wallas M40 Installation, Operation And Service Instructions

T0209 T0209

M40

T0209

INSTALLATION INSTRUCTIONS

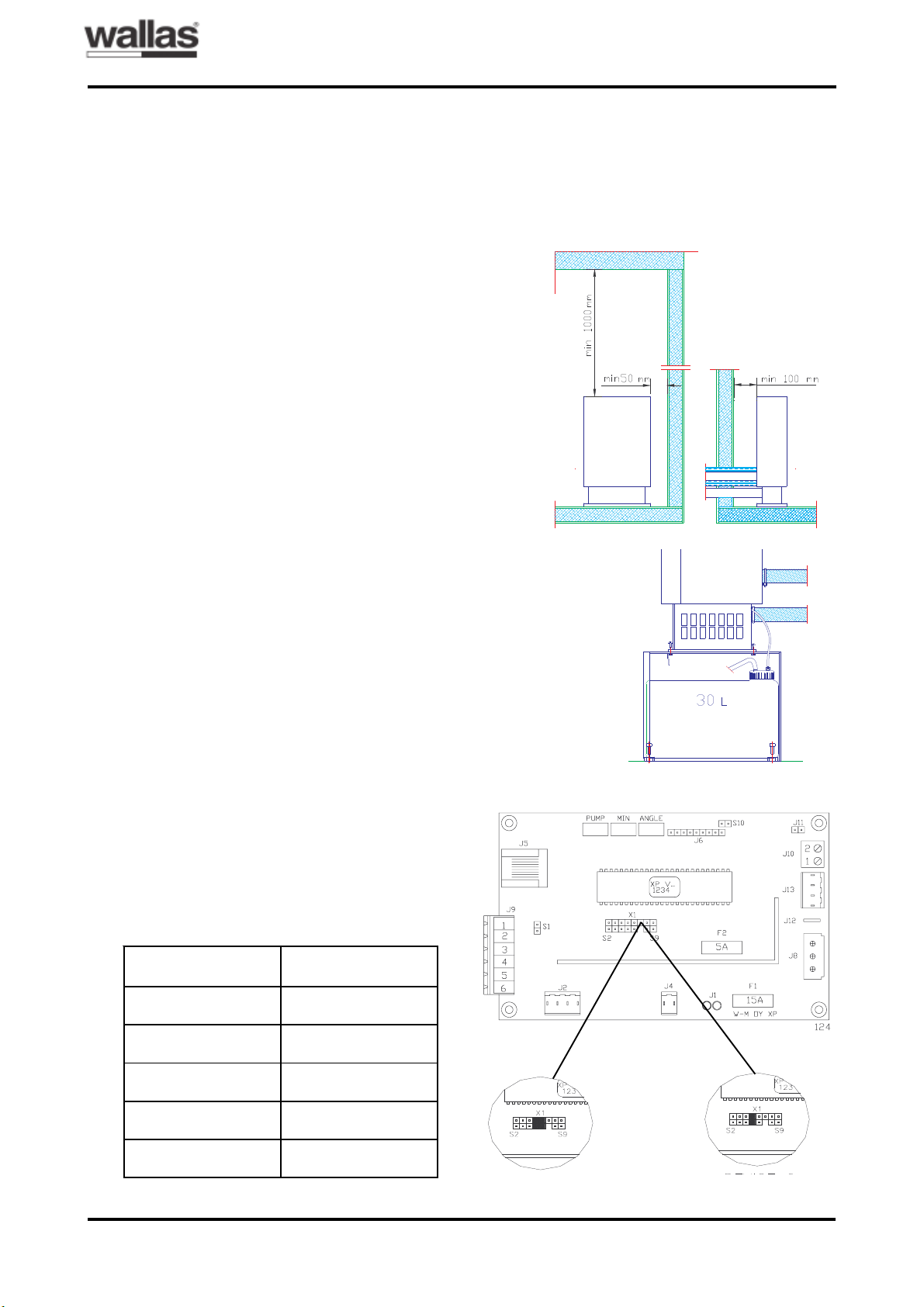

SPACE HEATER LOCATION

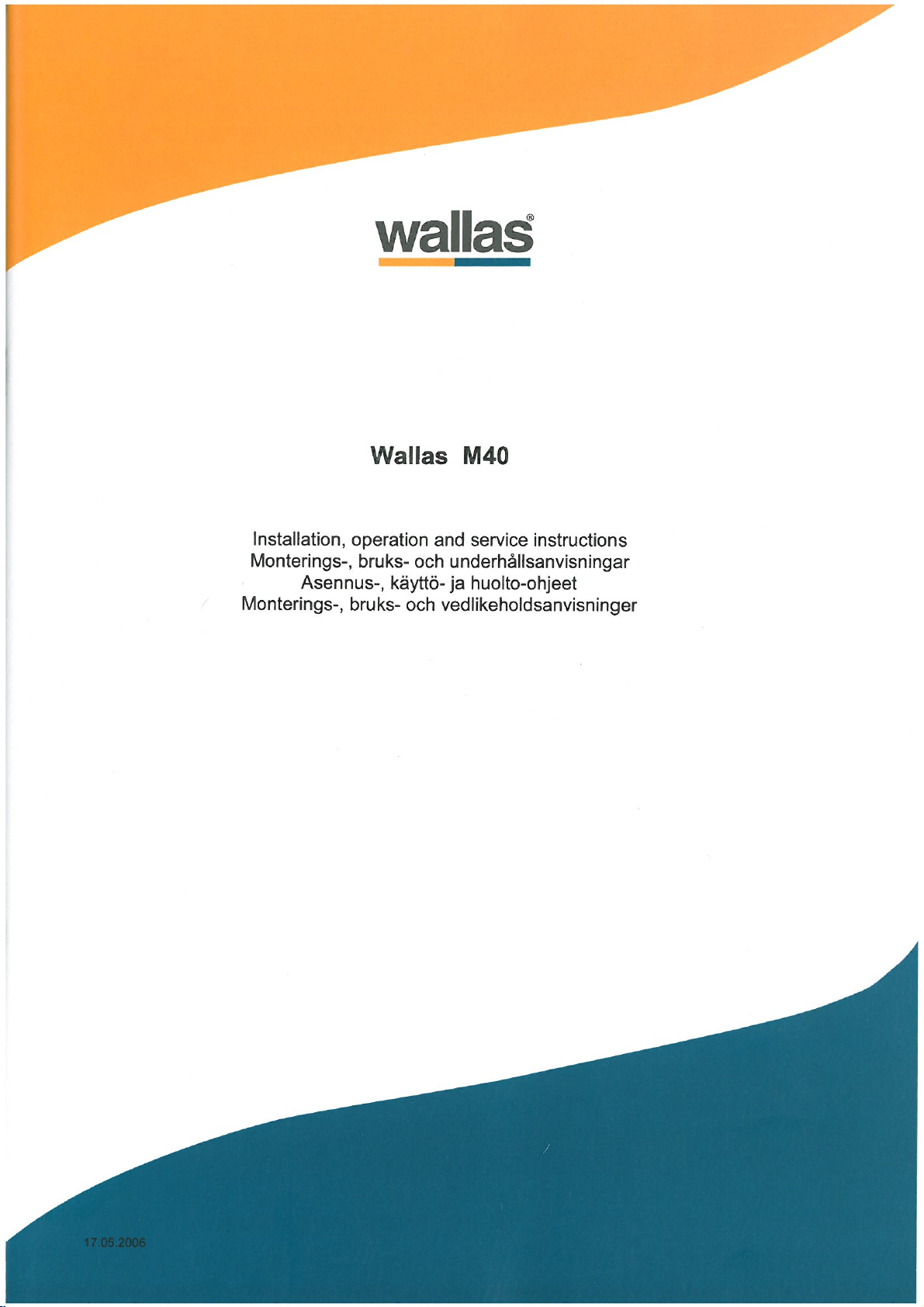

1.Free distance from the surrounding walls as

shown in fig. 1.

