OPERATOR’S MANUAL

AND

SAFETY INSTRUCTIONS

WITH INSPECTION AND MAINTENANCE INSTRUCTIONS

CIRCULAR ELECTRIC LIFTING MAGNETS

MODELS: CER-5, CER-7, CER-9, CER-12, CER-16, CER-20

CER-20

CER-12

CER-5

WALKER

Always stay clear of

the load.

O.S. Walker Inc., CER Lift Magnet

O.S. WALKER

DANGER

Never lift loads over

people or in close

proximity to people.

I/R CER-7

Never attempt to operate this magnet

until you have read and understand

this Operator’s Manual.

1

CONTENTS

INTRODUCTION ................................................................................................................................... 2

SAFETY INSTRUCTIONS .................................................................................................................... 3

GENERAL SAFETY RULES ......................................................................................................................................3

UNSAFE LIFTING APPLICATIONS FOR YOUR MAGNET ...................................................................................... 4

RECOGNIZE SAFETY INFORMATION ....................................................................................................................4

WAYS TO AVOID A REDUCTION OF LIFTING CAPACITY .....................................................................................5

ADDITIONAL WARNINGS ........................................................................................................................................5

SAFETY PERSON ....................................................................................................................................................5

IMPORTANT FACTS FOR THE OPERATION OF LIFT MAGNETS .................................................... 6

RECOMMENDED LIFTING PROCEDURES ...................................................................................... 10

OPERATING INSTRUCTIONS ............................................................................................................11

MODELS: I/R-CER-5 thru I/R-CER-12 .................................................................................................................... 11

GUIDELINES FOR THE REDUCTION OF THE RATED LIFTING CAPACITY: ................................. 12

ADDITIONAL OPERATING INFORMATION ........................................................................................................... 12

LIFTING GUIDELINES (PLATE) .............................................................................................................................13

LOAD WEIGHT GUIDELINE ...................................................................................................................................15

DUTY CYCLE ..........................................................................................................................................................15

INSPECTION AND MAINTENANCE INSTRUCTIONS ...................................................................... 16

EVERY LIFT ............................................................................................................................................................16

WEEKLY ..................................................................................................................................................................16

DAILY.......................................................................................................................................................................16

SPECIFICATION & PARTS LIST ........................................................................................................ 17

REPAIRS .................................................................................................................................................................18

CER-5, 7 & 9 Replacement Parts List ..................................................................................................................... 19

CER-12 Replacement Parts List .............................................................................................................................. 20

CER-12 with PC Board Replacement Parts List ...................................................................................................... 21

I/R-CER-5 THRU 12 Replacement Parts List ..........................................................................................................22

CER-16 & 20 Replacement Parts List ..................................................................................................................... 23

INTRODUCTION

Thank you for purchasing this O.S. Walker Product. If used and maintained properly, it should

serve you for many years. Thousands of O. S. Walker lift magnets are in service today doing safe, fast,

and efcient magnetic material handling applications. It is often the only way for one person to load,

transport, and unload material.

O.S. Walker Products have proven to be among the best designed and safest in our industry.

However, if used improperly, any CER magnet can be rendered inefcient and unsafe. Therefore, it is

absolutely essential that anyone who uses this lifting magnet and is responsible for its application be

trained on how to use it correctly.

READ THIS MANUAL CAREFULLY TO LEARN HOW TO OPERATE AND MAINTAIN YOUR

MAGNET. FAILURE TO DO SO COULD RESULT IN SERIOUS INJURY OR DEATH, TO YOURSELF

AND PEOPLE IN THE AREA.

THIS MANUAL AND SAFETY CD SHOULD BE CONSIDERED A PERMANENT PART OF

YOUR MAGNET AND SHOULD ALWAYS BE AVAILABLE TO ALL OPERATORS AND REMAIN

WITH THE MAGNET IF IT IS RE-SOLD.

To request additional copies of this manual #37-DD10505 call 1-800-962-4638 in the USA;

In Canada: 905-643-3338; In Europe: 31-4973-83835.

O.S. Walker Inc., CER Lift Magnet

2

SAFETY INSTRUCTIONS

GENERAL SAFETY RULES

Danger always exists when loads are transported by lifting devices, especially

when the equipment is not being used properly or is poorly maintained. Because accidents and severe bodily injury or death can result, special safety precautions apply

to the operation, inspection, and maintenance of the Walker Lift Magnets.

Following these simple rules can help to avoid lifting accidents:

DANGER

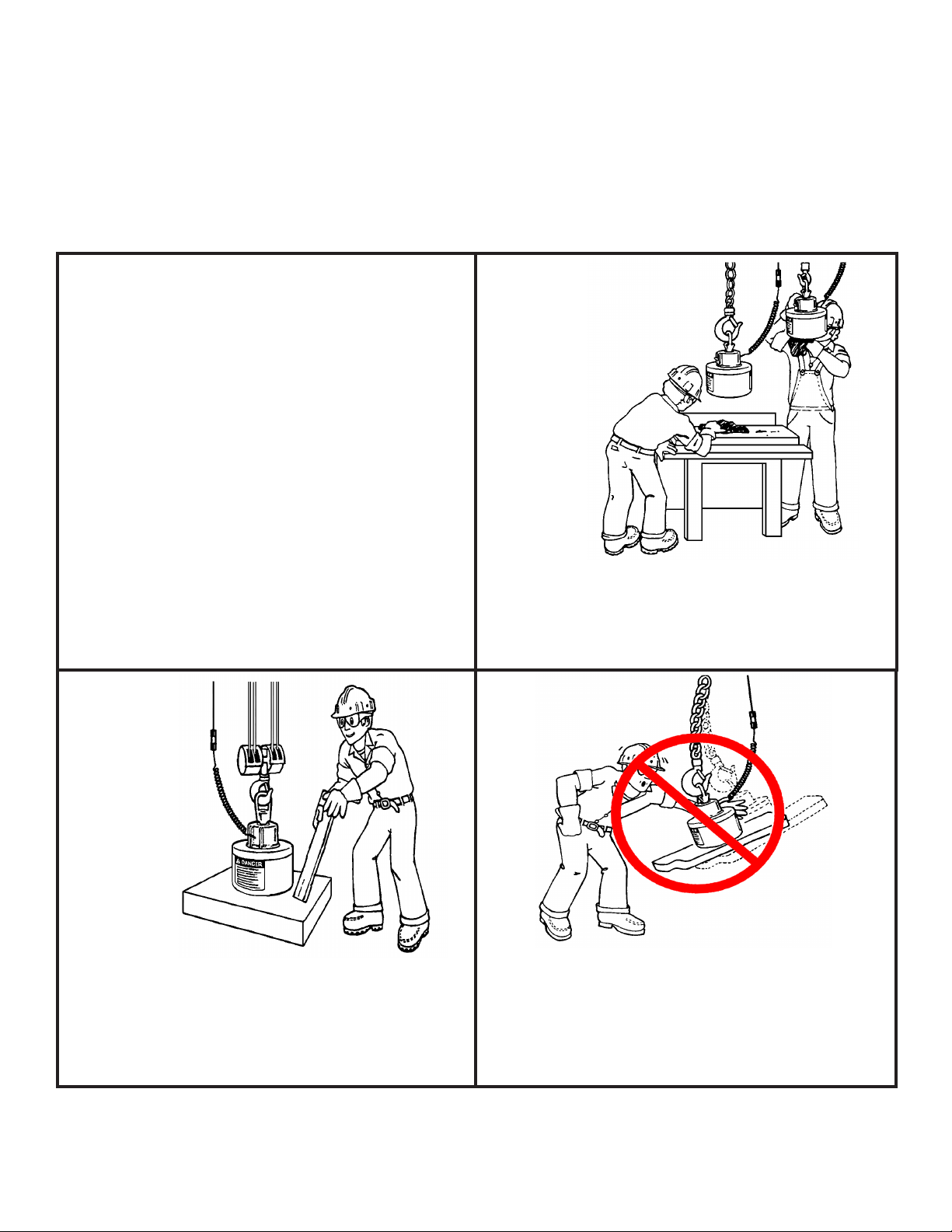

Always stay clear of the load.

