wallas Safe Flame 800 Installation Instructions Manual

SafeFlame 800 / 220

1

INSTALLATION INSTRUCTIONS

W allas Safe Flame 800 kerosen stove and 220 heat

blower lid

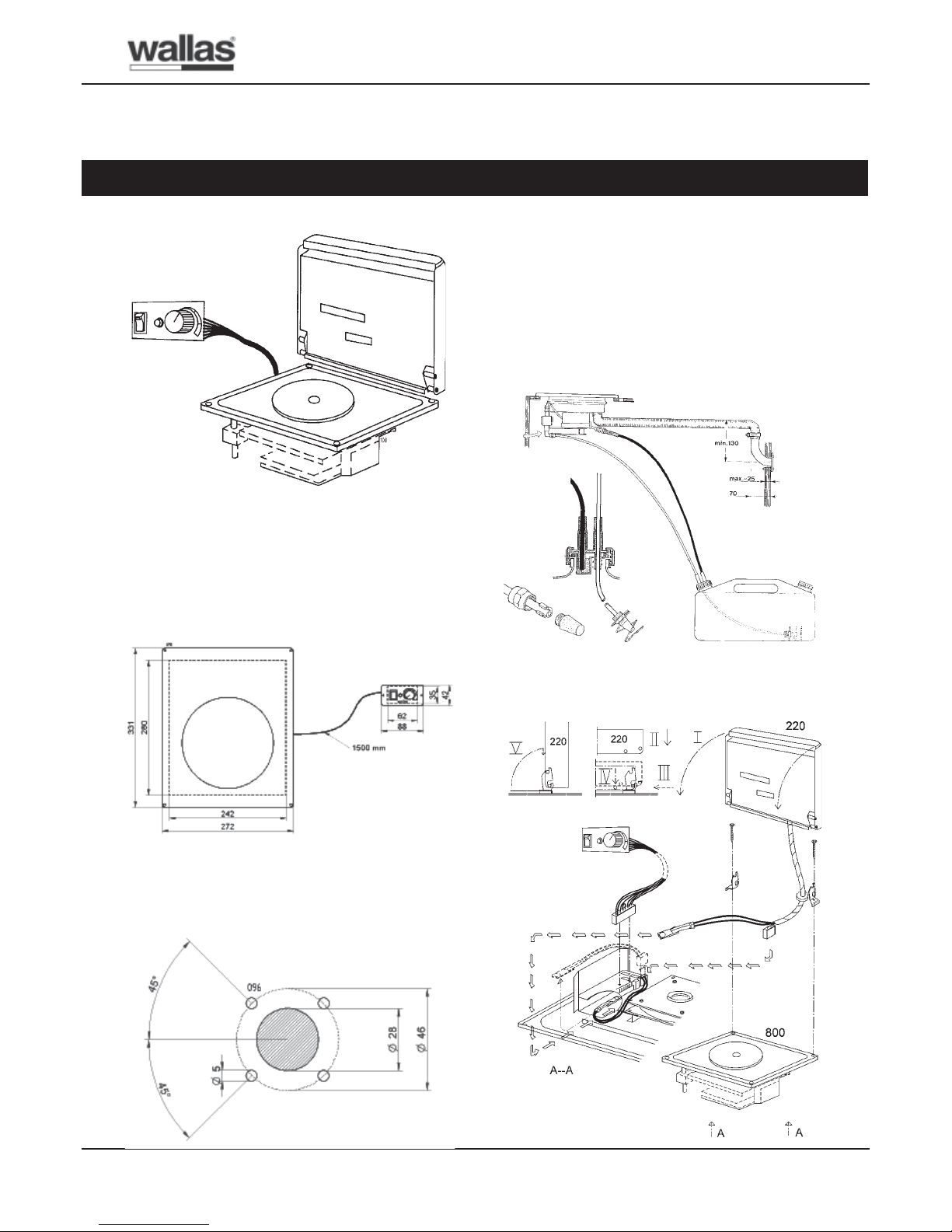

Figure 1:Wallas SafeFlame 800 and Wallas 220.

