Wallgate WDC200 Product Manual

Product Manual

WDC200 Electronic Control

For Basins/Baths, Showers and WCs

2

Product Manual WDC200 Electronic Control

Revision 18

AS 1172

Certificate No

23167

RCM Mark

Australia

3

Product Manual WDC200 Electronic Control

Revision 18

Table of Contents

1. Disclaimer & Copyright Notice ............................................................................................... 4

2. Conventions ........................................................................................................................... 5

2.1. Warning ............................................................................................................................... 5

2.2. Note .................................................................................................................................... 5

2.3. Numbered procedures ....................................................................................................... 5

2.4. Bullet lists ............................................................................................................................ 5

2.5. Tick Bullet lists .................................................................................................................... 5

2.6. Menu items ......................................................................................................................... 5

3. Glossary .................................................................................................................................. 6

4. Product summary ................................................................................................................... 8

5. Installation and Commissioning ............................................................................................. 9

5.1. Package Contents ............................................................................................................... 9

5.2. Site Preparation .................................................................................................................. 9

5.2.1. Advice on attaching the unit ............................................................................................ 9

5.2.2. Electrical connections ...................................................................................................... 9

5.3 Attach the Controller Unit ................................................................................................ 10

5.4. Connect the Input and Output Cables .............................................................................. 11

5.5. Connect the 3-pin output connector ................................................................................ 13

5.6. Connect the 3.5mm input connector ............................................................................... 13

5.7. Connect the Electrical Supply ........................................................................................... 13

5.8. Commission the Unit ........................................................................................................ 14

5.9. Purge Cycle function ......................................................................................................... 14

5.10. Lockout function ............................................................................................................. 15

5.11. Piezo touch button and infrared sensor controls ........................................................... 16

5.12. System Test function ....................................................................................................... 17

5.13. Product Time Slots .......................................................................................................... 18

5.14. Hygiene Purge ................................................................................................................. 18

5.15. Data Logging .................................................................................................................... 18

5.16. Auto-Run ......................................................................................................................... 19

5.17. Technical Specifications .................................................................................................. 19

6. User and Maintenance Instructions ..................................................................................... 20

6.1. Operation .......................................................................................................................... 20

6.2. Maintenance ..................................................................................................................... 22

7. WDC200 Menu Settings ....................................................................................................... 22

8. Related Documentation ....................................................................................................... 30

9. Model Variations .................................................................................................................. 31

4

Product Manual WDC200 Electronic Control

Revision 18

9.1. WDC200-1 ......................................................................................................................... 31

9.2. WDC200-2 ......................................................................................................................... 31

9.3. WDC200-3 ......................................................................................................................... 32

1. Disclaimer & Copyright Notice

Every effort has been made to supply information within this manual which is correct.

Wallgate Limited will not be liable for any damage or loss that arises if the person

installing, operating or maintaining the unit has not read or not complied with the

manual

In any event, and without prejudice to any warranties in Wallgate Limited’s terms and

conditions of sale, Wallgate Limited’s liability for all damages and losses (including

negligence) shall not in any circumstances exceed the amount paid by the customer

for the unit.

Wallgate reserves the right to alter, update or improve its product specification at any

time without prior notice. This manual is specific to the product that it has been

supplied with at the date of supply.

Without prejudice to any warranties in Wallgate Limited’s terms and conditions of

sale, any warranty will be invalidated if the equipment is installed or serviced by

unqualified personnel.

No part of this publication and the information contained may be reproduced,

transmitted, stored in a retrieval system, used or disclosed wholly or partly without

prior written permission from Wallgate Limited.

For full warranty details please see Wallgate Limited Terms and Conditions.

Please ensure this manual is passed to the end user. The manual forms an integral

part of the product and should be kept for its working life. Additional copies of this

and other supporting documents are available by contacting Wallgate Limited or by

visiting www.wallgate.com

5

Product Manual WDC200 Electronic Control

Revision 18

2. Conventions

Certain conventions are used in this manual to make it easier to read and

understand. They are given in the sections below.

2.1. Warning

A warning with red text on a white background is used to give information about

hazards that can cause injury or death. Read and understand the warnings before

you install and commission the WDC200. Failure to heed these warnings can have

serious consequences.

