Page 1

OPERATOR'S MANUAL

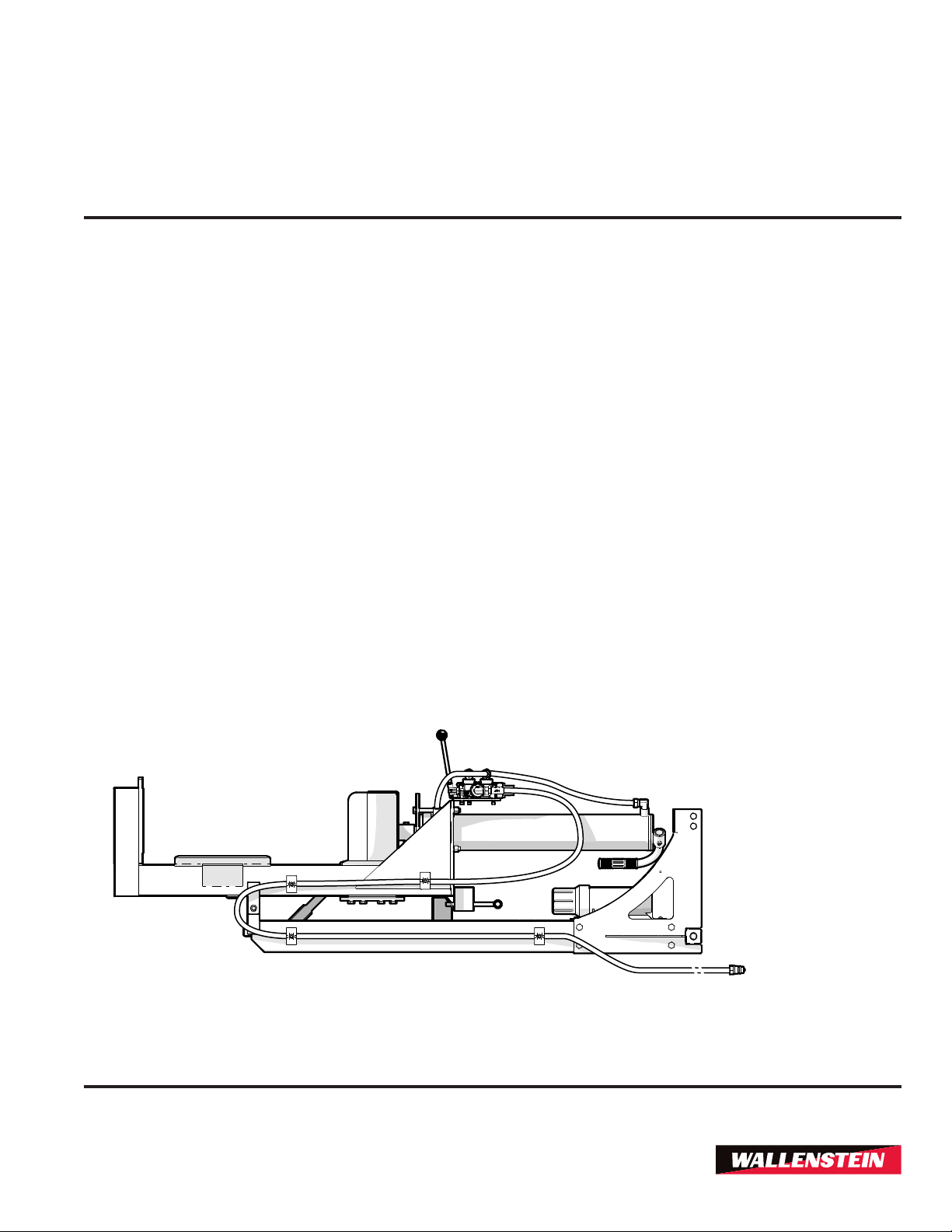

WX

3-point Hitch Wood Splitter

370

Part Number: Z97140_EnRev May-2019

Page 2

Introduction

WX370

3-point Hitch Wood Splitter

1. Introduction

1.1 Foreword

Congratulations on choosing a Wallenstein Threepoint Hitch Wood Splitter!

This high-quality machine is designed and

manufactured to meet the needs of an efcient wood

splitting operation.

This manual covers the Wallenstein 20-ton WX370.

The 3-point hitch mounted WX370 features horizontal

and vertical splitting.

The standard splitter models are equipped with an

open-center control valve. For tractors with a closedcenter system, the splitters are equipped with a closed

center control valve and the model is identied as

WX370C.

Units of measurement in Wallenstein Equipment

technical manuals are written as:

US Customary (SI metric).

Review all safety, operation and maintenance

information contained in this manual.

WARNING!

Do not attempt to start or operate the machine

without thoroughly reviewing this manual for

safe and proper operation.

Keep this manual with the machine at all times.

W034

Keep this manual handy for frequent reference and

to pass on to new operators or owners. Call your

Wallenstein dealer or distributor if you need assistance,

information or additional copies of the manuals.

