Rambler Sprayer

Handbook

Operating Instructions

& Parts List

www.walkoversprayers.com

sales@walkoversprayers.com

Tel: 0845 521 1209 Fax: 01269 844636

CONTENTS OF THE PACKING CASE

1 x Machine body complete

2 x Handle bars

1 x Spray Boom assembly

1 x Plastic bag containing:

4 x Handle bolts, wingnuts and washers

2 x Cable Clamps

1 x Instruction manual and Warranty

ASSEMBLY INSTRUCTIONS

The RAMBLER sprayer has been factory

tested prior to packing and only requires

the handles and the spray boom assembly

to be fitted.

Fit the handlebars into position using the

nuts, bolts and washers from the fixing bag.

The boom assembly can be fitted to the

main frame in two positions. The upper

position should be suitable for most

purposes. Take the boom assembly and

attach it to the main frame by using the

clamps. The boom is marked showing its

centre position, and this should be carefully

aligned into the centre of the fixing clamp.

BEFORE tightening the clamp the machine

should be lifted into its normal working

position and the boom nozzles checked to

ensure they are parallel to the ground.

Adjust the boom position and rotation as

necessary, re-check, then tighten the clamp

fixings. Attach the inlet wing nut to the

boom inlet housing. The machine is now

ready for testing.

TESTING

A trial run should be carried out on a dry

concrete surface to check that the nozzles

are in alignment. This should be carried out

using clean water to ensure everything is in

working order.

Half fill the container with cold water,

replace the filler cap & filter and move off at

a steady working place similar to the speed

of mowing.

This will prime the pump mechanism and

water will spray from the nozzles, showing

that all air has been bled from the system.

If an airlock remains in the system, unscrew

the two diaphragm check valve caps and

push the machine until water flows through

the system. Tighten the two caps and then

push. The machine will then start to spray.

DO NOT over tighten the diaphragm caps.

They are fitted in order to clear the spray

system of air & other small blockages.

OPERATING INSTRUCTIONS

When filling the machine, add sufficient

liquid treatment to cover the area needing

treatment or a pro-rata amount if only part

filling. Pay careful attention to which colour

nozzle is fitted at the time of spraying to

avoid any over or under application of

chemical. Always follow the chemical

manufacturers instructions relating to the

specific area. In many instances dilution

rates of chemicals are not critical, but in

some cases where a greater volume of

water is needed, then two x half strength

applications are recommended, spraying

where possible in a chequer board fashion

in North to South and East to West

directions.

SPRAY WIDTH

The RAMBLER has a spray width of 40

inches (1016mm). In common with all

Walkover sprayers, the spray pattern tails

off on the extreme edge of the treated

swath which is compensated for when

treating the return track. You must therefore

always ensure your return track is 40”

(1016mm) from the datum point of your

previous pass to achieve correct coverage.

A set of red nozzles are provided with the

machine. Nozzles giving alternative

coverage areas for the 25 litre (5.5 gallons)

loading as follows:

(a) With standard nozzle fitted, Red

ANDT 2.0, one full tank covers 825

sq. metres (1000 sq. yards)

equivalent to 298.6 litres/hectare

(26.6 gallons/acre)

(b) Alternative nozzle, Grey TF VP 3

delivers to one full tank 500 sq.

metres (670 sq. yards) equivalent

to 449 litres/ hectare (40

gallons/acre)

N.B The coverage areas for each nozzle

may vary plus or minus 5% depending on

the speed of operation and variations of the

terrain.

NOZZLE ASSEMBLY

The diaphragm control valve assembly is

fitted with a quick fit self- aligning cap.

When fitting the cap and nozzle, the selfaligning cap will ensure that the nozzle

remains in alignment. If the nozzle drips or

the spray pattern is distorted, this may be

caused by a minute blockage in the

diaphragm valve or nozzle. To remove the

nozzle tip, rotate the cap a half turn

anticlockwise, when viewing from the front.

Always ensure the nozzle seal is in place

on reassembling.

Treat all components with care, as they are

precision made to give a long and accurate

working life.

PUMP AND WHEEL REMOVAL

Should the pump at any stage during the

machine’s working life cause trouble it can

easily be removed and returned to Aztec for

repair or replacement. Work on the inside

of the pump can only be carried out by the

manufacturer and NO attempt should be

made to dismantle this unit otherwise the

guarantee becomes invalid.

