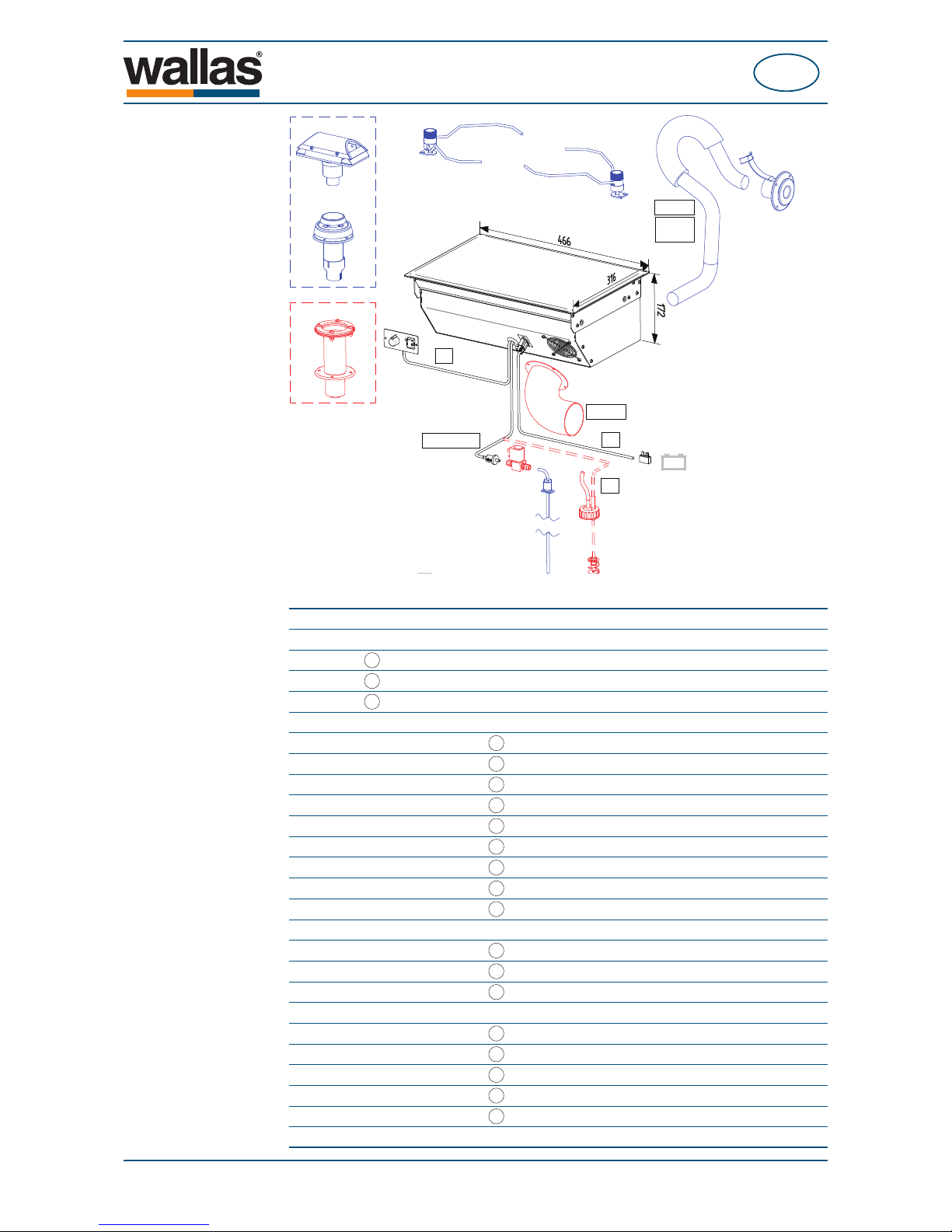

wallas 88DU Installation, Operation And Service Instructions

88DU

Technical information

GB

490070GB

Installation, operation and maintenance instructions

Control panel fastening screws 3.5 x 13 (black)

Screw for iron fastener M6 x 12 (hexagonal socket 4 mm)

Fastening screw M6 x 30 (hexagonal socket 4 mm)

Cover plug

Hose binder 20 – 32 mm

Fuse box

1 pcs

2 pcs

4 pcs

4 pcs

4 pcs

1 pcs

1 pcs

88DU

Stove 88DU (fuel hose and control panel cable installed)

