Page 1

A13 Operator Soft Cab

Operator’s Manual

Assembly, Attaching, Operation and Maintenance

Compatible with models: MC

Please Read and Save These Instructions

For Safety, Read All Assembly and Operation Instructions

Prior to Operating Attachment

Eective Date: 03.12.18

P/N: 7662-12

Page 2

Foreword

Thank you. . .for purchasing a Walker Operator Soft Cab. Every effort has been made to provide

you with the most reliable machine on the market, and we are sure you will be among our many

satised customers. If for any reason this product does not perform to your expectations, please

contact your local dealer. Every customer is important to us. Your satisfaction is our goal.

Please. . .read this manual thoroughly! Before you operate your machine, please read this entire

manual. Some of the information is crucial for proper operation - it will help protect your investment

and ensure that the machine performs to your satisfaction. Some of the information is important

to your safety, and must be read and understood to help prevent possible injury to the operator

or others. If anything in this manual is confusing or hard to understand, please contact your local

authorized dealer or call our service department, at (970) 221-5614, for clarication before operating

or servicing this machine.

This manual covers the A13 Operator Soft Cab.

All shields and guards must be in place for the proper and safe operation of this machine.

Where they are shown removed in this manual, it is for illustration purposes only. Do not operate

this machine unless all shields and guards are in place.

Walker Mfg. Co. is continually striving to improve the design and performance of its products.

We reserve the right to make changes in specications and design without thereby incurring any

obligation relative to previously manufactured products.