Never lift loads over people or in close proxim-

ity to people.

Never attempt to operate this magnet until you

read and understand the Operator’s Manual.

Never use this magnet to lift, support or trans-

port people.

Never leave any lifted load unattended.

Never lift more than one work piece at a time

with this magnet.

Always make sure that the supporting struc-

ture and load attaching devices (i.e. crane,

chains and hook) are rated to support the

weight of the magnet and load.

Always make sure that the load’s weight and

dimensions are within the Magnet’s Lifting

Guidelines. These Guidelines are located in

the Operator’s Manual.

Always let those near you know that a lift is to

begin.

Remember, proper lifting knowledge and techniques are the responsibility of the operator. Be sure to read and understand the instructions and safety warnings contained in

this manual before using your magnet.

If you do not understand everything in this manual contact O.S. Walker for assistance

before using the magnet.

Call 1-800-W-MAGNET

(In Canada: 905-643-3338; In Europe: 31-4973-83835.)

O.S. Walker Inc., CER Lift Magnet

IN THE USA;

3

SAFETY INSTRUCTIONS

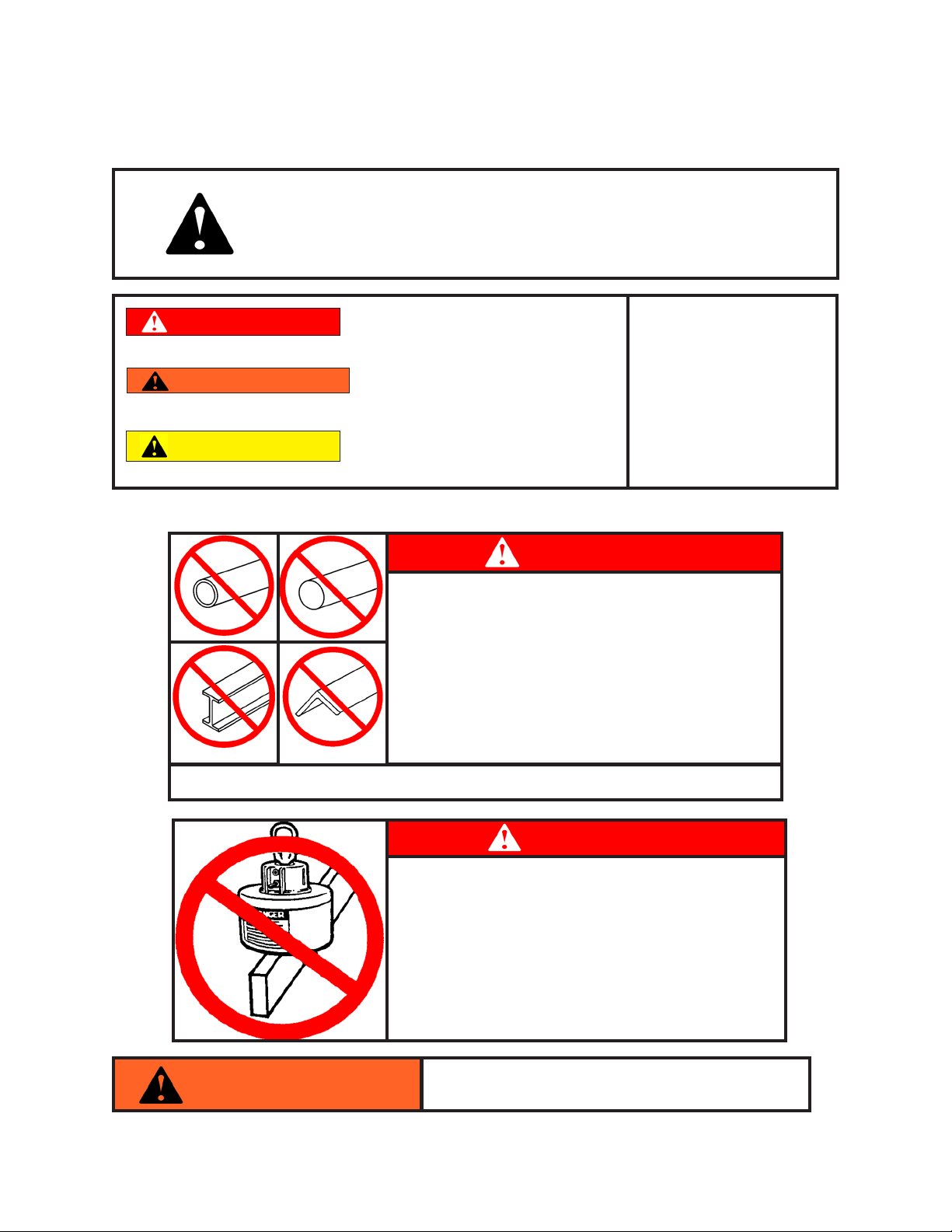

RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on

your magnet or in this manual, be alert to the potential for personal injury. Follow recommended precautions and safe operat-

ing practices at all times.

DANGER

Red Background, White Letters

WARNING

Orange Background, Black Letters

CAUTION

Yellow Background, Black Letters

UNSAFE LIFTING APPLICATIONS FOR YOUR MAGNET

This indicates a situation in which a hazard

is imminent and will result in a high probability of serious injury or death.

This indicates a potentially hazardous situation, which could result in some probability of serious injury or death.

This indicates a potentially hazardous situation, which could result in minor injury or

moderate injury.

DANGER

Never lift any pipe, solid round or struc-

tural shapes with this magnet.

Never lift any castings that do not have

a machined at lifting surface for the

magnet. The location of the lifting surface should be such to permit the load

to remain level when lifted.

These Hazard

Signal Words

Deserve your

Full Attention

O.S. Walker can provide other type magnets for these applications.

For Model CER type magnets see Lifting Guidelines on Page 11.

DANGER

Never lift a load by its narrowest

dimension.

If you have any difculty lifting a load, DON’T LIFT IT!