Wallenstein Equipment Inc. • © 2019

www.wallensteinequipment.com

2

Page 3

WX370

3-point Hitch Wood Splitter

Table of Contents

1. Introduction ............................................................2

1.1 Foreword .........................................................2

1.2 Delivery Inspection Report ..............................4

1.3 Serial Number Location ...................................5

1.4 Decal Information ............................................6

2. Safety ......................................................................7

2.1 Safety Alert Symbol .........................................7

2.2 Signal Words ...................................................7

2.3 Why is SAFETY important? .............................8

2.4 Safety Rules ....................................................8

2.5 Equipment Safety Guidelines ..........................9

2.6 Safety Training ................................................9

2.7 Hydraulic System Safety .................................9

2.8 Be Prepared ..................................................10

3. Safety Signs .........................................................12

3.1 Safety Sign Locations ....................................12

3.2 Safety Sign Explanations ...............................13

3.3 Replacing Damaged Safety Signs .................14

4. Familiarization......................................................15

4.1 To the New Operator .....................................15

4.2 Machine Components ....................................16

5. Controls ...............................................................17

5.1 Hydraulic Valve ..............................................17

5.2 Stroke Limiter Accessory ...............................18

5.3 Splitter Frame Latch ......................................19

6. Operating Instructions ........................................20

6.1 Attaching to Tractor .......................................20

6.2 Connecting Hydraulic Hoses .........................21

6.3 Operating Safety ............................................22

6.4 Before Start up ..............................................22

6.5 Splitting Logs .................................................23

6.6 Machine Break-In ..........................................25

6.7 Transporting ..................................................25

7. Storing the Wood Splitter ...................................26

7.1 Removing from Storage .................................26

8. Service and Maintenance ....................................27

8.1 Maintenance Safety .......................................27

8.2 Maintenance Schedule ..................................27

9. Troubleshooting ...................................................28

10. Specications ....................................................29

10.1 Machine Specications ..................................29

10.2 Common Bolt Torque Values ........................30

10.3 Hydraulic Fitting Torque ................................31

11. Warranty .............................................................32

12. Alphabetical Index .............................................33

Introduction

3

Page 4

Introduction

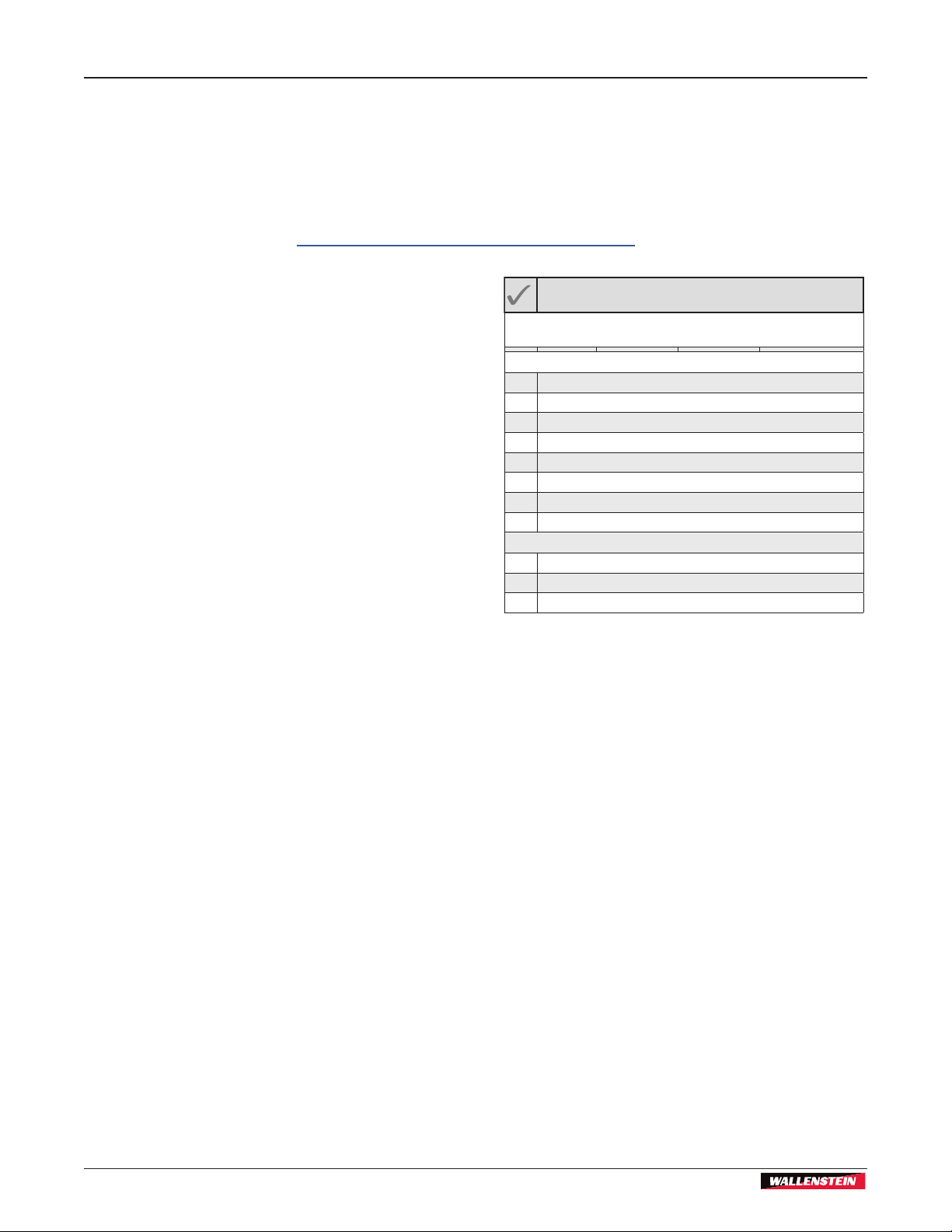

1.2 Delivery Inspection Report

WALLENSTEIN

WX370 Three-point Hitch Wood Splitter

To activate warranty, register your product online at

http://www.wallensteinequipment.com

_________________________________________

Customer’s Name

_________________________________________

Contact Name

_________________________________________

Dealer Name

(_________)_______________________________

Phone Number

_________________________________________

Serial Number

WX370

3-point Hitch Wood Splitter

Pre-delivery Inspection

Inspect for damage from shipping. Immediately contact the

shipping company if damage is found.

Three-point Hitch Wood Splitter

Hydraulic Valve Control Function

Hydraulic Cylinder Function

Horizontal / Vertical Pivot Moves Freely (as equipped)

Front and Rear Support Stands Move freely

All fasteners are Tight

Lubricate all Pivot Points (as equipped)

Check that all Hydraulic Connections are tight

Review Operating and Safety Instructions

Safety Checks

All Safety Decals Installed

Guards and Shields Installed and Secured

Review Operating and Safety Instructions

__________ /__________ /__________

Delivery Date

I have thoroughly instructed the buyer on the equipment care, adjustments, safe operation and applicable

warranty policy and reviewed the manual.

_________________________________________

Dealer’s Rep. Signature

__________ /__________ /__________

Date

The product manuals have been received by me and

I have been thoroughly instructed as to care, adjust-

ments, safe operation and applicable warranty policy.

_________________________________________

Owner's Signature

__________ /__________ /__________

Date

4

Page 5

WX370

3-point Hitch Wood Splitter

Introduction

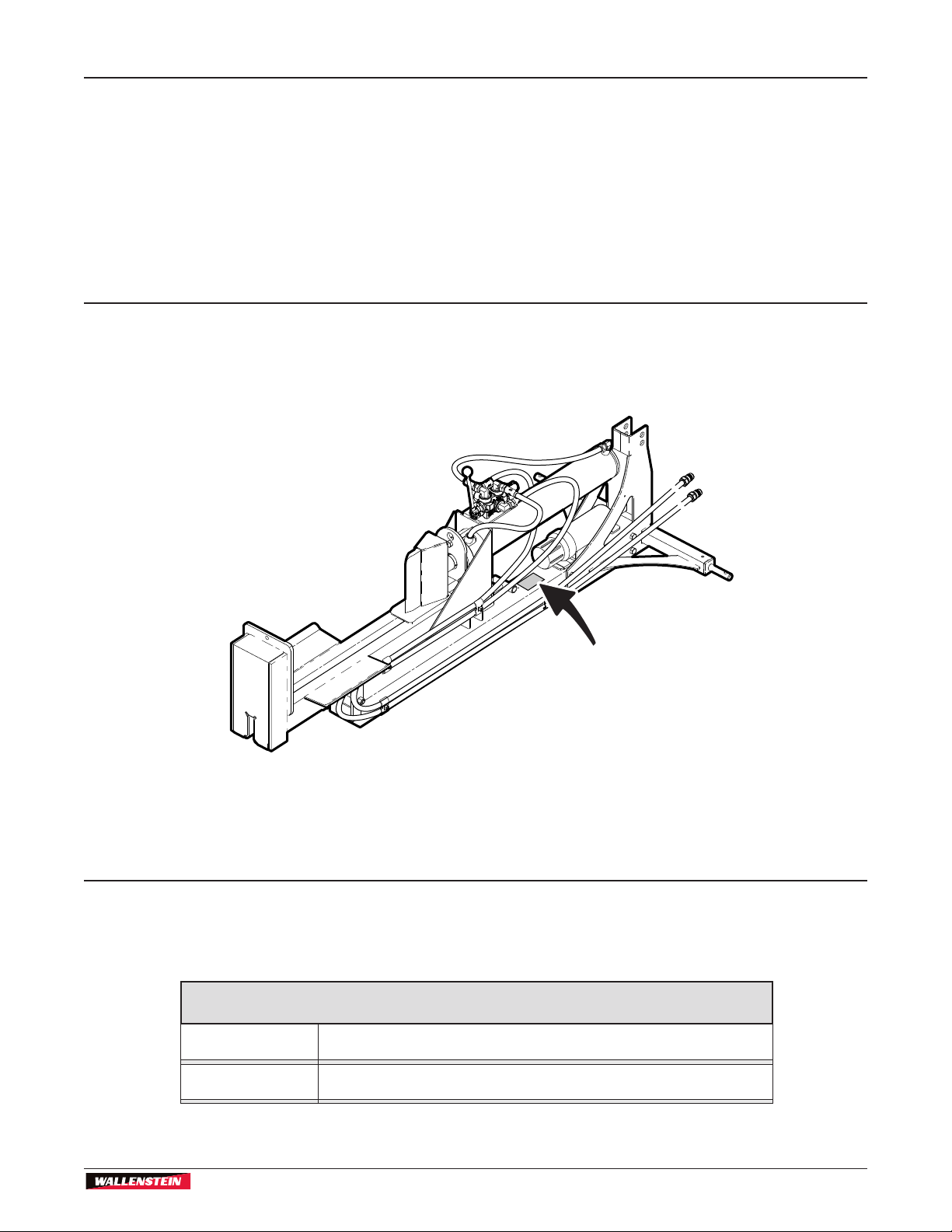

1.3 Serial Number Location

Always provide the model and serial number of your

Wallenstein product when ordering parts, or requesting

service or other information. The product information

plate location is shown below.

WX370

For future convenience, record the product Model

and Serial Number in the spaces provided below.

