Wallas 1066, 2460, 2467, 3468, 3467 User Manual

...

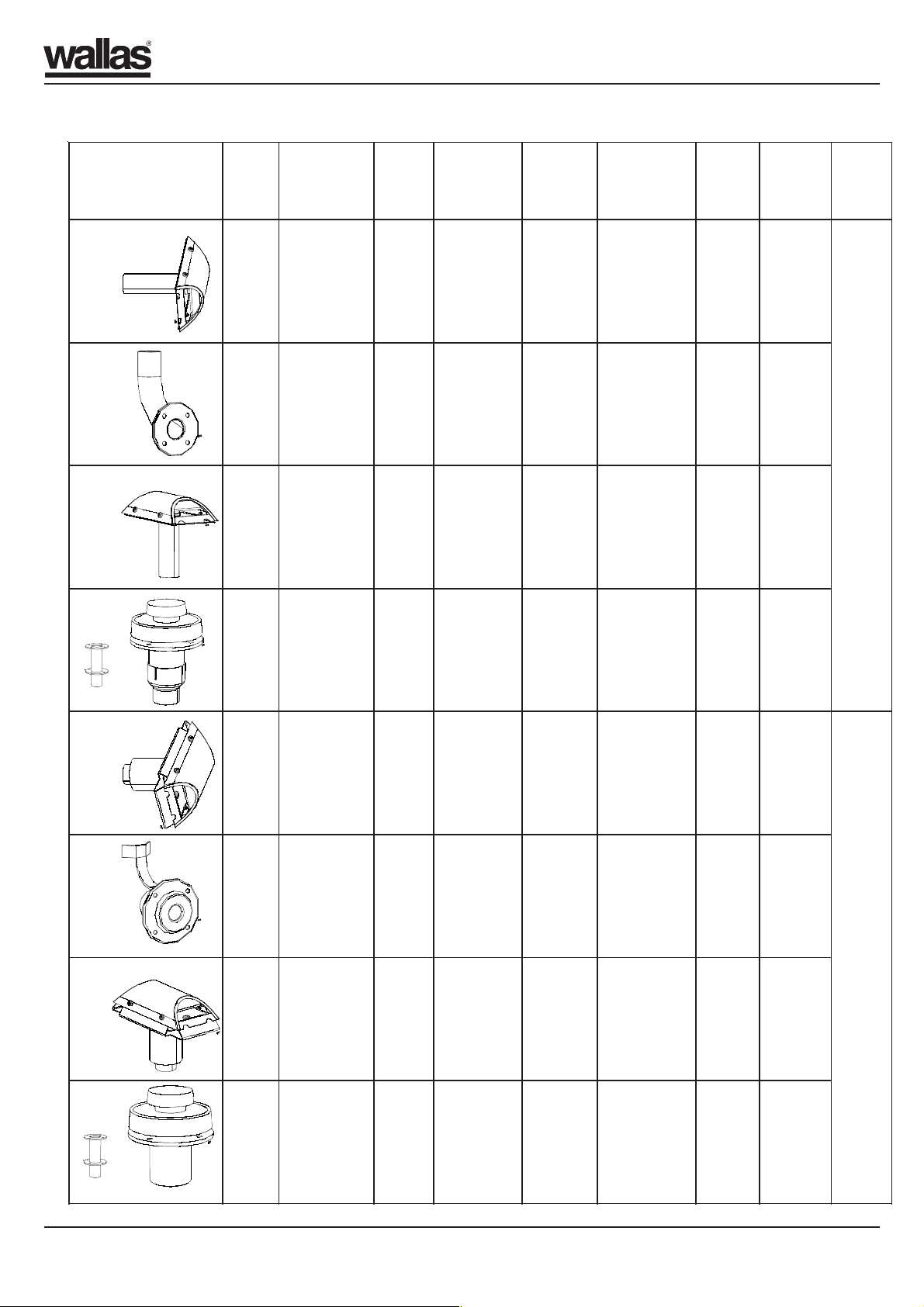

Lead-throughs

-

W ALLAS LEAD-THROUGHS 1066, 2460, 2466, 2467, 3467, 3468

Table 1: The mutual properties of different Wallas lead-throughs. Please use this table in choosing the most suitable leadthrough.

erutciP

lluH

.trA

.oN

)epip(

tsuahxE

roylno

noitanibmoc

hsalpS

draug

maertS

*ecnatsiser

dniW

ecnarelot

erutarepmeT

folevel

gnitnuom

ecafrus

eziS

dna

thgih

)mm(

elbalaeS

cilppA

ytiliba

7643

)8201(

lluH

6601

)8201(

kceD

7643

)8201(

kceD

6642

)8201(

9602

tsuahxE

ylno

tsuahxE

ylno

tsuahxE

ylno

tsuahxE

ylno

x041

37

04

56ø

4

x041

37

04

29ø

05

oN

oN

oN

seY

,UD59

,PD59

,008

,009

,0001

001,09

dna

.051

lluH

8643

)8442(

lluH

7642

)8442(

kceD

8643

)8442(

kceD

**0642

8442(

ro

)8242

9602

* Relevant especially in long exhaust pipes.