Control panel

Accessory bag

Power cord with connector (4 m)

Iron fastener

1 pcs

1 pcs

1 pcs

2 pcs

Hose binder 32 – 50 mm

Pipe connection box

Tightening screw M4 x 8

Pipe connection box kit

Hose binder 8 mm

1 pcs

1 pcs

Fuel fi lter

Hose binder 10 mm

Fuel fi lter package

Rubber hose ø 5 mm

Rubber hose ø 6 mm

1 pcs

4 pcs

2 pcs

2 pcs

1 pcs

1 pcs

1 pcs

2 pcs Push on contact 6.3 x 0.8 (yellow)

Fuse 15 A (blue)

1 pcs

1 pcs

1 pcs

Locking nut M64 pcs

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

7

Package contents

2448

2467

3468

2466

30012

30011

367215

O28/45mm

12V

4m, MAX 8m

2m

4m

4m

MAX 2m

2069

3430

MAX 1m

1012

MAX 4m

3430

- 65 -

88DU

Technical information

GB

490070GB

Stove operation

The 88DU is a safe diesel stove with no open fl ame. The stove is equipped with

a single burner which burns either diesel oil or light furnace oil. The stove takes

the air needed for the burning process from the boat and discharges the resultant

smoke with a combustion air blower. This means that, when the stove is being

used, the air in the boat circulates and stays fresh and dry. The steam in the fl ue

gas does not remain in the boat and increase interior humidity.

The fuel pump in the stove dispenses fuel, and the electronics control the combustion air and the amount of fuel automatically to keep the fl ame of the burner clean.

When the stove is switched on, the glow plug in the burner ignites the fuel that has

been pumped into the burner. The glow time is fi xed: it begins and ends automati-

cally.

The heat sensor in the stove detects the heat of the fl ame and lights the red LED

light to signal that the fl ame has been ignited.

The heat which is released as the fuel burns is transferred into the ceramic stove

top. The left side of the stove top is hotter, as the burner is located under it. The

power of the stove can be adjusted steplessly. The control adjusts both sides of the

stove simultaneously.

When the stove is switched off, it cools down automatically. The cooling function

ventilates the burner and discharges the fl ue gases generated during the switch-off

outside the boat.

The stove lends itself extremely well to cooking and warming up all kinds of foods.

It has been manufactured entirely from stainless materials.

Fuel Diesel oil, light furnace oil

12 V DC

0,09 - 0,19 l/h

900 - 1900 W

0.3 A (when ignited ca. 4 min. 8 A)

466 x 316 x 172 mm

ca. 9 kg

2 m (4 m, Intake connection set 3430)

8 m

100 cm

2

2467, 3468 and 2460

1012 Kettle holder set

1150 Toasting grill

3430 Intake connection set

Operating voltage

Consumption

Heating power

Power consumption

Measurements

Weight

Max. permissible length of the fl ue

gas pipe

Max. permissible length of the fuel

hose

Minimum size of the replacement air opening

Suitable fl ue gas lead-throughs

Accessories

Technical information

- 66 -

88DU

Installation

GB

490070GB

Things to note when selecting the installation location

When installing the device, bear in mind that the device must be detached for

maintenance. Therefore, it is advisable to make the connections easy to open and

disconnect.

The stove should be installed level. The inclination must not exceed 5°. While the

device might not break if it is temporarily tilted to a steep angle (even for some

hours), the burner will not yield optimal performance if it is constantly inclined.

Also consider where you will place the control panel, as the length of the control

panel’s cable may pose some limitations.

Avoid installing the control panel in the immediate vicinity of a water outlet.

If possible, install the control panel on a vertical surface.

Moreover, the stove should not be installed on top of a refrigerator. The stove will

heat its surroundings and thus decrease the power of the refrigerator.

We recommend that the device be installed by an authorised Wallas service shop.

Things to note when installing pipes, hoses and cables

Power cables and fuel hoses must be protected in locations where they are susceptible to mechanical damage due to sharp edges or heat.

In a metal-hulled boat, you must ensure that the device, the fl ue gas

lead-through, the fuel connection, the control panel, and all other parts are

insulated from the boat’s hull. This must be done to:

- prevent electrochemical corrosion

- prevent voltage from being transmitted from the hull to the device or vice

versa during electrical faults.

Always use original Wallas accessories and parts with Wallas equipment.