If the tyre in the machine is punctured, the

wheel and pump need to be removed as

follows:

Remove the stainless steel elbow retaining

the spring clip and then each of the pipe

elbows from the pump. These elbows are a

push fit and are detached by pulling at a

slight angle. Remove the spring dome nuts

from either side of the wheel. Pull the pump

and axle assembly away from the bearing

spacers, taking care to remember their

respective positions for re-assembly. To

reassemble the unit, reverse the foregoing

operation ensuring that the wheel valve is

mounted on the opposite side to the pump.

CLEANING AND STORAGE

Always thoroughly clean the sprayer

after use. Flush through the whole system

with clean water using a small amount of

mild household detergent when toxic

chemicals have been used. It is very

important not to allow chemicals to dry out

in the pump mechanism that could

granulate and score the interior surfaces.

This could impair the performance of your

machine.

Where temperatures below zero degrees

are likely to be experienced, ensure that all

liquid has been drained from the machine

by removing the hose from the pump. This

elbow is a snap fit and pulls out quite easily

at a slight angle. Rotate the drive wheel to

empty the pump and pipe work and

reconnect the pipe into the pump. A small

amount of car anti-freeze introduced into

the pipe and pump system will give

excellent protection.

DO NOT empty chemicals in areas where

contamination may occur.

FILTRATION

A basket filter is located under the filler cap

in the tank and should remain in position at

all times, except when removing for

cleaning. Clean as required.

TYRE PRESSURES

The tyre pressure should be maintained at

20 to 22 p.s.i. DO NOT inflate over 25 p.s.i.

NEVER

1. Add concentrated active

ingredients to an empty tank, this

will result in pure product entering

the delivery pump and pipe lines.

2. Leave the sprayer in winter storage

with liquid in the tank or pipe work.

Severe frost could distort the pump

and burst the pipes.

ALWAYS

Ensure the container is half full of clean

cold water at the outset of your spraying

operation and the pump primed before

adding concentrated chemical.

In the case of highly viscous concentrates

and soluble powders, pre-dilute the product

to be applied in a watering can or bucket

with sufficient water to ensure it is

completely dissolved.

Half fill the tank with clean cold water. Add

the required amount of product and top up

to the 20 litre (4.4 gallon) level with water

and replace the cap. Rock the unit

backwards and forwards a few times to

ensure satisfactory mixing and then

commence spraying, maintaining a steady

pace. If a smaller are is to be treated fill the

tank to the appropriate level.

The RAMBLER sprayer stops spraying

immediately it ceases to travel forward. To

move the sprayer in a full condition (from

one area to another) without spraying, pull

backwards, or switch the valve on the

handle to the off position.

PRECAUTIONS

The manufacturer sets the pump

mechanism. Any tampering with the pump

setting may change the performance of

your machine and will render your

guarantee void.

Some of the chemicals that can be applied

by this machine onto grass areas and

driveways require special precautions for

use. Protective clothing including boots,

gloves and masks may be necessary and

therefore individual manufacturer’s

recommendations for the particular

chemical must be closely adhered to.

WALKOVER Sprayers Ltd. disclaims any

responsibility for misuse of any proprietary

brand of chemical applied by a machine of

their manufacture. All reasonable care is

taken to ensure correct dosage application

of known chemical formulations but

Walkover do not guarantee either their

efficiency or accept any responsibility or

damage resulting from user’s mistakes in

assessing dilution rates.

Experience has shown that combined

mixes of chemicals, i.e. fungicides and

weed killers, can often interact, resulting in

the formation of gelatinous substance

which can crystallise if left in the machine

after use. This solidifies within the pump

and nozzles and can in extreme instances

completely destroy the pump mechanism.

Many propriety brands of garden and

horticultural chemical are sold in the form of

Soluble powder or Crystals.

The RAMBLER sprayer will satisfactorily

apply these chemicals always providing

that the crystals or powder are

pre-mixed

tank and assuming that the chemical in

question is entirely soluble.

NEVER leave a soluble powder or a crystal

solution, or even an organic product, to

stand in the machine for any period of time

as sediment may form in the system and

the concentration being applied may be too

strong and cause scorching. It may also

find it’s way into the pump mechanism

before adding to the sprayer

completely

causing damage to the seals or internal

components.

