Walinga ULTRA-VEYOR SYSTEM Operator's Manual

ULTRA-VEYOR SYSTEM

OPERATOR'S MANUAL

ULTRA-VEYOR SYSTEM

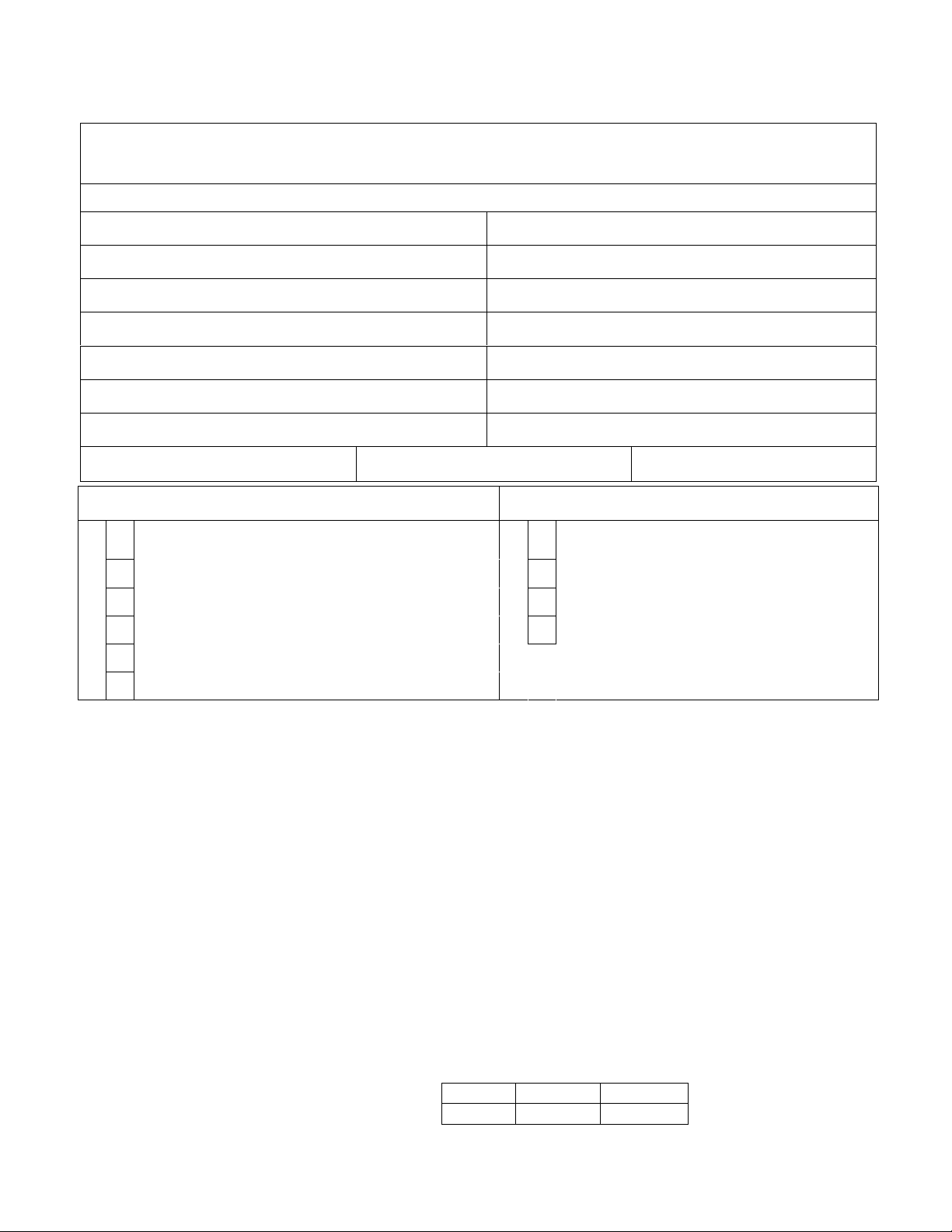

Warranty Registration Form & Inspection Report

WARRANTY REGISTRATION (3 part form - please print)

This form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery.

Delivery Date: mm / dd / yyyy

COMPANY / CUSTOMER NAME

Phone:

Mobile phone:

Email: @

StreetAddress:

City: Prov/State

Postal/Zip Country

Machine Serial Number

DEALER INSPECTION REPORT

Blower and Airlock Turn Freely

Airline Connections Tight

Blower Serial No.