2.The spaces between the walls must be kept

clean and free from dust, litter and foreign

objects.

3.The air inlets of the lower part of the heater

jacket at the front, sides and back must be

kept free from objects and hindrances preventing air intake.

4.There must not be any surfaces, constructions or objects presenting fire hazard or preventing the heat flow directly above the heater closer than 1 metre from the top of the

heater. Fig. 1.

5.The heater must be properly fastened by

screws to the floor or to its foundation casing,

which is also fastened to the floor. The equipment must be in vertical position. Fig. 2.

Fig. 1.

Fig. 2.

6.The heater must be placed so that no water

can drip, flow or splash into it.

7.The maximum lenght of uninsulated exhaust

pipe is 3 m, insulated 6 m.

8.If needed notice the change of air density by

changing mountain parameters on the electronics (PCB), when the heater is situated

over 1500 m altitude above the sea level for

example on an arctical hill.

Fig. 3.

Over 1500 m

Under 1500 m

1 / ENGLISH

M40

T0209

INSTALLATION INSTRUCTIONS

TANK LOCATION

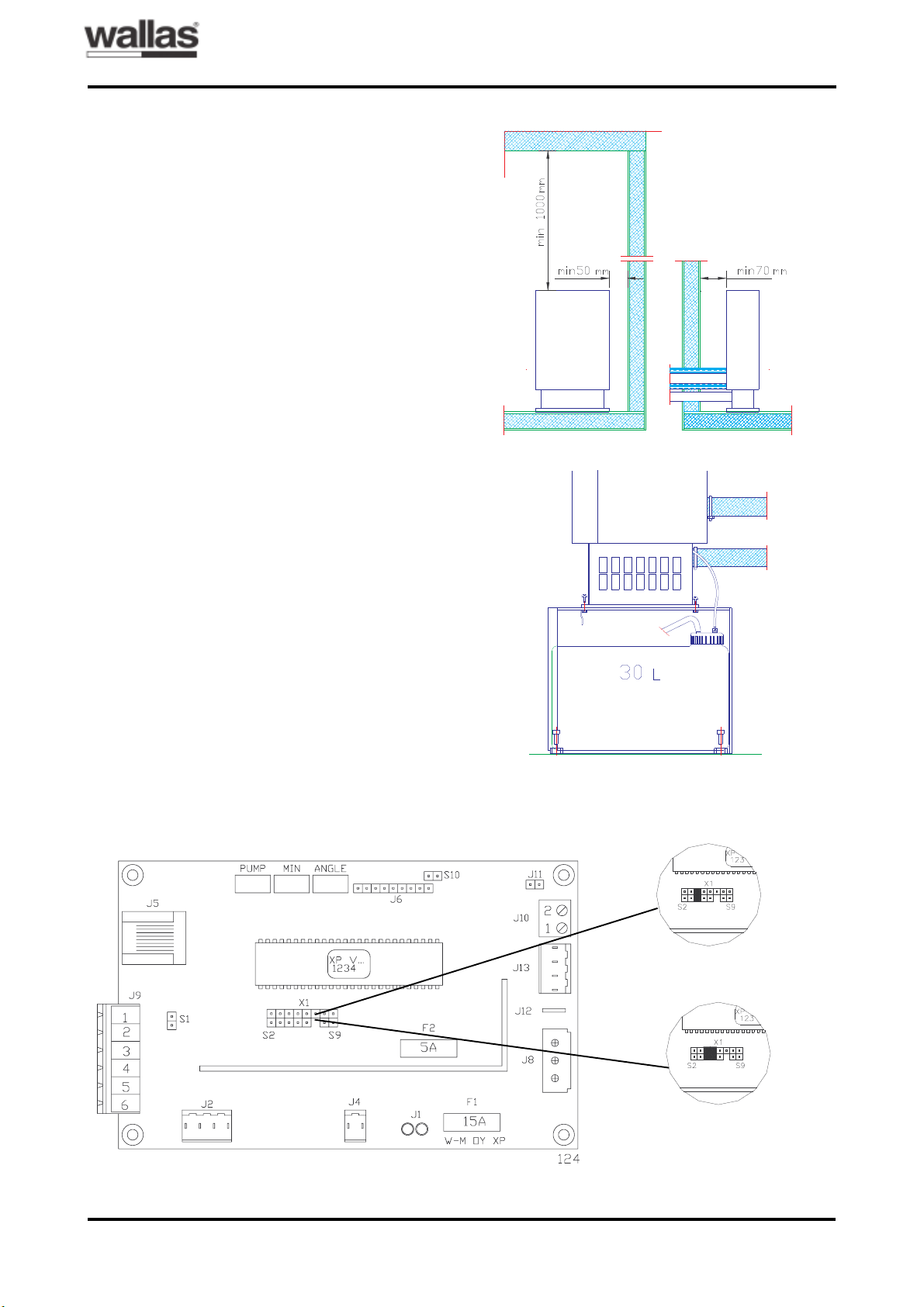

1.The fuel tank is good to be placed beneath

the heater foot. Fig. 4. (The surface of the

liquid fuel must be beneath the foot). When

the liquid surface is above the heater foot, a

magnetic valve is recommended to install

near the tank end.

2.The fuel tank may be installed into its foundation casing or outside, for example, into

the basement of the house or inside a suitable, protective casing. The fuel tank and

hose must be protected from direct sunlight.

3.The fuel hose inlet through the constructions

must be protected by a metal pipe.

4.The basic length of the fuel hose is 3 metres. It may be extended by using a 2-metre

extension hose which makes the total hose

length 5 metres. The hoses are linked by

using threaded quick connectors. Fig. 4

shows the maximum limits of the installation.

Fig. 4.

N.B. The voltage must be primarily taken directly from the battery, not from the control unit

of the solar battery. This will ensure that the

system bears the ignition current and does not

receive excess voltage. Contact your system

supplier for further details.