- 67 -

88DU

Installation

GB

490070GB

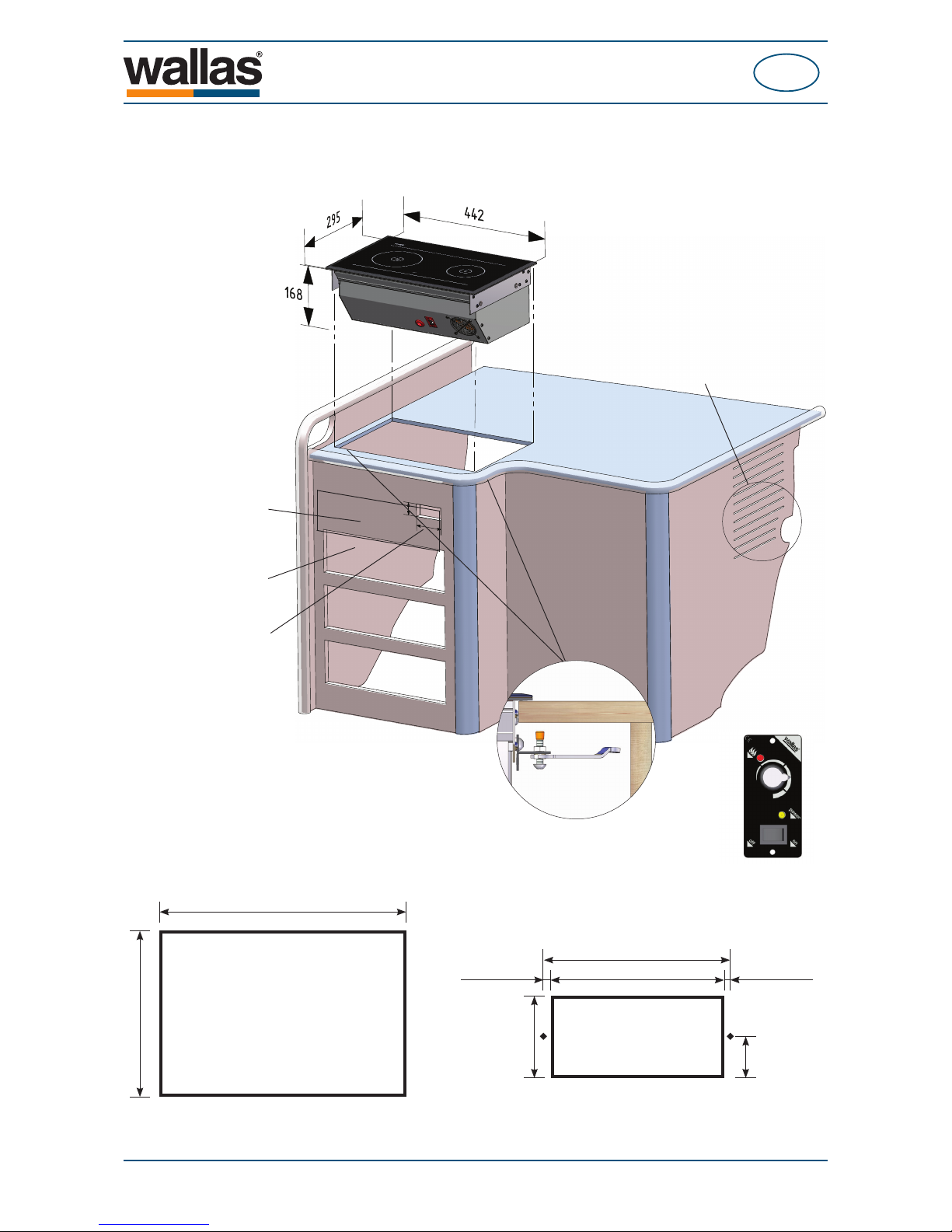

Stove installation

Saw a cut-out (see picture) for the stove and the control panel in your chosen location.

The length of the control panel cable is 2 m.

Measurements of the stove

installation cut-out

Measurements of the control panel installation cut-out

If necessary, predrill holes for the ø 2 mm ( 3/32”) screws.

The stove requires a replacement

air opening of at least 100 cm2.

Ensure that the air circulation under

the stove is suffi cient

Ensure that there is suffi cient space under the

stove for cables and hoses.