Model:

Serial Number:

Fig. 1 – Product Information Plate Location

Record Product Information Here

5

Page 6

Introduction

WX370

3-point Hitch Wood Splitter

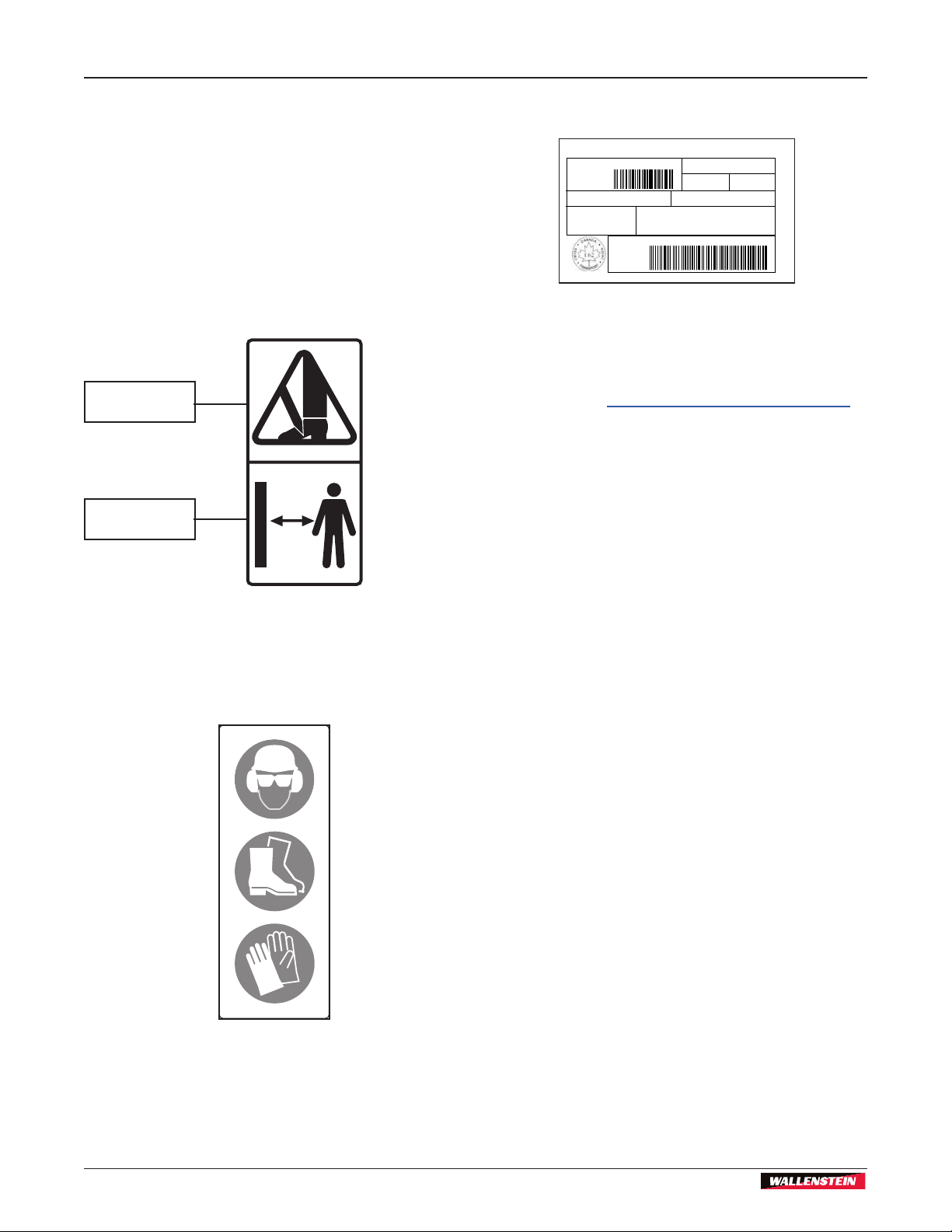

1.4 Decal Information

When getting familiar with the Wallenstein product,

notice that there are numerous decals located on the

machine. There are different types of decals for safety,

information, and product identication. The following

section explains what they are for and how to read

them.

Safety Decals are pictorial with a yellow background

and generally two panel. The top panel shows the

safety alert (the potential hazard) and the bottom panel

shows the message (how to avoid the hazard).

Safety alert

Message

Product Decals indicate machine model and serial

number, and other important information.

Manufactured by:

Wallenstein Equipment Inc., 7201 Line 86, Wallenstein ON N0B2S0, Canada

MODEL: ##########

DIMENSION- RIM/JANTE /ERIT : PNEU:

###

COLD INFL. PRESS/PRESS DE

CONFLA A FROID (PSI/LPC):

THIS VEHICLE CONFORMS TO ALL APPLICABLE STANDARDS

PRESCRIBED UNDER THE CANADIAN MOTOR SAFTEY REGULATIONS

IN EFFECT ON THE DATE OF MANUFACTURE / CE VEHICLE EST

CONFORME A TOUTES LES NORMES QUI LUI SONT APPLICABLES EN

VERTU DU REGLEMENT SUR LA SECURITE DES VEHICLES

###

AUTOMOBILES DU CANADA EN VIGUEUR A LA DATE DE SA FABRICATION.

VIN/

NLV:

TYPE OF VEHICLE/TYPE DE VEHICLE:

GAWR/PNBE (KG): GVWR/PNBV (KG):

#########

TRA / REM

###

###

###

See the section on safety signs for safety decal

denitions. For a complete illustration of decals and

decal locations, download the parts manual for your

model product at www.wallensteinequipment.com.

Safety Notice Decals are pictorial with a blue

background and generally rectangular with single or

multiple symbols. This decal informs what Personal

Protective Equipment is required for safe operation.

6

Page 7

WX370

3-point Hitch Wood Splitter

2. Safety

2.1 Safety Alert Symbol

This Safety Alert Symbol means:

ATTENTION! BE ALERT!

Safety

YOUR SAFETY IS INVOLVED!

The Safety Alert Symbol identies important safety

messages on the Wallenstein wood splitter and in

the manual. When you see this symbol, be alert to

the possibility of personal injury or death. Follow the

instructions in the safety message.

2.2 Signal Words

The signal words DANGER, WARNING and CAUTION

determine the seriousness level of the warning

messages in this manual. The appropriate signal word

for each message in this manual has been selected

using the following guidelines:

DANGER –

Indicates an imminently hazardous situation that,

if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme

situations typically for machine components which, for

functional purposes, cannot be guarded.

IMPORTANT – To avoid confusing equipment

protection with personal safety messages, a signal

word IMPORTANT indicates a situation that if not

avoided, could result in damage to the machine.

NOTE:

(plus text) – indicates an additional

explanation for an element of information.

Safety

WARNING –

Indicates a potentially hazardous situation that, if not

avoided, could result in death or serious injury, and

includes hazards that are exposed when guards are

removed. It may also be used to alert against unsafe

practices.

CAUTION –

Indicates a potentially hazardous situation that, if not

avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices.

7

Page 8

Safety

WX370

3-point Hitch Wood Splitter

2.3 Why is SAFETY important?

Three Big Reasons:

Safety

The policy of Wallenstein Equipment Inc. is to produce

products that are safe and reliable. However, even

when using well-engineered equipment, there is always

an element of risk. To minimize the risks and promote

safety at all times, this section of the operator’s manual

details a number of safety rules that must always be

followed and obeyed.

YOU are responsible for the SAFE operation and

maintenance of your Wallenstein Trailer Wood Splitter.

YOU must ensure that you and anyone else who

is going to use, maintain or work around the wood

splitter be familiar with the operating and maintenance

procedures and related safety information contained

in this manual. This manual provides good safety

practices that should be followed while using the wood

splitter.

Remember, YOU are the key to safety. Good safety

practices not only protect you but also the people

around you. Make these practices a working part of

your safety program. Be certain that EVERYONE using

this equipment is familiar with the recommended use

and maintenance procedures and follows all the safety

precautions.

