AGRI-VAC

3510

TOUGH TO BEAT IN THE LONG RUN

Model 3510

Gas and Electric

OPERATOR'S MANUAL

and PARTS BOOK

3510 AGRIVAC -VAC MODELS GAS & ELECTRIC

WARRANTY REGISTRATION (3 part form - please print)

Warranty Registration Form & Inspection Report

This form must be filled out by the dealer and signed by both the dealer and the customer at the time of delivery.

Delivery Date: mm / dd / yyyy

COMPANY / CUSTOMER NAME DEALER NAME:

Phone: Phone:

Mobile phone: Mobile phone:

Email : @ Email : @

Street Address: Street Address:

City: Prov/State City: Prov/State:

Postal/Zip: Country Postal/Zip: Country:

Machine Serial Number

Blower Serial No.

Airlock Serial Number

DEALER INSPECTION REPORT SAFETY

I have thoroughly instructed the buyer on the above described equipment which review included the Operator’s

Manual content, equipment care, adjustments, safe operation and applicable warranty policy.

Date ____________________Dealer's Rep. Signature _________________________________________

Blowers and Airlock Turn Freely

Air Line Connections Tight

Check Tire Pressure

Wheel Bolts Tight

Lubricate Machine

Check Oil Level in Reservoirs

Belts are Tight

O-Rings in Place

Guards Installed and Secured

All Safety Signs Installed

Reflectors and Signs Clean

Review Operating and Safety Instructions

Operating Manual Supplied

The above equipment and Operator’s Manual have been received by me and I have been thoroughly instructed as to

care, adjustments, safe operation and applicable warranty policy.

Date ___________________ Owner's Signature ________________________________________

199 05042016

3 Part Form

Please Print

WHITE YELLOW PINK

WALINGA DEALER CUSTOMER

Walinga Inc.

Pneumatic Conveying System

Warranty Terms

Walinga Inc. is committed to providing a quality product that will meet or exceed your expectations for many years

to come. Our warranty terms and our warranty claim process has been designed to ensure that each warranty claim

will be resolved in an orderly, fair and timely manner.

The Warranty

Walinga Inc. (“Walinga”) warrants that all new pneumatic products sold by Walinga Inc. will be free from defects in material

and workmanship (the “Walinga Warranty”).

Warranty Period

The warranty period for the Walinga Warranty shall expire on the date that is the earlier of: two (2) years after the date of

delivery to the original customer; or upon the expiration of five hundred (500) hours of operation; whichever date comes first.

Limitations of and exclusions from the Walinga Warranty

The Walinga Warranty applies to material and workmanship only.

With respect to any component parts that are supplied or manufactured by others, the warranty coverage on such

component parts will be strictly limited to the warranties of the manufacturers of such component parts.

The Walinga Warranty shall only be for the benefit of the original purchaser of the pneumatic products.

A Walinga Warranty may be transferable by the original purchaser to a third party for the balance of the warranty

period then remaining, provided that Walinga consents in writing to such transfer of warranty.

The Walinga Warranty is conditional upon proper storage, installation, use, maintenance, operation and compliance

with any applicable recommendations of Walinga.

Warranty Claim Procedure

Should you encounter any difficulties with your unit within its warranty period, please contact your local Walinga dealer or

sales representative, your local Walinga Service department or Walinga's Warranty Department to submit a warranty claim

application.

To speak with a Walinga Warranty Coordinator, contact:

Canada

International

USA

Australia

Required Warranty Claim information

The following information must be provided to Walinga in order for us to properly process and consider your warranty

application:

Customer name and contact information (email if available).

The equipment serial number and/or Vehicle Identification Number (if applicable).

Date of claimed failure.

Equipment hours of operation.

Details, description and photos (upon request) of the claimed failure and the corrective repairs attempted.

Warranty Conditions

Equipment must be registered within 30 days of being received by the buyer. It will be within the sole and

unfettered discretion of Walinga as to whether it will honour its warranty on non-registered equipment.

1-888-WALINGA (ext 273)

+1-519-824-8520 (ext 273)

Email – warranty.canada@walinga.com

1-800-466-1197 (ext 8)

Email – warranty.usa@walinga.com

07-4634-7344

Email – mail@customvac.com.au

Warranty Conditions (continued)

The buyer is responsible for promptly notifying Walinga of any defects to the equipment. The buyer is also

responsible for making the equipment available to Walinga or its authorized repair facility for evaluation and repair.

Prior to making any repairs or parts replacements, a warranty application and any estimated associated costs must

be approved with the issuance of a claim number by an authorized Walinga representative. Undertaking any work

prior to receiving warranty authorization may result in a partial or complete loss of warranty coverage.

At Walinga's discretion, warranty repairs may be authorized to be completed at a repair facility convenient to the

buyer. In such situations the estimated labour time must be approved by Walinga prior to undertaking any work.

Labour hours will be reimbursed at the facilities posted hourly labour rate.

At Walinga's request, parts in question must be returned to the nearest Walinga service facility for evaluation. In such

situations a Returned Goods Authorization (RGA) number will be provided to the buyer. The returning shipment must

be clearly labeled with the assigned RGA number and include a copy of the RGA form. Unless otherwise arranged,

these parts are to be returned to Walinga within 30 days to ensure timely processing of your warranty claim. Failure

to return such parts may result in partial or complete loss of warranty coverage.

Replacement parts provided under warranty are covered for the remainder of the original equipment warranty period.

Walinga reserves the right to use new, remanufactured or refurbished components when performing warranty repairs

and replacements.

Walinga is entitled to a reasonable amount of time and a reasonable number of attempts to assess the claim,

diagnose the problem, and perform any necessary repairs.

The warranty offered on used or refurbished equipment is limited to that specified on the purchase contract. Where a

warranty period has not been stipulated on the purchase contract., and where such equipment is “used”, then such

equipment is considered by Walinga to be sold “as is, where is” without the Walinga Warranty. Where such

equipment is refurbished, then the Walinga Warranty shall apply.

Without limitation, Walinga reserves the right to reject a warranty claim or for any one or more of the following

reasons:

The warranty claim information provided is insufficient.

The product evaluation does not substantiate the claim.

The unit has been operated above and beyond its capacity or not maintained or serviced properly, resulting in

damages incurred to major components.

If the unit was equipped with a factory installed hour meter which has been disconnected, altered or inoperative for

an extended period of time; with the result being that the equipment’s operating hours cannot be verified.

It is apparent that the operator’s manuals have not been followed.

The equipment is not registered.

Without limitation, Walinga’s Warranty does not cover:

Damage or deterioration due to lack of reasonable care or maintenance.

Damage caused or affected by unapproved modifications to the equipment.

Damage caused by negligence or misuse of the equipment.

Damage caused by using the equipment for purposes for which it was not designed or intended.

Walinga’s liability under this warranty, whether in contract or tort, is limited to the repair, replacement or adjustment of

defective materials and workmanship. In no event will Walinga be responsible for any direct, indirect, loss of time, incidental

or consequential expenses including, but not limited to, equipment rental expenses, towing, downtime, inconvenience, or any

losses resulting from the inability to use the equipment. Further, Walinga shall not be liable for any damages or

inconvenience caused by any delay in the supply or delivery of any equipment or component parts thereof.

The selling Dealer/Sales Person makes no warranty of its own and has no authority to make any representation or promise

on behalf of Walinga, or to modify the terms or limitations of the Walinga Warranty in any way.

Punitive, exemplary or multiple damages may not be recovered unless applicable law prohibits their disclaimer.

Warranty related claims may not be brought forward as a class representative, a private attorney general, a member of a

class of claimants or in any other representative capacity.

The Walinga Warranty and all questions regarding its enforceability and interpretation are governed by the law of the country,

state or province in which you purchased your Walinga equipment. The laws of some jurisdictions limit or do not allow the

disclaimer of consequential damages. If the laws of such a jurisdiction apply to any claim against Walinga, the limitations and

disclaimers contained here shall be to the greatest extent permitted by law.

