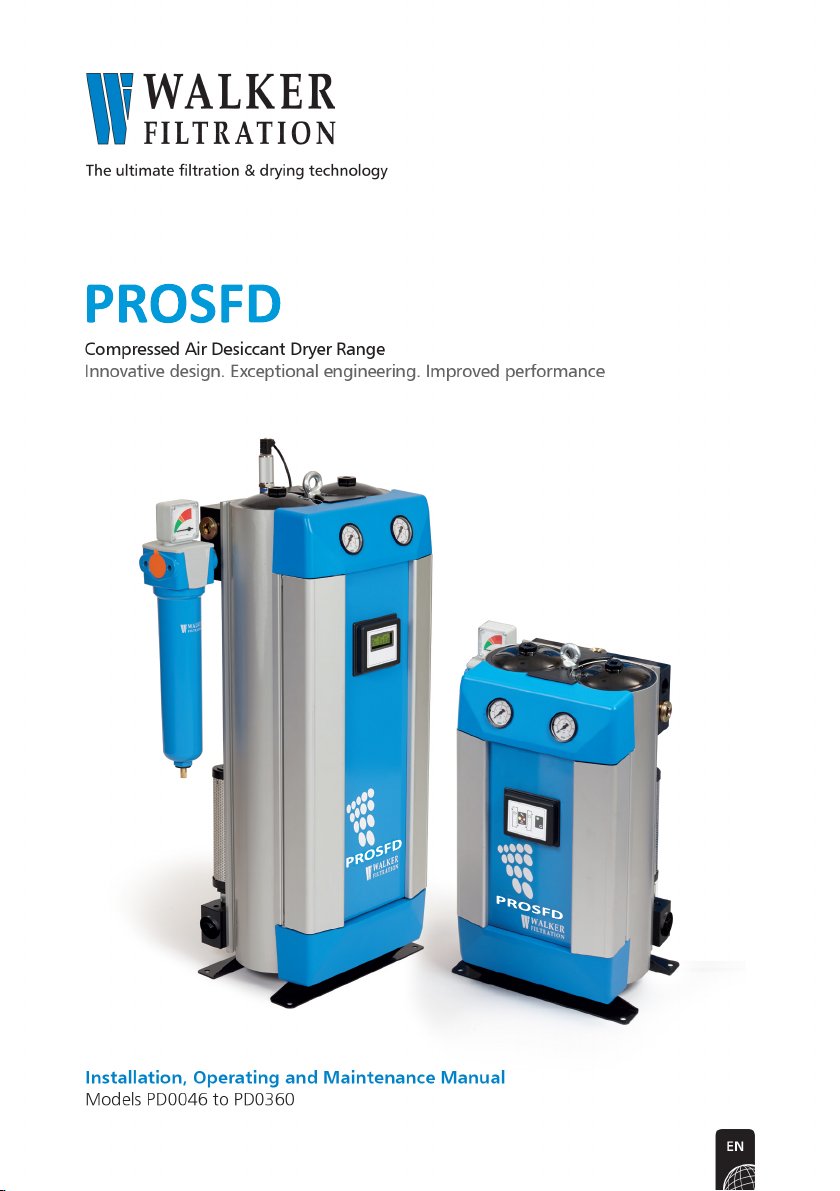

WALKER FILTRATION PROSFD, PROSFD PD0046, PROSFD PD0056, PROSFD PD0075, PROSFD PD0110 Series Manual

...Page 1

PROSFD

PROSFD

PROSFD

Page 2

The product to which this manual refers must not be supplied, installed,

used, operated or serviced until the contents of the manual has been

fully read and understood by all relevant personnel.

Please complete the following information at the time of installation

found on the rating label on the upper right hand side of dryer

Model Number

Serial Number

Regulated Inlet Pressure

Filtration present with Dryer

Inlet Flow of Dryer

Supply Voltage

Page 3

Contents

1 Safety 5

Safety Guidelines 5

Symbols 6

2 General Description 7

Function of the Dryer 7

Controller Options 7

Package Contents 8

Primary Components 9 - 10

3 Technical Data 11

Environmental Conditions 11

Dimensional Specications 12

Sizing 13

4 Mechanical Installation 14

Orientation 16

Conguration of the inlet /outlet ports 17

Connecting the pre-lter to the dryer 18

Connecting the optional pre-lter drain valve 18

Installing the hygrometer (DMC models only) 19

Conguring the purge orice 20

5 Electrical Installation 22

PRODRY Controller power supply options 22

PRODRY Recommended power cable specications 22

LED Controller specications 23

DMC Controller specications 24

How to wire a DIN connector 25

Alarm connection details 26

Page 4

6 Operation 27

Background / Function of the Dryer 27

Detailed operational description - LED Controller 27

Detailed operational description - DMC Controller 27

Start-up procedure 28

Shut-down procedure 28

Operational schematics 29

7 Energy Management 35

Overview 35

Developing a purge control strategy 35

Using a manual switch for purge control 35

Using a standard pressure switch for purge control 36

Using an electronic pressure switch for purge control 37

Using a hygrometer and process controller for purge control 38

Making connections between a switching device and dryer EM contact 39

8 Maintenance 40

9 Spares Information 41

Service kits 41 - 43

Accessory kits 44 - 45

10 Component Parts 46

11 Troubleshooting 50

12 Warranty 56

13 Declaration of Conformity 57

Page 5

Section 1: Safety

Safety

The following safety guidelines must be

strictly observed.

• Leave this manual at the place of installation of

the product.

• It is essential that only Walker Filtration or it’s appointed

agents carry out maintenance and servicing work.

Users, maintenance and servicing personnel must be familiar

with:

• Accident prevention regulations.

• Safety information (general and specic to the unit).

• Safety devices of the unit.

• Measures to be taken in case of an emergency.

• Allow only suitably trained persons to be involved with

installation, start-up, operation, servicing and maintenance

of the product.

• It is the responsibility of the installer to ensure that the

pipe work to and from the dryer is suitable, in accordance

with applicable legislation and subject to inspection and

testing prior to being put into service. All piping must be

adequately supported.

• Before carrying out any maintenance or servicing work the

unit must be taken out of operation. Users and others will

be exposed to risk if work is carried out whilst the unit is

running. This means electrical disconnection plus isolation

from the compressed air supply and full depressurisation.

• Only trained and competent persons familiar with the

electrical requirements of the unit as laid out in this

manual and electrical safety rules and regulations should

be allowed to carry out work on the electrical components

and power supply to the unit.

• When carrying out any work on the unit, use only

correctly sized appropriate tools in good condition.

• Only use original spare parts and accessories from the

manufacturer. There is no guarantee that non-original

parts have been designed and manufactured to meet

the safety and operational requirements of the unit.

Walker Filtration assume no liability for any equipment

malfunction resulting from the use of non-approved parts.

• If carrying out installation work above head height, use

suitable and safe working platforms or other means of

working access.

• Do not make any constructional changes to the product.

Any changes or modications may only be carried out by

the manufacturer, Walker Filtration.

• Any faults or defects that could affect safety must be put

right fully before using the unit.

• Used items and materials must be disposed of in the

correct manner, complying with local laws and regulations,

in particular the desiccant cartridge.

5

Page 6

Section 1: Safety

Figure 1.1: Definition of symbols

Risk of Danger

Risk of High Pressure

Risk of Electric Shock

Warning

Manual Handling

As with all areas of the workplace, Health and Safety is of

great importance and must be given due care and attention.

While working with this equipment, manual handling

regulations must be considered and adhered to.

Full advice, support and guidance should be detailed in your

Health and Safety Policy and Manual Handling guide, please

take the time to familiarise yourself with these documents.

The Manual Handling Operations Regulations apply to a wide

range of manual handling activities, including lifting, lowering,

pushing, pulling or carrying.

We ask every person handling this product to take the

responsibility for their own Health and Safety and the Health

and Safety of others around them. If you feel there is a

signicant risk, you must take steps to either remove the risk

altogether, or reduce the risk prior to carry out the activity. If

you need further support or guidance with this, please consult

your line manager or the HR Department.

There are safe systems of work and correct procedures in

relation to manual handling, please consult these documents

available within the workplace.

We ask everyone handling this product to:

• Follow appropriate systems of work laid down

for their safety.

• Make proper use of any equipment provided for

their safety.

• Inform the company if they identify hazardous

handling activities.

• Take care to ensure that their activities do not put

others at risk.

If in doubt, please seek further advice and ensure you always

follow the correct procedures and guidance.

For more information please see our Health and

Safety manual attached.

Equipment Protected by

Double Insulation

Important Note

A 3 amp fuse should be tted as per the wiring diagram.

6

Page 7

Section 2: General Description

Controller Options

RESET

Controller Options

RESET

Dewpoint Hold (-40)

Dryer Dewpoint -43 PDP

Hours Run 1234

Service History # 0

General Description

This manual is valid for the following dryer models

PD0046

PD0056

PD0075

PD0090

PD0110

PD0150

PD0180

PD0220

PD0300

PD0360

Function of the Dryer

PRODRY is designed to provide a smooth, controlled and

uninterrupted delivery of dry compressed air. Wet air passes

through a pre-lter and travels down to the bottom valve

assembly. The air is then fed through the bottom of the

desiccant bed and moves through the high performance

desiccant until it becomes dry. On exit from the desiccant

cartridge, the air is passed through the outlet valve assembly.

During this process, the dryer control system cycles the process

air between the two desiccant towers. While one tower is on

stream removing water vapour, the other is being carefully

depressurised in preparation for regeneration. The desiccant

bed is regenerated by expanding a small amount of dry

process air, or purge air, through the saturated desiccant.

Purge air passes to atmosphere through the silencer, which

is tted to an exhaust valve. The tower is then repressurised,

with the control system assuring each tower is at full

operational pressure prior to changeover.

This ensures a reliable and efcient operation. The air stream is

switched and the cycle repeats on a continuous basis.

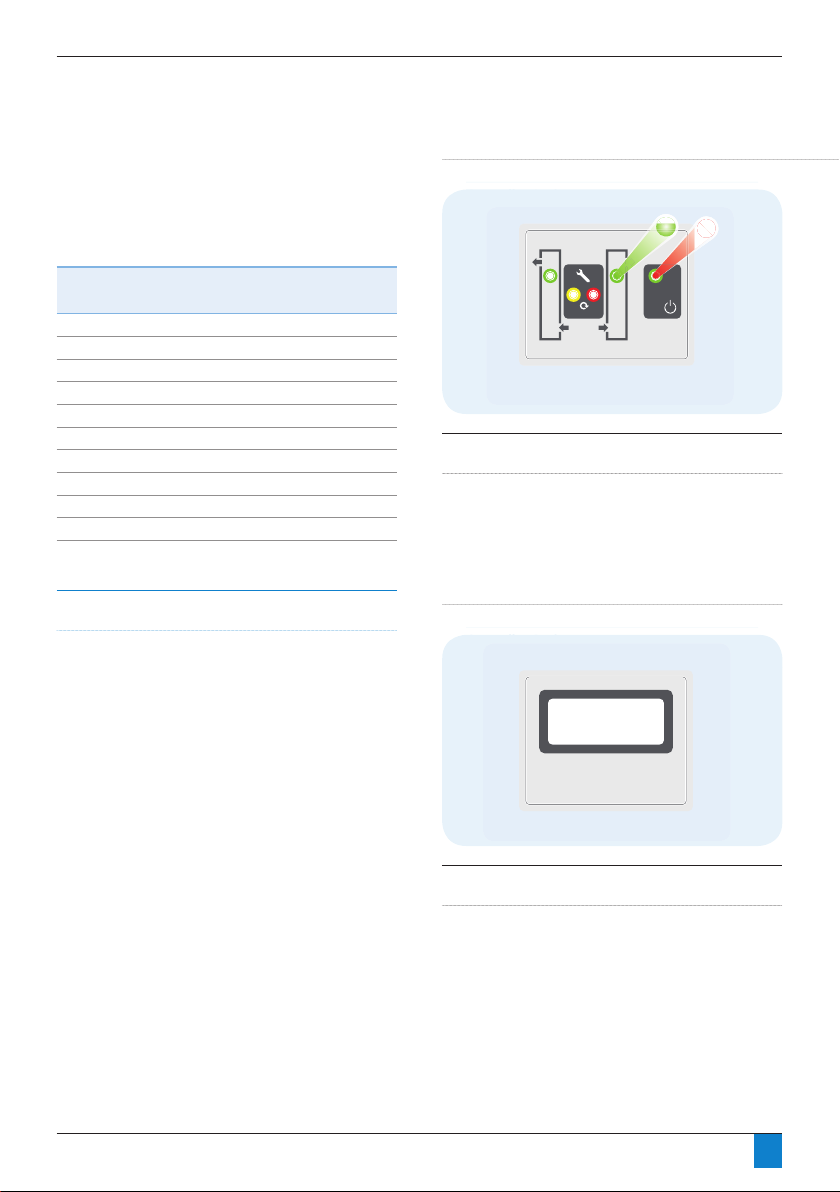

Figure 2.1: LED Controller

Features:

• Supplied as standard controller

• Microcontroller based design

• Available in 115V or 230VAC

• Energy Management Feature (EM)

• Alarm Outputs

Figure 2.2: DMC Controller

Features:

• (Optional) full feature controller

• PLC based design

• 24VDC only

• Includes Hygrometer

• Energy Management Feature (EM)

• Alarm Outputs

• Selectable output dewpoint levels (-20°C, -40°C, -74°C)

• Engages Dewpoint Hold during periods of low demand

• resulting in energy savings up to 81%.

7

Page 8

Controller Options

Controller Options

Section 2: General Description

1

2

3

4

1

6

2

3

4

5

1

6

2

3

4

5

Package Contents

The dryer is delivered in protective packaging. Take care when transporting, loading and unloading the unit.

The package contains the following items (refer to gure 2.3):

1. Dryer unit

2. Instruction manual (including certicate of conformity)

3. Power connector

Figure 2.3: Package contents (All dryer models)

4. Purge Kit

Figure 2.4: Optional Items for DMC Dryer

Hygrometer Sample Block

(Installed into top valve block)

Hygrometer

Instruction manual

(including certicate of conformity)

Note: All dryers come equipped with

eyebolts to facilitate removing the dryer

from it’s crate. Simplex dryers include one

eyebolt and duplex models include two.

