Wallnofer Walltherm Operating Instructions Manual

progress & innovation 1/46

OPERATING MANUAL:

Instructions for use & maintenance of the

Walltherm® Version / 12.1

The first natural down-draught wood gasification stove

for the living room.

Dear stove-owner,

You have made an excellent choice purchasing the Walltherm® stove/boiler for

your living room. Especially in connection with a heat storage tank, it offers you

all the advantages of a radiant heat stove for the living room and furthermore,

an economical heating system for your whole house. Please study this manual, it

explains how the stove works, how you should operate it and how it has to be

maintained.

For further information, please contact the manufacturer or any authorized

Walltherm dealer

progress & innovation Vers. 12.1 2/46

! In any case the laws and norms valid in the installation country

have to be respected.

This stove has been developed for the following uses:

due to the contemporary design and the visible fire it can be perfectly put up in the living

room

heating of the living room through radiant heat

heating of distant rooms with water based radiators, underfloor- or wall heating from the

boilerDHW through the hot-water tank/store

integrated hotplate for cooking and therefore ideal for holiday homes

THEREFORE: the requirements for the complete heating of an average country house

are covered (heating of rooms and domestic hot water)!

FEATURES OF THE STOVE:

two times visible fire through temperature resistant glass

rapid heating due to big radiant surfaces

boiler function with integrated heat exchanger

wood-burning system, consequently economical and clean burning

small hotplate for cooking

GENERAL INFORMATION:

PURPOSE:

The Walltherm® stove has been developed for the optimal burning of air-dried natural

wood, wood chips and (partly) briquetts. Do not burn any wood/paper/cardboard that

has been painted or colored, not should you use barbecue igniters or coals because

anything that isn´t natural wood can produce acids while burning. Those acids can

damage the stove and the heat exchanger!

The stove must not be used for burning any other

materials including coal or waste.

The heater (wood gasification stove) Mod. Walltherm®, invented by the company

Wallnöfer H.F. GmbH, complies with the Machine- and Safety Regulations of the

European Union guideline 98/37/EWG and consequent amendments. The stove has been

tested and registered by BLT-Wieselburg (AUT), VKF (Switzerland) and TÜV

Rheinland (GER).

This operation manual is directed at the owner of the stove Mod. Walltherm, the

tradesman who installs it, the operators, and the service personell.

In any case of doubt or for further information concerning the manual, please contact the

producer or any authorized Walltherm dealer. Please quote the number of the paragraph

and name the topic in question.

progress & innovation Vers. 12.1 3/46

This operating manual is protected by copyright and it (or any part thereof) must not be

printed, copied or reproduced without prior consent of Wallnöfer H.F. GmbH.

Technical information, graphics, and specifications included in this manual must not be

published/distributed.

The principle of the double combustion and its advantages

Generally: In a wood burning stove, a correctly burning flame emits the same amount

of carbon dioxide (CO2) as would be emitted through the natural decomposition of the

wood itself.

The quantity of CO2 produced by combustion or decomposition of a tree is equal to the

quantity of CO2 that the tree would have extracted from the environment, releasing

oxygen into the air whilst utilising the carbon for growth during its lifetime.

Unlike wood, when fossil fuels are burned – which are not renewable, like coal, diesel oil,

gas – a huge amount of CO2 accumulated in the course of millions of years is emitted

into the atmosphere, increasing the green-house effect. Consequently, the use of wood

as fuel maintains the perfect equilibrium of nature because it is a renewable fuel of which

burning is compatible with nature’s life cycle.

The principle of clean combustion is in perfect harmony with these characteristics and

Wallnöfer H.F. GmbH always adheres to it when designing their products.

