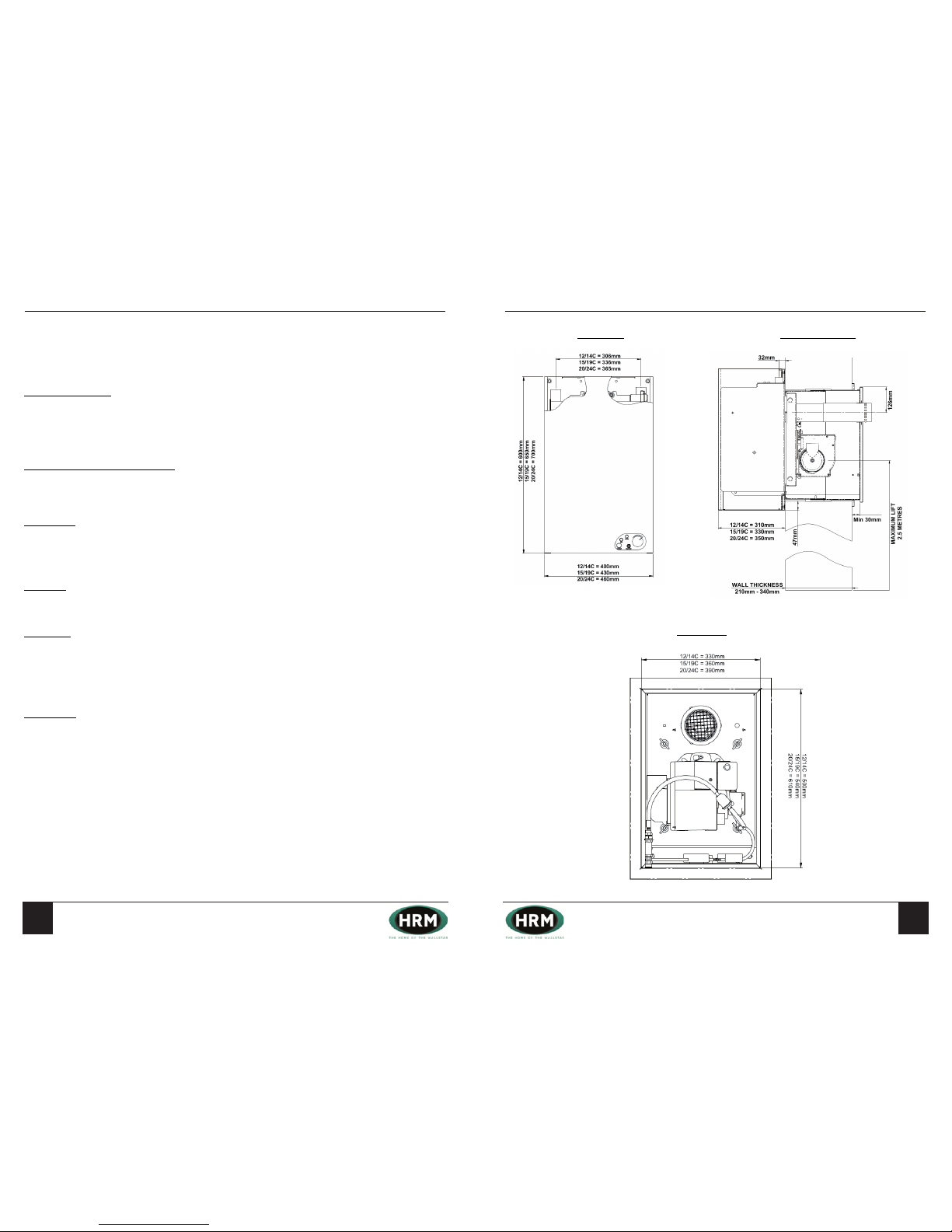

Technical Specifications – Boiler Dimensions – Standard Wallstar

Internal View

Cross-sectional View

External View

If the burner fails to lift oil, the pump may be dry and require priming. To prime the burner, ll a suitable container,

such as a jar, with heating oil, disconnect the exible oil line at the isolating valve and place the end into the container.