noitanibmoC

noitanibmoC

noitanibmoC

noitanibmoC

** 2069 always with Nautic 40D.

1

x551

38

65

29ø

91

x551

38

65

29ø

05

oN

oN

oN

seY

22.4.2002

,D69

,D03

,D04

,0031

,0081

0042

dna

0023

Lead-throughs

FEATURES AND RECOMMENDATIONS FOR USE

Exhaust lead-throughs:

- Exhaust lead-throughs are intended primarily for use

with Wallas products in which combustion air is not

drawn from a suction air pipe located around the

exhaust pipe.

- Exhaust lead-throughs may be used in other Wallas

products if the suction pipe for the combustion air is

cut off before the lead-through.

- With devices where the exhaust pipe shall be

insulated with a larger diameter metal pipe, the

combination lead-through has to be used.

- Exhaust lead-throughs are intended primarily for the

following Wallas units: 95DU, 95DP, 800, 900, 1000,

90, 100, 150.

- It is possible to use the 602293 drainage lock with

the exhaust lead-throughs to remove occasional

splash water and condensation from the exhaust

pipe.

- All of the exhaust lead-throughs are st ainless steel.

- The exhaust lead-throughs fit into the ø 28 mm 1028

exhaust pipe.

3467 Standard lead-through:

- The standard lead-through may be used as a hull

lead-through in rough conditions and as a deck leadthrough in mild and normal conditions.

- The standard lead-through has the best splashguard

of all Wallas lead-throughs.

- The standard lead-through cannot be sealed. For this

reason it cannot be used as a deck lead-through,

which may be occasionally submerged under water.

The standard lead-through’s splashguard is more

effective than using a sealable lead-through in the

open position.

- The standard lead-through withstands wind well and

may therefore be used as both hull lead-through and

deck lead-through.

- The arched design of the standard lead-through

makes it easier, for example, to slide a rope over it.

Likewise, a standard lead-through used in the hull

will not get caught if the hull comes into contact

with a post, for example.

1066 Hull lead-through:

- The hull lead-through has a slight flow resistance

and thermal effect surrounding it.

- The hull lead-through is sensitive to wind; under some

circumstances the wind can blow directly into the

hole. A strong wind exceeding 15 m/s may shut the

unit off.

2466 Sealable deck lead-through:

- The sealable lead-through withstands wind well.

- The lead-through may be installed into the deck

because of its sealability. It is therefore suitable in

rough conditions in which the deck may become

submerged under water.

- Always remember to open the lead-through before

turning the unit on and to seal it when sailing

conditions become rough.

- The lead-through is opened and sealed by

simultaneously pressing and turning its cap.

- Under exceptionally rough conditions, the use of the

deck lead-through upgrade, 2069, is recommended.

Combination lead-throughs:

- Combination lead-throughs contain both the exhaust

and combustion air jacket tube in the same leadthrough.

- Combination lead-throughs are intended primarily for

Wallas products in which the combustion air is preheated in the suction pipe around the exhaust pipe.

- The combination lead-through may also be used in

other Wallas units if the splash guard of the fresh air

duct is taken care of for example with an insulation

pipe which is cut of after a gooseneck.

- With devices where the exhaust pipe shall be

insulated with a larger diameter metal pipe, the

combination lead-through has to be used, although

a combustion air is taken otherwise.

- Combination lead-throughs are intended primarily for

the following Wallas units: 96D, 1300, 1800, 2400,

3200, 30D, 40D.

- All combination lead-throughs are stainless steel.

- Combination lead-throughs fit the ø 28 mm exhaust

pipes and the ø 45 mm jacket tube, 2448.

3468 Standard lead-through:

- The standard lead-through is suitable for use as a

hull lead-through in rough conditions and as a deck

lead-through in mild and normal conditions.

- The standard lead-through has the best splashguard

of all Wallas lead-throughs.

- The standard lead-through cannot be sealed. For this

reason it cannot be used as a deck lead-through,

which may be occasionally submerged under water.

The standard lead-through’s splashguard is more

effective than using a sealable lead-through in the

open position.

- The arched design of the standard lead-through

makes it easier, for example, to slide a rope over it.

Likewise, a standard lead-through used in the hull

will not get caught if the hull comes into contact

with a post, for example.

2467 Hull lead-through:

- The combination lead-through increases the wind

tolerance of the hull lead-through to some extent as

long as wind blowing directly into the pipe does not

completely offset it.

- The thermal effect on the hull of the boat is in all

cases minimal, because the suction pipe serves as

a thermal insulator.

2

Loading...

Loading...