DO NOT mix proprietary brands of

chemicals or treatments unless assured

of their compatability.

Please Note. Powder or crystalline

substances which require diluting & mixing

( not liquid concentrates ) such as sulphate

of iron should be used with caution.

Treatments that have not been thoroughly

mixed or that have been allowed to settle in

the tank can damage your sprayer because

such materials are abrasive. Please

exercise care and flush your sprayer

thoroughly after use.

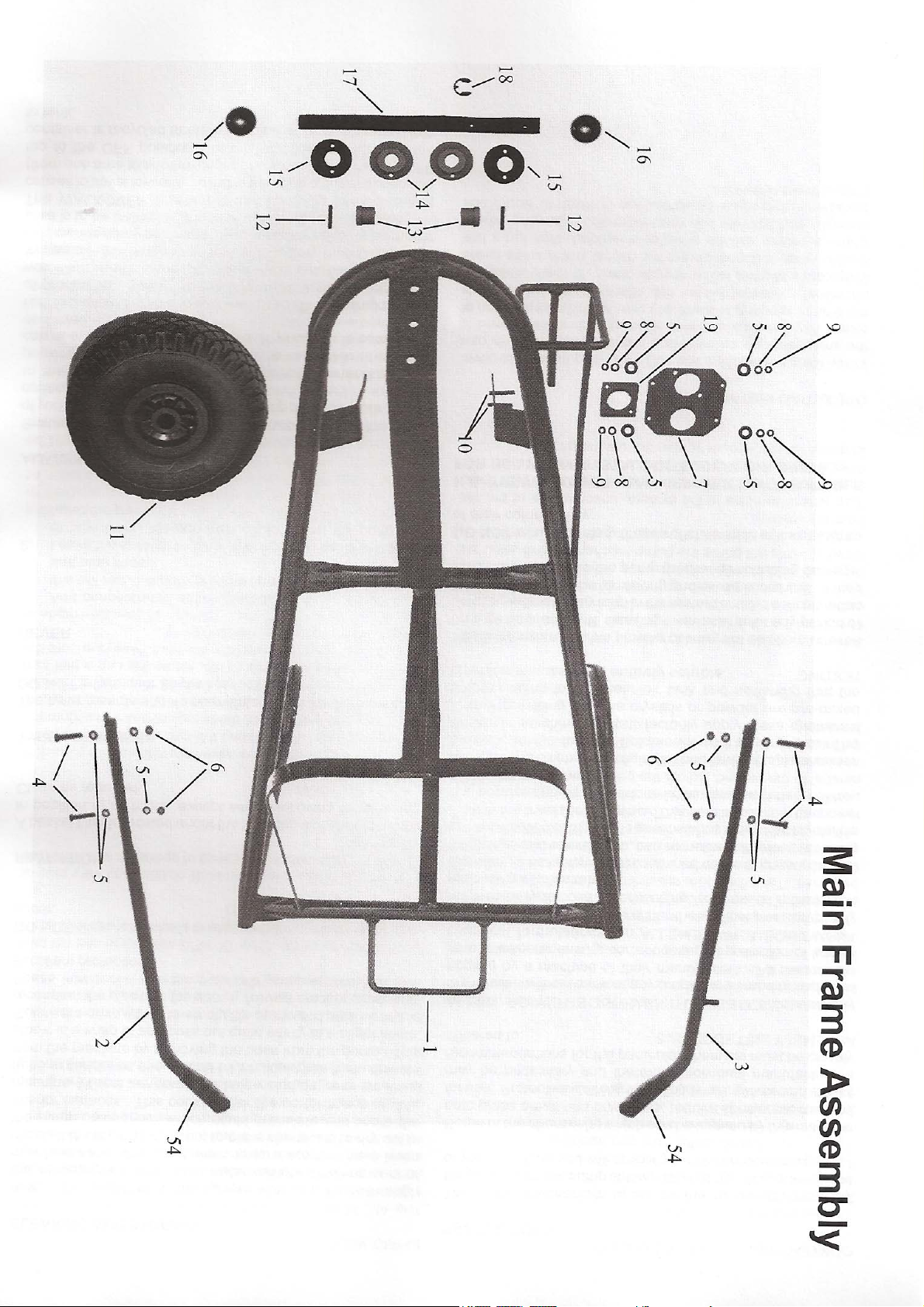

RAMBLER PARTS LIST:

Item Number Quantity Part Number Description

1 1 W1106 Main Frame

2 1 W1619 Handle L/H

3 1 W1633 Handle R/H

4 6 W1130 M6 x 35 Hex Head Set Screw

5 10 W1036 M6 Plain Washer

6 6 W1041 M6 Nut

7 1 W1108 Plate - Pump

8 4 W1068 M4 Spring Washer

9 4 W1043 M4 Nut

10 2 W1113 Dowel Pin

11 1 W1345 12” Pneumatic Wheel PW400-4-4/11

12 2 W1028 Dowel Pin

13 2 W1112 Bush

14 2 W1110 Bush

15 2 W1111 Drive Coupling

16 2 W1033 ⅜” Spring Dome Nut

17 1 W1109 Axle

18 1 W1132 Circlip

19 1 W1353 Washer - Pump Spacer

20 1 W1571 Hose Shank Connector NYB 8400-406

21 1 W1570 Wing Nut CP1803A – NYB

22 1 W1569 Inlet Connector ½ ” Pipe QJ7421 – ½” - NYB

23 2 W1572 End Plug

24 2 W1566 Split Eyelet DCV for ½” Tube QJ17560- 1 ½” NYB

25 2 W1568 Seal CB19438 EPR

26 2 W1574 2.0 TF VP Nozzle – Red

27 2 W1581 Nozzle Cap CP25599 – 1 NYB

28 2 W1575 3.0 TF VP Nozzle – Grey

29 1 W1116 ½” Bridge Clamp

30 1 W1117 ½” Rectangular Clamp

31 1 W1573 ½” ID x 22” Long Durapipe PP ½” Class ‘E’47335

32 1 W2057 Pump Hex Drive

33 1 W1069 Outlet Securing Clip

34 1 W1279 ½” BSP Cap and Liner

35 1 W1276 Elbow & Nut 11/16” NPT x ⅜” Hose Tail

36 1 W1415 ⅜” ID x ⅛” x 27” Long Tube (Tap to Tank)

37 1 W1166 ¼” BSP x ⅜” Hose Tail Elbow

38 1 W1628 ¼” BSP Ball Valve

39 1 W1121 ¼” BSP x ⅜” Hose Tail

40 1 W1414 ⅜” ID x ⅛” x 24” Long Tube (Tap to Tee)

41 1 W1125 ⅜” Equal Tee

42 1 W1413 ⅜” ID x ⅛” x 18” Long Tube (Tee to Boom Inlet)

43 1 W1122 Taper Sleeve

44 4 W1096 Stepless Clamp 22.6

45 2 W1006 Elbow

46 2 W1004 Elbow ‘O’ Ring

47 1 W1667 5/8” ID x ⅛” x 8 ½” Long Tube (Pump to Elbow)

48 7 W1223 Stepless Clamp 18.5

49 1 W1126 Tank Only

50 1 W1046 Filter

51 1 W1590 Decal

52 1 W1139 Content Label (not shown)

53 1 W2071 Tank Assembly (Includes items

35,44,47,49,51,52,56,57,58,59,60,61)

54 1 W1134 Handle Grip – Black

55 1 W1629 Extension Tube ¼” Female/Female

56 - - Not Used

57 1 W1635 ½” BSP Tank Connector – 8050151

58 1 W1636 ½” BSP Back Nut – 8042151

59 1 W1637 Gasket Washer – G00002008

60 1 W1666 ⅝” ID x ⅛” x 3 ½” Long Tube (Elbow to Tank)

Conversion Tables

To Convert Multiply

Feet to metres 0.3048

Metres to feet 3.2808

Yards to metres 0.9144

Metres to yards 1.09361

Sq. metres to sq. feet 10.7639

Sq. Feet to Sq. Metres 0.092903

Sq. Yards to Sq. Metres 0.83612

Sq metres to sq. yards 1.19599

Acres to Hectares 0.40468

Hectares to Acres 2.47105

Gallons to Litres 4.545

Litres to gallons 0.22

1 sq foot 144 sq inches 0.0929 sq metres

1 sq yard 9 sq feet 0.8361 sq metres

1 Acre 4840 sq yards 4046.9 sq metres

1 Hectare 10,000 sq. metres 11,960 sq. metres

1 Gallon 8 Pints 4.5461 Litres

USA Fluid Measurements

1 US Pint (16 fl. Oz) 0.8327 Imp. Pints 0.4732 litres

1 US Gallon 0.8327 Imp Gallons 3.7853 Litres

User Notes

Date Purchased Serial Number

ALWAYS: Flush thoroughy after use & add some household detergent to lubricate pump seals.