Sincerely,

WALKER MANUFACTURING COMPANY

Bob Walker, President

i

Page 3

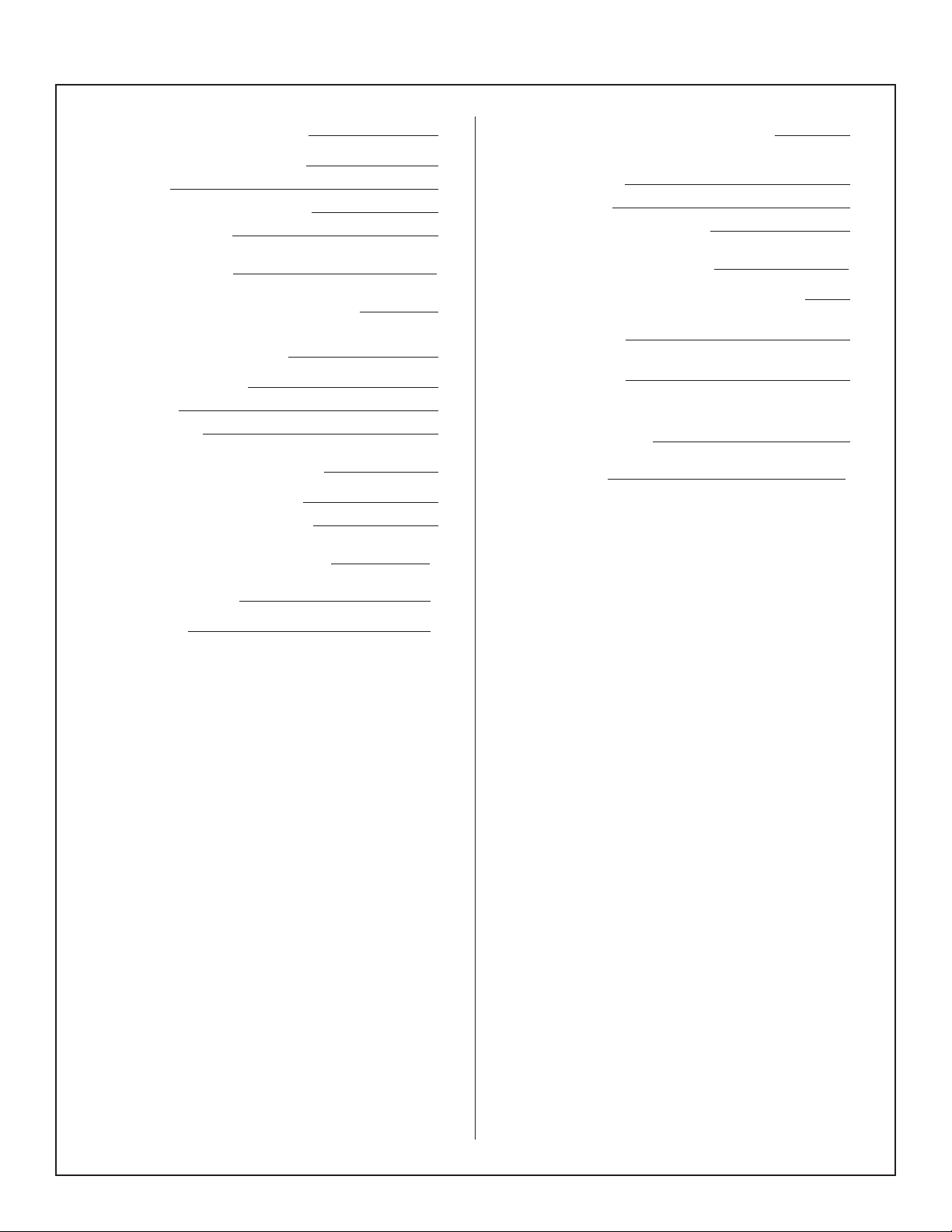

Table of Contents

General Information 1

HIGHLIGHTED INFORMATION 1

GLOSSARY 1

SERVICING OF COMPONENTS 1

UNIT DESCRIPTION 1

Specications 2

Component Identication 3

Safety Instructions 4

BEFORE OPERATING 4

OPERATING 5

MAINTENANCE 6

Assembly Instructions 8

INSTALL SOFT CAB MOUNTS 8

ASSEMBLE SOFT CAB FRAME 9

Operating Instructions 14

Maintenance Instructions 14

WINDSHIELD WIPER BLADE

REPLACEMENT 14

LUBRICATION 14

END OF SEASON STORAGE 14

Parts List/Diagram 15

OPERATOR SOFT CAB ASSEMBLY (A13) 16

ELECTRICAL - OPERATOR

SOFT CAB (A13) 17

FABRIC AND MOUNTS - OPERATOR

SOFT CAB (A13) 18

Maintenance and Service

Records Sheet 19

Warranty 20

WINDSHIELD WIPER 14

HEADLIGHTS 14

ii

Page 4

General Information

HIGHLIGHTED INFORMATION

Walker Manufacturing recommends that any service

requiring special training or tools be performed by

an authorized Walker Mower Dealer. There are several general practices to be aware of in the area of

safety. Most accidents associated with the operation or maintenance of a Walker Tractor are caused

by disregarding basic safety precautions or specic

warnings. Such accidents, in most cases, can be

prevented by being aware of the dangers present.

Information of special importance has been high-

lighted in bold type in this manual. Refer to Safety

Instructions for the meanings of DANGER, WARN-

ING, CAUTION, IMPORTANT, and NOTE.

GLOSSARY

There are many terms that are either unique to this

equipment or that are used as acronyms. The following terms and their denitions will help while using

this manual:

● FORWARD SPEED CONTROL (FSC) controls

the maximum forward speed of the tractor; func-

tioning as a cruise control.

● IMPLEMENT refers to the dozer blade, rotary

broom, two-stage snowblower, or debris blower

used with the tractor with an implement hitch

installed.

● LEFT HAND (LH) refers to the left-hand side of

the tractor when the operator is seated facing

forward in the tractor seat.

SERVICING OF OPERATOR SOFT CAB

Only routine maintenance and general service instructions are provided in this manual. Any unau-

thorized work done during the warranty period

may void the warranty. If you have any difculty

nding an authorized outlet or obtaining warranty

service, please contact our Service Department for

assistance:

Walker Manufacturing Company

5925 E. Harmony Road

Fort Collins, CO 80528

1-970-221-5614

www.walker.com

UNIT DESCRIPTION

The Operator Soft Cab is designed to shield the

operator from winter weather when using the 42”

Snow Blower, 47” Rotary Broom and 48” Dozer

Blade. The cab features a hinged door for operator

entry, glass windshield, electric windshield wiper

and LED headlights. A removable canvas ap attaches to the rear of the cab and covers the open

area between the operator seat and top of the

catcher box or dump box; the canvas ap raises to

allow the tractor body to be raised for maintenance.

The Implement Mount Hitch (H10) is required to

mount the operator soft cab on the tractor. The hitch

mounts on the tractor in place of the mower deck in

less than a minute. The operator soft cab ts into

mounts that will be added to the side of the implement hitch and tractor chassis during the assembly

process described in this manual.

● MACHINE consists of the implement installed

on the tractor, functioning as a single unit.

● POWER TAKE-OFF (PTO) transmits engine

power to run the cutter blades and GHS blower.

● RIGHT HAND (RH) refers to the right-hand side

of the tractor when the operator is seated facing

forward in the tractor seat.

● STEERING LEVERS steer the tractor by con-

trolling the two transaxles.

● TRACTOR is the prime mover, including the en-

gine, drivetrain, operator seat, and controls to

operate the mower.

1

Page 5

Specications

OPERATOR SOFT CAB

MODEL A13

Height* in. (cm) 64 (163)

Width in. (cm) 35 (89)

Length in. (cm) 42 (107)

Weight lb (kg) 54 (25)

Windshield Wiper Motor 12 Volt DC Electric, Operated by Toggle Switch Mounted in

Soft Cab

Headlights 10-30 Volt DC LED (25 Watts)

NOTE: The manufacturer reserves the right to make changes in specications shown herein at any time without

notice or obligation.

* When installed on tractor

NOTE: An optional Front Cab Extension Flap (P/N 7661-4) is available to enclose the front of the cab and pro-

tect the operator when using the Dozer Blade Implement. Do not use when operating an implement with a PTO

drive shaft.

