Page 1

OWNER’S MANUAL

Safety, Assembly, Operating, and Maintenance Instructions

and ILLUSTRATED PARTS MANUAL

IH6620 Implement Hitch, RB6650 Rotary Broom, DB6660 Dozer Blade,

SB6670 Two-Stage Snowblower and DB6680 Debris Blower

Please Read and Save These Instructions Effective Date 06-01-01

For Safety, Read All Safety and Operation P/N I375

Instructions Prior to Operating Machine Price $5.00

Page 2

Foreword

Thank you. . .for purchasing a Walker implement. Every effort has been made to provide you with

the most reliable product on the market, and we are sure you will be among our many satisfied customers. If for any rea son thi s produ ct d oes no t per fo rm to y our expectations, please contact u s at

(970) 221-5614. Every customer is important to us. Your satisfaction is our goal.

Please. . .read thi s manual thoroughl y! This manual is to be use d in conjunction with the mo wer

owner’s manual and the engine manufacturer's manual for the specific engine on the mower

model you are using. Before you operate your new impl ement, please read this enti re manual.

Some of the information is crucial for proper operation and maintenance of this product - it will help

protect your investment and ensure that the implement performs to your satisfaction. Some of the

information is important to yo ur safety and must be r ead and understo od to help prev ent possibl e

injury to the operator or others. If anything in this manual is confusing or hard to understand,

please call our service department, at (970) 221-5614, for clarification before operating or servicing this product.

This manual cove rs the Model IH6620 Imple ment Hitch, RB6650 Rotary Broom, DB6660 Dozer

Blade, SB6670 Two-Stage Snowblower, and DB6680 Debris Blower.

All shields and guards must be in place for the proper and saf e operation of these implements. Where they are shown removed in this manu al , it i s for i ll ust ra tio n purpo ses only. Do not

operate this product unless all shields and guards are in place.

Specifications given are based on the latest information available at the time this manual was

produced.

Walker Mfg. Co. is continuall y str iv ing to improve the desi gn and per for ma nc e of its prod uc ts. We

reserve the right t o m ake chan ges i n sp ecifi catio ns and desi gn wi thout th ereby i ncur ring an y obl igation relative to previously manufactured products.

Sincerely,

WALKER MANUFACTURING COMPANY

Bob Walker, President

Page 3

Table of Contents

Owner’s Manual

General Information ________________ 1

HIGHLIGHTED INFORMATION _____________ 1

GLOSSARY ____________________________ 1

IDENTIFYING NUMBER LOCATIONS________ 1

SERVICING OF DRIVETRAIN GEARBOX ____ 3

UNIT DESCRIPTIONS ____________________ 3

Implement Hitch _______________________ 3

Dozer Blade __________________________ 3

Rotary Broom _________________________ 3

Two-Stage Snowblower_________________ 3

Debris Blower_________________________ 3

Specifications _______________________ 4

IMPLEMENT HITCH ______________________ 4

DOZER BLADE__________________________ 4

ROTARY BROOM________________________ 4

TWO-STAGE SNOWBLOWER _____________ 5

DEBRIS BLOW ER _______________________ 6

Component Identification___________ 7

IMPLEMENT HITCH ______________________ 7

DOZER BLADE__________________________ 8

ROT ARY BROOM ________________________ 9

TWO-ST A GE SNOWB LOWER_____________ 10

DEBRIS BLOW ER ______________________ 12

Safety Instructions _________________ 14

BEFORE OPERATING___________________ 14

OPERATING ___________________________ 15

MAINTENANCE ________________________ 16

SAFETY, CONTROL,

AND INSTRUCTION DECALS _____________ 17

Assembly Instructions _____________ 19

SETUP INSTRUCTIONS _________________ 19

IMPLEMENT HITCH_____________________ 19

Implement Hitch Installation ____________ 19

Implement Hitch Wiring________________ 20

DOZER BLADE_________________________ 23

Dozer Blade Assembly ________________ 23

Dozer Blade Installation _______________ 24

ROTARY BROOM_______________________ 24

Rotary Broom Installation______________ 24

Optional Gauge Wheel Installation_______ 26

TWO-STAGE SNOWBLOWER ____________ 27

Snowblower Assembly ________________ 27

Snowblower Installation _______________ 28

DEBRIS BLOWER ______________________ 31

Debris Blower Installation______________ 31

PREOPERATING CHECKLIST ____________ 32

Implement Hitch______________________ 32

Dozer Blade _________________________ 32

Rotary Broom________________________ 32

Two-Stage Snowblower________________ 33

Debris Blower _______________________ 33

Operating Instructions_____________ 34

TRACTOR CONTROLS__________________ 34

STARTING THE MACHINE _______________ 34

IMPLEMENT HITCH CONTROLS __________ 34

Implement Lift Switch _________________ 34

Hitch Locking Lever __________________ 34

DOZER BLADE CONTROLS______________ 35

Angle Adjustment Pin _________________ 35

Trip Spring __________________________ 35

DOZER BLADE OPERATION _____________ 35

Raising and Lowering the Blade ________ 35

Normal Operation ____________________ 35

Rigid Blade Operation_________________ 36

Speed Recommendations______________ 36

ROTARY BROOM CONTROLS____________ 36

Ground Contact Knob_________________ 36

Angle Adjustment Lever _______________ 37

ROTARY BROOM OPERATION ___________ 37

Raising and Lowering the Broom _______ 37

Engaging the Rotary Broom____________ 37

General Sweeping ____________________ 37

Snow Removal_______________________ 38

Lawn Thatching and Leaf Raking _______ 38

TWO-STAGE SNOWBLOWER CONTROLS__ 38

Chute Rotation Handle ________________ 38

Deflector Position Control Knobs _______ 38

TWO-STAGE SNOWBLOWER OPERATION _38

Raising and Lowering the Snowblower___ 38

Engaging the Snowblower _____________ 39

Recommendations For Snowblowing ____ 39

Removing Snow______________________ 40

Clogging Checklist ___________________ 40

DEBRIS BLOWER CONTROLS ___________ 41

Chute Rotation Handle ________________ 41

Deflector Position Control Knob ________ 41

DEBRIS BLOWER OPERATION___________ 41

Raising and Lowering the Debris Blower _41

Engaging the Debris Blower____________ 42

Recommendations for

Operating the Debris Blower ___________ 42

STOPPING THE MACHINE _______________ 42

Page 4

Table of Contents

Maintenance Instructions__________ 43

MAINTENANCE SCHEDULE CHART _______ 43

LUBRICATION _________________________ 44

Rotary Broom Gearbox ________________ 44

Rotary Broom Drive Chain _____________ 44

Two-Stage Snowblower Gearbox ________ 45

Two-Stage Snowblower

Reduction Chain______________________ 45

Grease Fitting and Oil Point Lubrication__ 45

Implement HItch _____________________ 46

Dozer Blade ________________________ 48

Rotary Broom _______________________ 50

T wo-Stage Snowblower _______________ 52

Debris Blower _______________________ 54

REPLACING/REPAIRING ________________ 56

Dozer Blade Cutting Edge______________ 56

Rotary Broom Brush __________________ 56

Rotary Broom Gearbox ________________ 57

Rotary Broom Drive Chain _____________ 57

Rotary Broom Drive Shaft Sprocket______ 58

Two-Stage Snowblower Cutting Edge ____ 59

Two-Stage Snowblower Gearbox ________ 60

Two-Stage Snowblower

Reduction Chain______________________ 60

Two-Stage Snowblower

Reduction Sprocket___________________ 61

Debris Blower Drive Belt _______________ 61

Debris Blower Rotation Pinions _________ 62

ADJUSTMENTS ________________________ 62

Dozer Blade Skid Shoes _______________ 62

Rotary Broom Brush Leveling __________ 63

Rotary Broom Gauge Wheels ___________ 63

Rotary Broom Drive Chain Tension ______ 64

Two-Stage Snowblower Skid Shoes______ 64

Two-Stage Snowblower

Reduction Chain Tension ______________ 64

Debris Blower Front Gauge Wheel_______ 65

Debris Blower Drive Chain Tension ______ 65

Debris Blower Rotation Pinions _________ 66

Debris Blower Rotation Handle _________ 66

TORQUE SPECIFICATIONS ______________ 67

Removal and Storage Instructions _68

REMOVAL ____________________________ 68

Removing Attachments

From Implement Hitch_________________ 68

Dozer Blade ________________________ 68

Rotary Broom _______________________ 68

T wo-Stage Snowblower _______________ 69

Debris Blower_______________________ 69

Removing Implement

Hitch From T ractor ___________________ 70

END OF SEASON STORAGE _____________ 70

Implement Hitch______________________ 70

Dozer Blade _________________________ 70

Rotary Broom________________________ 71

Two-Stage Snowblower________________ 71

Debris Blower _______________________ 71

Illustrated Parts Manual

IMPLEMENT HITCH ASSEMBLY __________ 72

IMPLEMENT HITCH

ELECTRICAL COMPONENTS ____________ 74

DOZER BLADE ASSEMBLY ______________ 76

ROTARY BROOM ASSEMBLY ____________ 78

ROTARY BROOM DRIVE COMPONENTS ___ 80

SNOWBLOWER HOUSING COMPONENTS _82

SNOWBLOWER DRIVE COMPONENTS ____ 84

DEBRIS BLOWER COMPONENTS_________ 86

DEBRIS BLOWER MANUAL

ROTATION COMPONENTS_______________ 88

KEY TO ABBREVIATIONS

USED IN ILLUSTRATED PARTS LIST ______ 90

Warranty___________________________ 91

Page 5

General Information

HIGHLIGHTED INFORMATION

Walker Manufacturing recommends that any service requiring special training or tools be performed

by an authorized Walker Mower Dealer. There are

several general practices to be aware of in the area

of safety. Most accidents associated with the operation or maintenance of a Walker product are

caused by disregardi ng bas ic saf ety pr ecautio ns or

specific warnings. Such accidents, in most cases,

can be prevented by being aware of the dangers

present.

Information of special importance has been highlighted in bold type in this man ual. Refer to Safety

Instructions for the mean ing s of DANGE R, WARNING, CAUTION, IMPORTANT, and NOTE.

GLOSSARY

There are many ter ms th at ar e ei ther uni que to th is

equipment or that ar e used as acronyms. T he following terms and their defin iti ons wil l help whi le using this manual.

• FORW ARD SPEED CONTROL (FSC) controls

the maximum forward speed of the tractor; functioning as a cruise control.

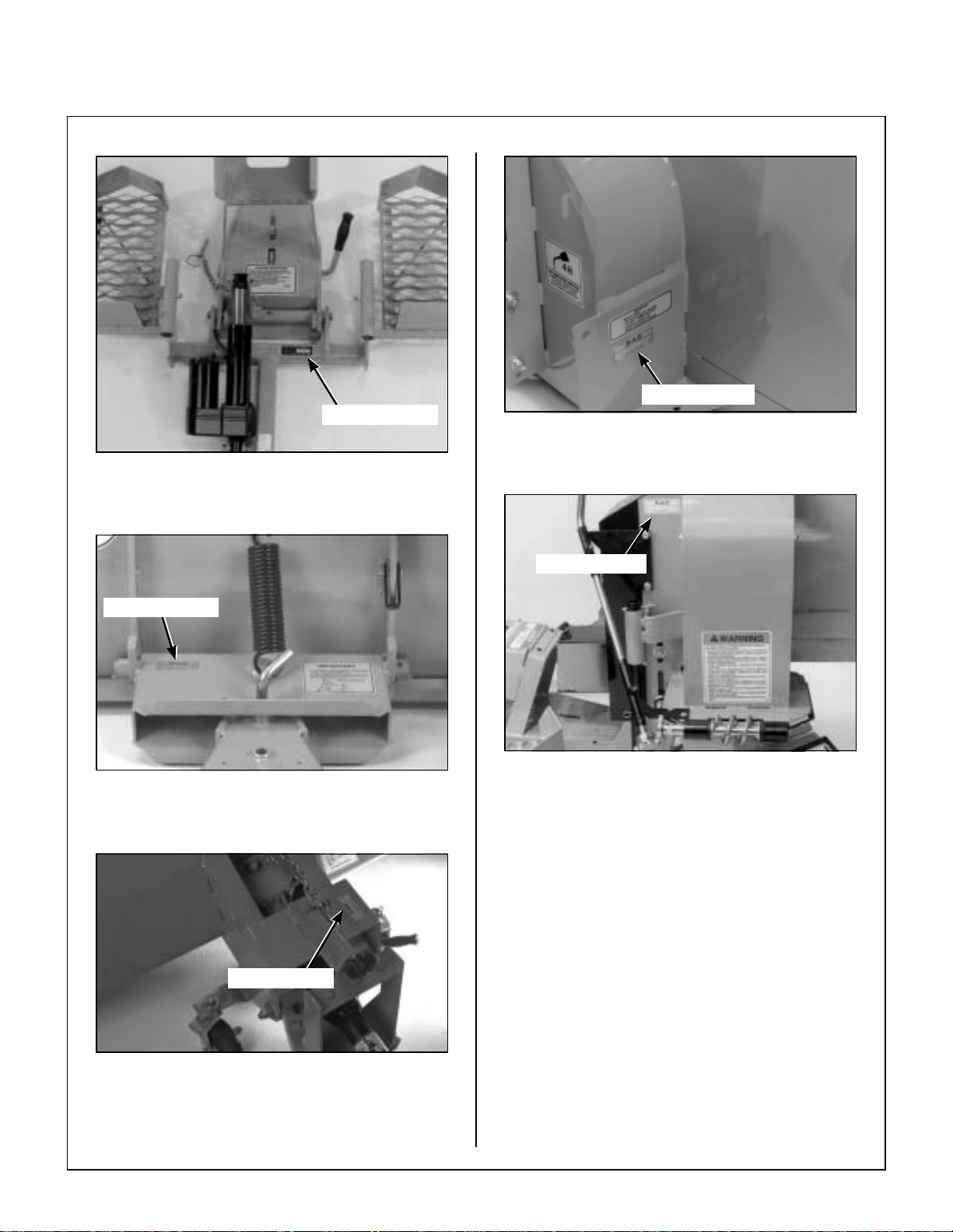

IDENTIFYING NUMBER LOCATIONS

The implement hitch seri al number is affixed to the

top of the male hitch assembly, underneath the

PTO shield. The dozer blade serial num ber is affixed to the LH side of the hitch box on the back

side of the blade. The rotary broom serial number

is affixed on the RH side of the pivot bracket. The

snowblower serial number is affixed on the RH side

of the snowblower head frame. The de bris blower

serial number is a ffixed to th e top RH side of the

hitch. Model and serial numbers are helpful when

obtaining replacement parts and maintenance assistance. For ready refere nce, please record thes e

numbers in the space provided.

Implement Hitch Model No. _______________

Implement Hitch Serial No. _______________

Dozer Blade Model No. __________________

Dozer Blade Serial No. __________________

Rotary Broom Model No. _________________

Rotary Broom Serial No. _________________

IH6620

DB6660

RB6650

• IMPLEMENT r efers to the dozer blade, rotary

broom, two-stage snowblower, or debris blower

used with the tractor with an implement hitch installed.

• LEFT HAND (LH) refers to the left-hand side of

the machine when the operator is seated facing

forward in the tractor seat.

• MACHINE consists of the implemen t installed

on the tractor, functioning as a single unit.

• POWER TAKE-OFF (PTO) transmits engine

power to run the rotary broom, two-stage snowblower, or debris blower.

• RIGHT HAND (RH) refers to the right-hand side

of the machine when the operator is seated facing forward in the tractor seat.

• TRACTOR is the prime mover, including the en-

gine, drivetrain, o perator seat, and contr ols to

operate the implement.