Double combustion: What exactly do we mean by

clean double combustion and how does it work? By

controlling the flow of primary air and by adding

secondary air, secondary combustion, or postcombustion, takes places. This is indicated by a

second characteristically clearer and stronger flame

below (?) the main flame. By adding new oxygen,

this flame consumes the unburned gasses,

remarkably improving heat production and reducing

the harmful emission of CO (carbon monoxide)

caused by incomplete combustion. This is a unique

feature of the Walltherm stove for the living room.

progress & innovation Vers. 12.1 4/46

Index

1) Introduction

1.a. Symbols

1.b. Intended use

1.c. Purpose and contents of the

manual

1.d. Keeping the manual

1.e. Updates of the manual

1.f. General information

1.g. Main accident prevention

regulations to comply with

1.h. Guarantee

1.i. Manufacturer’s liability

1.j. User characteristics

1.k. Technical assistance

1.l. Spare parts

1.m. Identification plate

1.n. Delivery of the stove

2 Safety Instructions

2.a. Instructions for installers

2.b. Instructions for users

2.c. Instructions for maintenance

engineers

3 Parts list for the stove

3.a. Parts

4 Handling and Transport

5 Preparing the place of

installation

5.a. Safety precautions

5.b. Combustion

5.c. Preparing the place of

installation

5.c.1. Limitation of space around the

stove

5.c.2. Limitation of space above the

stove

5.c.3. Combustion air

5.c.4. Smoke outlet pipe

6 Installation

6.a. Leveling the stove

6.b.1 Connecting Electricity

6.b.2 Earthing

6.c. Important information

6.c.1. Doors

6.c.2. Thermal safety drain

6.c.3. Circulation pump

6.c.4. Density

6.c.5. Permissible max/min

temperatures

6.c.6. Cleaning

7 Using the stove - Lighting

7.a. Control

7.b. Lighting phase

7.c. Loading the fuel

7.d. Permissible and suited fuels

8 Maintenance and cleaning

8.a. Safety precautions

8.b. Routine maintenance for the

user

8.b.1. Cleaning the stove

8.b.2. Cleaning the glass

8.b.3. Cleaning the smoke outlet

8.b.4. Controlling seals

9 Recognizing errors and taking

measures against faults

10 Saving energy

11 Concept of water pipes

12 Safety functions

13 Technical features/data

progress & innovation Vers. 12.1 5/46

!

1. Introduction

Do not install or use the stove before you have read and understood the contents of this

manual. In case of doubt at any time do not hesitate to contact Wallnöfer H.F. GmbH for

information.

Wallnöfer H.F. GmbH reserves the right to modify the technical and/or functional

specifications and features at any time without prior notice.

1.a. Symbols

Important points in this manual are highlighted with the following symbols:

Indication: indications concerning the correct use of the stove and the

responsibilities of those using it.

Attention: a particularly important note is written here.

Danger: Here you are warned of the possibility of bodily harm or material

damages.

1.b. Use of the stove

Walltherm is an innovative, technologically advanced stove for heating, burning fuels like

firewood and wood briquettes providing a healthy and safe way of heating.

This stove features the dual primary and secondary combustion system with positive

effects both on efficiency and on emission of “cleaner smoke”.

The application of the stove and its configurations as described above are the only ones

permisable by the manufacturer. Do not use the stove in disagreement with the

instructions provided.

The described use of the stove is applicable only for stoves in full structural,

mechanical and engineering condition.

The Walltherm, produced by Wallnöfer H.F. GmbH, must only be used indoors.

1.c. Purpose and contents of the manual

Purpose

The purpose of the manual is to provide the operator with the fundamental knowledge to

allow the user to take the necessary precautions and to have all the human and material

resources required for its correct, safe and lasting use.

progress & innovation Vers. 12.1 6/46

Contents

This manual contains all the information necessary for installation, use and maintenance

of the Walltherm stove. By complying scrupulously with the contents of this manual you

will ensure a high degree of safety and productivity of the stove.

1.d. Keeping the manual

Keeping and consulting the manual

The manual must be kept in a safe, dry place and be available at all times for

consultation by the user and by those who see to its installation and maintenance.

The manual with its instructions for operation and maintenance is an integral part of the

stove.

Deterioration or loss

If required, ask Wallnöfer H.F. GmbH for another copy of the manual.

Selling the stove

If the stove is sold, the user must give the manual to the new owner.

1.e. Updating the manual

This manual reflects the state-of-the-art at the time the appliance was put on the

market.

1.f. General information

Information

If there is an exchange of information with the stove manufacturer, please quote the

serial number and identification data which you will find on the stove’s identification

plate.

Liabilities

Upon delivery of this manual Wallnöfer H.F. GmbH declines all liabilities, both civil and

penal, for any accidents that may derive form the total or partial failure to comply with

the specifications contained in it.