2

Page 6

Component Identication

LED Headlights

Windshield Wiper

Glass Windshield

Soft Cab

LH Cab Mount

Door Handle

H10 Implement

Mount Hitch

3

Door

A13 Operator Soft Cab, LH View

Front Cab

Mount, LH

Page 7

Safety Instructions

Pay particular attention to any information labeled

DANGER, WARNING, CAUTION, IMPORTANT, and

NOTE in this manual.

When you see the Safety Alert Symbol ( ), read,

understand, and follow the instructions. Fail ure to

comply with safety instructions may result in personal

injury.

The seriousness or degree of importance of each type

of information is dened as follows:

DANGER

An IMMEDIATE hazard that WILL result in severe personal injury or DEATH, if warning is

ignored and proper safety precautions are

not taken.

WARNING

A POTENTIAL hazard that COULD result in

severe personal injury or DEATH, if warning

is ignored and proper safety precautions are

not taken.

Walker Manufacturing cannot predict every potentially

dangerous situation. Therefore, items labeled as such

in this manual do not cover all conceivable situations.

Any person using procedures, tools, or control techniques not recommended by Walker Manufacturing

must take full responsibility for safety.

The Walker Rider Lawnmower has been designed

with many safety features to protect the operator from

personal harm or injury. However, it is necessary for

the operator to use safe operating procedures at all

times. Failure to follow safety instructions con-

tained in this manual may result in personal injury

or damage to equipment or property.

If you have any questions concerning setup, operation, maintenance, or safety, please contact your

authorized Walker Mower dealer or call Walker

Manufacturing Company at (970) 221-5614.

BEFORE OPERATING

1. Read and understand the contents of this Operator’s Manual before starting and operating

the machine. Become thoroughly familiar with all

machine controls and how to stop the machine

and disengage the controls quickly. Replacement

Operator’s Manuals are available by sending the

Model and Serial Number to:

Walker Manufacturing Company

5925 East Harmony Road

Fort Collins, CO 80528

CAUTION

Possible hazards or unsafe practices that

MAY result in MODERATE personal injury or

property damage, or machine damage, if

warning is ignored and proper safety precautions are not taken.

IMPORTANT: Identies mechanical information

demanding special attention, since it deals with the

possibility of damaging a part or parts of the machine.

NOTE: Identies information worthy of special

attention.

2. Never allow children to operate rider mower.

Do not allow adults to operate without proper instruction.

3. Do not allow anyone other than the operator on

the machine.

4. Keep everyone, especially children and pets, a

safe distance away from the area of operation.

Do not mow with bystanders in the area.

5. Do not operate the machine barefoot or wearing

sandals, sneakers, tennis shoes, or similar lightweight footwear. Wear substantial protective

footwear.

6. Do not wear loose tting clothing that could get

caught in moving parts. Do not operate this ma-

chine while wearing shorts; always wear adequate protective clothing, including long pants.

Wearing safety glasses, safety shoes, and a helmet is advisable and required by some local ordinances and insurance regulations.

4

Page 8

Safety Instructions

7. Prolonged exposure to loud noise can cause im-

pairment or loss of hearing. Operator hearing

protection is recommended. Wear a suitable

hearing protective device, such as earmuffs or

earplugs.

8. Keep all protective shields and safety devic-

es in place. If a protective shield, safety device,

or decal is damaged, unusable, or missing, repair or replace it before operating the machine.

9. Be sure interlock switches are functioning

correctly, so the engine cannot be started unless the Forward Speed Control lever is in the

NEUTRAL-PARK position, and the PTO clutch

is in the DISENGAGED position. Also, the engine should stop if the operator lifts off the seat

with either the Forward Speed Control (FSC)

out of the NEUTRAL-PARK position or the PTO

clutch in the ENGAGED position.

10. Handle gasoline with care. Gasoline is highly

ammable and its vapors are explosive:

a. Use an approved fuel container.

b. Never add fuel to a running engine or hot

engine (allow hot engine to cool several

minutes).

c. Keep matches, cigarettes, cigars, pipes,

open ames, or sparks away from the fuel

tank and fuel container.

d. Always ll the fuel tank outdoors using care.

Fill to about one inch from the top of the tank.

Use a funnel or spout to prevent spilling.

e. Replace the machine fuel cap and container

cap securely and clean up any spilled fuel

before starting the engine.

11. Never attempt to make any adjustments while

the engine is running, except where specical-

ly instructed to do so.

WARNING

This product can expose you to chemicals

including Di-(2-ethylhexyl) phthalate which

is known to the State of California to cause

cancer, and Di-(2-ethylhexyl) phthalate,

which is known to the State of California

to cause birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

OPERATING

NOTE: Refer to your tractor Operator’s Manual for

safety instructions for operating the tractor.

1. Operate the machine only in daylight or in

good articial light with good visibility of areas

being cleaned.

2. Sit on the seat when starting the engine and operating the machine. Keep feet on footrests at

all times when the tractor is moving and/or the

implement is operating.

3. For a beginning operator, learn to steer (ma-

neuver) the tractor with a slow engine speed

before attempting any implement operation.