Two-Stage Snowblower Model No. _________

Two-Stage Snowblower Serial No. _________

Debris Blower Model No. _________________

Debris Blower Serial No. _________________

Date of Purchase _______________________

Fill In By Purchaser

SB6670

DB6680

1

Page 6

General Information

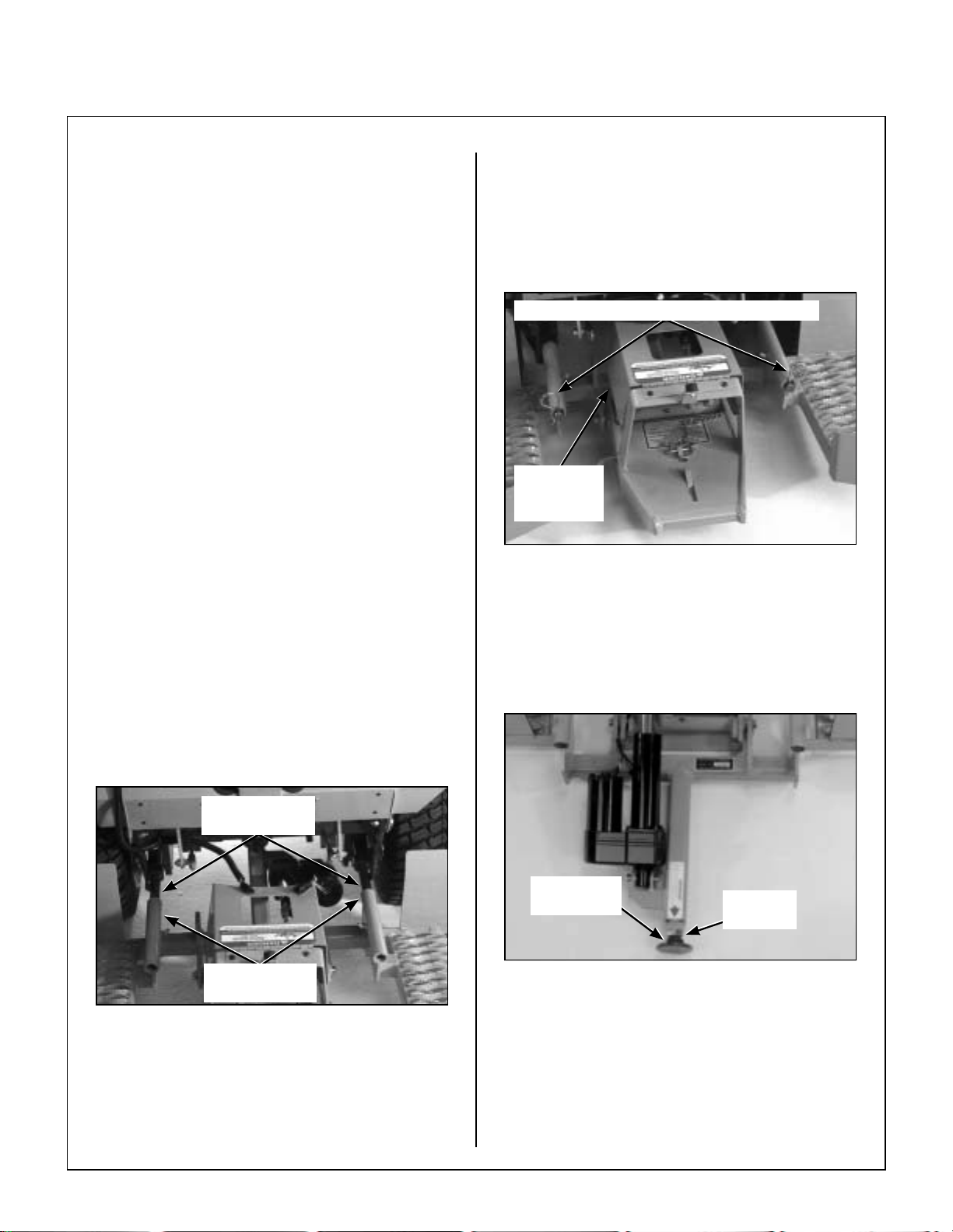

Implement Hitch Serial Number Location

(Top View)

Serial Number

Serial Number

Two-Stage Snowblower Serial Number Location

(Rear View and RH View)

Serial Number

Dozer Blade Serial Number Location

(Rear View)

Serial Number

Serial Number

Debris Blower Serial Number Location

(Rear View and RH View)

Rotary Broom Serial Number Location

(Rear View)

2

Page 7

General Information

SERVICING OF DRIVETRAIN GEARBOX

Detailed servicing an d repair of the gearbox used

on the implement attachments is not covered in this

manual. Only routine maintenance and general

service instructions are provided. For the service

of the gearbox during the lim ited warranty period, i t

is important to find a local, authorized servicing

agent of the component manufacturer. Any unau-

thorized work done on these components during

the warranty period may void the warranty. If you

have any difficulty finding an authorized outlet or

obtaining warranty service, please contact our Service Department for assistance:

Walker Manufacturing Company

5925 E. Harmony Road

Fort Collins, CO 80528

1-970-221-5614

A service manual is available for the gearbox from:

Tecumseh Products Co.

900 North Street

Grafton, Wl 53024

Rotary Broom

The rotary broom has a 47- inch (119 cm) sweeping

path and five-position RH/LH ang le head . It is su itable for light snow removal, lawn dethatching/raking and general hard surfa ce sweep ing. It is raised

and lowered automatically with the lift control

switch. The rotary broom is powered by the tractor

PTO through the PTO shaft, gearbox and chain fi nal drive to brush drive shaft. Tire chains and a soft

cab are available as optional equipment.

Two-Stage Snowblower

The 42-inch (107 cm) two-stage snowblower

throws snow up to 40 ft (12 m). It is raised and lowered automatically with the l ift control switch. The

blower spout is controlled with a simple position

control handle. The snowbl ower is pow ered by the

tractor PTO through the PTO shaft, snowblower

drive shaft, and gearbox. Tire chains and a soft

cab are available as optional equipment.

Debris Blower

UNIT DESCRIPTIONS

Implement Hitch

The implement hi tch is required to mount each of

the implements to the tra ctor. It clips on the tractor

in place of the mower dec k in less than a minute.

Each implement slides on the male hitch and easily

locks in place. The mount assembly also includes

operator footrests and an electric power lift. The lift

control switch is mounted on the FSC lever for convenient operator use , and is powered by th e linear

actuator on the implement hitch.

Dozer Blade

The 46-inch (117 cm) dozer blade has a five-position RH/LH angle adjustment. It is used for removal

of snow, loose dirt, and gravel, and is raised and

lowered automatically with the lift control switch.

The dozer blade is d esigned to “trip” forward when

striking a large object, eliminating shock to the tractor and operator. Tire chains and a soft cab are

available as optional equipment.

The debris blower is us ed for parking lot cleaning

and leaf control. It is raise d and lowered autom atically with the lift control switch. The directional

spout adjusts manually. The debris blower is powered by the tractor PTO through the PTO shaft.

Tire chains and a soft cab are availabl e as opt ional

equipment.

IMPORTANT: These imp lements are not intended

for use with Model MS tractors.

3

Page 8

Specifications

MODEL IMPLEMENTS

IMPLEMENT HITCH

Height 10 in. (25 cm)

Width 33-1/2 in. (85 cm)

Length 30 in. (76 cm)

Overall Length Installed on Tractor 69-3/4 in. (177 cm)

Weight 70 lb (32 kg)

Lift 12 Volt DC Electric Ram Linear Actuator, Operated by Toggle Switch

Mounted on FSC Lever

DOZER BLADE

Height 17-1/2 in. (44 cm)

Width 46 in. (117 cm)

Length Standard Hitch: 22-1/2 in. (57 cm)

Long Hitch: 28-1/2 in. (72 cm)

Longest Hitch: 35 in. (89 cm)

Overall Length Installed on Tractor 87 in. (221 cm), Typical

Weight (minimum) 102 lb (46 kg)

Lift 12 Volt DC Electric Ram Linear Actuator, Operated by Toggle Switch

Mounted on FSC Lever

Hitch System Patented Quick Hitch Syste m

Type Blade Multi-Purpose Blade with Reversible and Replaceable Cutting Edge,

Spring Forward Trip Action with Lock Out

Angle Adjustment Five Positions, 0° (Straight Ahead), 15° and 30° LH or RH

Body Construction Blade Thickness: 11 Gauge Steel

Frame Thickness: 3/8 in. (10 mm)

Cutting Edge Thickness: 1/4 in. (6 mm)

Depth Guide Two Adjustable, Replaceable Skid Shoes,

Adjustable from 1/4 to 3/4 in. (6 to 19 mm)

ROTARY BROOM

Height With Broom: 18-3/8 in. (47 cm)

Without Broom: 11-3/8 in. (29 cm)

Overall Width 47-3/8 in. (120 cm)

Sweeping Path Width (Brush Length) 43-1/4 in. (110 cm)

Length (With Female Hitch) Approx. 45 in. (114 cm)

Overall Length Installed on Tractor 105-1/2 in. (268 cm)

Weight (With Female Hitch) 205 lb (93 kg)

Lift 12 Volt DC Electric Ram Linear Actuator, Operated by Toggle Switch

Mounted on FSC Lever

4

Page 9

Specifications

MODEL IMPLEMENTS

ROTARY BROOM (continued)

Hitch System Patented Quick Hitch Syste m

Type Brush 18 in. (46 cm) Diameter Polypropylene or Steel, Clockwise Rotation

Brush Drive PTO Shaft Driving Center Mounted Gearbox

Primary Reduction Gearbox, 2.78:1 Ratio

Secondary Reduction #40 Chain and Sprockets, 3.27:1 Ratio

Maximum Brush Speed 260 RPM

Broom Angle Adjustment Five Positions, 0° (Straight Ahead), 12.5° and 25° LH or RH

Working Width At Maximum Angle (25°) 39-3/16 in. (100 cm)

Ground Contact Pressure Screw Adjustment with Viscous Damper

Body Construction 14 Gauge Steel

Capacity Clears up to 4 in. (10 cm) snow

TWO-STAGE SNOWBLOWER

Height (Without Chute) 20-3/4 in. (53 cm)

Width 42 in. (107 cm)

Clearing Width 42 in. (107 cm)

Length (With Female Hitch) 22-1/2 in. (57 cm)

Overall Length Installed on Tractor 95 in. (241 cm)

Weight (With Female Hitch) 210 lb (95 kg)

Lift 12 Volt DC Electric Ram Linear Actuator, Operated by Toggle

Switch Mounted on FSC Lever

Hitch System Patented Quick Hitch Syste m

Type Blower Two-Stage with 12-7/8 in. (33 cm) Diameter Auger and

15-3/4 in. (40 cm) Diameter, 3-Blade Impeller, Clockwise Rotation

Snowblower Drive PTO Shaft Driving Blower Wheel

Impeller Drive Chain, #40

Driving Sprocket: H40C11

Driven Sprocket: H40B32

Auger Drive Worm Gearbox, 5:1 Ratio

Discharge Angle Adjustment Chute Direction Rotation 228° by Crank, Adjustable Spout

Deflector, Adjustable from Operator Seat, Up to 40 ft (12 m)

Discharge Distance

Body Construction Frame Thickness: 14 Gauge Steel

Side Thickness: 11 Gauge Steel

Impeller Housing Thickness: 14 Gauge Steel

Cutting Height 19 in. (48 cm)

Depth Guide Two Adjustable, Replaceable Skid Shoes,

Adjustable from 1/4 to 3/4 in. (6 to 19 mm)

5

Page 10

Specifications

MODEL IMPLEMENTS

DEBRIS BLOWER

Height 28-1/2 in. (72 cm)

Width 26 in. (66 cm)

Length 34-3/4 in. (88 cm)

Overall Length Installed on Tractor 102-1/2 in. (260 cm)

Weight (With Female Hitch) 130 lb (59 kg)

Lift 12 Volt DC Electric Ram Linear Actuator, Operated by Toggle

Switch Mounted on FSC Lever

Hitch System Patented Quick Hitch Syste m

Type Blower 13-1/2 in. (34 cm) Diameter, 8-blade Aluminum Impeller,

Counterclockwise Rotation

Blower Drive PTO Shaft Driving Blower Wheel

Recommended RPM 3600 RPM (4000 RPM Maximum)

Airflow at 4000 RPM 2000 cfm

Noise Level at 4000 RPM Approx. 90 Dba

Approximate Required Horsepower 14 HP (10.4 kw)

Air Velocity Mean: 125 mph (201 km/h)

Maximum: 160 mph (257 km/h)

Discharge Angle Adjustment Chute Direction Rotation 230° by Crank,

Adjustable from Operator Seat

Outlet Area 25 in.² (161 cm²)

NOTE: The manufacturer reserves the right to make changes in specifications shown herein at any time

without notice or obligation.

6

Page 11

Component Identification

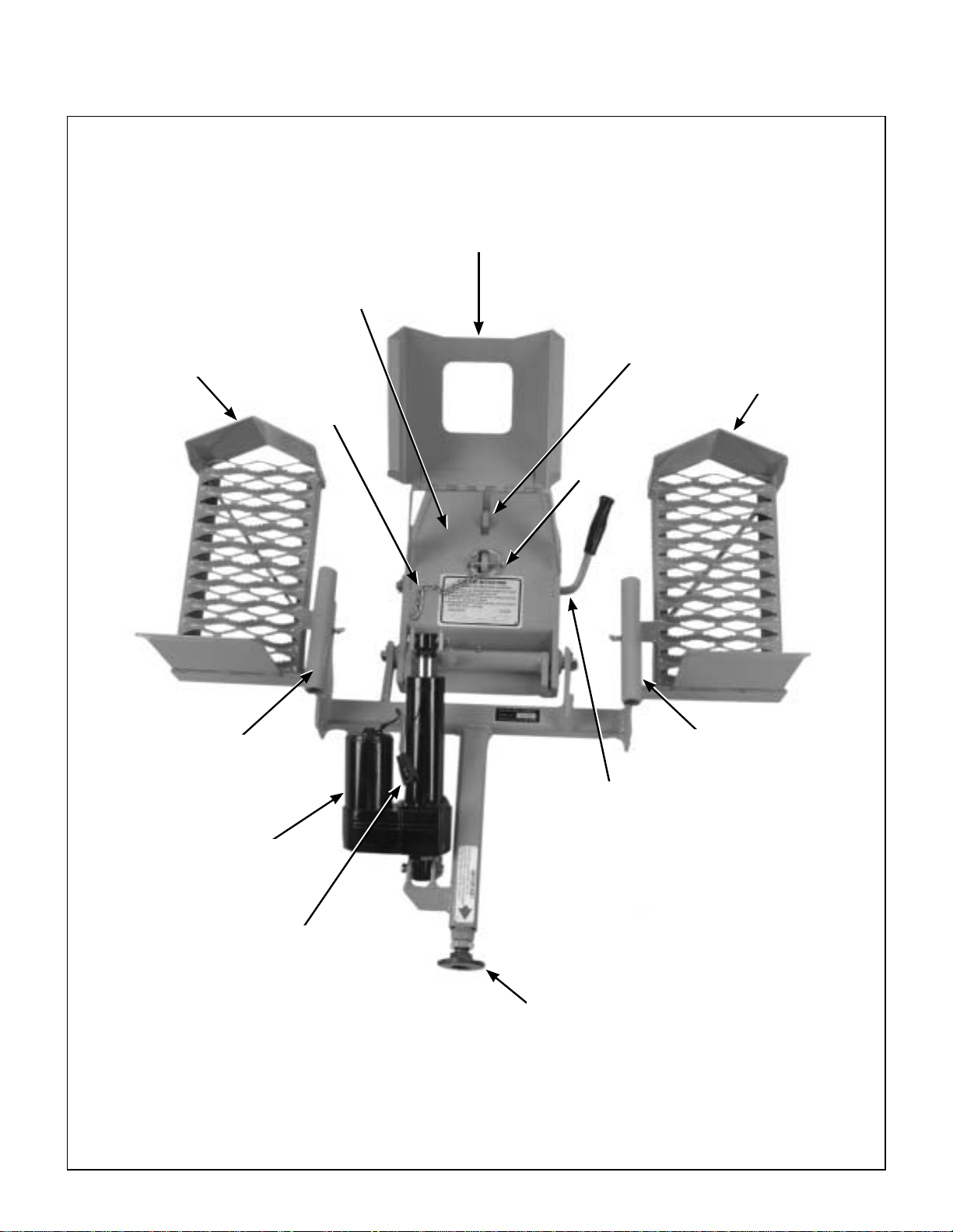

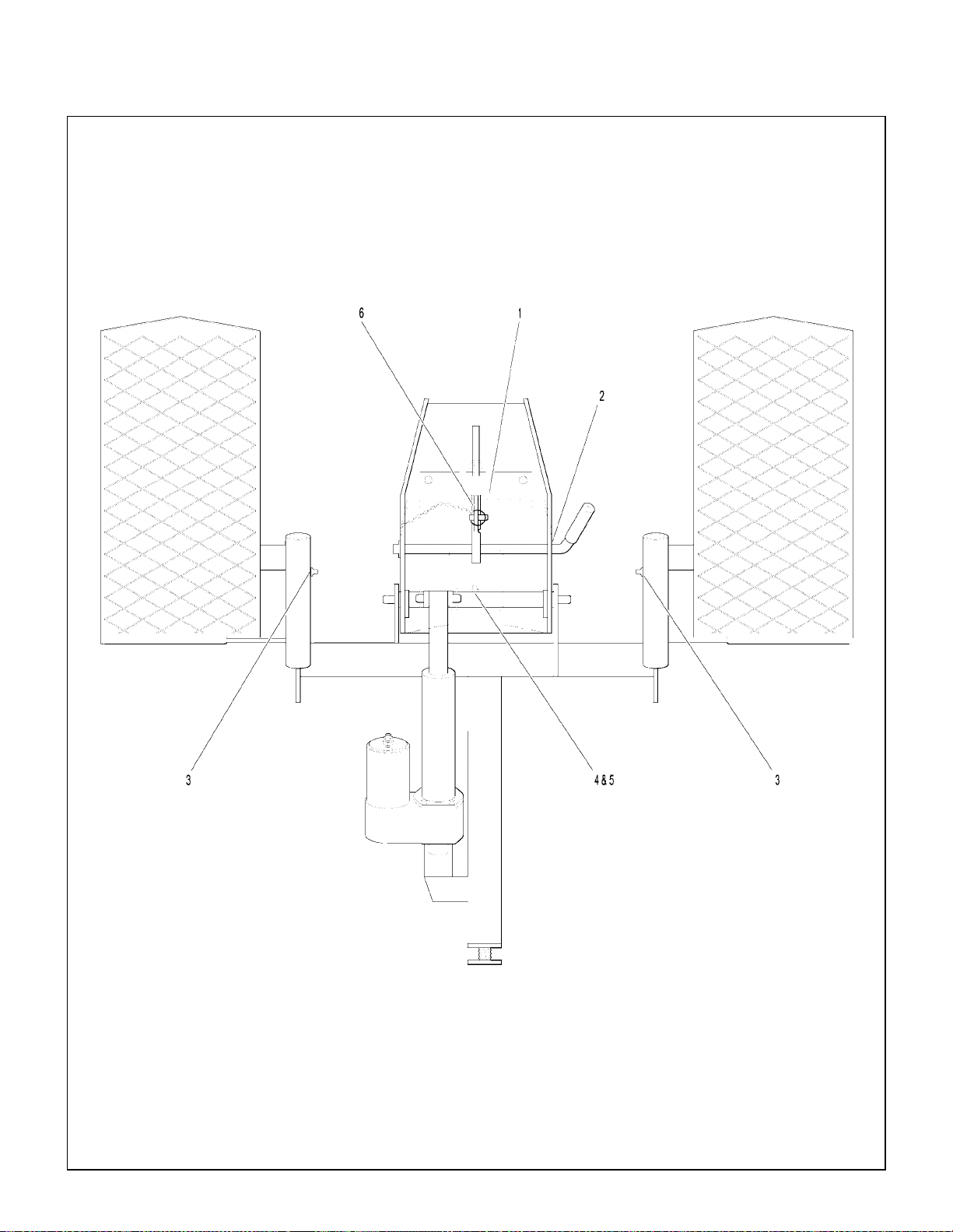

IMPLEMENT HITCH

Footrest

Male Hitch

Assembly

Safety Chain

Assembly

PTO Shie ld

NOTE:Control Identification shown in

Operating Instructions section

and in

Illustrated Parts Manual.