WARNING

4

Call Walker for advice at 1-800-962-4638

O.S. Walker Inc., CER Lift Magnet

SAFETY INSTRUCTIONS

WAYS TO AVOID A REDUCTION OF LIFTING CAPACITY

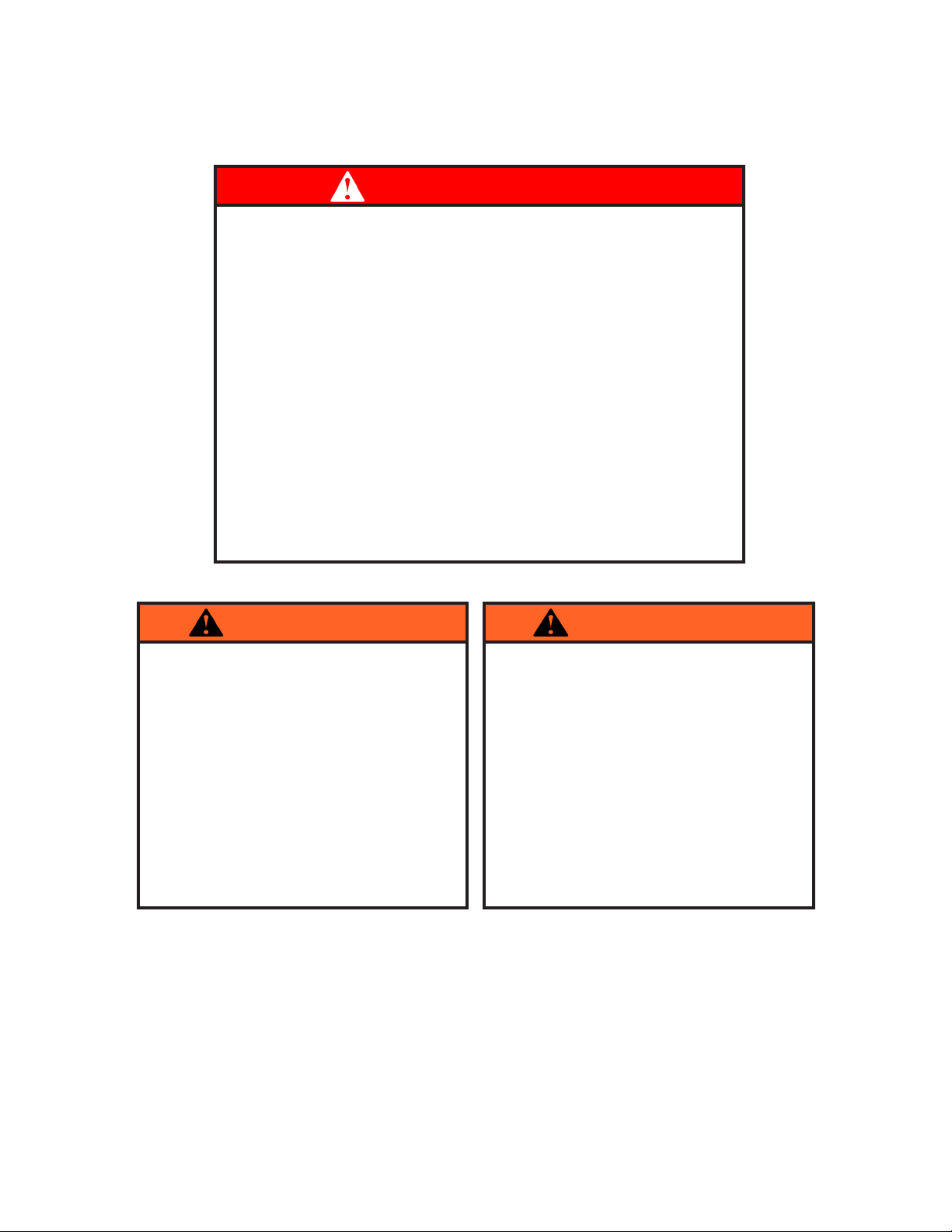

DANGER

To Avoid any Reduction of Lifting Capacity:

The lifting surfaces of the magnet and the area of the load where the magnet will

be located must be clean, smooth, at and free of nicks and burrs.

The full area of the magnet’s lifting surface must be in contact with the load.

The load must be at least 1.0" (24.5 mm) thick for CER-5, 1.5” (38.1 mm) for CER-

7, 2” (51 mm) for models CER-9 through 12 and at least 2.5” (63 mm) for models

CER-16 and 20.

The load must be low carbon steel such as SAE 1020.

The magnet’s lifting surface must stay level and the contacting surface of the load

remain at.

The temperature of the magnet and/or the load must not be greater than 110°F

(43°C).

Repair of this magnet should only be done by the O. S. Walker Co. or a Qualied

Person.*

Do not exceed the magnet duty cycle. Exceeding the duty cycle will result in

reduced lifting capacity.

If you have any difculty lifting a load, DON’T LIFT IT! Call O. S. Walker for advice

at 1-800-962-4638.

ADDITIONAL WARNINGS

WARNING

Never lift loads with any dimension greater than

those shown in the LIFTING GUIDELINES.

Never operate damaged or malfunctioning mag-

nets.

Never remove or damage Operating and Warning

labels.

Persons using pacemakers or other medical de-

vices should not use this magnet until they have

consulted with their physician.

If your magnet was provided with a remote

control unit, NEVER place the control unit in a

position where the switch could be accidentally

turned to “OFF”, “DROP”, OR “LIFT”.

Disassembly or repair of this magnet can result in

reduced holding power and/or cause an unsafe

condition. Therefore, anytime the magnet is disassembled beyond the parts list shown in this manual,

the magnet must be re-tested for breakaway force

in accordance with the test described in ANSI/

ASME B30.20.

Modication of any operating mechanism or

structure of this magnet can reduce the magnet’s

effectiveness and/or cause an unsafe condition.

Repair or modication of this magnet should only be

done by O.S. Walker*.

WARNING

SAFETY PERSON

O.S. Walker recommends that a person be assigned to review all magnetic

handling applications for these magnets to ensure that safe practices and

procedures are being followed.

*Walker replacement parts may be installed by a **Designated Person.

** Designated Person - A person selected or assigned by the employer as being competent to

replace specic replacement parts listed in this manual and is able to verify the proper functioning

of the specic replacement parts and the entire product after the completion of the installation.

O.S. Walker Inc., CER Lift Magnet

5

IMPORTANT FACTS FOR THE

OPERATION OF LIFT MAGNETS

LOAD CHARACTERISTICS OTHER THAN JUST WEIGHT

MUST BE CONSIDERED IN ORDER TO DETERMINE

THE LOAD THAT ANY MAGNET CAN LIFT.

This statement is true for all lifting magnets because they all operate using the same fundamental laws of physics. Magnetic power is often pictured as lines of magnetic force owing

from north pole to south pole. Anything that limits the ow of these magnetic lines of force

obviously reduces the magnet’s lifting capacity. There are many important factors which limit

the ow of these lines of force.

1. LOAD THICKNESS

The greater the number of lines of magnetic force owing from a magnet into the load,

the greater the effectiveness of the magnet. The thicker the load, the more lines of magnetic force are able to ow. After a certain thickness of load, no additional lines of force

will ow because the magnet has reached its full capacity.