Be aware that, with the front mounted implement

conguration, the back of the machine swings to

the outside during turns.

DANGER

Do not operate around overhanging tree

branches or bushes at the same height as

the operator’s torso and head where inadvertent contact may cause injury.

12. The snow or leaves can sometimes hide objects

that might clog the snowblower or debris blower

chute, or otherwise cause damage. Clear the

area of doormats, sleds, boards, wires and other

debris.

13. The electrical system battery contains sulfuric

acid. Avoid any contact with skin, eyes, and

clothing. Keep the battery and acid out of reach

of children.

5

4. Remember, for an emergency stop, the forward

motion of the tractor can always be stopped by

pulling the Forward Speed Control (FSC) into the

NEUTRAL-PARK position.

Page 9

Safety Instructions

5. In case the transmission drive belt breaks during

operation, and if the machine is on a slope, the

machine will freewheel down the slope. To

maintain control, immediately (1) Release the

steering levers and simultaneously (2) Move the

FSC to the NEUTRAL-PARK position. When

the machine is stopped or moving slowly, engage the parking brake.

NOTE: The emergency stop procedure is exact-

ly the same procedure used to normally stop and

park the machine.

6. Disengage the PTO clutch and put the FSC in

the NEUTRAL-PARK position before starting

the engine (an ignition interlock switch normally

prevents starting of the tractor if these controls

are in the OPERATING position).

7. Do not operate the machine if the operator

presence safety switch system is not working. Verify proper operation by having the oper-

ator lift off the seat with the engine running and

moving two controls, one at a time; (1) Move the

FSC lever out of the NEUTRAL-PARK position,

and (2) Engage the PTO Clutch. Moving either

control should stop the engine immediately.

14. Never adjust gauge wheels or skid shoes with

the engine running. Before adjusting height or

servicing, disengage the PTO clutch, stop the

engine, and remove the ignition key. Wait for

all movement to stop before getting off the seat.

NOTE: The PTO brake should stop drive line

rotation within ve (5) seconds of disengaging

the PTO clutch. If the brake is not functioning

properly, have it repaired by an authorized dealer immediately.

15. If the implement strikes a solid object or the ma-

chine begins to vibrate abnormally, immediately

disengage the PTO clutch, stop the engine,

and wait for all moving parts to stop. Dis-

connect the fuel solenoid wire [diesel engines]

or the spark plug wire(s) [gasoline engines] to

prevent accidental starting. Thoroughly inspect

the implement and repair any damage before restarting the engine and operating the machine.

Make sure implement components are in good

condition and all bolts are tight.

16. Do not touch the engine or mufer while the

engine is running or immediately after stopping

the engine. These areas may be hot enough to

cause serious burns.

8. Do not run the engine in a conned area

without adequate ventilation. Exhaust fumes

are hazardous and can be deadly.

9. Do not carry passengers - maximum seating

capacity is one (1) person.

10. Avoid sudden starts or stops. Before backing

the machine up, look to the rear to be sure no

one is behind the machine. Watch carefully for

trafc when crossing or working near roadways.

11. When moving forward, do not suddenly put the

tractor in reverse by rapidly pulling on the steering levers, especially when going downhill, as

this can lift the tractor tail wheel off the ground

and set up a bucking motion due to operator

overcontrol. If bucking does occur, immediately stop the bucking action by pulling the Forward Speed Control (FSC) lever into the NEU-

TRAL-PARK position.

12. Disengage the PTO clutch when transporting

the machine.

13. Do not operate across the face of slopes. Use

extreme caution when changing direction on

slopes. Do not attempt to operate on steep

slopes.

17. When leaving the machine unattended, disengage the PTO clutch, stop the engine, and remove the ignition key.

MAINTENANCE

NOTE: Refer to your tractor Operator’s Manual for

safety instructions for tractor maintenance.

1. To prevent accidental starting of the engine

when servicing or adjusting the machine, remove the key from the ignition switch and disconnect the fuel solenoid wire [diesel engines]

or the spark plug wire(s) [gasoline engines].

2. To reduce re hazards, keep the engine free of

grass, leaves, excessive grease, and dirt.

3. Keep all nuts, bolts, and screws tight to ensure

the machine is in a safe, working condition.

4. Perform only maintenance instructions described in this manual. Unauthorized mainte-

nance operations or machine modications may

result in unsafe operating conditions.

5. If the engine must be running to perform a main-

tenance adjustment, keep hands, feet and

clothing away from moving parts. Do not

wear jewelry or loose clothing.

6

Page 10

Safety Instructions

6. Always use proper engine service manuals

when working on the engine. Unauthorized

maintenance operations or modications to the

engine may result in unsafe operating conditions.

7. Altering the machine in any manner which adversely affects its operation, performance, durability or use will VOID the warranty and may

cause hazardous conditions.

8. Never attempt to disconnect any safety devices

or defeat the purpose of these safety devices.

9. Do not change the engine governor settings or

overspeed the engine. The governor has been

factory-set for maximum-safe engine operating

speed.

10. Use genuine factory replacement parts. Sub-

stitute parts may result in product malfunction

and possible injury to the operator and/or others.