Hold the container above the height of the burner while bleeding pump and press the lockout reset button, once the

pump has pulled the oil from the container through, it is primed and can be reconnected to the main supply.

Switch the boiler off during an oil delivery, wait for at least 1 hour before switching the boiler back on to allow sediment

in the bottom of the oil supply tank to settle.

Clear oil line shown

is a BS099A with an

integral lter.

All boilers are now

supplied with a

BS012 clear oil line

with no lter.

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

1110

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

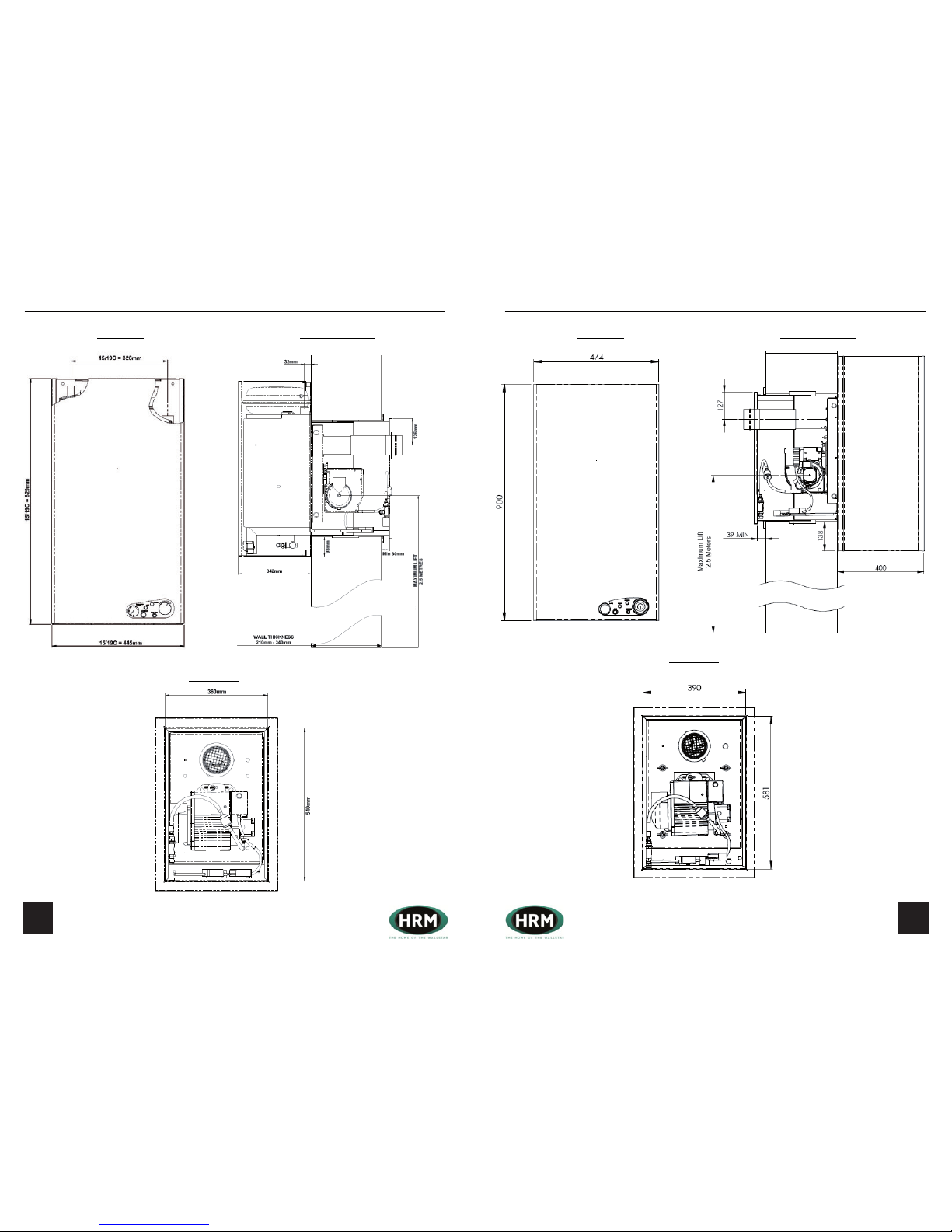

Technical Specifications – Boiler Dimensions – System Wallstar

Internal View

Cross-sectional View

External View

Technical Specifications – Boiler Dimensions – Wallstar Combi

Internal View

Cross-sectional View

External View

Clear oil line shown

is a BS099A with an

integral lter.

All boilers are now

supplied with a

BS012 clear oil line

with no lter.

Clear oil line shown

is a BS099A with an

integral lter.

All boilers are now

supplied with a

BS012 clear oil line

with no lter.