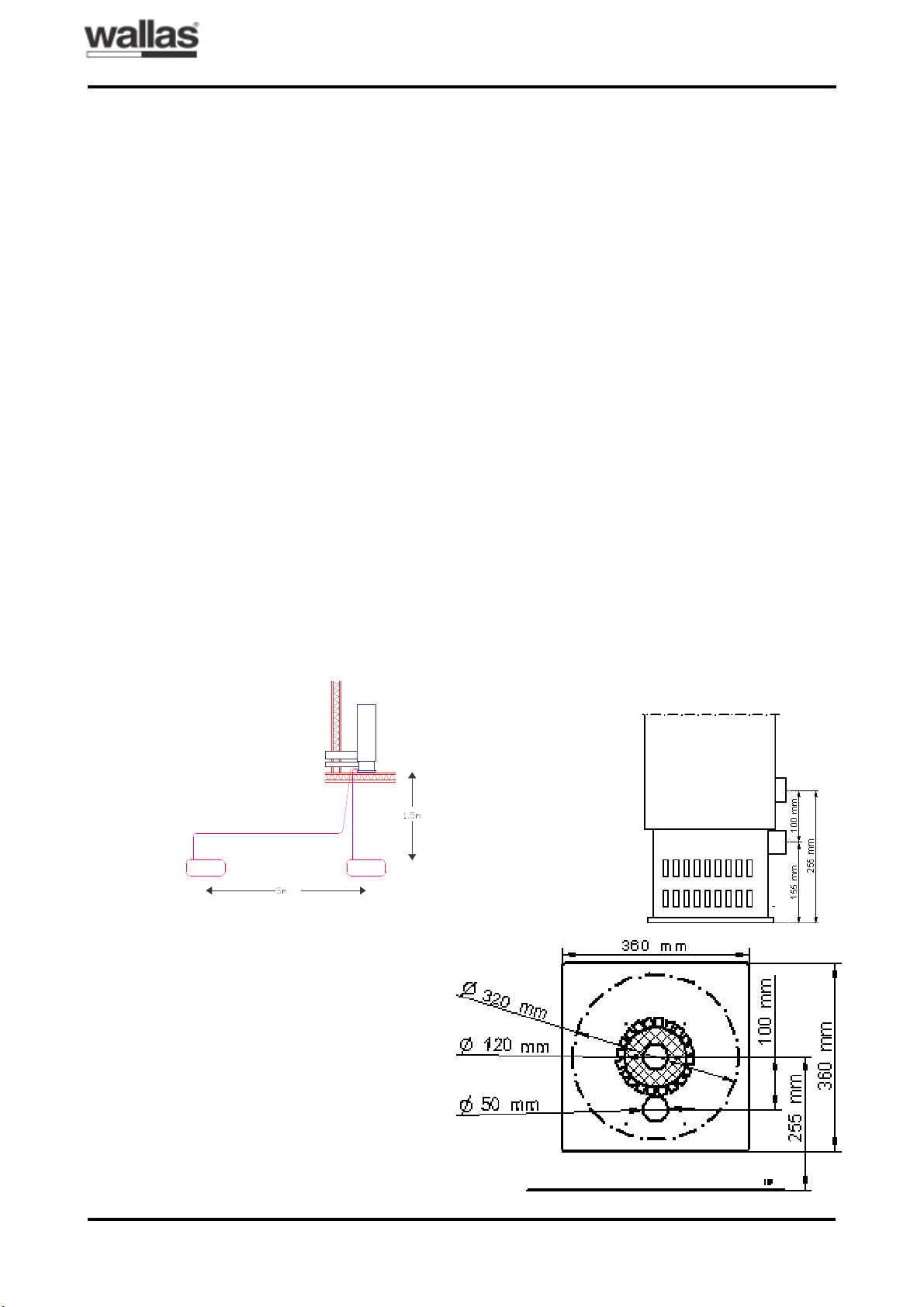

INSTALLATION HOLES

1.Choose the place for the heater. See instructions above.

2.Exhaust gases shall always be led out. If desired, they can be led out directly through the

wall. In this case, the combustion air is also

taken from outside, which contributes to balancing the pressure fluctuations caused by

the wind. See the separate leaflet describing

installation alternatives.

3.Make holes through the wall according to the

dimensions given in fig. 5. In the case of duct

installation, the hole for exhaust gas (diameter 120 mm) shall be dimensioned in its correct location. Make a separate hole for fresh

air (diameter 50 mm) in the fresh air duct or

through the floor. (For sizes of the holes, see

fig. 5). As far as a duct installation is concerned, the fire ventilation air may also be

taken from indoors.

BATTERY LOCATION

1.The equipment contains 4 metres of electrical wire with a thickness of 4 mm2. In case

the distance between the battery and equipment is 6 metres, the cabel thickness must

be 6 mm2 and so on.

2.The electrical wires must be protected by placing a 15 A fuse at the battery end of the positive cable of the electrical wire.

3.The battery should be located so that there

will not be any danger when the battery is

charged or used.

Fig. 5.

2 / ENGLISH

M40

T0209

INSTALLATION INSTRUCTIONS

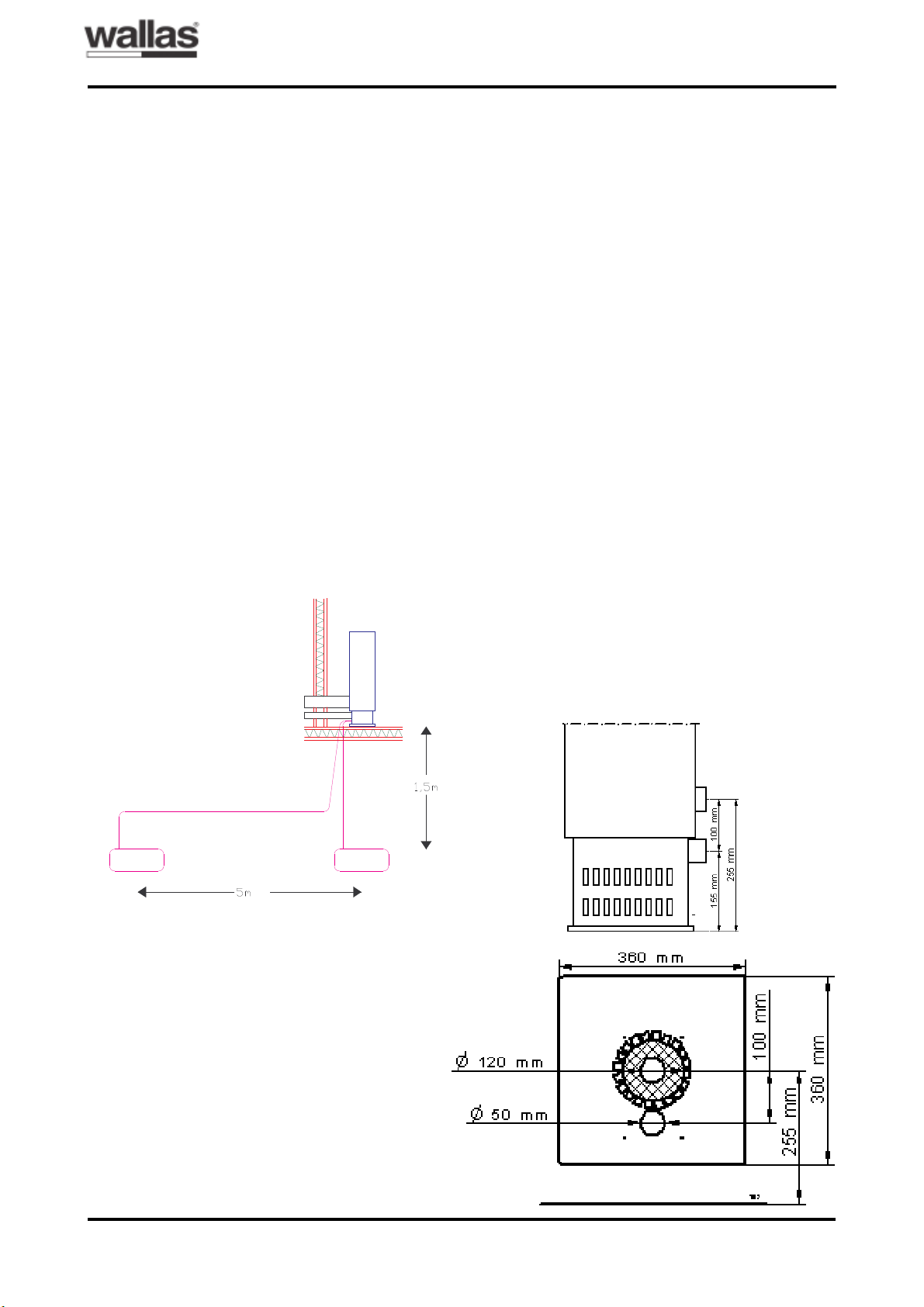

INSTRUCTIONS FOR INSTALLATION

THROUGH THE WALL

1.Install the covering plates on the wall and tighten the joint by acrylic mass. Put a plate with

8 holes on the outer wall.

2.Cut the ducts and insulating channels as

shown in fig. 6 (items A and B).

ACut them so that the insulation will be 10

mm outside the wall (the insulating plate

shall also be 10 mm outside the wall).