The control panel should

be installed on a vertical

surface.

You can also fabricate a

detachable panel to go in

front of the stove. This will

facilitate installation and

maintenance.

442 mm (17 13/32”)

295 mm (11

5

/

8

”)

Ensure that there is suffi cient space

between the stove and the vertical

surface to facilitate installing and

detaching the device.

The control panel

can also be installed

in a vertical position.

7 mm (

9

/32”)

71 mm (2 25/32”)7 mm (9/32”)

35 mm (1

3

/8”)

17,5 mm (

11

/16”)

85 mm (3 11/32”)

- 68 -

88DU

Installation

GB

490070GB

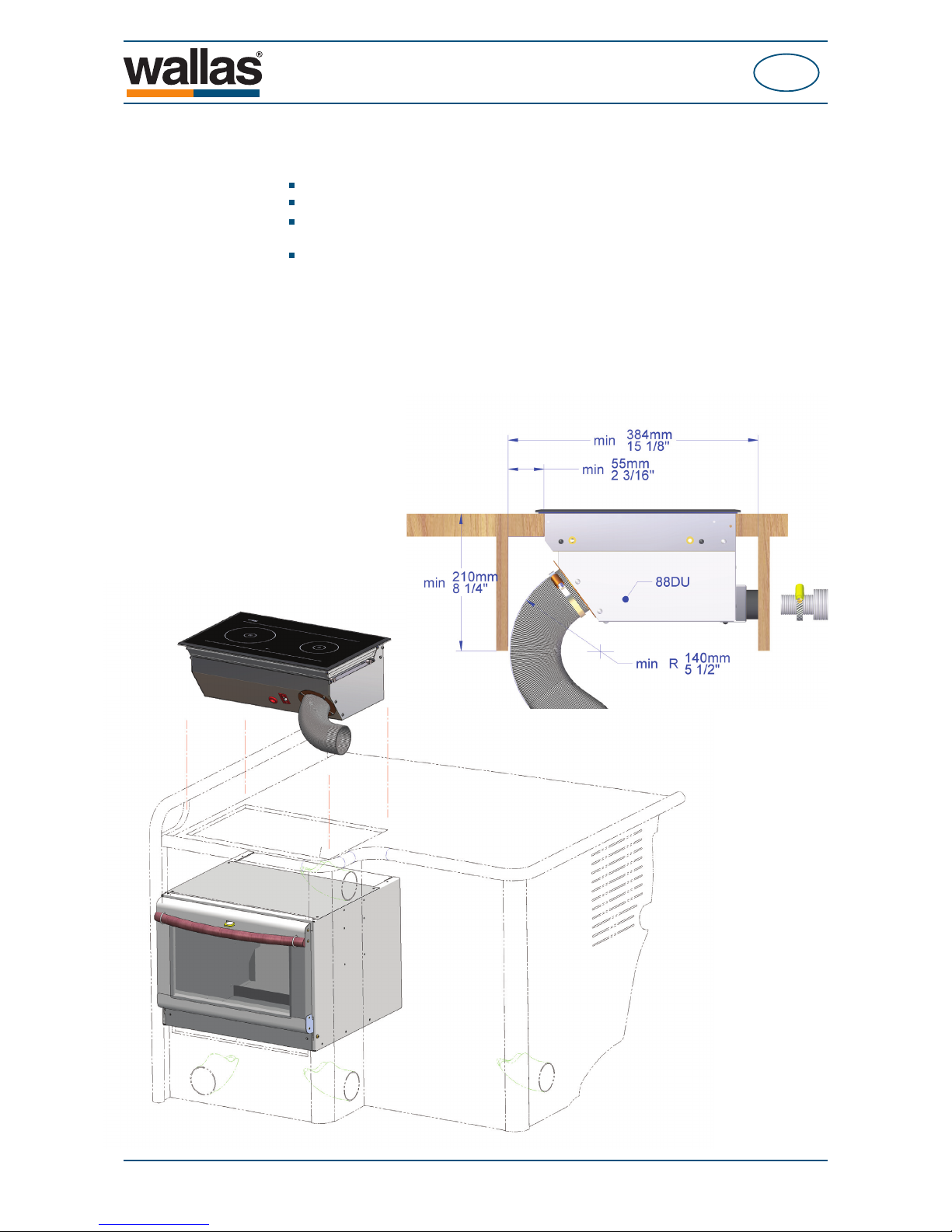

Installing in demanding conditions

If the device is installed or will be used in demanding conditions, e.g.

the fl ue gas hose is 2 to 4 metres long,

the stove is surrounded by thick thermal insulation,

there is another heat source under the stove (e.g. a Wallas oven 86D or a refrigerator),

the climate is particularly warm,

the intake connection set 3430 must be installed on the stove.

