Wallenstein PTO62, PTO72 Installation Instructions Manual

EMB Manufacturing Inc.

4144 Boomer Line · St. Clements, Ontario · N0B 2M0 · Canada

www.wallensteinequipment.com

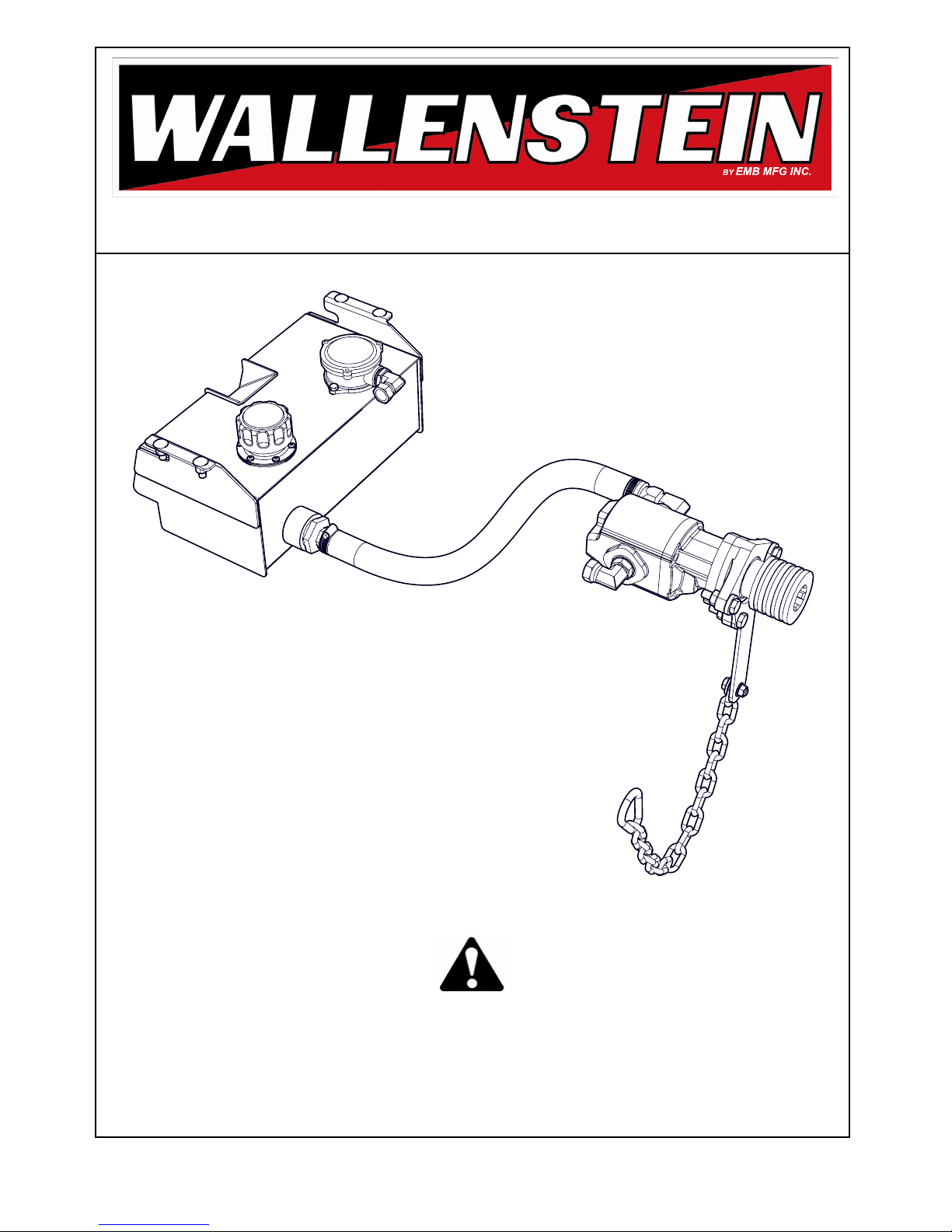

PTO62 & PTO72

HYDRAULIC PUMP KIT

Accessory Installation

Instructions

PTO62 PTO Hydraulic Pump Kit - 7GPM - 9.4 Litres (2.5 gal) uid tank - ts GX620

PTO72 PTO Hydraulic Pump Kit - 7GPM - 12.3 Litres (3.25 gal) uid tank - ts GX720, GX920, GX920XT

Do not attempt to start or operate the equipment without thoroughly reviewing this

manual for safe and proper operation.