Male Quick

Hitch Latch

Footrest

Linchpin

Mounting

Tube

Linear Actuator

Linear Actuator

Electrical Connector

Mounting

Tube

Hitch Locking

Lever

Jam Nut

Implement Hitch Top View (Not Installed)

7

Page 12

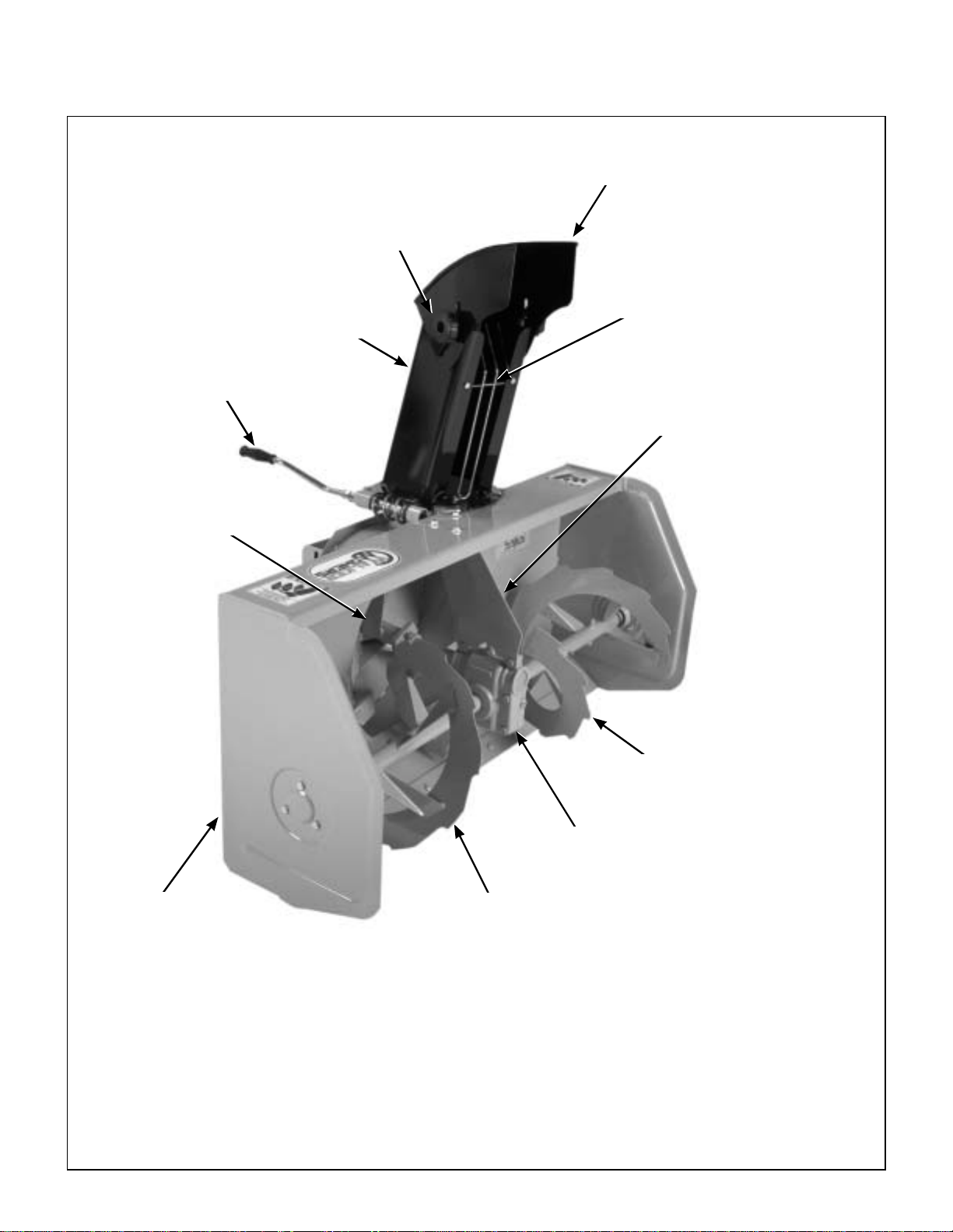

Component Identification

DOZER BLADE

Welded Blade

Angle

Adjustment Pin

Trip Spring

Trip Spring

Lockout Pin

Hitch

Box

Female

Quick Hitch

Trip Spring

Lockout Bracket

Skid Shoe

Skid Shoe

Bracket

Skid Shoe

Pin

Dozer Blade Rear View and Right Side View (Not Installed)

8

Page 13

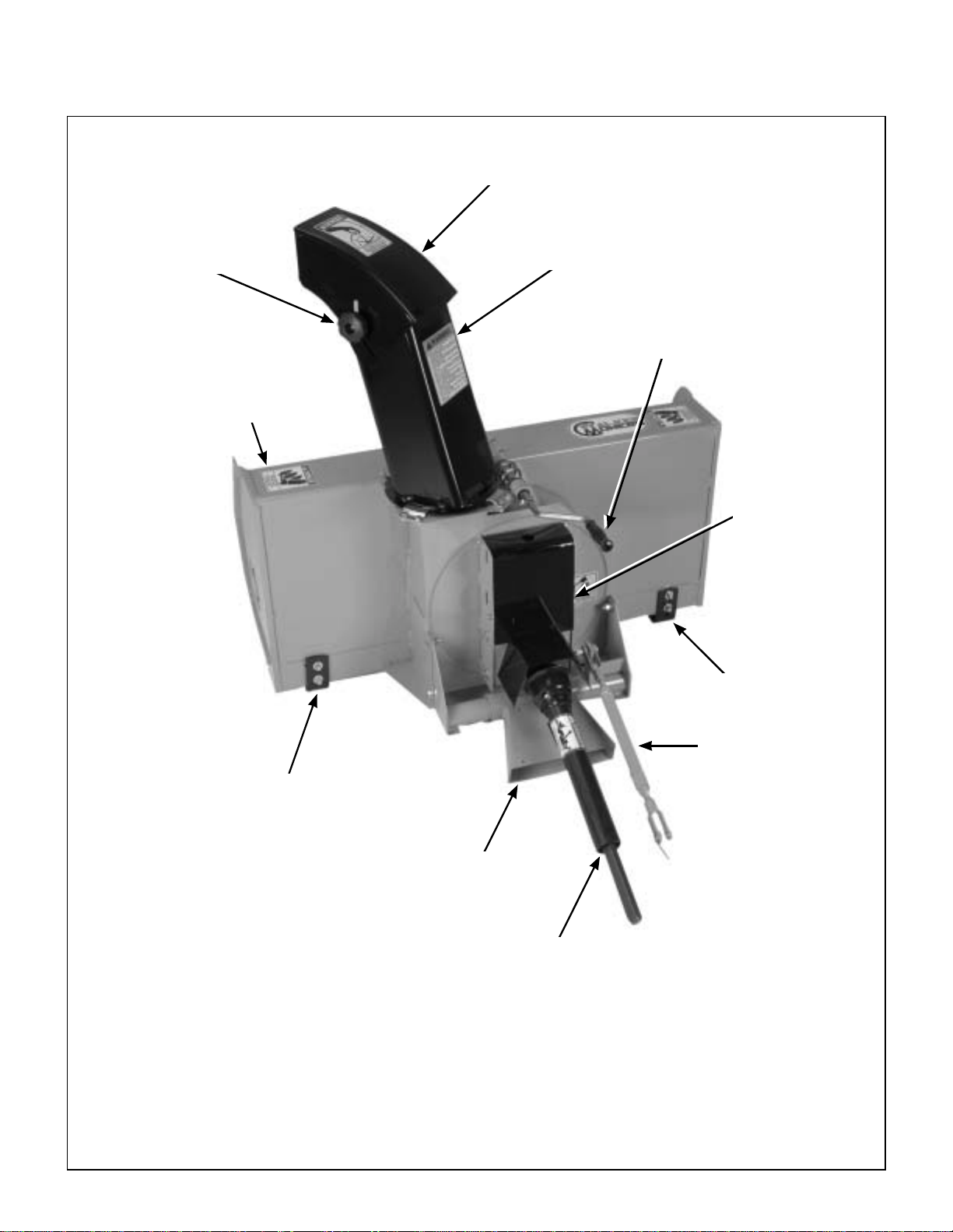

Component Identification

ROTARY BROOM

Tension Spring

Ground Contact

Knob

Stopper

Pin

Rotary Broom

Housing

Pivot Bracket

PTO Shaft

Female Hitch

Plastic

Wheel

Broom Angle

Adjustment Lever

Brush

Parking

Stand

Rotary Broom Rear View and Right Side View (Not Installed)

9

Page 14

Component Identification

TWO-STAGE SNOWBLOWER

Deflector Position

Chute Rotation

Handle

Fan

Deflector

Control Knob

Hand Guard

Chute

Gearbox Support

Bracket

10

Frame

Auger

Gearbox

Auger

Two-Stage Snowblower Front View and Right Side View (Not Installed)

Page 15

Component Identification

Deflector

Deflector Position

Control Knob

Snowblower

Housing

Chute

Chute

Rotation Handle

Reduction

Box Cover

Skid Shoe

Skid Shoe

Two-Stage Snowblower Rear View (Not Inst alled)

Parallel Bar

Female Quick Hitch

PTO Drive Shaft

11

Page 16

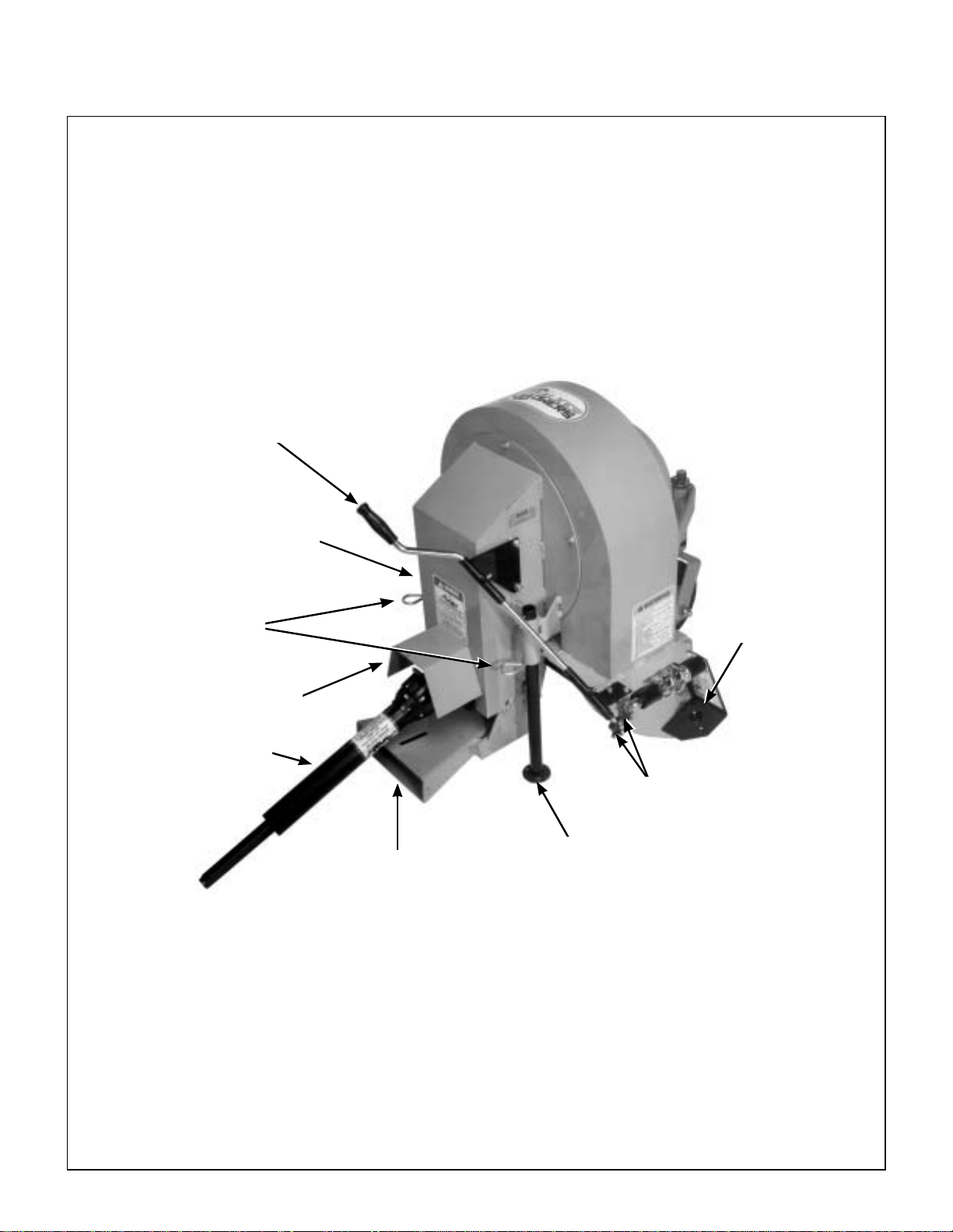

Component Identification

DEBRIS BLOWER

Blower Motor

Housing

Chute Rotation Handle

Belt Guard

Linchpin

Pivot Wheel

Parking Stand

PTO Drive Shaft

Female Quick

Hitch

12

Debris Blower Front View and Left Side View (Not Installed)

Page 17

Component Identification

Chute Rotation Handle

Belt Guard

Parking Stand

Pins

Driveline Guard

PTO Drive Shaft

Deflector Position

Control Knob

Rotation Pinions

Parking Stand

Female Quick

Hitch

Debris Blower Rear View and Right Side View (Not Installed)

13

Page 18

Safety Instructions

Pay particular attentio n to any information labeled

DANGER, WARNING, CAUTION, IMPORTANT,

and NOTE in this manual.

When you see the Safety Alert Symbol ( ),

read, understand, and follow the instr uctions. Failure to comply with safety instructions may result in

personal injury.

The seriousness or degree of imp ortance of each

type of information is defined as follows:

DANGER

An IMMEDIATE hazard that WILL result in

severe personal injury or DEATH, if warning is ignored and proper safety precautions are not taken.

WARNING

A POTENTIAL hazard that COULD result in

severe personal injury or DEATH, if warning is ignored and proper safety precautions are not taken.

Walker Manufacturing cannot pred ict every potentially dangerous situat ion . The re fore, i tem s la bel ed

as such in th is m anu al do n ot cover all conc eiv ab le

situations. Any pe rson using procedure s, tools, or

control techniques not recommended by Walker

Manufacturing must take full responsibility for safety.

The Walker Tractor and Implement attachments

have been designed wi th many safety features to

protect the operator from personal harm or injury.

However, it is necessary for the operator to use safe

operating procedures at all times. Failure to follow

safety instructions contained in this manual

may result in personal injury or damage to

equipment or property.

If you have any questions concerning setup, operation, maintenance, or safety, please contact your

authorized Walker Mower Dealer or call Walker

Manufacturing Company at (970) 221-5614.

BEFORE OPERATING

1. Read and understand the contents of this

OWNER'S MANUAL before operating the

machine. Become thoro ughly familiar with all

controls and how to stop the machine and disengage the controls quickly. Replacement Owner's

Manuals are available by sending the Model and

Serial Number to:

Possible hazards or unsafe practices that

MAY result in MODERATE personal injury

or property damage, or machine damage, if

warning is ignored and proper safet y precautions are not taken.

IMPORTANT: Identifies mechanical information de-

manding special attention, since it deals with the possibility of damaging a part or parts of the machine.

NOTE: Identifies information worthy of s pecial attention.

CAUTION

Walker Manufacturing Company

5925 E. Harmony Road

Fort Collins, CO 80528

2. Never allow children to operate or give rides

on the machine. Do not allow adults to operate

without proper instruction.

3. Do not allow anyone other than the operator on

the machine.

4. Keep everyone, especially children and pets, a

safe distance away from the area being cleaned.

Do not operate with bystanders in the area.

5. Do not ope rate the mac hine wearing sneakers,

tennis shoes, or similar lightweight footwear.

Wear substantial protective footwear that will

improve footing on slippery surfaces.

6. The snow or leaves can sometimes hide objects

that might clog the snowblower or debris blower

chute, or other wise cause damage . Clear the area of doormats, sle ds, boards, wires an d other

debris.

14

Page 19

Safety Instructions

7. Do not wear loose fitting clothing that could

get caught in moving par ts. Always wear ade-

quate protective clothing including long pants.

Wearing safety glasses, safety shoes, and a

helmet is advisable and required by some local

ordinances and insurance regulations.

8. Prolonged exposure to loud noise can cause

impairment or loss of he aring. Oper ator hear-

ing protection is recommended. Wear a suitable hearing pro tective devi ce, such as e armuffs

or earplugs.

9. K eep all prote cti ve shiel ds and safety devic -

es in place. If a protective shield, safety device,

or decal is da maged, unusabl e, or missing, re pair or replace it before operating the machine.

10. Be sure any interlock switches are function-

ing correctly so th e engine canno t be started

unless the Forward Speed Control lever is in

the NEUTRAL position and the PTO clutch is in

the DISENGAGED position. Also, the engin e

should stop if the operator lifts off the seat wit h

the PTO clutch in the ENGAGED position.

OPERATING

NOTE: Refer to the Walker Rider Lawnmowers

OWNER’S MANUAL for safety instructions for

operating the tractor.

1. O per ate th e machi ne onl y in dayl ight or in goo d

artificial light with good visibility of areas being

cleaned.

2. Sit on the seat when starting the engine and operating the ma chine. Keep feet on footrests at all

times when the tracto r is moving and/ or the implement is operating.

3. An inexpe rienced opera tor should learn to steer

(maneuver) the tractor with a slow engine

speed before attempting any operating. Be

aware that, with the front mounted implement

configuration, the back of t he ma chine s wing s to

the outside during turns.

4. Re memb er, for an emerg enc y st op, th e for ward

motion of the tractor can always be stopped by

pulling the Forward Speed Control (FSC) into

the NEUTRAL-PARK position.

11. Never attempt to make any adjustments

while the engine is running, except where specifically instructed to do so.