Thin material (load) means less iron available, and thus fewer lines of magnetic force

ow from the magnet into the load. Therefore, the lifting capacity of the magnet is

reduced. In some cases the magnet will attract more than one thin plate of material

when set on a stack of thin plates. DO NOT LIFT more than one plate at a time since

the lower plate may not be held sufciently.

The lifting guidelines provide the user with what minimum thickness of load is re-

quired to reach full lifting capacity. Below such thickness of load, the user must accept the reduced lifting capacity of the magnet as shown in the guidelines.

2. SURFACE CONDITIONS

Magnetic lines of force do not ow easily through air. They need iron in order to ow

freely; therefore, anything that creates a space or an air gap between a magnet and the

load limits the ow of magnetic lines of force and, thus, reduces the lifting capacity of a

magnet.

MAGNET’S LIFTING SURFACE CONDITION — The lifting surfaces of a magnet

must be clean, smooth, at and free of nicks and burrs to minimize the air gap between a magnet and the load. This magnet has been designed with soft, low carbon

steel lifting surfaces in order to maximize the lifting capacity; therefore, special care

must be taken to protect these surfaces. Follow the Inspection Instructions in this

manual. Attaching or welding other materials to the lifting surfaces in order to reduce

wear should not be done with this magnet because it will reduce the lifting capacity.

LOAD SURFACE CONDITION — Paper, dirt, rags, rust, paint, and scale act

the same as air. Also, a rough surface nish on the load creates an air gap between the magnet and load. Any of these conditions will reduce the magnet’s

lifting capacity.

O.S. Walker Inc., CER Lift Magnet

6

3. LOAD ALLOY

Low carbon steels, such as SAE 1020 steel, are nearly as good conductors of magnetic

lines of force as pure iron. However, many other alloys contain non-magnetic materials

which reduce the ability of magnetic lines of force to ow into the load. An alloy such as

SAE 300 series of stainless steel is almost as poor a conductor of magnetic lines of force

as air.

Type 416 stainless steel is considered magnetic, but it contains enough chromium

so that a magnet can develop only one-half as much force on a type 416 stainless

steel load as it can on a SAE 1020 steel load. Also, because of the carbon content,

the force developed on cast iron is less than one-half of that developed on SAE 1020

steel. (Chilled cast iron further reduces the force to less than one-quarter.)

4. LOAD LENGTH OR WIDTH

As the length or width of a load increases, it ceases to remain at when lifted and the

edges begin to droop. This drooping or sagging of the load can create an air gap between

the load and the magnet. This is called peel. If this occurs, the lifting capacity of the magnet is greatly reduced.

For plate lifting, where drooping often occurs, rectangular shaped magnets must be positioned so that the length of the magnet is parallel to the width of the load.

5. POSITION OF MAGNET’S LIFTING SURFACE

As the position of the magnet’s lifting surface changes from horizontal to vertical, the lifting capacity of the magnet decreases. When the magnet’s lifting surfaces are vertical, the

lifting capacity of the magnet is minimum and dependent upon the coefcient of friction

between the magnet’s lifting surface and the load.

6. PORTION OF MAGNET SURFACE IN CONTACT WITH

LOAD

The full surface of the magnet must contact the load if the magnet is to achieve rated lift

capacity.

7. LOAD TEMPERATURE

The temperature of the load can cause damage to the magnet and, if high enough, can

even change the magnetic characteristics of the load. For Standard Lift Magnets, Walker

should be consulted if the load or air temperature exceeds 110° F (43° C).

O.S. Walker Inc., CER Lift Magnet

7

SAFETY

FOR FAST, EASY LIFTING WITH YOUR WALKER LIFT

1 NEVER

attempt to operate

this lift magnet until you

read and understand the

OPERATOR’S MANUAL &

SAFETY INSTRUCTIONS

(Manual #37-DD10505)

for CER Lifting Magnets.

MAGNET

2

Check the condition of the magnet prior to

every lift. WIPE clean the bottom of the magnet

and the area on the load where the magnet will

be located. File away burrs.

5 6

Check to be sure no one is near the load to be

lifted. Inform others in the area that a lift is to begin. Lift the load 2 to 3 inches (50 to 75 mm) and

then jar the load to insure that adequate holding

power is available.

ALWAYS STAY CLEAR OF THE LOAD.

If you have any difculty lifting a load, DON’T LIFT IT.

Ask your supervisor for help or call O.S. Walker Co.,

Inc., for advice at 1-800-W-MAGNET

8

When working in an area using lifting magnets, wear safety

glasses, work gloves, steel-toed shoes and a safety hat.

Lift and move the load SMOOTHLY. Avoid jarring

and swinging the load while it is in transit. KEEP

THE LOAD LEVEL. NEVER let the load come in

contact with any obstruction.

O.S. Walker Inc., CER Lift Magnet

RULES

MODELS: CER-5 thru CER-20

3

Position the magnet so the load remains level.

& I/R-CER-5 thru I/R-CER-12

4

Energize the magnet by selecting the “LIFT”

position. An indicator light will illuminate

when electrical power is applied to the

magnet. To obtain maximum lift, allow a few

seconds for the magnet to reach full power

before lifting load.

7

ALWAYS STAY

CLEAR OF THE LOAD.

Guide the load by pushing or pulling the edges.

This keeps your entire body clear of the load at all

times. DO NOT guide the load by pushing or pulling the Magnet. NEVER get in a position where

you could get hit with load if it is dropped.

NEVER re-energize the magnet until it has been placed in contact with the load to

CAUTION

O.S. Walker Inc., CER Lift Magnet

be lifted. Prematurely energizing the magnet could cause unwanted materials to

be attracted to the magnet. PERSONAL INJURY MAY RESULT.

8

Carefully set the load down. De-energize

the magnet by selecting the “DROP” position. Hold for two to three seconds, when

released the magnet will return to the

“OFF” position. Then lift the magnet slightly

to be sure the load has been released.

9

RECOMMENDED LIFTING PROCEDURES

SAFETY HOOK LATCH

Always use a safety hook latch on your

crane hook to hold your magnets.

STAY CLEAR OF THE LOAD

Guide the load by pushing or pulling the

edges of the load.

Keep your entire body clear of the load

at all times.

PLATE LIFTING

Position the magnet so that it is centered

on the plate. Never lift any plate less

than 1/4” (6mm) thick. (See Important

Facts 2 & 4).

BAR LIFTING

When the load width is greater than the

magnet diameter, position the magnet

length so the entire lifting surface of the

magnet is in contact with the load.

When the load width is narrower than the

magnet’s diameter, position the magnet

so that it is centered on the width of the

load.

10

UNSAFE LIFTING APPLICATIONS FOR YOUR CER MAGNET

DANGER

• Never lift any pipe, solid round or struc-

tural shapes with this magnet.

• Never lift any castings that do not have

a machined at lifting surface for the

magnet. The location of the lifting surface should be such to permit the load

to remain level when lifted.