IMPORTANT: Keep all applicable manuals immediately accessible to anyone who may operate or service this machine.

7

Page 11

Assembly Instructions

INSTALL SOFT CAB MOUNTS

1. Remove the two (2) bolts and two (2) whiz lock

nuts that fasten the clutch lever assembly to the

fuel tank mount. Install the RH cab mount (P/N

7669-7), as shown in Install RH Cab Mount In-

stallation photo and tighten hardware as shown

in Fabric and Mounts - Operator Soft Cab

(A13) on page 18.

RH Cab Mount

P/N 7669-7

F255 Hex Bolts

and F009 Whiz

Lock Nuts

RH Cab Mount Installation

2. Position and clamp the LH cab mount (P/N

7669-11) into place making sure there is a 1/4

in. gap between the LH cab mount and the motor mount straps as shown in LH Cab Mount

Installation photo and Motor Mount Strap and

LH Cab Mount Gap illustration.

LH Cab Mount

P/N 7669-11

Clamp

LH Cab Mount Installation

MOTOR MOUNT

STRAP

(REF)

1/4” GAP

PLACE 7669-11 1/4”

AWAY FROM CHASSIS

BEFORE MARKING

AND DRILLING HOLES

MARK AND DRILL

5/16” DIA HOLE

USING 7669-11 AS

TEMPLATE

MARK AND DRILL

5/16” DIA HOLE

USING 7669-11 AS

1/4” GAP BETWEEN FRONT AND REAR

MOTOR MOUNTS AND LH CAB MOUNT

Motor Mount Strap and LH Cab Mount Gap (1/4 in.)

TEMPLATE

MOTOR MOUNT

STRAP

(REF)

(TWO PLACES)

8

Page 12

Assembly Instructions

3. Using the LH cab mount as a template, mark and

drill both the rear hole and the lower mounting

hole using a 5/16 in. drill as shown in Rear Bolt

Location For LH Cab Mount illustration.

NOTE: In order to drill the lower mounting hole,

it will be necessary to lift the tractor or tilt-up from

the rear for access to the front motor mount.

MARK AND DRILL

5/16” DIA HOLE

USING 7669-11 AS

TEMPLATE

VIEW FROM REAR OF TRACTOR

Rear Bolt Location For LH Cab Mount

4. Using the 5/16-18 x 5/8 (F091) hex bolt and

5/16-18 (F009) whiz locknut at the rear hole,

and the 5/16-18 x 1 (F093) hex bolt and F009 at

the hole drilled under the chassis, fasten the LH

cab mount to the tractor as shown in Fabric and

Mounts - Operator Soft Cab (A13) on page 18.

5. Install the H10 implement hitch and H10 implement wiring onto the tractor as indicated by the

instructions included with the H10 implement

hitch.

ASSEMBLE SOFT CAB FRAME

1. Assemble the cab frame as shown in Assemble

Soft Cab Frame illustration. Lay the right side

cab frame (P/N 7664-2) at with the pins pointing

upward. Attach the front support (P/N 7669-1),

top support (P/N 7669-2), and cross tubes (P/N

7669-3), to the right side cab frame. Note the

rope hook on one side of the front support–install

the rope hook toward the RH side (as shown).

Attach the left side cab frame (P/N 7664-20) to

the front support, top support and cross tubes.

DRILL 3/8” DIA.

HOLES

1-3/4”

5/8”

(IF NECESSARY)

1-3/4”

5/8”

HEADLIGHT WIRE

ROUTING HOLE

WINDSHIELD

FRAME

(REF)

VIEW FROM FRONT

OF TRACTOR

Drill Windshield Frame Dimensions

3. Rotate the cab frame and stand the cab up.

Mount the windshield and frame assembly (P/N

5674) to the cab frame using four (4) 10-24 x 3/8

(F128) screws, and four (4) 10-24 (F002) keps

nuts as shown in Assemble Soft Cab Frame

illustration.

NOTE: Do not install wiper motor at this time.

4. Attach the LH and RH front cab mounts (P/N

7669-8 and 7669-9) to the front pins on the cab

frame. Secure the RH and LH front cab mounts

to the cab frame using the hitch pins (P/N 7666).

Refer to FABRIC AND MOUNTS - OPERATOR

SOFT CAB (A13) on page 18 for correct po-

sition.

5. Install the On-Off Toggle Switch (P/N 5995)

and connect the tap wire (P/N 5670-6) and 36

in. electrical power lead wire (P/N 5670-5) to

the switch as shown in Connect Wire Harness

illustration. Route the power wire to the cab

connection point at the RH rear position of the

cab as shown and secure the wire to the tractor

chassis using wire ties.

2. Drill the headlight lead wire holes in the wind-

shield frame as shown in Drill Windshield

Frame Dimensions (if holes are not present).

9

NOTE: If the optional light bar is already installed

on your tractor, disconnect the light bar wiring

harness from the tractor’s main wiring harness,

and connect the operator cab wiring harness to

the tractor’s main wiring harness (see step 9).