Wallnöfer H.F. GmbH also declines all liabilities resulting from an improper use

of the stove, incorrect use by the user or resulting from unauthorised

alterations and/or repairs, or the use of spare parts that are either not

genuine or not specific for this particular model.

Extraordinary maintenance

Extraordinary maintenance must be carried out by personnel qualified to work on the

stove model to which this manual refers.

Responsibility for installation

It is not the manufacturer’s responsibility to carry out the works

needed to install the stove. Such works are entirely up to the installer who is

requested to check the flue and air intake and to check if the installation

solutions proposed are feasible. In addition, all the safety standards

established by the relevant law in force in the place of installation must be

complied with.

progress & innovation Vers. 12.1 7/46

Use

Use of the stove is subject to compliance with all the safety standards established by the

relevant laws in force in the place of installation besides the prescriptions contained in

this manual.

1.g. Main accident prevention regulations to comply with

a) EEC directive 73/23: “electrical material for use within certain voltage limits”.

b) EEC directive 89/336: “grouping of the laws of the member states relative to EMC”.

c) EEC directive 89/391: “putting into practice the measures to promote improvement

of the safety and health of workers during their working hours”.

d) EEC directive 89/106: “concerning the grouping of legislative, regulating and

administrative guidelines of the state members on the subject of construction

products”.

e) EEC directive 85/374: “concerning the grouping of legislative, regulating and

administrative guidelines of the state members on the subject of liability for

damages due to faulty products”.

1.h. Legal guarantee

Wallnöfer H.F. offers 5 years of guarantee for the body of the Walltherm, exclusiv spare

parts like combustion jets, grid, glass, seals, cat, fireclay.. For all the valves an other

components the user may only make use of the legal guarantee, as under the EEC

directive 1999/44/CE, if he has scrupulously complied with the regulations indicated in

this manual, and more specifically:

to work always within the stove’s range of use

maintenance must be constant and accurate

only allow people who are capable and who have been suitably trained to use the

stove.

Failure to comply with the regulations contained in this manual will invalidate the

guarantee immediately.

In any case of possible legal guarantee the installation of the stove must have been

carried out by people who are capable and who have been suitable trained to use the

stove. Furthermore, a copy of the installation record has to be delivered to Wallnöfer H.F.

GmbH.

Wallnöfer informs that the following cases aren`t query reason:

Fireclay:

Because of the high temperature loading, the fireclay can get cracks, in this case it isn`t

necessary to exchange the components, the isolation function is still ensure. The

exchange is only necessary if the fireclay falls apart.

Noise:

Until the warming and cooling phase of the body made of steal it is normal that you hear

some noise.

progress & innovation Vers. 12.1 8/46

Coating:

Please control the external coating before you install the Walltherm, when you find defect

parts please contact immediately your reseller.

After the installation of the Walltherm we can only resolve the problem with sprays.

To avoid coating problems during the operation please take note of the following tips:

a) Please clean the external parts only with water and soap, do never use alcohol or

similar agressiv cleaning liquids.

b) To protect the upper side of the Walltherm® please close the exhaust fume flap

(5) when the gas temperature reaches about 300 - 350°C. (look chapter: 7 Using

the stove – Lighting)

Cooking plate and doors:

Because of the high temperature loading, the colour of the doors and the cooking plate

will change. When you grid of this parts you can get the origal colour.

1.i. The manufacturer’s liabilities

The manufacturer declines all civil and penal liabilities, direct or indirect, due to:

an installation that fails to comply with the laws in force in the country and with the

safety rules and regulations;

failure to comply with the instructions given in the manual;

an installation by unqualified and untrained personnel;

use that fails to conform to the safety directives;

alterations and repairs on the appliance not authorised by the manufacturer;

use of spare parts that are either not genuine or specific for this particular model;

lack of maintenance;

exceptional events.

1.j. User characteristics

The person who uses the stove must be an adult and responsible, with al the necessary

technical know-how to carry out routine maintenance of the mechanical and electrical

components of the stove.

Do not let children near the appliance to play with it when it is working.