Note: All dryers include spare orice

components to allow the dryer to be

modied from the factory 7 barg (100 psig)

pressure setting to any pressure within the

specied operating range. The internal

purge valves within models PD046 & PD056

can be modied to suit all pressure settings

whilst models PD0075 to PD0360 require

additional components (which are supplied

with the dryer).

Figure 2.5: Optional Items for DMC Dryer

Pre-lter drain valve

7

8

Page 9

Section 2: General Description

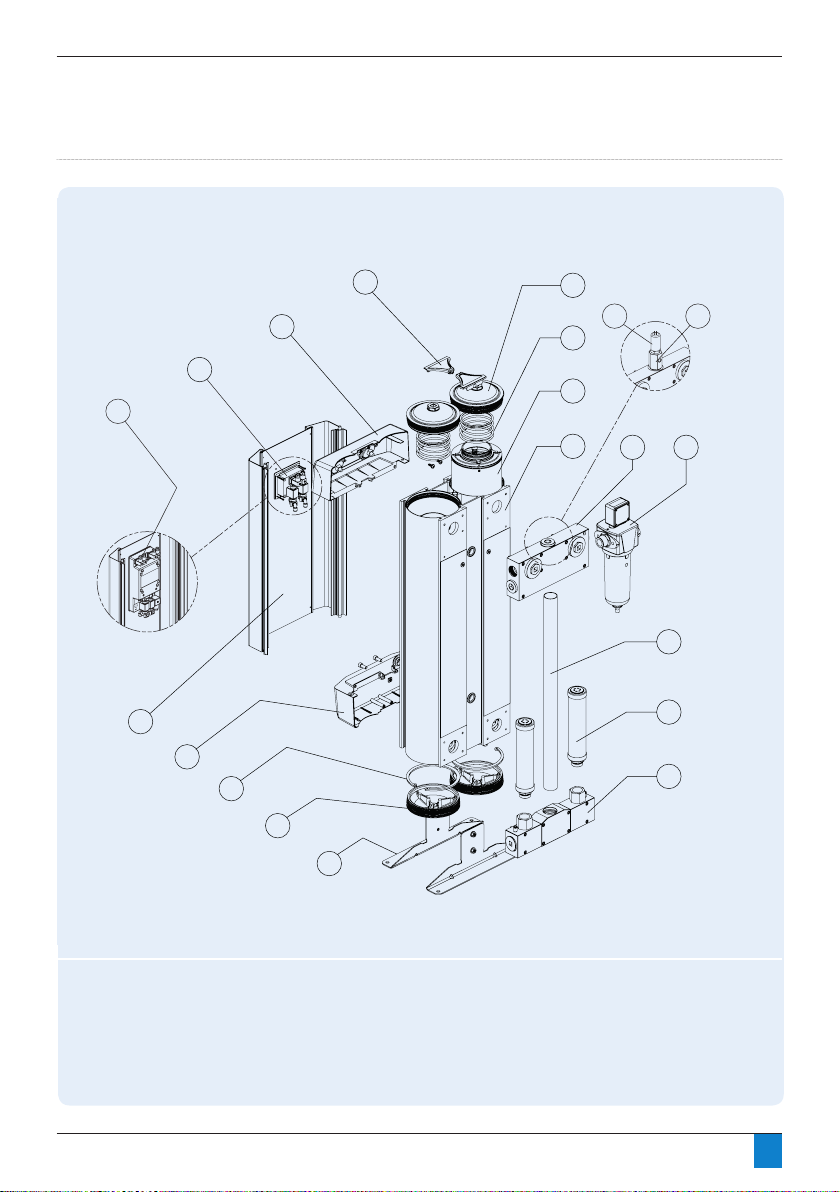

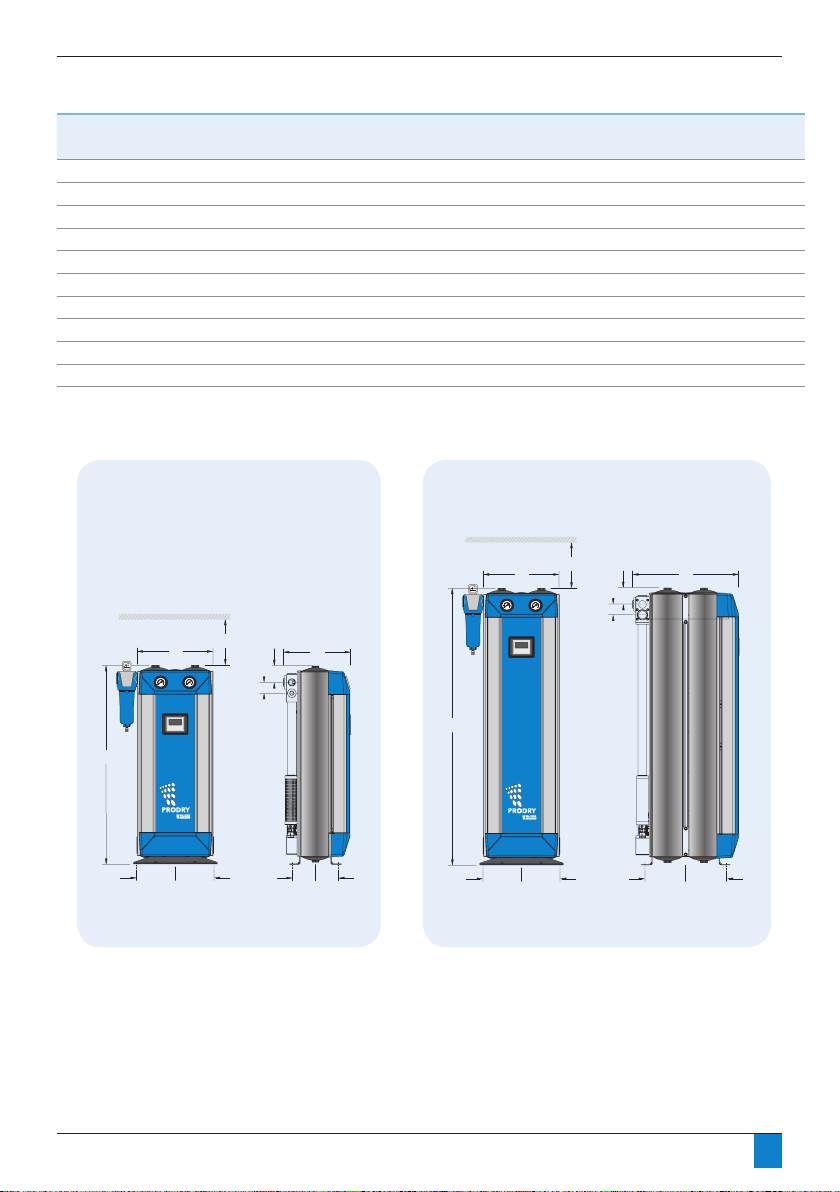

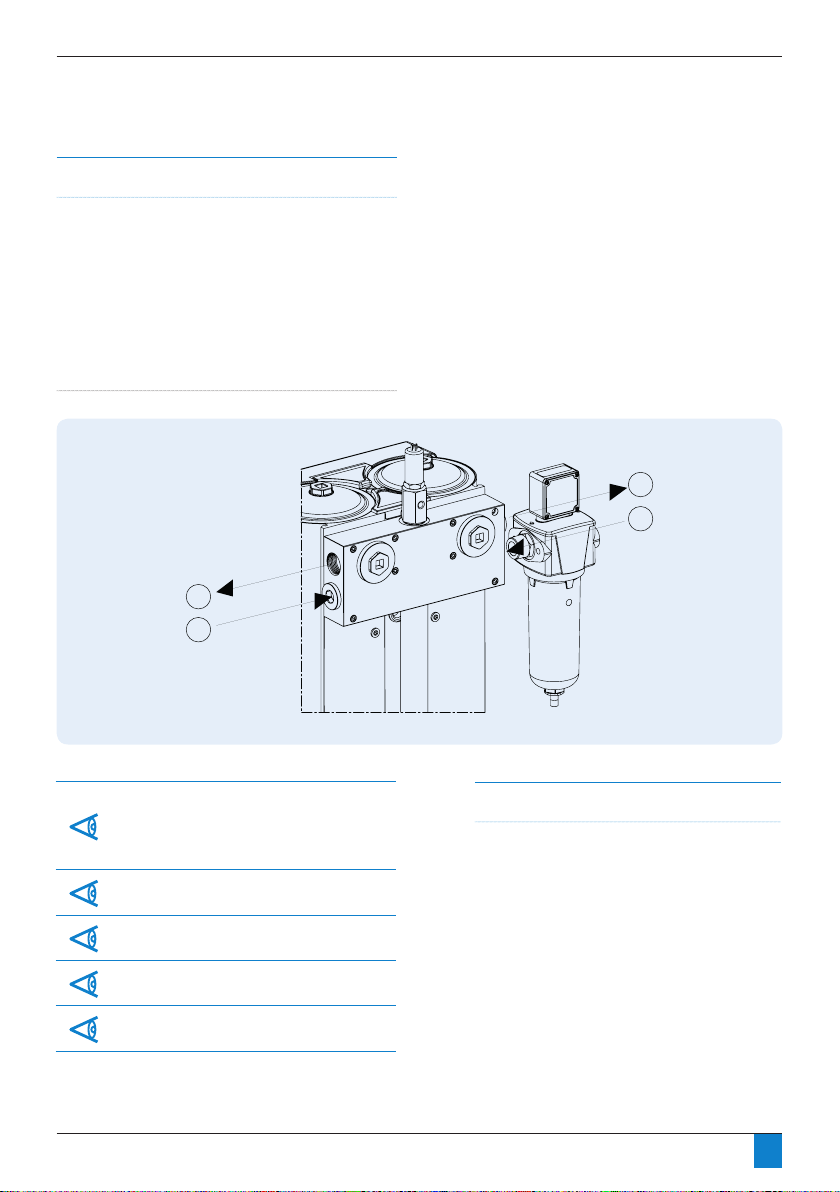

Figure 2.6: Primary Components (Simplex Models PD0046 - PD0180)

DMC Models2b

1

2a LED Models

17

16

4

3

5

19

18

6

DMC Models

7

8

9

10

11

12

13

15

14

1. Front panel

2a. LED controller

2b. DMC controller

3. Top trim cover

4. Extrusion cover

5. Top extrusion tower plug

6. Tower spring

7. Desiccant cartridge

8. Extrusion tower

9. Top manifold assembly

10. Pre-filter (Optional)

11. Downpipe

12. Exhaust silencer

13. Bottom manifold assembly

14. Dryer stand

15. Bottom extrusion tower plug

16. Tower circlip

17. Bottom trim cover

18. Hygrometer sample block*

19. Hygrometer*

* DMC models only

9

Page 10

Section 2: General Description

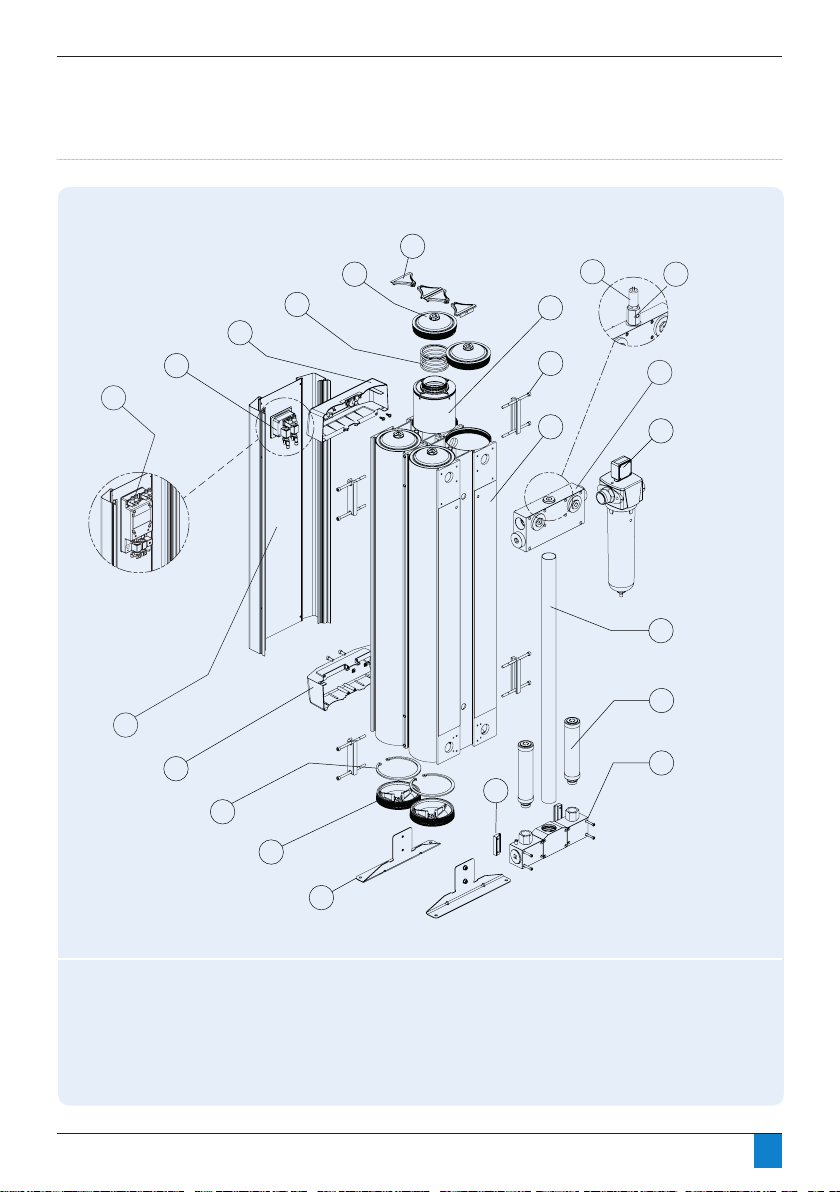

Figure 2.7: Primary Components (Duplex Models PD0220 - PD0360)

Se ctio n 2: General Description

Figure 2.7: Primary Components (Duplex Models PD0220 - PD0360)

6

2

DMC Models2b

3

4

5

21

7

8

9

20

DMC Models

10

11

12

13

1

19

14

15

18

17

16

1. Front panel

2a. LED controller

2b. DMC controller

3. Top trim cover

4. Extrusion cover

5. Top extrusion tower plug

6. Tower spring

7. Desiccant cartridge

8. Extrusion link

9. Extrusion tower

10. Top manifold assembly

11. Pre-filter (Optional)

12. Downpipe

13. Exhaust silencer

14. Bottom manifold assembly

15. Bottom manifold support clip

16. Dryer stand

17. Bottom extrusion tower plug

18. Tower circlip

19. Bottom trim cover

20. Hygrometer sample block*

21. Hygrometer*

* DMC models only

10

Page 11

Section 3: Technical Data

Technical Data

Environmental Conditions

All dryers are designed to be safe under the following conditions:

• Indoor use

• Altitude up to 2,000m

• Ambient temperature 5°C (41°F) to 50°C (122°F)

• Mains supply voltage uctuations not to exceed +/- 10% of nominal

For operation extended from the above conditions, please contact Walker Filtration.