NEVER: Add concentrated substances to an empty tank. Half fill the tank with water first.

RAMBLER Trouble shooting Guide.

FAULTS ACTION TO TAKE

1. Nozzles failing to spray together.

Check that the diaphragm control valve units

are not over tightened. Slacken all control valve

units and retighten finger tight, The idea of

these units is to allow air to bleed from the

spray boom when operating the machine.

Diaphragm control valves should never be

over tightened.

2. Nozzles failing to spray

3. Blocked tubes or tank.

4. Drop in pressure

(4. Drop in pressure… continued)

Check your walking speed.

You could be walking too slowly to operate the

unit.

Taps in off position. ( on handle )

Nozzle strainer or inline filter blocked.

Air lock.

Unscrew one diaphragm control valve unit,

push or pull the machine until liquid flows.

Tighten diaphragm control valve as in 1 above.

Do not over tighten.

Blocked Nozzle.

Remove nozzle cap by turning the cap one half

turn anti- clockwise. Clean nozzle or replace.

Replace cap and try machine again.

Remove diaphragm control valves and nozzle

caps. Disconnect a convenient tube joint. Using

the water pressure from a garden hose, force

blockage through the system, increasing the

water pressure as necessary.

Reassemble when blockage is clear.

Leak from pump

Remove the pump from the machine and return

to dealer for repair.

Worn pump.

If the pressure drops as your walking speed

increases the pump is worn.

Replace the pump.

Leak in pipe work or pipe joints.

Replace pipe tube or connector as necessary.

Tighten or replace pipe clips as required.

If pneumatic wheels fitted.

Check that the wheel is not spinning on the

axle.

Change to a larger type nozzle.

Blocked or damage nozzle.

5. Streaking- uneven spray pattern Remove as in 2 and clean or replace

Machines fitted with an on / off tap.

6. Machine still sprays when the tap is turned off. The return tube to the tank is blocked.

Material buildup on nozzle.

Clean nozzle cut out, with stiff card. Preferably

wash. Soak overnight in “Milton” sterilising

solution.

Nozzle incorrectly aligned.

Release nozzle cap by turning the cap one half

turn anti-clockwise, realign nozzle and

retighten the cap.

Mixed nozzles.

You may have different nozzles fitted.

Refit matching nozzles as required.

Remove and flush with garden hose to clear

blockage.

If the unit is being towed, the towing speed is

too fast.

Users Notes

GUARANTEE

Please return your completed Warranty

information on the form provided. You

should also note the serial number of your

RAMBLER sprayer in this handbook .

This ensures that as a user you will

automatically appear on our mailing list

which is periodically used to advise

Walkover owners of any new developments

relating to the machine.

If there is any component, or item,

manufactured by Walkover that is found to

be defective within 12 months from the date

of purchase (or in the case of a machine

used for hire purposes, 45 days), Walkover

undertake to replace the faulty

component(s) free of charge either directly,

or through authorised dealers.

sales@walkoversprayers.com

www.walkoversprayers.com

Unit 44 Crofty Industrial Estate

The following are NOT covered under this

guarantee:

(1) A NEW MACHINE- which has been

subject to operation in excess of

recommended capacities, misuse,

negligence or accident, or has

been altered or modified in a

manner not authorised by

Walkover.

(2) TRANSPORTATION CHARGES –

to and from an authorised dealer.

This does not affect your statutory

rights.

Walkover operate a policy of continuous

improvement and reserve the right to alter

product specification without giving prior

notice.

After each season, we recommend that you

have your machine serviced by your dealer,

preferably between October and January,

to avoid delay at the start of the following

season. Walkover may also be able to

assist with your maintenance requirements,

so please call & enquire.

TEL: 0845 521 1209

FAX: 01792 850495

Penclawdd

Swansea

SA4 3RS

Loading...

Loading...