Never lift loads with any dimension greater than:

5 feet (1.5 meters) with CER-5 10 feet (3.1 meters) with CER-12

6 feet (1.8 meters) with CER-7 12 feet (3.7 meters) with CER-16

WARNING

8 feet (2.4 meters) with CER-9 15 feet (4.6 meters) with CER-20

If you have any difculty lifting a load, DON’T LIFT IT!

Call Walker for advice at 1-800-962-4638

DANGER

• Never lift a

load by its

narrowest

dimension.

O.S. Walker Inc., CER Lift Magnet

OPERATING INSTRUCTIONS

MODELS: I/R-CER-5 thru I/R-CER-12

LOCAL PUSH BUTTON OPERATION:

“LIFT MODE”

To Energize the Magnet press and hold the “LIFT” push button until the green ring of the pushbutton

illuminates. The magnet is now in the full “ON” position and will remain on until a release is selected.

As a safety reminder the green lift led will begin to ash after 10 minuets in the “LIFT MODE” indicating you maybe exceeding the magnets rated duty cycle.

“RELEASE MODE”

To De-Energize the magnet press and hold both of the “RELEASE” push buttons until the red rings

of the pushbuttons illuminate this indicates a release pulse is being sent to the magnet. For models

I/R-CER-5 and I/R-CER-7 one to three pulses will be needed to achieve a clean release of the work

piece. For models I/R-CER-9 and I/R-CER-12 three to ve pulses will be needed to achieve a clean

release of the work piece. When the two release push buttons are released the magnet will return to

the off position. There is maximum of twelve release pulses for each release cycle.

REMOTE CONTROL OPERATION:

Check the remote control to verify that the 9-volt battery has been installed. (Alkaline type)Then check

by pressing the Green “LIFT” button while checking the small, Red, LED light at the top center of the

remote. If battery is installed LED should ash when the button is depressed.

With the I/R-CER magnet connected to power point the remote control at the I/R lens above the local

lift drop push buttons. Press and hold the remotes Green “LIFT” button and the top Red “RELEASE”

button simultaneously, the Green lift LED and the 1st Red drop LED will ash hold both buttons until

LED’s stop ashing. This should take about 5 seconds. The I/R remote control is now programmed

and ready for use with your magnet.

Perform a trial lift / drop to verify that the remote is properly programmed. Aiming the remote toward

the magnets I/R lens press and hold the Green “LIFT” button on the remote until the locals Green

“LIFT” LED illuminates. This indicates the magnet is now in the full “ON” position. Press and hold the

two Red “RELEASE” buttons on the remote, both of the local Red “RELEASE” LED’s will ash indicating a release pulse is being sent to the magnet. Operators can select from one to twelve pulses

to achieve a clean release from work piece. When the remotes two release buttons are released the

magnet will return to the off position. The remote control should operate your magnet between one

and fteen feet.

O.S. Walker Inc., CER Lift Magnet

11

GUIDELINES FOR THE REDUCTION OF

THE RATED LIFTING CAPACITY:

CAUTION

: Each Walker magnet model is rated for a different weight limit. Load characteristics will

affect the lifting capacity of the magnets. The lifting guidelines for the various models are shown on the

following pages.

The Lifting Guidelines charts show the effect of air gap, load thickness, load length, and load width on

lifting capacity. As the thickness of the load decreases, so does the rated lifting capacity of the magnet. The tables show the maximum weight or load size, which can be lifted for each thickness under

varying air gap conditions. DO NOT EXCEED EITHER THE MAXIMUM WEIGHT OR SIZE FOR

EACH THICKNESS.

Each value shown on the Lifting Guidelines charts is for SAE 1020 steel, and any increase in alloy

content will result in further reduction of the lifting capacity of the magnet.

THIS TABLE PROVIDES SOME REDUCTION

MATERIAL OTHER THAN SAE 1020 STEEL

Materials

Cast Steel 0.90

3% Silicon Steel 0.80

SAE 1095 Steel 0.70

FACTORS FOR

Reduction Factors for Materials

Other than SAE 1020 Steel

REDUCTION FACTOR

416 Stainless Steel 0.50

Cast Iron (non-chilled) 0.45

Pure Nickel 0.10

For Other Materials Consult O.S. Walker

Rated lift Capacity (For these materials) = Reduction Factor multiplied by Maximum Load Value (For 1020

Steel) from Lifting Guidelines (plate). See page 12.

Example: Lifting SAE 1095 STEEL, ½” thick, ROUGH machined at surfaces (use .020” air gap) with a Model

CER-9 lifting magnet.

Rated Lift Capacity = 0.70 multiplied by 600 = 420 pounds.

ADDITIONAL OPERATING INFORMATION

Avoid dropping, banging, or slamming the magnet into other objects.

These lifting magnets are electromagnetic devices. Therefore, do not allow water to enter the magnet body. Water is

an electrical conductor and could short out the magnet.

DO NOT EXCEED THE RATED 50% DUTY CYCLE OF THESE MAGNETS. (Exceeding the duty cycle will result in

reduced lifting capacity and a shorter magnet life.) (Refer to Page 14 for denition of Duty Cycle.)

If you have any difculty lifting a load, DON’T LIFT IT!

WARNING

Call Walker for advice at 1-800-962-4638

12

O.S. Walker Inc., CER Lift Magnet

MAGNET

MODELS

CER-5

CER-7

LIFTING GUIDELINES (PLATE)

CER-5, CER-7, and CER-9 (plate)

TYPE OF SURFACE CONDITION

CLEAN & SMOOTH

LOAD

THICK-

NESS

Over 1” 600 - 400 - 370 -

* 1” 600 3 x 4 400 3 x 3 370 3 x 3

*3/4” 530 4 x 4 375 3 x 4 350 3 x 3

*1/2” 480 4 x 5 350 4 x 4 330 4 x 4

*3/8” 400 5 x 5 275 4 x 4 200 3 x 4

*1/4” 180 4 x 4 150 3 x 4 125 3 x 4

Over 1-1/2” 1200 - 1100 - 900 -

*1-1/2” 1200 4 x 4 1100 4 x 4 900 3 x 4

*1” 1000 4 x 5 950 4 x 5 900 4 x 5

*3/4” 850 5 x 5 775 5 x 5 700 4 x 5

*1/2” 700 5 x 6 650 5 x 6 550 5 x 5

*3/8” 450 5 x 5 420 5 x 5 400 5 x 5

*1/4” 200 4 x 4 190 4 x 4 180 4 x 4

Similar to a Flat

(32 micro-inch RMS)

Ground Surface

.000” Max. Air Gap †

Max. Load

(lbs.)

NEVER LIFT ANY LOAD WITH ANY DIMENSION GREATER THAN 5 FEET

NEVER LIFT ANY LOADS WITH ANY DIMENSION GREATER THAN 6 FEET

NEVER LIFT ANY LOADS WITH ANY DIMENSION GREATER THAN 8 FEET

Max. Size

(ft.)

RUST OR SCALE

Similar to a Flat Hot

Rolled

Steel Surface

.010” Max. Air Gap †

(.254mm)

Max. Load

(lbs.)

Max. Size

(ft.)

IRREGULAR OR ROUGH

Similar to a Flat Smooth

Cut File

.020” Max. Air Gap †

(.508mm)

Max. Load

(lbs.)