12. Handle gasoline or diesel fuel with care.

Gasoline is highly flammable and its vapors are

explosive:

a. Use an approved fuel container.

b. Never add fuel to a run ning engine or ho t

engine (allow hot engine to cool several

minutes).

c. Keep matches, cigarettes, cigars, pipes,

open flames, or sparks away from the fuel

tank and fuel container.

d. Always fill the fuel tank outdoors using

care. Fill to about one inch from the top of

the tank. Use a funnel or spout to preven t

spilling.

e. Replace the machine fuel cap and contain-

er cap securely and clean up any spilled

fuel before starting the engine.

5. Di sengage the PTO clutch and put the FSC in

the NEUTRAL-PARK position before starting

the engine (an ig nition inter lock swi tch norm ally

prevents starting of the tr actor if these controls

are in the OPERATING position).

6. Do not run the engine in a confined area with-

out adequate ventilation. Exhaust fumes are

hazardous and can be deadly.

7. Do not carry passengers - maximum seating

capacity is one (1) person.

8. Make sure the au ger, brush, or debris blower is

clear of snow, ice, or debris before engaging the

PTO clutch .

9. Be careful never to throw snow or blow debris towards people or cars, and never allow anyone in

front of the implement.

10. Watch out for hazards hidden under snow or

leaves that coul d enter t he chute or blower w hile

operating.

11. Avoid sudden start s or stops. Before backing

the machine up, look to the rear to be sure no

one is behind the machine . Watch carefully for

traffic wh en cr oss ing or w ork i ng ne ar ro ad wa ys.

15

Page 20

Safety Instructions

12. Disengage the PTO clutch when transporting the

machine.

13. Do not operate across the face of slopes. Use

extreme caution when changing direction on

slopes. Do not attempt to clear steep slopes.

14. Never adjust gauge wheels or skid shoes

with the engine running. Before adjusting

height or se rvicing, disengage the PTO clu tch,

stop the engine, and remove the ignition key.

Wait for all movement to stop before getting off

the seat.

NOTE: The PTO brake should normally stop

drive line rotation within 5 seconds of disengaging the PTO clutch.

15. D o not operate the snow blower with the blower

spout assembly rem oved.

16. If snowblower clogs:

a. Disengage the PTO clutch, stop the en-

gine, and remove the ignition key before

leaving the seat.

b. LOOK to make sure PTO shaft and auger

movement has stopped before trying to unclog the snowblower.

c. Disconnect the fuel solenoid wire [diesel

engines] or spark plug wire(s) [gasoline

engines].

d. Do not use hands or feet to unclog the

snowblower - use a stick or similar tool.

17. If the implement strikes a solid object or the machine begins to vi brate abnorma lly , immediately

disengage the PTO clutch, stop the engine,

and wait for all moving parts to stop. Dis-

connect the fuel so lenoid wire [die sel engines] or

the spark plug wire(s) [gasoline engines] to prevent accidental starting. Thoroughly inspect the

implement and repair any damage before restarting the engine and operating the machine.

Make sure imp lement compon ents are in good

condition and al l bo lts are tight.

18. D o not touch the engine or muffler while the

engine is running or immediately after stopping

the engine. These areas may be hot enough to

cause serious burns.

19. When leaving the machine unattended, disengage the PTO clutch , stop the engine, and remove the ignition key.

MAINTENANCE

NOTE: Refer to the Walker Rider Lawnmowers

OWNER’S MANUAL for proper tractor maintenance procedures.

1. To prevent accidental starting of the engine

when servicing or adjusting the machine, remove the key from the ignition switch and disconnect the fuel solenoid wire [diesel engines] or

the spark plug wire(s) [gasoline engines].

2. To re duce fire hazards, keep the engine free of

grass, leaves, exc essi ve g rea se , an d di rt .

3. K eep al l nuts, bo lts, an d scr ews ti ght to ensure

the machine is in a safe, working condition.

4. Perform only maintenance instructions described in this manual. Unauthorized mainte-

nance operations or machine modifications may

result in unsafe operating conditions.

5. If the engine must be running to perform a maintenance adjustment, keep hands, feet, and

clothing away from moving parts. Do not

wear jewelry or loose clothing.

6. Always use proper engine service manuals

when working on the engine. Unauthorized

maintenance operations or modifications to the

engine may result in unsafe operating conditions.

7. Alt ering the machine in any m anner which adversely affects its operation, performance, durability, or use will VOID the wa rranty and may

cause hazardous cond it ions.

8. Never attempt to disconnect any safety devices

or defeat the pur p ose of th ese safet y d evi ces.

9. Do not chan ge the eng ine gov ernor set ting s or

overspeed the engine. The governor has been

factory-set for ma ximum-safe engine operating

speed.

10. Use genuine factory replacement parts. Substitute parts may result in product malfunction

and possible in jury to the o perator and/or othe rs.

IMPORTANT: Keep all applicable manuals

immediately accessible to anyone who may

operate or service this machine.

16

Page 21

Safety Instructions

Implement Hitch

(Walker P/N 6632)

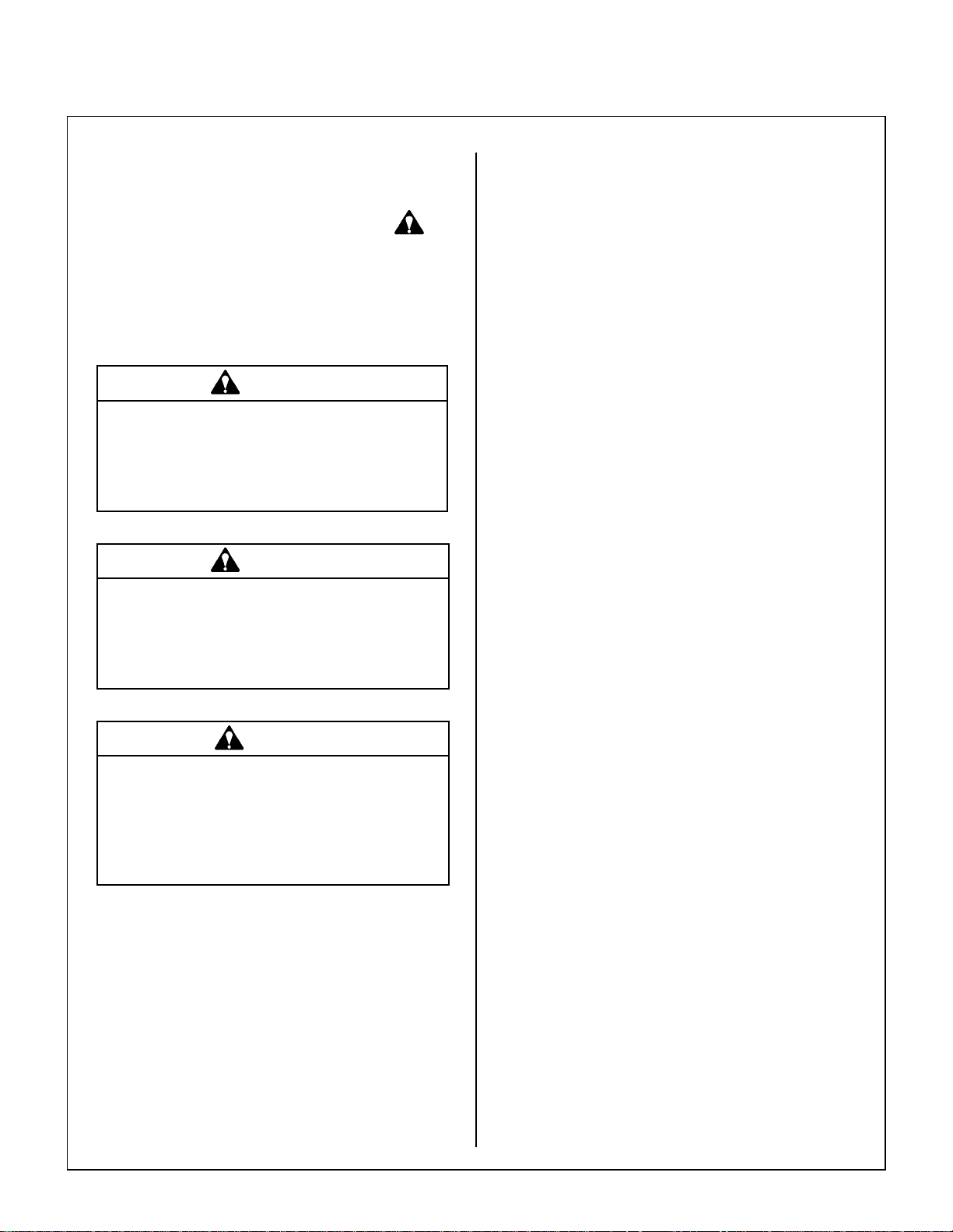

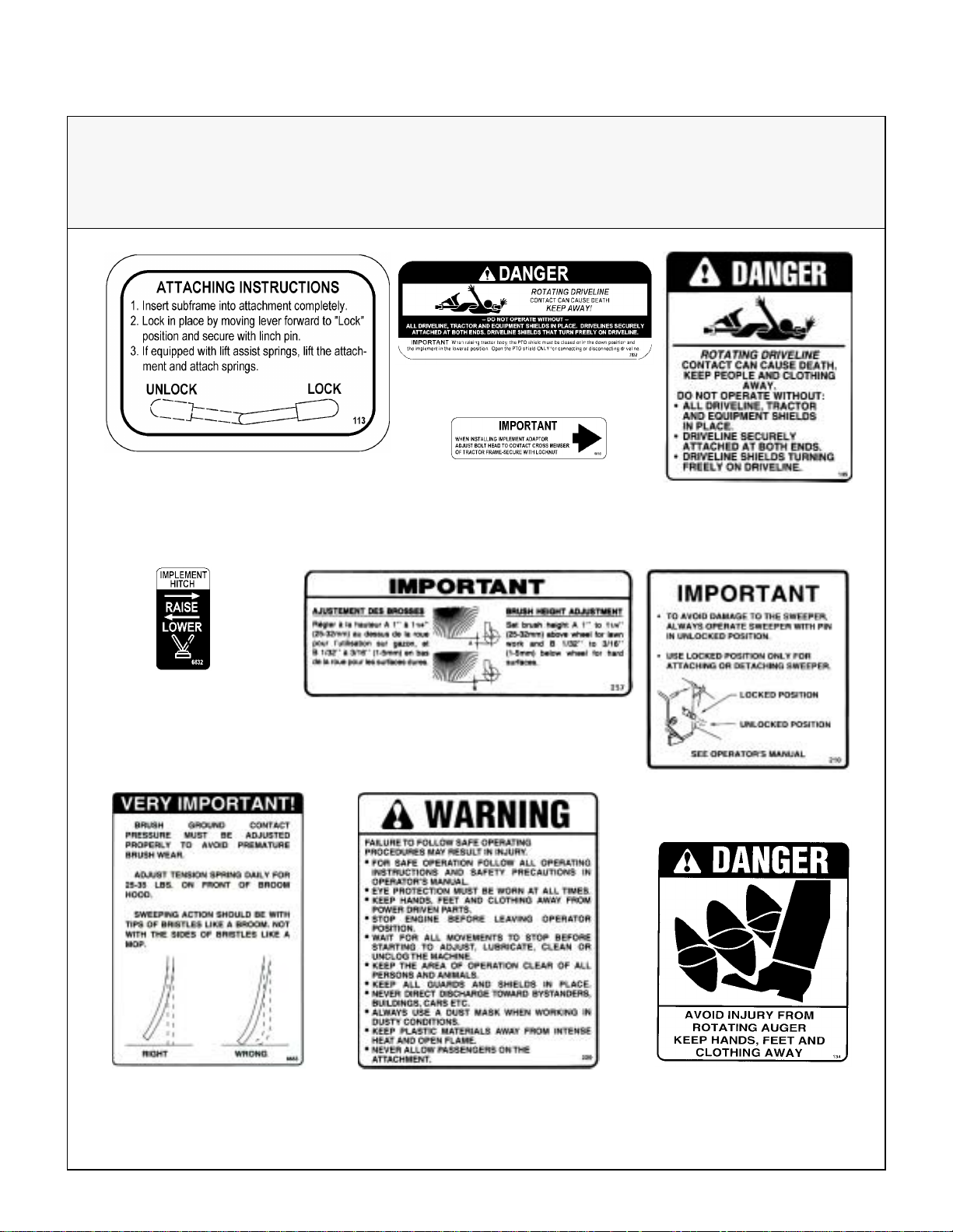

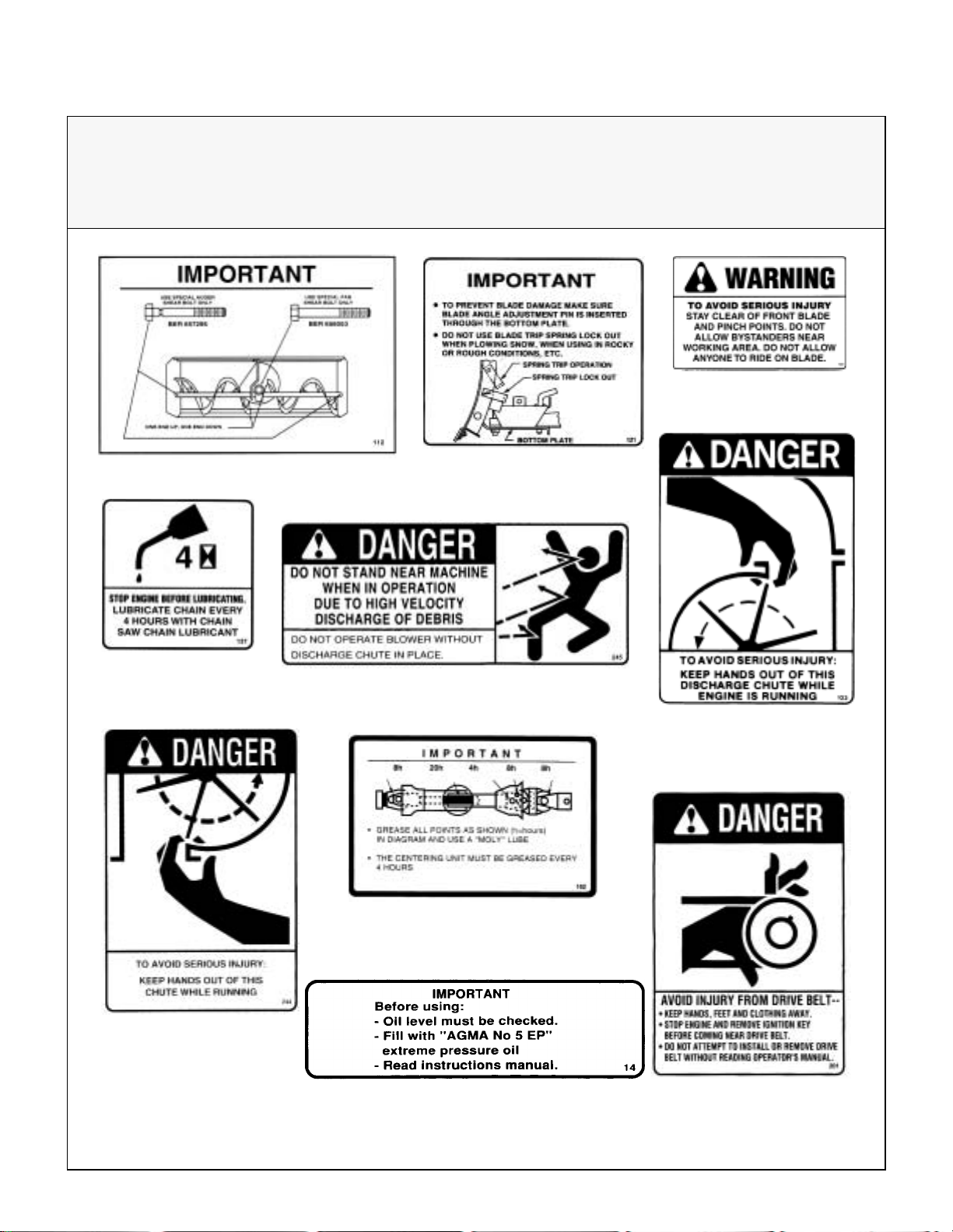

SAFETY, CONTROL, AND INSTRUCTION DECALS

Safety, Control, and Instruction Decals are installed on the machine. If any are missing, illegible, or

damaged, a replacement should be ordered and installed before putting the machine into operation. The

Decal Part Number i s listed below and in the Parts Manual; the Decal Location is shown in the Parts Manual.

PTO Shield (Walker P/N 7822)

Attaching Hitch

(Walker P/N I393)

(RAD P/N 657364)

Hitch Mount Adjust

(Walker P/N 6618)

Brush Height (RAD P/N 661521)

Rotating Driveline

(Walker P/N I395)

(RAD P/N 657763)

Important - A void Damage

(RAD P/N 660328)

Brush Ground Contact

(RAD P/N 661052)

Safety Procedures

(RAD P/N 660988)

Rotating Auger

(Walker P/N I394)

(RAD P/N 657762)

17

Page 22

Safety Instructions

Lubricate Chain

(RAD P/N 657804)

SAFETY, CONTROL, AND INSTRUCTION DECALS

Safety, Control, and Instruction Decals are installed on the machine. If any are missing, illegible, or

damaged, a replacement should be ordered and installed before putting the machine into operation. The

Decal Part Number is listed below and in the Parts Manual; the Decal Location is shown in the Parts Manual.

Stay Clear Blade

(RAD P/N 657524)

Use Shear Bolts (RAD P/N 657346)

Danger, High Velocity (RAD P/N 661248)

Trip Spring Lockout

(RAD P/N 657503)

Keep Hands Out

(Walker P/N I396)

(RAD P/N 657761)

Avoid Serious Injury

18

(RAD P/N 661247)

Grease All Points (RAD P/N 6586708)

Check Oil Level (RAD P/N 655683)

Drive Belt Injury

(RAD P/N 660265)

Page 23

Assembly Instructions

SETUP INSTRUCTIONS

Walker Implements are shipped partially assembled. After uncrati ng t he imp le men t ad apto r and /or

implement(s), initial setup is required.