Keep this manual with the

machine at all times

PRINTED IN CANADA

Rev 240517

Z97824 PTO62.PTO72 Backhoe Hydraulic Pump Kit.230517

SAFETY ALERT SYMBOL

This Safety Alert symbol means

ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Why is SAFETY important to you?

3 Big Reasons

SIGNAL WORDS:

Note: The use of the signal words DANGER,

WARNING, CAUTION and NOTICE with the

safety messages. The appropriate signal

word for each message has been selected

using the following guide-lines:

The Safety Alert symbol identies

important safety messages on the

Surge Master Wood splitter and in the

manual. When you see this symbol,

be alert to the possibility of personal

injury or death. Follow the instructions

in the safety message.

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

DANGER - Indicates an imminently hazardous situation

that, if not avoided, will result in death or

serious injury. This signal word is to be limited

to the most extreme situations typically for

machine components which, for functional

purposes, cannot be guarded.

WARNING - Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious injury, and includes hazards that are

exposed when guards are removed. It may

also be used to alert against unsafe practices.

If you have any questions not answered in this manual or require additional copies or the manual is damaged,

please contact your dealer or EMB Mfg, 4144 Boomer Line, St. Clements, ON, N0B 2M0. Phone (519)

699-9283 or Fax (519) 699-4146.

Page 2 of 12

CAUTION - Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

NOTICE -

Indicates a situation that could result in

damage to the machine or other property.

Accessory Installation Instructions

PT062 & PT072 HYDRAULIC PUMP KIT

Always wear the appropriate safety gear when installing

this kit or working around the machine. This includes but is

not limited to:

• Hard hat for protection to the head.

• Safety glasses protection for the eyes.

• Gloves for hand protection.

• Safety shoes with slip resistant soles and steel toes.

Caution: this kit is constructed of heavy gauge steel, be sure to use caution moving and installing the kit, avoid

dropping or pinching body parts on corners and edges of the kit.

Wallenstein PTO Hydraulic Pump Kit is required when mounting a Wallenstein backhoe on a tractor which has no or limited

hydraulics and will provide a 7GPM ow sufcient to power the back hoe. The PTO62 is used when mounting a GX620

Wallenstein backhoe, and the PTO72 is used when mounting a GX720, GX920 or GX920XT Wallenstein backhoe.

The PTO kits consists of a PTO mounted hydraulic pump, hydraulic tank with return hose and ttings and hardware in a

parts baggie.

There are 2 PTO Hydraulic Pump Kits:

PTO62 PTO Hydraulic Pump Kit - 7GPM - 9.4 Litres (2.5 gal) hydraulic tank - ts GX620

PTO72 PTO Hydraulic Pump Kit - 7GPM - 12.3 Litres (3.25 gal) hydraulic tank - ts GX720, GX920, GX920XT

Ensure you have the correct kit for your model backhoe.

Both PTO Hydraulic Pump Kits install in the same way for all models Installation and setup instructions apply to both kits

unless specied. Please read this manual thoroughly.

The PTO Hydraulic Pump Kit comes partially assembled. Illustrations show typical assembly. This assembly procedure is

one time only. Once assembled only regular maintenance and minor adjustments are required.

Tighten all hardware using the “Bolt Torque” chart at the back of this manual unless otherwise specied.

Tighten all hydrualic connections using the “Hydraulic Fitting Torgue” chart at the back of this manual unless otherwise

specied.

