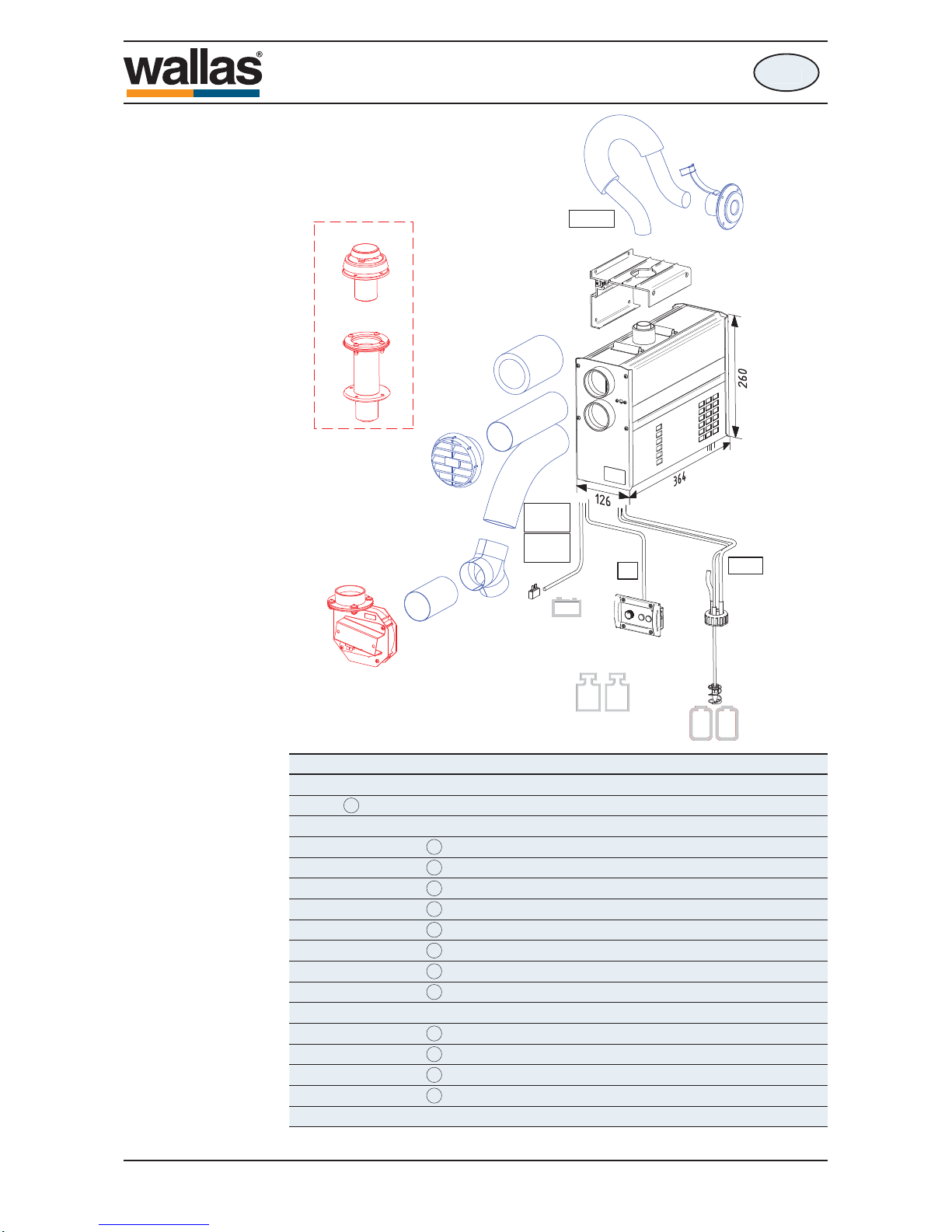

wallas 2400 t, 1800 t Installation Manual

10L

5L

2413

2411

2410

2412

2467

2448

2460

28/45mm

MAX 2m

1800,

MAX 5m

6m

6,2

kg

60

1,55m

7

kg

1800

2400

3415

12V

2400,

MAX 8m

2069

- 67 -

1800 t / 2400 t

1

2

3

4

5

7

8

9

10

12

6

11

13

en

Technical information

Mounting bolt M8 x 120 mm DIN 931 / ISO 4014

Corrugated base plate M8 DIN 137 A

Hose binder 32 - 50 mm

Fuse box

2 pcs

2 pcs

1 pcs

1 pcs

Heater (fuel hose and control panel cable installed)