BCut them so that the ducts will be 40-45

mm outside the wall.

3.Fasten the ducts to the heater by using hose

clamps. The exhaust gas pipe must be tightened properly by using power press binding.

4.Mount the heater and its ducts to their places.

5.Mount the insulating channels and protective plate from the outside. Cut small tongues

on one of the protective plates (Fig. 6, item

C) and install this one with the tongues

against the covering plate on the outer wall.

6.Install the exhaust gas discharge casing and

the shroud (protection against contact) so

that the pipe ends reach the limit stops of the

casing. Tighten the joint between the casing

and covering plate by using acrylic mass.

7.Fasten the heater on the floor or foundation

casing by screws.

Fig. 6.

8.The equipment is ready for use after the

electrical wire and fuel hose have been connected.

INSTRUCTIONS FOR INSTALLATION IN

THE DUCT

1.Cut the hoses, insulating channels and protecting plates so that they each the inner surface of the duct.

2.Fasten the hoses to the heater by using

clamps. The exhaust pipe must be tightened

properly by using power press binding.

3.Mount the heater to its place.

4.Tighten the joint between the exhaust pipe

and the duct by using acrylic mass.

5.The equipment is ready for use after the

electrical wire and fuel hose have been connected.

N.B. When taking the combustion air from under the floor, make sure that the base floor has

sufficient ventilation. Install a protective spiral

at the end of the hose.

- In a high (over 5 metres) and large (crosssectional surface over 15 x 15 cm) duct, exhaust gases are cooled down so that the

moisture in them is condensed, thus causing

the chimney to decay, as well as decreasing

the draught. Therefore, a brick duct should

be lined with stainless steel pipe (diameter

50-70 mm), as well as filling the space between the pipe and duct by, for example, expanded clay.

- Air for fire ventilation cannot be taken from

the same duct through which exhaust gases

are discharged.

Covering plate

Insulating plate

Insulating

channels

Hose

clamps

Covering plate

Discharge casing

Shroud (protection

against contact)

3 / ENGLISH

M40

ruoloC

DELfo

gniknilB

lavretni

gninaeM

noitcnuF

wolleY

sthgiL

.ylsuounitnoc

notnerruC

deR

sthgiL

.ylsuounitnoc

,thgilrenruB

nehw

noitsubmoc

nugebsah

.yllamron

deR s52,0 gniloocretfA

;eruliaF

eruliaf

langis

5sekat

setunim

retfadna

ylnotaht

DELder

.gniknilbsi

wolleY s2

gulpwolG

eruliaf

wolleY s2ajs521,0

nafrenruB

eruliaf

wolleY s52,0

rednU

egatloV

wolleY

derdna

s521,0

;gnikcoL

ecapseht

siretaeh

gnikcol

2retfa

*.tratsdeliaf

deR s52,0 taehrevO

deR s03

retfasthgiL

eruliaf

.langis

T0209

OPERATION INSTRUCTIONS

FUEL

The following alternative fuels can be used in

the space heater :

Remember to take operating temperature

into account while choosing the fuel type.

Following temperature limits are for reference only. Check temperature limits from

your local fuel supplier.

- Furnace oil / Diesel oil, summer quality, ambient temperature must be higher than –5°C

- Furnace oil / Diesel oil, winter quality, ambient temperature must be higher than –24°C

- Furnace oil / Diesel oil, arctic quality, ambient temperature must be higher than –40°C

- Paraffin (kerosene), ambient temperature

must be higher than –40°C

If ambient temperature is lower than recommended fuel can be waxing (fuel becomes

cloudy). Wax can block fuel filter and pump.

Wax won’t dissolve until the ambient temperature is clearly over 0°C. In winter conditions

arctic quality or paraffin (kerosene) must be

used.

N.B. Do not start at the same time as the battery will be charged from a generator or battery charger (danger of over voltage)

NORMAL START-UP

1. Press the starting switch on: position I. The

red signal light comes on after about 2.5 - 4

minutes from the start-up, and then the combustion is normal. After the start-up stage

(about 5 minutes), the heater’s output remains at the set value.

SIGNAL LIGHTS OF M40 CONTROL

PANEL

The less aromatic substances are contained

in the fuel, the less crust will be formed. The

aromatic substances content in normal fuel oils

is about 35 - 40%, in dyed city-diesel oils (for

example, Tempera 3G and 5G) about 20%. The

aromatic substances content of paraffin is

about 0.5%, and consequently, almost no crust

is formed during combustion.

THE FIRST START-UP

1.Press the starting switch on: position 1.

2.The device does not necessarily start at the

first time, as the fuel hose is empty. In such a

case, the red light begins to blink after about

4.5 minutes from the start-up. Press the starting switch to position 0. The device cannot

be re-started until both signal lights are out

(after-ventilation period). Start again after the

signal lights have gone out. The red signal

light comes on after about 2.5 - 4 minutes

from the start-up, and then the combustion is

normal.

* Opening of the locking:

1 Switch ON the heater (blinking of locking).

2 Disconnect the main current wire of the heater (heater (blinking) switches off).

3 Reconnect the main current wire (yellow LED lights

1 - 3 second).

4 When yellow LED dies switch OFF the heater.

4 / ENGLISH

M40

T0209

CHECK-LIST AT SERVICE FAILURES

OPERATION INSTRUCTIONS

The fuel is not moving: The movement can

be checked by lifting the suction hose out of

the tank for a few seconds; there will be an air

bubble moving with the fuel.

- Check the tightness of the joint: if necessary,

make the joint tighter.

- Check the hose: replace a leaking hose with

a new one.

- Make sure that the pump receives voltage;

the pumping sound or voltage variation when

measuring the voltage.

No voltage is received: the yellow light is not

on.

- Check the charging of the battery.

- Check the connections of the battery or power-supply unit.

- Check if the automatic fuse has tripped and

come up, press it down if necessary. Check

the main fuse connected to the electric conductor and replace it if necessary.

Under-voltage: the yellow light is blinking.

- Charge the battery or replace it with a more

powerful one.

- Replace the electric conductors with thicker

ones; see installation instructions.

Too much fuel is received: the heater is overheated and cuts off its function by itself.

- Check that the fuel surface of the tank is below the lower surface of the heater

- The exhaust gas or fire ventilation hose is

blocked.

- Remove obstacles and blockages

Fuel and voltage is received normally, but

the device will not start:

- Check through the inspection port whether

the glow plug is glowing at start-up, change

it if necessary.

- Check the fuel composition and if there is any

suspicion that water may have condensed

into the tank, remove the water; see maintenance instructions.

N.B. The device cannot be re-started until the

red and yellow signal lights have gone out.

If necessary, contact the nearest Wallas service or your supplier.

TECHNICAL DETAILS

Fuel:

Furnace oil / Diesel oil (anti-freezing properties according to the operating conditions) or

paraffin (kerosene)

Fuel consumption:

M40: 0.16 - 0.4 litres/hour = 3.8 – 9.6 litres/

day

Thermal power:

M40: 1600 – 4000 W

Power adjustment:

Stepless manual adjustment or room thermostat

Starting:

By manual switch or automatic, weekly timer

(additional equipment) or by remote control

starter (additional equipment)

Operating voltage:

12 V. Power source: battery or Wallas powersupply apparatus equipped with a 12 V/15 Ah

mini battery.

Current consumption:

0.2 – 0.4 A = 4.8 – 9.6 Ah/day

Heater current 8 A for 4.5 minutes after startup.

Dimensions and weight:

M40 730 x 440 x 240 mm / 25.5 kg

5 / ENGLISH

M40

T0209

SERVICE INSTRUCTIONS

The fuel contains aromatic substances that

form crust at the bottom of the burner. The

speed of encrustation depends on the quality

of the fuel and the output of the heater, and

consequently, the need for service may be varying. During servicing, the crust will be removed from the burner and the fuel needle and

bottom carpet will be replaced by new ones, if

necessary.

