wallas SafeFlame 96 D, SafeFlame 97 D User Manual

SafeFlame 96 D / 97 D

1

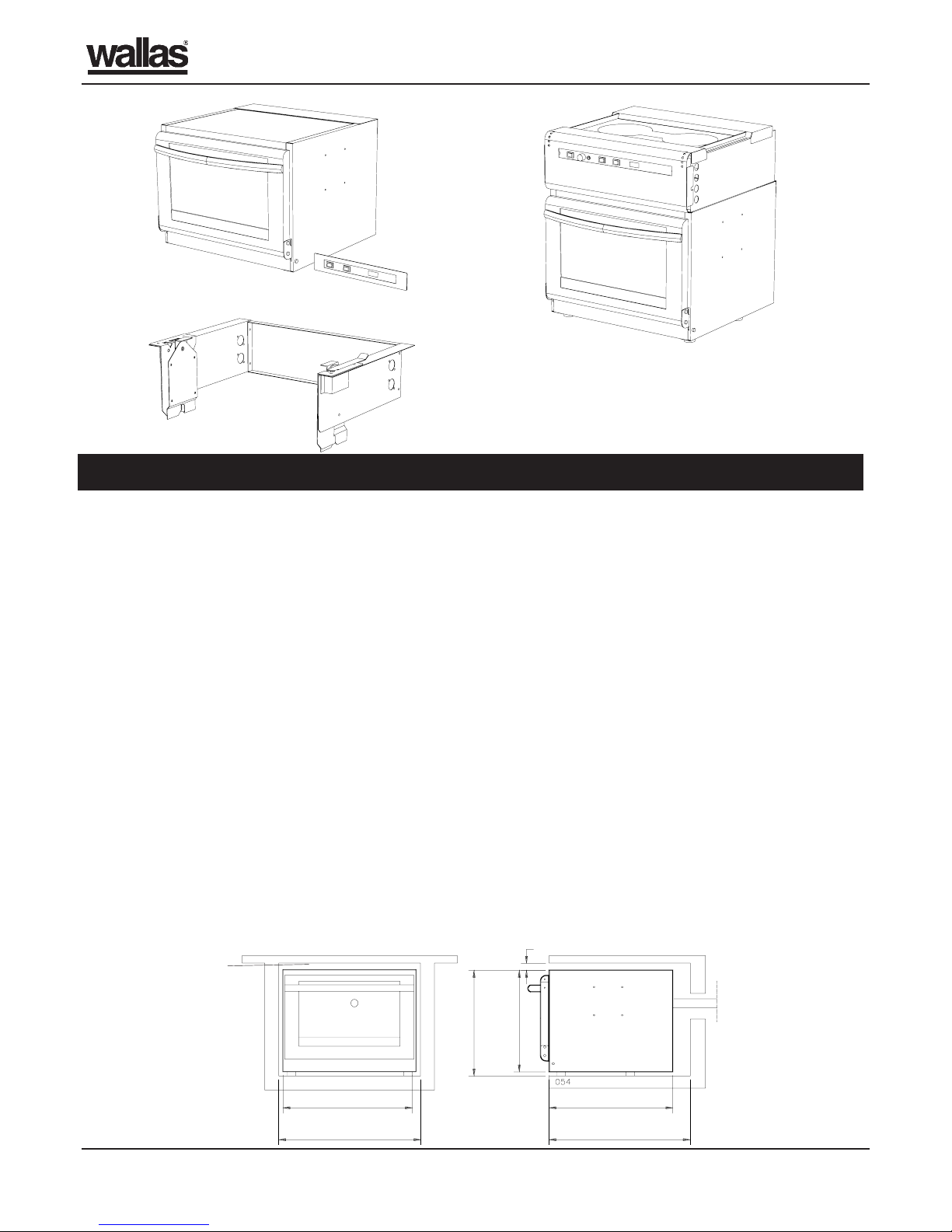

Figure 1: Wallas SafeFlame 96 D Diesel Oven

INSTALLATION INSTRUCTIONS

Figure 4: Minimum dimensions of the space required for installation. If the oven is mounted in a closed space or covered

by a board, the cooling air opening must be reserved above the oven for air circulation, minimum 100 cm2.

Space Requirements

- The dimensions of the space required for installation

are illustrated in figures 4 and 5.

- Drilling cooling air holes in the bottom of the

installation opening is recommended. Collective area

of the holes should be about 30 cm2.

- The dimensions of the space required for installation

of the 96 D oven’s control panel are illustrated in

figure 6.

- The gimbal-mounting frame defines the amount of

space required for a gimbal-mounted appliance.