DEALER NAME

Phone

Mobile phone

Email: @

StreetAddress

City: Prov/State

Postal/Zip Country

Airlock Serial Number

SAFETY

Guards Installed and Secured

All Safety Signs Installed

Airline Intake Caps Secured

Drive Chains and Belts Tensioned and Aligned

Lubricate Machine

Check Oil Level in Reservoirs

Review Operating and Safety Instructions

Operating Manual Supplied

I have thoroughly instructed the buyer on the above described equipment which review included the Operator’s Manual

content, equipment care, adjustments, safe operation and applicable warranty policy.

Date ___________________ Dealer's Rep. Signature ____________________________________________

The above equipment and Operator’s Manual have been received by me and I have been thoroughly instructed as to

care, adjustments, safe operation and applicable warranty policy.

Date____________________ Owner’s Signature _______________________________________

3 Part Form Please Print

WHITE YELLOW PINK

WALINGA DEALER CUSTOMER

Dear Customer,

Thank you for choosing WALINGA PNEUMATIC CONVEYING SYSTEMS. For your convenience, should

you require any information related to Parts, Service or Technical Engineering, please contact one of the

following Walinga Personnel in Guelph at 1-888 925-4642 unless noted

TECHNICAL - ENGINEERING:

Duane Swaving 226-979-8227 duane.swaving@walinga.com

Ken Swaving 519 787-8227 (ext:100) ks@walinga.com

WARRANTY CLAIMS:

Canada: (ext:258) warranty.usa@walinga.com

USA: (800) 466-1197 (ext 8) warranty.can@walinga.com

SERVICE MANAGER:

Andy Nijenhuis (519) 763-7000 (ext:260) andy@walinga.com

SALES MANAGER:

Canada: Tom Linde (519) 787-8227 (ext 5) thl@walinga.com

USA: Peter Kingma (800) 466-1197 jpk@walinga.com

ORIGINAL PARTS SALES:

Ontario and Eastern Canada:

Scott Lodder spl@walinga.com (ext: 224) Parts Department Fax: (519) 824-0367

Manitoba and Western Canada:

Chad Yeo 204-745-2951 chad.yeo@walinga.com

USA:

John VanMiddlekoop (800) 466-1197 (ext 3) jvm@walinga.com

CORPORATE HEAD OFFICE:

5656 Highway 6N

RR#5, Guelph, Ontario Canada N1H 6J2

Tel: (888) 925-4642 Fax: (519) 824-5651

FACTORY DISTRIBUTION AND SERVICE CENTRES:

938 Glengarry Cres. Fergus, Ontario Canada N1M 2W7

Tel: (519) 787-8227 Fax: (519) 787-8210

1190 Electric Ave. Wayland, MI.USA 49348

Tel (800) 466-1197 Fax (616) 877-3474

70 3rd Ave. N.E. Box 1790 Carman, Manitoba Canada R0G 0J0

Tel (204) 745-2951 Fax (204) 745-6309

24 Molloy Street Toowoomba, Queensland Australia 4350

PRINTED IN CANADA

Walinga Inc.

Pneumatic Conveying System

Warranty Terms

Walinga Inc. is committed to providing a quality product that will meet or exceed your expectations for many

years to come. Our warranty terms and our warranty claim process has been designed to ensure that each

warranty claim will be resolved in an orderly, fair and timely manner.

The Warranty

Walinga Inc. (“Walinga”) warrants that all new pneumatic products sold by Walinga Inc. will be free from defects in

material and workmanship (the “Walinga Warranty”).

Warranty Period

The warranty period for the Walinga Warranty shall expire on the date that is the earlier of: two (2) years after the date of

delivery to the original customer; or upon the expiration of five hundred (500) hours of operation; whichever date comes

first.

Limitations of and exclusions from the Walinga Warranty

The Walinga Warranty applies to material and workmanship only.

With respect to any component parts that are supplied or manufactured by others, the warranty coverage on

such component parts will be strictly limited to the warranties of the manufacturers of such component parts.

The Walinga Warranty shall only be for the benefit of the original purchaser of the pneumatic products.

A Walinga Warranty may be transferable by the original purchaser to a third party for the balance of the

warranty period then remaining, provided that Walinga consents in writing to such transfer of warranty.

The Walinga Warranty is conditional upon proper storage, installation, use, maintenance, operation and

compliance with any applicable recommendations of Walinga.

Warranty Claim Procedure

Should you encounter any difficulties with your unit within its warranty period, please contact your local Walinga dealer

or sales representative, your local Walinga Service department or Walinga's Warranty Department to submit a warranty

claim application.