1.k. Technical assistance

Wallnöfer H.F. GmbH is able to solve any technical problem concerning the use and

maintenance of the appliance’s whole life cycle. The main office will help you find the

nearest authorised assistance centre.

progress & innovation Vers. 12.1 9/46

Abb.1 .m

1.l. Spare parts

Use genuine spare parts only!

Do not wait until the components are worn from use before changing them.

Changing a worn component before it breaks makes it easier to prevent accidents that

could otherwise lead to serious harm to people or damage to things.

Carry out routine maintenance checks as described in the “machine

maintenance and repair” chapter!

1.m. Identification plate

The plate shown in fig. 1 m can be found on the stove’s left and gives all the machine’s

features including the manufacturer’s data, serial number and CE marking relative to the

electrical system.

1.n. Delivering the stove

The stove is delivered accurately packed in cardboard and fixed to a wooden pallet so it

can be handled by elevator trucks and/or other means.

You will find the following items inside the stove:

use, installation and maintenance manual;

cleaning brushes for the vertical and horizontal flue and air intake

a brush for the ashes

a fire hook

a cold handle for pulling the hearth out;

progress & innovation Vers. 12.1 10/46

2. Safety Precautions

2.a. Instructions for the installer

comply with the indications given in this manual

check that the flue and air intake are suitable for the type of installation opted for

(12 pa draft)

the electrical connections must not be done using temporary or non-insulated leads

make sure the electrical system’s earthing is effective

always use individual safety devices and other protections means.

2.b. Instructions for the user

the stove must not be used without having it filled with water

Since the stove is an appliance that heats, its outer surfaces can get very hot. For

this reason we advise maximum caution when it is working, in particular:

not to touch or go near the glass door as you could get burnt;

not to touch the flue and air intake;

not to do any type of cleaning;

not to pull out the ashes;

not to touch the lower glass door;

make sure that children are kept away.

comply with the indications given in this manual

comply with the instructions and warnings given on the plates on the stove

these plates are accident prevention devices and as such must be easily and

perfectly illegible it; it is compulsory to change them, asking the manufacturer for

an original plate

only use fuel that complies with the indications given in the chapter referring to fuel

characteristics

keep strictly to the routine and extraordinary maintenance programme

do not use the stove if there is a malfunction, a suspicion of breakage or unusual

noises

do not throw water on the stove when it is lit or to put the fire out in the hearth

do not clean the stove until the structure and ashes are completely cold

all works must be carried out in maximum safety and calmly.

2.c. Instructions for the maintenance engineer

comply with the indications given in this manual

always use individual safety devices and other protection means

before embarking on any maintenance work the stove must be completely cold

even if only one of the safety devices is incorrectly calibrated or not working, the

stove is to be considered “not working”

the electricity must be disconnected before any work is done on switches and

connectors.