Page 13

Assembly Instructions

= WIRE ROUTING

8

Install rope hook

on RH side

27

DRILL

29

F052

9

10

NUT INCLUDED

WITH LIGHT

9

(REF)

12

11

9

32

19

18

26

F128

13

F085

F002

16

15

14

F002

F002

17

4

F026

31

24

(REF)

29

DRILL

20

21

24

F129

F128

SEE ELECTRICAL

WIRING PAGE

23

25

22

Assemble Soft Cab Frame

10

Page 14

Assembly Instructions

9

9

F129

26

32

F129

F085

F002

14,15,16

F002

9

11

16

14

7 AMP CIRCUIT BREAKER

(REF)

SPLICE TO HOT (PURPLE)

WIRE FROM “ACC” ON

IGNITION SWITCH

30

34

HOT (PURPLE) WIRE FROM

“ACC” ON IGNITION SWITCH

28

Connect Wire Harness

Page 15

Assembly Instructions

REF.

5

REF.

MT/MD CHASSIS

FRONT OF

TRACTOR

LH FRONT UPRIGHT

CHASSIS TUBING

CHASSIS PANEL BOX AND

GUARD MOUNT ANGLE

DRILL (2) 5/16” DIA.

HOLES

2 5/8”

6. Install the cab frame onto the tractor. Secure

cab on RH and LH rear mounts using two (2)

hitch pins (P/N 7666). With the cab frame in

place, position the RH and LH front cab mounts

to the RH and LH sides of the implement hitch

footrest as shown in Install Front Cab Mounts

illustration. Adjust the cab so it runs parallel with

the top of the tractor body and clamp the cab

mounts to the implement hitch footrest. Using the

front cab mounts as a template, drill the mounting

hole locations using a 1/4 in. drill bit. Install the

front cab mounts to the implement hitch footrest

using the two (2) 1/4-20 x 1/2 (F029) hex bolts

on each mount, and the two (2) 1/4-20 (F004)

keps nuts.

Align bottom edge of mount

angle with implement hitch

F029 (4 Places)

Install Front Cab Mounts

7. With the cab frame attached to the tractor, install

the operator cab fabric (P/N 7661-1). Place

the operator cab fabric over the cab frame and

align as closely as possible. Fasten the velcro

around the windshield rst. Then route the

drawstring for the RH side, fastening it to the

drawstring hooks and tension the drawstring

using the extension spring (P/N 5222) as shown

in Drawsting Routing illustration. Fasten the

velcro on the LH side and across the back.

NOTE: This step will be more easily accomplished with the help of an assistant.

NOTE: It may be necessary to repeat the above

procedure several times in order to achieve

a proper t as the operator cab fabric will

stretch, especially within the rst 48 hours after

installation.

NOTE: It is highly recommended to wait 48

hours after initial installation of the canvas cov-

er before cutting holes in the cover and installing

lights and wiper motor.

2

6

DRAWSTRING

HOOKS

6

6

Drawstring Routing

8. Using the windshield frame as a template, use a

sharp knife to cut ve (5) holes in the canvas for

the headlight mount bolts, headlight wires, and

windshield wiper as shown in Cut Holes in Can-

vas illustration.

NOTE: Prior to cutting holes in canvas, verify

that canvas is positioned properly on the windshield frame.

HEADLIGHT WIRE

(2 PLACES)

NO HOLE NEEDED IN CANVAS

FOR TOGGLE SWITCH BRACKET OR

1-3/4”

5/8”

HEADLIGHT MOUNT

HOLE (2 PLACES)

WIPER MOTOR BODY BRACKET

WIPER MOTOR

HOLE

VIEW FROM FRONT OF TRACTOR

WINDSHIELD

FRAME

(REF)

TIE

DRAWSTRING

3

4

6

DRAWSTRING

ROUTING

1-3/4”

5/8”

Cut Holes in Canvas

12

Page 16

Assembly Instructions

9. Install wiper motor, headlights and On-Off toggle

switch mount. Install grommets (P/N 5977-1)

into the headlight wiring holes and route the wiring for the windshield wiper motor, headlights,

and windshield wiper toggle switch as shown

in Route Wiring for Windshield Wiper Motor,

Headlights, and Windshield Wiper Toggle

Switch illustration. Route and secure wire har-

ness (P/N 5670-1) inside cab to cab frame using

wire ties. Make all wiring connections as shown

in Connect Wiring Harness illustration (page

11).

9

9

14,15,16

F002

9

F128

F085

32

F129

F002

11. Install windshield wiper arm.

NOTE: Before installing wiper arm (P/N

5668-1), operate wiper motor to determine the

proper arc of travel for the wiper.

12. Install door fabric onto cab door frame (P/N

7662). Route the drawstring for the cab door

frame and fasten it to the drawstring hooks. Ten-

sion the drawstring using the extension spring

(P/N 5222) as shown in Soft Cab Door Draw-

string Routing illustration. Mount the cab door

handle (P/N 7667) to the cab door frame and attach the cab door to the operator cab.