Dear Customer,

Thank you for choosing WALINGA PNEUMATIC CONVEYING SYSTEMS. For your convenience, should you

require any information related to Parts, Service or Technical Engineering, please contact one of the

following Walinga Personnel in Guelph at 1-888 925-4642 unless noted

TECHNICAL - ENGINEERING:

Duane Swaving 226-979-8227 duane.swaving@walinga.com

Ken Swaving 519 787-8227 (ext:100) ks@walinga.com

WARRANTY CLAIMS:

Canada:

USA: Jonathan Medemblik

Kevin Vanderzwaag (273) warranty

(800) 466-1197 (ext 8) jtm@walinga.com

@walinga.com

SERVICE MANAGER:

Andy Nijenhuis (519) 763-7000 (ext:260) andy@walinga.com

SALES MANAGER:

Canada: Tom Linde (519) 787-8227 (ext 5) thl@walinga.com

USA: Peter Kingma (800) 466-1197 jpk@walinga.com

ORIGINAL PARTS SALES:

Ontario and Eastern Canada:

Scott

Lodder (ext: 224) sp

Parts Department Fax: (519) 824-0367

Manitoba and Western Canada:

Chad Yeo 204-745-2951 chad.yeo@walinga.com

USA: John VanMiddlekoop (800) 466-1197 (ext 3) jvm@walinga.com

l@walinga.com

CORPORATE HEAD OFFICE:

5656 Highway 6N

RR#5, Guelph, Ontario,N1H 6J2

PHONE: (888) 925-4642 FAX: (519) 824-5651

www.walinga.com

AGRI-VAC MANUFACTURING FACILITY:

938 Glengarry Cres., Fergus, Ontario Canada N1M 2W7

Tel: (519) 787-8227 Fax: (519) 787-8210

DISTRIBUTION AND SERVICE CENTRES:

5656 Highway 6N, Guelph, Ontario Canada, N1H 6J2

Tel: (888) 925-4642 FAX: (519) 824-5651

1190 Electric Ave. Wayland , MI.USA 49348

Tel: (800) 466-1197 Fax: (616) 877-3474

rd

70 3

Tel: (204) 745-2951 Fax: (204) 745-6309

24 Molloy Street, Toowoomba, Queensland Australia 4350

Tel: 07-4634-7344 mail@customvac.com.au

Ave. N.E. Box 1790 Carman, Manitoba Canada R0G 0J0

SERIAL NUMBER LOCATION

Always give your dealer the serial numbers of your Walinga

®

Inc. Agri-Vac® when ordering parts or requesting

service or other information.

Serial number plates are located where indicated. Please mark the numbers in the spaces provided for easy

reference.

SERIAL NUMBER LOCATION

Airlock Serial Number

__________________________________

Machine Serial Number

__________________________________

Blower Serial Number

__________________________________

NOTES:

TABLE OF CONTENTS

SECTION DESCRIPTION PAGE

1 Introduction ............................................................................1

4BGFUZ.......................................................................................2

2.1 General Safety ...............................................................3

2.2 Equipment Safety Guidelines.........................................4

2.3 Storage Safety ...............................................................4

2.4 Safety Training................................................................5

2.5 Safety Signs...................................................................5

2.6 Preparation.....................................................................6

2.7 Installation Safety...........................................................6

2.8 Lock-Out Tag-Out Safety................................................6

2.9 Operating Safety ............................................................7

2.10 Maintenance Safety .......................................................7

2.11 Electrical Safety .............................................................8

2.12 Transport Safety.............................................................8

2.13 Refueling Safety .............................................................8

2.14 Tire Safety ......................................................................8

2.15 Battery Safety.................................................................8

2.16 Gas Motor Safety ...........................................................9

2.17 Safety Around Bins, Silos, Tanks etc............................10

2.18 Employee Sign-Off Form.............................................. 11

4BGFUZ4JHO-PDBUJPOT..........................................................13

4 Operation...............................................................................17

4.1 To the New Operator or Owner ....................................17

4.2 Machine Components ..................................................18

4.3 Machine Break-In.........................................................19

4.4 Pre-Operation Checklist ...............................................19

4.5 Machine Preparation ....................................................20

4.6 Controls........................................................................21

4.7 Field Operation.............................................................23

4.8 Transport ......................................................................29

4.9 Storage.........................................................................30

4.10 Conveying Oilseeds......................................................30

4FSWJDFBOE.BJOUFOBODF....................................................31

5.1 Service .........................................................................31

5.2 Maintenance.................................................................37

6 Trouble Shooting..................................................................

7 Specications.......................................................................53

7.1 Mechanical...................................................................53

7.2 Bolt Torque ...................................................................54

8 Parts ......................................................................................55

*OEFY......................................................................................57

1 INTRODUCTION

Congratulations on your choice of a Walinga® Agri-Vac® to complement your operation. This equipment has been

designed and manufactured to meet the needs of the discriminating buyer for the efficient moving of grain.

Safe, efficient and trouble free operation of your new Walinga

who will be operating or maintaining the Agri-Vac

®

, read, understand and practice ALL of the Safety, Operation,

®

Agri-Vac® requires that you, and anyone else

Maintenance and Trouble Shooting recommendations contained within this Operator's Manual.

This manual applies to the Walinga

guide to nd required information.

OPERATOR ORIENTATION - The directions left, right, front and rear as mentioned throughout this manual are

when viewed from the airlock end of the machine. The steering handle is the front, drive system left and airlock

rear.

®

3510 gas or electric Agri-Vac®. Use the Table of Contents and Index as a

1

2 SAFETY

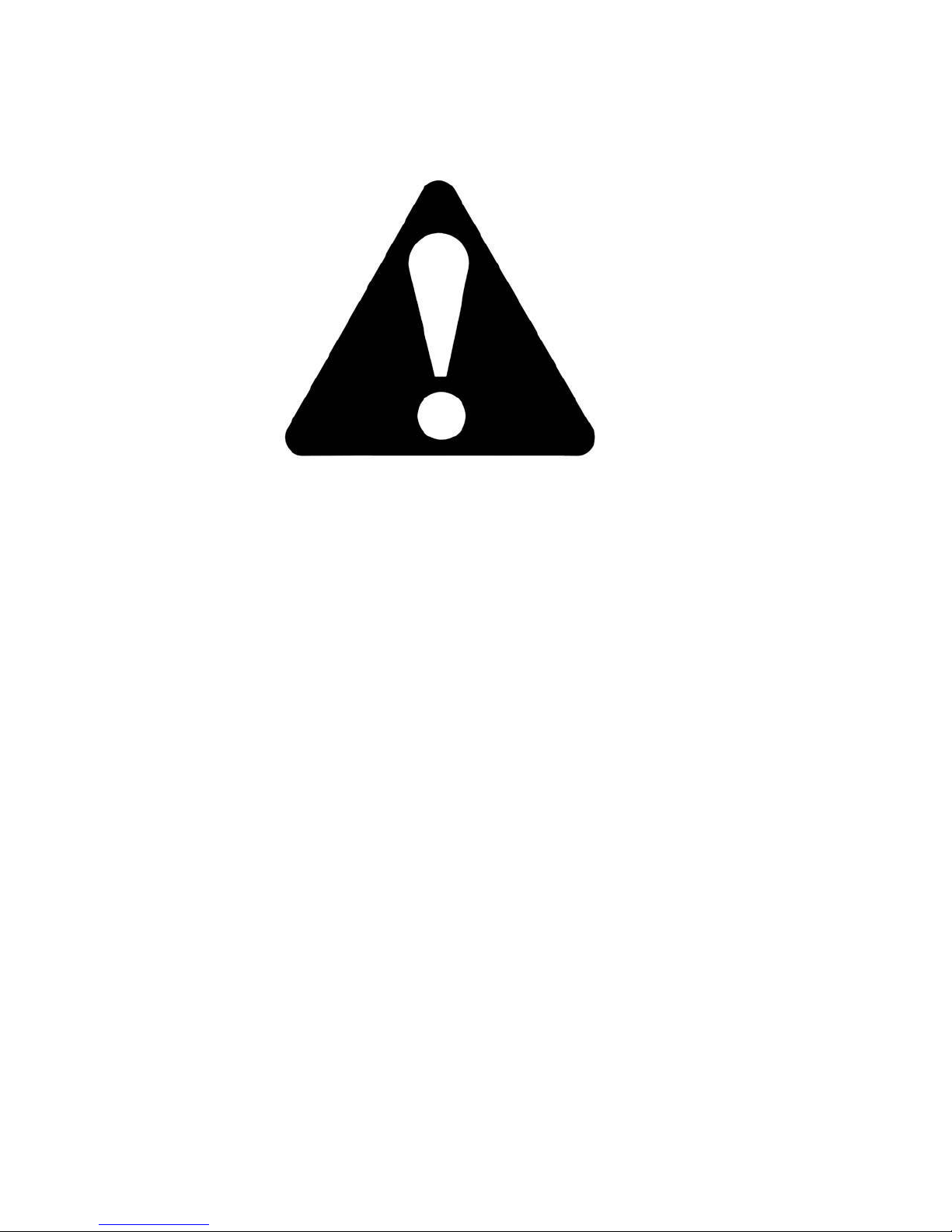

SAFETY ALERT SYMBOL

This Safety Alert symbol means

ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

Why is SAFETY important to you?