Cleaning of the burner

Lift the protective grating of the heater. Open

the front wall of the heater by lifting the wall

upwards. After this, the front wall can be pulled

out. The front wall is fastened with tongues to

the screws on the sides, loose the screws, if

necessary. Arrows in fig. 7. Detach the protective plate of the plinth by undoing the screw in

the middle. See the circle in fig. 7. Pull the protective plate forwards and lift it up.

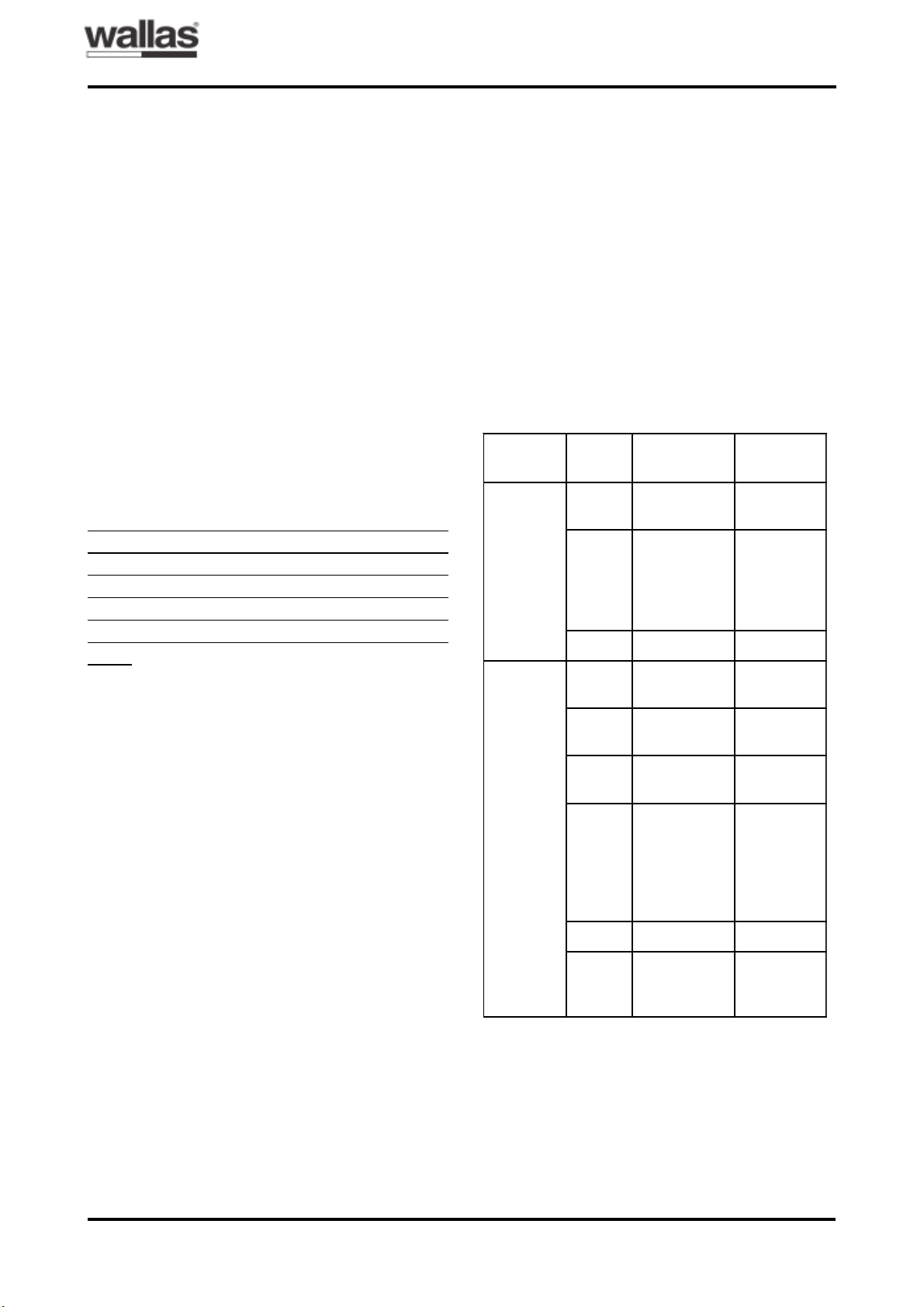

Fig. 7: M40 heater.

temperature sensor carefully. If the packing has

become brittle, it must be replaced with a new

one. If the glow plug is damaged, replace the

old plug with a new one. Fig. 9 shows an intact

glow plug and a typical glow plug in short circuit. A glow plug does not usually look different

if there is a cut-off.

Fig. 8: How to detach the temperature sensor, glow

plug and fuel needle.

Glow plug

Temperature sensor

A

B

Detach the screw and clamp of the temperature sensor and the corresponding glow plug

clamp from the combustion chamber cover.

See fig. 8. Pull the glow plug and temperature

sensor carefully out; do not pull from the wires

of the parts. Remove the white packing of the

Fig. 9: Intact glow plug (above) and damaged glow

plug in short circuit (below).

Unscrew the fuel needle clamp and pull the fuel

needle carefully out by rotating it. See the arrow in fig. 8. The fuel needle is equipped with

a locking ring that defines the depth to which

the needle is installed. In model M40 the installation depth is 50 mm. If the fuel needle is

blocked, replace it with a new needle by pulling the fuel hose out of the upper clamp of the

pump and install the hose for the new needle.

See the circle in fig. 8. Undo the 5 fixing screws and one distance screw on the combustion chamber cover. Detach the combustion

chamber cover.

The packing inside the combustion chamber

cover must be intact as shown in fig. 10. Detach the burner assembly from the heater by

pulling out the spring that holds it in position.

See fig. 11.

6 / ENGLISH

M40

T0209

SERVICE INSTRUCTIONS

Fig. 10: M40 burner chamber opened.

Fig. 11: Detaching the burner.