Excessive vibrations from external sources may cause

failure of this product.

Rated Conditions

Measurement

Inlet pressure 7 barg 101.5 psig

Inlet temperature 35°C 95°F

Relative humidity of air at inlet 95%

Pressure dewpoint, standard version -40°C -40°F

Performance

Specified Limitation for Operation

Measurement

Maximum inlet air pressure 13 barg 188.5 psig

Minimum inlet air pressure 4 barg 58 psig

Maximum ambient air temperature 50°C 122°F

Minimum ambient air temperature 5°C 41°F

Pressure dewpoint (LED & DMC Controller) -20°C to -74°C -4°F to -100°F

Electrical supply voltage (LED Controller) 115 VAC or 230 VAC

Electrical supply voltage (DMC Controller) 24 VDC

Performance

11

Page 12

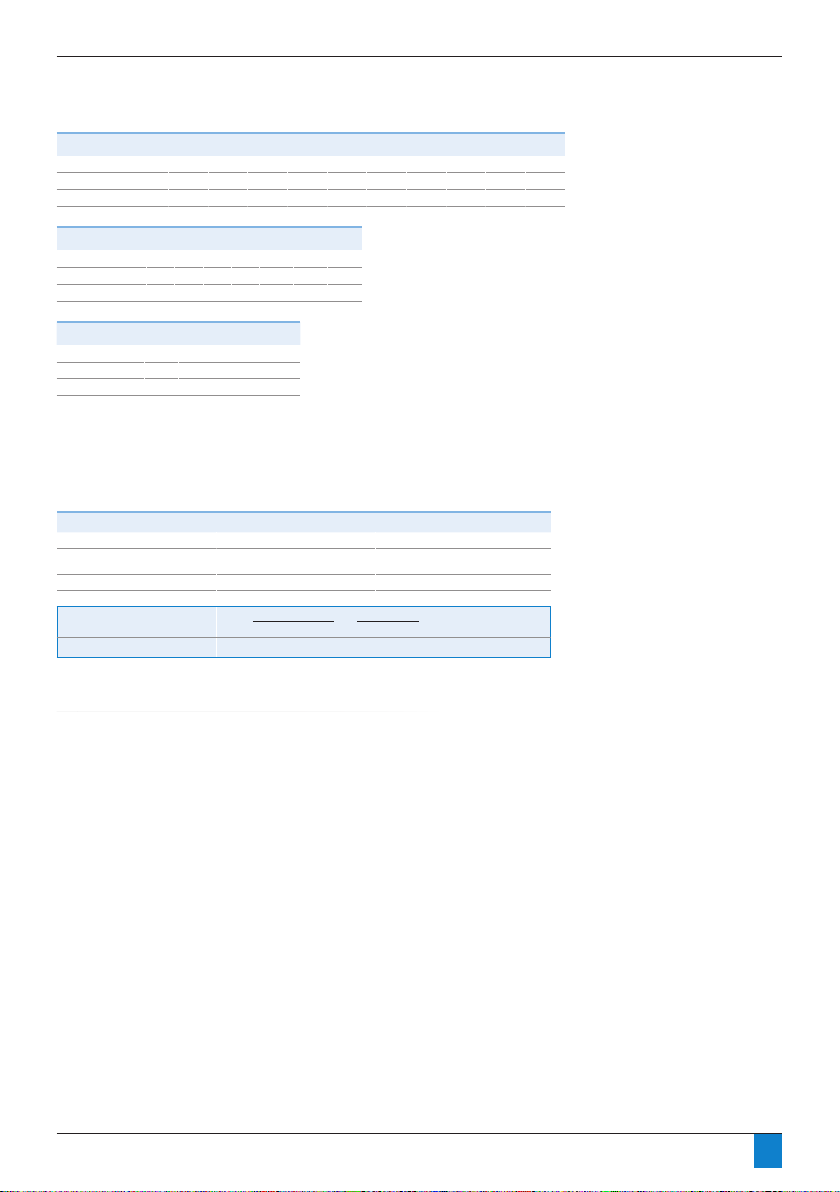

Section 3: Technical Data PD0046 - PD0360

Section 3: Technical Data PD0046 - PD0360

Dryer

model

Pipe

size

Inlet flow rate* Dimensions mm (inches)

Weight KgNo. of

cartridges

Recommended

Filter model

Filter

pipe size

Nm³/h

SCFM

ABCDEF

17745 655 (25.8) 76 (3) 50 (2) 600 (23.6) 50 2 ½

19455 735 (29) 76 (3) 50 (2) 700 (27.6) 58 2 ½

1 128 75 905 (35.6 76 (3) 50 (2) 850 (33.5) 66 2 ½

1 153 90 1030 (40.5) 76 (3) 50 (2) 1000 (39.4) 75 2

1 187 110 1260 (49.6) 76 (3) 50 (2) 700 (27.6) 105 4

1 255 150 1595 (62.8) 76 (3) 50 (2) 850 (33.5) 130 4 1

1 306 180 1845 (72.6) 76 (3) 50 (2) 1000 (39.4) 150 4 1

1½ 374 220 1262 (49.7) 76 (3) 62 (2.4) 700 (27.6) 250 8

1½ 510 300 1596 (62.8) 76 (3) 62 (2.4) 850 (33.5) 315 8

1½ 612 360 1845 (72.6) 76 (3) 62 (2.4) 1000 (39.4) 362 8 A159XA 1 ½

A

189189

175175

Models PD0046-PD0180

Models PD0220-PD0360

C

601601

B

A

175175

F

E

D

B

C

F

E

D

* Stated flows are for an inlet pressure of 7 barg (100 psig) with reference to 20°C (68°F), 1 barg (abs.), 0% relative water vapour pressure. For flow at other

pressures, apply the appropriate correction factors, terms and dewpoint.

380(15) 310 (12.2)

380(15) 310 (12.2)

380(15) 310 (12.2)

380(15) 310 (12.2)

380(15) 490 (19.3)

380(15) 490 (19.3)

380(15) 490 (19.3)

380(15) 310 (12.2)

380(15) 310 (12.2)

380(15) 310 (12.2)

Weight KgNo. of

cartridges

Recommended

Filter model

Filter

pipe size

A

189189

175175

Models PD0220-PD0360

B

C

F

E

D

Dryer

model

PD0046 1 77 45 655 (25.8) 380 (15) 310 (12.2) 76 (3) 50 (2) 600 (23.6) 46 2 A058XA ½

PD0056 1 94 55 735 (29) 380 (15) 310 (12.2) 76 (3) 50 (2) 700 (27.6) 51 2 A059XA ½

PD0075 1 128 75 905 (35.6) 380 (15) 310 (12.2) 76 (3) 50 (2) 850 (33.5) 62 2 A059XA ½

PD0090 1 153 90 1030 (40.5) 380 (15) 310 (12.2) 76 (3) 50 (2) 1000 (39.4) 70 2 A078XA ¾

PD0110 1 187 110 1260 (49.6) 380 (15) 325 (12.8) 76 (3) 50 (2) 700 (27.6) 85 4 A079XA ¾

PD0150 1 255 150 1595 (62.8) 380 (15) 325 (12.8) 76 (3) 50 (2) 850 (33.5) 105 4 A108XA 1

PD0180 1 306 180 1845 (72.6) 380 (15) 325 (12.8) 76 (3) 50 (2) 1000 (39.4) 122 4 A109XA 1

PD0220 1½ 374 220 1262 (49.7) 380 (15) 490 (19.3) 76 (3) 62 (2.4) 700 (27.6) 154 8 A128XA 1 ¼

PD0300 1½ 510 300 1596 (62.8) 380 (15) 490 (19.3) 76 (3) 62 (2.4) 850 (33.5) 195 8 A128XA 1 ¼

PD0360 1½ 612 360 1845 (72.6) 380 (15) 490 (19.3) 76 (3) 62 (2.4) 1000 (39.4) 225 8 A159XA 1 ½

* Stated ows are for an inlet pressure of 7 barg (100 psig) with reference to 20°C (68°F), 1 barg (abs.), 0% relative water vapour pressure. For

ow at other pressures, temperatures and dewpoints apply correction factors on page 13.

Inlet flow rate* Dimensions mm (inches)

Pipe

size

Nm³/hr SCFM A B C D E F

Weight KgNo. of

cartridges

Recommended

Filter model

Filter

pipe size

12

Page 13

Section 3: Technical Data PD0046 - PD0360

Dryer correction factors

Operating pressure (PCF)

barg

psig

Correction factor

4 5 6 7 8 9 10 11 12 13

58 72 87 100 115 130 145 160 174 189

0.62 0.75 0.87 1 1.12 1.25 1.37 1.5 1.62 1.75

Temperature (TCF)

Celcius °C

Farenheit °F

Correction factor

Pressure dewpoint (DCF)

Celcius °C

Farenheit °F

Correction factor

PRODRY Sizing Example

To correctly select the PRODRY model suitable for your application the following information is required: Minimum

Inlet Pressure, Maximum Inlet Temperature, Maximum Compressor Inlet Flow and Required Pressure Dewpoint (PDP).

Requirements Correction Factor

Maximum compressor inlet ow

Actual minimum inlet pressure

to the dryer

Maximum inlet temperature

Pressure dewpoint (PDP)

Corrected dryer ow rate

Appropriate Dryer Size

20 25 30 35 40 45 50

68 77 86 95 104 113 122

1.3 1.2 1.1 1 0.75 0.65 0.45

-20 -30 -40 -70 -74

-4 -22 -40 -94 -100

1.23 1.2 1 0.8 0.77

56 scfm -

6 barg PCF = 0.87

25°C (77°F) TCF = 1.2

-74°C (-100°F) DCF = 0.77

Inlet ow rate

PCF x TCF x DCF56(0.87 x 1.2 x 0.77)

Dryer model is selected based on the corrected ow rate, i.e. PD0075.

= =

69.7 scfm

(118 Nm³/hr)

Technical notes

Pre-filtration, including a water separator is essential to maintain dryer performance.

1.

An appropriate Water Separator must be installed. If bulk water enters the adsorption dryer it can cause heat

expansion to the desiccant, substantial rise in the dryer differential pressure, lead to poor outlet dewpoint, and

2.

cause potential dryer failure.

Walker Filtration recommends fitting an RXA dust filter to the outlet.

3.

Call your nearest Walker Filtration sales team for further information.

4.

13

Page 14

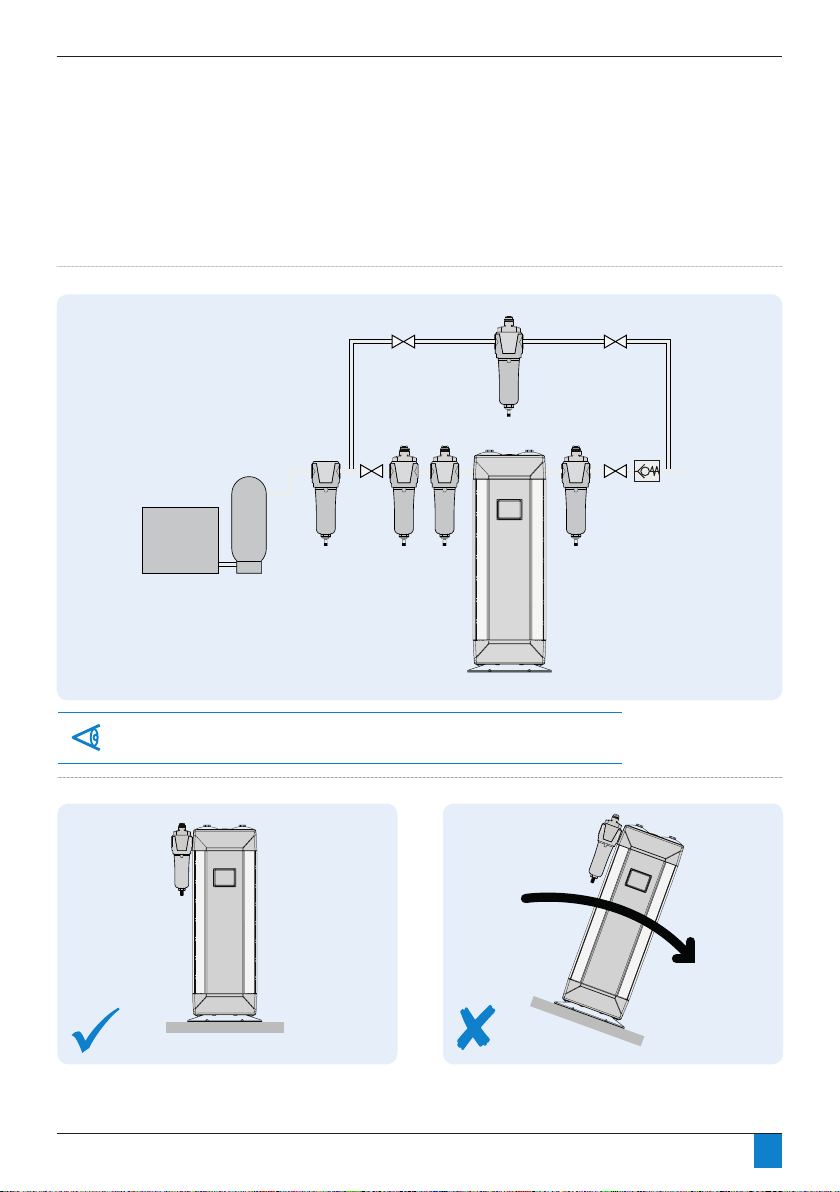

Section 4: Mechanical Installation

Mechanical Installation

Figure 4.1: Typical installation

C

XA

To prevent back flow into the dryer a non-return valve should be placed in-line, downstream

of the dryer. This is essential when more than one dryer is used in a single application.