Accessory bag 17662B

Mounting plate

1 pcs

1 pcs

1 pcs

1 pcs

2 pcs Push on contact 6.3 x 0.8 (yellow)

Fuse 15 A (blue)

Fastening screw 4,8 x 16 mm DIN 7981 / ISO 70496 pcs

Installation, operation and maintenance instructions1 pcs

Control panel

Control panel fastening screws 3,5 x 20 mm (black) TX10

Control panel package 3610661 pcs

1 pcs

4 pcs

Hose binder 50 - 70 mm2 pcs

Extension collar1 pcs

Control panel fastening screws 3,5 x 40 mm (black) TX104 pcs

Package contents

1800 t / 2400 t

490535

en

- 68 -

12 V DC

1800 t 2400 t

0,35 - 0,5 A 0,6 - 1,0 A

0,10 - 0,18 l/h 0,12 - 0,23 l/h

900 W 1100 W

1700 W 2200 W

2 x ø 60 mm

en

Technical information

Fuel Paraffi n

6,2 kg

13,7 lbs

Operating voltage

Fuel consumption

Heating power, max

Power consumption

Dimensions (L x H x W)

Weight

Maximum permitted length of

exhaust pipe

Maximum permitted length of

fuel hose

Minimum area of the replacement air

opening

Suitable Exhaust gas lead-throughs

Technical information

2467 and 2460

Heating power, min

Maximum permitted length of

warm air duct

Warm air connection

Remote control

Timer

Connections

364 x 260 x 126 mm

14 3/8“ x 10 1/4” x 5”

8 m

26’

100 cm

2

16 square inches

8 + 8 m

26’ + 26’

2 m (ø 28/45 mm)

6,5’ (ø 28/45 mm)

5 + 5 m

16’ + 16’

7 kg

15,4 lbs

(when ignited ca. 2 min. 5 A)