2.4 Safety Rules

• Accidents Disable and Kill

• Accidents Cost

• Accidents Can Be Avoided

• DO wear appropriate Personal Protective

Equipment (PPE). The suggested equipment

includes but is not limited to the following:

- Hearing Protection

- Protective glasses, goggles or face shield

- Heavy work gloves

- Protective shoes with slip resistant soles

• DO have a rst-aid kit available

should the need arise and know

how to use it.

• DO read and understand all safety signs located

on the machine before operating, servicing,

adjusting, or cleaning.

• DO inspect and secure all guards before starting.

• DO have a re extinguisher available

should the need arise. Know how to use

it.

• DO think SAFETY! Work SAFELY!

• DO NOT expect a person who has not read and

understood all operation and safety instructions

to use the machine. An untrained operator is

not qualied and is exposed to possible serious

injury or death. It is the owner's responsibility

to make sure to the operator has familiarity and

understanding of the machine.

• DO NOT allow riders during transport.

• DO NOT risk injury or death by ignoring good

safety practices.

• DO give operating instructions to operators or

employees before allowing them to operate the

machine.

• DO read and understand ALL

Safety and Operating instructions

in the manual and follow them.

The most important safety device

on this equipment is a SAFE

operator.

• DO review safety related items annually with

all personnel who are operating the machine or

performing maintenance.

8

Page 9

WX370

3-point Hitch Wood Splitter

Safety

2.5 Equipment Safety Guidelines

Always place the machine in a Safe Condition before

performing any service work, maintenance procedures,

or storage preparation.

SAFE CONDITION

• Shut off engine.

• Make sure all moving parts have stopped.

• Disconnect battery ground (-) cable.

• Block or chock wheels.

1. Never use equipment with safety shields removed.

Keep all shields in place. If shield removal

becomes necessary for repairs, reinstall the shield

prior to use.

2. Replace any safety sign or instruction sign that is

not readable or is missing. Location of safety signs

is indicated in this manual.

3. Do not allow anyone other than a responsible,

properly trained and physically able person to

operate this machine. This equipment is dangerous

to children and persons unfamiliar with its

operation.

4. Do not modify the equipment in any way.

Unauthorized modication may result in serious

injury or death and may impair the function and life

of the equipment.

5. Never exceed the limits of the machine. If its ability

to do the job or to do it safely is in question—

STOP IMMEDIATELY!

2.6 Safety Training

bystanders to possible serious injury or death. If

elderly people are assisting with the work, their

physical limitations need to be recognized and

accommodated.

3. Learn the controls and how to stop the machine

quickly in an emergency.

4. If this machine is loaned or rented, it is the

machine owner's responsibility to make certain that

every operator:

• Reads and understands the owner's manual

• Is instructed in safe and proper use of the

equipment

• Understands and knows how to perform the

Safe Condition procedure

2.7 Hydraulic System Safety

1. Make sure that all the components in the hydraulic

system are kept in good condition and are clean.

2. Before applying pressure to the

system, make sure all components

are tight, and that lines, hoses and

couplings are not damaged.

3. Do not attempt any makeshift repairs to the

hydraulic lines, ttings or hoses by using tapes,

clamps or cements. The hydraulic system operates

under extremely high pressure. Such repairs can

fail suddenly and create a hazardous and unsafe

condition.

4. Wear proper hand and eye

protection when searching for a

high-pressure hydraulic leak. Use

a piece of wood or cardboard as

a backstop instead of hands to

isolate and identify a leak.

Safety

1. The best safety feature is an

informed, careful operator—we

ask you be that kind of operator.

It is the operator's responsibility

to read, understand and follow

ALL safety and operation

instructions in the manual.

2. Train all new personnel and review instruc tions

frequently with existing workers. Only properly

trained and physically able operators should

use this equipment. A person who has not

read and understood all operation and safety

instructions is not qualied to use the machine.

Untrained operators expose themselves and

5. If injured by a concentrated high-pressure

stream of hydraulic uid, seek medical attention

immediately. Serious infection or toxic reaction

can develop from hydraulic uid piercing the skin

surface.

6. Relieve pressure in the hydraulic system before

working on it.

9

Page 10

2.8 Be Prepared

Safety

Safety

1. Determine where the split wood is going to be piled

ahead of time. Make sure it does not interfere with

safe loading of wood into the splitter.

2. Precut logs so wood is ready to load into the

splitter. Do not run a chain saw and the splitter at

the same time.

3. Determine a safe work area location:

• Area must be clear of stones, branches or

hidden obstacles that might cause a tripping,

hooking or snagging hazard.

• Ground should be rm and level.

4. Operate only in daylight or good articial light.

5. Make sure machine is properly adjusted and in

good operating condition.

6. Perform the Pre-operation Checklist before

starting work (see Pre-operation Checklist on page

23).

WX370

3-point Hitch Wood Splitter

7. Do not operate on hillsides or when working area is

cluttered, wet, muddy or icy to prevent slipping and

tripping. Operate only on level ground.

8. Position machine so prevailing winds blow engine

exhaust fumes away from the operator.

9. Do not operate machine inside a closed building to

prevent asphyxiation from engine exhaust.

10. Stop engine when leaving the machine

unattended.

10

Page 11

WX370

3-point Hitch Wood Splitter

Safety

2.8.1 Sign-Off Form

Anyone using this machine must read and thoroughly

understand all Safety, Operation and Maintenance

information in this manual. An untrained operator

should never use this machine.

To help document this training, the sign-off sheet

provided below can be used.

Make periodic reviews of Safety and Operation a

standard practice for all operators. Review again at the

startup of every season.

Sign-off Form

Date Owner Employee

The design and manufacture of this product conforms

to relative provisions in the following standards:

ISO 4254-1 Agricultural machinery – Safety

ASABE S318 Safety for Agricultural Field Equipment

ISO 3600 Operator’s Manual – Machinery for

Agriculture, Forestry & Lawn Equipment

Safety

11

Page 12

3. Safety Signs

3.1 Safety Sign Locations

The types of safety signs and locations on the

equipment are shown in the illustrations that follow.

Good safety requires that you familiarize yourself with

Safety

the various safety signs, the type of warning and the

area, or particular function related to that area, that

requires your SAFETY AWARENESS.

Think SAFETY! Work SAFELY!

WX370

Safety Signs

WX370

3-point Hitch Wood Splitter

41 2 3

Fig. 2 – Safety Decal Locations

12

00717

Page 13

WX370

3-point Hitch Wood Splitter

3.2 Safety Sign Explanations

1. Warning!

Always wear appropriate Personal Protective

Equipment when using this machine. For example:

• A hard hat

• Heavy gloves

• Hearing protection

• Protective shoes with slip resistant soles

• Protective glasses, goggles or face shield

2. Caution!

Refer to the operator's manual. Read ALL operating

instructions in the manual and learn the meaning of

ALL safety signs on the machine.

Safety Signs

Safety

The best safety feature is an informed operator.

3. Warning!

Pinch point / crushing danger! Keep your hands away

from all moving parts during and after split operation!

Never try to clear a jammed log with your hands! Wait

for all moving parts to come to a complete stop before

loading or clearing obstructions.

13

Page 14

Safety

3.3 Replacing Damaged Safety

Safety Signs

4. Warning!

Keep feet away from falling split wood. Always wear

steel toed foot wear while machine is operating to

avoid serious personal injury.

Signs

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have

become illegible.

• Parts that were replaced with a safety decal on

them must also have the safety sign replaced.

• Replacement safety signs are available from your

authorized Distributor or Dealer Parts Department

or the factory.

WX370

3-point Hitch Wood Splitter

3.3.1 How to Install Safety Signs

Ambient temperature must be above 50 °F (10 °C) to

install decals.

1. Clean and dry the installation area.

2. Determine exact position before removing the

backing paper.

3. Peel back the corner of the backing paper.

4. Align the sign over the specied area and carefully

press the small portion with the exposed sticky

backing in place.

5. Slowly peel back the remaining paper and carefully

smooth the remaining portion of the sign in place.

6. Small air pockets can be pierced with a pin and

smoothed out using the piece of sign backing

paper.

14

Page 15

WX370

3-point Hitch Wood Splitter

Familiarization

4. Familiarization

4.1 To the New Operator

It is the responsibility of the owner or operator to

read this manual and to train all other operators

before they start working with the machine. Follow

all safety instructions exactly.