WARNING! This is a warning!

2.2. Note

A note with amber text on a white background is used to draw your attention to

important and useful information.

NOTE: This is a note.

2.3. Numbered procedures

Steps in procedures are numbered, starting from 1.

1. This is step 1.

2. This is step 2 etc.

2.4 Bullet lists

2.4. Bullet lists

• A bullet list is used to give information that is not sequential.

2.5. Tick Bullet lists

✓ A tick bullet list is used to imply a checklist of components or actions (not

sequential).

2.6. Menu items

Menu items, submenu items and settings, where available, are given in bold.

6

Product Manual WDC200 Electronic Control

Revision 18

3. Glossary

The glossary lists all words, abbreviations and technical terminology used in this

manual, along with a short description of these terms.

Table 1. Glossary

Term

Description

Auto-run

The outputs to the water valves for basin, shower and

WC can be set to automatically operate at a set time

every day. The water valve will operate for the cycle set

run time as per a user activation. The Auto-run feature

can be used for maintaining hygiene standards similar to

the Hygiene Purge function detailed below, note that

only the Auto-run or Hygiene Purge would be utilized

and not both together.

Building Management

System

BMS

A Building Management System is a computer-based

control system installed in buildings that controls and

monitors the building’s mechanical and electrical

equipment such as ventilation, lighting, power systems,

fire systems, and security systems.

WDCMS

The WDCMS Wallgate system is use for standalone

networking of the WDC control units to a dedicated PC

or laptop computer. You can manage the WDC units

through the network. You can also adjust time cycle

settings, lockout settings, remote water isolation on

individual units or groups, RTC settings, etc. You can

also view the unit status in real time and log data.

Data Logging

Activations of the Hygiene Purge function detailed below

are logged in memory and then using additional software

the logs can be downloaded from the WDC200 and

imported into a spreadsheet report.

Dual Flush

This option is used when both full and half flush options

must be provided, using either one or two inputs.

Exclusivity

This feature prevents more than one water outlet from

being operated at a time.

Full Flush

This feature uses a 6 litre or 4.5 litre flush.

Reduced & Half Flush

The reduced flush is ⅔ of a full flush and the half flush ½

of a full flush.

Hygiene Purge

This feature operates services unused for a specified

number of days. This avoids water stagnation when the

services are unused for longer periods.

Latching

A latching switch is a switch that maintains its state after

being activated.

7

Product Manual WDC200 Electronic Control

Revision 18

Term

Description

Lockout

The term Lockout refers to regulating services by

restricting the number of usage cycles.

Momentary

A momentary switch returns to its normal OFF position

when released.

Piezo touch button

A piezoelectric touch button converts the force applied to

the face of the touch button into an electrical signal.

Power Rating

The power rating of a device is a guideline set by the

manufacturer as a maximum power to be used with that

device.

Purge Cycle

This feature is used to assist in removing air trapped in

the plumbing system.

Remote Lockouts

The term Remote Lockout refers to isolating water

services from a remote location.

RJ45 connection

The RJ-45 connectors are used to connect the WDC unit

to a PC or laptop.

RTC

Real Time Clock. This is a 24 hour 7 day clock used by

the WDC200 for program features such as Time Slots

and Hygiene Purge.

System Test

The System Test is a feature that allows you to operate

switches and touch buttons and make sure that these

operate the necessary outputs such as lights or valve

solenoids.

Time Slots

Usage of services such as basins, showers and WC

pans can be controlled using preset time slots. For

example, this feature can be used to prevent all the

showers in a facility being operated simultaneously

during peak periods, straining the capacity of the water

supply. The day is divided into 4 time slots, normally set

at 00:00 to 06:00, 06:00 to 12:00, 12:00 to 18:00 and

18:00 to 00.00.

Toggle type switch

A toggle switch is a class of electrical switches that are

actuated by a mechanical lever, handle, or rocking

mechanism.

Water Lockouts

Water Lockout means regulating water services by

restricting the number of usage cycles.