- T o remove the burner unit for service, the oven has to

be removed from its position.

- The installation opening must be manufactured from

a fire-resistant material or be lined with a fire-resistant

material.

- Note that the control panel cable for the basic 96 D

is 1.5 m long.

Fuel hoses

- The maximum length of the fuel hose is 8 m; the

standard fuel hose is 4 m.

Considerations on the installation place and on its effect on the installation

Figure 2: Wallas SafeFlame 97 D Diesel Stove

Figure 3: Optional gimbal-mounting 113 for both the oven

and stove

A 4-metre long electric cable and a 4-metre long fuel

pipe with a cork and an internal filter are delivered as

standard.

- The recommended position for the fuel tank is 0.5 –

1 m below the oven.

Exhaust pipes

- The maximum length of the exhaust pipe is 4 m.

Exhaust pipe must be insulated with ø 45 mm

insulation pipe.

- The Combination lead-through may be installed into

the hull or deck.

- The hull lead-through should be situated as far aft as

possible, preferably in the stern.

- If it is possible that the deck lead-through

transiently dips under water it has to be used a

sealable deck lead-through (2460).

- Air must be allowed to flow freely past the leadthrough.

- T ake care not to blow hot gases against other boats.

Important:

- Y ou must not mount the 95D cooking range and the

96D oven to the same installation opening. 95D and

96D require an installation opening of their own.