Max. Size

(ft.)

Over 2” 2400 - 2300 - 2000 -

*2” 2400 5 x 5 2300 5 x 5 2000 4 x 5

*1-1/2” 2200 6 x 6 2100 5 x 6 1800 5 x 5

CER-9

*1” 1700 6 x 6 1550 6 x 6 1400 5 x 6

*3/4” 1400 6 x 7 1300 6 x 7 1250 6 x 6

*1/2” 700 5 x 6 650 5 x 6 600 5 x 5

*3/8” 525 5 x 6 480 5 x 6 450 5 x 5

*1/4” 250 4 x 5 220 4 x 5 200 4 x 4

* LIFTING CAPACITY AFFECTED BY PEEL AND THICKNESS. SEE NOTES 1 & 4 OF THE “IMPORTANT FACTS” (PAGE 6 & 7) IN THIS INSTRUCTION MANUAL.

† SEE NOTE 6 OF THE “IMPORTANT FACTS” (PAGE 7) IN THIS INSTRUCTION MANUAL. ALSO READ RECOMMENDED LIFTING PROCEDURES

(PAGE 10).

Values shown are for maximum rated capacities when operating instructions and warnings are followed.

Values are based upon SAE 1020.

Higher alloy steels and other magnetic materials will require further reductions of these rated capacities.

(See Guidelines for the Reduction of Rated Lifting Capacity page 11.)

O.S. Walker Inc., CER Lift Magnet

13

LIFTING GUIDELINES (PLATE)

CER-12, CER-16, and CER-20 (plate)

MAGNET

MODELS

CER-12

CER-16

TYPE OF SURFACE CONDITION

CLEAN & SMOOTH

LOAD

THICK-

NESS

Over 2” 4000 - 3850 - 3475 -

*2” 4000 7 x 7 3850 6 x 7 3475 6 x 7

*1-1/2” 3500 7 x 8 3250 7 x 7 3000 7 x 7

*1” 2800 8 x 8 2600 7 x 8 2300 7 x 8

*3/4” 2100 8 x 8 2000 8 x 8 1900 7 x 8

*1/2” 1100 7 x 7 1050 7 x 7 1000 7 x 7

*3/8” 600 6 x 6 550 6 x 6 500 5 x 6

*1/4” 300 5 x 5 250 4 x 5 200 4 x 4

Over 2-1/2” 7250 - 6750 - 6250 -

*2-1/2” 7250 8 x 8 6750 8 x 8 6250 7 x 8

*2” 6000 8 x 9 5500 8 x 8 5000 7 x 8

*1-1/2” 5000 9 x 9 4600 8 x 9 4300 8 x 8

*1” 4000 9 x 10 3750 9 x 10 3500 8 x 9

*3/4” 2500 9 x 9 2300 8 x 9 2200 8 x 8

*1/2” 1300 7 x 8 1200 7 x 8 1100 7 x 7

*3/8” 750 7 x 7 700 6 x 7 600 6 x 6

*1/4” 350 5 x 6 300 5 x 5 250 4 x 5

Similar to a Flat

(32 micro-inch RMS)

Ground Surface

.000” Max. Air Gap †

Max. Load

(lbs.)

NEVER LIFT ANY LOADS WITH ANY DIMENSION GREATER THAN 10 FEET

NEVER LIFT ANY LOADS WITH ANY DIMENSION GREATER THAN 12 FEET

NEVER LIFT ANY LOADS WITH ANY DIMENSION GREATER THAN 15 FEE

Max. Size

(ft.)

RUST OR SCALE

Similar to a Flat Hot

Rolled

Steel Surface

.010” Max. Air Gap †

(.254mm)

Max. Load

(lbs.)

Max. Size

(ft.)

IRREGULAR OR ROUGH

Similar to a Flat Smooth

Cut File

.020” Max. Air Gap †

(.508mm)

Max. Load

(lbs.)

Max. Size

(ft.)

Over 2-1/2” 10500 - 9800 - 9200 -

*2-1/2” 10500 10 x 11 9800 10 x 10 9200 10 x 10

*2” 10000 11 x 11 9500 10 x 11 9000 10 x 11

CER-20

*1-1/2” 8000 11 x 12 7600 11 x 11 7200 10 x 11

*1” 5500 11 x 12 5200 11 x 11 5000 10 x 11

*3/4” 3000 10 x 10 2800 9 x 10 2600 9 x 9

*1/2” 1500 8 x 9 1400 8 x 8 1300 7 x 8

* LIFTING CAPACITY AFFECTED BY PEEL AND THICKNESS. SEE NOTES 1 & 4 OF THE “IMPORTANT FACTS” (PAGE 6 & 7) IN THIS INSTRUCTION MANUAL.

† SEE NOTE 6 OF THE “IMPORTANT FACTS” (PAGE 7) IN THIS INSTRUCTION MANUAL. ALSO READ RECOMMENDED LIFTING PROCEDURES

(PAGE 10).

Values shown are for maximum rated capacities when operating instructions and warnings are followed.

Values are based upon SAE 1020.

Higher alloy steels and other magnetic materials will require further reductions of these rated capacities.

(See Guidelines for the Reduction of Rated Lifting Capacity page 11.)

O.S. Walker Inc., CER Lift Magnet

14

LOAD WEIGHT GUIDELINE

To estimate the weight of a steel work piece, rst determine the volume of the Load in cubic

inches. Then multiply the volume (cubic inches) by the density of steel (.283) pounds per

cubic inch.

Load Weight (steel) = (volume) multiplied by (density)

= (W x T x L) x (.283)

Example: What is the weight of a 10” wide x 5” thick x 96” long piece

of steel?

Load Weight = (10 x 5 x 96) x (.283) = 1358 lbs

DO NOT EXCEED THE RATED 50% DUTY CYCLE OF THESE MAGNETS. (Exceeding the duty cycle will result

in reduced lifting capacity, and a shorter magnet life.)

Duty cycle rating (D.C.%) is dened as:

(Time On x 100) / (Time Off + Time On) = D.C. % and is expressed as a Percent (with a maximum of 10 minutes

Time On).

Therefore, to maximize the effectiveness of your magnet, keep the power off when the magnet is not in use.

EXAMPLES:

3 MINUTES ON, 1 MINUTE OFF EQUALS: (3 x 100) / (3 + 1) = 75%

5 MINUTES ON, 5 MINUTES OFF EQUALS: (5 x 100) / (5 + 5) = 50%

WARNING

O.S. Walker Inc., CER Lift Magnet

DUTY CYCLE

If you have any difculty lifting a load, DON’T LIFT IT!

Call Walker for advice at 1-800-962-4638

15

INSPECTION AND MAINTENANCE INSTRUCTIONS

EVERY LIFT

Keep the lifting surfaces of the magnet CLEAN, SMOOTH, FLAT, FREE OF RUST and any

FOREIGN MATERIALS. Nicks and burrs on the lifting surfaces will reduce the lifting capacity. If burrs occur, they can be removed by ling them away. However, care must be taken to

protect the neighboring lifting surfaces.