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

1312

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

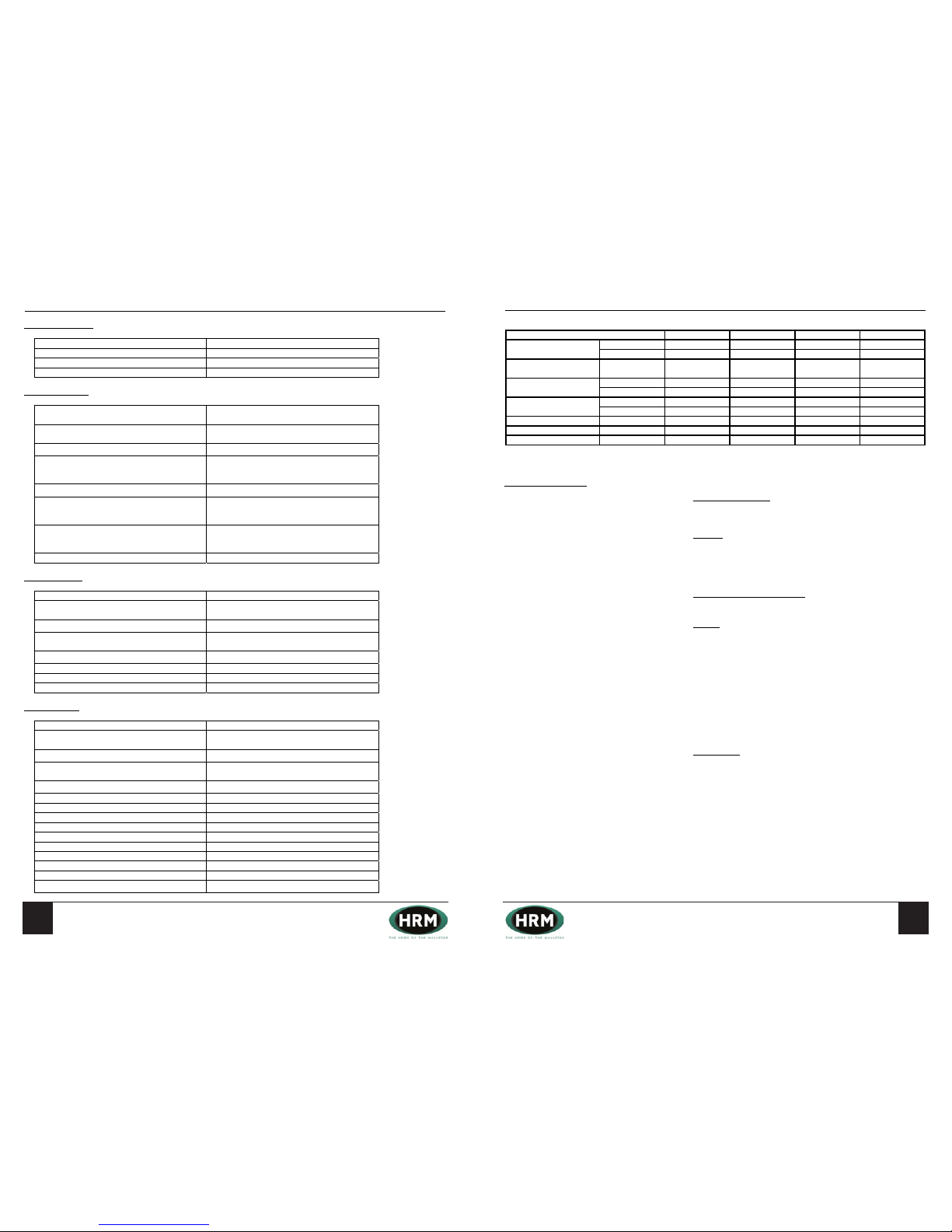

Technical Specifications

All Wallstar Models

Electrical Supply 230V Single Phase, Fused 5amp

Max Power Consumption 125W

Fuel Class C2 (28 Sec Kerosene)

Oil Supply Connection 10mm Compression, Single Pipe

Standard Wallstar

Heating Systems Requirements

Fully Pumped, Conventional Open Vented, or

Sealed System

Max Operating Pressure

3 Bar (43.5psi) Static Head 30.59 Meters

(100ft)

Operating Temperature Range

60

°C to 82°C

Resistance To Water Flow Between Return

and Flow Connections (10 Deg Temp Rise)

12/14C – 26mm

15/19C – 35mm

20/24C – 48mm

Cut Out Temperature

100

°C

Weight Empty

12/14C – 84kg

15/19C – 96kg

20/24C – 107kg

Water Capacity

12/14C – 17.5 Litres

15/19C – 19.25 Litres

20/24C – 21 Litres

SEDBUK Rating A

System Wallstar

Heating Systems Requirements Sealed Systems Only

Max Operating Pressure

3 Bar (43.5psi) Static Head 30.59 Meters

(100ft)

Operating Temperature Range

60

°C to 82°C

Resistance To Water Flow Between Return

and Flow Connections (10 Deg Temp Rise)

35mm

Cut Out Temperature

100

°C

Weight Empty 107kg

Water Capacity 19.25 Litres

SEDBUK Rating A

Wallstar Combi

Heating Systems Requirements Sealed Systems Only

Max Operating Pressure

3 Bar (43.5psi) Static Head 30.59 Meters

(100ft)

Operating Temperature Range

60

°C to 82°C

Resistance To Water Flow Between Return

and Flow Connections (10 Deg Temp Rise)

48mm

Cut Out Temperature