380 mm

min. 20 mm

475 mm

min. 500 mm

360 mm

min. 530 mm

475 mm

min. 100 cm

2

SafeFlame 96 D / 97 D

2

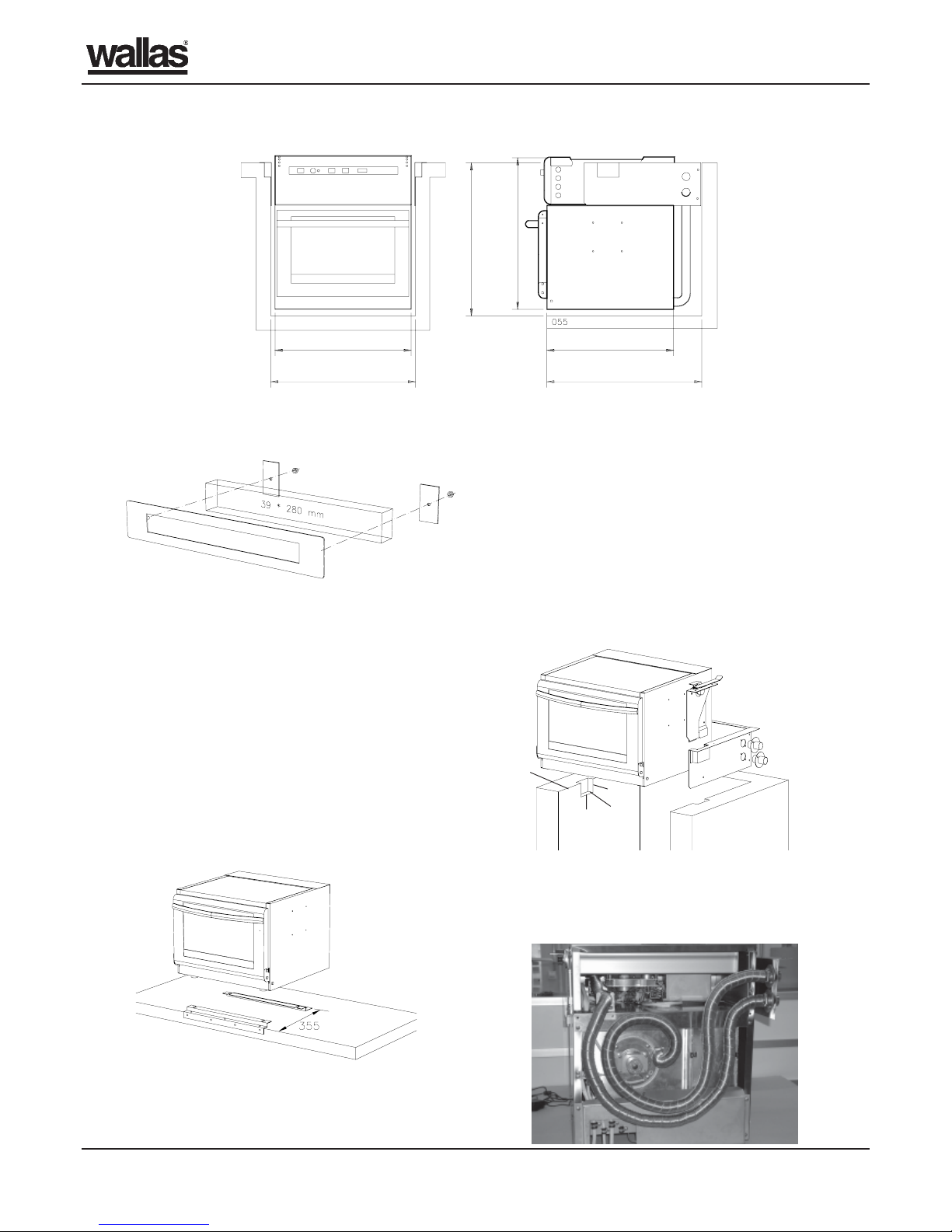

Figure 5: Minimum dimensions of the space required for installation of stove. When installing the stove into a fixed

position, the width and depth measurements of the installation opening are identical to those shown in the oven installation

diagram 495 mm and 530 mm. Figure 4. When installing a gimbal-mounted oven, the width and depth measurements of

the installation opening are identical to those shown in the installation diagram for the stove 510 mm and 550 mm. Figure

5.

Figure 6: The dimensions of the space required for

installation of the 96 D oven’s control panel. Heat will

make electronics life time shorter; It is not recommended

to mount the control panel right above the shutter of the

oven.

Figure 7:

Figure 8:

Figure 9: Installation of the exhaust pipes in a

gimballed stove. Length of the exhaust pipe: to the

right 900 mm and 1500 mm., to the left 1000 mm

and 1200 mm.

Fitting the Appliance into the

Installation Opening

Fixed Installation of the Oven or Stove

1.Fit the back edge of the fastening cleat for the rear

pads 355 mm from the front edge of the installation

opening.

2.Lift the oven into the installation opening so that the

rear pads slide into the grooves on the fastening

cleat.

3.Fit the fastening cleat for the front pads onto the

front edge of the installation opening.

4.Fit the oven with an exhaust pipe, which should follow

the most direct route to the lead-through. The exhaust

pipe are insulated with a second, larger diameter

metal pipe.

3.Attach the gimbal-mounting rockers to the oven or

stove.

4.Use screws to attach the rockers to the gimbalmounting frame.

5.For exhaust pipes not to prevent the oven movements

the pipes are formed into a loop behind the oven and

led through the apertures in the frame to the leadthrough. Figure 9.

6.Protect the exhaust pipe with a second, larger

diameter metal pipe.

7.The fuel hose and the wires must allow the unit to

swing freely in all conditions and they must not come

into contact with the exhaust pipe. The play is best

to turn under the oven.

510 mm

550 mm

min. 635 mm

475 mm 475 mm

530 mm

30

26

25

175

056

Gimbal-mounted Installation of the Oven or

Stove

1.Do not fit pads underneath the oven.

2.Fit the gimbal-mounting frame into the installation

opening.