Figure 4.2: Level ground

WS X1 XA

RXA

14

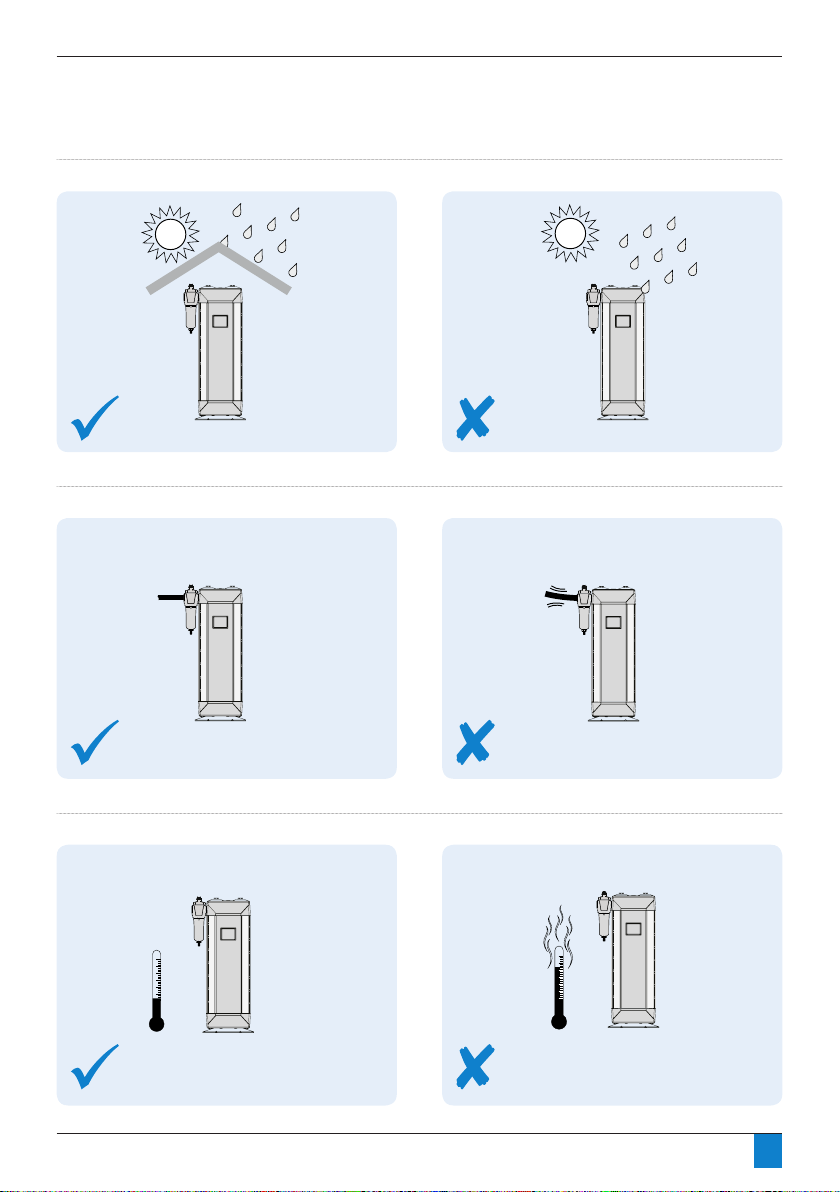

Page 15

Section 4: Mechanical Installation

>Max 50OC (122OF)

Figure 4.3: Location

Figure 4.4: Hard piped installation

Figure 4.5 Exposure to heat

Max 50OC (122OF)

>Max 50OC (122OF)

15

Page 16

Section 4: Mechanical Installation

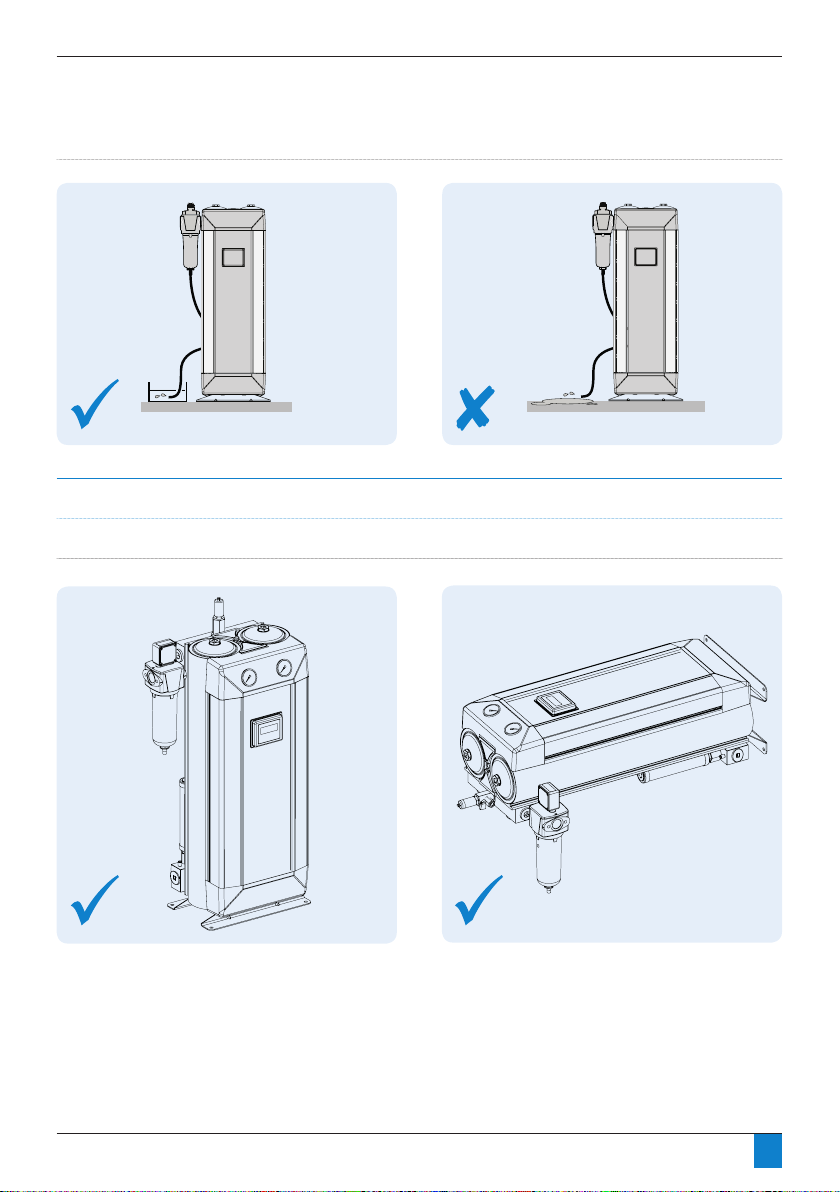

Figure 4.6: Drainage (all tubing should be secured up to the point of drain to prevent whipping during discharge)

Orientation

Figure 4.7: The PRODRY range of dryers is designed to operate in both vertical and horizontal orientation.

16

Page 17

Section 4: Mechanical Installation

Re conguration of the inlet / outlet ports

PD0046 – PD0360 models

• Dryer can be recongured to interchange position of

inlet and outlet ports as per gure 4.8.

• PRODRY has two inlet ports (A and B) and two outlet

ports (C and D). Either (A or B) can be used for inlet

and (C or D) for outlet. Make sure the un-used ports are

blanked off with provided pressure plugs.

Figure 4.8: Inlet/outlet ports

C

A

D

B

Any of the two outlet ports can be used on

Tools required

occasion. Please ensure flow at outlet should not

exceed specification. Please adhere to regional

regulations.

It is strongly advised to connect a non-return

valve to the outlet port of the dryer.

• Adjustable spanner

• Ratchet with 17mm Hexagonal connection

(PD0046 - PD0180)

• Ratchet with 1” Hexagonal connection

(PD0220 - PD0360)

Only use one inlet port at any one time

Ensure original seals are in place.

Check dryer is leak-free prior to operation.

17

Page 18

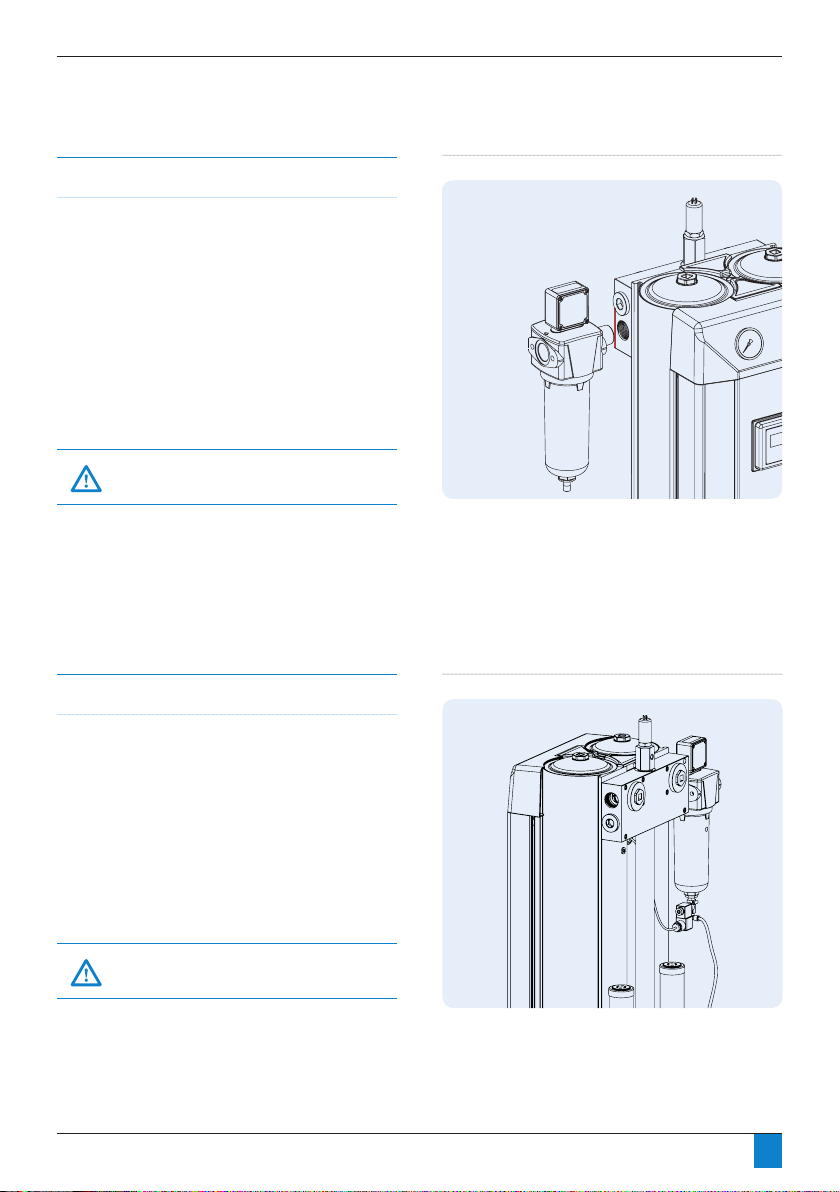

Section 4: Mechanical Installation

Figure 4.9: Co nnecting a pre- filter

Figure 4.9: Conn ecting a pre- filte r

Figure 4.10 : Conn ecting filte r dr ain

Connecting the pre-lter to the dryer

PD0046 – PD0360 models

• Attach pre-lter (purchased separately) utilising a pipe

nipple and/or pipe adapter.

• Pipe away condensate with tubing from drain outlet.

Ensure condensate is drained into an oil/water

separator.

• Fit any further ltration and/or ancillary equipment.

• Pre-lter is typically supplied with an autodrain installed

in the bowl drain port. On DMC models, this can

be replaced with a solenoid drain valve which is an

optional extra sold separately.

All tubing should be secured up to the point of

drain to prevent whipping during discharge.

• It is recommended that a bypass line including XA lter

is installed, as per gure 4.1.

Connecting the optional pre-lter drain valve

• Available on DMC models only.

• If necessary, remove existing autodrain valve from

pre-lter.

• Install pipe adapter into pre-lter drain port.

• Install optional solenoid drain valve onto pipe adapter(s)

taking care to note ow direction as indicated by arrow

etched into the side of the drain valve body.

• Pipe away condensate with tubing from drain outlet.

Ensure condensate is drained into an oil/water

separator.

Figure 4.9: Connecting a pre-filter

Figure 4.10: Connecting filter drain

All tubing should be secured up to the point of

drain to prevent whipping during discharge.

18

Page 19

Section 4: Mechanical Installation

Hygrometer

Sample Block

Hygrometer

Hygrometer

DIN Plug

PD0046 – PD0360 models

•

Installing the hygrometer (DMC models only)

•Remove hygrometer from packaging.

• Carefully remove plastic cover from the

sensor.

•

•

•

•

Hygrometer sample block is pre-installed in the dryer’s

top manifold assembly. Remove cover from threaded

port.

Confirm the threads on the hygrometer sample block

are clean and free from any dirt, water, cutting

lubricant, liquid thread sealant, oil and/or grease.

Per figure 4.11, insert hygrometer into the hygrometer

sample block and turn to clockwise to tighten .

Tighten

lightly with adjustable spanner.

Fit hygrometer DIN plug to the hygrometer and

tighten screw with pozi-head screwdriver.

Section 4: Mechanical Installation

Do not touch white sensor tube.

Open 2 full turns = 5Nl/min

Hygrometer Silencer Setting

Installing the hygrometer (DMC models only)

PD0046 – PD0360 models

• Remove hygrometer from packaging.

• Carefully remove plastic cover from the sensor.

Do not touch white sensor tube.

• Hygrometer sample block is pre-installed in the dryer’s

top manifold assembly. Remove cover from threaded

port.

• Conrm the threads on the hygrometer sample

block are clean and free from any dirt, water, cutting

lubricant, liquid thread sealant, oil and/or grease.

• Per gure 4.11, insert hygrometer into the hygrometer

sample block and turn to clockwise to tighten.

Tighten lightly with adjustable spanner.

• Fit hygrometer DIN plug to the hygrometer and tighten

screw with pozi-head screwdriver.