3 Big Reasons

SIGNAL WORDS:

No t e th e use o f th e sign a l wo rds DANGER,

WARNING and CAUTION with the safety messages. The app ropriate signa l word for each

message has been selected using the following

guide-lines:

The Safety Alert symbol identifies

impor tant safety messages on the

Walinga

When you see this symbol, be alert

to the possibility of personal injury or

death. Follow the instructions in the

safety message.

®

Agri-Vac® and in the manual.

Accidents Disable and Kill

Accidents Cost

Accidents Can Be Avoided

DANGER

- Indicates an imminently hazardous

situation that, if not avoided, will result

in death or serious injury. This signal

word is to be limited to the most extreme situations typically for machine

components which, for functional purposes, cannot be guarded.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your Walinga

dealer if you need assistance, information or additional copies of the manual.

Contact your dealer for a complete listing of parts.

2

WARNING - Indicates a potentially hazardous situ-

ation that, if not avoided, could result

in death or serious injury, and includes

hazards that are exposed when guards

are removed. It may also be used to

alert against unsafe practices.

CAUTION - Indicates a potentially hazardous situ-

ation that, if not avoided, may result in

minor or moderate injury. It may also

be used to alert against unsafe practices.

®

SAFETY

2.1 GENERAL SAFETY

YOU are responsible for the SAFE operation and

maintenance of your Walinga

®

Agri-Vac®. YOU must

ensure that you and anyone else who is going to

operate, maintain or work around the Agri-Vac

be familiar with the operating and maintenance

procedures and related SAFETY information

contained in this manual. This manual will take you

step-by-step through your working day and alerts you

to all good safety practices while operating the Agri-

®

Vac

.

Remember, YOU are the key to safety. Good safety

practices not only protect you but, also the people

around you. Make these practices a working part of

your safety program. Be certain that EVERYONE

operating this machine is familiar with the procedures

recommended and follows safety precautions.

Remember, most accidents can be prevented. Do

not risk injury or death by ignoring good safety

practices.

• Agri-Vac

®

owners must give operating instructions

to operators or employees before allowing them

to operate the machine, and at least annually

thereafter.

• The most important safety device on this equipment is a SAFE operator. It is the operator’s responsibility to read and understand ALL Safety

and Operating instructions in the manual and to

follow these. Most accidents can be avoided.

• A person who has not read and understood all operating and safety instructions is not qualied to

operate this machine. An untrained operator exposes himself and bystanders to possible serious

injury or death.

• Do not modify the equipment in any way.

Unauthorized modication may impair the function and/or safety and could aect the life of the

equipment.

1. Read and understand the

Operator’s Manual and all

safety signs before supplying

®

power, operating, maintaining ,

adjusting or unplugging.

2. Only trained, competent persons shall operate the

Agri-Vac

®

. An untrained operator is not qualied to

operate this machine.

3. Provide a rst-aid kit for use in

case of an accident. Store in a

highly visible place.

4. Provide a re extinguisher for use in

case of an accident. Store in a highly

visible place.

5. Install and properly secure all guards

and shields before operating.

6. Wear appropriate protective gear. This list

includes but is not limited to:

- A hard hat

- Protective shoes

with slip resistant

soles

- Protective glasses or goggles

- Heavy gloves

- Wet weather gear

- Hearing protection

7. Turn machine OFF, shut down and lockout power

supply and wait for all moving parts to stop before servicing, adjusting, maintaining, repairing,

cleaning or unplugging. (Safety lockout devices

are available through your Walinga

®

dealer parts

department).

• Think SAFETY! Work SAFELY!

8. Know the emergency medical center number for

your area.

9. Wear appropriate hearing protection when operating the machine.

10. Review safety related items with all operators

annually.

3

2.2 EQUIPMENT SAFETY

GUIDELINES

1. Safety of the operator and bystanders is one of

the main concerns in designing and developing a

machine. However, every year many accidents occur which could have been avoided by a few seconds of thought and a more careful approach to

handling equipment. You, the operator, can avoid

many accidents by observing the following precautions in this section. To avoid personal injury or

death, study the following precautions and insist

those working with you, or for you, follow them.

2. In order to provide a better view, certain photo-

graphs or illustrations in this manual may show an

assembly with a safety shield removed. However,

equipment should never be operated in this condition. Keep all shields in place. If shield removal

becomes necessary for repairs, replace the shield

prior to use.

3. Replace any safety sign or instruction sign that is

not readable or is missing. Location of such safety

signs is indicated in this manual.

4. Never use alcoholic beverages or drugs which

can hinder alertness or coordination while operating this equipment. Consult your doctor about

operating this machine while taking prescription

medications.

5. Under no circumstances should young chil-

dren be allowed to work with this equipment.

Do not allow persons to operate or assemble

this unit until they have read this manual and

have developed a thorough understanding of

the safety precautions and of how it works.

Review the safety instructions with all users

annually.

6. This equipment is dangerous to children and

persons unfamiliar with its operation. The operator should be a responsible, properly trained and

physically able person familiar with farm machinery and trained in this equipment's operations.

If the elderly are assisting with farm work, their

physical limitations need to be recognized and

accommodated.

9. In addition to the design and conguration of this

implement, including Safety Signs and Safety

Equipment, hazard control and accident prevention are dependent upon the awareness, concern,

prudence, and proper training of personnel involved in the operation, transport, maintenance,

and storage of the machine. Refer also to Safety

Messages and operation instruction in each of the

appropriate sections of the auxiliary equipment

and machine Manuals. Pay close attention to the

Safety Signs axed to the auxiliary equipment

and the machine.

2.3 STORAGE SAFETY

1. Store the Agri-Vac® on a rm level surface.

2. If required, make sure the unit is rmly blocked

up.

3. Make certain that all mechanical locks are safely

and positively connected before storing.

4. Store away from areas of human activity.

5. Do not allow children to play on or around the

stored Agri-Vac

6. Lock out power by turning o master control panel

or junction box and padlocking the door shut to

prevent electrocution or unauthorized start up of

the Agri-Vac

7. Stop engine, remove ignition key and store in a

secure place for the gas model.

®

.

®

for the electric model.

7. Never exceed the limits of a piece of machinery. If

its ability to do a job, or to do so safely, is in question - DON'T TRY IT.

8. Do not modify the equipment in any way.

Unauthorized modication result in serious injury

or death and may impair the function and life of the

equipment.

4

2.4 SAFETY TRAINING

2.5 SAFETY SIGNS

1. Safety is a primary concern in the design and man-

ufacture of our products. Unfortunately, our eorts

to provide safe equipment can be wiped out by a

single careless act of an operator or bystander.

2. In addition to the design and conguration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, prudence and proper training of personnel

involved in the operation, transport, maintenance

and storage of this equipment.

3. It has been said, "The best

safety feature is an informed,

careful operator." We ask you

to be that kind of an operator.

It is the operator's responsibility

to read and understand ALL Safety and Operating

instructions in the manual and to follow these.

Accidents can be avoided.

4. Working with unfamiliar equipment can lead

to careless injuries. Read this manual, and the

manual for your auxiliary equipment, before

assembly or operating, to acquaint yourself

with the machines. If this machine is used by

any person other than yourself. It is the machine owner's responsibility to make certain

that the operator, prior to operating:

a. Reads and understands the operator's

manuals.

b. Is instructed in safe and proper use.

5. Know your controls and how to stop the Agri-Vac

and any other auxiliary equipment quickly in an

emergency. Read this manual and the one provided with your other equipment.

1. Keep safety signs clean and legible at all times.

2. Replace safety signs that are missing or have become illegible.

3. Replaced parts that displayed a safety sign should

also display the current sign.

4. Safety signs are available from your authorized

Distributor or Dealer Parts Department or the

factory.

How to Install Safety Signs:

• Be sure that the installation area is clean and dry.

• Be sure temperature is above 50°F (10°C).

• Determine exact position before you remove the

backing paper. (See Section 3).

• Remove the smallest portion of the split backing

paper.

• Align the sign over the specied area and carefully

press the small portion with the exposed sticky

backing in place.

• Slowly peel back the remaining paper and carefully smooth the remaining portion of the sign in

place.