NOTE: During the process of unpacking, any damaged or missing parts should be noted and reported

to the delivering ca rrier immediately (put in wri ting

within 15 days). The carrier will provide directions

for proceeding with a claim to receive compensation

for damage.

IMPLEMENT HITCH

Implement Hitch Installation

1. Remove the mower deck from the tractor if necessary. Refer to the appropriate Tractor Owner’s Manual.

2. Lightly grease each tractor support arm (2) on

the tractor. Refer to Implement Hitch Installa-

tion photo for location of tractor support arms.

IMPORTANT: If the tractor body needs to be raised,

the PTO shield must be in the closed or down position and the implement must be in the lowered

position. The only time the PTO shield needs to be

open or raised is when connecting or disconnecting

the driveline for the rotary broom, snowblower, or

debris blower.

Hitch Pins Lock Hitch on Support Arms

PTO Shield

in CLOSED

Position

PTO Shield in CLOSED Position

3. Engage the hitch frame tube sockets on the

tractor support arms. Slide the implement hitch

onto the support arms approxim ately 3 in. (76

mm).

4. Install the hitch pin through the hole on the end

of each support arm to loc k the hitch in place.

Two (2) hitch pins are included i n the owner’s

packet of materials.

Grease Tractor

Support Arms

Hitch Frame

Tube Sockets

Implement Hitch Installation

5. Loosen the 3/4-10 jam nut on the end of the implement Hitch. Adjust the 3/4-10 x 2 in. hex bolt

until it contacts the cross-member of the tractor

frame. Securely tighten the 3/4-10 jam nut to

prevent the bolt from moving.

3/4 - 10 x 2"

Hex Bolt

Implement Hitch Jam Nut Adjustment

IMPORTANT: This adjustment will need to be

made only once if the same tractor and hitch are

used together. If the hitch will be used on more

than one tractor , this adjustment will be required

every time the hitch is mounted on a different

tractor.

3/4 - 10

Jam Nut

19

Page 24

Assembly Instructions

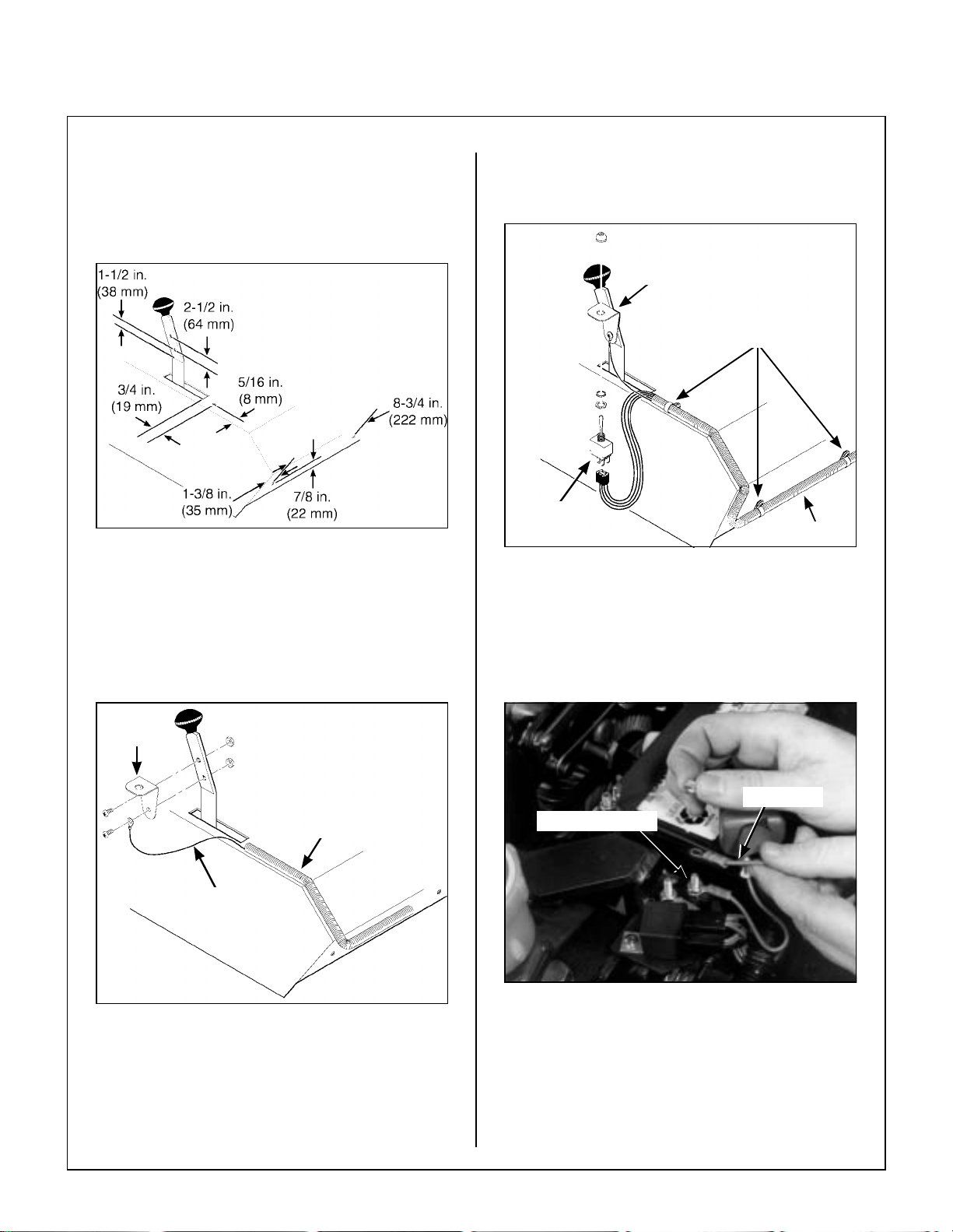

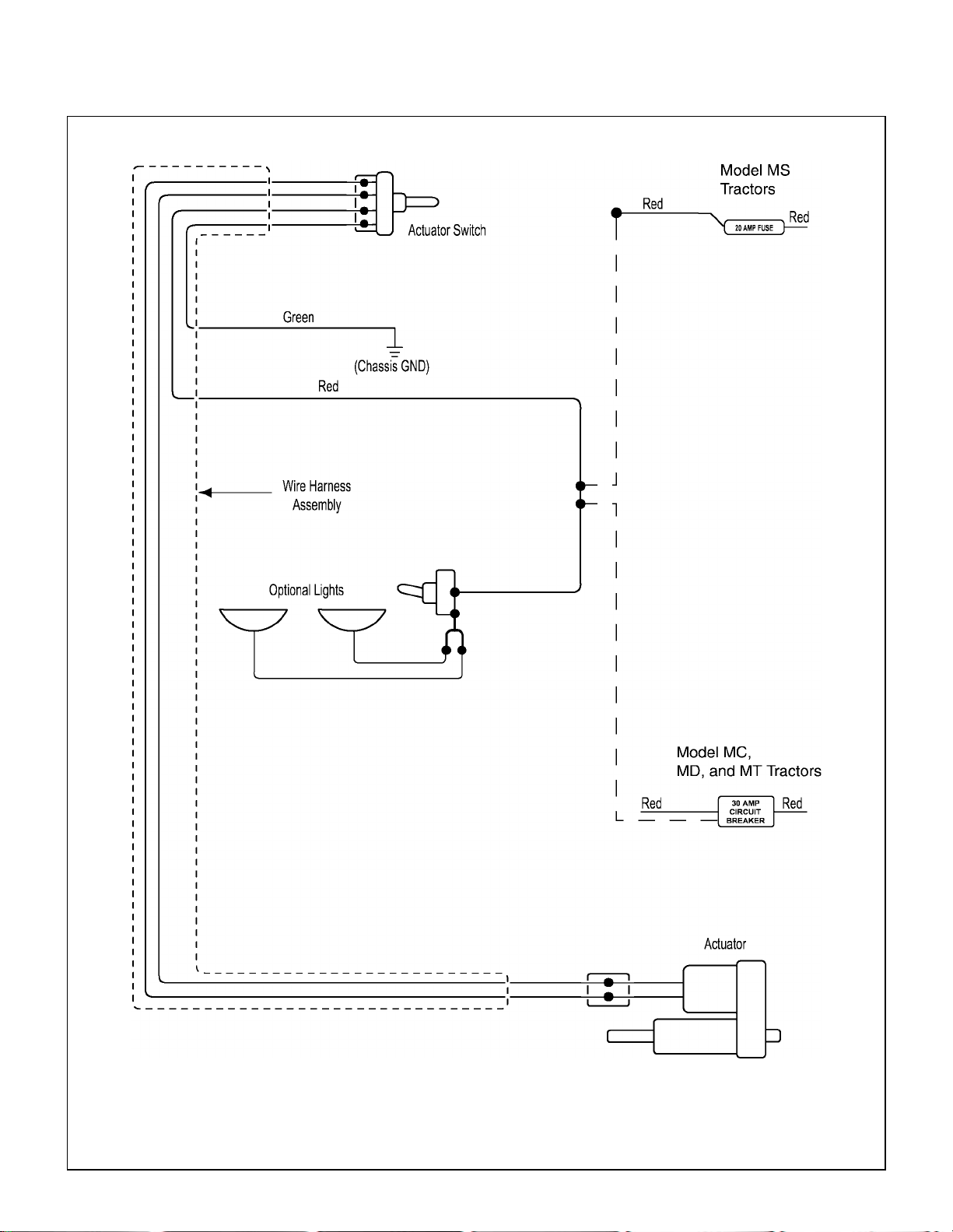

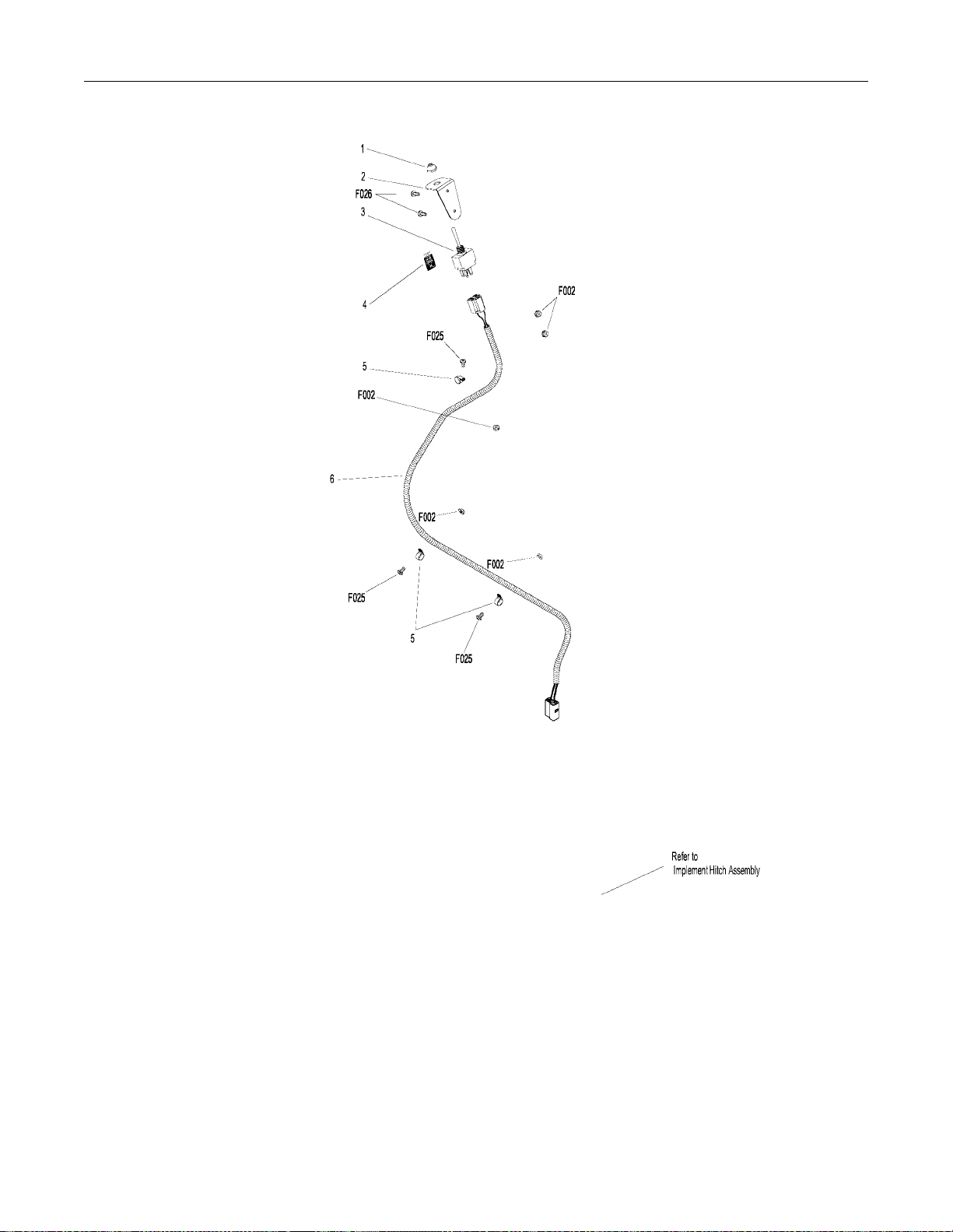

Implement Hitch Wiring

1. Drill five (5) 13/64 in. (5 m m) diame ter holes in

the tractor, two in the FSC lever and three in the

body, as shown in the illustration.

Drill Holes for Implement Hitch Wiring

2. Attach the toggle switch mounting bracket on

the FSC lever using two (2) 10-24 x 1/2 in. bolts

and Keps nuts. Connect the green ground wire

from the actuator wir ing harness to one o f the

bolts of the switch mounting bracket.

4. Attach the toggle switch to the mounting bracket, placing the switch terminals toward the front

of the mower.

Mounting Bracket

Wiring Clamps

Switch

Terminals

Attach Wiring Harness and Toggle Switch

5. On Models MC, MDD/MDG, and MT, connect

the harness red wire to the load side of the ci rcuit breaker mounted on the bracket behind the

battery.

Harness

Mounting

Bracket

Wiring

Harness

Ground

Wire

Attach Toggle Switch Mounting Bracket

3. Install the wiring harness to the tractor body using the three wiring clamps, three 10-24 x 3/8 in.

bolts and Keps nuts.

Red Wire

Circuit Breaker

Connect Harness Wire to Circuit Breaker

IMPORTANT: For all 1987-1997 Model MC

tractors (with Kohler Magnum engine), connect

the harness red wire to the free connector of the

PTO clutch switch red wire. Refer to Implement

Hitch Wiring Diagram illustration.

20

Page 25

Assembly Instructions

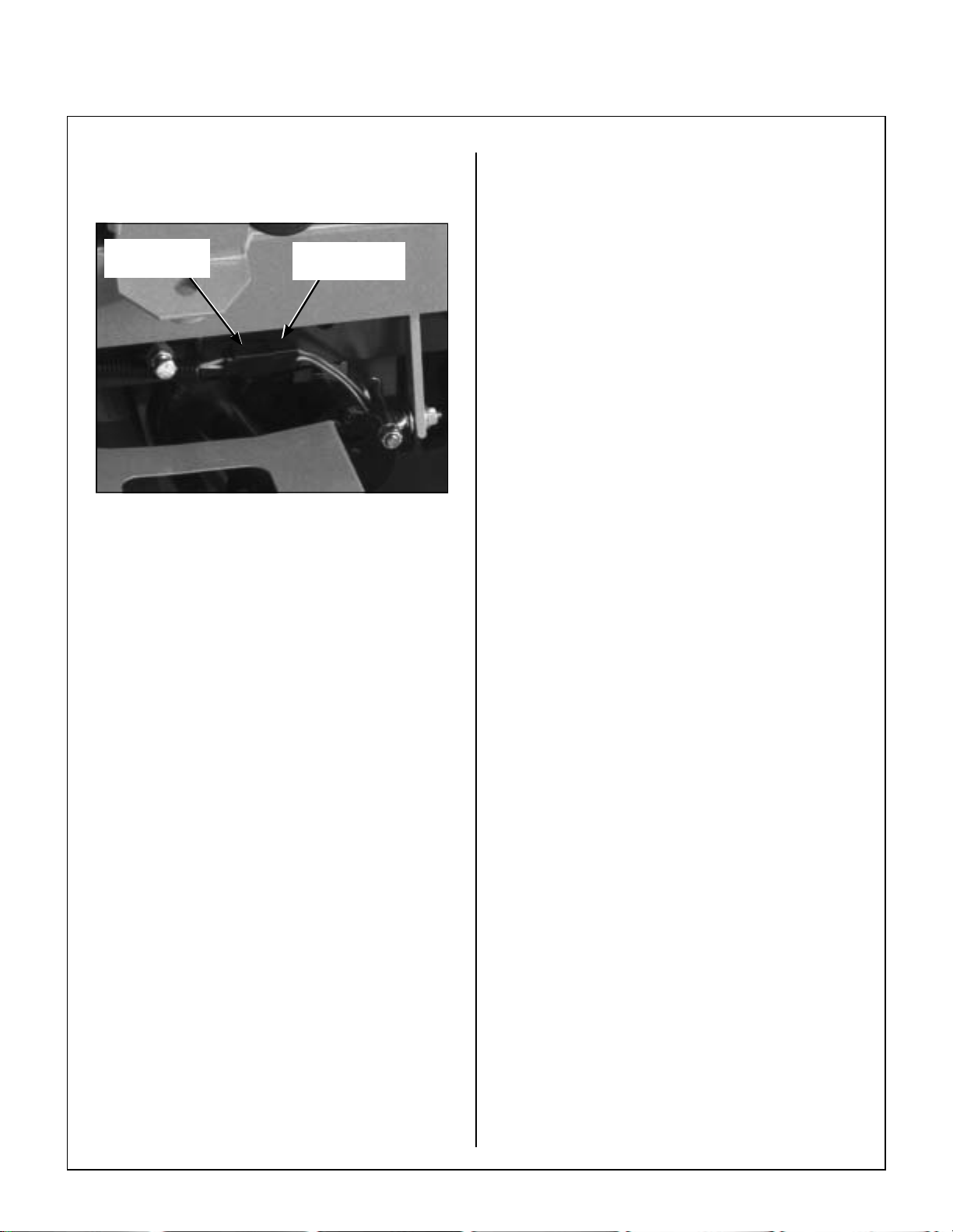

6. Complete the wiring by connecting the wiring

harness ends to the toggle switch and to the actuator motor of the implement hitch.