Figure 4.11 Attaching hygrometer

Figure 4.12 Hygrometer attached

Tools required

• Adjustable spanner

• Pozi-head screwdriver

19

Page 20

Section 4: Mechanical Installation

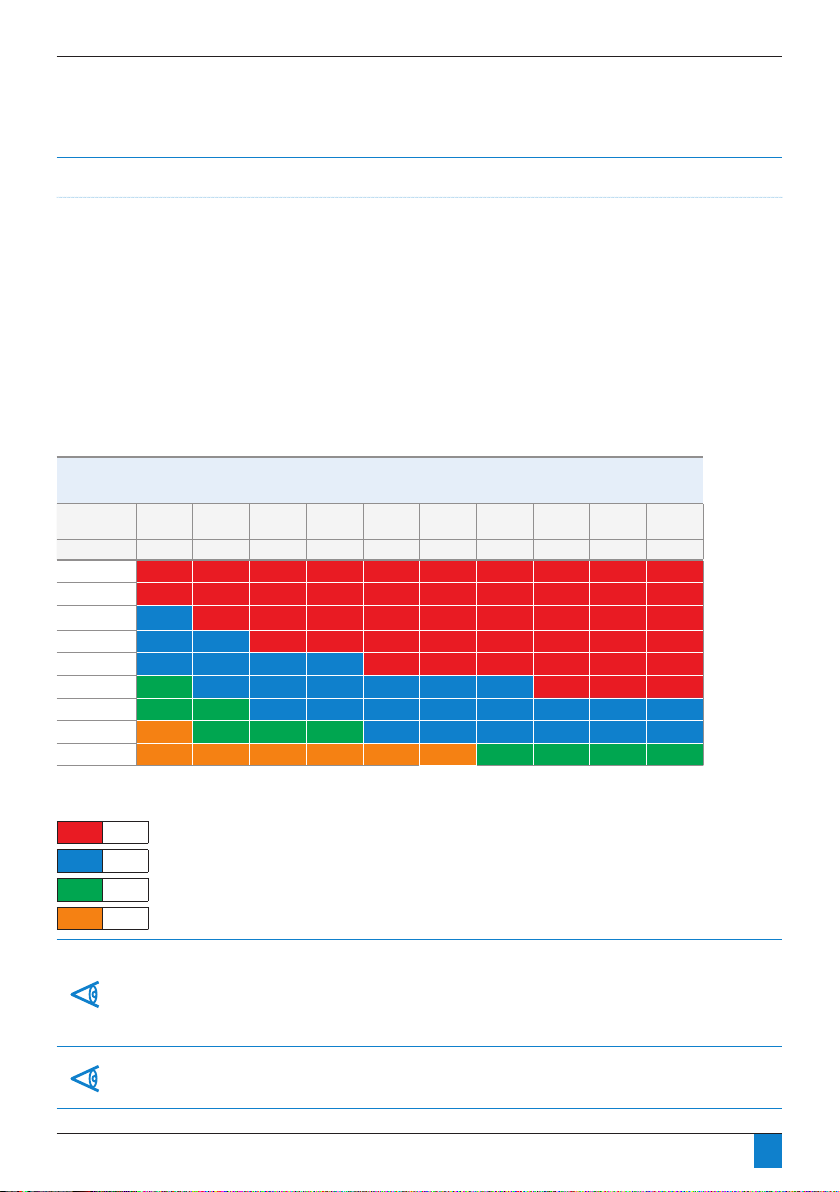

Purge Orice Size Identication

• Reference gure 4.13 and the Purge Plug Identication Table.

• Each dryer is pre-set with the correctly sized purge valve for an operating pressure of 7 barg (100 psig) at point of order.

• The lettering (A through S), located on the purge valve body, indicates the orice size selected to suit the operating pressure of

the dryer per the chart below.

• If the inlet pressure to the dryer will be different than the pre-set orice size, the purge valve can be adjusted.

• Most dryers use a single orice purge valve represented by the Blue and Green single letter references in the table below.

• Larger dryers may require a two or three hole purge valve as represented by the Red and Yellow two and three letter references.

• To select the correct orice size, locate the appropriate dryer model at the left side of the table and then the operating pressure

at the top.

• Make sure that the correct valve body (1, 2 or 3 hole) and orice disc (01, 02, 03 or 04) has been supplied with the dryer. The

discs have the number (01, 02, 03 or 04) stamped out at the top.

Purge Plug Identification

Operating

pressure

Dryer

PD0046

PD0056

PD0075

PD0090

PD0110

PD0150

PD0180

PD0220

PD0360

4 5 6 7 8 9 10 11 12 13

M K I H G F E E E D

P M L K J I H G F F

B S P M L L K I I H

C A P P N L K J I H

I E C A P M K K J I

CK M G F C B A S S P

EM CK P I G E C B A A

AFK FN DL P K H F E D C

EJP DIN CHM AFK AFK GP EM DL BJ AI

Disc

01

02

03

04

Every dryer is shipped with a purge orifice set up for 7 barg (100 psig) operation. The dryer will also include the necessary

purge valve components to configure the dryer to operate at any pressure from 4 barg (58 psig) to 13 barg (189 psig). For

example: A PD0150 dryer will be supplied with a single hole purge assembly with an 02 purge disc installed and indexed to

position F. Additional purge valve components will be included to allow the dryer to be configured to purge settings, CK, M,

H, D, B, A, S, P and N.

Appropriate purge plug selection is very important for function of the dryer. Failure to comply with this may affect your

warranty.

20

Page 21

Section 4: Mechanical Installation

Section 4: Mechanical Installation

Figure 4.13 Purge valve assembly

Orifice

Discs

Valve

Body

(Common to all dryers)

1 Hole Valve

Stem

2 Hole Valve Stem

Valve Control Spring

M4 Screw

3 Hole Valve Stem

Valve Stem O-ring(s)

(Fit into recess in

Valve Stem(s))

Gasket and Valve Stem are

rotated to align with index reference

letters on Valve Body

Index reference letters

Purge Sealing Gasket(s)

(1, 2 or 3 hole)

Disc

I.D.

Number

(01, 02, 03, 04)

Alignment

notches

Alignment

notches

3mm allen key

Figure 4.13 Purge valve assembly

Purge Valve Assembly

• Reference gure 4.13 and the Purge Plug Identication Table on Page 20.

• Once the correct purge body (1, 2 or 3 hole) and orice disc (01, 02, 03 or 04) has been selected per the instructions on Page

20, the purge valve may be assembled.

• The index letters located on the purge valve body correspond with the selected orice sizes per the Table on Page 20.

• Place the appropriate orice disc onto the valve body, taking care to align the notches. The disc will only t in one position.

• Place the valve stem O-ring(s) into their corresponding recesses on the back of the valve stem.

• Align the holes in the purge sealing gasket with the corresponding holes in the valve stem.

• Rotate the valve stem assembly so that the correct orice letters align with the notches corresponding to the holes (1, 2 or 3) in

the valve stem.

• Press the assembly together and fasten with the M4 screw.

• Double check to make sure that the open orice holes correspond with the correct orice selection as identied earlier.

21

Page 22

Section 5: Electrical Installation

Electrical Installation

PRODRY Controller power supply options

Models PD0046 - PD0360

• The dryer is designed to operate on either AC or DC

supply voltage dependant on controller option.

• Electrical wiring must comply with local regulations.

Voltage requirements must be conrmed to be within

the specication on the dryers rating plate.

• Ensure only one power source is connected at any one

time and is connected to the correct socket as shown in

gures 5.1 (LED Controller) and 5.2 (DMC Controller).

• The LED and DMC controller require a earth to be

connected within the DIN connector.

• The cable selection must suit local installation

regulations and be appropriate to power consumption

as shown in the Controller specication tables on pages

23 and 24.

PRODRY Recommended power cable specications

Controller Type

24VDC DMC 3

110/230VAC LED 3

Number

of cores

Cross Sectional

Area / AWG

0.75mm2 /

18 AWG

Recommended

Max. Length

3 Metres

Type

SJOW for Thermoset cable types

SVT and SJT for Thermoplastic cable types

or

Standard

Compliance

IEC 60227

or

IEC 60245

22

Page 23

Section 5: Electrical Installation

PIN OUTPUT

2

1

PIN

Earth

INPUT

N

L1 (110 VAC or 220 VAC*)

* Unit voltage rating must match supply voltage.

** Supplied from factory with jumper in female DIN

between pins 1 and 2.

12

3

12

POWER SUPPLYENERGY MANAGEMENT / ALARM

INPUT

N.C.

2

1

Energy Management Connections**

Alarm Connections

5VDC (+)

N.O.

3

12-24VDC

Section 5: Electrical Installation

Figure 5.1: LED Controlle r electrical connections

LED Controller Specifications

Ambient temperature 1.5°C to 50°C (35°F to 122°F)

Max. relative humidity 80% up to 31°C (88°F), decreasing linearly to 50% RH at 50°C (122°F)

Input voltage range (115V LED Controller) 115V, 50–60Hz,

Mains supply voltage not to exceed ±10% of nominal

Power Rating 16W (Max)

Input voltage range (230V LED Controller) 230VAC, 50-60Hz,

Mains supply voltage not to exceed 10% of nominal

Power Rating 16W (Max)

Protection class IP65

Transient over voltage IEC 60664 Class II

Pollution degree 2, IEC 60664

A circuit breaker or switch must be installed near the dryer. This should be easy to reach and shall be certified according to

EN60947-1 and EN60947-3. The switch or circuit breaker shall be marked as the disconn ecting device for th e dryer and needs

to be marked with on and positions.

Outp ut connections do not provide isolation from the mains connect ors and in terconnecting wiring must meet EN61010-1:2001

requireme nts for reinforced insulation.

LED Controller Specifications

Ambient temperature 5°C to 50°C (35°F to 122°F)

Input voltage range (115V LED Controller) 115V, 50–60Hz,

Input voltage range (230V LED Controller) 230VAC, 50-60Hz,

Protection class IP65

A circuit breaker or switch must be installed near the dryer. This should be easy to reach and shall be certified according

to EN60947-1 and EN60947-3. The switch or circuit breaker shall be marked as the disconnecting device for the dryer and

needs to be marked with on and off positions.

Figure 5.1: LED Controller electrical connections

Output connections do not provide isolation from the mains connectors and interconnecting wiring must meet EN610101:2001 requirements for reinforced insulation.

Mains supply voltage not to exceed ±10% of nominal

Mains supply voltage not to exceed 10% of nominal

Power Rating 16W (Max)

Power Rating 16W (Max)

23

Page 24

Section 5: Electrical Installation

2

3

24VDC (-)

Not used

Not used

Not used

N.O.

N.O.

Not used

Not used

Not used

Not used

Not used

Not used Not used

Not used

Not used Not used

Earth

1

PININPUT

INPUT

OUTPUT

OUTPUT

V.F.* OUTPUT

24VDC (+)

2

3

24 VDC (+)

24 VDC (-)

1

PIN

Signal (Hyg Pin 1)

Hygrometer Pin 2

Hygrometer Pin 3

2

3

1

PIN

24VDC (+)

2

3

* Volt Free

1

PIN

12-24VDC

OUTPUT

2

24VDC (-) Remote Valve Pin 2

1

PIN

24VDC (+) Remote Valve Pin 1

INPUT

INPUT

INPUT

1

2

3

1

2

3

1

2

3

1

2

3

1

2

POWER SUPPLY

HYGROMETER

ENERGY MANAGEMENT

ALARM

REMOTE DRAIN VALVE

Section 5: Electrical Installation

Figure 5.2: DMC Controller electrical connections

DMC Controller Specifications

Ambient temperature1.5°C to 50°C (35°F to 122°F)

Max. relative humidity 80% up to 31°C (88°F), decreasing linearly to 50% RH at 50°C (122°F)

Input voltage range (24VDC DMC Controller)

24VDC

Power Rating 16W (Max)

Protection class IP65

Transient over voltage IEC 60664 Class II

Pollution degree 2, IEC 60664

A circuit breaker or switch must be in stalled near the dryer. This should be easy to reach and shall be certified according to

EN60947-1 and EN60947-3. The switch or circuit breaker shall be marked as the disconnecting device for th e dryer and needs

to be marked with on and

positions.

Output co nnections do no t provide isolation from the mains connectors and in terconnecting wiring must meet EN61010-1:2001

requireme nts for reinforced insulation.

1-green

control

2-blue

3-red

1-brown

2-blue

DMC Controller Specifications

Ambient temperature 5°C to 50°C (35°F to 122°F)

Input voltage range (24VDC DMC Controller) 24VDC

Protection class IP65

Figure 5.2: LED Controller electrical connections

A circuit breaker or switch must be installed near the dryer. This should be easy to reach and shall be certified according

to EN60947-1 and EN60947-3. The switch or circuit breaker shall be marked as the disconnecting device for the dryer and

needs to be marked with on and off positions.

Output connections do not provide isolation from the mains connectors and interconnecting wiring must meet EN610101:2001 requirements for reinforced insulation.

Power Rating 16W (Max)

24

Page 25

Section 5: Electrical Installation

20 mm

3 mm

Outer insulation

must extend

through grommet

to ensure that

IP65 specification

is met

Gasket

Insert

Case

Grommet

Washer

Cable

Cable Gland

How to wire a DIN connector

Models PD0046 - PD0360

• Locate the DIN connector on the back of the controller.

• Remove the screw completely from the centre of the

connector.

• Remove the blanking plug, if present, from the

connector and discard.

• Insert a small at screwdriver into the small recess at

the edge of the insert, pry the insert out of the DIN

connector’s outer shell per gure 5.3.

• Per gure 5.4, slip cable end through DIN connector’s

cable gland, washer, grommet and out through the

front of the DIN connector case.

Cable diameter should be no greater than 6mm

(1/4”). Larger diameters do not fit well into the

cable gland of the DIN connectors.

Cable should be round as rectangular cable

or ribbon cable will not seal properly in DIN

connectors grommet.

• Strip the outer insulation of the cable back approx

20mm (3/4”).

• Strip the conductor insulation back approx 3mm (1/8”).

• Insert conductors into appropriate pins of insert.

Tighten retaining screws securely.

• Determine which direction the cable gland should

point.

• Carefully pull the cable back through the case until the

insert snaps back into place. Take care to work the wires

around the retaining screw hole as they can become

fairly easily pinched.

• Plug the DIN connector back onto the appropriate

electrical connection on the back of the dryer’s

controller per gure(s) 5.1 and 5.2. Take care to make

sure that sealing gasket is in place.