To speak with a Walinga Warranty Coordinator, contact:

Canada 1-888-WALINGA (ext 273)

International +1-519-824-8520 (ext 273)

Email – warranty.canada@walinga.com

USA 1-800-466-1197 (ext 8)

Email – warranty.usa@walinga.com

Australia 07-4634-7344

Email – mail@customvac.com.au

Required Warranty Claim information

The following information must be provided to Walinga in order for us to properly process and consider your warranty

application:

Customer name and contact information (email if available).

The equipment serial number and/or Vehicle Identification Number (if applicable).

Date of claimed failure.

Equipment hours of operation.

Details, description and photos (upon request) of the claimed failure and the corrective repairs attempted.

Warranty Conditions

Equipment must be registered within 30 days of being received by the buyer. It will be within the sole

and unfettered discretion of Walinga as to whether it will honour its warranty on non-registered

equipment.

Warranty Conditions (continued)

The buyer is responsible for promptly notifying Walinga of any defects to the equipment. The buyer is also

responsible for making the equipment available to Walinga or its authorized repair facility for evaluation and

repair.

Prior to making any repairs or parts replacements, a warranty application and any estimated associated costs

must be approved with the issuance of a claim number by an authorized Walinga representative. Undertaking

any work prior to receiving warranty authorization may result in a partial or complete loss of warranty coverage.

At Walinga's discretion, warranty repairs may be authorized to be completed at a repair facility convenient to the

buyer. In such situations the estimated labour time must be approved by Walinga prior to undertaking any work.

Labour hours will be reimbursed at the facilities posted hourly labour rate.

At Walinga's request, parts in question must be returned to the nearest Walinga service facility for evaluation. In

such situations a Returned Goods Authorization (RGA) number will be provided to the buyer. The returning

shipment must be clearly labeled with the assigned RGA number and include a copy of the RGA form. Unless

otherwise arranged, these parts are to be returned to Walinga within 30 days to ensure timely processing of

your warranty claim. Failure to return such parts may result in partial or complete loss of warranty coverage.

Replacement parts provided under warranty are covered for the remainder of the original equipment warranty

period.

Walinga reserves the right to use new, remanufactured or refurbished components when performing warranty

repairs and replacements.

Walinga is entitled to a reasonable amount of time and a reasonable number of attempts to assess the claim,

diagnose the problem, and perform any necessary repairs.

The warranty offered on used or refurbished equipment is limited to that specified on the purchase contract.

Where a warranty period has not been stipulated on the purchase contract., and where such equipment is

“used”, then such equipment is considered by Walinga to be sold “as is, where is” without the Walinga

Warranty. Where such equipment is refurbished, then the Walinga Warranty shall apply.

Without limitation, Walinga reserves the right to reject a warranty claim or for any one or more of the following

reasons:

The warranty claim information provided is insufficient.

The product evaluation does not substantiate the claim.

The unit has been operated above and beyond its capacity or not maintained or serviced properly, resulting in

damages incurred to major components.

If the unit was equipped with a factory installed hour meter which has been disconnected, altered or inoperative

for an extended period of time; with the result being that the equipment’s operating hours cannot be verified.

It is apparent that the operator’s manuals have not been followed.

The equipment is not registered.

Without limitation, Walinga’s Warranty does not cover:

Damage or deterioration due to lack of reasonable care or maintenance.

Damage caused or affected by unapproved modifications to the equipment.

Damage caused by negligence or misuse of the equipment.

Damage caused by using the equipment for purposes for which it was not designed or intended.

Walinga’s liability under this warranty, whether in contract or tort, is limited to the repair, replacement or adjustment of

defective materials and workmanship. In no event will Walinga be responsible for any direct, indirect, loss of time,

incidental or consequential expenses including, but not limited to, equipment rental expenses, towing, downtime,

inconvenience, or any losses resulting from the inability to use the equipment. Further, Walinga shall not be liable for

any damages or inconvenience caused by any delay in the supply or delivery of any equipment or component parts

thereof.

The selling Dealer/Sales Person makes no warranty of its own and has no authority to make any representation or

promise on behalf of Walinga, or to modify the terms or limitations of the Walinga Warranty in any way.

Punitive, exemplary or multiple damages may not be recovered unless applicable law prohibits their disclaimer.

Warranty related claims may not be brought forward as a class representative, a private attorney general, a member of a

class of claimants or in any other representative capacity.

The Walinga Warranty and all questions regarding its enforceability and interpretation are governed by the law of the

country, state or province in which you purchased your Walinga equipment. The laws of some jurisdictions limit or do not

allow the disclaimer of consequential damages. If the laws of such a jurisdiction apply to any claim against Walinga, the

limitations and disclaimers contained here shall be to the greatest extent permitted by law.