110

°C

Weight Empty 140kg

Water Capacity 35 Litres

Maximum Cold Water Pressure 5 bar / 72.5psi

Minimum Cold Water Pressure 1.5 bar / 21.7psi

Expansion Vessel Capacity 12 Litres

Expansion Vessel Pressure 1 bar / 14.5psi

Safety Relief Valve 3 bar / 43.5psi

Heating Output 18kW

Domestic Hot Water Output 24kW

Hot Water Flow Rate

35

°C Rise @ 10.5 Litres/Min

Technical Specifications – Burner Settings

Burner Fault Diagnosis

Burner fails to start - Mains lamp not illuminated

Blown fuse

Time clock/programmer not calling for heat

Room or hot water thermostats not calling for heat

Burner lockout lamp is illuminated - Lack of oil

Faulty solenoid coil

Blocked nozzle

Faulty fire valve

Air in oil supply

Empty oil tank

Blocked Oil Filter

Flame extinguishes after a short period

Photocell faulty

Faulty cont rol box

No spark

Faulty cont rol box

Faulty ignition tra nsformer

Incorrect electrode setting

Motor does not run - Seized oil pump

Motor faulty

Control box faulty

Capacitor faulty

Radio/T.V interference - Incorrect electrode setting

Poor earth bonding

Faulty ignition transformer

Smokey exhaust - Blocked nozzle

Incorrect burner settings

Burner starts violently - Delayed Ignition

Incorrect electrode adjustment

Electrode insulation damaged

HT leads faulty

Air in oil supply

Incorrect air adjustment

Oil odours - Incorrect combustion settings

Oil leak

Unstable flame - Incorrect head settings

Low oil pressure

Excess air

Faulty nozzle

btu /h

Kw

No zzle

US /GP H

Size & Ty pe

BAR

PSI

Kg/ hr

Litres /hr

Smoke No.