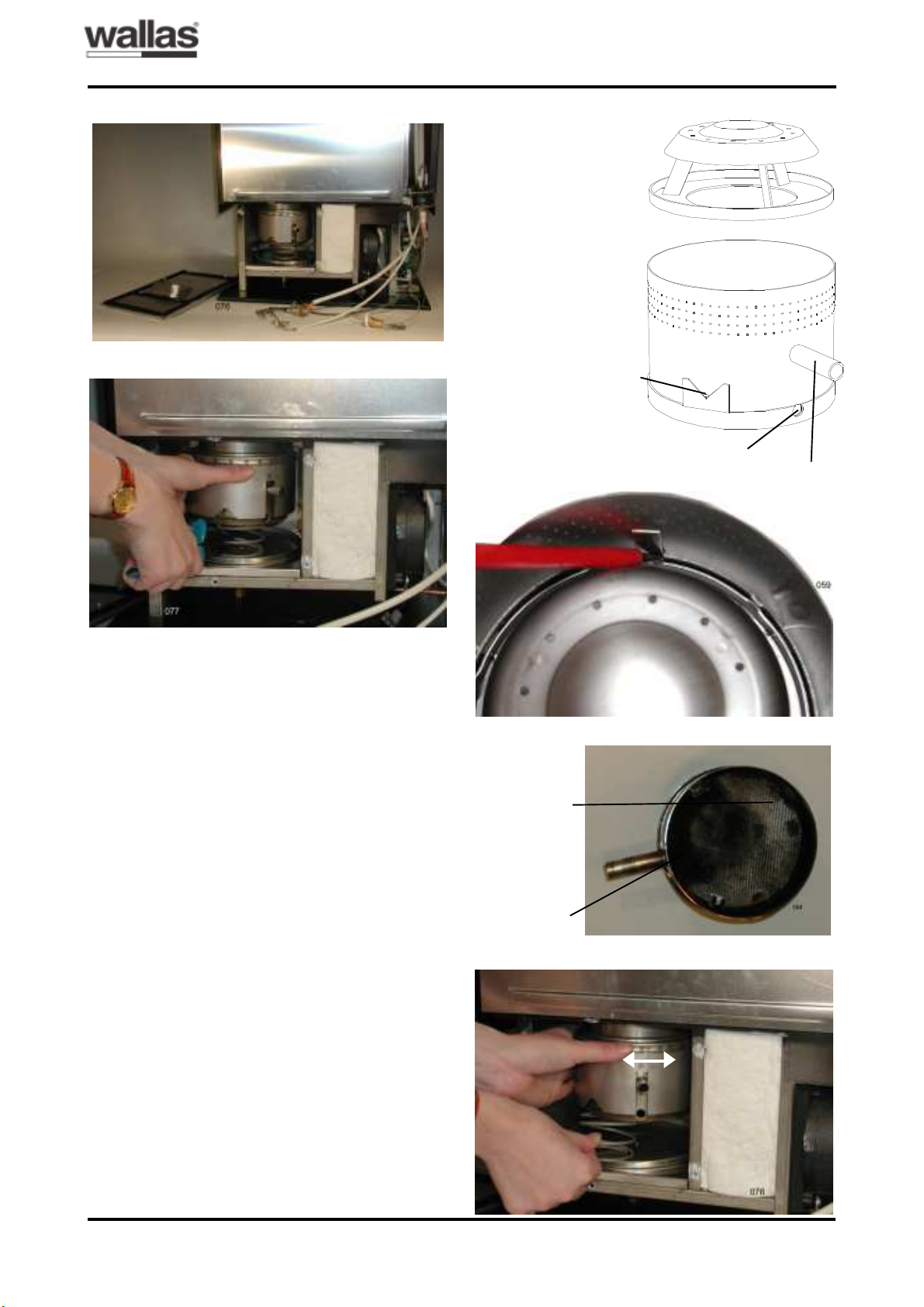

Fig. 12: M40 burner parts.

Heat radiator

Burner cylinder

Fuel needle hole

Glow plug hole

Fig. 13: Detaching the heat radiator.

Temperature

sensor pipe

Fig. 12 shows the burner parts of M40. Detach the heat radiator by pressing the locking

tongue towards the burner cylinder wall and by

inclining the heat radiator. Fig. 13.

Crust is mainly formed on the bottom of the

burner cylinder. Scratch the crust carefully off,

for example, by using a screwdriver. If necessary, also clean the walls of the burner cylinder

and the heat radiator. It is advisable to replace

the bottom carpet in position when cleaning

the cylinder. Fig. 14. The bottom carpet acts

as a heat insulator of the burner cylinder during ignition, and consequently, the carpet must

be intact at least under the glow plug.

The burner is reassembled in the same way

as it was demounted, but in the reverse order.

When assembling the burner cylinder make

sure that the heat radiator is locked into its

position. To secure the locking, tap the burner

upside down, which makes the heat radiator

come off from its clamps, if it is not locked.

When installing the burner assembly move it

back and forth to make it settle tightly into the

heat exchanger. See the arrows in fig. 15. Turn

the burner to its position and push the spring

under the burner. Fig. 15.

Fig. 14: Burner cylinder.

Bottom carpet.

Crust

Fig. 15: Installation of the burner.

7 / ENGLISH

M40

T0209

SERVICE INSTRUCTIONS

The fuel needle is in correct position, when it

is bent to the right (towards the fuel pump). To

prevent the burner chamber cover from

sticking, it is advisable to apply heat resistant

grease on the fixing screws.

Checking the function of the heater

The functioning of the burner must always be

checked after the heater has been serviced.

- Start the heater and let it burn for 15 minutes.

- Check through the inspection window that the

heat radiator is glowing red and that the flame is burning smoothly.

- There should be many separate flames with

smooth edges in the burner. The flame may

be either all blue or blue and yellow.

- If the flame is burning smoothly and the heat

radiator is red, the burner and heater are functioning normally.

- If the flames cannot be discerned from each

other or if the flames are all yellow or entangled, there are air leakages in the burner. In

this case, reopen the heater and check all

the burner joints for air leakages.

- An unstable burner flame during operation is

probably a sign that the burner needs cleaning.

Fuel system and electronics card

Measuring the fuel feed

If any parts of the fuel system have been replaced, the fuel feed of the heater must be

checked by measuring it.

1. Start the heater at full capacity.

2. Pour some fuel into a measuring glass, e.g.

50 ml. Place the fuel pipe into the measuring

glass and start the clock at the same time.

3. Take the fuel pipe out of the measuring glass

after six minutes.

4. Multiply the amount of fuel in millilitres consumed in six minutes by ten to obtain the fuel

consumption per hour. Normal fuel consumption at full capacity is 0.4 ± 0.02 l/h.

5. Compare the measured value with the normal value; if there are differences, adjust the

fuel feed by turning the trimmer shown in fig.

17.

At the same time, it is easy to check the power adjustment of the heater.