SERIAL NUMBER LOCATION

Machine Serial Number

Blower Serial Number

Airlock Serial Number

Always give your Dealer the Serial Number of your

Walinga Ultra-Veyor System when ordering parts

or requesting service or other information.

4

TABLE OF CONTENTS

1 Introduction..........................................................................8

Safety ....................................................................................9

2.1 General Safety.....................................................................10

2.2 Equipment Safety Guidelines ..............................................11

2.3 Storage Safety .....................................................................11

2.4 Safety Training.....................................................................12

2.5 Safety Signs.........................................................................12

2.6 Preparation ..........................................................................13

2.7 Installation Safety ................................................................13

2.8 Operating Safety ....................................................15

2.9 Maintenance Safety .............................................................14

2.10 Electical Safety ....................................................................15

2.11 Lock-Out Tag-Out Safety.....................................................15

2.12 Employee Sign-Off Form .....................................................16

3 Safety Sign Locations .......................................................17

4 Operation............................................................................21

4.1 To the New Operator or Owner ..........................................21

4.2 Machine Components .........................................................22

4.3 Machine Break-In ................................................................23

4.4 Pre-Operation Checklist .....................................................23

4.5 Controls ...............................................................................24

4.5.1 Standard Controls................................................................24

4.5.2 Smart-Flo Controls...............................................................25

4.6 Operating .............................................................................27

4.7 Storage ................................................................................31

5 Service and Maintenance..................................................32

5.1 Service.................................................................................32

5.1.1 Fluids and Lubricants...........................................................32

5.1.2 Greasing ..............................................................................32

5.1.3 Servicing Intervals ...............................................................33

5.1.4 Service Record ....................................................................36

5.2 Maintenance ........................................................................37

5.2.1 Belt Tension and Alignment.................................................37

5.2.2 Blower Oil and Breather Cleaning .......................................41

5.3.3 Airlock ..................................................................................43

5.2.4 Gear Box..............................................................................45

6 Trouble Shooting ...............................................................47

7 Specifications ....................................................................49

7.1 Mechanical...........................................................................53

7.2 Bolt Torque ..........................................................................54

8 Index ...................................................................................51

1 INTRODUCTION

Congratulations on your choice of a Walinga Ultra-Veyor System to complement your operation. This equipment

has been designed and manufactured to meet the needs of the discriminating buyer for the efficient moving of

granular or powder products.

Safe, efficient and trouble free operation of your Ultra-Veyor System requires that you and anyone else who will be

operating or maintaining the machine, read and understand the Safety, Operation, Maintenance and

Trouble shooting information contained within the Operator's Manual.

This manual covers all Ultra-Veyor Systems made by Walinga Inc. Many systems are custom designed for the

specific application. However they are all similar and specific differences are explained where appropriate.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your Walinga

dealer if you need assistance, information or additional copies of the manual. Contact your dealer for a complete

listing of parts.

8

ATTENTION! BECOME ALERT! YOUR

Veyor System and in the

DANGER

ation that, if not avoided, could result in

SIGNAL WORDS:

2 SAFETY

SAFETY ALERT SYMBOL

This Safety Alert symbol means

SAFETY IS INVOLVED!

Why is SAFETY important to you?

3 Big Reasons: Accidents Disable and Kill Accidents Cost Accidents Can Be Avoided

Note the use of the signal words DANGER,

WARNING and CAUTION with the safety messages.

The appropriate signal word for each message has

been selected using the following guidelines.

The Safety Alert symbol identifies

important safety messages on the

Walinga® Ultramanual. When you see this symbol, be

alert to the possibility of personal injury

or death. Follow the instructions in the

safety message.

- Indicates an imminently hazardous

situation that, if not avoided, will result

in death or serious injury. This signal

word is to be limited to the most extreme situations typically for machine

components which, for functional purposes, cannot be guarded.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your Walinga®

dealer if you need assistance, information or additional copies of the manual.

Contact your dealer for a complete listing of parts.

WARNING

CAUTION

- Indicates a potentially hazardous situ-

death or serious injury, and includes

hazards that are exposed when guards

are removed. It may also be used to

alert against unsafe practices.

- Indicates a potentially hazardous situation that, if not avoided, may result in

minor or moderate injury. It may also

be used to alert against unsafe practices.

9

SAFETY

2.1

GENERAL SAFETY

YOU

SAFE

Veyor System be familiar with the operating and

are the key to safety. Good safety

practices not only protect you but, also the people

ing part of

EVERYONE

operating this machine is familiar with the procedures

recommended and follows safety precautions.