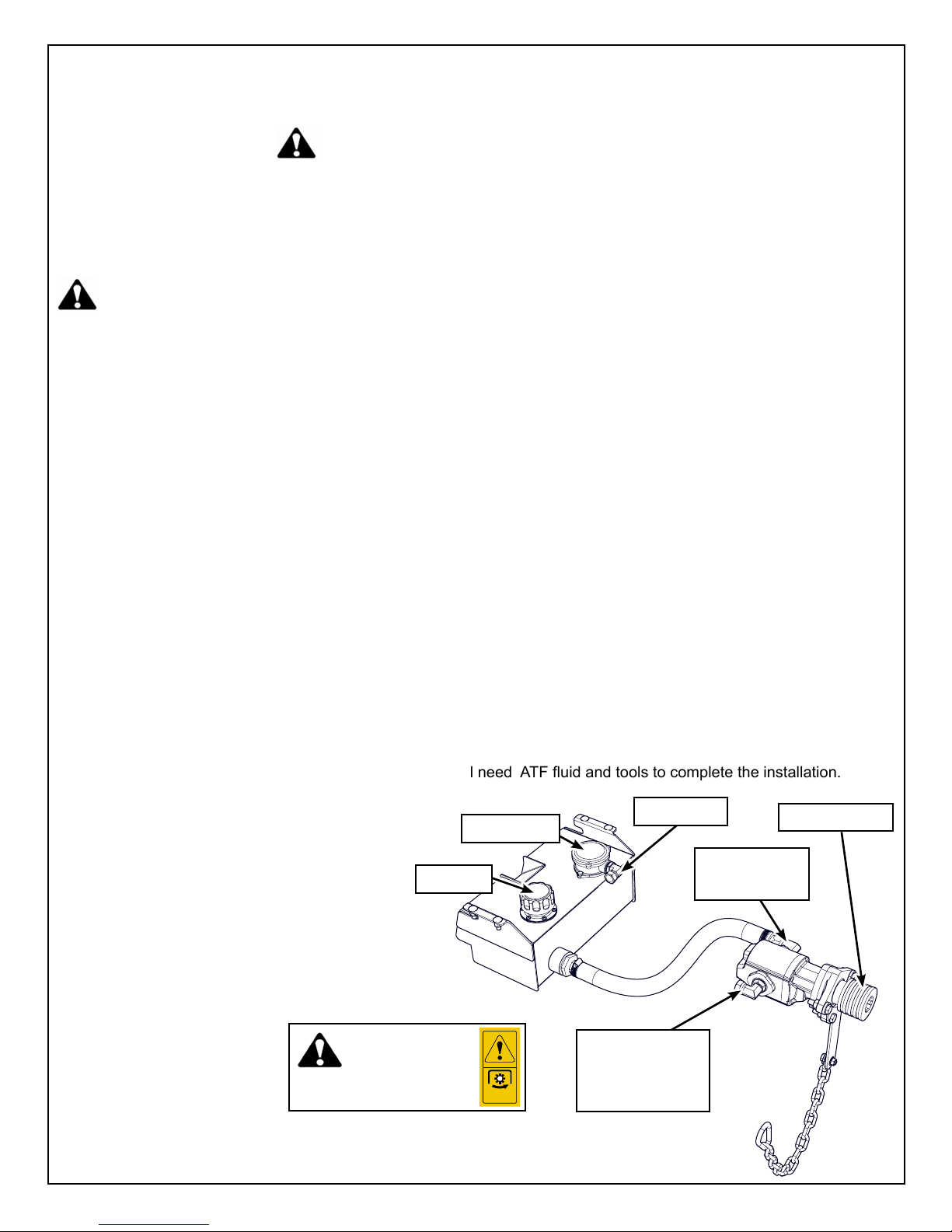

The #PTO62 / PTO72 kit comes partially assembled, you will need ATF uid and tools to complete the installation.

Before you start, you’ll need:

• Work bench, wrenches and sockets

• Dexron III ATF uid:

• PTO62: 9.4 Litres (2.5 gal)

• PTO72: 12.3 Litres (3.25 gal)

• Model specic instructions that came

with the backhoe mounting kit to

complete the hookup.

• Funnel and rags.

• Thread Sealant

Pump is rated to run at 540

RPM only

Filler Cap

Notice:

Operation Hazard:

Filter Cover

540 RPM

Z94246

input to backhoe

pressure line)

Return line

control (high

locking collar

Suction from

Tank

Page 3 of 12

Installation Instructions:

Ensure the Backhoe and the area around it is clean and free of debris, resting on dry level

ground, and detached from the tractor. Leave enought working space between the tractor and

backhoe.

Install the Reservoir

1. Before starting, clear the area of bystanders,

especially small children.

2. On the workbench, attach the 1/2” elbow con-

nector to the lter head. (pre-installed on PTO72)

3. Next attach the 3/4” barbed hose tting to the

tank.

4. Tighten connections as specied in the Hydrau-

lic Fitting Torque Chart.

5. Slip the gear clamps over the suction hose,

6. Attach one end of the suction hose to the tank

and to the other end to the input of the PTO

pump, and tighten gear clamps.

7. Prepare to install the reservoir tank by ensuring the backhoe frame is clean and clear

and the hydraulic hoses are out and won’t be

caught behind the tank.

8. Mount the oil reservoir to the backhoe frame:

• Move the tank into position.

• Install bolts thru rectangular holes in the

foot rest into the tank mounting holes.

• Adjust the tanks position as required

then tighten mounting bolts. (see torque

chart)

Page 4 of 12

Mounting

Loading...

Loading...