progress & innovation Vers. 12.1 11/46

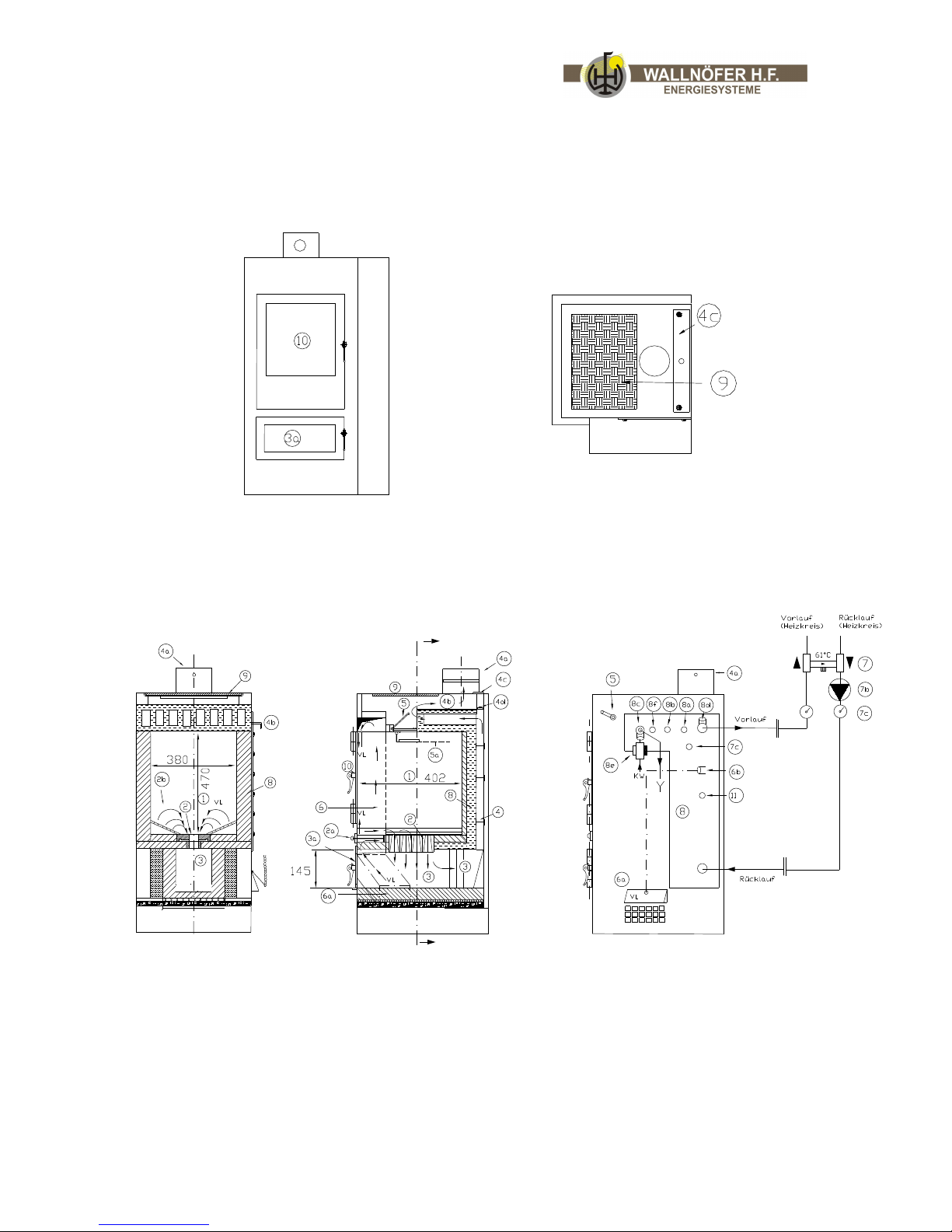

3. Parts list of the stove

3.a. Spare parts/components

1 Upper combustion chamber

2 injektor block with secondary air feed

2a Secondary air knob

2b Grid

3 Lower combustion chamber (gas combustion tunnel)

3a Door with glass to lower combustion chamber

4 Smoke channels

4a Stove pipe flange with thermometer

4b Horizontal smoke channels

4c Opening with lid for access to smoke channels for cleaning

4d Adjustable lid for smoke diversion

5 Exhaust fume flap (function: lever in horizontal position = flap closed, lever

pointing down = flap open)

5a Smoke baffle with opening and cover for hotplate (cooking)

6 Combustion air intake channel to upper and lower cross channel

6a Air inlet with thermostatically controlled flap

6b Safety thermostat for control of combustion air intake

7 Thermostatically controlled 3-way valve set to open at 60°C – 70 °C

7b Circulation pump

7c Thermometer

8 heat exchanger

8a Thermostat/sensor for pump on/off control

8b Safety valve to 3 bar for draining how water in case of overheating

8c heat exchanger (lance) for cooling with connections for cold water intake and hot

water outlet

8d Bleeder valve. Attention: when connected to unpressurised system use this stove

connector

8e Valve for thermal safety drain

8f Probe/sensor for safety drain

9 Cooking plate

10 Door to upper combustion chamber

11 Pressure gauge

N.B. The best position of the pump group (Pos 7, 7b, and 7 c) including 3-way valve is at

the storage tank in utility area.

progress & innovation Vers. 12.1 12/46

!