Remember, most accidents can be prevented. Do not

sponsibility to read and understand ALL Safety

and Operating instructions in the manual and to

ed to

poses himself and bystanders to possible serious

tion

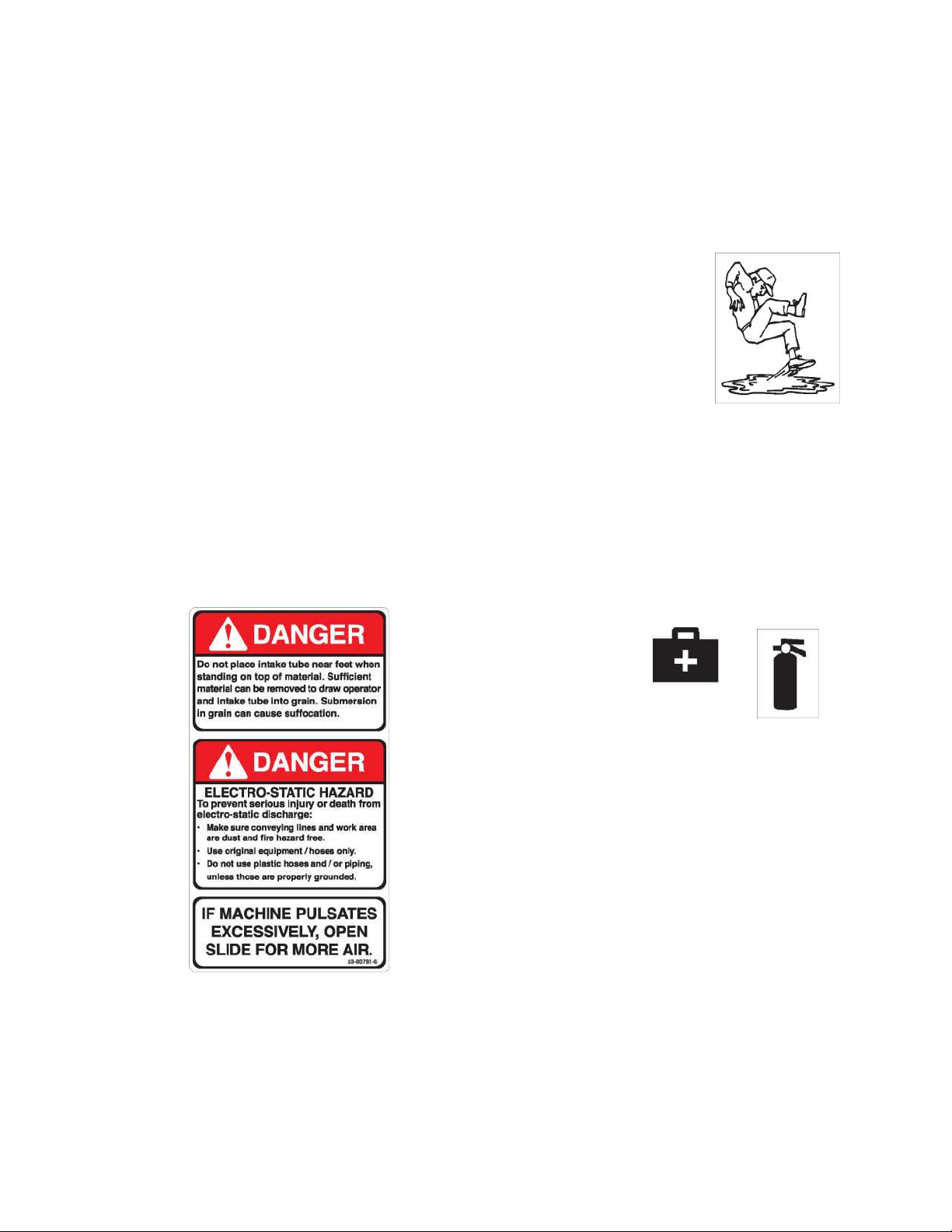

could affect the life of the

understand the

Operator’s Manual and all safety

signs before supplying power,

operating, maintaining , adjusting or

aid kit for use in

case of an accident. Store in a

re extinguisher for use in

case of an accident. Store in a highly

Install and properly secure all guards

7 Turn machine OFF, shut down and lockout power

fore

servicing, adjusting, maintaining, repairing,

ning or unplugging. (Safety lockout devices are

available through your Walinga® dealer parts

are responsible for the

maintenance of your Walinga® Ultra-Veyor System.