• Small air pockets can be pierced with a pin and

smoothed out using the piece of sign backing

®

paper.

6. Train all new personnel and review instructions

frequently with existing workers. Be certain only

a properly trained and physically able person will

operate the machinery. A person who has not read

and understood all operating and safety instructions is not qualied to operate the machine. An

untrained operator exposes himself and bystanders to possible serious injury or death. If the elderly are assisting with work, their physical limitations

need to be recognized and accommodated.

5

2.6 PREPARATION

2.7 INSTALLATION SAFETY

1. Never operate the Agri-Vac® and auxiliary equipment until you have read and completely understand this manual, the auxiliary equipment

Operator's Manual, and each of the Safety

Messages found on the safety signs on the and

auxiliary equipment.

2. Personal protection

equipment including hard hat, safety glasses, safety

shoes, and gloves

are recommended

during assembly, installation, operation,

adjustment, maintaining, repairing, removal, or moving the implement. Do not allow long hair, loose tting clothing

or jewelery to be around equipment.

3. PROLONGED EXPOSURE

TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS!

Motors or equipment attached

can often be noisy enough to

cause permanent, partial hearing loss. We recommend that you wear hearing

protection on a full-time basis if the noise in the

Operator's position exceeds 80db. Noise over

85db on a long-term basis can cause severe hearing loss. Noise over 90db adjacent to the Operator

over a long-term basis may cause permanent,

total hearing loss. NOTE: Hearing loss from loud

noise (from tractors, chain saws, radios, and other

such sources close to the ear) is cumulative over

a lifetime without hope of natural recovery.

4. Clear working area of debris, trash or hidden obstacles that might be hooked or snagged, causing

injury, damage or tripping.

5. Operate only in daylight or good articial light.

6. Be sure machine is properly anchored, adjusted

and in good operating condition.

7. Ensure that all safety shielding and safety signs

are properly installed and in good condition.

1. Disconnect and remove all mechanical locks, anchor chains and any other transport devices that

would hinder or prohibit the normal functioning of

the Agri-Vac

®

upon start up. Serious damage to

the machine and/or personal injury to the operator and bystanders may result from attempting to

operate the machine while mechanical locking devices are still attached.

2. Position the machine on rm, level ground before

operating.

3. Level the frame before using or loading.

4. Have at least one extra person available to assist

when elevating, moving or connecting to other

equipment.

5. Make certain that sucient amperage, at the proper voltage and frequency (60Hz) is available before

connecting power for the electric model. Have a

licensed electrician provide power to the machine.

Always follow ANSI/NFPA 70 Standard and all local codes when providing electrical power.

6. If using Agri-Vac

®

as part of grain handling sys-

tem, anchor securely before starting.

7. Attach exhaust piping to engine or good cross ventilation to the outside if operating the gas model

inside a building or enclosed area.

2.8 LOCK-OUT TAG-OUT SAFETY

1. Establish a formal Lock-Out Tag-Out program for

your operation.

2. Train all operators and service personnel before

allowing them to work around the Agri-Vac

3. Provide tags at the work site and a sign-up sheet

to record tag out details.

4. Do not perform any service or maintenance work

unless motor and engine are OFF and the power

locked out.

®

.

8. Before starting, give the machine a "once over" for

any loose bolts, worn parts, cracks, leaks, frayed

belts and make necessary repairs. Always follow

maintenance instructions.

6

2.9 OPERATING SAFETY

2.10 MAINTENANCE SAFETY

1. Read and understand the Operator’s Manual and

all safety signs before operating, maintaining, adjusting or repairing the Agri-Vac

2. Before servicing, adjusting, repairing or maintain-

ing unit, ensure that unit power source is completely shut down and can not start up.

3. Do not operate when any guards are damaged

or removed, Install and secure guards before

starting.

4. Keep hands, feet, clothing and hair away from all

moving and/or rotating parts.

5. Clear the area of all bystanders, especially small

children, before starting.

6. Before supplying electrical power to the machine,

be sure you have adequate amperage at the proper phase and voltage to run it. If you do not know

or are unsure, consult a licensed electrician.

7. Clean reectors, SMV signs and lights before

transporting.

8. Wear appropriate ear protection when operating

machine.

9. Do not place intake nozzle near feet when stand-

ing on the top of grain.

®

.

1. Good maintenance is your responsibility. Poor

maintenance is an invitation to trouble. Follow all

operating, maintenance and operating instructions in this manual.

2. Follow good shop practices:

- Keep service area clean

and dry.

- Be sure electrical outlets

and tools are properly

grounded.

- Use adequate light for the

job at hand.

3. Make sure there is plenty of ventilation. Never operate the engine of the gas model in a closed building. The exhaust fumes may cause asphyxiation.

4. Before working on this machine, stop engine or

motor and remove ignition key (gas) or turn power

o at the master panel (electric). Lock-out tag-out

machine.

5. Never work under equipment unless it is blocked

securely. Only use tools, jacks and hoists of sufcient capacity for the job.

6. Always use personal protection devices such as

eye, hand and hearing protectors, when performing any service or maintenance work.

10. Review safety instructions annually.

7. A re extinguisher

and rst aid kit should

be kept readily accessible while performing maintenance on

this equipment.

8. Periodically tighten all bolts, nuts and screws and

check that all electrical and hydraulic connections

are properly secured to ensure unit is in a safe

condition.

9. When completing a maintenance or service function, make sure all safety shields and devices are

installed before placing unit in service.

7

2.11 ELECTRICAL SAFETY

2.13 REFUELING SAFETY

1. Have only a qualied licensed electrician supply

power to the electric model by following ANSI/

NFPA 70 Wiring Standard.

2. Make certain that the Agri-Vac

ed at the power source.

3. Make certain that all electrical switches are in the

OFF position before plugging the Agri-Vac

4. Turn machine OFF, shut down and lock out power supply (safety lockout devices are available

through your Walinga

and wait for all moving parts to stop before servicing, adjusting, maintaining or repairing.

5. Disconnect power before resetting any motor or

breaker overload.

6. Replace any damaged electrical plugs, cords,

switches and components immediately.

7. Do not work on Agri-Vac

cal system unless the power cord

is unplugged or the power supply is

locked-out tagged-out.

®

®

is properly ground-

®

in.

dealer parts department)

®

electri-

1. Handle fuel with care. It is highly ammable.

2. Allow engine to cool for 5 minutes before refuelling.

Clean up spilled fuel before restarting engine.

3. Do not refuel the machine while

smoking or when near open

ame or sparks.

4. Fill fuel tank outdoors.

5. Prevent res by keeping machine clean of accumulated trash, grease and debris.

2.14 TIRE SAFETY

1. Failure to follow proper procedures when mounting a tire on wheel or rim can produce an explosion which may result in serious injury or death.

2. Do not attempt to mount a tire unless you have the

proper equipment and experience to do the job.

2.12 TRANSPORT SAFETY

1. Comply with state and local laws governing safety

and transporting of machinery on public roads.

2. Mount a lighting bar on the rear of the frame (when

transporting on public roads) and connect to tow

unit.

3. Check that all the lights, reectors and other lighting requirements are installed and in good working

condition.

4. Disconnect grain and vacuum lines and plug before transporting.

5. Do not drink and operate.

3. Have a qualied tire dealer or repair service perform required tire maintenance.

4. When replacing worn tires, make sure they meet

the original tire specications. Never undersize.

2.15 BATTERY SAFETY

1. Keep all sparks and ames away from batteries as

gas given o by the electrolyte is explosive.

2. Avoid contact with battery electrolyte: wash o

spilled electrolyte immediately.

3. Wear safety glasses when working near batteries.

4. Do not tip batteries more than 45° to avoid electrolyte loss.

5. To avoid injury from spark or short circuit, disconnect battery ground cable before servicing any

part of the electrical system.

8

2.16 GAS MOTOR SAFETY

BEFORE STARTING ENGINE, READ AND UNDERSTAND THE OPERATING AND MAINTENANCE IN-

STRUCTIONS THAT CAME WITH YOUR ENGINE.

WARNING: DO NOT

1. DO NOT run engine in an enclosed area. Exhaust

gases contain carbon monoxide, an odorless and

deadly poison.

2. DO NOT place hands or feet near moving or rotating parts.

3. DO NOT store, spill, or use gasoline near an open

ame, or devices such as a stove, furnace, or water heater which use a pilot light or devices which

can create a spark.

4. DO NOT refuel indoors where area is not well ventilated. Outdoor refuelling is preferred.

5. DO NOT refuel while engine is running. Allow engine to cool for 5 minutes before refuelling. Store

fuel in approved safety containers.