Install the set in front of the blower in the stove’s cooling case.

Lead the ø 75 mm hose (max length 1 m) to a location with fresh air. Ensure that

the air fl ows freely into the hose. Do not crimp the hose.

- 69 -

88DU

Installation

GB

490070GB

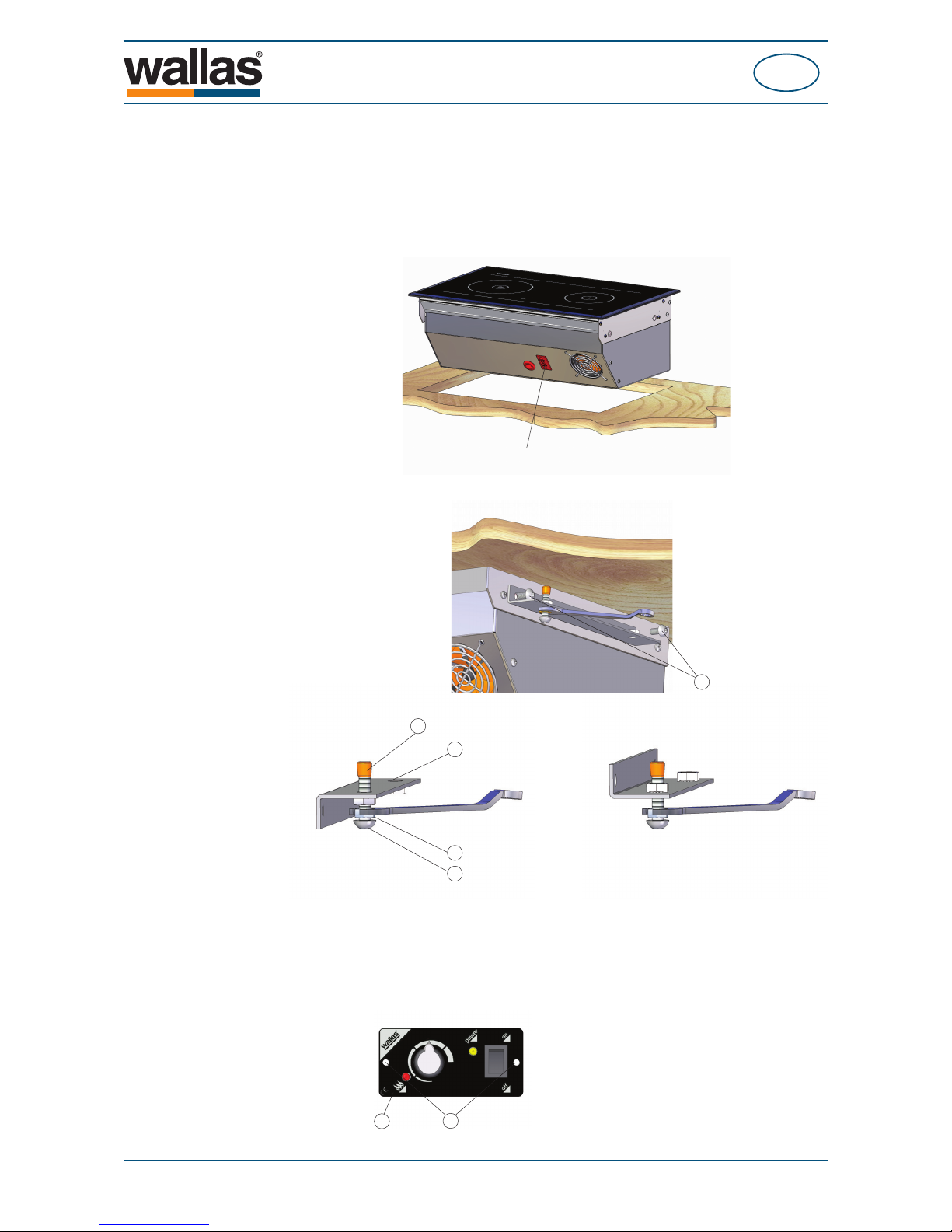

Fastening the device

Place the stove in the installation cut-out and attach the iron fasteners (3) with the

screws (5) to the rivet nuts at the ends. After this, install the cover plug (8) on the

end of the screw and tighten the iron fasteners against the table with the screw (6).