SafeFlame 96 D / 97 D

3

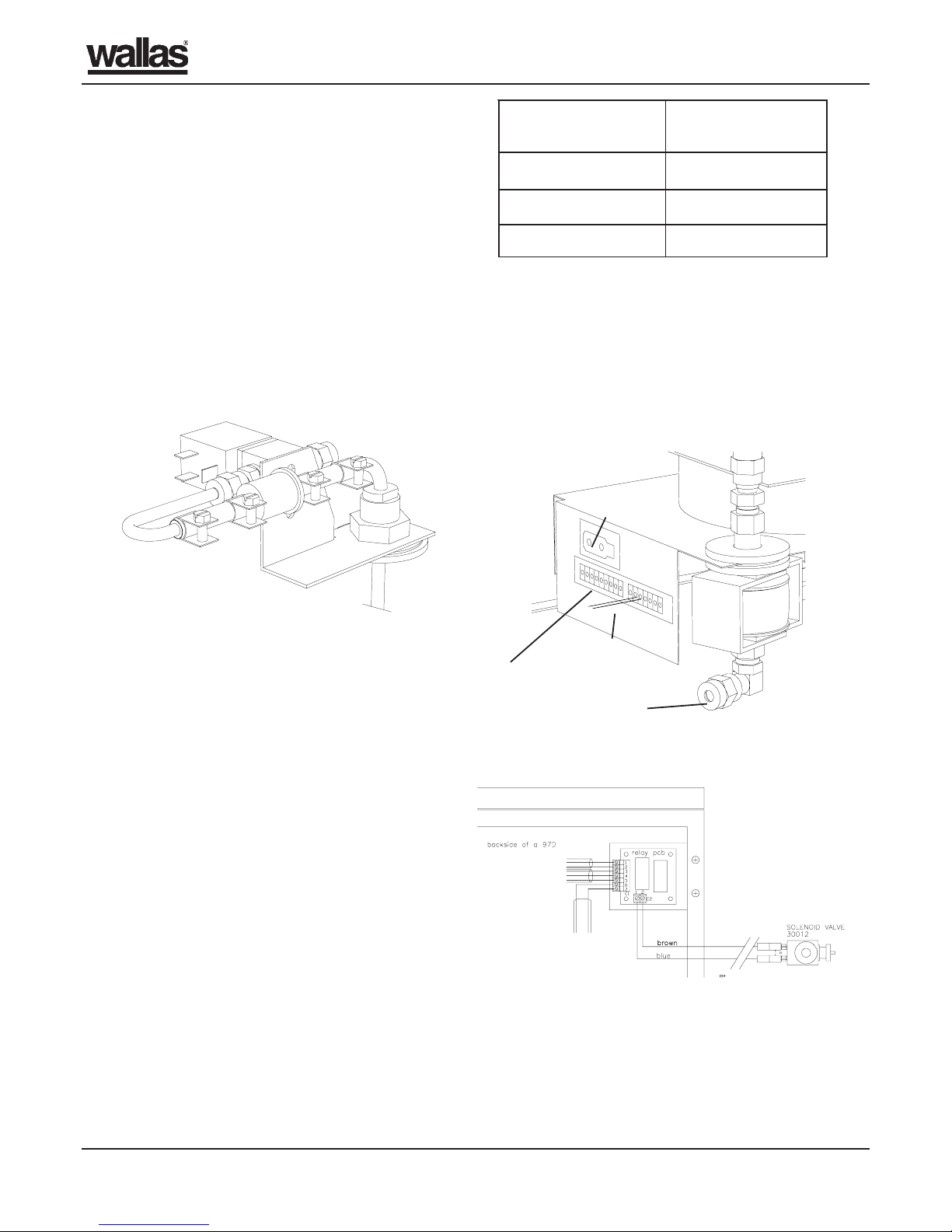

30014

30012

30011

Figure 11:

Table 1:

- Inclusion of a solenoid valve in the fuel hose near the

tank is necessary if the tank’s fuel level is above the

oven’s or stove’s bottom.

- If the fuel tank is more than 0.5 m above or 1.5 m

below the oven or stove, check the fuel feed and

make any necessary adjustments in accordance

with the separate instructions.

- The fuel hose must always have a fuel filter .

- In the combined unit there is a T -connector for fuel

hoses. The common fuel hose of the oven and stove

is connected into the branch downwards so the play

can be turned under the oven.

- The fuel hose joints must be fully tightened!

Check the joining surfaces for dirt before

tightening.

Electrical Connection

Important:

- During start-up, the appliance uses approx. 8 amps

of current for 2.5 – 6 minutes.

- A 15 amp fuse must be mounted close to the battery .

- T ake the appliance’s power directly from the battery

terminals, not the fuse box or distributing box, to

minimise voltage loss.

- The cables must be protected if there is a risk of

mechanical damage.

- T able 1 shows the minimum diameter of the cables.

- Connect the electric cable’s red lead to the plus (+)

terminal and the black lead to the minus (-) terminal.

- The cables are protected by rubber rings. In the

protection balk down back there are fixing points

for both oven and stove cables. Care must be taken

that the wires don´t come into contact with the

exhaust. Turn the play under the oven.

Figure 12: Oven connection.

Connector for the oven control panel

Solenoid valve

Power cable

Fuel hose

Solenoid valve with 97D oven-stove unit

Installing the Lead-Through

Installation Considerations

- The exhaust pipe should be bent into the shape of a

gooseneck to prevent water from splashing into the

unit.

- The exhaust pipe must be insulated a bendable metal

pipe that is larger in diameter than the normal

exhaust pipe.

- The Insulation pipe is connected to the fresh air duct

of combination lead-through.

- In a metal-hulled boat it is recommended to insulate

the lead-through to prevent electro-chemical

corrosion.

- There is an separate instruction for lead-throughs.

Connecting the Fuel System to the

Boat’s Main Tank

If solenoid valve must be installed to the fuel system,

it must open when one or both appliances are used.

97D oven-stove unit has in build a relay pcb. Install

solenoid valve wires to connection C2. Solenoid valve

uses always two wires; these wires are included in

the solenoid valve kit 30012.

lacirtcelefohtgneL

)m(elbac

ehtfonoitces-ssorC

)²mm(elbac

4-04

6-46

6revo01

Loading...

Loading...