1800 t / 2400 t

490535

en

- 69 -

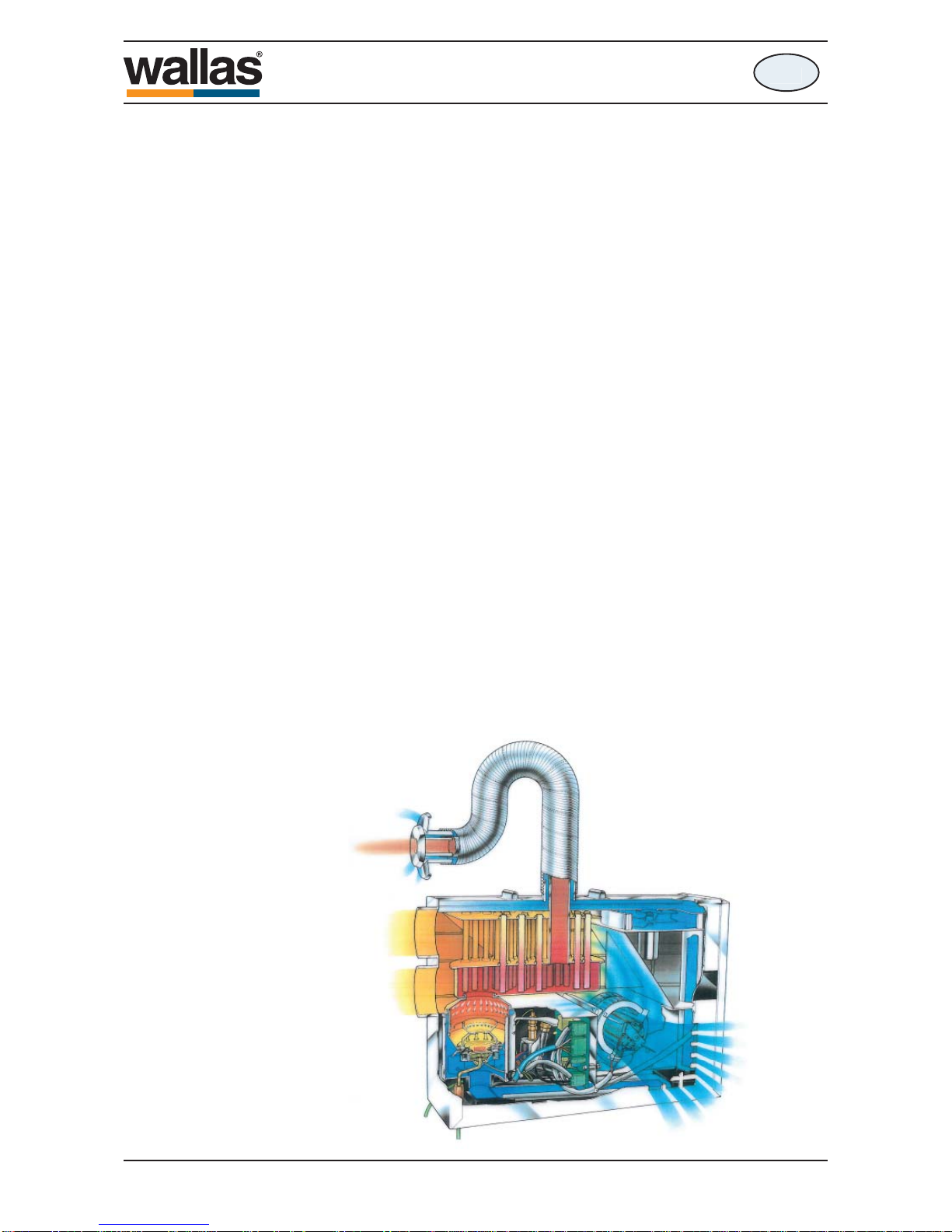

en

Installation

Operation description

The 1800 t and 2400 t heaters are forced air diesel heaters without an exposed

flame.

The 1800 t and 2400 t models take combustion air from outside the boat through

the outer coaxial exhaust gas pipe and blow their exhaust out through the inner

coaxial pipe. The coaxial pipe connects to a common through hull fi tting that allows

both inlet air and exhaust to pass separately. This process improves effi ciency ,

wind resistance and lowers the minimum power level.

The heat generated by forced air fuel combustion, is transferred to the circulation

air by a heat exchanger. The heating power can be adjusted freely between high

and low output settings by manual rheostat control or by thermostat.

The heated air is circulated through the cabin through the warm air ducting.

In hot and/or humid conditions, these heating units can be used for simple fresh air

ventilation and circulation.

When starting the device, the glow plug ignites the pumped fuel in the burner bowl.

The glow/start and shut down sequences are factory programmed, so - starts and

stops are automatically controlled.

The fuel pump inside the heater case regulates the fuel feed and the system

electronics control both the fuel and air mixture to maintain the ideal clean burning

process. The temperature sensor inside the burner feels the ignition and lights up

the red signal light (1) to indicate a successful start. When stopping the device, an

automatic after cooling process takes place. This process cleans the burner, purging any unburned fuel.

The heaters are completely made out of corrosion resistant materials.

1800 t / 2400 t

490535

en

- 70 -

en

Installation

Heater installation

Country specific regulations shall be followed in any installation.

The warranty of boat products is valid only in boat installations.

The warranty is not valid in installations to vehicles or other spaces.

The device is meant for marine pleasure craft use. The device is not designed for

continuous use for example in live aboard boats or commercial settings. In such

use the device will require more frequent servicing not covered by warranty.

Things to note when selecting the installation location

The device shall be installed into a dry space in a protected location.

The device must be mounted to a solid, stable bulkhead or wall.

When installing, please note that the device needs to be removable for servicing.

Connections and location should be made so that the device can be easily disconnected for removal. For maintenance, it is useful to leave 200 mm (7 7/8”) empty

space below the heater for the removal of the bottom cover of the heater.

The heater should be installed vertically level when the boat is on an even keel.

The static inclination must not exceed 5°. While the device will tolerate being

temporarily tilted to a steep angle (even for some hours), the burner will not yield

optimal performance if it is constantly inclined.

Please note specially the following things:

• Avoid installing the control panel in the immediate vicinity of a water outlet.

• If possible, install the control panel on a vertical surface.

• Select the place of installation to allow a minimum amount of bending in the

warm air ducting.

We recommend that the device be installed by an authorized Wallas service shop

or installer.

Things to note when installing pipes, hoses and cables

Power cables, warm-air ducting and fuel hoses must be protected in locations

where they are susceptible to mechanical damage due to sharp edges or heat.

All cables and hoses should have a fl uid precluding “drip loop” to prevent water or

other fl uids from following wires or hoses to the heater.

Installation space

The device can be installed within the heated space or outside of it.

The heater cannot be installed into a space which may include

gasoline fumes (danger for explosion).

1800 t / 2400 t

490535

en

- 71 -

13 mm

ø 35 / ø 50 mm

ø 60 mm

ø 67 mm

ø 2 mm

ø 5 / ø 6 mm

PZ 2

PH 2

TX 10

en

Installation

The necessary installation tools

Always use original Wallas accessories and parts with Wallas

equipment.