Remember the locking nuts (7).

Use the screws (4) in the accessory bag to fasten the control panel to the table.

1

4

Connect the control panel cable from the

device to the control panel (1).

Use the fastening screws to install the

control panel to the installation cut-out (4).

7

6

3

8

The iron fasteners can be installed in two ways depending on the thickness of the table board.

Push the cover plug (8) on the screw.

Tighten the screw (6) fi rmly against the table board and then tighten the locking nut (7).

Thin table Thick table

5

Attach the iron fasteners to the stove (3) with

screws (5).

Connect the power cord (2) to the connector in the

cooling case of the stove.

- 70 -

88DU

Installation

GB

490070GB

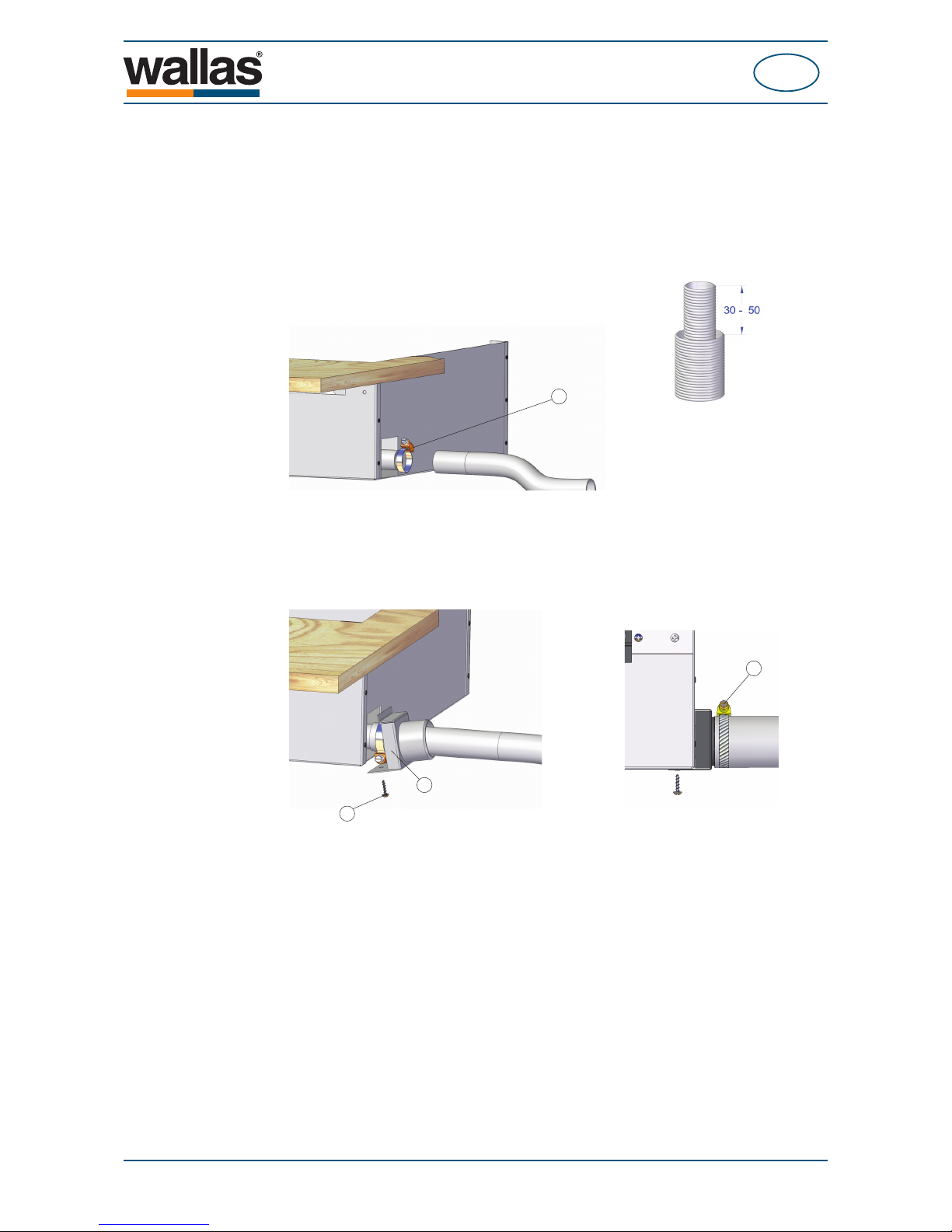

Installation of the fl ue gas pipe

Measure the length of the fl ue gas and exhaust pipe from the device to the gas

lead-through. Remember to add the required length for the swan neck section.