By following recommended procedures, a safe

working environment is provided for the operator,

bystanders and the area around the work site.

Untrained operators are not qualied to use the

machine.

Many features incorporated into this machine are

the result of suggestions made by customers like

you. Read this manual carefully to learn how to use

the machine safely and provide maximum operating

efciency. By following the instructions in conjunction

with a good maintenance program, your wood splitter

can provide many years of trouble-free service.

IMPORTANT! Make sure all operators

understand how to put the wood splitter in a Safe

Condition before working with this machine. See

Safe Condition page 9.

4.1.1 Training

Each operator must be trained in the proper set-up and

operating procedures before using the machine.

1. Move the unit to a large open area to allow the

operator to become familiar with control functions

and machine response.

2. Do not allow untrained operators to use the

machine. They can endanger themselves and

others, or damage property and the machine.

4.1.2 Job Site Familiarization

It is the responsibility of the operator to be thoroughly

familiar with the work site prior to starting.

1. Avoid close or cramped work spaces. Be sure

there is sufcient space and clearance for the

machine to operate.

2. Organize the working area to minimize movement.

3. Position the machine so prevailing winds blow

engine exhaust fumes away from you.

15

Page 16

Familiarization

4.2 Machine Components

6

WX370

3-point Hitch Wood Splitter

5

7

8

11

12

13

10

4

9

3

11

2

00741

1

Fig. 3 – WX370 Wood Splitter Components

1. Anvil

2. Log Saddle

3. Tilting Splitter Bed

4. Sliding Wedge

5. Control Valve

6. Hydraulic Cylinder

7. Splitter Frame Latch

8. Locking Latch

9. Splitter Frame

10. Product Manual Storage Tube

11. Category I, Three-point Hitch

12. Return (OUT) Line

13. Pressure (IN) Line

16

Page 17

WX370

3-point Hitch Wood Splitter

5. Controls

IMPORTANT! Before starting work with the wood

splitter, become familiar with the location and

function of all controls.

5.1 Hydraulic Valve

The control valve extends and retracts the wedge

to split the wood. The lever on the valve has three

positions—Extend, Neutral, and Retract.

Controls

00660

Fig. 4 – Extend–Neutral–Retract

Extend

• Push the lever forward (toward the wood) and hold

to extend the wedge and split the wood.

• Releasing the lever returns it to Neutral.

Fig. 5 – Extend Wedge to split Wood

Neutral Position

• Neutral is the center position on the valve.

• The wedge stops moving when the valve lever is

moved to Neutral.

• The valve lever can be moved to Neutral from

Extend or Retract at any time.

17

00636

Fig. 6 – Center (Neutral) Position

Page 18

Controls

WX370

3-point Hitch Wood Splitter

Retract

• Pull the lever fully backwards to retract the wedge.

The valve detent holds the lever in Retract allowing

a hands-free return cycle.

• The valve lever spring-returns to Neutral when

released from auto-retract.

00661

5.2 Stroke Limiter Accessory

The Stroke Limiter accessory improves productivity

when splitting shorter pieces. It stops the cylinder from

fully returning to the home position.

5.2.1 Stroke Limiter Adjustment

1. Place a typical sized log on the splitter bed, then

start / apply power to the wood splitter.

2. Using the hydraulic control, move the wedge up to

the log, but stop approximately 3" (8 cm) from it.

3. Shut off the engine. Make sure the hydraulic

control lever is in the neutral position.

4. Loosen the hex set screw on the rod adjusting

collar, and move the rod up to the wedge. (This is

the set position at which the wedge stops on the

return cycle.) Tighten the hex screw.

5. Test the set up by cycling the wedge through its

path. Split a log then put the hydraulic lever into

the return (detent) position. The lever should trip

the hydraulic control and the ram stops at the set

position. Adjust as required.

Fig. 7 – Retract Wedge

3"

(8 cm)

00734

Fig. 8 – Stroke Limiter

18

Page 19

WX370

3-point Hitch Wood Splitter

5.3 Splitter Frame Latch

WX370 splitters are designed with a pivoting main

frame that allows horizontal or fully vertical splitting. To

rotate the frame to vertical, follow these steps.

1. Remove the lynch pin from the locking latch and

swing it out of the way. (See below.)

2. While standing beside the controls, release the

splitter beam by pulling the spring loaded frame

latch outward.

3. At the same time, grab the cylinder end and tip

the splitter beam assembly up towards the vertical

position.

4. Continue tipping, while placing your foot on the

frame as a brace until splitter is in the full vertical

position.

5. Swing the locking latch around over the lock tab on

the splitter frame. Insert the lynch pin. (See right.)

Controls

00747

Fig. 9 – Locking Latch in Place

1. Splitter Frame Latch

2. Locking Latch

3. Lynch pin

1

Fig. 19 – Rotate Splitter to Vertical

19

3

2

00746

Page 20

Operating Instructions

WX370

3-point Hitch Wood Splitter

6. Operating Instructions

The operator has the responsibility of being

familiar with all operating and safety procedures

and following them.

IMPORTANT! Before starting work with the wood

splitter, become familiar with the location and

function of all controls.

6.1 Attaching to Tractor

WARNING!

Never let anyone stand between the tractor and

the implement during hitching. Too fast of an

approach or the operator’s foot slipping from the

clutch can lead to injury or fatality to the person

standing nearby.

IMPORTANT! Removing the drawbar may be

required for clearance.

1. On the tractor, place the 3-point hitch lift arms in

their full sway position, then reverse the tractor

up to the splitter. The tractor needs to be exactly

in-line with the mounting points of the splitter

otherwise attaching the 3-point hitch may require

moving the implement from side to side.

2. When reversing, lower/raise the lift arms so that

they are level with the lower attachment points on

the splitter.

W048

3. Back up slowly and align the balls in the lift arms to

the pins on the splitter.

4. Apply the tractor park brake.

5. Starting on one side, push the oating ball on the

tractor's lift arms over the lower attachment pin on

the splitter.

00752

Fig. 11 – Attach Lift Arms and Lynch Pins

6. Do the other side in the same manner, keeping the

lift arms even. Insert lynch pins on both sides to

secure the splitter to the tractor.

7. Attach the tractor top link to the upper attachment

point on the splitter. Insert the pin and lynch pin.

8. As with any implement, the turnbuckle on the top

link may need to be adjusted to level the splitter.

Raise the implement just off the ground to check.

Adjust top link length as required.

Fig. 10 – Back-up in line with Splitter

If not already done, level the splitter from side to

side using the lift arm jackscrew arm and the top link

turnbuckle. The splitter frame should always be kept

horizontal during operation.

00742

20

Page 21

WX370

3-point Hitch Wood Splitter

Operating Instructions

00743

Fig. 12 – Attached to Tractor

6.2 Connecting Hydraulic Hoses

WARNING!

Hydraulic oil under pressure can penetrate the

skin or eyes causing serious injury.

• Tighten all connections before applying

pressure.

• Search for leaks with a piece of cardboard or

wood, not a hand. Take care to protect hands

and body from high-pressure fl uids. Wear a

face shield or goggles for eye protection.

• If an accident occurs, see a doctor familiar

with this type of injury immediately.

W040

00744

Fig. 13 – Connecting Hydraulic hoses

1. Clean any dirt from the quick-disconnect couplers

on the tractor.

2. Route the splitter hoses along the tractor hitch to

avoid binding and pinching, then connect them to

the tractor couplers. The protective caps on the

hoses are colored to indicate function—red is the

pressure line, blue is return.

As an additional check, the ports on the

control valve are labeled IN (pressure from

tractor) and OUT (return to tractor).

3. Start up the tractor engine.

4. Move the splitter hydraulic lever to move the

wedge.

5. If the wedge does not move in the same direction

as the hydraulic lever, reverse the hoses.

6. Slowly raise the machine through its operating

range to make sure that there is no interference or

binding.

7. To unhook from the tractor, reverse the above

procedure. Always park the machine in a dry, level

area.