Bac harac h Sc ale

CO

2

%

Flue Gas Tem p

Les s amb iant °C

SEDBUK

Ban d

100

Output

47 ,800

TBA

A

TBA

TBA

TBA

Oi l P ressu re

85

64,8 50

19

0.55 8 0° EH

Bo iler M odel 12/14

Firing Rate

1.3 4

1.7

0.5 0 80° EH

6.9 TBA

TBA

TBA

15/ 19

A

0

11.5 12

85

A

14

2.0 5

0

20/ 24

8.6

125

1.6 3

81, 900

24

TBA

115

B

C ombi

83,00 0

24 .3

0.75 80° EH

7.2 5

105

2.1 5

2.7 5

0

12 .5

12/14 15/19 20/24 24/18 COMBI

btu/h 52,886 64,828 80,182 81,888

Kw 15.5 19.0 23.5 24.0

BAR 6.9 9.0 9.0 9.0

PSI 100 130 130 130

Kg/hr 1.29 1.69 2.13 2.13

Litres/hr 1.63 2.14 2.59 2.59

SMOKE NO Bacharach Scale 0 0 0 0

CO2 % 11.5 12 12.5 12.8

FLUE GAS TEMP Net Flue temp ˚C 85 85 85 85

BOILER MODEL

OUTPUT

NOZZLE Size and Type 0.50 80˚EH 0.55 80˚EH 0.65 80˚EH 0 .65 80˚EH

OIL PRESSURE

FIRING RATE

10

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

Householder Information

IMPORTANT!

Your boiler must be commissioned in order to:

- Validate your warranty

- Ensure the boiler has been installed correctly and avoid premature failure

- Set the boiler to its optimum efficiency. Operating conditions for the boiler will vary from site to site, your

commissioning engineer has specialised equipment to check the oil pressure and analyse the exhaust gases for

temperature, smoke and carbon dioxide content.

Your installer will organise the commissioning of your boiler. Should you experience any difficulty locating an

engineer, our service department may be able to provide you with details of an engineer in your area.

“Benchmark” Installation, Commissioning and Service Record Log Book

Please ensure that your installer has completed all sections of the log book (found at the back of this manual).

The log book will be required in the event of any warranty work. Ensure that the service record is completed.

Warranty

Your HRM boiler is under warranty for 2 years from the date of installation.

Warranty Conditions

- The boiler must be installed and commissioned in accordance with our handbook

- The boiler must not be repaired, modified or tampered with by any person not authorised by HRM

Extended Warranty

The “Benchmark” and warranty registration document at the end of this manual should be completed as

appropriate by your installer / engineer. This is your record that the boiler has been correctly installed in accordance

with our recommendations. Return the warranty registration document to HRM in order to qualify for a further 3 year

warranty of the heat exchanger – a total of 5 years.

Extended Warranty Conditions

- The boiler must be serviced annually and maintained in accordance with this handbook. The

“Benchmark” service log is located at the back of this manual

- This warranty is in addition to your statutory and other legal rights

After Sales Service

- If your boiler fails during the warranty period contact your installer, who will be able to identify the

cause of the problem. If appropriate, your installer will contact us.

- Under no circumstances should “in warranty” work be undertaken without authorisation from the HRM

service department

- If you are unable to contact your installer please contact our service department. Quoting your boiler’s

serial number when phoning – this can be found on the cover of this manual.