Cut the fl ue gas pipe 30–50 mm longer than the exhaust pipe. This way the pipe

will stay in place in the gas lead-through more fi rmly.

9

15

13

14

Connect the fl ue gas pipe (ø 28 mm) to the device using the

hose binder (9) in the accessory bag.

Attach the connection box of the exhaust pipe (13)

to the cooling case of the stove with a screw (15).

Connect the exhaust (ø 45 mm)

to the connection box with a hose

binder (14).

- 71 -

88DU

Installation

GB

490070GB

Total length of the power cord (m) Cross-sectional are of the cable (mm2)

0 - 4

4 - 6

6 - 10

4

6

10

Table 1.

Main switch

A main switch (accessory) must be installed on the device’s plus cord. Always cut

the power at the main switch, if the device is going to be left unused for a longer

period of time.

ELECTRICAL CONNECTIONS

Things to note about the connections

The device uses 12V direct current voltage. To minimise current losses, make the

power cable as short as possible and avoid jointing. The cross-sectional area of

the cable is dependent on the length of the power cord. See table 1. The crosssectional area of the cable must be consistent all the way from the stove to the

battery. The maximum length of the power cord is 10 m.

Never use the main switch to cut the power before the cooling phase,

which starts after stove is turned off, is completed.

If a thicker cable is required, make a separate joint in the power cord. See picture 1

on the next page.

- 72 -

88DU

Installation

GB

490070GB

Checking the connection

The device consumes most power when it is started up (glowing). At this point

voltage losses are also at their highest. During the glowing phase, the voltage must

be at least 10.7 V measured at the quick coupling. See picture 1. If the voltage is

lower than this, the device may not start.

If you handle an electronics card detached from the device, take care to

avoid damage due to static electricity.