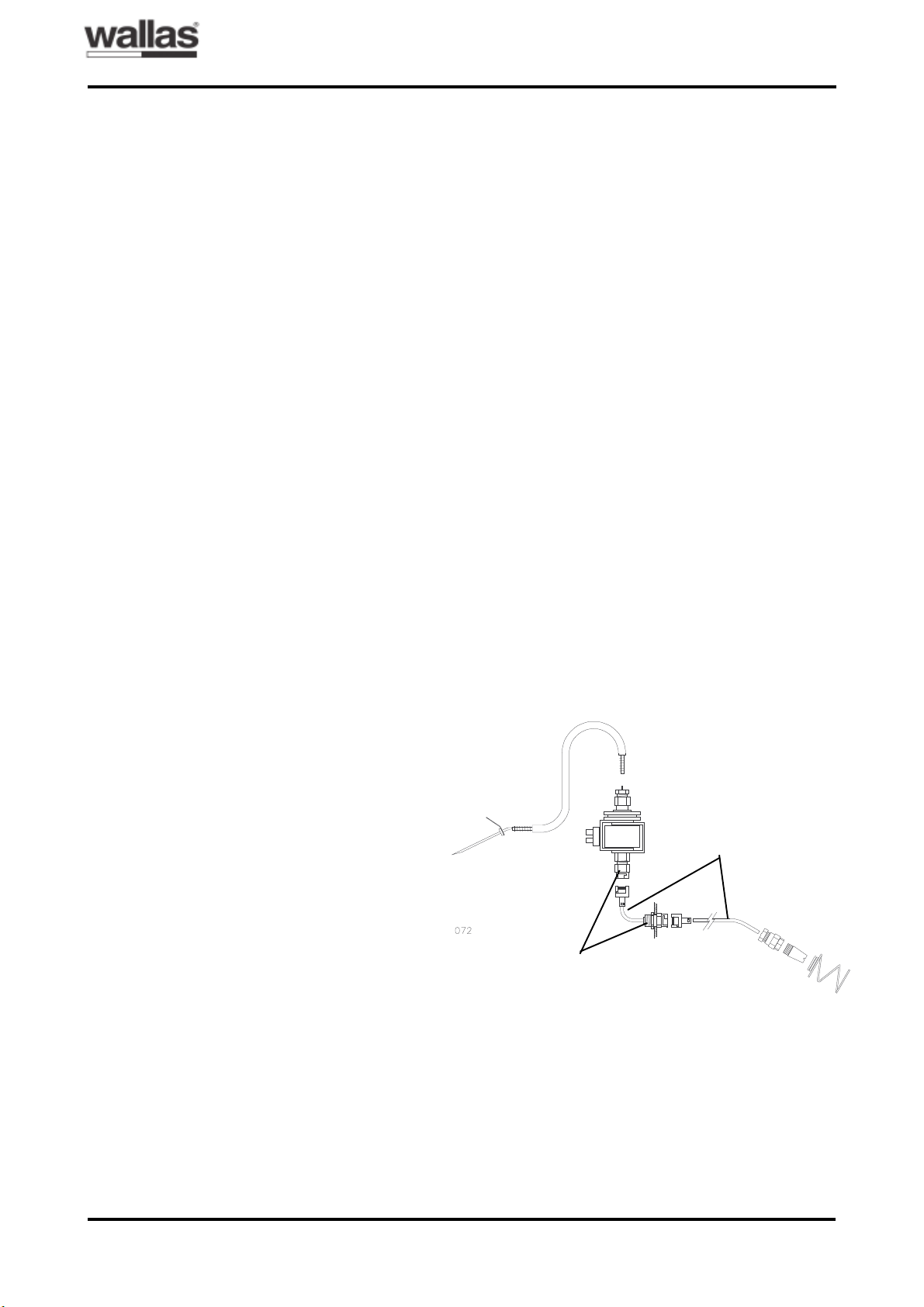

Fig. 16: Fuel system parts.

Fuel feed

pipe

Male connector for suction hose

Fuel pump

Fuel suction hose

Protective spiral

Filter

head

8 / ENGLISH

M40

T0209

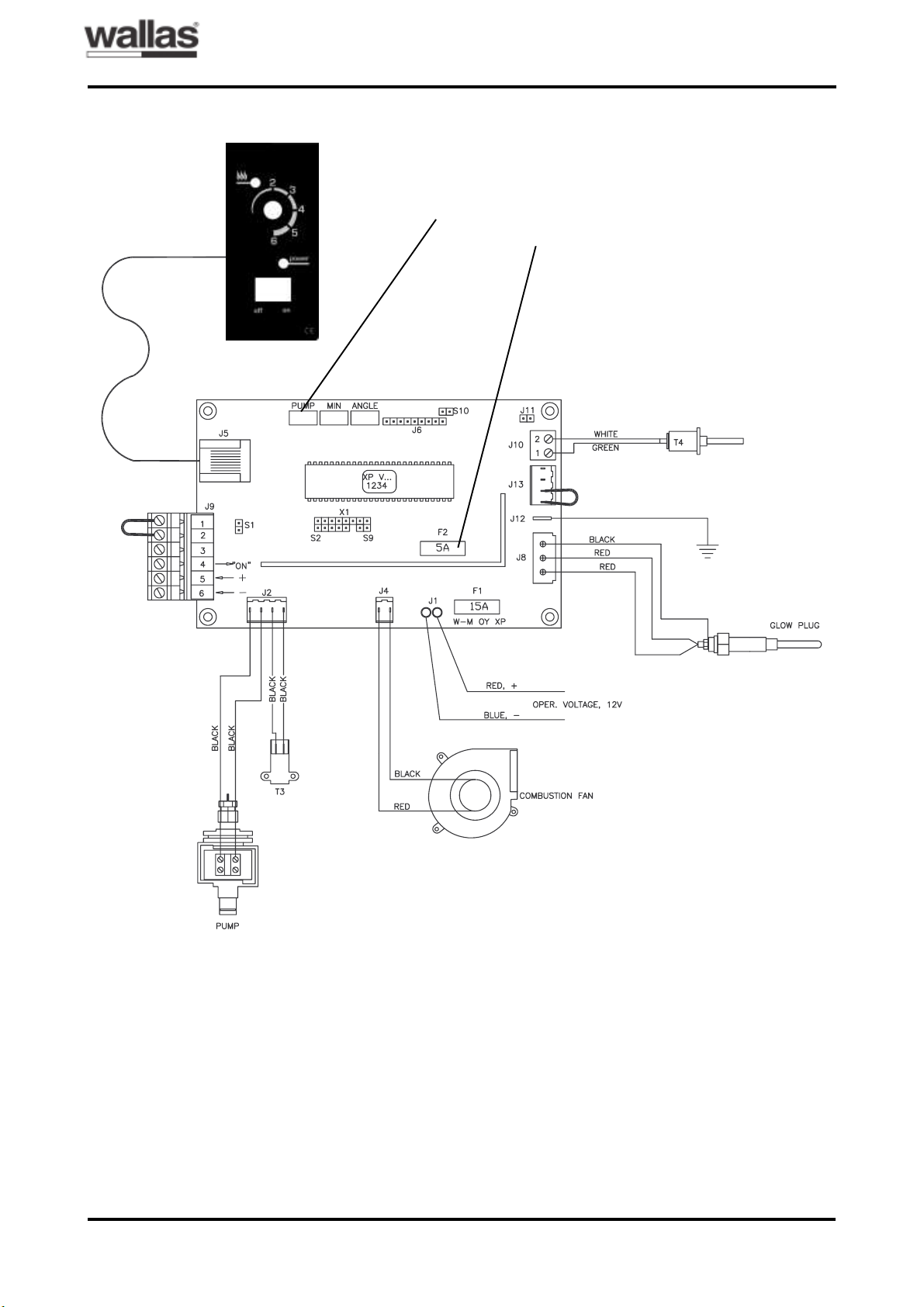

Fig. 17: Electronics card connections.