3

Standard X-ternal & System X-ternal

Handbook

1514

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

Contents Page

1

Standard Wallstar, System Wallstar &

Wallstar Combi Manual

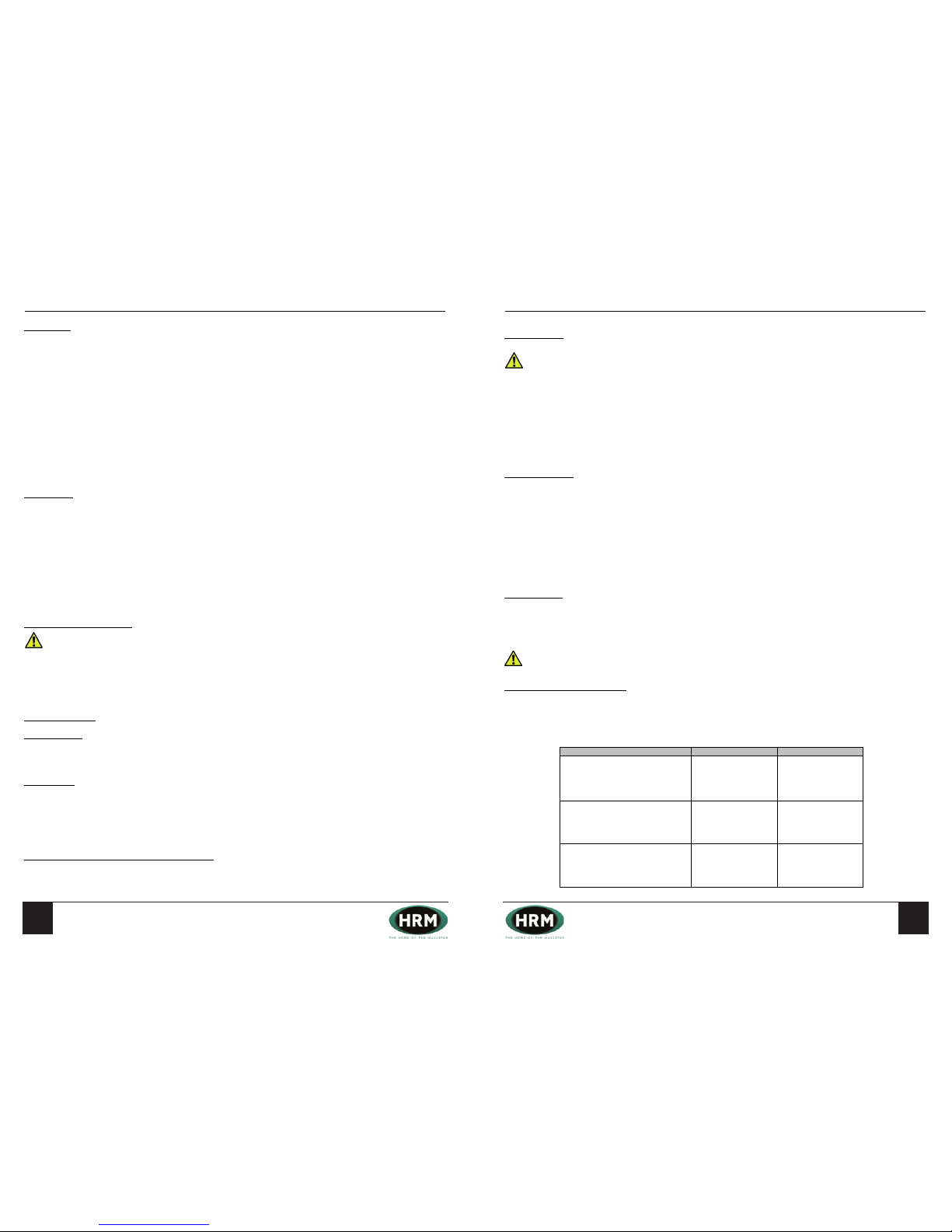

Boiler Installation

Regulations

The Installation of oil fired boilers must comply with the following Standards and Codes of Practice:

BS 5410-1:1997 Oil installations up to 45kW

BS 5449 Forced circulation hot water central heating systems for domestic premises

BS 7593:2006 Treatment of water in hot water central heating systems

Building Regulations Part L1 Part J 2006 England and Wales, Part F Scottish Regulations and Technical

Booklet L Northern Ireland

BS 7671:2008 Electrical Regulations

BS 7074 Code of practice for sealed systems

Boiler Sizing

It is important to establish the correct size of boiler required. Boiler output will depend on a number of factors,

including:

- The preferred room temperatures

- Location winter temperature

- Structural and ventilation heat losses

- Domestic hot water requirements

This is a complicated calculation. We recommend you employ the services of a heating engineer, who will determine

the correct size of boiler required for your property.

Refurbishing an Old System

IMPORTANT – Before installing a new boiler:

The system should be chemically cleaned to remove debris, in the form of black magnetite sludge and lime scale that

accumulates in radiators and pipe work. Failure to do this will result in debris adhering to the clean surfaces of a new

boiler, causing kettling or knocking noises. It also prohibits efficient heat transfer. A cleanser such as Fernox

Superfloc should be added to the system 48 hours prior to changing the boiler.

System Protection

After Installation

Flush the system with a cleanser such as Fernox Superfloc to remove traces of flux residues, grease, metal swarf,

solder pieces and oils used during component manufacture.

After Flushing

Add a corrosion inhibitor such as Fernox MB-1. This will minimise the chemical action and chemical change that takes

place in a systems primary water and system components.

Note: The manufacturer’s usage instructions for chemical cleaners and inhibitors should always be followed.

Please refer to BS 7593:2006 for a detailed explanation of cleansing procedures.

Protection of DHW Heat Exchanger (Wallstar Combi)

We recommend that a water scale reducer is installed in areas of hard water.

Boiler Installation - Continued

Boiler Location

IMPORTANT - Boilers should be installed on the ground floor only.

Noise levels – consideration should be given to the following:

- Small rooms will accentuate noise levels.

- Where a flue terminates near the boundary of an adjoining property, consideration should be given to

possible noise disturbance as some people are sensitive to even low noise levels.

Bathroom and bedroom installation should only be considered where there is no alternative.

Wall Construction

The boiler must be installed in a suitable load bearing external wall – a lintel is not normally required.

For walls constructed of timber, stramit or similar material, the structural material must support the weight

of the boiler when filled with water. A stud work frame should be constructed when appropriate.

It is not necessary to construct a heat barrier around the wall duct.

Where the external cladding is of weatherboard or similar, construct a “picture frame” for the wall duct trim

to seat against.

Wall Thickness

The Wallstar condensing models are supplied with telescopic wall ducts and flues, designed to fit through

exterior walls 210mm to 340mm thick. However with the addition of a 100mm extension kit, it is possible

to install a Wallstar condensing boiler in walls up to 440mm thick.

IMPORTANT - Be sure to measure your wall thickness before purchase.

Wall Duct & Flue Extension Kits

Note: Only one extension kit per boiler is permitted.

The extension kit is fitted to the inner half of the telescopic wall duct.

Extension Kit Size Part Number

Wallstar 12/14CA Wall Duct & Flue

Extension

100mm (4”) 12/14CX100

Wallstar 15/19CA Wall Duct & Flue

Extension Kit (Fits Standard & System

Models)

100mm (4”) 15/19CX100

Wallstar 20/24CA & Wallstar Combi Wall

Duct & Flue Extension Kit

100mm (4”) 20/24CX100

Flush the system with a cleanser such as Fernox or similar to remove traces of ux residues, grease, metal swarf,

solder pieces and oils used during component manufacture.

Add a corrosion inhibitor such as Fernox or similar. This will minimise the chemical action and chemical change that

takes place in a systems primary water and system components.

Boilers should be installed no higher than 2.5 m- See diagram on page 17.

Loading...

Loading...