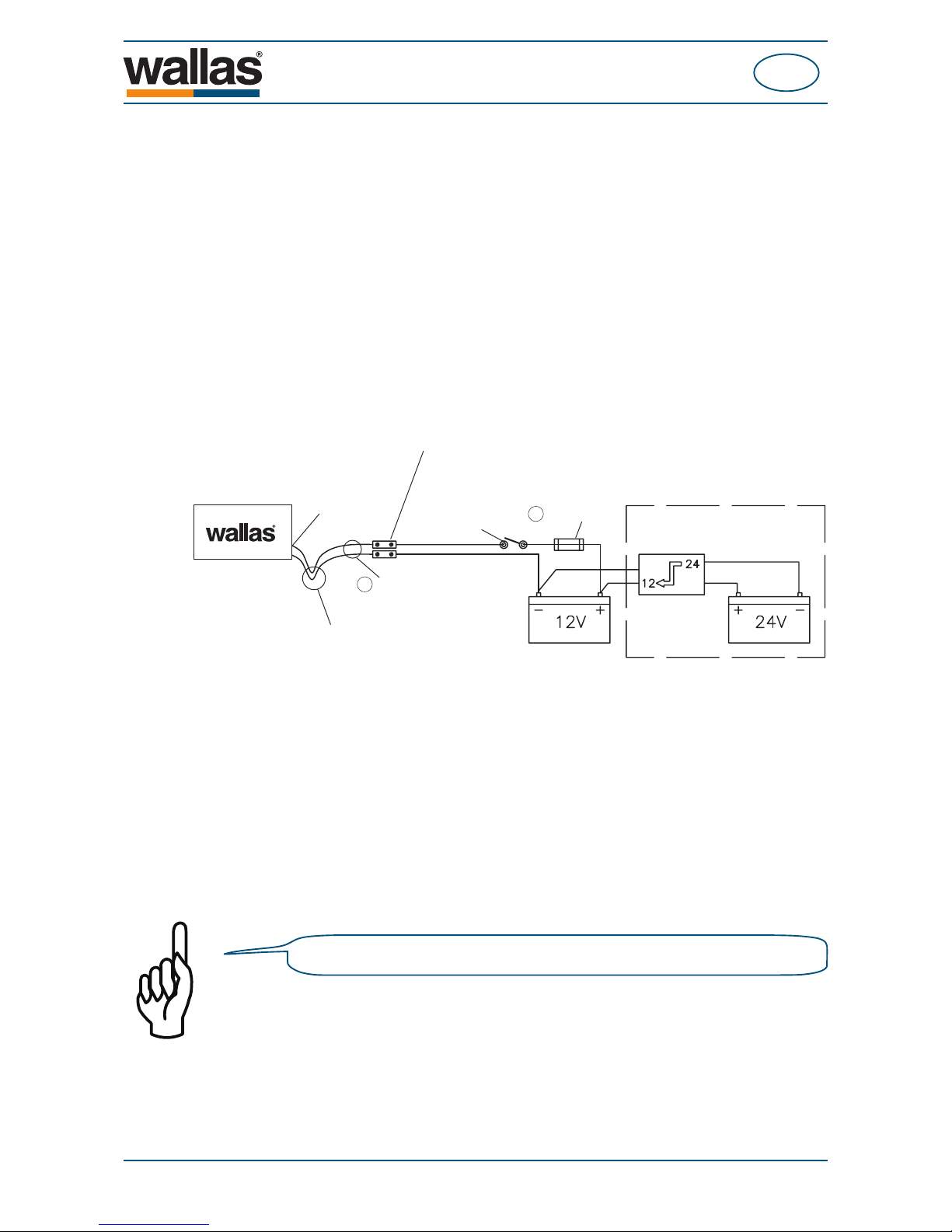

Picture 1.

24V direct current system

Dewatering loop

If the cables will be above the stove, a

dewatering loop is required. This prevents

condensated water from running to the

circuit board.

Device’s quick

coupling

Jointing

A jointing should only be made in long

power cords, if necessary, in which case

the cord must be replaced with a thicker

one. The jointing cannot be further than 1

meter from the device.

Main switch

Main fuse

Power cord

2

13

Electrical connections of the device

12V direct current system

Connect the red wire of the power cord to the plus terminal of the battery and the

black or blue wire to the minus terminal. A 15 A main fuse must be installed near

the battery on the red plus wire of the power cord. See picture 1.

24V direct current system

If the device is to receive power from a 24V system, always connect a charging

voltage reducer and a 12V battery before connecting the device. Without the battery the voltage reducer will not be enough on its own as it cannot generate the

large amount of current the glow plug requires. After the 12V battery, the connection is the same as in a 12 V system.

- 73 -

88DU

Installation

GB

490070GB

FUEL CONNECTIONS

Things to note about the connections

The standard length of the fuel hose is 4 m (max 8 m). Cut the fuel hose to a length

suitable for installation.

The lift height of the pump should be less than 2 m; preferably 0.5 – 1 m.

The fuel pipe must always have a fi lter. The fuel fi lter can be installed either near

the device, near the tank, or in another location where it can be easily checked and

replaced, when necessary.

All connections should be made with rubber or silicone hose which is resistant to

diesel.

Country-specifi c requirements

The standard fuel hose is plastic. Please observe country-specifi c requirements

with regard to the material of the fuel hose/pipe and the fuel fi lter. The inner diam-

eter of a new replacement hose must be equal to the inner diameter of the plastic

hose.

Copper pipe and metal fi lters are available as accessories.

The fuel connections must be tightened fi rmly so as to not allow air to

leak into the hose. Always check the cleanliness of the connection surfaces before tightening.

Air will cause the device to malfunction.

Fuel feed

If the lift height is outside the recommended 0.5 – 1 m, the fuel feed must be

checked and, if necessary, adjusted. The fuel feed must also always be checked,

if parts of the fuel system, such as the pump or the electronics card, have been

replaced.

Fuel system adjustments are device specifi c. We recommend that the adjustment

be carried out by an authorised service shop.

Optimal fuel tank

location

TANK

TANK

MAXIMUM

OPTIMUM

0,5 m

1 m

2 m

Checking /

adjustment

Checking /

adjustment

TANK

- 74 -

Loading...

Loading...