16. DO NOT operate engine without a muer. Inspect

periodically and replace, if necessary. If engine

is equipped with a muer deector, inspect periodically and replace, if necessary with correct

deector.

17. DO NOT operate engine with an accumulation of

grass, leaves, dirt or other combustible materials

in the muer area.

18. DO NOT use this engine on any forest covered,

brush covered, or grass covered unimproved land

unless a spark arrester is installed on the muer.

The arrester must be maintained in eective working order by the operator. In the state of California

the above is required by law (Section 4442 of the

California Public Resources Code). Other states

may have similar laws. Federal laws apply on federal land.

19. DO NOT touch hot muer, cylinder or ns because

contact may cause burns.

20. DO NOT run engine with air cleaner or air cleaner

cover removed.

WARNING: DO

6. DO NOT remove fuel tank cap while engine is

running.

7. DO NOT operate engine if gasoline is spilled.

Move machine away from the spill and avoid creating any ignition until gasoline has evaporated.

8. DO NOT smoke while lling fuel tank.

9. DO NOT choke carburetor to stop engine.

Whenever possible, gradually reduce engine

speed before stopping.

10. DO NOT run engine above rated speeds. This may

result in injury.

11. DO NOT tamper with governor springs, governor

links or other parts which may increase the governed speed.

12. DO NOT tamper with the engine speed selected

by the original equipment manufacturer.

13. DO NOT check for spark with spark plug or spark

plug wire removed.

1. ALWAYS DO remove the wire from the spark plug

when servicing the engine or equipment to prevent accidental starting. Disconnect the negative

wire from the battery terminal if equipped with a 12

volt starting system.

2. DO keep cylinder ns and governor parts free of

grass and other debris which can aect engine

speed.

3. DO examine muer periodically to be sure it is

functioning eectively. A worn or leaking muer

should be repaired or replaced as necessary.

4. DO use fresh gasoline. Stale fuel can gum carburetor and cause leakage.

5. DO check fuel lines and ttings frequently for

cracks or leaks. Replace if necessary.

14. DO NOT crank engine with spark plug removed. If

engine is ooded, crank until engine starts.

15. DO NOT strike ywheel with a hard object or metal

tool as this may cause ywheel to shatter in operation. Use proper tools to service engine.

9

17

2. SAFETY AROUND BINS,SILOS, TANKS AND BOOT PITS

Working in and around bins, silos, and tanks and boot pits.

Agri-Vac operators and all other personnel assisting should strictly adhere to the procedures outlined

below before entering a storage structure. For additional details regarding these procedures, reference

OSHA Standards, or your local regulations. (see also Sect 4.10.1)

Entering a bin, silo, tank or other type of storage structure is

hazardous. You can suffocate and die from the materials stored

inside these structures. There also may be explosive, harmful or

poisonous gas or dust in the air.

Before entering a storage structure, a Agri-Vac operator and all other

personnel assisting should strictly adhere to safety procedures as

follows: (adapted from the

Kansas Grain and Feed Association’s

Safety, Health and Environment Committee.)

1. The machine operator(s) and all assisting personnel should be aware

of the actions they will take in the event of an emergency.

2. The machine operator(s) and all assisting personnel should be trained in the general and specific

safety hazards associated with their work tasks.

3. The machine operator(s) and all assisting personnel should be trained in the general procedures and

safety practices for entering and working in bins, silos, tanks or other storage structures, as well as the

safety procedures for handling special tasks concerning entering and working in such structures.

4. The atmosphere within a bin, silo, tank or storage structure should be tested for the presence of

combustible gases, dusts, vapors and toxic agents.

5. Ventilation should be provided until the unsafe conditions are eliminated or as long as there is a

possibility of recurrence of the unsafe conditions while the bin, silo, tank or storage structure is

occupied by personnel.

6. Anyone entering the bin, silo, tank, storage structure or boot pit, should wear an appropriate

respirator and protective clothing, as long as there is a possibility of any unsafe atmospheric

condition.

7. When entering bins, silos, tanks or storage structures from the top, personnel should wear a body

harness with lifeline, or use a boatswain’s chair.

8. An observer equipped to provide assistance and trained in rescue procedures, including notification

methods, should be stationed outside the bin, silo, tank or storage structure being entered. Visual,

voice or signal line communications should be constantly maintained between the observer and the

party in the bin, silo, tank or storage structure.

9. Equipment for rescue operations which is specifically suited for the bin, silo, tank or storage structure

being entered should be provided.

10. Do not enter bins, silos, tanks or storage structures under a bridging condition, or where a buildup

of materials could fall and bury you. It is also recommended that you do not walk or stand on grain or

other materials where the depth is greater than waist high.

11. Be aware of the extremely high suction at the intake nozzle. Stay away from nozzle intake area.

10

2.18 EMPLOYEE SIGN-OFF FORM

Walinga® Inc. follows the general Safety Standards specied by the American Society of Agricultural and

Biological Engineers (ASABE) and the Occupational Safety and Health Administration (OSHA). Anyone who

will be operating and/or maintaining a Walinga

Operating and Maintenance information presented in this manual.

Do not operate or allow anyone else to operate this equipment until such information has been reviewed.

Annually review this information before the season start-up.

Make these periodic reviews of SAFETY and OPERATION a standard practice for all of your equipment. We feel

that an untrained operator is unqualied to operate this machine.

A sign-o sheet is provided for your record keeping to show that all personnel who will be working with the

equipment have read and understand the information in the Operator’s Manual and have been instructed in the

operation of the equipment.

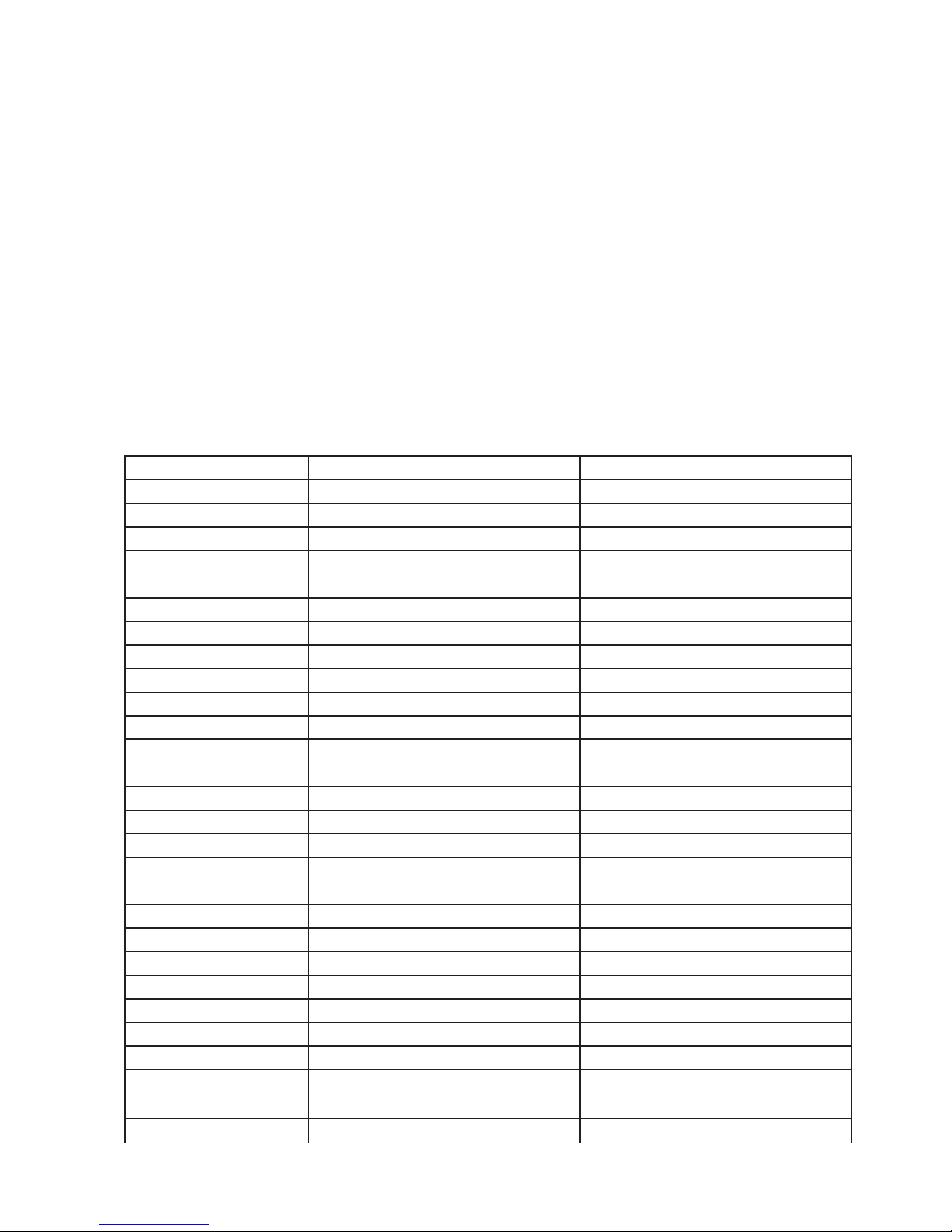

DATE EMPLOYEE'S SIGNATURE EMPLOYER'S SIGNATURE

®

built machine must read and clearly understand ALL Safety,

SIGN-OFF FORM

11

NOTES:

3 SAFETY SIGN LOCATIONS

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good safety

requires that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

D

BA

A

C

C

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without safety

signs, new signs must be applied. New safety signs are available from your authorized dealer.