YOU

must ensure that you and anyone else who is

going to operate, maintain or work around the Ultra-

maintenance procedures and related

information contained in this manual. This manual will

take you step-by-step through your working day and

alerts you to all good safety practices while operating

the Ultra-Veyor System.

Remember,

around you. Make these practices a work

your safety program. Be certain that

YOU

operation and

SAFETY

risk injury or death by ignoring good safety practices.

• Ultra-Veyor System owners must give operating

instructions to operators or employees before allowing

them to operate the machine, and at least annually

thereafter.

• The most important safety device on this equip

ment is a SAFE operator. It is the operator’s re-

follow these. Most accidents can be avoided.

• A person who has not read and understood all op

erating and safety instructions is not qualifi

operate this machine. An untrained operator ex-

injury or death.

• Do not modify the equipment in any way.

Unauthorized modification may impair the func

and/or safety and

equipment.

• Think SAFETY! Work SAFELY!

1

Read and

.

unplugging.

2. Only trained, competent persons shall operate the

Ultra-Veyor System. An untrained operator is not

qualified to operate this machine.

3.

Provide a first-

highly visible place.

4.

Provide a fi

visible place.

5.

and shields before operating.

6. Wear appropriate protective gear. This list

includes but is not limited to:

- A hard hat

- Protective shoes

with slip resistant

soles

- Protective glasses or goggles

- Heavy gloves

- Wet weather gear

- Hearing protection

supply and wait for all moving parts to stop be

clea

department).

8. Know the emergency medical center number for

your area.

9. Wear appropriate hearing protection

when operating the machine.

10. Ground all lines, hoses and wands to prevent static

build-up and electrical discharge/shocks.

11. Review safety related items with all operators

annually.

2.2

1. Safety of the operator and bystanders is one of the main

concerns in designing and developing a machine.

However, every year many accidents occur which could

have been avoided by a few seconds of thought and a

more careful approach to handling equipment. You, the

operator, can avoid many accidents by observing the

following precautions in this section. To avoid personal

injury or death, study the following precautions and insist

those working with you, or for you, follow them.

2. In order to provide a better view, certain photographs or

illustrations in this manual may show an assembly with a

safety shield removed. However, equipment should

never be operated in this condition. Keep all shields in

place. If shield removal becomes necessary for repairs,

replace the shield prior to use.

3. Replace any safety sign or instruction sign that is not

readable or is missing. Location of such safety signs is

indicated in this manual.

4. Never use alcoholic beverages or drugs which can hinder

alertness or coordination while operating this equipment.

Consult your doctor about operating this machine while

taking prescription medications.

Under no circumstances should young children be

5.

EQUIPMENT SAFETY GUIDELINES

9. In addition to the design and configuration of this

implement, including Safety Signs and Safety

Equipment, hazard control and accident prevention are

dependent upon the awareness, concern, prudence, and

proper training of personnel involved in the operation,

transport, maintenance, and storage of the machine.

Refer also to Safety Messages and operation instruction

in each of the appropriate sections of the auxiliary

equipment and machine Manuals. Pay close attention to

the Safety Signs affixed to the auxiliary equipment and

the machine.

2.3 STORAGE SAFETY

1. Store the Ultra-Veyor System on a firm level

surface.

2. If required, make sure the unit is firmly blocked up.

3. Make certain that all mechanical locks are safely and

positively connected before storing.

allowed to work with this equipment. Do not allow

persons to operate or assemble this unit until

4. Store away from areas of human activity.

they have read this manual and have developed a

thorough understanding of the safety precautions

and of how it works.

with all users annually.

6. This equipment is dangerous to children and persons

unfamiliar with its operation. The operator should be a

responsible, properly trained and physically able person

familiar with farm machinery and trained in this

equipment's operations. If the elderly are assisting with

farm work, their physical limitations need to be

recognized and accommodated.

Review the safety instructions

5. Do not allow children to play on or around the stored

Ultra-Veyor System.

6. Lock out power by turning off master control panel or

junction box and padlocking the door shut to prevent

electrocution or unauthorized start up of the Ultra-

Veyor System.

7 Never exceed the limits of a piece of machinery. If its ability

to do a job, or to do so safely, is in question -

TRY IT.

8. Do not modify the equipment in any way. Unauthorized

modification may result in serious injury or death and

may impair the function and life of the equipment.

DON'T

11

2.4 SAFETY TRAINING

2.5 SAFETY SIGNS

1. Safety is a primary concern in the design and manufacture of our products. Unfortunately, our efforts to

provide safe equipment can be wiped out by a single

careless act of an operator or bystander.