In a metal-hulled boat, you must ensure that the device, the exhaust

gas lead-through, the fuel connection, the control panel, and all other

parts are insulated from the boat’s hull. This must be done to

• prevent electrochemical corrosion

• prevent voltage from being transmitted from the hull to the device

or vice versa during electrical faults.

1800 t / 2400 t

490535

en

K00038

K00101

- 72 -

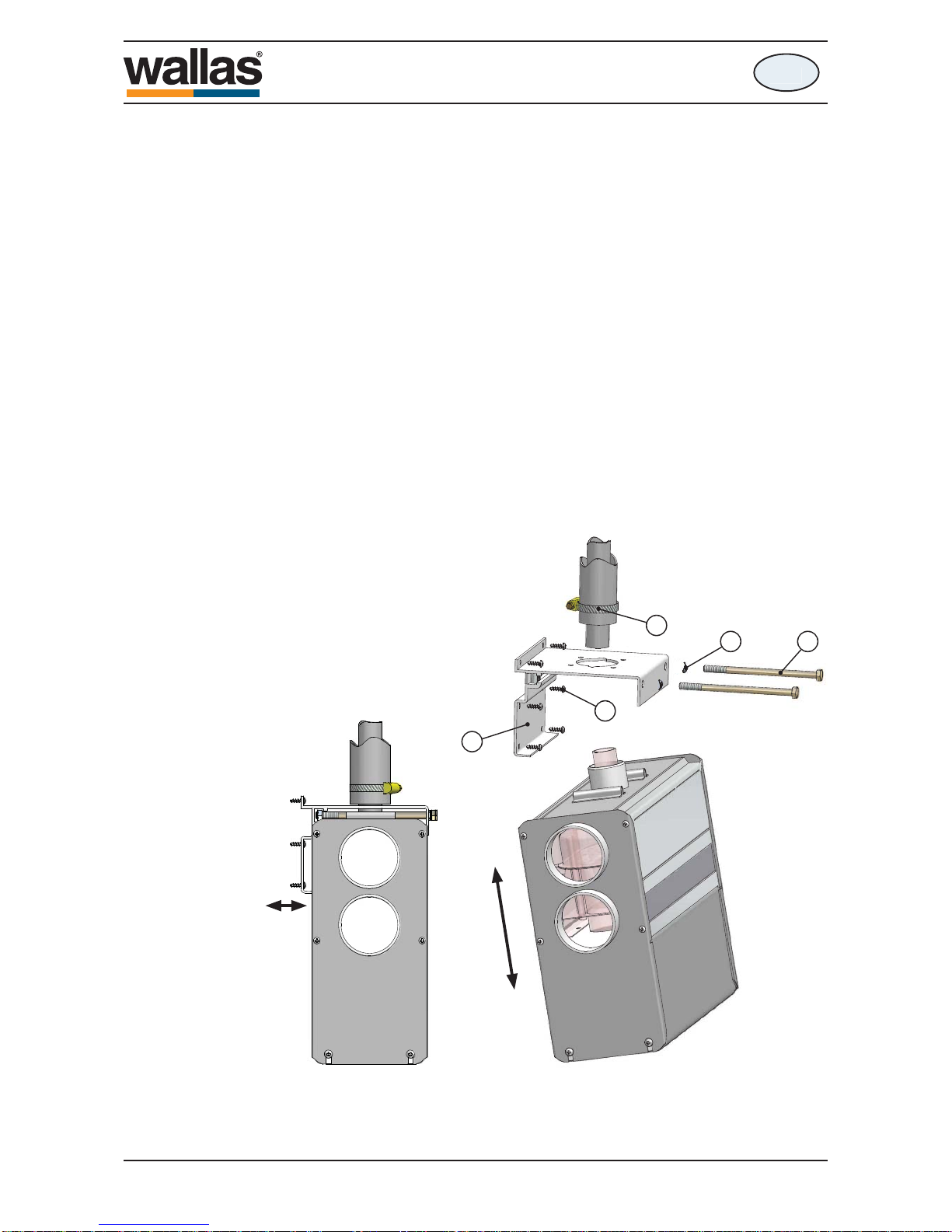

1

5

23

4

en

Installation

Fastening the device

Fix the mounting plate (1) with screws (4) to a suitable place and check that the

bottom of the heater is in horizontal position.

Lift the heater into the installation plate and lock the device with the mounting bolts

(2). There has to be a corrugated base plate (3) under the head of the screw. Be

sure that the edge of the mounting plate will lock to the slot in the side profi le of the

heater.

Connect the exhaust gas pipe with a hose clamp (5).