Figure 2: Flush opening size for stove is 280 x 242 mm

and Control panel opening is 62 x 35 mm. Control cable

length is 1.5 m. The stove requires for its ventilation to

avoid overheating an outlet opening of 30 - 40 cm

2

behind

the stove top and front of the stove. For example 3 - 4

about ø 2,5 - 3 cm holes or about 1,5 - 2 x 20 cm opening.

Figure 3: The “through hull” exhaust head 1066.

Figure 4: 1 Fuel suction line ø 5/2 m. 2 The return fuel

tube must have continuos fall to fuel tank with no loops

upward. All extra length is cut away below the tank adapter.

3 The end of the return tube must reach the bottom nib. 4

Filter head, sinterbronze. 5 Shield spiral hinders water

intake by holding the suction end free from tankbottom.

6 Exhaust tube 1028 ø 31/28 mm. Max length 5 m. 7 The

exhaust head 1066. 8 The fuel tank must always, under

all circumstances lie below the stove bottom level, secured

so it can not tip or come loose.

Figure 5: Installation of the heat blower lid

1

2

3

4

5

6

7

8

SafeFlame 800 / 220

2

OPERATION INSTRUCTIONS

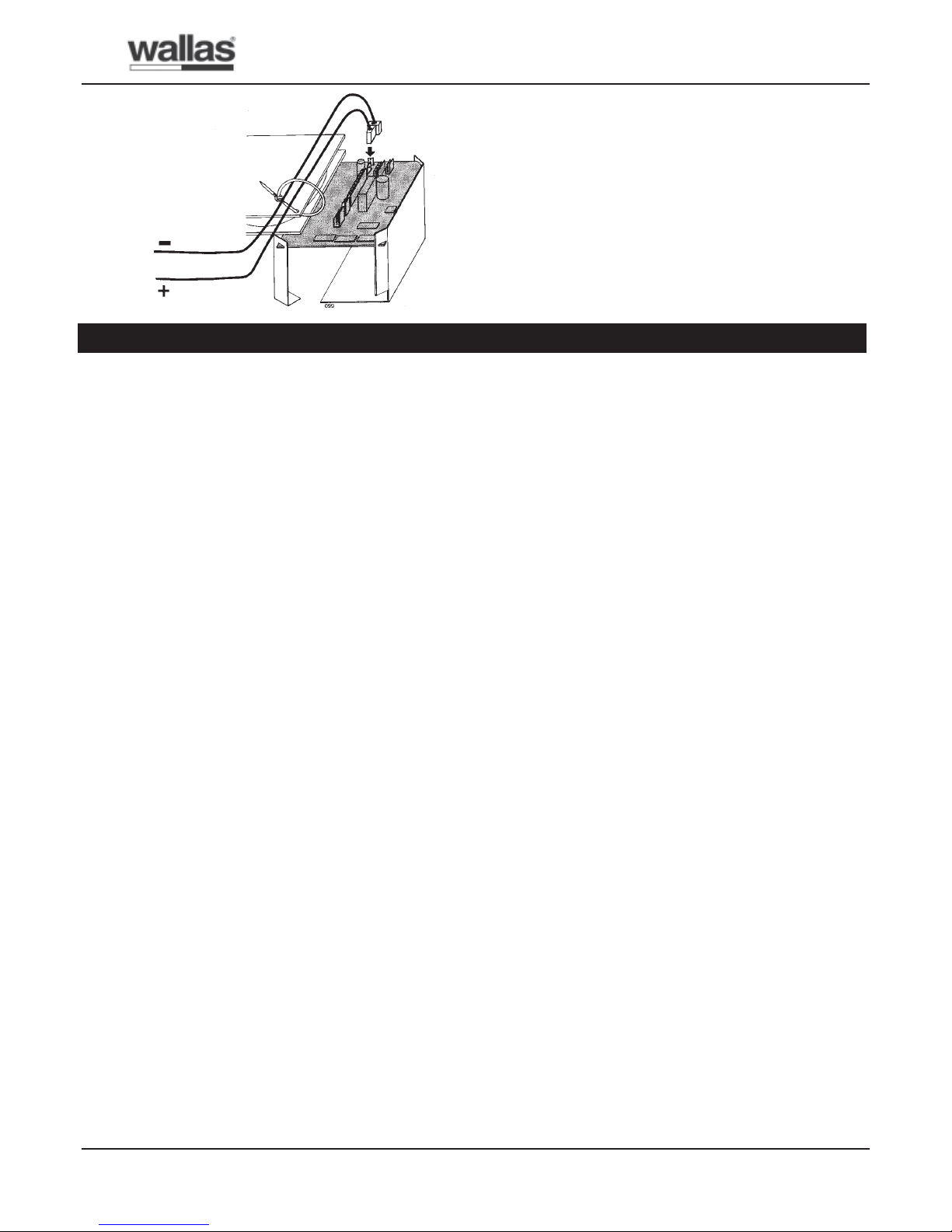

Figure 6:

- black

+ red

Safeflame stove 800

Function description

- Wallas 800 heater is a single hot plate compact stove.

- The combustion gases and also the water vapours

produced by the combustion are discharged out

which keeps the boat interior dry and fresh.

- The ignition and start are automatic and the cooking

effect steplessly adjustable.

- The stove top is stainless steel and the nitrided, anti-

rust coated hot plate of iron.

Start

- Cooker The priming and heating is started

automatically. The switch pilot lamp indicates that

the cooker is switched ON by switching ON the ON/

OFF switch. At st art the regulation knob should be

set on full effect until the red combustion control

lamp lights up. When switching off the cooker the

effect setting has no importance.

- A flashing switch lamp indicates too low supply

voltage caused by disharged battery, too weak

supply cable or poor contact in fuse or connections.

If flashing continues after the 2.5 min. priming (start)

cycle or occurs under operation the cooker will

switch off automatically .

- Re-start (after switching off) can not be made before

cycling the switch in OFF-position 5 min. and not

before the red combustion pilot lamp has gone out.

Combustion pilot lamp