2. In addition to the design and configuration of equipment,

hazard control and accident prevention are dependent

upon the awareness, concern, prudence and proper

training of personnel involved in the operation, transport,

maintenance and storage of this equipment.

It has been said, "The best safety feature is an

3.

informed, careful operator." We

ask you to be that kind of an

operator.

It is the operator's responsibility to

read and understand ALL

Safety and Operating instructions in the manual and to

follow these. Accidents can be avoided.

Working with unfamiliar equipment can lead to

4.

careless injuries. Read this manual, and the

manual for your auxiliary equipment, before

assembly or operating, to acquaint yourself with

the machines. If this machine is used by any

person other than yourself. It is the machine

owner's responsibility to make certain that the

operator, prior to operating:

a. Reads and understands the operator's

manuals.

b. Is instructed in safe and proper use.

5. Know your controls and how to stop the Ultra- Veyor

System and any other auxiliary equipment quickly in an

emergency. Read this manual and the one provided with

your other equipment.

6. Train all new personnel and review instructions

frequently with existing workers. Be certain only a

properly trained and physically able person will operate

the machinery. A person who has not read and

understood all operating and safety instructions is not

qualified to operate the machine. An untrained operator

exposes himself and bystanders to possible serious

injury or death. If the elderly are assisting with work, their

physical limitations need to be recognized and

accommodated.

1. Keep safety signs clean and legible at all times.

2. Replace safety signs that are missing or have become illegible.

3. Replaced parts that displayed a safety sign should

also display the current sign.

4. Safety signs are available from your authorized

Distributor or Dealer Parts Department or the factory.

How to Install Safety Signs:

• Be sure that the installation area is clean and dry.

• Be sure temperature is above 50°F (10°C).

• Determine exact position before you remove the

backing paper. (See Section 3).

• Remove the smallest portion of the split backing

paper.

• Align the sign over the specified area and carefully

press the small portion with the exposed sticky

backing in place.

• Slowly peel back the remaining paper and carefully

smooth the remaining portion of the sign in place.

• Small air pockets can be pierced with a pin and

smoothed out using the piece of sign backing paper.

How to Reorder Your Safety Signs:

1. Call you local dealer, or the factory branch nearest

you.

FACTORY DISTRIBUTION AND SERVICE CENTRES:

Head Office:

RR#5, Guelph, Ontario,N1H 6J2

PHONE (888) 925-4642

FAX (519) 824-5651

938 Glengarry Cres. Fergus, Ontario Canada N1M 2W7

Tel: (519) 787-8227 Fax: (519) 787-8210

70 3rd Ave. N.E. Box 1790 Carman, Manitoba

Canada R0G 0J0

Tel (204) 745-2951 Fax (204) 745-6309

1190 Electric Ave.Wayland, MI.USA 49348

Tel (800) 466-1197 Fax (616) 877-3474

24 Molloy Street Toowoomba, Queensland Australia 4350

Tel 07.4634.7344 Fax 07.4634.7606

2.6 PREPARATION

2.7

INSTALLATION

1. Never operate the Ultra-Veyor System and auxiliary

equipment until you have read and completely

understand this manual, the auxiliary equipment

Operator's Manual, and each of the Safety Messages

found on the safety signs on the and auxiliary equipment.

2. Personal protection equipment including hard hat, safety

glasses, safety shoes,

and gloves are

recommended during

assembly, installation,

operation, adjustment,

maintaining, repairing,

removal, or moving the

implement. Do not

allow long hair, loose

fitting clothing or jewelery to be around equipment.

PROLONGED EXPOSURE TO LOUD

NOISE MAY CAUSE PERMANENT

HEARING LOSS!

Motors or equipment attached can often be noisy

3.

enough to cause permanent, partial hearing loss. We

recommend that you wear hearing protection on a fulltime basis if the noise in the Operator's position

exceeds 80db. Noise over 85db on a long-term basis

can cause severe hearing loss. Noise over 90db

adjacent to the Operator over a long-term basis may

cause permanent, total hearing loss.

loss from loud noise (from tractors, chain saws, radios,

and other such sources close to the ear) is cumulative

over a lifetime without hope of natural recovery.

4. Clear working area of debris, trash or hidden ob-

stacles that might be hooked or snagged, causing

injury, damage or tripping.

NOTE:

Hearing

SAFETY

1. Disconnect and remove all mechanical locks, anchor

chains and any other transport devices that would hinder

or prohibit the normal functioning of the Ultra-Veyor

System upon start up. Serious damage to the machine

and/or personal injury to the operator and bystanders

may result from attempting to operate the machine while

mechanical locking devices are still attached.