8

Product Manual WDC200 Electronic Control

Revision 18

4. Product summary

The WDC200 electronic control units are designed to operate the water outlets to a

wash basin* (x2) (Hot & Cold), a shower (x2) (premixed warm water) and the flush

for toilet water closet pan (x2) (WC). The WDC200 therefore has the capacity to

control two suites of products and can be located between two rooms.

*The WDC200 can be set to operate with a bath instead of a basin if required. This

would entail the installer or client adjusting water run times to 180 seconds for hot

and cold, or as preferred.

The WDCA200 model based upon the WDC200 is for 120v 60Hz electrical supply

operation using an external power adapter (UL/CSA approved) to connect to the

12VDC input socket on the WDCA200 control unit.

The control unit comprises of a microprocessor that is programmed with a software

program that has the following operational features:

• User friendly Software menu system with security controlled access.

• Independent control of multiple outlets.

• Fully programmable precise time control of water valve operation that is fully

adjustable in situ by the installer / customer.

• “LOCKOUT” function to prevent product misuse that is fully adjustable for the

number of user operations, operations period, lockout period, and the

“LOCKOUT” function can be ENABLED or DISABLED to suit the individual

requirements.

• Single or dual flush for WC control.

• Piezo touch button or infrared sensor capable inputs.

• Auxiliary inputs for remote operation of:

• Remote lockouts (Room 1 / Room 2).

• WC remote flush.

• WC reduced flush using a second touch button.

• Clear lockouts.

• Purge function.

• Not used

• Flow sensor for hygiene purge data logging.

• Multiple outlet control feature (COMMUNAL mode setting), so that one unit can

be used to operate up to eight water valves instead of default pre-sets for basins

and WC pans.

• Diagnostic test routine to assist with fault finding.

• Networking units to remotely control from a central PC desk position(s).

• Data logging of hygiene purges.

9

Product Manual WDC200 Electronic Control

Revision 18

5. Installation and Commissioning

5.1. Package Contents

Before you begin the installation, make sure that you have the following items:

✓ 1 WDC200 Electronic control unit

✓ 1 Product manual.

5.2. Site Preparation

5.2.1. Advice on attaching the unit

• Attached the unit to a vertical surface that is able to support the weight of the unit.

• Attach the unit in dry surroundings above pipes carrying water, away from any

possible plumbing leaks.

• Attach the electronic control unit where there is easy access. Attach the unit so

that the keypad and display on the unit are readily visible and accessible.

WARNING! Do not mount the unit upside down

The control box has four feet with holes for attaching the unit to the wall using four

round head screws, No 8 x 30mm (1.25 inch). For the location of the mounting feet,

refer to Figure 1 on page 10.

5.2.2. Electrical connections

• All cables must be connected to the unit using the sockets at the bottom of the

unit enclosure.

• The power cable must be connected to the unit through the cable gland.

• The control unit requires an electrical supply of 115-230V AC (Fuse 2 Amp) 50Hz

60 Watts.

• The mains supply cable from the unit must be terminated into a double pole fused

spur connection unit with a contact separation of at least 3mm. Use a 2 Amp fuse

in the connection unit.

• Place the connection unit near the controller unit.

• Position all electrical fittings such that water cannot drip on the electrical fittings if

a leak occurs, or a pipe bursts.

WARNING! The controller unit must be earthed using the earth lead in the

power cable.

10

Product Manual WDC200 Electronic Control

Revision 18

5.3 Attach the Controller Unit

To attach the control unit to the wall, do the following:

Mark the attachment points for the control unit on the wall. Make sure the cables

from the solenoid valves and Piezo touch buttons are of sufficient length to reach

the control unit. Refer to figure 1 for the location of the mounting feet.

Drill four mounting holes using a suitable drill bit.

Use suitable wall plugs if necessary.

Attach the unit to the wall using four round head screws.

NOTE: When mounting the unit, make sure the cable sockets at the bottom of

the unit point downwards.