Wire Harness

Connector

Complete Implement Hitch Wiring

7. Move the implement lift switch backward to

raise the implement hitch to the UP position .

8. Move the implement lift switch forward to lower

the implement hitch to the DOWN position.

9. Raise and lower the hitch a few times to check

the operation and make sure it moves smoothly.

If not, make sure the wiring harne ss ends are

connected properly and sec urely. Refer to Im-

plement Hitch Wiring Diagram illustration.

Actuator Motor

Connector

21

Page 26

Assembly Instructions

22

Implement Hitch Wiring Diagram

Page 27

Assembly Instructions

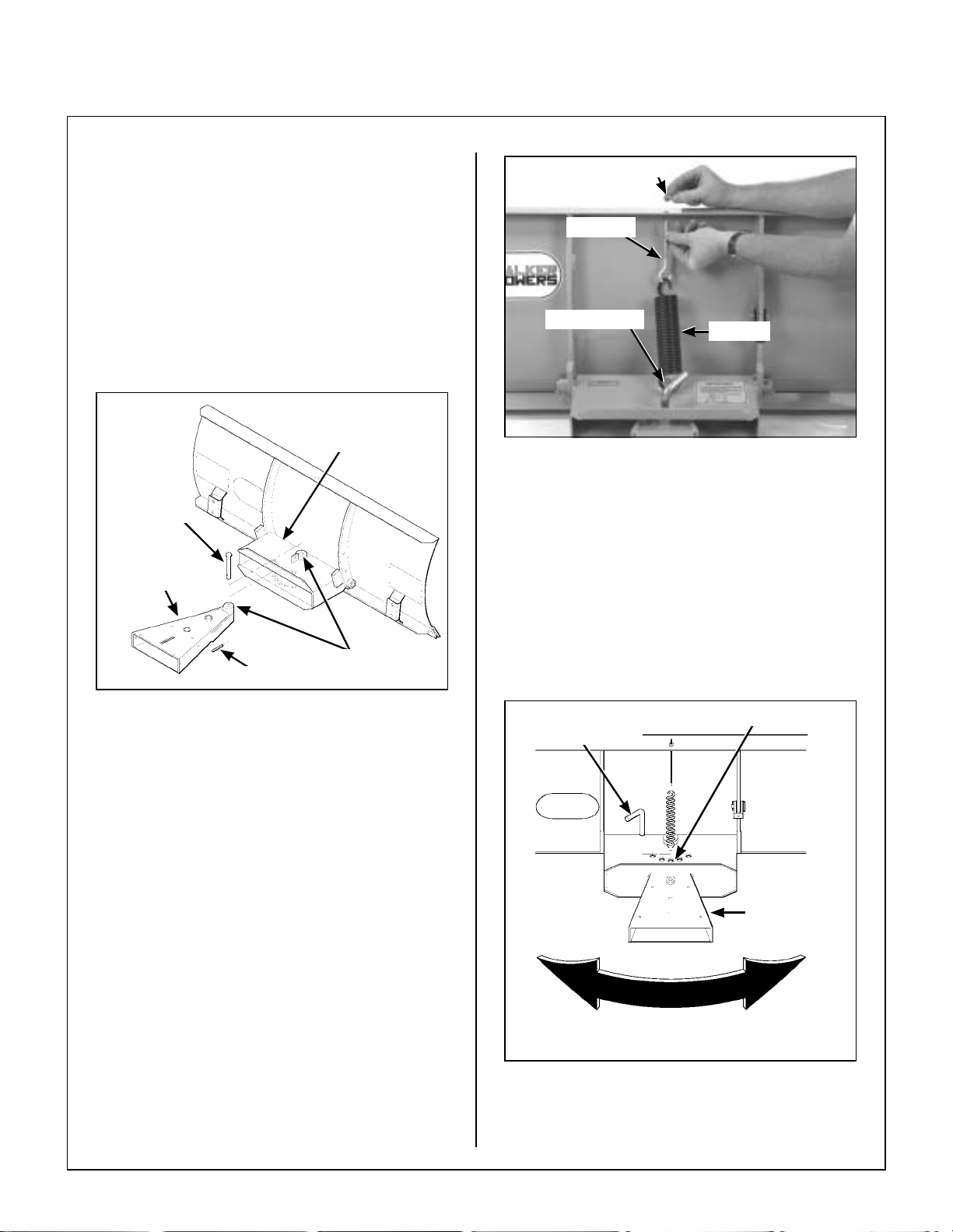

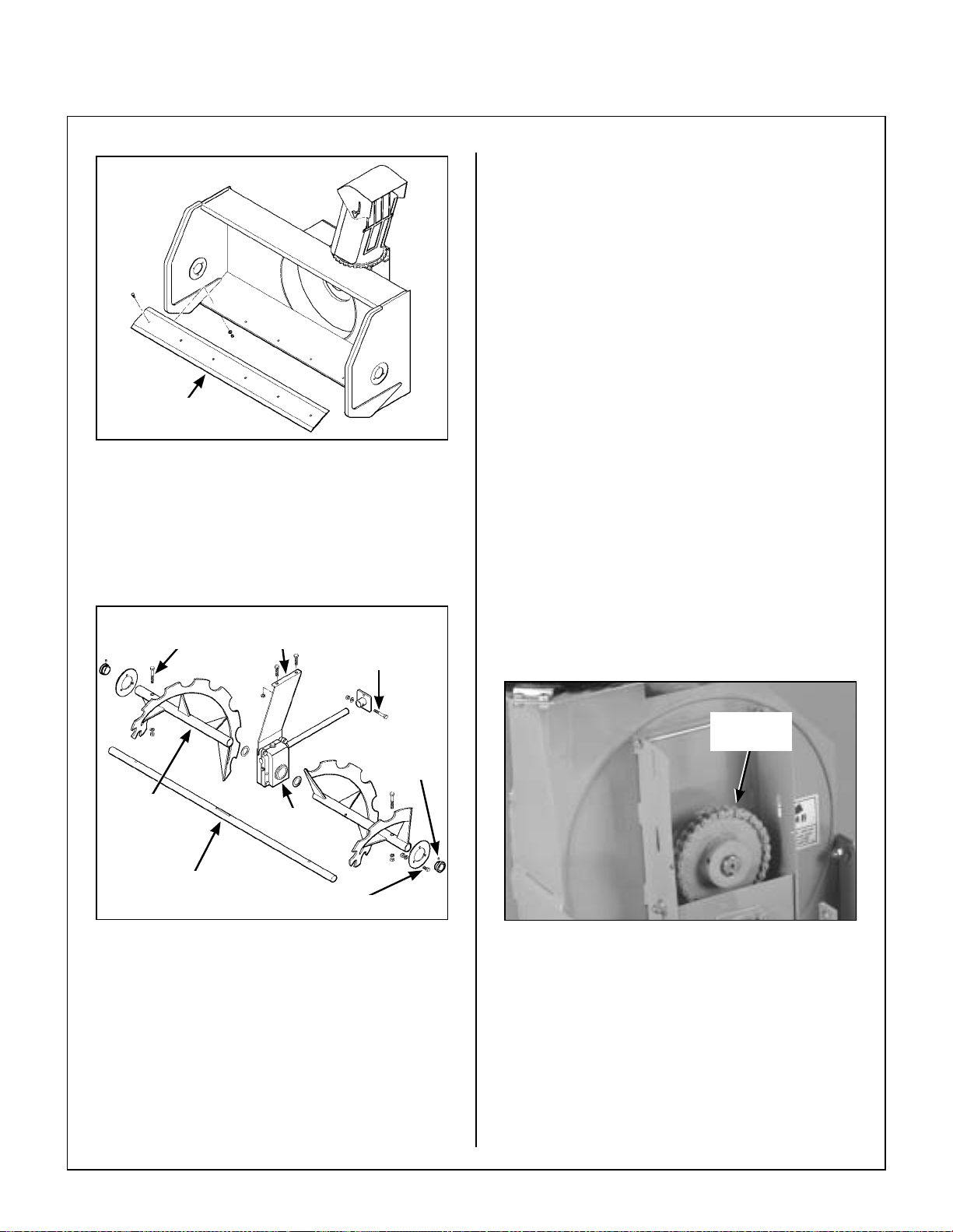

DOZER BLADE

Dozer Blade Assembly

1. Insert the female quick hitch in to the hitch box

on the blade attachment.

2. Align the single hole at the end of the female

quick hitch with the single hole in the hitch box

and insert the pivot pin through both holes. Secure the pivot pin on the underside with a 1/4 x

1 in. roll pin.

Hitch Box

Pivot Pin

Female

Quick Hitch

Align Holes

Roll Pin

Nut

Eyebolt

Welded Tab

Attach Spring to Blade Assembly

5. Insert a 3/16 x 1 in. split spring pin into the angle

adjustment pin.

6. Rotate the female quick hitch to ob tain the required blade angle. Align the hole in the center

of the female quick hitch with one of the five (5)

holes in the hitch box, and insert t he angle adjustment pin thro ugh the to p an d b otto m h ole s.

Refer to Angle Adjustment Pin in Operating

Instructions.

Spring

Insert Female Hitch into Blade Attachment

3. Hook one end of the spring onto the welded tab

on the hitch box. Hook the eyebolt onto the free

end of the spr ing.

4. Insert the eyebolt up through the hole in the upper bend of the blade and secure it with a flat

washer and nu t. Adju st the le ngth of t he eyeb olt

according to the amount of sp ring tension required for safe operation. Refer to Trip Spring

in Operating Instructions.

Angle Adjustment Hole(s)Angle Adjustment

Pin

Female Quick

Hitch

Rotate Female Quick Hitch

For Required Blade Angle

Insert Adjustment Pin and Set Blade Angle

7. Install the two (2) skid shoes in the two brackets

on the rear outer edges of the blade.

23

Page 28

Assembly Instructions

8. Adjust the skid shoes to allow the required

clearance under the blade. Install a skid shoe

pin in each shoe and lock in place with a 4 mm

x 80 mm hairpin. Refer to ADJUSTMENTS of

Dozer Blade Skid Shoes in Maintenance In-

structions.

Skid Shoe

Pin

Skid Shoe

Bracket

Hairpin

Skid Shoe

Install Skid Shoes

Male Quick

Linchpin

Hitch

Hitch Locking

Lever

Attach Blade to Tractor

2. To install the optional tire chains:

a. Remove the tractor wheels.

b. Attach the tire chains to the wheels.

Female

Hitch

9. Install the trip spring lockout bracket in the upper hole behind the blade using the lockout pin

and hairpin.

Hairpin

Trip Spring

Lockout Bracket

Install Trip Spring Lockout Bracket

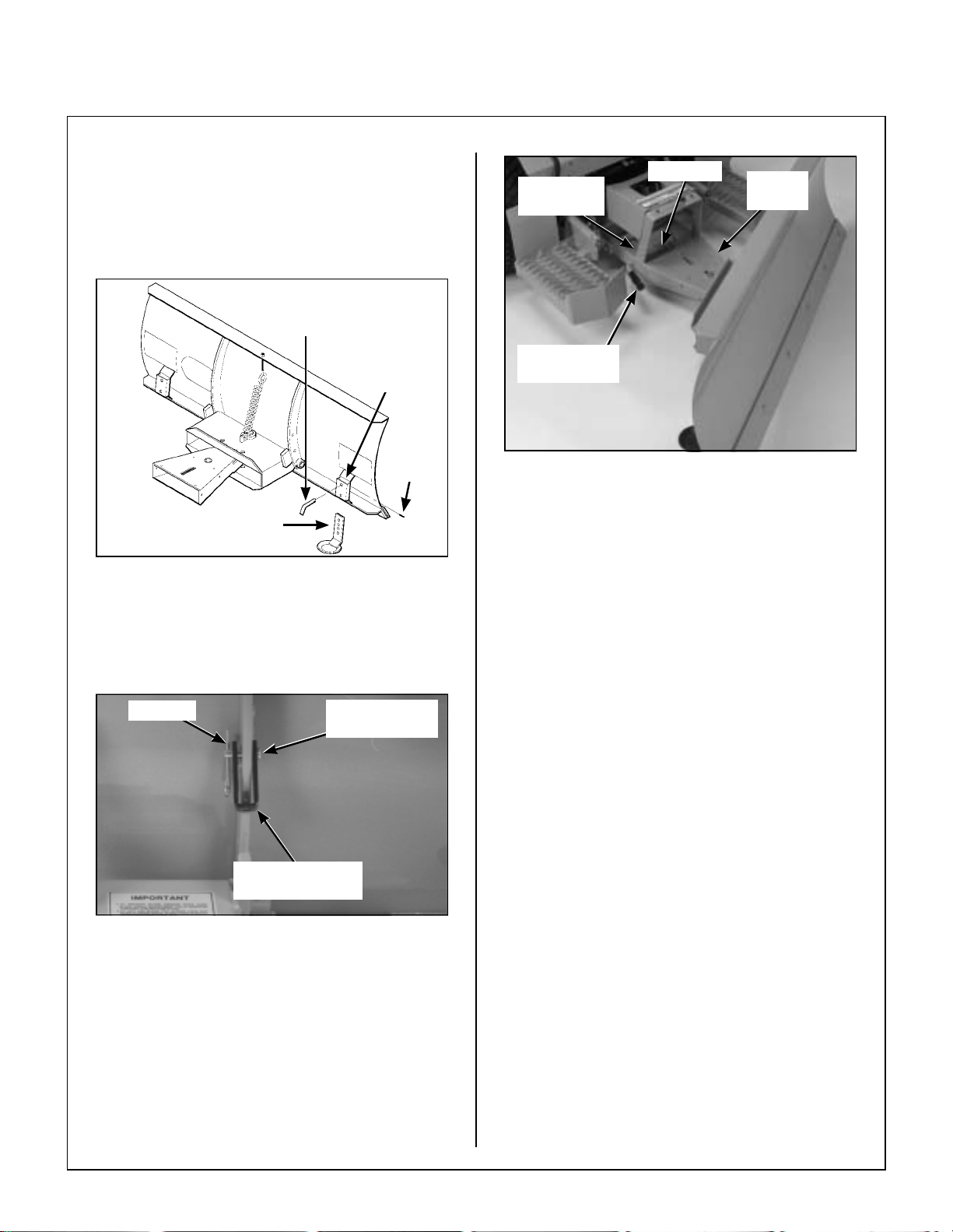

Dozer Blade Installation

1. Insert the male quick hitch section of the implement hitch into the female hitch of the blade.

Lock in place by moving the hitch locking lever

fully forward to the LOCKED position. Secure

the male qu ick hit ch la tch wi th th e linc hpi n. Refer to Hitch Locking Lever in Operating In-

structions.

Lockout Pin

in Upper Hole

c. Place the wh eel spacer plates on the lug

bolts. The wheel spacer plates provide

clearance for the chains bet ween the tires

and the tractor body.

d. Place the wheels back on the tractor.

e. Reinstall and tighten the lug bolts.

ROTARY BROOM

Rotary Boom Installation

1. Insert a parking stand into each stand su pport

bracket from the underside. Install a 5/32 x 1-1/

4 in. cotter pin in the upper hole of each parking

stand. Set the parking stands in their most ex-

tended position and secure each stand with

a 4 mm x 80 mm hairpin.

2. Check the pivot lock pin and mak e sure it is in

the innermost position to prevent bulking of

the female hitch member, and to facilitate quick

hitch attachment.

24

Page 29

Assembly Instructions

Stand Support

Bracket

Hairpin

Parking Stand

Prepare Rotary Broom for Installation

3. Attach the female broom driveline half (with

quick connect yoke ) over the male broom driv eline half. Set the driveline on its support.

NOTE: Driveline sliding surfaces must be

greased.

Reduction

Shaft

Male Quick

Hitch

Hitch Locking

Lever

Attach Broom to Implement Hitch

5. Connect the broom driveline to the tractor PTO

shaft by sliding back the l ocking collar on the

yoke, then push the y oke over the PTO shaft

until the locking collar snaps back fully. Make

sure the driveline is well secured at both ends.

Female Hitch

Drive Shaft

Yoke

Assemble Rotary Broom Driveline

4. Insert the male quick hitch section of the implement hitch into the female quick hitch of the rotary broom and place the male quick hitch lever

fully forward to the LOCKED position. Secure

the male qu ick hit ch la tch wi th th e linc hpi n. Refer to Hitch Locking Lever in Operating In-

structions.

DANGER

This shaft turns a t very high RPM. If the

collar is not locked to the PTO shaft at the

tractor end, or if the yoke at the broom

end is not secured properly, the driveline

can fly loose with gr eat force capable of

causing serious injury or death.

PTO Shaft

Locking Collar

Yoke

Connect Broom Driveline to Tractor PTO Shaft

25

Page 30

Assembly Instructions

6. Remove the hairpin from the welded sleeve on

the right hand side of the broom mounting

bracket. Carefully pull out the stopper pin to its

most extended position and lock in place with

the hairpin.

Welded Sleeve

Hairpin

Stopper Pin

Lock Stopper Pin in Place

8. Retract the parking stands and secure with the

hairpins prior to operation.

9. To install the optional tire chains:

a. Remove the tractor wheels.

b. Attach the tire chains to the wheels.

c. Place the wh eel spacer plates on the lug

bolts. The wheel spacer plates provide

clearance for the chains bet ween the tires

and the tractor body.

d. Place the wheels back on the tractor.

e. Reinstall and tighten the lug bolts.

10. For GHS (Grass Handling System) equipped

Walker tractors, install a blow er inta ke c over in

the blower intake tube. The cover “unloads” the

blower and seals the intake to effectively eli minate power loss and noise whe n the blower is

not being used.