2. Anchor the machine to firm, level ground before

operating.

3. Level the frame before using or loading.

4. Have at least one extra person available to assist when

elevating, moving or connecting to other equipment.

5. Make certain that sufficient amperage, at the proper

voltage and frequency (60Hz) is available before

connecting power for the electric model. Have a licensed

electrician provide power to the machine. Always follow

ANSI/NFPA 70 Standard and all local codes when

providing electrical power.

6. If using Ultra-Veyor System as part of material handling

system, anchor securely before starting.

7. Vent discharge air from blower to outside.

5. Operate only in daylight or good artificial light.

6. Be sure machine is properly anchored, adjusted and

in good operating condition.

7 Ensure that all safety shielding and safety signs are

properly installed and in good condition.

8. Before starting, give the machine a "once over" for any

loose bolts, worn parts, cracks, leaks, frayed belts and

make necessary repairs. Always follow maintenance

instructions.

13

2.8 OPERATING SAFETY 2.9 MAINTENANCE SAFETY

1. Read and understand the Operator’s Manual and

all safety signs before operating, maintaining, adjusting or repairing the Ultra-Veyor System.

1. Good maintenance is your responsibility. Poor

maintenance is an invitation to trouble. Follow all

operating, maintenance and operating instructions

in this manual.

2. Before servicing, adjusting, repairing or maintaining

unit, ensure that unit power source is completely

shut down and can not start up.

2. Support the machine with blocks of safety stands

when working beneath it.

3. Do not operate when any guards are damaged or

removed, Install and secure guards before starting.

4. Keep hands, feet, clothing and hair away from all

moving and/or rotating parts.

5. Clear the area of all bystanders, especially small

children, before starting.

6. Before supplying electrical power to the machine,

be sure you have adequate amperage at the proper phase and voltage to run it. If you do not know

or are unsure, consult a licensed electrician.

7 Wear appropriate ear protection when operating

machine.

8. Do not place intake nozzle near feet when standing

on the top of grain.

3.

Follow good shop practices:

- Keep service area clean

and dry.

- Be sure electrical outlets

and tools are properly

grounded.

- Use adequate light for

the job at hand.

4. Use only tools, jacks or hoists of sufficient capacity

for the job.

5. Before servicing, adjusting, repairing or maintaining

unit, ensure that power source is completely shut

down and locked-out, tagged-out.

6. Always use personal protection devices such as

eye, hand and hearing protectors, when performing

any service or maintenance work.

7.

A fire extinguisher

and first aid kit

should be kept

readily accessible

while performing

maintenance on this

equipment.

8. Make sure all guards are in place and properly se-

cured when maintenance work is completed.

9. Keep hands, feet, hair and clothing away from all

moving and/or rotating parts.

10. Lock-out, tag-out master panel before performing

any maintenance work on machine or opening airlock access door.

11. Clear the area of bystanders, especially small chil-

dren, when carrying out any maintenance and/or

repairs or making any adjustments.

9. Review safety instructions with all personnel 12. Be sure all lines, hoses and wands are grounded

annually. when maintenance work is completed.

2.10 ELECTRICAL SAFETY

1. Have only a qualified licensed electrician supply power to the electric model by following ANSI/ NFPA 70 Wiring

Standard. Make certain that the Ultra-Veyor System is properly grounded at

the power source.

2. Install safety decals on Master Control panel as per Section 3 - Safety Sign Locations (pg 17)/

3. Make certain that all electrical switches are in the OFF position before plugging the Ultra-Veyor System in.

4. Turn machine OFF, shut down and lock out power supply (safety lockout devices are available through your

Walinga® dealer parts department) and wait for all moving parts to stop before servicing, adjusting, maintaining

or repairing.

5. Disconnect power before resetting any motor or breaker overload.

6. Replace any damaged electrical plugs,

cords, switches and components immediately.

7. Do not work on Ultra-Veyor System electrical system

unless the power cord is unplugged or the power

supply is locked-out tagged-out.

8. Check continuity of all couplings.

2.8 LOCK-OUT TAG-OUT SAFETY

1. Establish a formal Lock-Out Tag-Out program for

your operation.

2. Train all operators and service personnel before

allowing them to work around the Ultra-Veyor

System.

3. Provide tags at the work site and a sign-up sheet to

record tag out details.

4. Do not perform any service or maintenance work

unless motor is OFF and the power locked out.

15

Loading...

Loading...