- The red pilot lamp indicates that combustion is going

on. The lamp will normally light up in abt. 5 min.

after start, - if not, switch the ON/OFF switch to

OFF, wait abt. 5 min. and re-start.

- After switching of f the cooker the red pilot lamp will

light until the cooker is cooled down, - about 10

min.

- A flashing red light indicates that the overheating cut-

out has switched off the fuel pump and cooker

because of overheating. The overheating cut – out

and fuel feeding will reset automatically after the

cooker is cooled down. Before continuing the use,

clear up the reason for overheating and take the

necessary steps to eliminate it.

Effect regulation

- The effect regulation is stepless (abt. 500 –1 100 W).

- The regulation effect is almost instantaneous.

Switching off

- The cooker is switched off by turning the switch in

OFF-position. After this the combustion blower goes

for aftercooling until the red combustion pilot lamp

goes out.

- The battery supply to the cooker shall never be

switched off by a battery master switch before this.

Maintenance

- Dish washing agent and olive oli recommended for

cleaning and for protection of the hot plate after every

use.

The heat blower lid type 220

Function description

- The heat blower lid 220 blows the heat from the hot

plate to the cabin and converts the cooker in a

handturn an effective cabin heater. The blower lid

can be attached to the cooker also afterwards.

Start

- The blowers in the lid start automatically with some

minutes delay when the lid is closed and the lids

heat sensor feels the heat of the hot plate. The

blowers stop automatically when the hot plate is

cooled down after switching off and after rising the

blower lid.

SafeFlame 800 / 220

3

Old fuel – water in fuel

- Long storage can cause water condence which

produces wax in paraffin oil. As this will fill up fuel

pumps and burner wicks, it is suggested that 3 –

5% of Iso-Propyl alcohol is mixed with the fuel.

- Filled up fuel pumps and burners can be cleaned by

running the heater in cold state for 15 - 30 minutes

with Iso-Propyl alcohol. For this remove the fuel pipe

from the tank, start the heater and allow it to run for

10 minutes without fuel before using the alcohol.

Fuel quality

- The fuel must be premium grade paraffin with a smokePoint of 35 mm, which should conform to BS 2869.