1800 t / 2400 t

490535

en

- 73 -

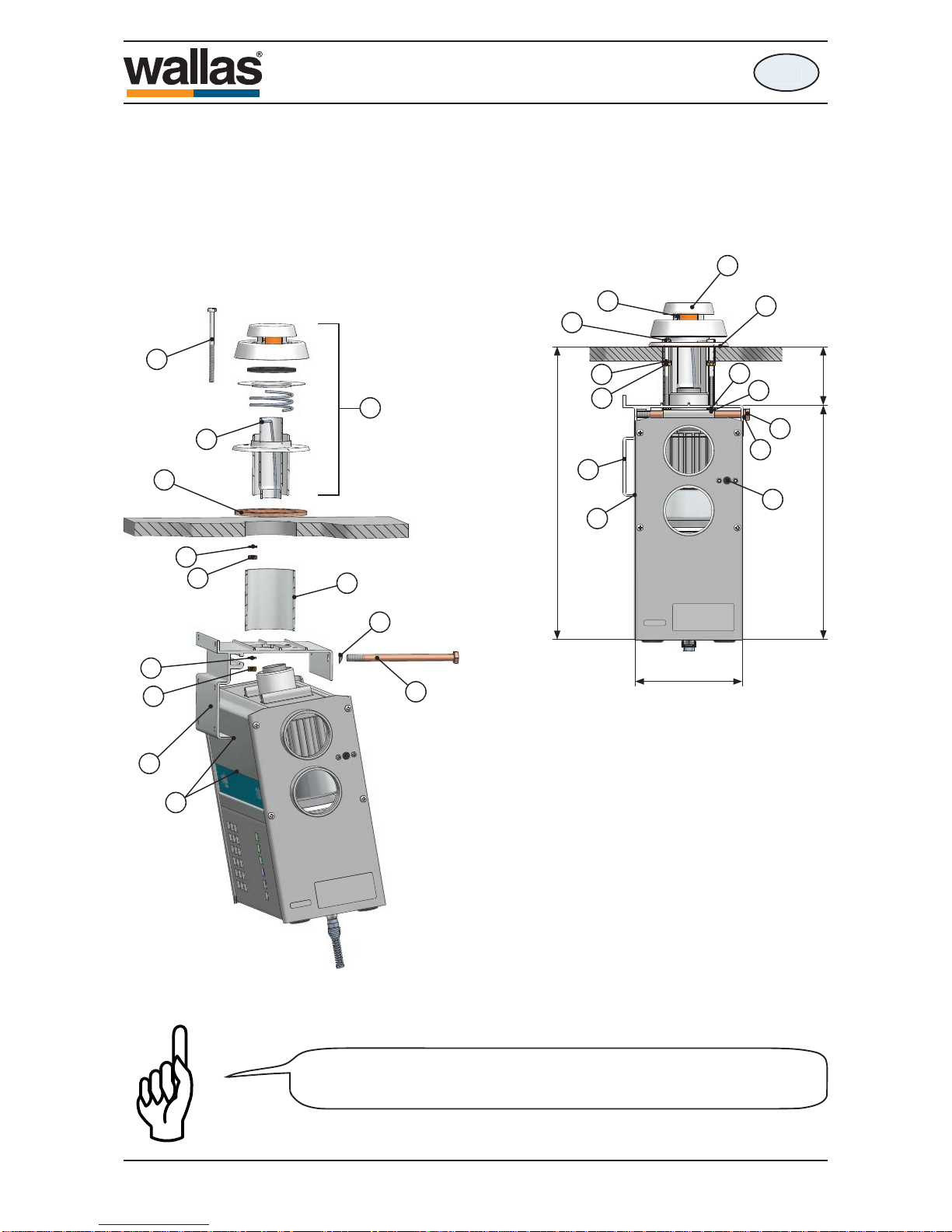

X

311 mm

125 mm

381 mm

70 mm

1k

1

43

2

43

45

42

47

44

43

41

3

2

1

J

40

J

47

40

44

45

43

1k

3

42

en

Installation

Direct attachement to exhaust on deck

• Exhaust head 2460 closes by pressing down and turning clockwise, opens by

turning counterlockwise.

• Exhaust head is opened for mounting by pressing in the pin (J) with screwdriver etc. from outside.

• Gasket (47). Important that the gasket surfaces and the take through hole are

carefully sealed with silicone seal.

• The exhaust head is mounted on deck with bolts

(42) M5 x 85 and nuts (43) with lock washer (44)

under. Tight the nuts, but not so hard the base

plate deforms.

• Place the spacing tube (41) and mounting plate

(1) on bolts (42) and fasten with nuts (43) with

lock washer (44) under. Tight the nuts, but not so

hard the exhaust base plate deforms.