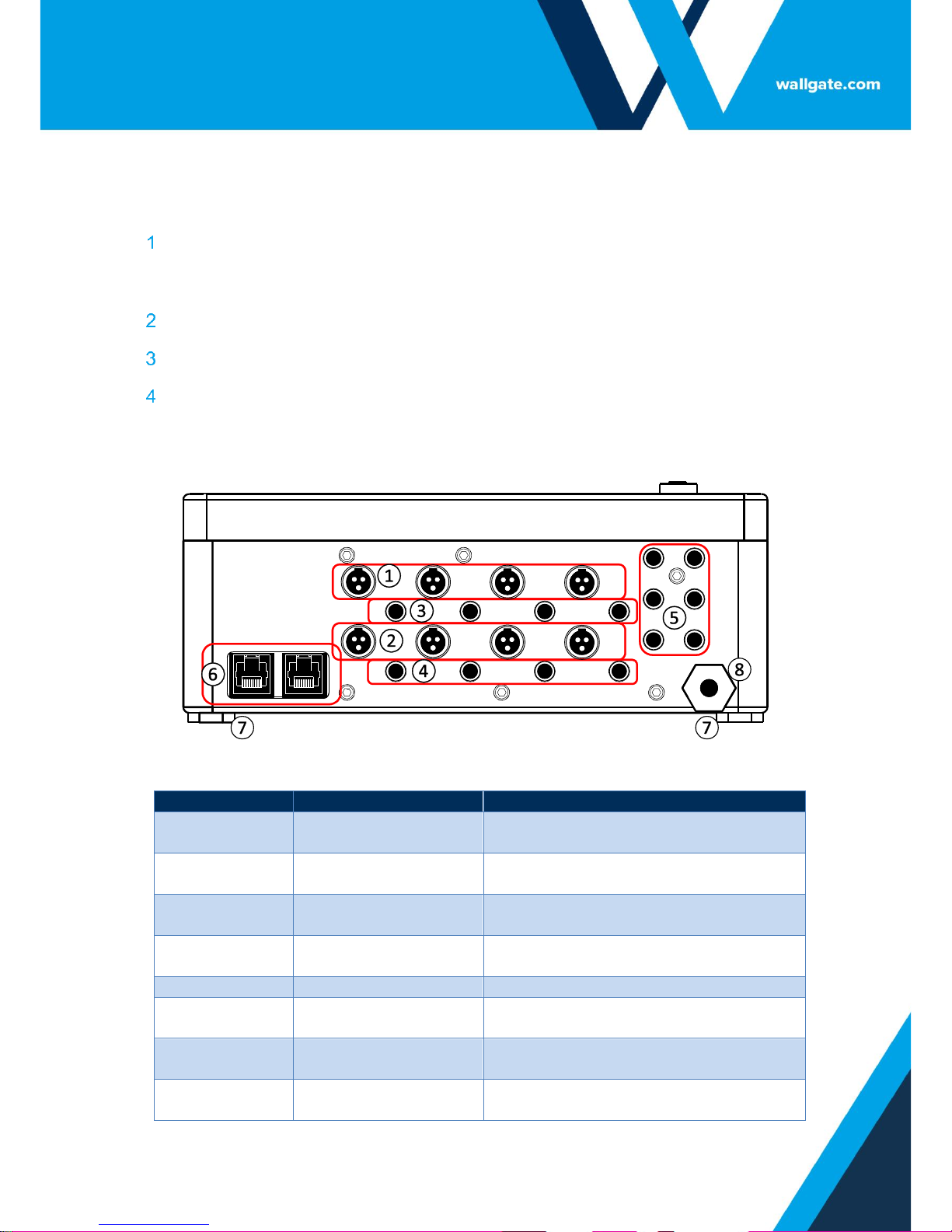

Figure 1.WDC200 Lower Panel

Table 2. Legend for Figure 1

Item number

Description

Function

1

Water Valve Cable

Sockets Room 1

Output to washbasin, WC and shower

valves in Room 1

2

Water Valve Cable

Sockets Room 2

Output to washbasin, WC and shower

valves in Room 2

3

Input Device Sockets

Room 1

Input from Piezo touch button or

infrared sensors Room 1

4

Input Device sockets

Room 2

Input from Piezo touch button or

infrared sensors Room 2

5

Auxiliary Inputs

Inputs for optional remote controls

6

Network Link Sockets

Input and output sockets for Ethernet

connection

7

Mounting feet

Use the feet to mount the control unit

to the wall

8

Power cable

Electrical power supply cable 1 metre

in length

Loading...

Loading...