Deep nicks may require regrinding of the entire lifting surfaces. (See Weekly Inspection In-

structions)

Check to assure indicator light has illuminated after selecting the “lift “when the switch is

turned to the “LIFT” position.

DAILY

Check the entire magnet’s case, lifting surfaces, bail or eyebolts, and welds for cracks or

other defects. If present, DO NOT USE THE MAGNET - Contact a Qualied Person or O.S.

Walker.

Check the eyebolt or lift bail for wear. If the eyebolt or lift bail is worn to 80% of its original

dimension, it should be replaced. Retighten the eyebolt if loose.

Check physical condition of power cord, lamp, and switch. Repair or replace any suspicious

components. Also, check that the twist lock type electric connector is securely attached to

the electrical receptacle.

Check the condition of the Operating Instruction label and Product Safety signs. Your mag-

net was supplied with one (1) Lifting Guidelines/Operating Instruction label and one (1) Product Safety sign. If these labels and signs are missing or damaged, they should be replaced.

WEEKLY

The lifting surfaces of the magnet should be checked for atness and wear. Uneven wear

and out of atness can greatly reduce the lifting capacity because it will cause a non-magnetic separation (air gap) between the magnet and the at surface of the load. Some nicks

and burrs will occur on the lifting surfaces due to normal usage. However, when the at

contact area of the entire magnet’s lifting surfaces becomes less than 90% of the original

total lifting surface, it should be taken out of service until the lifting surfaces are reground.*

Check the rigid epoxy of the encapsulated coil. Contact O.S. Walker or a Qualied Person

for repair instructions.

*Regrinding the lifting surfaces.

If regrinding is necessary, all the lifting surfaces must remain at and in the same plane.

After regrinding, the magnet must be re-tested for breakaway force in accordance with the

test described in ANSI/ASME B30.20.

O.S. Walker recommends that your lifting magnet be re-tested for breakaway force each year.

O.S. Walker Inc., CER Lift Magnet

16

SPECIFICATION & PARTS LIST

SPECIFICATIONS

Model No. CER-5 CER-7 CER-9 CER-12 CER-16 CER-20 I/R-CER-5 I/R-CER-7 I/R-CER-9 I/R-CER-12

Power

(Watts)

Net Wt. (LBS) 23 43 94 142 320 560

H2 9.75” 11.25” 11.75” 13.63” 14.5” 15”

Diameter “A” 5.12” 6.75” 9” 12” 16” 20”

Figure No. 1 1 1 2 3 3

58 80 135 340 545 1050

PERFORMANCE RATING ON SAE 1020

STEEL

CER-5 0-600 lbs. Rated Lift

CER-7 0-1,200 lbs. Rated Lift

CER-9 0-2,400 lbs. Rated Lift

CER-12 0-4,000 lbs. Rated Lift

CER-16 0-7,250 lbs. Rated Lift

CER-20 0-10,500 lbs. Rated Lift

FIGURE 1

58 80 135 340

30 50 101 142

10.25” 11.75” 12.25” 13.63”

5.12” 6.75” 9” 12”

4 4 4 4

FIGURE 2

FIGURE 3

O.S. Walker Inc., CER Lift Magnet

REPLACEMENT PARTS DIAGRAMS & LISTS

CER-5 See Page 19

CER-7 See Page 19

CER-9 See Page 19

CER-12 See Page 20

CER-12 with PC

Board

I/R CER-5 THRU 12 See Page 22

CER-16 See Page 23

CER-20 See Page 23

See Page 21

FIGURE 4

17

REPAIRS

For repair of your lift magnet, contact O.S. Walker for you’re nearest Authorized Service

Center TOLL FREE at 1-800-W-MAGNET. A return material authorization number will

be issued along with the address of the nearest Authorized Service Center. Your magnet, after receipt by the Service Center will be inspected and a free estimate of repair

charges will be provided. Authorization for repairs from magnet owners must be given to

the O.S. Walker Service Center before repairs are made. Transportation charges, both

to and from the factory, are to be paid by the magnet owner.

WARNING

Disassembly or repair of this magnet can result in reduced hold-

ing power and/or cause an unsafe condition. Therefore, anytime

the magnet is disassembled beyond the parts list shown in this

manual, the magnet must be re-tested for breakaway force in

accordance with the test described in ANSI/ASME B30.20.

Modication of any operating mechanism or structure of this

magnet can reduce the magnet’s effectiveness and/or cause

unsafe conditions.

Repair or modication of this magnet should only be done by

O.S. Walker.*

*Walker replacement parts may be installed by a **Designated Person.

** Designated Person - A person selected or assigned by the employer as

being competent to replace specic replacement parts listed in this manual and

is able to verify the proper functioning of the specic replacement parts and the

entire product after the completion of the installation.

This product is manufactured in accordance with ANSI/ASME B30.20

For further information, refer to Chapter 20-3 Close Proximity Operated Lifting Magnets.

O.S. Walker Inc., CER Lift Magnet

18

SPECIFICATION & PARTS LIST

WARNING: IMPROPER WIRING CAN RESULT IN REDUCED HOLDING POWER.

CER-5, 7 & 9 Replacement Parts List

ITEM

N0.

1 HOUSING 44-BB9185 44-BB9185 44-BB9185

2 INDICATOR ASSY 54-DD14747 54-DD14747 54-DD14747

3 PLUG, TWIST LOCK 11-2001 11-2001 11-2001

3a RECEPTACLE, TWIST LOCK 11-2010 11-2010 11-2010

4 CORD STRAIN RELIEF 14-1101 14-1101 14-1101

5 AC CORD ASSY 56-DD14748 56-DD14748 56-DD14748

6 PCB ASSY 56-BXM4351-1 56-BXM4351-2 56-BXM43513

7 EYEBOLT ASSY 54-DD14437 54-DD14437 54-DD14437

8 MAGNET ASSY 54-BB12693 54-BB12694 54-BB12695

9 THREAD LOCKING ADHESIVE 36-4015 36-4015 36-4015

10 ELECTRICAL ASSY 54-AA8893-1 54-AA8893-2 54-AA8893-3

11 OPERATING INSTRUCTIONS 37-DD12082 37-DD12082 37-DD12082

12 LIFTING GUIDELINES 37-DD12083 37-DD12084 37-DD12085

13 DANGER TAG 37-DD11636 37-DD10666 37-DD10963

14 DANGER TAG 37-DD11637 37-DD10667 37-DD10667

15 REMOTE ASSY 54-BXM4408 54-BXM4408 54-BXM4408

16 RIGID EPOXY PATCH KIT 06-DD14974 06-DD14974 06-DD14974

PART DESCRIPTION

CER-5 CER-7 CER-9

PART NO.

O.S. Walker Inc., CER Lift Magnet

19

SPECIFICATION & PARTS LIST

WARNING: IMPROPER WIRING CAN RESULT IN REDUCED HOLDING POWER.

CER-12 Replacement Parts List

ITEM

NO.