• Check and retight the nuts (43).

• Place the heater on mounting plate (1). The cant

(1k) helps to hold up the heater. Check that the

heater exhaust pipe goes well in the exhaust head

middle pipe.

• Fasten the heater on mounting plate (1) with bolts

(2) M8 x 120 mm and tight them..

Check that the heater is mounted so that the overheating cut-out reset

buttom (X) is accessible for hand.

1800 t / 2400 t

490535

en

K00114

- 74 -

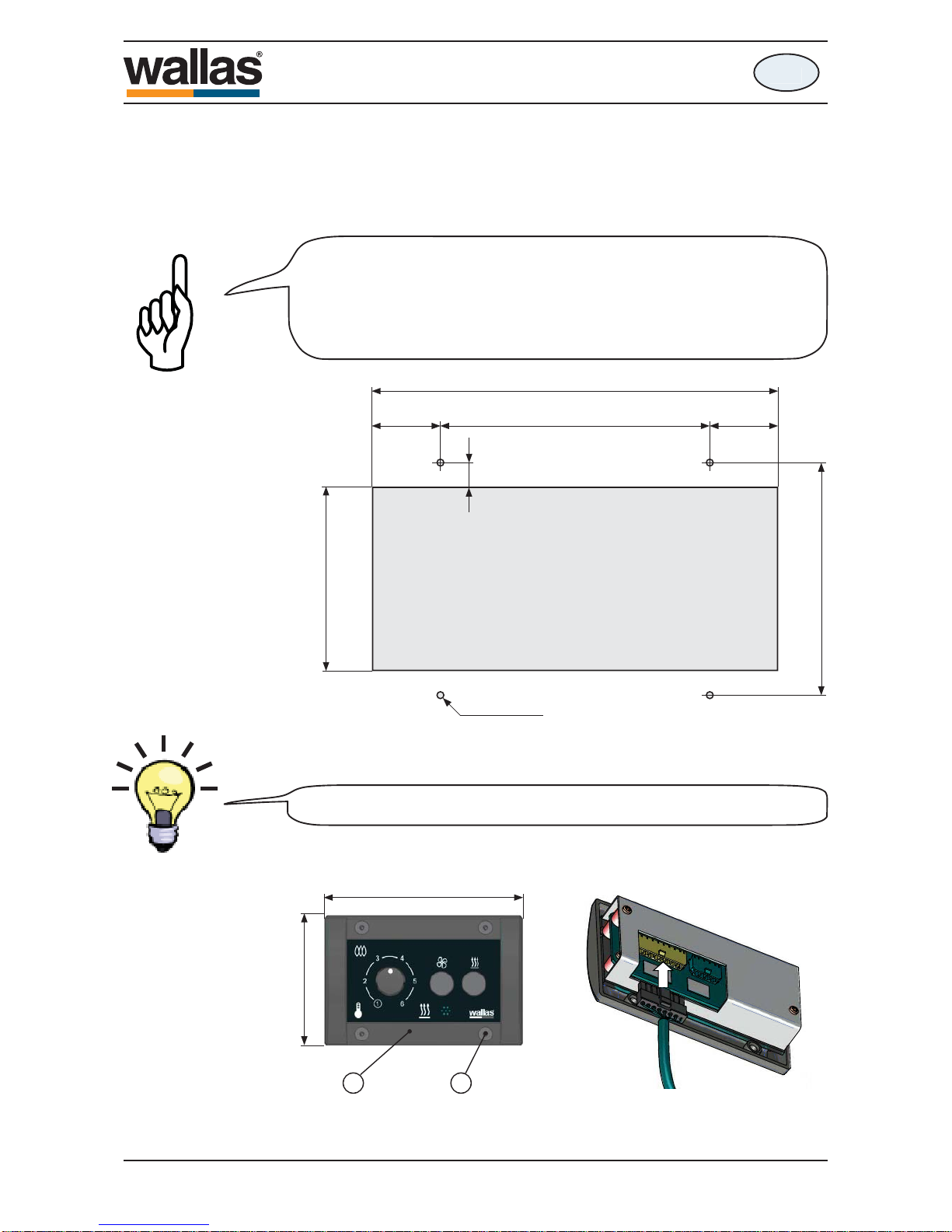

ø 2 mm (3/32’’)

100 mm (3

15

/16’’)

65 mm (2 9/16’’)

17,5 mm

(

11

/16’’)

4,5 mm (

11

/64’’)

47 mm (1

27

/

32

’’)