13

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good safety

requires that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

C

I

C

A

C

D

E

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without safety

signs, new signs must be applied. New safety signs are available from your authorized dealer.

14

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good safety

requires that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

F

F

E

G

B

C

H

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without safety

signs, new signs must be applied. New safety signs are available from your authorized dealer.

15

The types of safety signs and locations on the equipment are shown in the illustrations that follow. Good safety

requires that you familiarize yourself with the various Safety Signs, the type of warning and the area, or particular

function related to that area, that requires your SAFETY AWARENESS.

• Think SAFETY! Work SAFELY!

H

E

B

C

G

G

H

I

REMEMBER - If Safety Signs have been damaged, removed, become illegible or parts replaced without safety

signs, new signs must be applied. New safety signs are available from your authorized dealer.

16

4 OPERATION

OPERATING SAFETY

• Read and understand the Operator’s Manual

and all safety signs before operating, maintaining, adjusting or repairing the Agri-Vac

• Before servicing, adjusting, repairing or maintaining unit, ensure that unit power source is

completely shut down and can not start up.

• Do not operate when any guards are damaged

or removed, Install and secure guards before

starting.

• Keep hands, feet, clothing and hair away from

all moving and/or rotating parts.

• Clear the area of all bystanders, especially small

children, before starting.

®

.

4.1 TO THE NEW OPERATOR

OR OWNER

The Walinga® Agri-Vac® is designed to vacuum up

grain and move it in a stream of pressurized air. A high

capacity air pump moves the air through the machine

creating a vacuum on the intake side and pressure

on the outlet side. Be familiar with all operating and

safety procedures before starting.

In addition to the design and conguration

of equipment, hazard control and accident

prevention are dependent upon the awareness,

concern, prudence and proper training of

personnel involved in the operation, transport,

maintenance and storage of this equipment.

• Before supplying electrical power to the machine, be sure you have adequate amperage

at the proper phase and voltage to run it. If you

do not know or are unsure, consult a licensed

electrician.

• Wear appropriate ear protection when operating

machine.

• Do not place intake nozzle near feet when standing on the top of grain.

• Do not smoke while refueling.

• Do not place intake tube near feet when standing on top of material.

• Review safety instructions annually.

It is the responsibility of the owner or operator to

read this manual and to train all other operators

before they start working with the machine.

Follow all safety instructions exactly. Safety is

everyone's business. By following recommended

procedures, a safe working environment is

provided for the operator, bystanders and the

area around the worksite. Untrained operators are

not qualied to operate the machine.

Many features incorporated into this machine are the

result of suggestions made by customers like you.

Read this manual carefully to learn how to operate the

machine safely and how to set it to provide maximum

eciency. By following the operating instructions in

conjunction with a good maintenance program, your

Agri-Vac

service.

®

will provide many years of trouble-free

17

4.2 MACHINE COMPONENTS

The air pump or blower is the key component in the

Agri-Vac

1) gasoline engine or

2) electric motor

through a belt and chain drive system. The blower

moves air through the machine. On the intake side,

the blower creates a vacuum in the receiver tank and

intake lines for picking up grain. Grain is separated

from the stream of air in the receiver tank.

®

and is driven by the:

C

D

B

K

A

J

On the discharge side of the blower, the pressurized

air ows through the airlock where it picks up a

metered quantity of grain and moves it out the lines

to the discharge cyclone.

The airlock is rotated by the same power source as

the blower.

A Blower G Intake Port

B Airlock H Nozzles

C Receiver Tank J Drive Belts

D Gas Engine K Drive Chain

E Electric Motor L Lines

F Discharge Outlet M Electric Control

L

L

G

C

L

H

A

F

G

G

C

C

H

E

A

B

M

H

B

D

A

F

FIG. 1 MACHINE COMPONENTS

18

4.3 MACHINE BREAK-IN

4.4 PRE-OPERATION CHECKLIST

Although there are no operational restrictions on

®

the Agri-Vac

when used for the rst time, it is

recommended that the following mechanical items

be checked:

A. After operating for 1/2 hour:

1. Turn blower and airlock by hand. Be sure they turn

freely.

2. Retorque all fasteners and hardware.

3. Check the drive system. Re-tighten and re-align as

required.

4. Check for oil leaks. Stop leaks before continuing.

5. Check gas engine uid levels if so equipped.

6. Check oil level in blower reservoirs. Add as

required.

7. Lubricate all grease ttings.

B. After operating for 10 hrs:

Ecient and safe operation of the Walinga® Agri-Vac

requires that each operator reads and understands

the operating procedures and all related safety

precautions outlined in this section. A pre-operation

checklist is provided for the operator. It is important

for both the personal safety and maintaining the

good mechanical condition of the Agri-Vac

®

that this

checklist is followed.

Before operating the Agri-Vac

®

and each time

thereafter, the following areas should be checked o:

1. Lubricate the machine per the schedule outlined

in Section 5 Service and Maintenance.

2. Check gas engine uid levels if so equipped.

3. Check the oil level in the blower reservoirs.

4. Check the tires and ensure that they are inated to

the specied pressure.

5. Check that the blower and airlock turn freely.

6. Close and secure all guards.

®

1. Turn blower by hand. Be sure that it turns freely.

2. Retorque all fasteners and hardware.

3. Check the drive system. Re-tighten and re-align as

required.

4. Check for oil leaks. Stop leaks before continuing.

5. Check gas engine uid levels if so equipped.

6. Check oil level in blower reservoirs. Add as

required.

7. Then go to the normal servicing and maintenance

schedule as dened in the Maintenance Section.

19

4.5 MACHINE PREPARATION

Before the Agri-Vac® can be used it must be

set up and prepared for operation.

When setting-up, follow this procedure:

1. Clear the area of bystanders, especially

small children.

2. Be sure you select a spot that has sucient

space to locate the machine and allows

you to move around the unit to access the

controls.

3. Block the wheels to prevent movement.

4. Remove the plugs from the receiver tank

inlet and airlock outlet.

5. Connect the 12 foot suction and discharge

lines.

NOTE

Ensure couplings

have gaskets

properly installed.

6. Reverse the above procedure when nished working and placing into storage.

FIG. 2 SILO WARNING

a

b

a. Air Intake b. Grain Discharge

20

FIG. 3 PLUGS

4.6 CONTROLS

Before starting to work, all operators should familiarize

themselves with the location and function of controls.

1. Gas Engine:

Read the engine manufacturers operator's manual

before starting for more detailed instructions.

a. Ignition Switch:

This 3-position key-operated switch controls

the electric power to the engine.

OFF

Turn key fully counter-clockwise to stop the

electrical power and turn o the engine.

RUN

Turn clockwise on detent to the run position.

This is the position where the engine will continue to operate.

START

Turn fully clockwise to the last spring-loaded

detent position to engage the starter solenoid

and start the engine. Release the key when

the engine starts and it will return to the RUN

position.

b

c

a

FIG. 4 ENGINE

b. Choke:

This slide lever controls the position of the

choke. Move the lever to the left to close the

choke for starting when the engine is cold.

Move the lever to the right to open the choke

as the engine warms. Always move the lever

fully to the right when operating the machine.

c. Throttle:

This slide lever controls the engine RPM.

Move the lever to the left to increase engine

speed and to the right to decrease.