Blower Intake

Cover

NOTE: The pin in the innermost position is used

to prevent the female hitch on the broom from

being pulled up by the brush ground contact

adjustment spring, thus facilitating mounting and

dismounting of the broom.

7. Adjust brush ground contact by threading knob.

Refer to Ground Contact Knob in Operating

Instructions.

Ground Contact Knob

Adjust Brush to Ground Contact

GHS Blower Intake Cover

1 1. For stability of the tractor when transporting with

the rotary broom in raised position, approximately 80 lb (36 kg) of counterweight should be

installed on the tail of the tr actor. Optional tail

weights for the various tractor models are available from your Walker dealer or a sandbag or

similar weight may be used.

Optional Gauge Wheel Installation

NOTE: Gauge wheels are required for lawn

work or heavy loads.

26

Page 31

Assembly Instructions

1. Remove the pin and hai rpin from each gauge

wheel. Select the required number of spacer

sleeves to remain on t he bottom porti on of the

gauge wheels. Refer to ADJUSTMENTS of

Rotary Broom Gauge Wheels in Maintenance

Instructions.

2. Remove the parking stands and repla ce them

with the gauge wheels. Place the remaining

spacer sleeve(s) over the gauge wheels on the

upper part of the stand supports, and secure the

gauge wheels with the pins and hairpins.

Pin

Spacer

Sleeves

Optional Gauge Wheel Installation

Hairpin

Support

Gauge

Wheel

Hand

Guard

Chute Base

Ring

Stand

Install Hand Guard on Chute

2. Remove the bushing support from the chute

base lip and discard the existing bolt (refer to In-

stall Rotation Worm Assembly photo).

3. Place the plastic anti-friction insert over the

chute base (placing the nipple on the upper side

towards the center of th e fan housing). Only

one position provides a perfect fit. Apply grease

on top of the insert where it will contact the

chute base.

Apply Grease

TWO-STAGE SNOWBLOWER

Snowblower Assembly

1. Install the hand guard on the chute, with the top

section inside the chute and the bottom section

outside the chute base ring. Place two (2) 1/4 x

3/4 in. bolts through the chute and the hand

guard. Secure wit h a flat wash er, lock washer,

and nut. Position the bo lt wit h th e h ead on th e

outside of the chute and the nut on the inside.

Torque both bolts to 10 ft-lb. (13.6 N·m).

Nipple

Install Plastic Insert over Chute Base Lip

4. Insert the 1-5/16 in. (33 mm) plastic bushing into the tube weldment.

27

Page 32

Assembly Instructions

5. Insert the 1-11/16 in. (43 mm) plastic bushing into the bushing su pport and place th is over the

shaft on the rotation worm.

6. Install the rotation worm assembly through the

tube weldment with the attaching plate of the

support on the underside of the chute base lip.

Tube

Weldment

Rotation

Worm

Bushing Support

With Attaching Plate

Install Rotation Worm Assembly

7. Install the chute over the pl astic insert and secure with four retaining plates, using two (2) 1/4

x 1/2 in. bolts, lock washers, and nuts in each of

the three (3) standard retaining plates, and two

(2) 1/4 x 3/4 in. bolts, lock washe rs and nu ts in

the rear right retaining plate which also secures

the support. Torque all bolts to 10 ft-lb. (13.6

N·m).

Bushing

8. Insert two (2) 5/16 x 1 in. carriage bolts through

each of the skid shoes from inside the bend.

Place a flat washer, lock washer, and nut loosely on each bolt and place the bolt heads through

the round holes in the outer ends of the bottom

angle of the sno wblower body. Adjust the sk id

shoes to allow the required clearance under the

cutting edge. Slide the square shank portion of

the bolt head into the slot and torque to 19 ft- lb

(25.8 N·m). Refer to ADJUSTMENTS of Two-

Stage Snowblower Skid Shoes in Mainte-

nance Instructions.

Snowblower

Housing

Skid Shoe

Carriage Bolts

Install Skid Shoes

28

Chute

Retaining

Plate

Install Chute over Plastic Insert

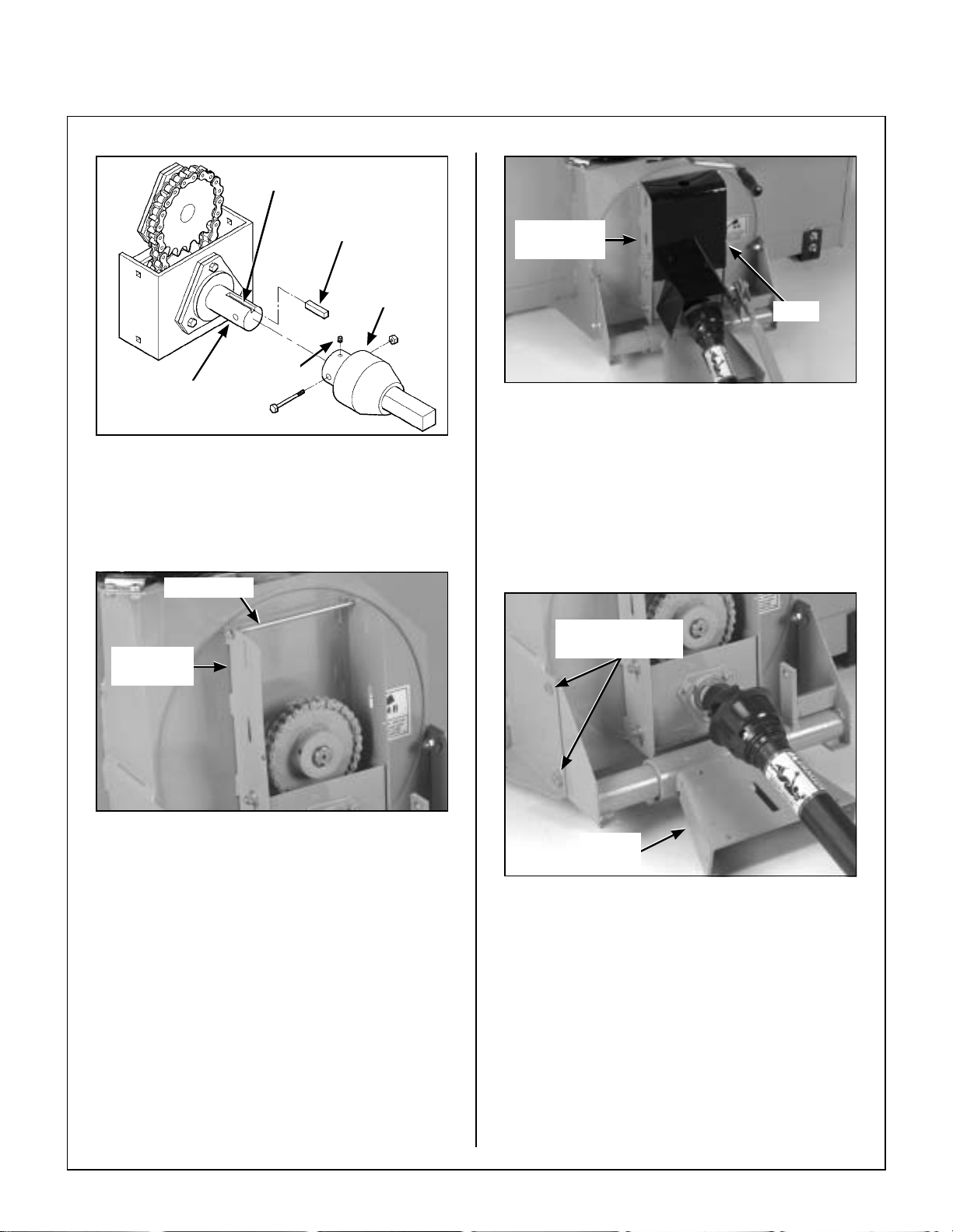

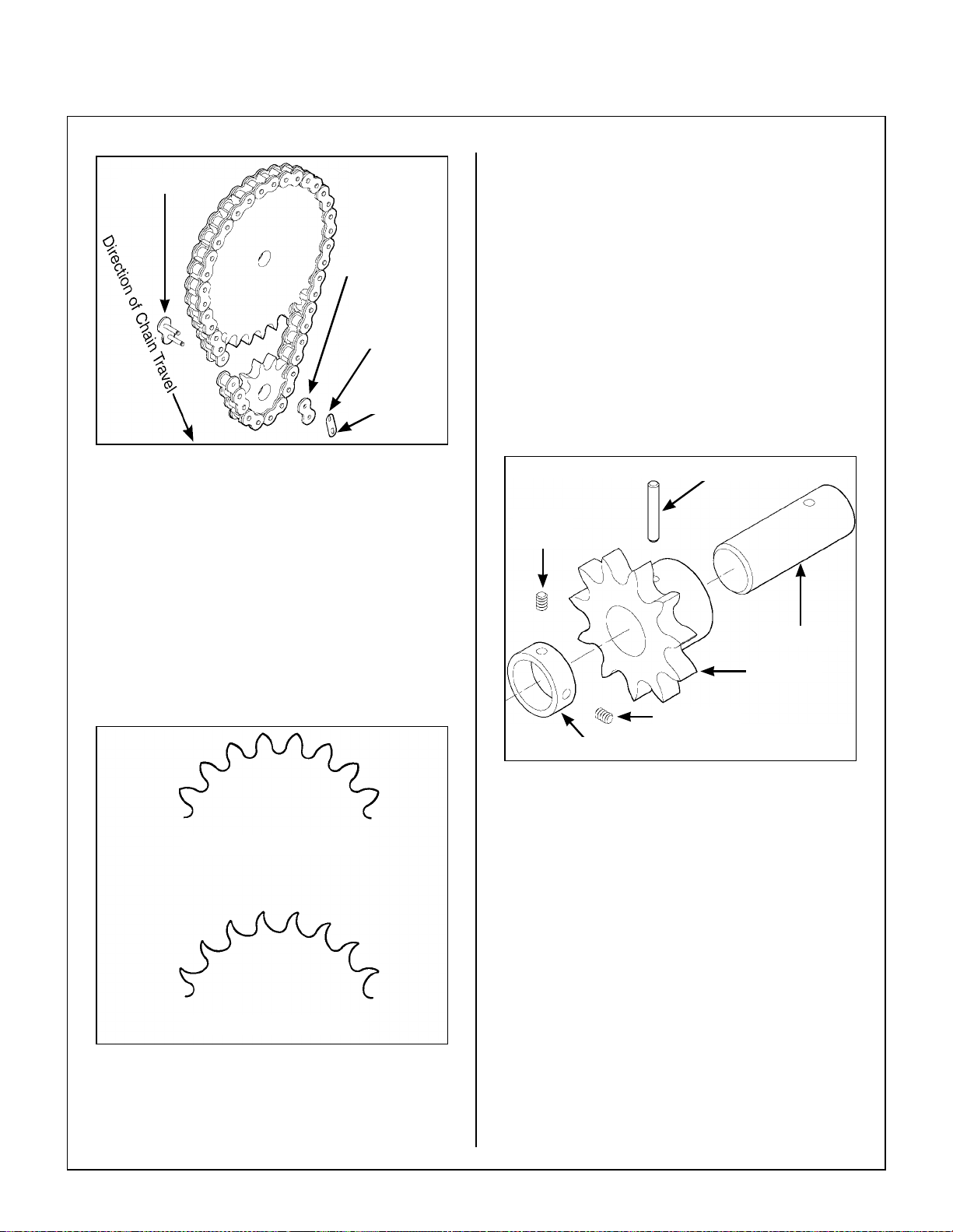

Snowblower Installation

1. Thoroughly clean the drive shaft yoke and install

a 1/4 x 1/4 x 1-1/4 in. key in the reduction shaft

keyway.

2. Slide the drive shaft yoke over the reduction

shaft.

3. Secure the yoke to the reduction shaft with a 1/4

x 2-1/2 in. bolt and nylon locknut. Tighten the

nut and the 3/8 x 3/8 in. allen set screw securely

over the key in the yoke.

Page 33

Assembly Instructions

Keyway

1/4 x 1/4 x

1-1/4 in. Key

Set Screw

Reduction

Shaft

Reduction

Box Cover

Drive

Shaft Yoke

Bolt

Install Reduction Box Cover

Attach Drive Shaft Yoke to Reduction Shaft

4. Install one 1/4 x 7-1/2 in. bolt through the upper

set of holes in the reduction box and secure

loosely with a lock washer and nut.

Install Bolt

Reduction

Box

Install Bolt in Reduction Box

5. Hook the reduction box cover over the bolt and

secure the cover with a second 1/4 x 7-1/2 in.

bolt, lock washer, and nut through the lower set

of holes in the reduction box. T orque both bolts

to 10 ft-lb (13.6 N·m).

6. Attach the female portion of the hitch to the

snowblower using one 3/8 x 1 in. bolt in the upper hole of each side, placing the bolt he ad on

the outside, with a flat washer, lock washer , and

nut on the inside. Use one 1/2 x 1 in. bolt, lock

washer and nut in the bottom hole of each side.

Tighten all four (4) bolts securely.

Bolt Heads On

Outside of Hitch

Female

Hitch

Mount Female Hitch to Snowblower

7. Insert the male quick hitch section of the implement hitch into the female hitch of the snowblower and lock in pla ce by moving the hitch

locking lever fully forward to the LOCKED position. Secure the latch with the linchpin. Refer

to Hitch Locking Lever in Operating Instruc-

tions.

8. Grease the drive shaft sliding surfaces and slide

the male shaft inside the female tube.

29

Page 34

Assembly Instructions

Clevis

Female

Hitch

Male Quick

Hitch

Hitch Locking

Lever

Attach Snowblower to Implement Hitch

9. Attach the driveline quick lock coupler to the

tractor PTO.

WARNING

This shaft turns at high RPM. If the collar

is not locked to the shaft at the tractor

end, or if the yoke at the blower end is not

secured properly, the drive shaft can fly

loose with great force, capable of causing

serious injury or death.

Parallel Bar

Clevis

Attach Parallel Bar to Female Hitch

1 1. Insert the rotation handle into the rotation worm.

Align the holes and lock in place with a 1/4 x

1 in. socket head cap screw and nylon locknut.

12. Install the plastic handle grip on the chute rotation handle.

Rotation

Handle

30

Driveline Coupler

Tractor PTO

Connect Driveline Coupler to Tractor PTO

10. Attach the parallel b ar to the female hitc h and

the implement adaptor using the two clevises

and spring clips.

Insert Rotation Handle into Rotation Worm

13. To install the optional tire chains:

a. Remove the tractor wheels.

b. Attach the tire chains to the wheels.

c. Place the wh eel spacer plates on the lug

bolts. The wheel spacer plates provide

clearance for the chains bet ween the tires

and the tractor body.

d. Place the wheels back on the tractor.

e. Reinstall and tighten the lug bolts.

Page 35

Assembly Instructions

14. For GHS (Grass Handling System) equipped

Walker tractors, install a blower intake cover in

the blower int ake tube. The cover “unloa ds” the

blower and s eal s the i ntake to effectively el im inate power loss and no ise when the blower is

not being used. Refer to GHS Blower Intake

Cover illustration for ROTARY BROOM in this

section.

15. For stability of the tractor when transporting with

the snowblower in raised position, approximately 80 lb (36 kg) of c ounterweight shou ld be installed on the tail of the tractor. Optional tail

weights for the various tractor models are available from your Walker dealer or a sandbag or

similar weight may be used.

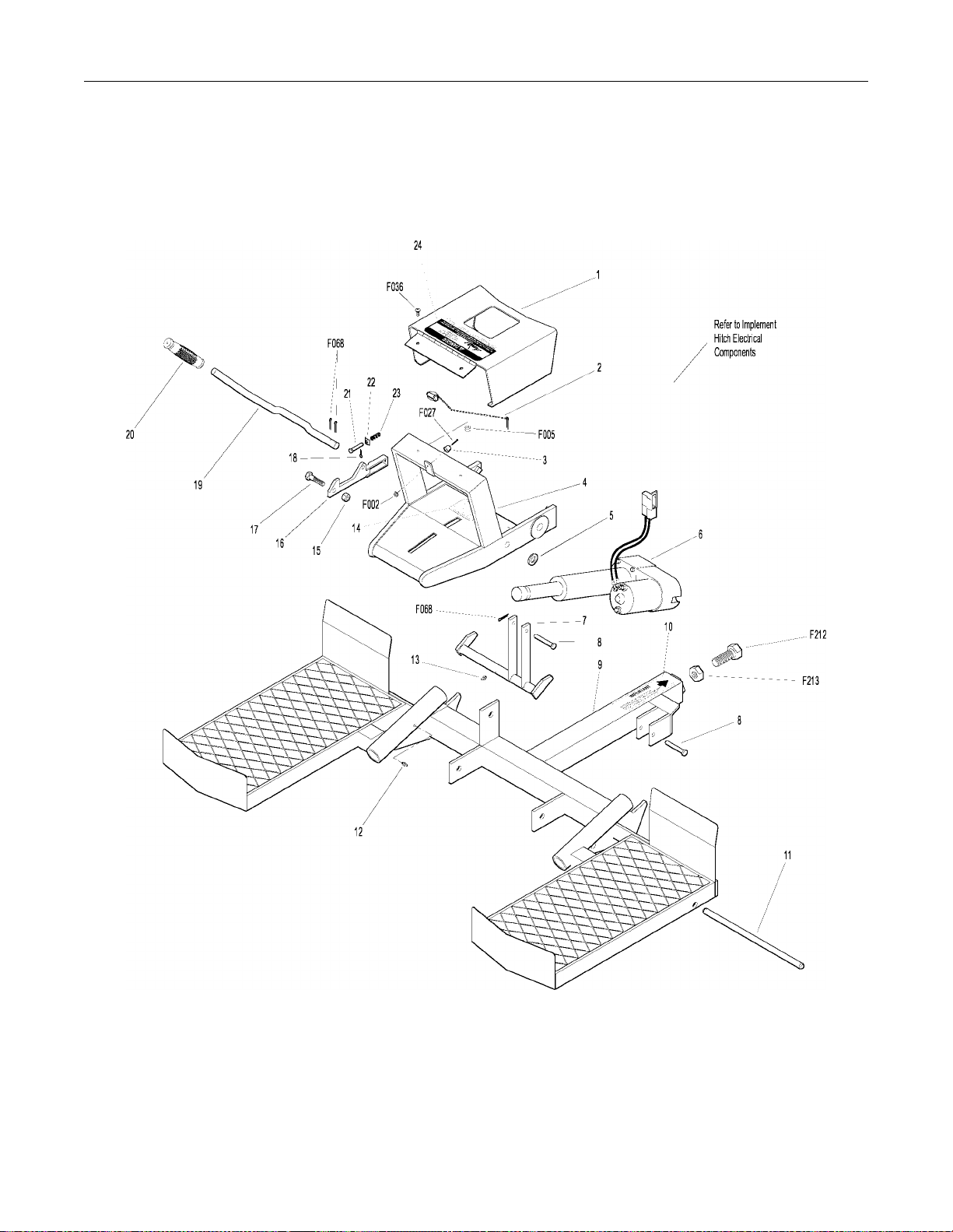

DEBRIS BLOWER

Debris Blower Installation

The debris blower is shipped completely assembled

except for the driveline, which must be connected to

the input shaft.