NOTE: Door hinges and cab door handle require

occasional lubrication.

DOOR DRAWSTRING

ROUTING

Route Wiring for Windshield Wiper Motor,

Headlights, and Windshield Wiper Toggle Switch

10. Mount the toggle switch (P/N 5995) to the switch

mount bracket (P/N 5667-1) as shown in Mount

Toggle Switch illustration.

32

F128

F129

F085

F002

16

15

14

2

3

TIE

DRAWSTRING

4

Soft Cab Door Drawstring Routing

13

Mount Toggle Switch

Page 17

Operating Instructions

WINDSHIELD WIPER

To use the windshield wiper, use the toggle switch

mounted on the upper, interior frame of the cab.

NOTE: The headlight switch must be turned on in

order to operate the windshield wiper (single circuit).

● Move the toggle switch to the right to operate the

windshield wiper.

● Move the toggle switch to the left to stop the

windshield wiper.

HEADLIGHTS

To turn on the headlights, use the headlight toggle

switch mounted on the instrument panel.

● Move the toggle switch UP to turn the headlights

on.

● Move the toggle switch DOWN to turn the head-

lights off.

WINDSHIELD WIPER BLADE REPLACEMENT

The windshield wiper blade will wear over time and

will need to be replaced.

1. To remove the windshield wiper blade: Pull

the windshield wiper arm away from the windshield, and remove the bolt and ESNA nut going

through the center of the windshield wiper as

shown in Windshield Wiper Blade Bolt photo.

Windshield Wiper

Blade Bolt

LUBRICATION

The Walker Operator Soft Cab is nearly mainte-

nance free. However, periodic lubrication to the door

hinges and door handle will be required.

Proper lubrication is an important maintenance procedure. It reduces wear and makes the machine

quieter and easier to operate.

WARNING

DO NOT attempt to lubricate the machine

with the tractor engine running. Disengage

the PTO clutch, shut off the machine, and

remove the ignition key.

NOTE: Tractor Lubrication Points are not shown

here. For Tractor Lubrication Points, refer to the

appropriate Tractor OPERATOR’S MANUAL or

ILLUSTRATED PARTS MANUAL.

END OF SEASON STORAGE

1. Clean and inspect the soft cab thoroughly, noting any replacement parts that will be needed

before the next season.

2. Repaint all parts from which paint has worn.

3. Check the soft cab fabric to ensure it is not

ripped, or fraying. If needed, order new fabric

(P/N 7661-1) for the cab before the next sea-

son.

4. Store the cab in a dry place.

Windshield Wiper Blade Bolt

2. Remove the worn wiper, and replace it with a

new wiper blade (P/N 5669-1).

14

Page 18

OPERATOR SOFT CAB ASSEMBLY (A13)

ITEM PART DESCRIPTION NO.

NO. NO. REQ’D

Soft Cab

1 7669-7 Cab Mount, RH 1

2 5222 Extension Spring (1/2 x 3-1/4) 2

3 7661-1 Snow Cab Fabric W/Rr Flap 1

4 7662 Door, Cab 1

5 7669-11 Cab Mount, LH 1

6 7666 Hitch Pin (#3) 4

7 7669-8 Front Cab Mount, RH 1

8 7664-2 Right Side, Cab 1

9 5670-1 Wire Assembly, 9 Ft., Cab 1

10 7669-1 Front Support 1

11 7669-2 Top Support 1

12 7669-3 Cross Tube 2

13 5519-5 Actuator Motor, 12V Snowcab Only 1

(Incl. 18 & 19)

14 5995 Toggle Switch (Off-On) 2

15 5667-1 Switch Mount Bracket 1

16 5995-2 Switch Boot 2

17 7664-20 Left Side, Cab 1

18 5519-3 Motor Mount Nut (5/8-24 Panel Nut) *

19 5519-2 Motor Mount Washer *

20 5668-1 Wiper Arm 1

21 5669-1 Wiper Blade 1

22 5674 Windshield and Frame 1

(Incl. 23, 24, 25)

23 7665 Glass Windshield *

24 7663 Windshield Frame *

25 7665-1 Glass Windshield Seal *

26 5670-5 Wire Assembly (36”) 1

27 7989-2 Light Assembly (LED) 2

28 8553 Splice Tap (18-14 Ga.) 1

29 5977-1 Grommet (1/8 x 3/8) 2

30 5877 Decal, Lights 1

31 7667 Door Handle, Cab 1

32 5519-6 Adapter Harness 1

33 7669-9 Front Cab Mount, LH 1

34 5670-6 Wire Assembly (9”) 1

ITEM PART DESCRIPTION NO.