21

2. Electric Motor:

Each customer is responsible to provide the appropriate power supply to the machine. It is recommended that the customer have a licensed electrician provide power per ANSI/NFPA 70 Standard

and all applicable local codes when providing

power to the motor.

The Agri-Vac

®

can be wired into a large control

room away from the machine or controlled by the

control box supplied with the unit. If part of a control system, the customer must provide all the necessary components.

Be familiar with the typical control box before

starting.

a. ON/OFF Switches:

This control box is provided by Walinga

®

and

can be used to operate the machine. Push the

top green button in to turn the machine ON.

Push the bottom red button to turn the machine OFF.

FIG. 5 ON/OFF SWITCHES

22

4.7 FIELD OPERATION

OPERATING SAFETY

• Read and understand the Operator’s Manual

and all safety signs before operating, maintaining, adjusting or repairing the Agri-Vac

• Before servicing, adjusting, repairing or maintaining unit, ensure that unit power source is

completely shut down and can not start up.

• Do not operate when any guards are damaged

or removed, Install and secure guards before

starting.

• Keep hands, feet, clothing and hair away from

all moving and/or rotating parts.

• Clear the area of all bystanders, especially small

children, before starting.

The Walinga® Agri-Vac® is used to pick up and move

grain from one location to another on a stream of air.

Before starting, the operator has the responsibility of

being familiar with all operating and safety procedures

and following them.

®

.

• Before supplying electrical power to the machine, be sure you have adequate amperage

at the proper phase and voltage to run it. If you

do not know or are unsure, consult a licensed

electrician.

• Wear appropriate ear protection when operating

machine.

• Do not place intake nozzle near feet when standing on the top of grain.

• Do not smoke while refueling.

• Do not place intake tube near feet when standing on top of material.

• Review safety instructions annually.

Each operator should review this section of the manual

at the start of the season and as often as required

to be familiar with the Agri-Vac

machine. follow this procedure:

1. Clear the area of bystanders, especially small children before starting.

2. Review and follow the pre-operation checklist (See

Section 4.4).

3. Move the machine to the working area and block

the wheels to prevent movement.

4. Attach the intake and discharge hoses.

5. Attach the appropriate nozzle to the end of the intake hose.

®

. When operating the

FIG. 6 ELECTRIC MODEL INSTALLED

23

5. Starting:

A. Electric:

a. Depress green ON button on control

B. Gas:

a. Move choke lever into its OPEN

b. Move the throttle lever midway be-

box.

position.

tween the "slow" and "fast" positions.

c. Turn the ignition key clockwise to

d. Slowly close the choke as the en-

e. Run for two minutes to fully warm

6. Stopping:

A. Electric:

a. Remove nozzle from grain and allow

b. Depress red STOP button on control

B. Gas:

start the engine. Release key when

engine starts.

gine warms. Close choke completely

when engine is warm and operating

Agri-Vac

®

.

engine before increasing to full RPM

(Refer to engine owner's manual for

complete start-up details).

to empty.

box.

Electric

Gas

FIG. 7 STARTING/STOPPING

a. Remove nozzle from grain and allow

to empty.

b. Slow engine to low idle RPM.

c. Use ignition key to stop engine.

7. Emergency Stopping:

If an emergency occurs, the machine must be

stopped immediately.

a. Stop electric model by pressing red STOP

button.

b. Stop gas model by turning ignition key

OFF.

c. Correct emergency condition before re-

suming work.

24

8. Operating:

a. Insert nozzle into grain with airslide complete-

ly open.

b. Close airslide slowly until hose pulsates and

then open slide an additional 1 ½ inches.

c. Operate machine at this setting for ten min-

utes to warm system before putting under full

load.

d. After warm-up period, bring machine to full

capacity.

e. Close airslide until intake line starts to pulsate.

Open slide slightly to stop pulsation.

f. Watch glass window in receiver tank. Material

should move past the window for the best

performance.

9. Maximum Capacity:

a. Place the nozzle into the grain with the inlet

below the surface of the grain but not below

the airslide. It is necessary that some air be

allowed to enter through the airslide.

FIG. 8 AIRSLIDE

b. Open the airslide completely to start. Close

airslide until the hose starts to pulsate. Then

open it until the pulsing stops. This will give a

balanced grain and airow condition.

c. Watch for grain build-up on the window in the

receiver tank. Grain must not lie stationary on

the window. If grain builds up on the window,

decrease the amount of grain entering the

nozzle by opening the airslide.

FIG. 9 WINDOW

25

10. Specialty Crops:

When handling specialty products such as sunower seeds, lentils etc, it is recommended that

the blower speed be reduced. This gives a gentler

action through the machine. Pulse crops are sensitive to cracking so a gentler action is required to

minimize cracking. Electric models may need a different drive system installed. (Contact your dealer

or the factory for details.).

11. Entering Bins:

a. Open the vents to provide ventilation and to

allow air to replace grain being removed.

b. Do not enter bin if the grain is crusted or has

built up a hard surface.

c. Turn all other grain extraction equipment o

and lock-out tag-out.

d. Do not enter silo or bin until grain level is low-

ered to less than 12 inches (25 cm) above the

oor or solid footing.

e. Always have another person outside the facil-

ity to assist if the need arises.

f. Go around the facility picking up all the re-

maining grain.

Grain level is less than 12" above oor.

FIG. 10 GATHERING NOZZLE

26

12. Optional Equipment:

Several pieces of optional equipment are available

to use with the Agri-Vac

not limited to:

a. Pre-Cleaner:

For removing abrasive material from the airow

to prevent it from going through the blower.

b. Reducer:

To change size from 3 inch diameter to 2 inch

diameter (or from 4 inch to 3"inch).

c. Brush End:

Brush for cleaning up dust and loose grain.

®

. The list includes but is

Pre-Cleaner

Reducer

d. Wheeled Nozzle:

For cleaning grain on the surface.

e. 3 inch hose

f. 2 inch hose.

g. Straight nozzle.

h. Flared nozzle.

Wheeled Nozzle

h

e

g

Attachments

Brush End

f

FIG. 12 OPTIONAL EQUIPMENT

27

i. Self-Dumping Hopper Bins.

13. Silo Bags:

Do not enter silo bags. To prevent pulling the plastic into the nozzle, always slice the sides open and

roll them back before starting.

SELF-DUMPING HOPPER BINS

DESCRIPTION

PART NO

11-78297-6 .5 47 33 31 11-78281-6

11-64331-6 1 59 40 38 11-78280-6

11-78298-6 1.5 63 52 42 11-78282-6

11-78196-6 2 70 58 44 11-78197-6

11-70845-6 3 80 64 50 11-106955-6

11-78299-6 4 78 84 50 11-78296-6

11-78324-6 5 90 76 60

11-78325-6 6 91 88 60

10 ga Steel Hopper, Self Dump C/W Safety Chains

Capacity

(CY) L (in) W (in) H (in)

Steel Lid (Optional)

Part No

14. Nozzle Use:

When on top of grain, do not push the nozzle into

the pile next to the feet. The suction will pull the

nozzle and the operator into the pile. If the pile is

deep enough, the operator can be submerged under the grain and is suocated.

15. Operating Hints:

a. Try to keep the hoses as full as possible to

have maximum capacity.

b. Pull the intake nozzle out of the grain and

empty the machine before shutting machine

o.

c. Route the lines to minimize bends and cor-

ners. If a corner is necessary, use a large radius elbow.

d. Keep lines as short as possible to minimize

friction losses.

e. If long distance moving is required, push the

grain rather than pull.

f. If long distance moving is required, use

solid metal tubing whenever and wherever

possible.

g. Always ground the air and grain lines to pre-

vent static electrical build-up and sparking.

h. Always push both clamps fully over-center to

seal the junction and prevent leakage.

28

FIG. 11 JUNCTION TYPICAL

4.8 TRANSPORT

TRANSPORT SAFETY

• Comply with state and local laws governing

safety and transporting of machinery on public

roads.

Walinga

conveniently moved from location to location.

When transporting, follow this procedure:

1. Be sure all bystanders are clear of the machine.

2. Disconnect air and grain lines and stow.

3. Install and secure plugs in ports.

4. Use a forklift to lift machine onto a pick-up or truck

®

Agri-Vacs® are designed to be easily and

and tie down securely.

• Disconnect grain and vacuum lines and plug before transporting.

• Do not drink and operate.

FIG. 13 FORKLIFT POCKETS

29

4.9 STORAGE

STORAGE SAFETY

• Store away from areas of human activity.

• Do not allow children to play on or around the

stored Agri-Vac

At the end of the season, the machine should be

thoroughly inspected and prepared for storage.