5. Reinstall the belt guard by reversing the removal procedure.

6. Insert the male quick hitch section of the implement hitch into the female hitch of the debris

blower and lock in pla ce by moving the hitch

locking lever fully forward to the LOCKED position. Secure the latch with the linchpin. Refer

to Hitch Locking Lever in Operating Instruc-

tions.

Linchpin

Hitch Locking

Lever

Female

Quick Hitch

1. Remove the belt guard from the debris blower

housing by removing the two (2) cover pins and

hairpins securing it to the housing.

2. Thoroughly clean the debris blower input sha ft

and install a 1/4 x 1/4 x 1-1/4 in. key in the input

shaft keyway.

3. Thoroughly clean the insi de of the tractor PTO

shaft and align the PTO shaft key way with the

key in the input s haft keyway.

4. Secure the PTO shaft to the input shaft with a

1/4 x 2-1/2 in. bolt and nylon loc knut. Tighten

the locknut and the set screw over the key.

Shear

bolt

Set Screw

Tractor

PTO

Attach Debris Blower to Implement Hitch

7. To install the optional tire chains:

a. Remove the tractor wheels.

b. Attach the tire chains to the wheels.

c. Place the wh eel spacer plates on the lug

bolts. The wheel spacer plates provide

clearance for the chains bet ween the tires

and the tractor body.

d. Place the wheels back on the tractor.

e. Reinstall and tighten the lug bolts.

8. For GHS (Grass Handling System) equipped

Walker tractors, install a blow er inta ke c over in

the blower intake tube. The cover “unloads” the

blower and seals the intake to effectively eli minate power loss and noise whe n the blower is

not being used. Refer to GHS Blower Intake

Cover illustration for ROTARY BROOM in this

section.

Attach Tractor PTO to Debris Blower Input Shaft

31

Page 36

Assembly Instructions

9. For stabili ty of th e tractor when tran sporting w ith

the debris blower in raised position, approximately 80 lb (36 kg) of counterweight should be

installed on the tail of the trac tor. Optional tail

weights for the various tractor models are available from your Walker dealer or a sandbag or

similar weight may be used.

PREOPERATING CHECKLIST

Before operating any of the imple ments for the first

time, and as a routine before dai ly operations, it is

important to make sure the machine is properly prepared and ready for operation. The following is a list

of items to be che cked. (For machines with frequent operation, some of these items will not need to

be checked every day, but the operato r should be

aware of the condition of each.)

CHECK TRACTOR PREOPERATING

CHECKLIST

Refer to the appropriate Tractor Owner’s Manual.

CHECK GAUGE WHEEL OR SKID SHOE

ADJUSTMENT

Implement Hitch

CHECK LIFT SWITCH OPERATION

Raise and lower the imp lement hitch to make sure

the lift switch and linear actuator operate properly.

CHECK HITCH LOCKING LEVER

Lock and unlock t he male hitch to make sure the

locking mechanism functions properly.

Refer to Hitch Locking Lever in Operating Instruc-

tions.

Dozer Blade

CHECK CUTTING EDGE

• Make sure the c utting edge is not nicked, bent

or worn.

Refer to REPLACING/REPAIRING of Dozer Blade

Cutting Edge in Maintenance Instructions.

CHECK TRIP SPRING

Refer to ADJUSTMENTS of Dozer Blade Skid

Shoes in Maintenance Instructions.

Refer to ADJUSTMENTS of Rotary Broom Gauge

Wheels in Maintenance Instructions.

Refer to ADJUSTMENTS of Two-Stage Snow-

blower Skid Shoes in Maintenance Instructions.

Refer to ADJUSTMENTS of Debris Blower Front

Gauge Wheel in Maintenance Instructions.

CHECK OPTIONAL TIRE CHAINS

Tire chains should always be used whe n operating

the machine in icy conditions. If the tractor is

equipped with the optional tire chains, make sure

the chains are in good c ondition and are installed

properly.

CHECK TRACTOR TAILWEIGHT

Make sure 80 lb (36 kg) weight has been installed on

rear of tractor.

• Check trip spring tension.

Refer to Trip Spring in Operating Instructions.

• Check trip spring lockout bracket.

Refer to Normal Operat ion or Rigid Blade Operation in Operating Instructions.

CHECK SWIVEL ADJUSTMENT

Refer to Angle Adjustment Pin in Operating In-

structions.

Rotary Broom

CHECK BRUSH

• Make sure the brush is clear of snow and/or

ice.

• Make sure the brush is free to rotate.

• Check that the bristles are in good condition

and are not worn or bent.

32

Page 37

Assembly Instructions

CHECK BROOM ANGLE ADJUSTMENT

Refer to Angle Adjustment L ever in Operating In-

structions.

CHECK DRIVE CHAIN

Refer to LUBRICATION for Rotary Broom Drive

Chain in Maintenance Instructions.

Refer to ADJUSTMENTS of Rotary Broom Drive

Chain T ension in Maintenance Instructions.

CHECK GEARBOX

Refer to LUBRICATION for Rotary Broom Gear-

box in Maintenance Instructions.

CHECK SIDE TO SIDE LEVEL ADJUSTME NT

Refer to ADJUSTMENTS of R otary Broom Brush

Leveling in Maintenance Instructions.

CHECK BRUSH TO GROUND CONTACT

PRESSURE ADJUSTMENT

Refer to Ground Contact Knob in Operating In-

structions.

CHECK CHUTE AND DEFLECTOR

• Make sure the chute and deflector are not

clogged with snow and/or ice.

• Turn the chute rotation handle and rotate the

chute. The chute should rotate freely.

• Use the deflector position control knobs and

raise and lower the deflector. The deflector

should move freely.

CHECK GEARBOX

Refer to LUBRICATION for Two-St age Snowblow-

er Gearbox in Maintenance I nstructions.

CHECK REDUCTION CHAIN

Refer to LUBRICATION for Two-St age Snowblow-

er Reduction Chain in Maintenance Instructions.

Refer to ADJUSTMENTS for Two-Stage Snow-

blower Reduction Chain Tension in Maintenance

Instructions.

Debris Blower

CHECK CHUTE AND DEFLECTOR

Two-Stage Snowblower

CHECK CUTTING EDGE

• Make sure the cutting edge is n ot nicked, bent

or worn.

Refer to REPLACING/REPAIRING of Two-Stage

Snowblower Cutting Edge in Maintenance Instruc-

tions.

CHECK AUGER

• Make sure the auger is clear of snow and/or

ice.

• Make sure the auger is free to rotate.

• Check that the auger flighting and paddle

blades are in good condition and not bent.

• Make sure the chute and deflector are not

clogged with leaves and/or debris.

• Turn the chute rotation handle and rotate the

chute. The chute should rotate freely.

• Use the deflector position control knob and

raise and lower the deflector. The deflector

should move freely.

CHECK GAUGE WHEEL TIRE PRESSURE

• Make sure the tire pressure is 20 PSI (137 kPa).

INSPECT DRIVE BELT

Refer to ADJUSTMENTS of Debris Blower Drive

Belt Tension in Maintenance Instructions.

CHECK BLOWER FAN

• Make sure the fan is clear of debris.

• Make sure the fan is free to rotate.

• Check that the fan blades are in good condition

and not bent.

33

Page 38

Operating Instructions

Snow Removal

WARNING

Foreign objects in snow may be thrown

farther than the snow. Use the slowest

brush speed that will perform the job.

Stay aware of the broom discharge direction at all times.

Rotate Chute

Clockwise

Rotate Chute

Counterclockwise

1. The rotary broom works best on snow depths of

4 in. (10 cm) or less. Larger amounts of snow

can be moved if the ground speed is reduced.

2. T o avoid snow being blown back onto the tractor

and operator, sweep with the wind blowing in

the direction of broom discharge.

Lawn Thatching and Leaf Raking

CAUTION

Optional gauge wheels must be installed

to perform these types of operation in order to avoid excessive brush ground c ontact.

1. Bristles should barely touch the ground for lawn

thatching, and barely touch the grass in leaf raking operations.

2. Slower brush speed and ground speed are

more adequate for lawn thatching. This will prevent “bouncing” which could damage the lawn

due to excessive ground contact.

Chute Rotation

Handle

Chute Rotation Handle

Deflector Position Control Knobs

Set the angle of the deflecto r according to the distance the snow must be thr own. To adjust the de flector angle, loosen the two knobs on the sides of

the deflector, slide the deflector to the required angle, and securely retighten the two knobs.

Deflector Position

Control Knobs

38

3. Minimize dust by sweeping when moisture is

high (but not wet) whenever possible.

TWO-STAGE SNOWBLOWER CONTROLS

Chute Rotation Handle

The chute rotation handle is located on the rear of

the snowblower head, on the lo wer RH side of the

discharge chute. The chute rotates in a 228 degree

arc, by cranking the rotation handle. Turning the

handle clockwise rotates the chute clockwise.

Turning the handle count erclockwise rotates the

chute counterclockwise.

Deflector Position Control Knobs

TWO-STAGE SNOWBLOWER OPERATION

CAUTION

Before operating the snowblower, read

and understand all Safety Instructions and

Operating Instructions.

Raising and Lowering the Snowblower Refer to Implement Lift Switch in this section.

Page 39

Operating Instructions

Engaging the Snowblower

1. Make sure that the snowblower is clear of snow

and/or ice before engaging the snowblower.

2. Make sure that the auger and fan operate freely.

3. Check the oil level in th e worm gearbox an d if

necessary, add SAE 90 E.P. (Extreme Pressure) oil. Make sure the oil level is up to the side

plug. (Refer to LUBRICATION of Two-Stage

Snowblower Gearbox in Maintenance Instructions.)

4. Check the three (3) shear bolts, one on each auger section, and one between the fan and gearbox for proper tight ness, approximately 8 ft-lb

(11 N·m).

5. Adjust the snowblower so that it runs level.

6. Set the engine throttle at about 1/3 speed. DO

NOT attempt to engage the PTO clutch at

high engine speeds. This will drastically short-

en drive belt life . Use only moderate engine

speed when engaging the PTO clutch.

DANGER

If the auger strikes a solid object or the

machine begins to vibrate abnormally , immediately disengage the PTO clutch, stop

the engine, and wait for all moving parts

to stop. Disconnect the fuel solenoid wire

[diesel engines] or the spark plug wire(s)

[gasoline engines] to prevent accidental

starting. Thoroughly inspect the snowblower and repair any damage before restarting the engine and operating the

machine. Make sure auger blades are in

good condition and all bolts are tight.

7. Pull the PTO clutch lever SLOWLY to engage

the snowblower.

NOTE: For cold weather operation, allow sufficient time for the snowblower components (i.e.,

gearbox oil) to warm up before beginning to blow

snow.

DANGER

A safety interlock switch (seat switch) will

cause the engine to stop if the PTO clutch

is engaged and the operator is not in the

seat. The function of this switch should

be checked by the operator raising off the

seat and engaging the PT O clutch; the e ngine should stop. If the switch is not

working, it should be rep aired or replaced

before operating the snowblower. DO

NOT disconnect the safety switche s; they

are for the operator’s protection.

IMPORTANT: DO NOT engage the PTO clutch

when transporting the machine. DO NOT engage

the PTO clutch with the PTO shaft disconnected

(the snowblower removed from the tractor).

Engaged

Position

PTO Clutch Engaged

Disengaged

Position

PTO Clutch Disengaged

Recommendations For Snowblowing

IMPORTANT: Operate the engine at full speed

when snowblowing, to allow the eng ine to produce

full horsepower and to increase efficiency of the engine cooling system.

39

Page 40

Operating Instructions

• When operati ng on a slope, re duce speed and

use caution to start, stop, and maneuver. Avoid

sharp turns or sudden changes in direction.

• When blowing through deep snow drifts, le t the

snowblower work its way through the drifts. For best

results, raise the snowblower and remove a top layer of snow, then pass through the area a second

time to remove the remaining snow.

• When snowblowing, operate the engine at or near

full throttle for the best snowblowin g action. The

engine is designed to be operated at full speed.

• Use optional tire chains or optional all-terrain tires

to improve traction.

• Disengage the PTO clutch to stop the snowblow-

er when driving the machine but not blowing snow.

• Avoid damage to property and extra snowblowing

work by carefully choosing the direction to move

the snow. Orient the blow er a w ay fr om p eop le and

property due to the possibility of thrown objects.

• T o momentarily increase traction in case the drive

wheels are slipping , use the lift switch to rai se the

snowblower slightly and transfer extra weight on the

drive wheels.

Throw Snow to One Side

Use the following pattern where snow can be thrown

to both sides. Start in the middle with the blower

spout directed to either the right or left. Drive

from one end to the other in an outward spiral,

without changing the position of the blower

spout to throw snow to both sides.

Removing Snow

DANGER

DO NOT blow snow with bystanders in the

area (especially children or pets).

A definite operating pattern is required to thoroughly

clean snow from an area. Each pattern described

below clears all the snow in one pass (of the pattern)

and prevents throwing snow in unwanted places.

IMPORTANT: DO NOT use the snowblower as a

dozer blade to push snow. Let the snowblower work

its way through deep snow. If the tractor is driven

forward into snow too fast, the snowblower may

become overloaded and clog.

Use the following pattern where snow can be thrown

only to one side. Start on the side farthest from

where the snow will be thrown. At the end of the

first pass, rotat e the blower spout 180 degrees for

the return pass. At the end of each following pass,

rotate the spout 180 degrees to keep throwing snow

in the same direction.

Throw Snow to Both Sides

Clogging Checklist

In case of clogging, the snow throwing action will decrease and finally stop. When this occurs, disengage the PTO clutch, stop the engine, disconnect

the fuel solenoid wire [diesel engines] or spark plug

wire(s) [gasoline eng ines], and rem ove the ignition

key. Make sure all movement has stopped be-

fore attempting to unclog.

40

Page 41

Operating Instructions

DANGER

DO NOT attempt to unclog the snowblower or make any adjustments with the tractor engine running. Disengage the PTO

clutch, stop the engine, and remove the

ignition key.

DANGER

Chute Rotation

Handle

NEVER place hands in the blower spout.

DO NOT use hands or feet to unclog the

snowblower. Use a short stick or si milar

tool to remove any clogged material.

The following list of items should be checked if a pattern of clogging begins to develop. All of these items

are capable of causing clogging.

• Check that the inside of the snowblower housing

is clean and free of snow and/or ice buildup.

• Check that the auger is in good condition and not

bent, both the auger f lighting and the center paddles.

• Check the insi de of t he bl ower s pout for smooth-

ness and freedom of obstruction.

Remember, anything that restricts airflow or material flow along the e ntire path from the auger to the

blower spout can cause clogging.

DEBRIS BLOWER CONTROLS

Chute Rotation Handle

Chute Rotation Handle

Deflector Position Control Knob

Set the angle of the deflector ac cording to the distance the debris must be thrown. To adjust the deflector angle, loosen the knob on the RH side of the

deflector, slide the deflector to the required angle,

and securely retighten the knob.

Deflector Position

Control Knob

Deflector Position Control Knob

DEBRIS BLOWER OPERATION

The chute rotation handle is lo cated on the rear of

the debris blower, on the upp er RH side of the impeller housing. The chut e rotates in a 230 degree

arc, by cranking the rotation handle. Turning the

handle clockwise rotates the chute clockwise.

Turning the handle counterclockwise rotates the

chute counterclockwise.

CAUTION

Before operating the debris blower, read

and understand all Safety Instructions and

Operating Instructions.

Raising and Lowering the Debris Blower

Refer to Implement Lift Switch in this section.

41

Page 42

Operating Instructions

Engaging the Debris Blower

1. Set the engine throttle at about 1/3 speed. DO

NOT attempt to engage the PTO clutch at

high engine speeds. This will drastically short-

en drive belt life . Use only moderate engine

speed when engaging the PTO clutch.

2. Pull the PTO clutch lever SLOWLY to engage

the debris blower.

NOTE: For cold weather operation, allow sufficient time for th e debris blower com ponents to

warm up before beginning to blow debris.

WARNING

A safety interlock switch (seat switch) will

cause the engine to stop if the PTO clutch

is engaged and the operator is not in the

seat. The function of this switch should

be checked by the operator raising off the

seat and engaging the PT O clutch; the e ngine should stop. If the switch is not

working, it should be rep aired or replaced

before operating the debris blower. DO

NOT disconnect the safety switche s; they

are for the operator’s protection.

IMPORTANT: DO NOT engage the PTO

clutch when transporting the machine. DO NOT

engage the PTO clutch with the PTO shaft

disconnected (the debris blower removed from

the tractor).

Recommendations For Operating the Debris Blower

IMPORTANT: Operate the engine at full speed

when operating the debr is blower, to allow the engine to produce full horsepow er a nd to i nc reas e efficiency of the engine cooling system.

• When operati ng on a slope, re duce speed and

use caution to start, stop, and maneuver. Avoid

sharp turns or sudden changes in direction.

the debris. Orient the blower away from people and

property due to the possibility of thrown objects.

• T o momentarily increase traction in case the drive

wheels are slipping, use the lift switch to rais e the