NO. NO. REQ’D

Fasteners

F002 10-24 Keps Nut 8

F004 1/4-20 Keps Nut 4

F009 5/16-18 Whiz Lock Nut 4***

F026 10-24 x 1/2 PPHMS 3

F029 1/4-20 x 1/2 Hex Bolt 4

F085 3/16 Rivet Backup Washer 1

F091 5/16-18 x 5/8 Hex Bolt 1

F093 5/16-18 x 1 Hex Bolt 1

F128 10-24 x 3/8 PTH Bolt 4

F129 10-24 x 1/2 PTH Bolt 2

F255 5/16-18 x 1-1/2 Hex Bolt 2**

THE FOLLOWING ITEMS ARE NOT ILLUSTRATED

5975-1 Cable Tie (18# x 3-3/4”) 10

5975-3 Cable Tie (50# x 7”) 8

5975-7 Cable Tie (50# x 11”) 2

* Service Part Only

** Use only if needed

*** Only 2 may be needed if using F255

Use only genuine Walker® replacement parts.

15

Page 19

OPERATOR SOFT CAB ASSEMBLY (A13)

= WIRE ROUTING

27

F002

14

12

16

15

17

F002

4

F026

F002

8

11

9

32

DRILL

F052

9

10

10

NUT INCLUDED

WITH LIGHT

9

(REF)

18

26

19

F129

13

F085

24

(REF)

20

21

29

29

24

DRILL

F129

F128

SEE ELECTRICAL

WIRING PAGE

31

23

25

22

Use only genuine Walker® replacement parts.

16

Page 20

ELECTRICAL - OPERATOR SOFT CAB (A13)

9

9

F129

26

32

F129

F085

F002

14,15,16

F002

9

16

14

30

34

7 AMP CIRCUIT BREAKER

(REF)

SPLICE TO HOT (PURPLE)

WIRE FROM “ACC” ON

IGNITION SWITCH

Use only genuine Walker® replacement parts.

HOT (PURPLE) WIRE FROM

“ACC” ON IGNITION SWITCH

28

17

Page 21

FABRIC AND MOUNTS - OPERATOR SOFT CAB (A13)

TIE

2

DRAWSTRING

DRAWSTRING

HOOKS

3

6

6

6

DRAWSTRING

ROUTING

4

6

C19/C19i CHASSIS

(REF.)

F029

7

REF.

CLUTCH LEVER

ASSEMBLY

1

F009

F004

F255

DRILL (2) 1/4” DIA.

HOLES

F004

33

F009

F029

F009

5

F093

TIE

DRAWSTRING

DOOR DRAWSTRING

ROUTING

F091

2

3

4

Use only genuine Walker® replacement parts.

18

Page 22

MAINTENANCE AND SERVICE RECORD SHEET

DATE SERVICE ENGINE

ITEM HOURS

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

______________________________________________________________________________________________________________

19

Page 23

LIMITED WARRANTY

FOR WALKER

SOFT CAB A13

1.

2.

3.

What this warranty covers, and for how long:

Walker Manufacturing company will, at its option, repair or replace, without charge, any part

covered by this warranty which is found to be defective in material and/or workmanship within

one (1) year after date of sale to the original retail purchaser unless the product is used for rental

purposes, in which case this warranty is limited to ninety (90) days. At Walker’s request, customer

will make the defective part available for inspection by Walker and/or return the defective part to

Walker, transportation charges prepaid. All parts and components of the Walker operator soft

cab are covered by this warranty.

What this warranty does not cover:

A. This warranty does not cover defects caused by depreciation or damage caused by normal

wear, accidents, improper maintenance, improper use or abuse of the product, alterations,

or failure to follow the instructions contained in the Operator’s Manual for operation and

maintenance.

B. The customer shall pay any charges for making service calls and/or for transporting the

attachment to and from the place where the inspection and/or warranty work is performed.

How to obtain service under this warranty:

Warranty service can be arranged by contacting the dealer where you purchased the machine or

by contacting Walker Manufacturing Company, 5925 East Harmony Road, Ft. Collins, CO 80528.

Proof of the date of purchase may be required to verify warranty coverage.

4.

Warranty limitation:

A. HERE IS NO OTHER EXPRESS WARRANTY. ANY WARRANTY THAT MAY BE IMPLIED FROM

THIS PURCHASE INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE IS HEREBY LIMITED TO THE DURATION OF THIS WARRANTY AND TO THE

EXTENT PERMITTED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. Some

states do not allow limitations on how long an implied warranty lasts, so the above limitations

may not apply to you.

B. WALKER WILL NOT BE LIABLE FOR ANY INCIDENTAL, CONSEQUENTIAL, OR SPECIAL

DAMAGES AND/OR EXPENSES IN CONNECTION WITH THE PURCHASE OR USE OF THE

MACHINE. Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitation(s) or exclusion(s) may not apply to you.

C. Only the warranty expressed in this limited warranty shall apply and no dealer, distributor, or

individual is authorized to amend, modify, or extend this warranty in any way. Accordingly,

additional statements such as dealer advertising or presentations, whether oral or written,

do not constitute warranties by Walker, and should not be relied upon.

D. This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

20

Page 24

WALKER MFG. CO. • 5925 E. HARMONY ROAD, FORT COLLINS, CO 80528 • (970) 221-5614

FORM NO. 082918 PRINTED IN USA www.walker.com ©2018 WALKER MFG. CO

Loading...

Loading...