The male ground pin is slightly wider than

pins 1 & 2. Take care to ensure that the female

connector is oriented correctly.

Figure 5.3: DIN connector

Figure 5.4: DIN connector for LED and DMC Controller

25

Page 26

Section 5: Electrical Installation

LED Controller

Pin 3

Pin

1

2

3

DC Power

Supply

(Field Installed)

Remote

Visual or

Audible

Indicator

(Field Installed)

-VDC

+VDC

LED Controller

Pin 3

Pin

Pin 1

Pin 2

DMC

Controller

1

2

3

1

2

3

DC Power

Supply

(Field Installed)

Remote

Visual or

Audible

Indicator

(Field Installed)

-VDC

+VDC

+24VDC

-24VDC/COM

Remote

Visual or

Audible

Indicator

(Field Installed)

Alarm connection details

Models PD0046 - PD0360

• To enable the alarm facility, it is recommended that a

suitable cable is brought into the controller via the rear

panel with a grommet. An external power source is

required.

• Per Figures 5.5 (LED Controller) or 5.6 (DMC Controller),

connect the switching pole of an externally powered

alarm indication device to the corresponding terminals

of the controller’s alarm output.

For details regarding wiring of female DIN

connector refer to “How to wire a DIN connector”

on page 25.

Hirschmann GDS 207 industrial std DIN connector

Alarm Contact Rating (LED Controller) 3.0 AMPS 28VDC

Alarm Contact Rating (DMC Controller) 0.5 AMPS 24VDC

Alarm Connection Details

or equivalent

Fig 5. 5 Alarm contact connections (LED Controller)

Fig 5.6 Alarm contact connections (DMC Controller)

26

Page 27

Section 6: Operation

Detailed Operational Description - DMC Controller

•

•

•

•

•

•

•

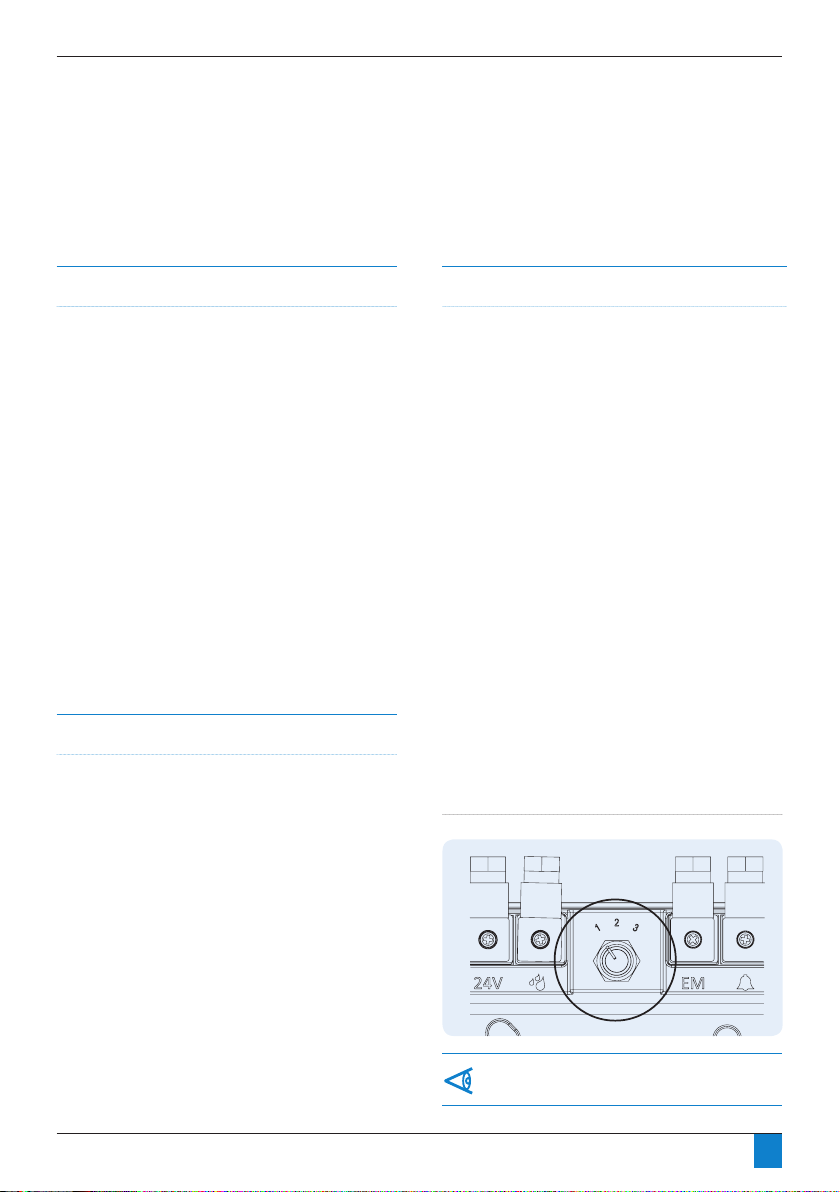

Figure 6.1: Dewp oint selection switch cont rol

Range 2: -40° (-40°F)

Required outlet pressure dewpoint:

Purge turn on value:

Range 3: -74°C (-100°F)

Required outlet pressure dewpoint:

Purge turn on value:

DMC Controller operates on a standard timed cycle as detailed

Operational status is displayed in text form on the LCD display.

Range 1: -20°C (-4°F)

Required outlet pressure dewpoint:

Purge turn on value:

-20°C (-4°F)

-23°C (-9.4°F)

-21°C (-5.8°F)

-40°C (-40°F)

-43°C (-45.4°F)

-11°C (-41.8°F)

-74°C (-100°F)

-76°C (-104.8°F)

-74°C (-100 °F)

When installed, a hygrometer allows the DMC controller to shut

selectable dewpoint ranges. The ranges are controlled by a

switch located on the upper back side of the DMC controller as

Operation

Background / Function of the dryer

PRODRY is designed to provide a smooth, controlled and

uninterrupted delivery of dry compressed air. Wet air passes

through a pre-lter and travels down to the bottom valve

assembly. The air is then fed through the bottom of the

desiccant bed and moves through the high performance

desiccant until it becomes dry. On exit from the desiccant

cartridge, the air is passed through the outlet valve assembly.

During this process, the dryer control system cycles the process

air between the two desiccant towers. While one tower is on

stream removing water vapour, the other is being carefully

depressurised in preparation for regeneration. The desiccant

bed is regenerated by expanding a small amount of dry

process air, or purge air, through the saturated desiccant.

Purge air passes to atmosphere through the silencer, which is

tted to an exhaust valve. The chamber is then repressurised,

with the control system assuring each chamber is at full

operational pressure prior to changeover.

This ensures a reliable and efcient operation. The air stream is

switched and the cycle repeats on a continuous basis.

Detailed Operational Description - LED Controller

• Refer to detailed operational schematics, gure(s)

6.3 - 6.8.

• LED Controller operates on a standard timed cycle as

detailed in Figures 6.3 through 6.8.

• Panel LED’s illuminate to indicate various service

warnings, refer to Troubleshooting in Section 11 for

specic details.

• To reduce purge loss during periods of low and / or no

air demand the Energy Management feature may be

utilised. A detailed description is given in Section 7.

• For remote indication of any faults, the Alarm Contacts

may be utilised to send a signal to a light or remote

service panel. Further details are given on page 26.

Detailed Operational Description - DMC Controller

• Refer to detailed operational schematics, gure(s) 6.3

- 6.8.

• DMC Controller operates on a standard timed cycle as

detailed in Figures 6.3 through 6.8.

• Operational status is displayed in text form on the LCD

display.

• When installed, a hygrometer allows the DMC controller

to shut off the purge when the outlet dewpoint is within

one of three selectable dewpoint ranges. The ranges are

controlled by a switch located on the upper back side of

the DMC controller as detailed in gure 6.1.

• Range 1: -20°C (-4°F)

Required outlet pressure dewpoint:

Purge shut off value:

Purge turn on value:

• Range 2: -40° (-40°F)

Required outlet pressure dewpoint:

Purge shut off value:

Purge turn on value:

• Range 3: -74°C (-100°F)

Required outlet pressure dewpoint:

Purge shut off value:

Purge turn on value:

Figure 6.1: Dewpoint selection switch control

-20°C (-4°F)

-23°C (-9.4°F)

-21°C (-5.8°F)

-40°C (-40°F)

-43°C (-45.4°F)

-41°C (-41.8°F)

-74°C (-100°F)

-76°C (-104.8°F)

-74°C (-100°F)

If the hygrometer is not installed, the DMC controller

will default to the standard timed cycle of operation.

27

Page 28

Section 6: Operation

Section 6: Operation

•

•

s

s

•

Please note that the Energy Management feature should

not be used when a hygrometer is installed in the dryer.

A

C

B

D

• If not utilising a hygrometer, purge loss may be reduced during periods of low or no air demand the

Energy Management Feature (EM) may be utilised. A detailed description is given in Section 7.

Please note that the Energy Management feature should not be used when a hygrometer is

installed in the dryer.

• For remote indication of any electrical faults, the Alarm Contacts may be utilised to send a signal to a

light or remote service panel. Further details are given on page 26.

• An optional pre-lter drain solenoid valve is available for the DMC controller. When installed per gure

4.10, the drain will open for 2 seconds at the beginning of each cycle. Operational schematic, gure

6.8 provides additional detail.

Figure 6.2: Typical installation

Start-up procedure

• Refer to gure 6.2

• Close valves A, B, C and D.

• Switch on compressor.

• Open valve A slowly.

• Check there are no leaks from the dryer

• Switch on electric power, the panel will display the

operational features.

• The dryer will enter standard cycle mode.

On initial commissioning, only run the dryer for

a minimum of 6 hours to ensure dewpoint is

adequate.

• Open valve B slowly.

Shut-down Procedure

• Close valve B.

• Close valve A.

• Leave dryer running for 15 minutes to fully depressurise.

• Switch off all electrical power to the dryer.

Under no circumstances must compressed air

be allowed to flow through the dryer following

switch off of electrical power. This will result in

terminal failure of the desiccant cartridges and

regeneration will not be possible.

28

Page 29

Section 6: Operation

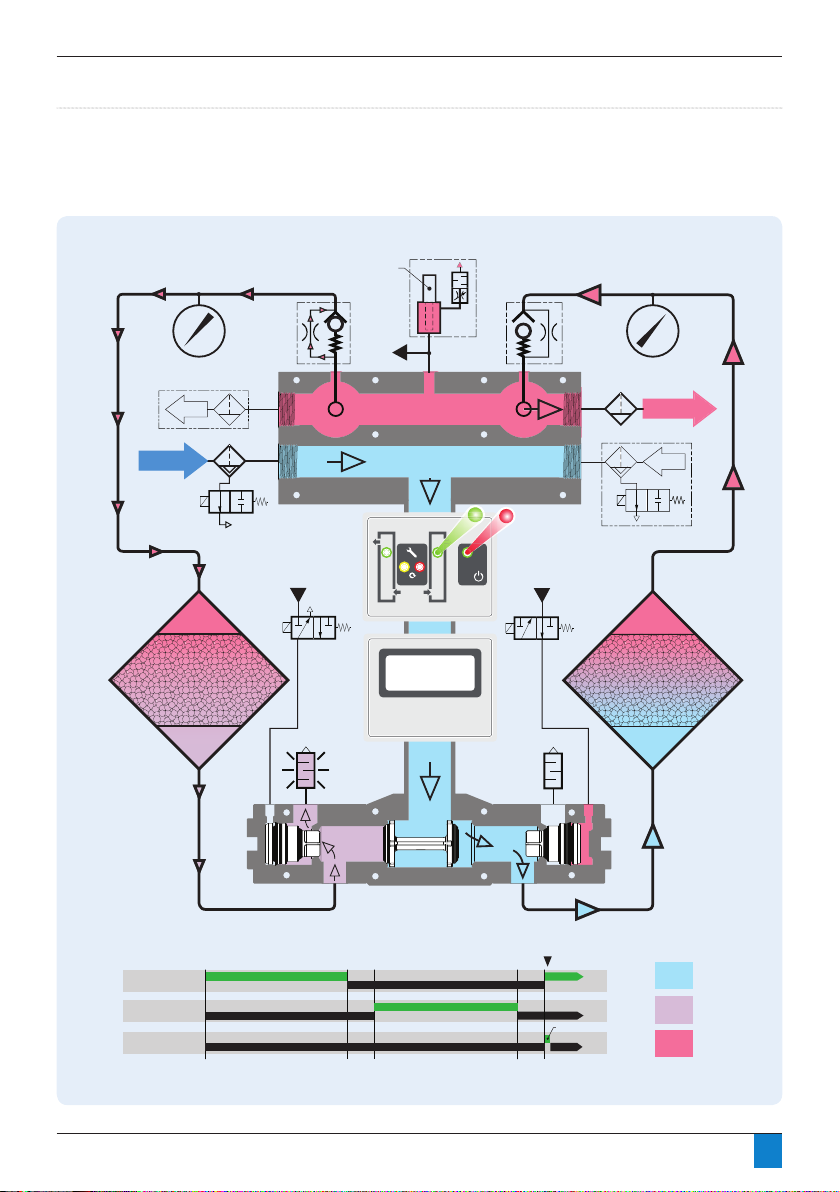

Figure 6.3: Initial Pressurisation (Power Off)

• With power off to the dryer, both towers pressurise to line pressure. All valves remain closed and the dryer remains air tight

(with the exception of a small bleed of air from the hygrometer sample block).

• Note: Any air owing through dryer, passes through both towers.

29

Page 30

Section 6: Operation

Figure 6.4: Stage 1: Left Tower Purging, Right Tower Drying

• After an initial 40 second delay, the left solenoid valve opens allowing the left exhaust shuttle valve to open. Air rushes from the

left tower out the silencer as it depressurises. For 120 seconds, a bleed of dry air from the outlet of the on-stream (right) tower

is directed through the left purge orice and down through the left tower to regenerate the off stream (left) desiccant bed.

30

Page 31

Section 6: Operation

Figure 6.5: Stage 2: Repressurisation

• At the completion of Stage 1, the left solenoid closes and the left tower repressurises for 25 seconds.

• Note: Any air owing through dryer, passes through both towers.