56,1 mm (2

13

/

64

’’)

10 12

17,5 mm

(11/16’’)

69 mm (2

23

/

32

’’)

104 mm (4 3/32’’)

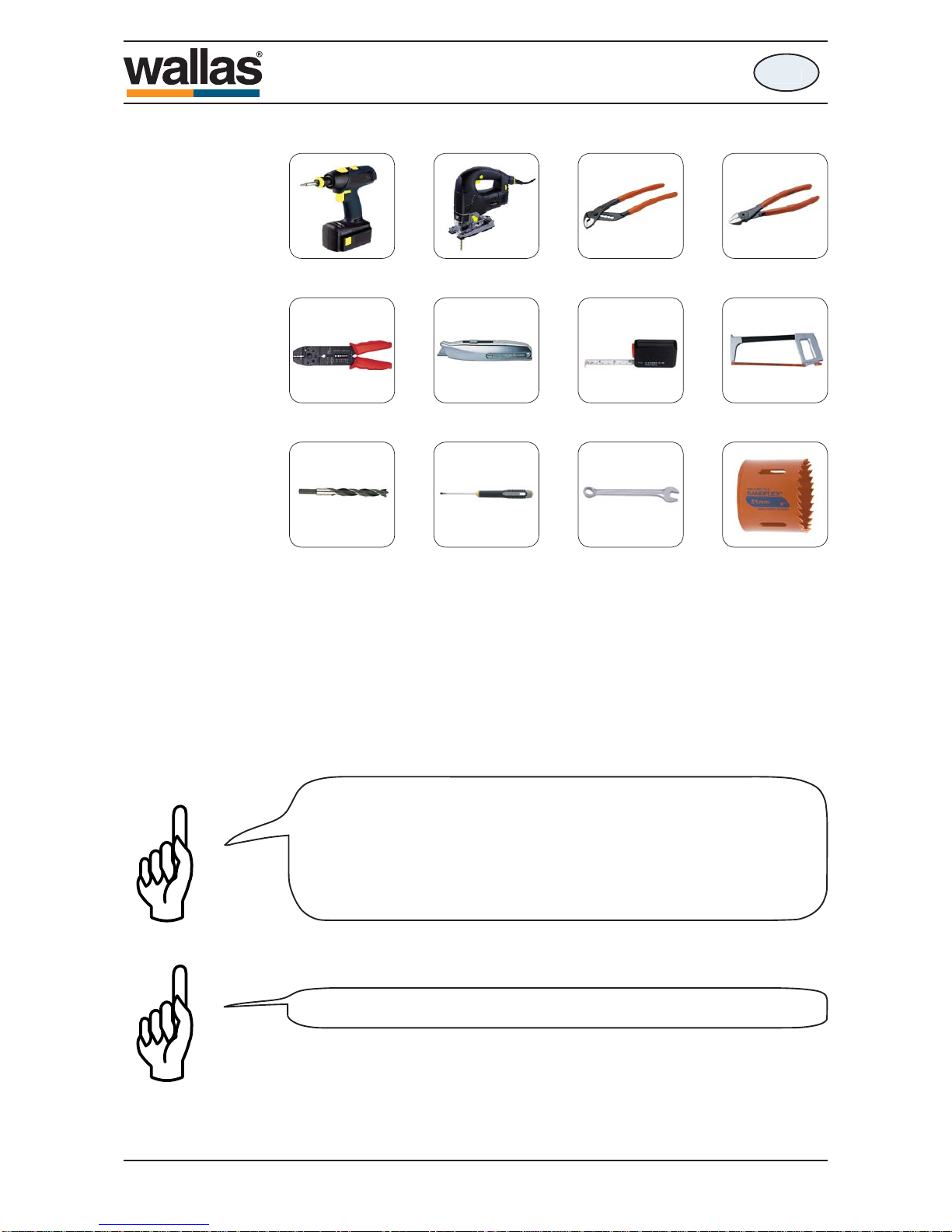

en

Installation

Control panel installation

Cut a suitable installation hole for the control panel in the selected location. Try to

install the panel in a vertical surface in a location that will remain dry.

Measurements of the control panel installation cut-out.

If necessary, predrill holes for the ø 2 mm ( 3/32”) screws.

You can utilize the sample of the box when drawing the lines of the

installation hole.

Connect the control panel cable from the device to the control panel (10).

Use the fastening screws to install the control panel to the installation cut-out (12).

The thermostat sensor is in the panel face, so select the location

with thermostatic operation/regulation in mind. Do not install close

to heat source or close to a window or door. Avoid locations that

might be contacted by direct sunlight. The length of the control

panel cable is 6 m.