8. Place the protective caps on the hose ends.

21

Page 22

Operating Instructions

WX370

3-point Hitch Wood Splitter

6.3 Operating Safety

There is no substitute for a cautious, safe-minded

operator who recognizes potential hazards and follows

reasonable safety practices. The operator must be in

control of the machine at all times.

Read and obey the safety signs on the machine. Clean

or replace them if they are not legible.

1. Wear appropriate personal protective equipment.

Tie back long hair, remove jewelry, and avoid loose

tting clothing. Prolonged exposure to loud noise

can cause permanent hearing loss! Wear hearing

protection on a full-time basis when using this

machine.

2. Never use engine-powered machinery indoors.

Engine exhaust contains toxic carbon monoxide,

which cannot be smelled or seen. Breathing

carbon monoxide can be lethal.

3. Always load logs by grasping the bark side, not the

cut ends.

4. Do not reach into or load the splitter when the

wedge is in motion.

6.4 Before Start up

1. Clear the area of bystanders, especially small

children.

2. Make sure each operator is trained and familiar

with the set up and operation of the wood splitter.

3. Follow the Pre-Operation Checklist.

4. Review the Controls section (see page 17).

5. Survey the work site and position the wood splitter

in a clear, level work area.

6. Set up the machine correctly. See Set-up on page

23.

5. Keep hands out of splitting area. Do not rest hands

on the log being split.

6. Do not step over or straddle splitter during

operation.

7. Do not try to split more than one log at a time. The

logs can y out and cause injury.

8. Keep your ngers and hands away from cracks in

the log that can open while splitting.

9. Do not try to split logs across the grain. Some

types of wood can burst or splinter causing pieces

to be thrown causing injury.

10. For uneven cut logs, always place the square-cut

end against the splitting wedge.

11. Never place any part of your body where it

would be in danger if machine movement should

occur during assembly, installation, operation,

maintenance, repairing or moving.

22

Page 23

WX370

3-point Hitch Wood Splitter

Operating Instructions

6.4.1 Pre-operation Checklist

Efcient and safe operation of the Wallenstein

wood splitter requires that each operator reads and

understands the operating procedures and all related

safety precautions outlined in this section.

A Pre-operation Checklist is provided for the operator.

The checklist is important for both personal safety and

keeping the wood splitter in good mechanical condition.

Before operating the machine and each time thereafter,

check the following:

Pre-operation Checklist

Wood splitter is mounted on a tractor less

than 100 horsepower.

Extra weights are mounted on the front of the

tractor, if required.

Wood splitter is properly attached to the

tractor. Lynch pin retainers are installed in

mounting pins.

Check the wedge and anvil. Be sure they are

not damaged or broken or badly worn. Repair

or replace as required.

Check and remove any entangled material.

6.5 Splitting Logs

IMPORTANT! Park the wood splitter on a level,

dry work area free of debris and other objects.

Position the splitter so the prevailing wind blows

engine exhaust away from the operator.

1. Make sure working area is clear of stones,

branches or other obstacles.

2. Precut logs to desired block size, ready to load

onto splitter bed.

3. Determine where the split wood is going to be

piled. Make sure that location does not interfere

loading splitter.

4. Move tractor into its working position, set the

3-point hitch and the splitter to a comfortable work

height. Set the park brake.

5. Set the throttle in its mid-range position. Place the

working hydraulic circuit in detent.

6.5.1 Log Placement

WARNING!

Risk of pinching or crushing hazard between the

wedge or push block and the log!

Check for hydraulic leaks. Tighten

connections or replace components to stop

leaks.

Check and tighten all fasteners. Make sure

the equipment is in good condition.

Check that appropriate equipment for

personal protection is being used and in good

condition.

Check that jewelry, loose-tting clothing are

not worn. Make sure long hair is tied back.

Never place hands at the ends of the log.

Always grasp logs by the sides when loading or

removing.

• Always grasp the log by the sides not the

ends when placing in or removing logs from

the splitter. This minimizes the chance of getting

ngers, hands or an arm between the wedge and

the log.

WARNING!

Risk of pinching or crushing hazard! The worker

loading the splitter MUST be the only one in

control of the hydraulic cylinder and splitting

wedge.

Only one worker should operate and load the

wood splitter.

6.5.2 Horizontal Splitting

1. Place wood or log on the splitter.

W035

W036

2. Push control lever forward and hold to split wood.

23

Page 24

Operating Instructions

00644

WX370

3-point Hitch Wood Splitter

3. Release the lever when the log splits or cylinder

reaches full stroke and stops.

4. Pull the lever back to retract the wedge. The detent

holds the lever until the cylinder fully retracts,

allowing hands-free operation.

6.5.3 Vertical Splitting

WARNING!

Risk of pinching or crushing hazard between the

wedge or push block and the log!

Never place hands at the ends of the log.

Always grasp logs by the sides when loading or

removing.

1. Place wood or log on the splitter anvil.

2. Push control lever down and hold to split wood.

3. Release the lever when the log splits or cylinder

reaches full stroke and stops.

4. Pull the lever back up to retract the wedge. The

detent holds the lever until the cylinder fully

retracts, allowing hands-free operation.

5. If the log is large enough to require another split,

reposition and repeat steps.

W035

Fig. 14 – Hydraulic Control Valve Positions

IMPORTANT! Do not hold the valve lever to

extend or retract the cylinder once it has reached

the end of its stroke. Doing so can overheat the

oil.

5. If the log is large enough to require another split,

reposition and repeat steps.

00748

Fig. 16 – Log Placement

Fig. 15 – Single Blade Wedge

6. Pile the split wood close to the working area, but

do not allow pieces to pile up and clutter the area.

A cluttered working area can lead to tripping and

an accident.

24

Page 25

WX370

3-point Hitch Wood Splitter

Operating Instructions

6.7 Transporting

6.7.1 Transport Safety

1. Comply with local laws governing safety and

transporting of machinery on public roads.

2. Clean all debris off the splitter. Remove any tools

or other loose items.

3. Never allow riders on the machine.

4. Be a safe and courteous driver. Always yield to

oncoming trafc in all situations, including narrow

bridges, intersections, and so on.

5. Watch for other trafc when near or crossing

roadways.

6. Do not drink and drive.

7. Before transporting, perform a walk-around

inspection to ensure everything is safe.

00745

Fig. 17 – Vertical Splitting

6.6 Machine Break-In

Although there are no operational restrictions on

the wood splitter when used for the rst time, it is

recommended that the following items be checked:

After 1 hour of operation

1. Check that the wedge is adequately lubricated.

2. Check all nuts, bolts and other fasteners. Tighten

to their specied torque level.

3. Check hydraulic system for leaks. Tighten leaking

ttings and replace any leaking components.

4. Check for entangled material. Remove before

resuming work.

After 8 hours of operation

5. Repeat the above steps.

25

Page 26

Storing the Wood Splitter

WX370

3-point Hitch Wood Splitter

6.7.2 Prepare for Transport

• Make sure the pivoting main frame is fully lowered

to horizontal. The lock pin in the pivoting splitter

beam must be fully engaged.

• Swing the locking latch up to engage the tab on the

splitter frame. Insert the lynch pin.

00750

Fig. 18 – Lock Pin and Latch Engaged

• Clean all debris from the splitter that could fall off in

transport.

• Always be in compliance with all applicable local

regulations when transporting.

7. Storing the Wood Splitter

After the season's use and the wood splitter is going

to be put away in storage, it should be thoroughly

inspected and prepared. Repair or replace any worn

or damaged components to prevent any unnecessary

down time at the start of next season.

The wood splitter can have a long, trouble-free life by

following these steps:

1. Place the splitter in the horizontal conguration.

Fully retract the cylinder ram.

2. Thoroughly wash the machine using a pressure

washer to remove all dirt, mud, debris, and

residue.

3. Inspect the wedge, cylinder ram, anvil and wear

plates for damage or entangled material. Repair

or replace damaged parts. Remove all entangled

material.

4. Touch up all paint nicks and scratches to prevent

rusting.

5. Store the machine in an area away from human

activity. Select an area that is dry, level and free

of debris to park the wood splitter. Set it down on

wood blocking.

6. If the wood splitter is not stored inside a building,

cover with a waterproof tarp. Tie securely in place.