SERVICE INSTRUCTIONS

Connection to

thermostat and

remote control

Fuel feed trimmer

Fuse,

slow 5 A

9 / ENGLISH

M40

T0209

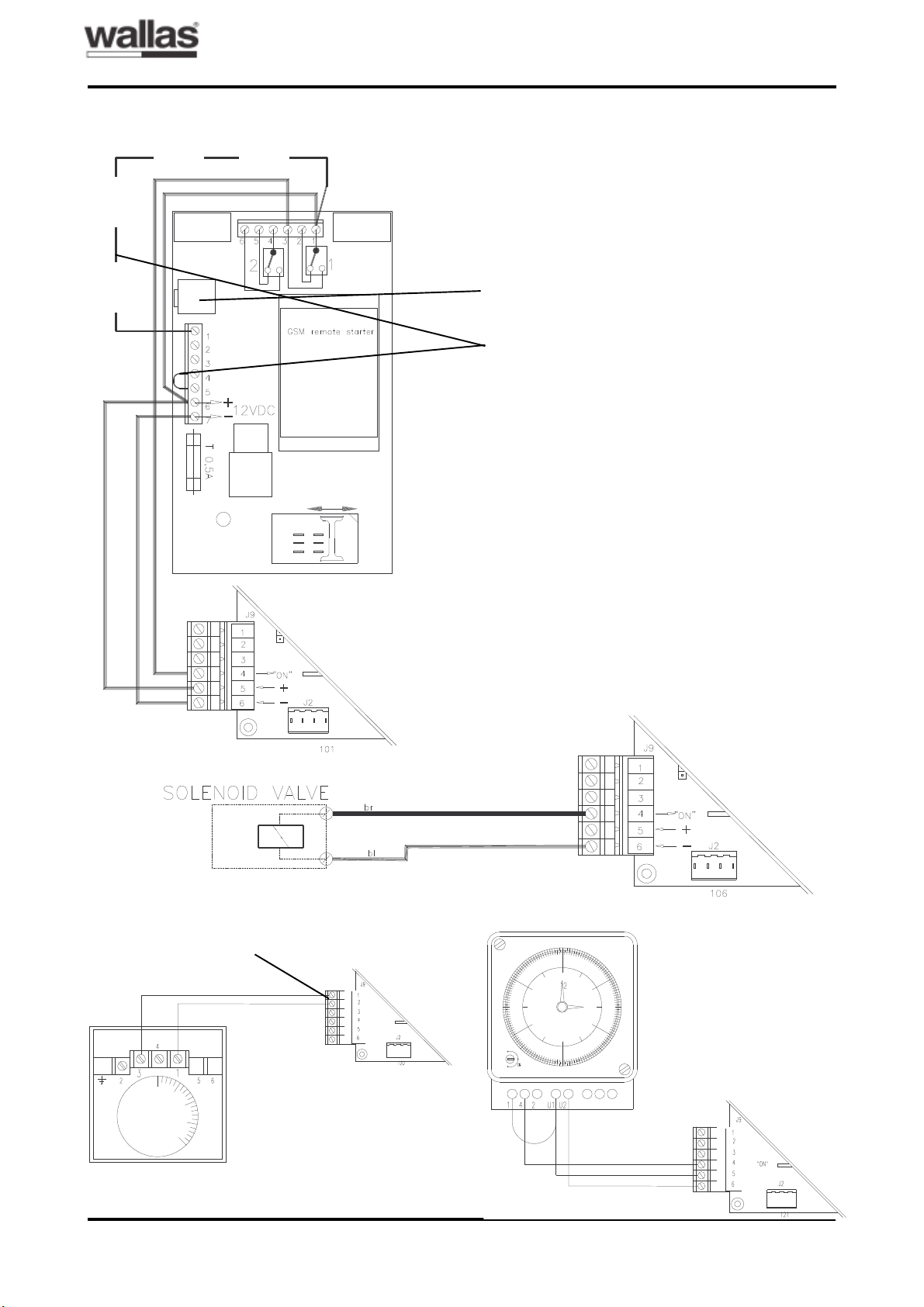

Fig. 18: Connecting a 4420 GSM remote control to the heater.

ACCESSORIES´ CONNECTIONS

Temperature sensor

Alarm

Fig. 19. Connecting a solenoid valve to the heater.

Fig. 20. Connecting a room thermostat (a) and a weekly timer (b).

a.

The short-circuit loop shall be eliminated.

b.

10 / ENGLISH

M40

gatnitfulsgninnärbröF

:kramrevö

m0,1

:gninnymsterörsagvA

kramnavO m1,1

trabsgninppönårF

retsnöf

m0,1

gninppösnoitalitnevnårF m5,1

rrödvanadisrellenavO m5,0

T0209

MONTERINGSANVISNINGAR

Värmeaggregat Wallas M40: Monterings-, bruks- och underhållsanvisningar / Sverige,

Finland

Notera i Sverige; Anvisningarna är godkända av SP med nr E12810. Typgodkännandennr. för M40 nr SP 585 K.

För att försäkra sig om en riktig installation, skall skorstensfejare i det berörda distriktet kontaktas. Före användin-

gen skall alla anslutningars (rökgaser, förbränningsluft, bränsle, rökgasrörets mynning) täthet kontrolleras.

PLACERING AV VÄRMEAGGREGAT

1.Fritt avstånd till omgivande väggar enligt figur 1. Övriga minimiavstånd i Sverige enligt

tabell 1.

2.Utrymmena mellan aggregat och väggar skall

hållas rena och fria från damm, skräp och

främmande föremål.

3.Luftingsöppningarna på framsidan, sidorna

och baksidan av aggregatets hölje (dess

nedre del) skall hållas fria från föremål och

hinder som hindrar ett fritt luftintag.

4.Det får inte finnas ytor, konstruktioner eller

föremål som är brandfarliga eller hindrar värmeströmningen rakt ovanför värmeaggregatet inom ett avstånd av 1 m från aggregatets

övre yta. Se figur 1.

5.Värmeaggregatet skall fästas stabilt vid golvet eller stativhöljet med skruvar. Även stativhöljet fästs vid golvet. Aggregatet skall stå

i lodrätt läge. Se figur 2.

Figur 1.

Figur 2.

6.Värmeaggregatet skall placeras så att vatten inte kan droppa, rinna eller stänka på det.

7.Obs! Den maximala längden för ej isolerat

avgasrör är 3 meter, för isolerat 6 m.

8.När aggregatet används på högre altituder,

t.ex. i fjällen över 1500 m kan luftdensitetens

ändring tas hänsyn till genom att efter behovet koppla bergsparameter på elektronikkortet.

Tabell 1: Minsta avstånd (m, linjär interpolation) i Sverige.

Figur 3.

Under 1500 m

Över 1500 m

1 / SVENSKA

M40

T0209

MONTERINGSANVISNINGAR

PLACERING AV TANK

OBS! Bränsletank skall vara utförd och placerad enligt gällande föreskrifter (statens industriverks kungörelse med tillämpningsföreskrifter till förordningen om brandfarliga varor SINDFS 1981:2 med ändring SÄIFS 1989:12).

1.Bränsletanken placeras bäst under botten av

värmeaggregatet. Se figur 4. (Bränslets ytnivå måste ligga under foten.) Om bränslenivån är högre än kaminens botten, rekommenderas montering av en magnetventil på

bränsleledningen.

2.Bränsletanken kan placeras i stativhöljet (se

fig. 2) eller externt, t.ex. i husets krypgrund

(se fig. 4) eller i en lämplig skyddslåda. Skydda tanken och bränsleröret mot direkt solljus.

3.Genomföringen av bränsleröret genom

konstruktioner måste skyddas med

skyddsrör av metall.

4.Standardlängden för bränsleröret är 3 m.

Den kan förlängas med en 2 m lång förlängningrör. Koppla samman rören genom att

skruva fast snabbkopplingarna. Figur 4 visar

maximigränserna för monteringen.

Figur 4.

OBS! Spänningen måste primärt tas direkt från

batteriet, inte t.ex. från solpanelsystemets styrenhet. Det säker-ställer att systemet håller för

tändningsströmmen och inte utsätts för överspänning. Be din systemleverantör om närmare information.

MONTERINGSHÅL I VÄGG/RÖKKANAL

1.Välj plats för aggregatet. Se placeringsanvisningarna ovan.

2.Avgaserna skall alltid ledas ut till det fria, antingen genom vägg eller via befintlig rökkanal. När ökgaserna leds ut genom vägg

skall även förbränningsluften tas utifrån vilket

stabiliserar lufttrycks örändringar beroende

på vindar. Se separat monteringsanvisning

nedan.

3.Vid montering genom vägg: Ta ut hål

(Ø 320 mm) i väggen enligt måtten i figur 5.

Vid rökkanalmontering: placera hålet

(Ø 120 mm) i rökkanalen på rätt plats. Ta ut

ett eget hål (Ø 50 mm) för förbränningsluft i

frisklufts kanalen eller golvet. (Se närmare om

hålets storlek i figur 5.) Vid rökkanalmåntering kan förbränningsluft också tas innenfrån.

I Finland olika dimensioner, se sida 24/figur

5.

Figur 5.

(I Finland olika

dimensioner, se

sida 2/suomi/figur 5)

PLACERING AV BATTERI

1.Anordningen har en 4 m. lång elkabel av

tjockleken 4 mm2. Om avståndet mellan

anordningen och batteriet är 6 m, måste kabelns tjocklek vara 6 mm2 o.s.v.

2.För att skydda elledningarna kan man montera en 16 A:s säkring i elkabelns plusledning på batterisidan.

3.Placera batteriet så att det inte förorsakar

fara vid uppladdning och användning och så

att det kan luftas till det fria.

4.Elkablar skall vara väl fastsatta och skyddade mot nötning.

2 / SVENSKA

Loading...

Loading...