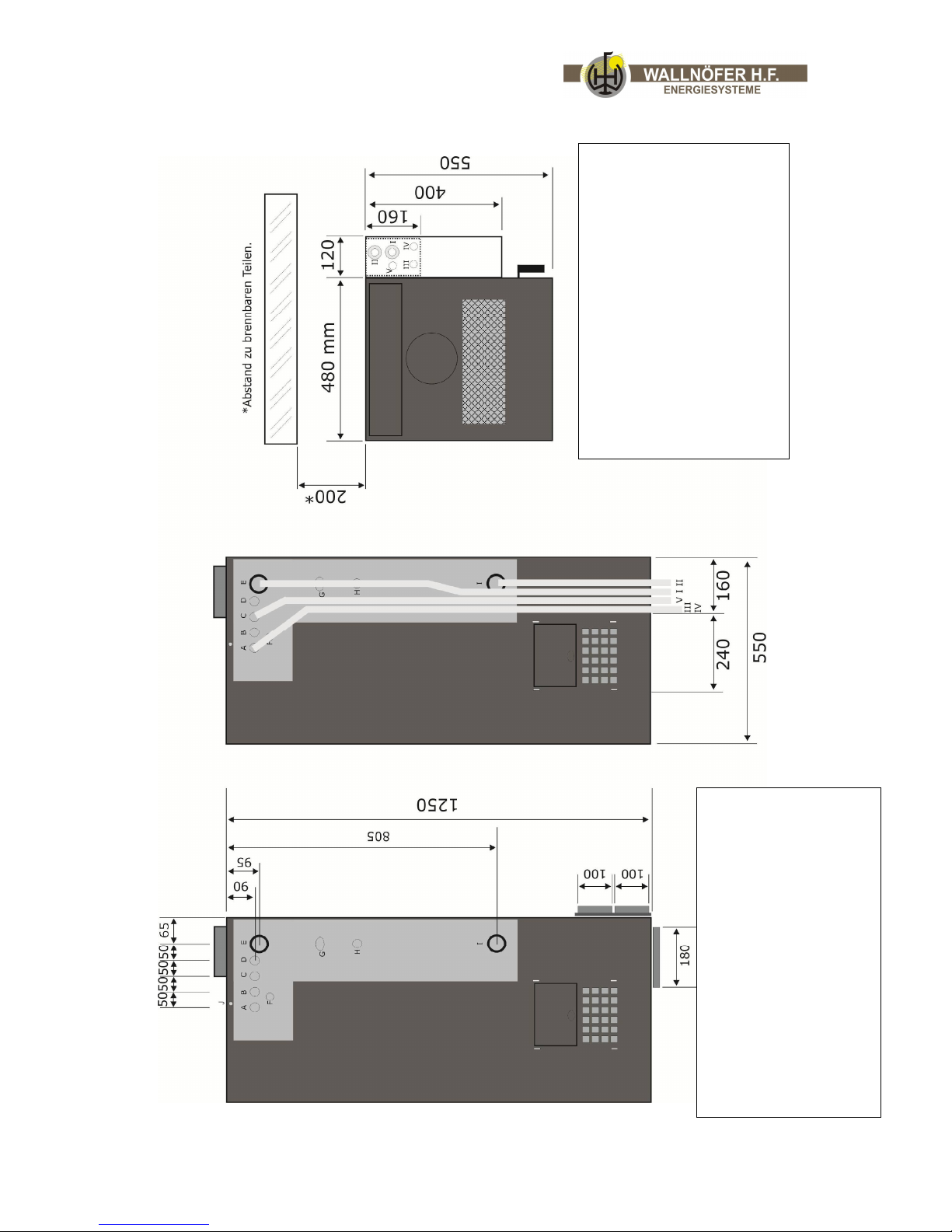

Front view top view

Parts list of the stove:

4 Handling und Transport

Der Ofen wird mit allen vorgesehenen Teilen geliefert.

Der Schwerpunkt des Heizofens liegt im hinteren Bereich.

Dies ist auch beim Verstellen des Heizofens auf seinem Transport-

Untergestell zu beachten.

Gefahr: Sicherstellen, dass die Belastbarkeit des Hubstaplers über

dem Gerätegewicht liegt. Der Bediener der Hebevorrichtung hat

die gesamte Verantwortung für das Anheben der Lasten.