7. Do not allow children to play on or around the

stored machine.

7.1 Removing from Storage

1. Review and follow the Pre-operation Checklist.

See page 23

2. Review safety and operation procedures. See

page 8.

26

Page 27

WX370

3-point Hitch Wood Splitter

Service and Maintenance

8. Service and Maintenance

WARNING!

Risk of serious personal injury. Stop engine

before performing ANY service or maintenance

procedure. Reinstall all covers and guards

removed before putting machine back into

service.

8.1 Maintenance Safety

1. Follow good shop practices:

• Keep service area clean

and dry.

• Be sure electrical outlets

and tools are properly

grounded.

• Use adequate light for

the job at hand.

2. Never operate the machine in a closed building.

The exhaust fumes may cause asphyxiation.

W033

8.2 Maintenance Schedule

As Required

Check the condition of all hydraulic lines, hoses and

ttings. Replace any that are damaged.

Remove any entangled material from splitter.

Check that all fasteners are tight.

Every 100 hours or Annually

Grease wedge slide on splitter bed and pivot points..

Clean machine. Remove debris and entangled

material.

00751

3. Before servicing or repairing, place the machine in

a Safe Condition. See page 9.

4. Never work under equipment unless it is properly

supported.

5. When performing any service or maintenance

work always use appropriate personal protective

equipment.

6. Where replacement parts are necessary, use only

OEM parts to restore your equipment to original

specications. Wallenstein Equipment is not

responsible for injuries or damages caused by use

of unapproved parts or accessories.

7. When completing a maintenance or service

function, make sure all safety shields and devices

are installed before placing splitter in service.

8. When cleaning any parts, do not use gasoline. Use

a cleanser designed for that purpose.

9. Always use proper tools in good condition. Make

sure you understand how to use them before

performing any service work.

Fig. 20 – Splitter Bed Slide

27

Page 28

Troubleshooting

3-point Hitch Wood Splitter

9. Troubleshooting

The following table lists some problems that may be

encountered, with possible causes and solutions.

If a problem persists after reading through the

Troubleshooting section, contact the local dealer,

distributor or Wallenstein Equipment. Have the

machine serial number ready.

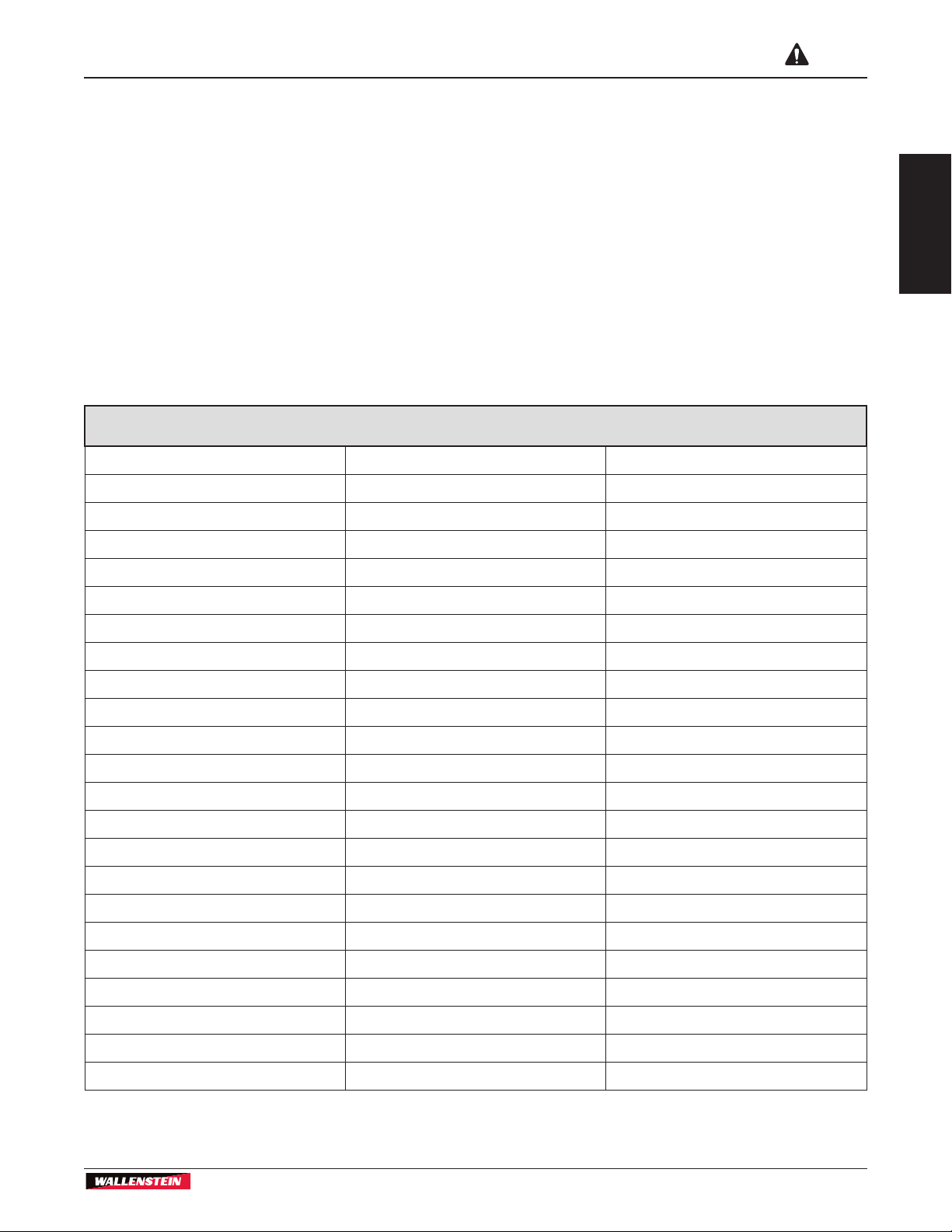

Problem Cause Solution

Oil lter plugged. Change lter.

No hydraulic oil pressure.

Cylinder rod moves slowly or

does not move. Screeching or

hissing noise.

Control handle does not go

to neutral after rod is fully

retracted.

Control handle goes to neutral

before rod is fully retracted.

Control handle does not go to

neutral when released.

Cylinder stops on contact with

wood.

Wedge jumps. Wedge frame jamming. Lubricate slider wear plates.

Leaking hydraulic hose. Hose worn or damaged. Replace hose.

Leaking cylinder. Seals worn.

Wood jammed around wedge.

Low engine speed.

Valve detent set too tight.

Hydraulic oil too cold. Allow machine to warm up.

Hydraulic uid is contaminated. Change hydraulic uid and lter.

Detent set too loose.

Control may be damaged.

Second stage on pump not

functioning.

Low hydraulic oil level. Add oil.

System relief pressure setting too low.

Call technician.

Shut machine off and safely remove

wood.

Check throttle is set to maximum.

Check that choke is off.

Adjustment required to detent on

valve.

Adjustment required to detent on

valve.

Control may need service or be

replaced. Call technician.

Pump may need to be serviced or

replaced. Call technician.

Seal replacement may be required.

Call technician.

WX370

28

Page 29

WX370

3-point Hitch Wood Splitter

10. Specications

Specications

10.1 Machine Specications

Model WX370

Mounting

Splitter Cylinder

Bore x Stroke

Splitting Force @ 2550 psi

(176 bar)

Splitting Force @ 3000 psi

(207 bar)

Valve Type

Recommended minimum

hydraulic ow

Splitter Orientation

Weight

Dimensions

(L x W x H)

Accessories

3-point Hitch Mounted

(102 mm x 609 mm)

Closed center, auto return detent

10 gpm (38 Lpm)

Horizontal or Vertical

290 lb (132 kg)

86" x 30" x 30"

(219 cm x 77 cm x 77 cm)

4-way Splitting Wedge

Stroke Limiter

1

4" x 24"

16 ton

20 ton

1 Specications subject to change without notice.

29

Page 30

Specications

10.2 Common Bolt Torque Values

WX370

3-point Hitch Wood Splitter

Checking Bolt Torque

The tables shown give correct torque values for

various bolts and capscrews. Tighten all bolts to

the torque values specied in the table, unless

indicated otherwise. Check tightness of bolts

periodically.