Suitable types are “Pink” and “Blue” in U.K., Esso

Blue in Skandinavia and in Europe generally the Esso

Exol D 60 (D180 – 220).

Water int ake through exhaust head

- The exhaust heads 2466 (cookers) and 2460

(heaters) will, opened, leak water in the heater when

submerged or flushed.

- The penetrating water can then damage the heaters

electronics or blower motor.

- Limited water penetration in a hot running heater may,

however, not be harmful as such water is immediately

vaporized and expelled.

IMPORTANT TO OBSERVE

- When closed these exhaust heads do not take water

in the heater under above circumstances, provided:

1. that the exhaust head is properly closed.

2. That the telescope inner tube slide joint of the

exhaust head 2460 is tightened by Silicon grease.

The greasing is made in factory but it can be removed

in mounting – must be checked. New Silicon grease

is available from Wallas-Marin representatives or

Wallas-Marin.

3. That the gaskets in the exhaust head are not

defective and that the take through deck joint will

not leak.

- Observe, that the exhaust heads are not pressure

water tight when closed and will not stand continuous

submerging or overflooding without some leaking.

- The water intake can be reduced through raising the

exhaust head from the deck with the collar 2069 or

by using the through hull boardfittings 3467 or 1066

(for cookers) or 3468 or 2467 (for heaters).

Current supply connection

- To reduce radio interference created by the heater

and to avoid accindental supply interruption to an

operating heater, we suggest using a cable direct to

the ships battery and not via the master switch. This

cable must be at least (AWG 13) 2,5 mm² [min 4

mm² (AWG 1 1) with Ceramic cookers and 150 ovens]

with an own. appr. 15 A fuse and own master switch.

TECHNICAL SPECIFICA TIONS

Table 1:

tceffEtaeH

/008

022

W0021tuoba

leuF008lioniffaraP

noitmusnocleuF008h/l31,0-70,0

egatloVylppuS

/008

022

V21

noitmusn

octnerruC008A51,0tuoba

noitmusnoctnerruC022A4,0tuoba

thgieW008gk7,5tuoba

thgieW022gk6,2tuoba

WARNINGS

- Never leave the cooker on full effect alone for longer

time without supervision.

- Before leaving the yacht always check that the cooker

has not been left on!

- Avoid unnecessary, quick forth and back adjusting

of the effect knob, this can cause sooting!