31

Page 32

Section 6: Operation

Figure 6.6: Stage 3: Left Tower Drying, Right Tower Purging

• At the completion of Stage 2, the right solenoid valve opens allowing the right exhaust shuttle valve to open. Air rushes

from the right tower out the silencer as it depressurises. For 120 seconds, a bleed of dry air from the outlet of the on-stream

(left) tower is directed through the right purge orice and down through the right tower to regenerate the off stream (right)

desiccant bed.

32

Page 33

Section 6: Operation

Figure 6.7: Stage 4: Repressurisation

• At the completion of Stage 3, the left solenoid closes and the left tower repressurises for 25 seconds.

• Note: Any air owing through dryer, passes through both towers.

33

Page 34

Section 6: Operation

A

INLET

OUTLET

Purge

Control

Non-Return

Valve

Purge

Control

Non-Return

Valve

To Drain Point

A

A

ON

OFF

ON

Wet

Purge

Dry

OFF

SV 2

(Right Solenoid Control Valve)

LEGEND:

SV 1

(Left Solenoid Control Valve)

ON

OFF

DV 1

(Prefilter Drain Solenoid Valve)

Seconds: 0 120 154 274308

Alternate Outlet Position

Alternate Inlet Position

RX-1

After Filter

2 Seconds

RESET

Standard Running Mode

-

Hours Run 456

Service History # 0

31

2

31

2

Left

Solenoid

Control Valve

Silencer Silencer

Right

Solenoid

Control Valve

LED

Controller

DMC

Controller

XA Pre-Filter

DV1 Optional

Drain Valve

(Optional on

DMC Models Only)

Left Tower

Pressure Gauge

Right Tower

Pressure Gauge

Left

Desiccant

Tower

Right

Desiccant

Tower

Hyg

Sample

Cell

Optional Hygrometer

(DMC Models Only)

TIMING CHART:

SV1 SV2

Figure 6.8: Drain Valve Activation

• At the completion of Stage 4, the dryer moves back to Stage 1.

• The drain valve opens at the beginning of the cycle (Stage 1) for a period of 2 seconds.

34

Page 35

Section 7: Energy Management

Fig 7. 1 Manu al switch purge contro l (LED Controller)

The following schemati

er an overview

of the devices mentioned as they might be connected for use in

details d er between device ma nufacturers, so in all cases th e

N.C.*

Manual Switch

(Field Installed)* Normally Closed, open to turn purge off

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

Signal Out to Switch

Signal Back

1

2

3

Fig 7. 1 Manu al switch purge contro l (LED Controller)

The following schemati

er an overview

of the devices mentioned as they might be co nnected for use in

details d er between device manufacturers, so in all cases the

N.C.*

Manual Switch

(Field Installed)* Normally Closed, open to turn purge off

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

Signal Out to Switch

Signal Back

Fig 7.2 Ma nual switch purge contro l (DMC Controller)

N.O.*

Signal Out to Switch (+24 VDC)

Manual Switch

(Field Installed)* Normally open, close to turn off purge

Pin 1

Pin 2

Signal Out to Switch

Signal Back

DMC

Controller

1

2

3

1

2

3

Energy Management

Please note that the Energy Management feature

should not be used when a hygrometer is

installed in the dryer.

Overview

Regenerative dryers must expel a portion of the process air

in order to free themselves of accumulated moisture. During

periods of low air demand, however, this air loss is not

necessary and is therefore undesirable. In many cases, the

compressor runs almost continuously in order to keep up with

the dryer’s purge loss.

All Walker Filtration dryers are equipped with an Energy

Management feature that allows the purge to be shut off

during periods of low or no demand. The dryer controller

is tted with a set of eld accessible contacts, that can be

employed to shut off the solenoid valves which control the

purge function of the dryer, therefore eliminating any air loss

from the dryer.

Developing a Purge Control Strategy

In order to utilise this function, the operator must provide a

switching system that provides acceptable logic to indicate to

the dryer that there is little or no air demand. On the following

pages, some examples of commonly used switching systems

are provided in ascending order of complexity.

Using a Manual Switch for Purge Control

The simplest of arrangements, a manual switch may be

employed to shut the purge off when the air downstream of

the dryer is not being used. Commonly used on point of use

systems. For example, if the dryer is only used to supply air of

an appropriate dryness to a specic machine or application,

the dryer will only be required when the machine is in use and

may be shut off either manually or possibly via extra contacts

provided in the machine’s on/off switch.

It is extremely important to understand that the purge may

only be shut off during periods of low or no demand. This

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mechanical failure. The cartridges must not be

allowed to become fully saturated at any time.

The following schematic ( Fig 7.1) offers an overview of the

devices mentioned as they might be connected for use in

controlling a dryer’s purge function. Please note that specic

details differ between device manufacturers, so in all cases the

manufacturer’s specications should be adhered to.

Fig 7. 1 Manual switch purge control (LED Controller)

Fig 7.2 Manual switch purge control (DMC Controller)

35

Page 36

Section 7: Energy Management (LED Controller)

Fig 7. 3 Standard pressure switch purge contro l (LED Controller)

Pressure Switch

(Field Installed)* Normally Closed, open to turn purge off

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

Signal Out to Switch

Signal Back

1

2

3

N.C.*

N.O.

Fig 7. 3 Standard pressure switch purge contro l (LED Controller)

Pressure Switch

(Field Installed)* Normally Closed, open to turn purge off

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

Signal Out to Switch

Signal Back

Fig 7.4 Standard pressure switch purge contro l (DMC Controller)

(Field Installed)* Normally open, close to turn off purge

Pin 1

Signal Out to Switch (+24 VDC)

Pin 2

Signal Out to Switch

Signal Back

DMC

Controller

1

2

3

1

2

3

N.C.*

N.O.

N.C.

N.O.*

Pressure Switch

Using a Standard Pressure Switch for Purge Control

Many compressors come equipped with pressure switches

with extra contacts that can be utilised to switch off the

dryer’s purge when the compressor is in an unloaded state.

Unfortunately, many of these switches have signicantly large

dead bands (difference between the load (on) and unload (off)

settings that in most cases cannot be altered). The amount of

air that can pass downstream, through the dryer, while the

compressor is unloaded must be taken into consideration as it

can be signicant, especially if there is a large dead band and/

or large wet receiver.

Often, a stand-alone pressure switch is a better option

as it allows the user to adjust it independently from the

compressor’s pressure switch. When selecting a stand-alone

pressure switch, the smaller the dead band the better.

When using a stand-alone pressure switch, the dryer is wired

into the normally closed (LED Controller) or normally open

(DMC Controller) contacts on the pressure switch. When the

switch is actuated (at 100 psig in the example), the purge

shuts off until the pressure switch deactuates (at 95 psig in

example). The point at which the switch deactuates, may be

adjusted to suit the system.

If it is determined that the dewpoint drops to an unacceptable

level, the deactuation point must be increased. Please note

that with most standard pressure switches, the dead band is

xed such that the activation and deactuation points move

together.

It is extremely important to understand that the purge may

only be shut off during periods of low or no demand. This

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mechanical failure. The cartridges must not be

allowed to become fully saturated at any time.

Figures 7.3 and 7.4 offer an overview of the devices

mentioned as they might be connected for use in controlling

a dryer’s purge function. Please note the specic details

differ between device manufacturers, so in all cases the

manufacturer’s specications should be adhered to.

Fig 7. 3 Standard pressure switch purge control (LED Controller)

Fig 7.4 Standard pressure switch purge control (DMC Controller)

36

Page 37

Section 7: Energy Management

signal)

Using an elec tronic pressure switch for purg e cont rol

The best choice if using a pressure switch is to select an

electronic programmable type pressure switch which is

effectively a pressure transmitter an d process controller

a standard pressure switch, an electronic programmable

pressure switch can be setup to provide a much more

customised operation. Typically, the dead band can be

reduced or eliminated so that an immediate reaction to

It is extremely important to understand that th e purge may

only be shut

during periods of low or no demand. Th is

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mech anical failure. Th e cartridges must not be

allowed to become fully saturated at any time.

an overview of the devices

mentioned as they might be connected for use in controlling

d er between device manufacturers, so in all cases the

Se ctio n 7: Energy Management

This setup is for example only. This configuration can be

amended, depending on application.

SYSTEM PRESSURE (psig)

PURGE ON (switch deactivated) PURGE ON (switch deactivated)

PURGE OFF (switch activated)

PURGE OFF

ON

OFF

105

100

95

90

85

85

80

ADJUST TO SUIT SYSTEM

(pressure switch deactivation point)

Fig 7.5 Pressu re switch setting

DC Power

Supply

-VDC (COM)

+VDC

+VDC

Output

COM

Electronic

Pressure Switch

Relay

N.C.*

Figure 7.6 Electr onic press ure switc h f or purge co ntro l (LED Cont)

Figure 7.7 Electr onic pressure switch for purge co ntro l (DMC Cont)

* Normally open, close to turn off purge

Pin 1

Pin 2

Signal Out to Switch (+24VDC)

DMC

Controller

1

2

3

* Normally Closed, open to turn purge off

Signal Back

DC Power

Supply

-VDC (COM)

+VDC

+VDC

Output

COM

Electronic

Pressure Switch

Relay

N.O.*

Signal Back

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

1

2

3

signal)

only be shut

during periods of low or no demand. Th is

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mech anical failure. Th e cartridges must not be

allowed to become fully saturated at any time.

an overview of the devices

mentioned as they might be connected for use in controlling

d er between device manufacturers, so in all cases the

This setup is for example only. This configuration can be

amended, depending on application.

PURGE OFF

ADJUST TO SUIT SYSTEM

Figure 7.7 Electr onic pressure switch for purge co ntro l (DMC Cont)

* Normally open, close to turn off purge

Pin 1

Pin 2

Signal Out to Switch (+24VDC)

DMC

Controller

1

2

3

DC Power

Supply

-VDC (COM)

+VDC

+VDC

Output

COM

Electronic

Pressure Switch

Relay

N.O.*

Signal Back

signal)

Se ctio n 7: Energy Management

SYSTEM PRESSURE (psig)

PURGE ON (switch deactivated) PURGE ON (switch deactivated)

PURGE OFF (switch activated)

PURGE OFF

ON

OFF

105

100

95

90

85

85

80

ADJUST TO SUIT SYSTEM

(pressure switch deactivation point)

Fig 7.5 Pressu re switch setting

Figure 7.5: Typical installation

Using an Electronic Pressure Switch for Purge Control

The best choice if using a pressure switch is to select an

electronic programmable type pressure switch which is

effectively a pressure transmitter and process controller

built into one device. While signicantly more costly than

a standard pressure switch, an electronic programmable

pressure switch can be setup to provide a much more

customized operation. Typically, the dead band can be

reduced or eliminated so that an immediate reaction to

system pressure in system indicating air ow, can

be obtained.

Figure 7.6 Electronic pressure switch for purge control (LED Controller)

It is extremely important to understand that the purge may

only be shut off during periods of low or no demand. This

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mechanical failure. The cartridges must not be

allowed to become fully saturated at any time.

Figures 7.6 and 7.7 offer an overview of the devices

mentioned as they might be connected for use in controlling

a dryer’s purge function. Please note that specic details

differ between device manufacturers, so in all cases the

manufacturer’s specications should be adhered to.

This setup is for example only. This configuration

can be amended, depending on application.

Figure 7.7 Electronic pressure switch for purge control (DMC Controller)

37

Page 38

Section 7: Energy Management

Process Controller

Dewpoint

Transmitter

Relay

Signal

+VDC

COM

N.C.*

Figure 7.8 : Process controller & hygrometer (LED Controller)

DC Power

Supply

-VDC (COM)

+VDC

+VDC

COM

Signal In

Signal Out

* Normally Closed, open to turn purge off

Signal Back

Signal Out

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

1

2

3

Process Controller

Dewpoint

Transmitter

Relay

Signal

+VDC

COM

N.C.*

Figure 7.8 : Process controller & hygrometer (LED Controller)

Figure 7.9 : Process controller & hygrometer (DMC Controller)

DC Power

Supply

-VDC (COM)

+VDC

+VDC

COM

Signal In

Signal Out

* Normally Closed, open to turn purge off

Signal Back

Signal Out

LED Controller

Pin 1

(Puts out

+5 VDC

signal)

Pin 2

1

2

3

Process Controller

Dewpoint

Transmitter

Relay

Signal

+VDC

COM

N.O.*

DC Power

Supply

-VDC (COM)

+VDC

+VDC

COM

Signal In

Signal Out

Signal Back

Signal Out

Pin 1

Pin 2

Signal Out to Switch (+24VDC)

DMC

Controller

1

2

3

* Normally open, close to turn off purge

Using a hygrometer and process controller for

purge control

The best option for purge control if the delivered dryness

(pressure Dewpoint) of the air from the dryer is critical. If the

air is deemed dry enough, than the purge can be shut off until

the air’s moisture starts to climb. If the purge is turned off,

care must be taken to ensure that the desiccant beds are not

allowed to wet out too far before the purge is turned back

on. Also, after turning the purge back on, the air’s pressure

Dewpoint may increase a bit before starting to drop again.

This should be taken into consideration to ensure that the air

ow remains sufciently dry.

It is extremely important to understand that the purge may

only be shut off during periods of low or no demand. This

feature, if used otherwise, can result in permanent damage

to the desiccant beds resulting in loss of drying capacity

and possibly mechanical failure. The cartridges must not be

allowed to become fully saturated at any time.

Figures 7.8 and 7.9 offer an overview of the devices

mentioned as they might be connected for use in controlling

a dryer’s purge function. Please note that specic details

differ between device manufacturers, so in all cases the

manfacturer’s specications should be adhered to.

Making connections between a switching device &

dryer Energy Management contact

Cable / Wire Selection Criteria:

Selected wire should have:

At least 2 conductors. More conductors can be useful in

the case of a conductor break. Conductors can be swapped

without having to run new cable.

• A conductor gauge of no greater than 18 awg is

• An outside diameter of no greater than 6mm (1/4”).

• An insulation type compatible with the environment that

recommended to t comfortably into the DIN connector

insert.

Larger diameters do not t well into the cable gland of the

EM DIN connectors.

it will be run in.

Figure 7.8: Process controller & hygrometer (LED Controller)

Figure 7.9: Process controller & hygrometer (DMC Controller)

This setup is for example only. This configuration

can be amended, depending on application.