IMPORTANT! If replacing hardware, use

fasteners of the same grade.

IMPORTANT! Torque gures indicated in the

table are for non-greased or non-oiled threads.

Do not grease or oil threads unless indicated

otherwise. When using a thread locker,

increase torque values by 5%.

NOTE:

Bolt grades are identied by their

head markings.

Imperial Bolt Torque Speci cations

Bolt

Diameter

1/4" 6 8 9 12 12 17

5/16" 10 13 19 25 27 36

3/8" 20 27 33 45 45 63

7/16" 30 41 53 72 75 100

1/2" 45 61 80 110 115 155

9/16" 60 95 115 155 165 220

5/8" 95 128 160 215 220 305

3/4" 165 225 290 390 400 540

7/8" 170 230 420 570 650 880

1" 225 345 630 850 970 1320

SAE Gr. 2 SAE Gr. 5 SAE Gr. 8

lbf•ft N•m lbf•ft N•m lbf•ft N•m

Torque Value

Metric Bolt Torque Speci cations

Bolt

Diameter

M3 0.4 0.5 1.3 1.8

M4 2.2 3 3.3 4.5

M6 7 10 11 15

M8 18 25 26 35

M10 37 50 52 70

M12 66 90 92 125

M16 166 225 229 310

M20 321 435 450 610

M30 1,103 1 495 1,550 2 100

M36 1,917 2 600 2,700 3 675

Gr. 8.8 Gr. 10.9

lbf•ft N•m lbf•ft N•m

Torque Value

30

Page 31

WX370

3-point Hitch Wood Splitter

Specications

10.3 Hydraulic Fitting Torque

Tightening Flare Type Tube Fittings

1. Check are and are seat for defects that

might cause leakage.

2. Align tube with tting before tightening.

3. Hand-tighten swivel nut until snug.

4. To prevent twisting the tube, use two

wrenches. Place one wrench on the

connector body and tighten the swivel nut

with the second. Torque to values shown.

If a torque wrench is not available, use the FFFT

(Flats From Finger Tight) method.

Hydraulic Fitting Torque

Tube

Size

OD

Inches Inches

3/16 7/16 6 8 2 1/6

1/4 9/16 11–12 15–17 2 1/6

5/16 5/8 14–16 19–22 2 1/6

3/8 11/16 20–22 27–30 1-1/4 1/6

1/2 7/8 44–48 59–65 1 1/6

5/8 1 50–58 68–79 1 1/6

3/4 1-1/4 79–88 107–119 1 1/8

1 1-5/8 117–125 158–170 1 1/8

Values shown are for non-lubricated connections.

Hex

Size

Across

Flats

Torque value

lbf•ft

Flats From

Finger Tight

N•m Flats Turns

31

Page 32

Warranty

11. Warranty

Wallenstein products are warranted to be free of defects in materials and

from the date of purchase, when operated and maintained in accordance with the operating

and maintenance instructions supplied with the unit. Warranty is limited to the repair of the

product and/or replacement of parts.

This warranty is extended only to the original purchaser and is not transferable.

WX370

3-point Hitch Wood Splitter

LIMITED WARRANTY

workmanship under normal use and service, for a period of

Five Years for Consumer Use

Two Years for Commercial/Rental Use

Repairs must be done by an authorized dealer. Products will be returned to the dealer at the

customer’s expense. Include the original purchase receipt with any claim.

This warranty does not cover the following:

1) Normal maintenance or adjustments

2) Normal replacement of wearable and service parts

3) Consequential damage, indirect damage, or loss of profits

4) Damages resulting from:

• Misuse, negligence, accident, theft or fire

• Use of improper or insufficient fuel, fluids or lubricants

• Use of parts or aftermarket accessories other than genuine Wallenstein parts

• Modifications, alteration, tampering or improper repair performed by parties other

than an authorized dealer

• Any device or accessories installed by parties other than an authorized dealer

5) Engines. Engines are covered by the manufacturer of the engine for the warranty period

they specify. For the details of your engine warranty, see your engine owner’s manual.

Information about engine warranty and service is also available in the FAQ section at

www.wallensteinequipment.com

rev. Nov-2018

32

Page 33

WX370

3-point Hitch Wood Splitter

Alphabetical Index

12. Alphabetical Index

A

Attaching to Tractor ............................................................. 20

B

Before Starting the Engine .................................................. 22

Bolt torque ........................................................................... 30

Break-in ............................................................................... 25

C

Checking Bolt Torque .......................................................... 30

Controls ............................................................................... 17

Control Valve ................................................................. 17

Splitter Frame Latch ...................................................... 19

Stroke Limiter Accessory ............................................... 18

Control Valve ....................................................................... 17

D

Decal Information .................................................................. 6

Delivery Inspection Report .................................................... 4

E

Equipment Safety Guidelines ................................................ 9

F

Familiarization ..................................................................... 15

Job Site Familiarization.................................................. 15

Machine Components .................................................... 16

To the New Operator...................................................... 15

Training .......................................................................... 15

H

Horizontal Splitting .............................................................. 23

How to Install Safety Signs ................................................. 14

Hydraulic Fitting Torque ...................................................... 31

Hydraulic Hoses, Connecting .............................................. 21

I

Informative Labels ................................................................. 6

Introduction ........................................................................... 2

Foreword.......................................................................... 2

L

Log Placement .................................................................... 23

M

Machine Components ......................................................... 16

Machine Specications ....................................................... 29

Maintenance........................................................................ 27

O

Operating Instructions ......................................................... 20

Attaching to Tractor........................................................ 20

Before Starting the Engine............................................. 22

Connecting Hydraulic Hoses ......................................... 21

Log Placement ............................................................... 23

Machine Break-In........................................................... 25

Machine Set-up.............................................................. 23

Operating Safety ............................................................ 22

Pre-operation Checklist ................................................. 23

P

Personal Protective Equipment (PPE) .................................. 8

Pre-operation ...................................................................... 23

Pressure (IN) Line ............................................................... 16

Product Labels ...................................................................... 6

Product Manual Storage Tube ............................................ 16

Product Warranty ................................................................ 32

Putting Wood Splitter in Storage

Removing from Storage ................................................. 26

R

Replace Damaged Safety Signs ......................................... 14

Return (OUT) Line............................................................... 16

S

Safe Condition....................................................................... 9

Safety .................................................................................... 7

Equipment Safety Guidelines .......................................... 9

How to Install Safety Signs ............................................ 14

Hydraulic Safety............................................................... 9

Maintenance Safety ....................................................... 27

Operating Safety ............................................................ 22

Personal Protective Equipment (PPE) ............................. 8

Preparation .................................................................... 10

Safety Alert Symbol ......................................................... 7

Safety Do's and Don'ts .................................................... 8

Safety Training ................................................................. 9

Signal Words ................................................................... 7

Transport Safety ............................................................ 25

Safety Alert Symbol ............................................................... 7

Safety Notice Labels ............................................................. 6

Safety Sign Explanations .................................................... 13

Safety Sign Locations ......................................................... 12

Safety Signs ........................................................................ 12

Safety Sign Explanations ............................................... 13

Safety Sign Locations .................................................... 12

Safety Training ...................................................................... 9

Serial Number Location......................................................... 5

Service and Maintenance.................................................... 27

Maintenance Schedule .................................................. 27

Sign-off form .........................................................................11

Specications ...................................................................... 29

Common Bolt Torque Values ......................................... 30

Hydraulic Fitting Torque ................................................. 31

Machine Specications .................................................. 29

Splitter Frame Latch ............................................................ 19

Splitter Operation

Before Starting the Engine............................................. 22

Machine Break-In........................................................... 25

Pre-operation Checklist ................................................. 23

Storing the Wood Splitter .................................................... 26

Stroke Limiter Accessory..................................................... 18

Stroke Limiter Adjustment ................................................... 18

T

Transporting ........................................................................ 25

Prepare for Transport..................................................... 26

Troubleshooting Guide ........................................................ 28

V

Vertical Splitting................................................................... 24

33

Page 34

www.wallensteinequipment.com

Loading...

Loading...