SafeFlame 800 / 220

4

MONTAGEANLEITUNG

Wallas SafeFlame 800 Petroleumkocher und Wallas 220

Wärmegebläsedeckel

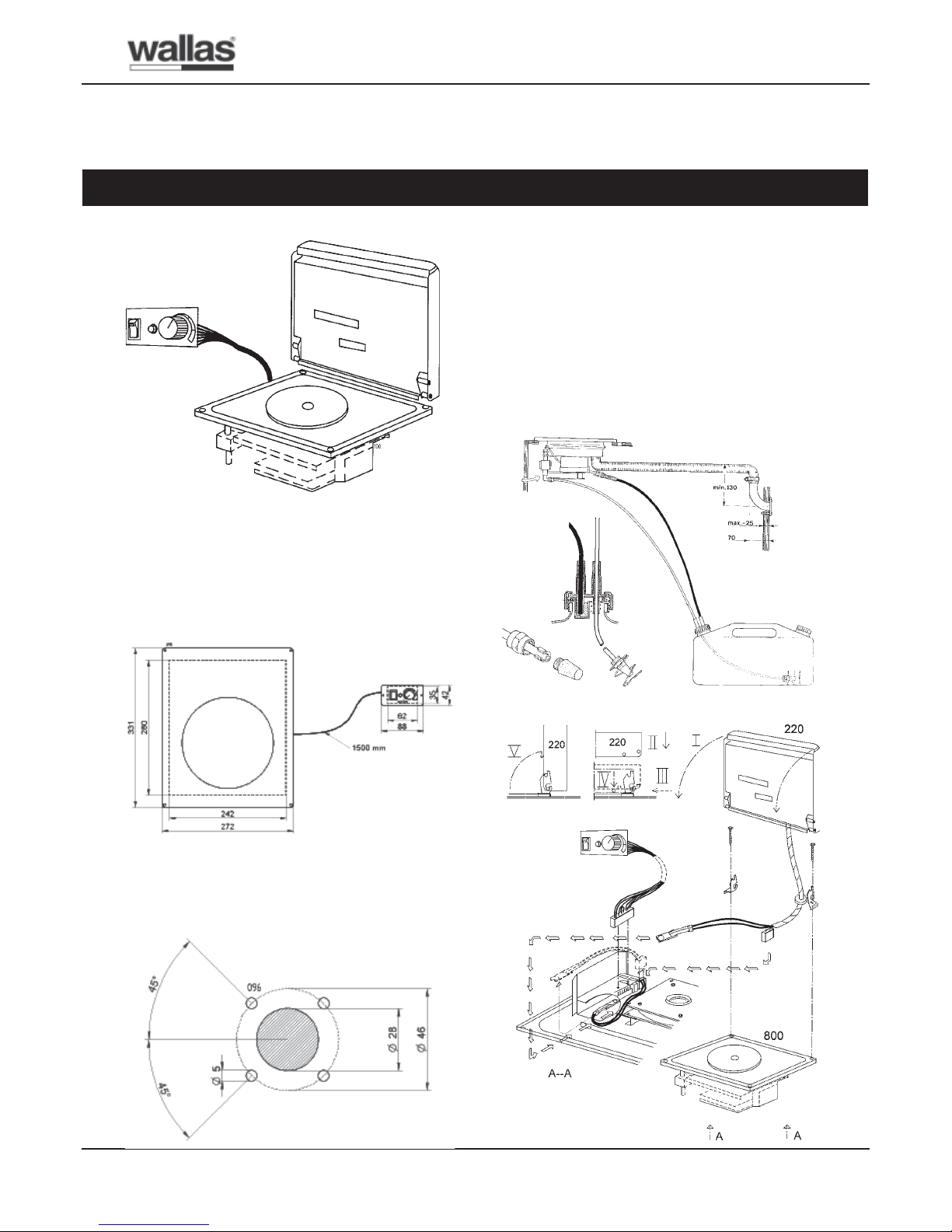

Abb. 1: Wallas SafeFlame 800 und Wallas 220.

Abb. 2: Masse für Einbauöffnung sind 280 x 242 mm und

Kontroll Panel Einbauöffnung 62 x 35 cm. – Kontrollkabel

Länge 1.5 m. Der Herd fordert für die notwendige

Ventilation eine Luft einnahme – Öffnung um 30 – 40 cm

2

unter dem Herd, wahlweise in Form von 3 - 4 ST Löchern

mit einem Diameter von 2.5 – 3 cm oder ein Spalt mit ca

20 cm Länge und 1.5 – 2 cm Breite.

Abb. 3: Lochbild für Durchführung des Abgasstutzens

1066. Durchführung muss sorfältigt abgedichtet werden,

z.B. mit Silicon.

Abb. 4: 1 Ansaugschlauch ø 5/2 mm. 2 Der

Brennstoffschlauch muss fallend zum Tank, ohne

Schlingen oder Biegungen aufwärts gelegt werden.

Überflüssige Länge sofort unter Tankdurchführung

abscheiden. 3 Die Schlauchende muss den

Bodennabsatz erreichen. 4 Filterkopf, Sinterbronze. 5

Schutzspiral hindert Wassereinahme durch halten die

Einsaugende frei von T ankboden. 6 Abgasschlauch 1028

ø 31/28 mm. Max. Länge 5 m. 7 Abgasstutzen 1066 für

Rumpfdurchführung. 8 Brennstofftank muss so placiert

werden, dass der Brennstoffniveau im Tank immer, unter

allen Verhältnissen unter dem Kocherboden bleibt. Der

Tank muss gestützt werden, um Fallen und Loskommen

zu verhindern.

Abb. 5: Montageanleitung für Wärmegebläsedeckel.

1

2

3

4

5

6

7

8

Loading...

Loading...