38

Page 39

Section 7: Energy Management

Figure 7.11 : Connecting to EM port (LED Controller)

LED Controller

EM Port

Figure 7.11 : Connecting to EM port (LED Controller)

DMC

Controller

LED Controller

EM Port

Figure 7.12 : Connecting to EM port (DMC Controller)

EM Port

Figure 7.11 : Connecting to EM port (LED Controller)

Figure 7.13 : Din co nnector for LED and DMC Controller

DMC

Controller

LED Controller

EM Port

Figure 7.12 : Connecting to EM port (DMC Controller)

EM Port

20 mm

3 mm

Outer insulation

must extend

through grommet

to ensure that

IP65 specification

is met

Gasket

Insert

Case

Grommet

Washer

Cable

Cable Gland

Se ctio n 7: Energy Management

Making connections between a switching device and dryer

Energy Management contact.

•

check continuity at the dryer end before connecting to the

dryer. Make sure that the co ntacts on the switch are normally

closed for the LED Controller and normally open for the DMC

Controller. Pi n 1 of the dryer EM co nnection puts out a 5 VDC

signal on the LED Controller and 24VDC on the DMC Controller.

Take care to ensure that the contacts on the switching

device are ‘dry’ and free of any voltage which could harm the

dryer controller.

•Locate the DIN connector on the ba ck of the controller

(Figure(s) 7.11 and 7.12).

•Remove the screw completely from the centre of the

connector.

•Remove the blanking plug from the connector and discard.

of the insert, pry the insert out of the DIN connectors outer

shell per

ure 7.10.

•

•For LED Controller, remove the jumper wire which is between

plug 1 and 2 and di scard.

•Slip cable en d through DIN connector’s cable gland, washer,

grommet and out through the front of the DIN connector case.

•Strip the outer insulation of the cable back a

pprox 20mm

(3/4”).

•Strip the conductor insulation back approx 3mm (1/8”).

•If possible using a meter, ve rify the switch function.

•Insert conductors into pins 1 & 2 of insert. Tighten retaining

screws securely.

•Determine which direction the cable gland should point.

•Carefully pull the cable back through the shell until the insert

snaps back into place. Take care to work the wires around the

retaining screw hole as they can become fairly easily pinched.

•Plug the DIN connector back onto the dr yer’s EM co nnection

taking care to make sure that sealing gasket is in place.

Figure 7.10: DI N conn ecto r

Figure 7.11 : Connecting to EM port (LED Controller)

Figure 7.13 : Din co nnector for LED and DMC Controller

DMC

Controller

LED Controller

EM Port

Figure 7.12 : Connecting to EM port (DMC Controller)

EM Port

The male ground pin is slightly wider than pins 1 & 2.

Take care to ensure that the female connector is

oriented corectly.

20 mm

3 mm

Outer insulation

must extend

through grommet

to ensure that

IP65 specification

is met

Gasket

Insert

Case

Grommet

Washer

Cable

Cable Gland

Making connections between a switching device and

dryer Energy Management contact.

• Make the connection at the switch end rst. This way you

can check continuity at the dryer end before connecting

to the dryer. Make sure that the contacts on the switch are

normally closed for the LED Controller and normally open

for the DMC Controller. Pin 1 of the dryer EM connection

puts out a 5 VDC signal on the LED Controller and 24VDC

on the DMC Controller. Take care to ensure that the

contacts on the switching device are ‘dry’ and free of any

voltage which could harm the dryer controller.

• Locate the DIN connector on the back of the controller

• Remove the screw completely from the centre of the

• Remove the blanking plug from the connector and

• Insert a small at screwdriver into the small recess at

• For LED Controller, remove the jumper wire which is

(Figure(s) 7.11 and 7.12).

connector.

discard.

the edge of the insert, pry the insert out of the DIN

connectors outer shell per gure 7.10.

between plug 1 and 2 and discard.

• Slip cable end through DIN connector’s cable gland,

washer, grommet and out through the front of the DIN

connector case.

• Strip the outer insulation of the cable back approx 20mm

(3/4”).

• Strip the conductor insulation back approx 3mm (1/8”).

• If possible using a meter, verify the switch function.

• Insert conductors into pins 1 & 2 of insert. Tighten

retaining screws securely.

• Determine which direction the cable gland should point.

• Carefully pull the cable back through the shell until the

insert snaps back into place. Take care to work the wires

around the retaining screw hole as they can become fairly

easily pinched.

• Plug the DIN connector back onto the dryer’s EM

connection

Figure 7.10: DIN connector

The male ground pin is slightly wider than

pins 1 & 2. Take care to ensure that the female

connector is oriented correctly.

Figure 7.11: Connecting to EM port (LED Controller)

Figure 7.12: Connecting to EM port (DMC Controller)

Figure 7.13: Din connector for LED and DMC Controller

39

Page 40

Section 8: Maintenance

Maintenance

Information

All maintenance information is provided in service /

maintenance leaets. These leaets are provided with each

serviceable item / kit showing how to carry out the change-out

component. The service leaet part numbers are shown

below:-

04 1220 001 01 (Desiccant Cartridge service leaet)

04 1220 002 01 (Purge Orice disc service leaet)

04 1220 003 01 (Exhaust Silencer service leaet)

04 1220 004 01 (Main Shuttle service leaet)

04 1220 005 01 (Exhaust Shuttle service leaet)

Service Intervals / Applicable Service Kits

Pre- Filter Element Every 1 year or 6000 hours

Exhaust silencer Every 1 year or 6000 hours

Desiccant cartridges Every 2 years or 12000 hours

Main shuttle Every 4 years or 24000 hours

Exhaust shuttle Every 4 years or 24000 hours

Solenoid valves Every 4 years or 24000 hours

Purge orice Every 4 years or 24000 hours

Important information.

Ensure shutdown and start-up procedures are

followed prior to carrying out any maintenance

work on the dryer.

Walker Filtration will not accept responsibility

for physical injury, damage or delays caused by

failure to observe the instructions in this manual

and manuals provided with your equipment.

40

Page 41

Section 9: Spares Information

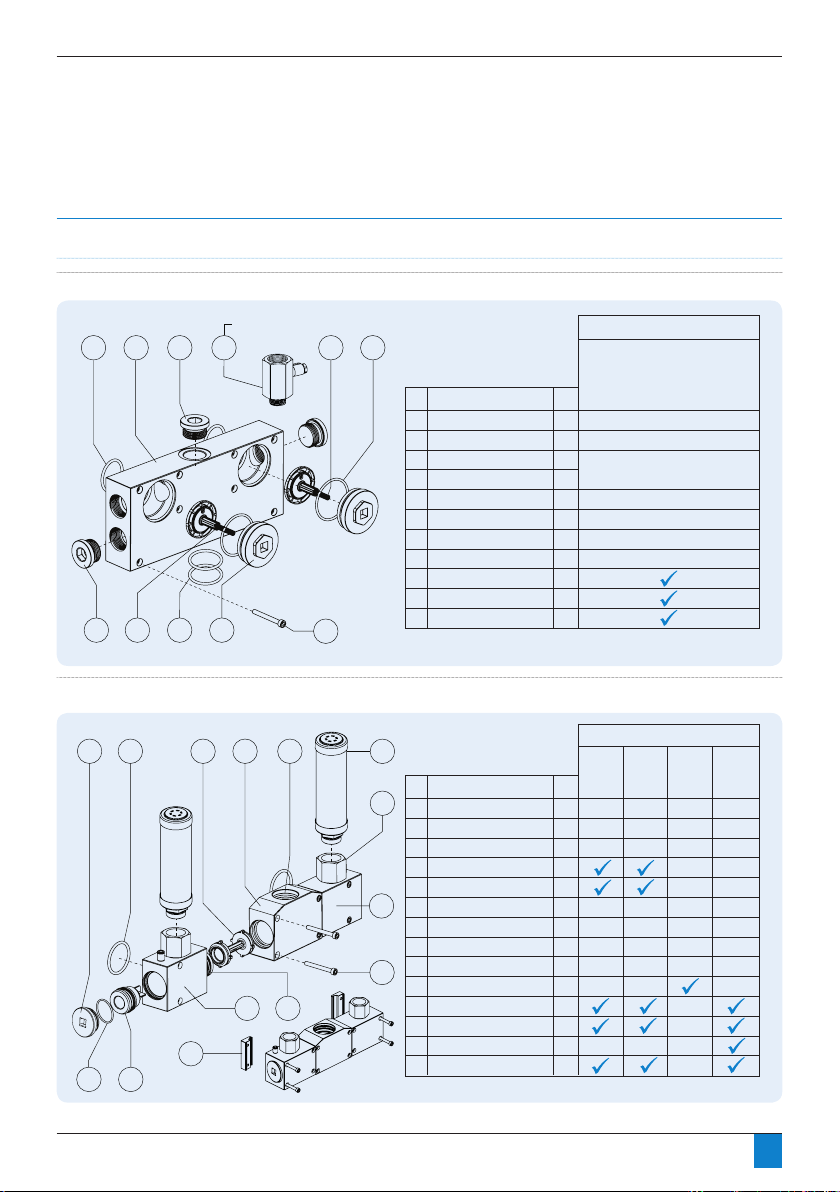

Service kits

6,000 hour, Silencer Service kit

Dryer Model Kit Part Number Description Change-Out Period

PD0046 - PD0360 PD3SK01

Silencer Kit (Kit includes (2) silencers; reference gure 10.2)

12,000 hour, Desiccant Cartridge & Silencer Service Kit

Dryer Model Kit Part Number Description Change-Out Period

PD0046 PDSK0046-12000

PD0056 PDSK0056-12000 12,000 Hours or 2 Years

PD0075 PDSK0075-12000 12,000 Hours or 2 Years

PD0090 PDSK0090-12000 12,000 Hours or 2 Years

PD0110 PDSK0110-12000 12,000 Hours or 2 Years

PD0150 PDSK0150-12000 12,000 Hours or 2 Years

PD0180 PDSK0180-12000 12,000 Hours or 2 Years

PD0220 PDSK0220-12000 12,000 Hours or 2 Years

PD0300 PDSK0300-12000 12,000 Hours or 2 Years

PD0360 PDSK0360-12000 12,000 Hours or 2 Years

12,000 Hour Desiccant Cartridge and Silencer Kit

(Kit includes desiccant cartridges and associated

seals, and silencer service kit;

reference gures 10.2, 10.3 and 10.4)

12,000 hour, High Performance Desiccant Cartridge & Silencer Service Kit - for use where -74°C (-100°F) dewpoint is required

Dryer Model Kit Part Number Description Change-Out Period

PD0046 PDSK0046BA-12000

PD0056 PDSK0056BA-12000 12,000 Hours or 2 Years

PD0075 PDSK0075BA-12000 12,000 Hours or 2 Years

PD0090 PDSK0090BA-12000 12,000 Hours or 2 Years

PD0110 PDSK0110BA-12000 12,000 Hours or 2 Years

PD0150 PDSK0150BA-12000 12,000 Hours or 2 Years

PD0180 PDSK0180BA-12000 12,000 Hours or 2 Years

PD0220 PDSK0220BA-12000 12,000 Hours or 2 Years

PD0300 PDSK0300BA-12000 12,000 Hours or 2 Years

PD0360 PDSK0360BA-12000 12,000 Hours or 2 Years

12,000 Hour High Performance Desiccant Cartridge

(Kit includes High Performance desiccant cartridges and

associated seals, and silencer service kit;

and Silencer Kit

reference gures 10.2, 10.3 and 10.4)

6,000 Hours or 1 Year

12,000 Hours or 2 Years

12,000 Hours or 2 Years

18,000 hour, Silencer Service kit

Dryer Model Kit Part Number Description Change-Out Period

PD0046 - PD0360 PD3SK01

Silencer Kit (Kit includes (2) silencers; reference gure 10.2)

18,000 Hours or 3 Years

41

Page 42

Section 9: Spares Information

Service kits

24,000 Hour, Desiccant Cartridge, Silencer, Valve & Purge Valve Service Kit

Voltage

Dryer Model Kit Part Number Description Change-Out Period

PD0046 PDSK0046-24000-S24

PD0056 PDSK0056-24000-S24 24,000 Hours or 4 Years

PD0075 PDSK0075-24000-S24 24,000 Hours or 4 Years

PD0090 PDSK0090-24000-S24 24,000 Hours or 4 Years

PD0110 PDSK0110-24000-S24 24,000 Hours or 4 Years

PD0150 PDSK0150-24000-S24 24,000 Hours or 4 Years

DMC 24VLED 115VLED 230V

PD0180 PDSK0180-24000-S24 24,000 Hours or 4 Years

PD0220 PDSK0220-24000-D24 24,000 Hours or 4 Years

PD0300 PDSK0300-24000-D24 24,000 Hours or 4 Years

PD0360 PDSK0360-24000-D24 24,000 Hours or 4 Years

PD0046 PDSK0046-24000-S115

PD0056 PDSK0056-24000-S115 24,000 Hours or 4 Years

PD0075 PDSK0075-24000-S115 24,000 Hours or 4 Years

PD0090 PDSK0090-24000-S115 24,000 Hours or 4 Years

PD0110 PDSK0110-24000-S115 24,000 Hours or 4 Years

PD0150 PDSK0150-24000-S115 24,000 Hours or 4 Years

PD0180 PDSK0180-24000-S115 24,000 Hours or 4 Years

PD0220 PDSK0220-24000-D115 24,000 Hours or 4 Years

PD0300 PDSK0300-24000-D115 24,000 Hours or 4 Years

PD0360 PDSK0360-24000-D115 24,000 Hours or 4 Years

PD0046 PDSK0046-24000-S230

PD0056 PDSK0056-24000-S230 24,000 Hours or 4 Years

PD0075 PDSK0075-24000-S230 24,000 Hours or 4 Years

PD0090 PDSK0090-24000-S230 24,000 Hours or 4 Years

PD0110 PDSK0110-24000-S230 24,000 Hours or 4 Years

PD0150 PDSK0150-24000-S230 24,000 Hours or 4 Years

PD0180 PDSK0180-24000-S230 24,000 Hours or 4 Years

PD0220 PDSK0220-24000-D230 24,000 Hours or 4 Years

PD0300 PDSK0300-24000-D230 24,000 Hours or 4 Years

PD0360 PDSK0360-24000-D230 24,000 Hours or 4 Years

24,000 hour Desiccant Cartridge, Silencer,

Valve & Purge Valve Service Kit

(Kit includes desiccant cartridges and associated