1 INDICATOR ASSY 56-DD14747

2 PLUG, TWIST LOCK 11-0201

3 RECEPTACLE, TWIST LOCK 11-2010

4 CORD STRAIN RELIEF 17-0014

5 AC CORD ASSY 54-DD14856

6 RECTIFIER ASSY 54-DD11298A

7 TOGGLE SWITCH 15-1010

8 TINNERMAN CLIP 18-4026

9 ELECTRICAL ASSY 54-AA9227

10 MAGNET ASSY W/COIL 54-AA8075

11 OPERATING INSTRUCTIONS 37-DD12082

12 LIFTING GUIDELINES 37-DD12086

13 DANGER TAG 37-DD10963

14 DANGER TAG 37-DD10667

15 EYEBOLT ASSY 54-DD14437

16 REMOTE ASSY 54-BXM2999-10

17 RESISTOR REPAIR KIT 54-DD14929

18 SUPPRESSION RESISTOR REPAIR KIT 54-DD14930

19 SUPPRESSOR REPAIR KIT 54-DD14931

20 RIGID EPOXY PATCH KIT 06-DD14974

PART DESCRIPTION PART NO.

20

O.S. Walker Inc., CER Lift Magnet

SPECIFICATION & PARTS LIST

WARNING: IMPROPER WIRING CAN RESULT IN REDUCED HOLDING POWER.

CER-12 with PC Board Replacement Parts List

ITEM

NO.

1 HOUSING 44-CC9887

2 INDICATOR ASSY 56-DD14747

3 PLUG, TWIST LOCK 11-0201

3A RECEPTACLE, TWIST LOCK 11-2010

4 CORD STRAIN RELIEF, AC 17-0014

5 AC CORD ASSY 54-DD14856

6 PCB ASSEMBLY COMPLETE 56-BXM4872

7 EYEBOLT ASSEMBLY 54-DD14437

8 MAGNET ASSEMBLY W/COIL 54-AA8075

9 THREAD LOCKING ADHEASIVE 36-4015

10 ELECTRICAL ASSEMBLY 54-AA13486

11 OPERATING INSTRUCTIONS 37-DD12082

12 LIFTING GUIDELINES 37-DD12086

13 DANGER TAG 37-DD10963

14 DANGER TAG 37-DD10667

15 REMOTE ASSY 54-BXM-2999-10

16 RIGID EPOXY PATCH KIT 06-DD14974

17 DROP RESISTOR REPAIR KIT 22-9178

18 CERAMIC LIFT RESISTOR REPAIR KIT 22-4360

19 SUPPRESSOR REPAIR KIT 23-6085

PART DESCRIPTION PART NO.

O.S. Walker Inc., CER Lift Magnet

21

ITEM

NO.

PART D ESCRIPTION

PART N O.

I/R-CER-5 I/R-CER-7 I/R-CER-9 I/R-CER-12

1 I/R LEN SE 39-DD16797 39-DD16797 39-DD16797 39-DD16797

2 PLUG, TWIST LOCK 11-2001 11-2001 11-2001 11-2001

3 RECEPTACLE, TWIST LOCK 11-2010 11-2010 11-2010 11-2010

4 CORD GRIP 17-0014 17-0014 17-0014 17-0014

5 COIL CORD 10-5052 10-5052 10-5052 10-5052

6 PCB ASSEMBLY 56-BXM4940 56-BXM4940 56-BXM4940 56-BXM4940

7 TOP COVER 39-CC16255 39-CC16255 39-CC16255 39-CC16255

8 OVERLAY 37-CC16301 37-CC16301 37-CC16301 37-CC16301

9 PUSHBU TTON ( RED) 15-0127 15-0127 15-0127 15-0127

10 PUSHBUTTON ( GREEN) 15-0128 15-0128 15-0128 15-0128

11 RECTIFIER ASSEMBLY COMPLETE 54-AA13988 54-AA13988 54-AA13988 54-AA13988

12 OPERA TING INSTRUCTIONS 37-DD12082 37-DD12082 37-DD12082 37-DD12082

13 LIFTIN G GUIDELI NES 37-DD12083 37-DD12084 37-DD12085 37-DD12086

14 DANGER TAG 37-DD11636 37-DD11666 37-DD11663 37-DD11663

15 DANGER TAG 37-DD11637 37-DD11667 37-DD11667 37-DD11667

16 REMOTE CONTR OL 39-DD14069 39-DD14069 39-DD14069 39-DD14069

17 RIGID EPOXY PATCH KIT 06-DD14974 06-DD14974 06-DD14974 06-DD14974

WARNING: IMPROPER WIRING CAN RESULT IN REDUCED HOLDING POWER.

I/R-CER-5 THRU 12 Replacement Parts List

22

O.S. Walker Inc., CER Lift Magnet

SPECIFICATION & PARTS LIST

WARNING: IMPROPER WIRING CAN RESULT IN REDUCED HOLDING POWER.

CER-16 & 20 Replacement Parts List

ITEM

NO.

1 INDICATOR (PILOT LIGHT) 18-0201

2 DRUM SWITCH 54-BXM3638

3 PLUG, TWIST LOCK 11-2001

4 RECEPTACLE, TWIST LOCK 11-2010

5 CORD STRAIN RELIEF, AC 17-0014

6 CORD STRAIN RELIEF, SWITCH 17-0027

7 RECTIFIER ASSY 54-DD11298A

8 AC CORD ASSY 54-DD14857

9 SWITCH CORD ASSY 54-DD14858

10 CABLE CLAMP 14-1415

11 OPERATING INSTRUCTIONS 37-DD12082

12 LIFTING GUIDELINES 37-DD12088

13 DANGER TAG 37-DD11001

14 DANGER TAG 37-DD10963

15 REMOTE ASSY 54-BB7866-1

16 SUPPRESSOR REPAIR KIT CER-16 54-DD14926

17 RESISTOR REPAIR KIT (7.5 OHM) CER-16 54-DD14927

18 RESISTOR REPAIR KIT (15 OHM) CER-16 54-DD14928

19 SUPPRESSOR REPAIR KIT CER-20 54-DD14904

20 RESISTOR REPAIR KIT (10 OHM) CER-20 54-DD14905

21 RESISTOR REPAIR KIT (5 OHM) CER-20 54-DD14906

22 RIGID EPOXY PATCH KIT 06-DD14974

PART DESCRIPTION PART NO.

O.S. Walker Inc., CER Lift Magnet

23

ALWAYS

STAY CLEAR

OF THE LOAD

Guide the load by pushing

or pulling the edges. This

keeps your entire body clear

of the load at all times.

DO NOT guide the load

by pushing or pulling the

magnet. NEVER get in a

position where you could

get hit with the load if it is

dropped.

FOR FAST RESPONSE, CALL 1-800-W-MAGNET

O.S. WALKER

Rockdale Street, Worcester, MA 01606

(508) 853-3232 FAX (508) 852-8649

1-800-W-MAGNET

WALKER

3508 Glenridge Drive, Chino Hills, CA 91709

(909) 597-4785 FAX (909) 597-0581

901 Arvin Avenue, Stoney Creek, Ontario, L8E5N9 Canada

(905)643-3338

In Canada: 1-800-267-4678 FAX (905) 643-6111

www.walkermagnet.com

e-mail: info@walkermagnet.com

37-DD-10505J Rev. J, April 14, 2009

Loading...

Loading...