1800 t / 2400 t

490535

en

K00143

- 75 -

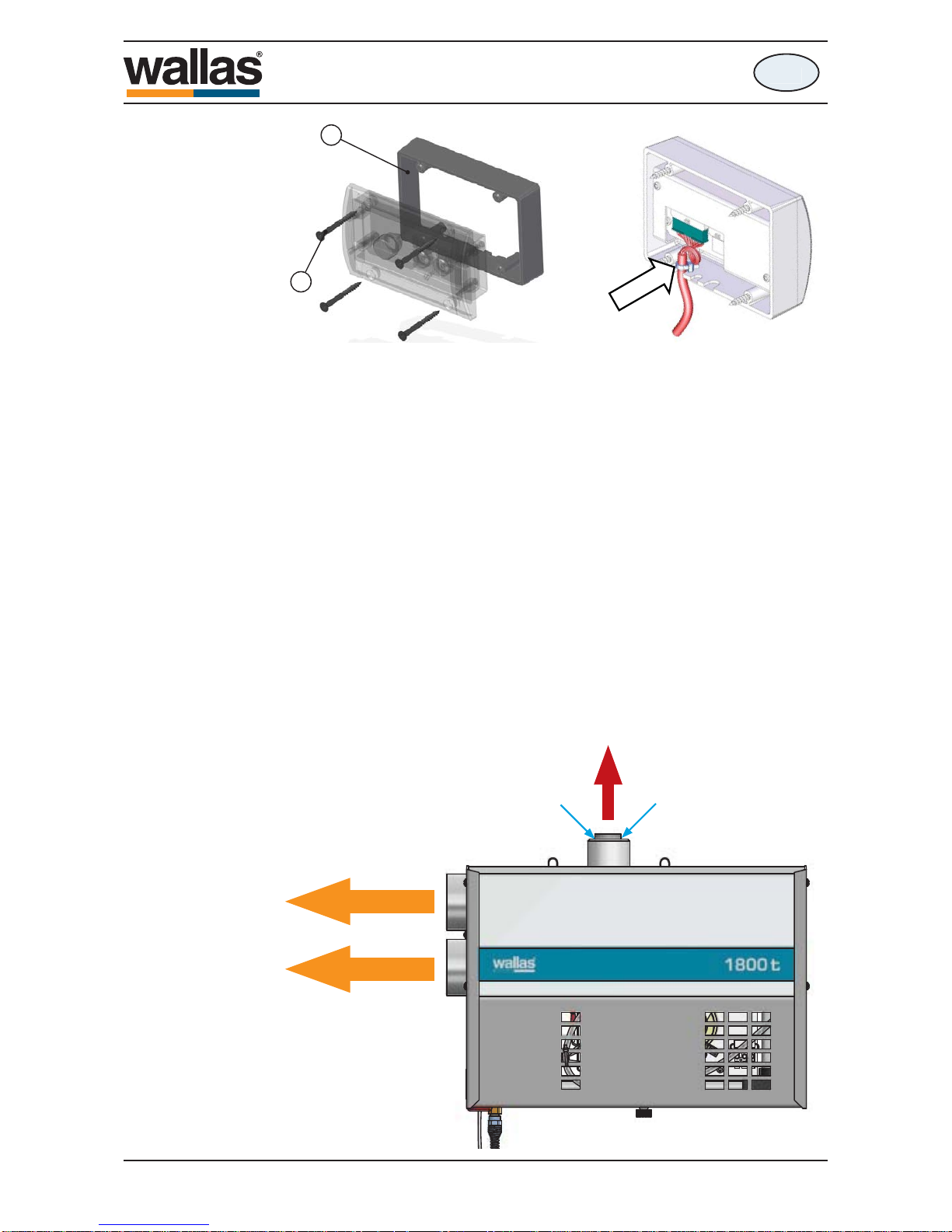

11

13

en

Installation

An extension collar (11) is used when control

panel is surface mounted.

The box of the panel includes 4 pcs screws 3,5

x 40mm (black) TX10 (13).

When installing the control panel surface

mounted (using the collar) , a loop to the

control panel cabel must be done. A cable

tie must be attached to cable in order to

avoid the cable detach from the connector.

Connections of the device

Things to note about the connections

In installation, to make the mounting and demounting for service easier, it is recommended to leave some extra length of loose cables and fuel line by creating a coil.

WARM AIR

OUT

EXHAUST

OUT

COMBUSTION AIR

IN

1800 t / 2400 t

490535

en

Loading...

Loading...