Fig. 3.a.3 Fig.3.a.4 Fig.3.a.5

Vorlauf (Heizkreis) = how water outlet (heating circuit)

Rücklauf (Heizkreis) = cold water inlet (heating circuit)

progress & innovation Vers. 12.1 13/46

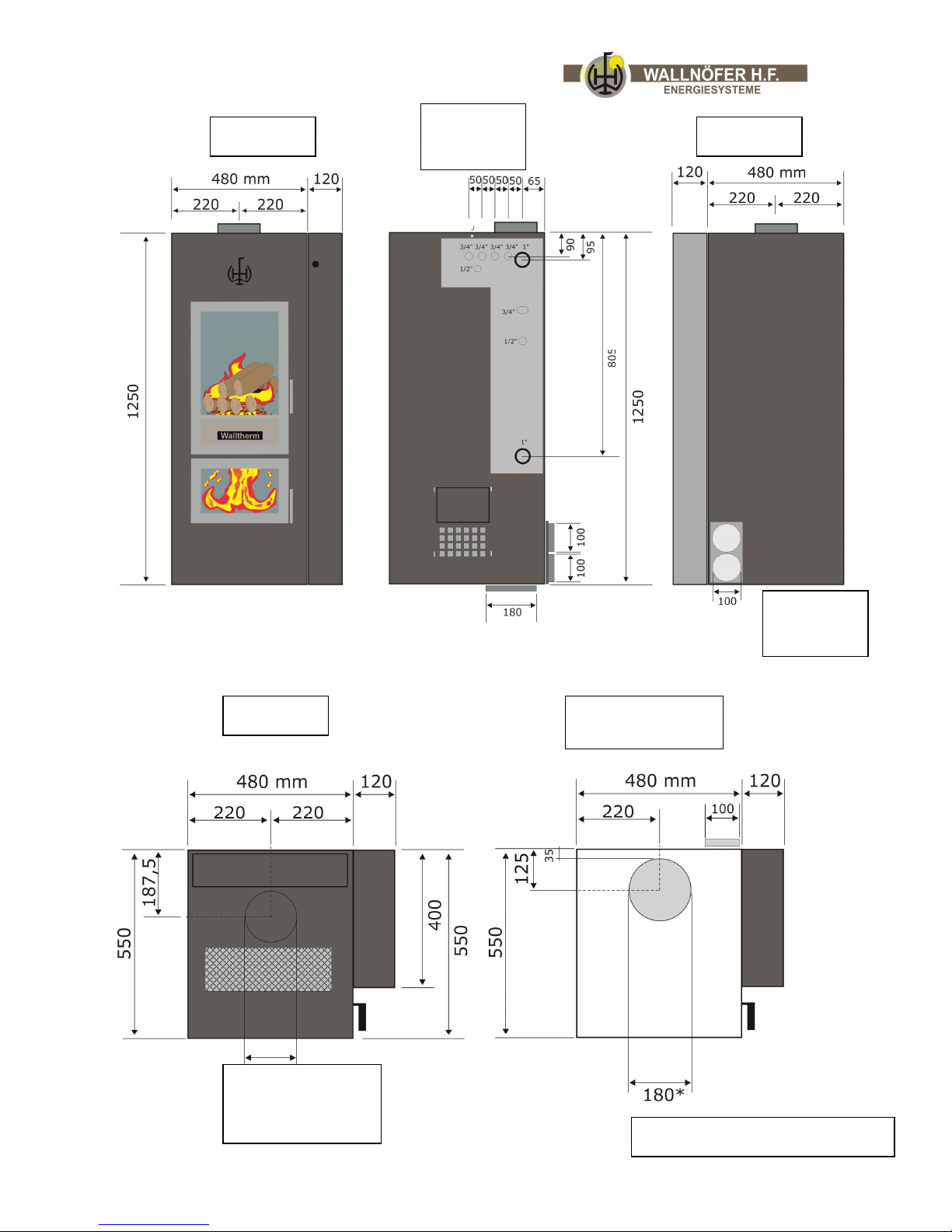

Top view

Front view

View from

right side

Backside

All

dimensions

are in mm

View from under the

stove

Air intake from under the stove

Chimney muff

progress & innovation Vers. 12.1 14/46

A Security heat exchanger

B Sensor thermal safety drain

C Overpressure valve

D Thermostat(sensor

E Forward flow

F Thermometer

G Thermostat for air intake

H Pressure gauge

I Backflow

J Fume sensor

I Forward flow

II Backflow

III Cold water

IV Drain for thermal safety

V Drain for overpressure valve

Loading...

Loading...