Repair or replace any worn or damaged components

to prevent any unnecessary down time at the start of

next season.

Follow this procedure:

1. Wash the entire machine thoroughly using a water

hose or pressure washer to remove all dirt, mud,

debris or residue.

2. Lubricate all grease points. Make sure all grease

cavities have been lled with grease to remove

any water residue from the washing.

3. Check the oil level in the blower reservoirs. Bring

to the recommended level.

®

.

• Store unit in a dry, level area. Support the base

with planks if required.

4.10 CONVEYING OILSEEDS

For conveying oil seed commodities (such as

sunflower seeds or canola) we recommend a

raised tip blower and washout ports.

The raised tip blowers have a tip on the impellor

that cleans the casing as the blower rotates.

After conveying oilseeds, we recommend washing

the internal surfaces to remove any residue.

This will reduce the risk of seizing caused by a

build up of oil residue.

4. Install the plugs into the receiver tank inlet and airlock outlet.

5. Touch up all paint nicks and scratches to prevent

rusting.

6. All hoses should be stored inside or under a

shelter.

7. Move the machine to its storage position.

8. Select an area that is dry, level and free of debris.

9. Motors should be stored in a clean, dry, ventilated

location. When in storage the motor shaft should

be turned several rotation every month and the

bearings re-lubricated every year.

10. It is recommended that the starter be powered up

once per year, for one hour continuously to avoid

deterioration of electrolyte and subsequent starter

failure.

30

5 SERVICE AND MAINTENANCE

MAINTENANCE SAFETY

• Follow ALL the operating, maintenance and

safety information in the manual.

• Support the machine with blocks or safety

stands when changing tires or working beneath it.

• Follow good shop practices:

- Keep service area clean and dry.

- Be sure electrical outlets and tools are

properly grounded.

- Use adequate light for the job at hand.

• Stop engine or motor, remove ignition key or

lock-out tag-out electrical power and wait for

all moving parts to stop before servicing, adjusting, repairing, unplugging or tting.

• Use only tools, jacks and hoists of sucient

capacity for the job.

• Before servicing, adjusting, repairing or maintaining unit, ensure that unit power source is

completely shut down and can not start up.

5.1 SERVICE

5.1.1 FLUIDS AND LUBRICANTS

1. Grease:

Use an SAE multi-purpose high temperature

grease with extreme pressure (EP) performance

rating meeting or exceeding the NLGI #2 rating for

all requirements.

2. Blower Oil:

Use Walinga

3. Storing Lubricants:

Your machine can operate at top eciency only if

clean lubricants are used. Use clean containers to

handle all lubricants. Store them in an area protected from dust, moisture and other contaminants.

5.1.2 GREASING

Use the Maintenance Checklist provided to keep a

record of all scheduled maintenance.

®

Blower Oil part number 98-13813-5.

Model 3510

Front 1 liter (1.1 qts)

Rear 1.35 liters (1.4 qts)

• Make sure all guards are in place and properly secured when maintenance work is

completed.

• Keep hands, feet, hair and clothing away from

all moving and/or rotating parts.

• Clear the area of bystanders, especially small

children, when carrying out any maintenance

and repairs or making any adjustments.

1. Use only a hand-held grease gun for all greasing. Air powered greasing systems can damage

the seals on bearings and lead to early bearing

failure.

2. Wipe grease tting with a clean cloth before greasing to avoid injecting dirt and grit.

3. Replace and repair broken ttings immediately.

4. If a tting will not take grease, remove and clean

thoroughly. Also clean lubricant passageway.

Replace tting if necessary.

31

5.1.3 SERVICING INTERVALS

8 Hours or Daily

1. Use the sight glasses to check the oil level in the

blower reservoirs (2 locations).

Schematic

2. Check engine uid levels (gas model only).

a. Fuel

b. Oil level

Blower (Typical)

FIG. 14 RESERVOIRS

b

a

FIG. 15 GAS ENGINE

32

40 Hours or Weekly

1. Grease airlock drive jack shafts and bearings.

2. Check drive belt and chain tension.

FIG. 16 JACK SHAFT BEARINGS

3. Clean gas engine air lter.

Gas

Electric

FIG. 17 BELT AND CHAIN TENSION

FIG. 18 AIR FILTER

33

100 Hours or Annually

1. Change the oil in the blower oil reservoirs (2 locations) and clean head plate vent holes.

Schematic

2. Change engine oil - drain plug.

3 Change engine oil lter.

4. Change inline fuel lter.

Blower (Typical)

FIG. 19 BLOWER

3

2

FIG. 20 ENGINE

34

FIG. 21 INLINE FUEL FILTER

5. Grease steering wheel bushing.

FIG. 22 STEERING WHEEL BUSHING

35

5.1.4 SERVICE RECORD

See Lubrication and Maintenance sections for details of service. Copy this page to continue record.

ACTION CODE: CL CLEAN G GREASE CK CHECK

CH CHANGE

MAINTENANCE

HOURS

SERVICED BY

8 Hours or Daily

CK Blower Oil Level (2 locations)

CK Engine uid levels (2 locations)

40 Hours or Weekly

G Airlock Drive Jack Shafts

G Airlock Drive Bearings

CK Drive Belt and Chain Tension

CL Gas Engine Air Filter

100 Hours or Annually

CH Blower Oil

CH Engine Oil

CH Engine Oil Filter

CH Inline Fuel Filter

G Steering Wheel Bushing

36

5.2 MAINTENANCE

By following a careful service and maintenance program on your machine, you will enjoy many years of troublefree use.

5.2.1 CLEANING AIR CLEANER

1. Review the Operator's Manual for the engine.

2. Place all controls in neutral, stop engine, remove

ignition key and wait for all moving parts to stop

before maintaining.

3. Remove the cover over the air cleaner.

4. Remove the lter from the engine.

5. Use an air hose to blow the dust and debris out of

the lter.

6. Install lter.

7. Install and secure the cover.

FIG. 23 AIR CLEANER

37

5.2.2 CHANGING ENGINE OIL AND FILTER

1. Review the Operator's Manual for the engine.

2. Place all controls in neutral, stop engine, remove

ignition key and wait for all moving parts to stop

before maintaining.

3. Allow the engine to cool before changing the oil.

Hot oil can cause burns if it contacts exposed skin.

It is best to change oil while the engine is warm to

keep the contaminants in suspension.

4. Place a pan under the drain plug.

5. Remove the drain plug and allow the oil to drain for

10 minutes.

6. Install and tighten the drain plug.

7. Dispose of the used oil in an approved container.

8. Remove engine oil lter.

9. Apply a light coat of oil to the O-ring and install

the replacement lter. Snug up by hand and then

tighten ½ turn.

c

b

d

a

a. Drain Plug b. Fill Plug

c. Dip Stick d. Oil Filter

FIG. 24 ENGINE OIL AND OIL FILTER

10. Fill the crankcase with the specied oil.

11. Run the engine for 1-2 minutes and check for oil

leaks.

12. If leaks are found around the drain plug tighten

slightly. Repeat step 9.

13. Check engine oil level. Top up as required.

38

5.2.3 CHANGING INLINE FUEL FILTER

The gas model Agri-Vac® is designed with an inline

fuel lter to insure clean fuel goes to the engine.

Change the inline fuel lter annually or more often if its

gets dirty. To change the lter, follow this procedure:

1. Place all controls in neutral, stop engine, remove

ignition key and wait for all moving parts to stop

before maintaining..

2. Apply clamps to fuel line on each side of the fuel

lter.

3. Remove fuel lter and wipe up any spilled fuel.

4. Install replacement fuel lter.

5. Remove clamps on fuel lines.

6. Clean up any spilled fuel.

FIG. 25 INLINE FUEL FILTER

39

5.2.4 BELT TENSION AND ALIGNMENT

Rotational power from the power source is transmitted

to the blower and airlock through the belt drive (electric

model). To obtain ecient transmission of power and

good belt life, the belts must be properly tensioned

and the pulleys aligned.

Belts that are too tight will stretch and wear quickly

or overload the bearings. Belts that are too loose will

not transmit the required power and will slip, overheat

and wear quickly. Pulleys that are not aligned will

result in rapid belt wear.

Follow this procedure when checking and adjusting

belt tension and pulley alignment.

1. Clear the area of all bystanders, especially small

children.

2. Stop the unit wait for all moving parts to stop before maintaining.

3. Ensure that the unit power source is completely

shut down and can not start up. Lock-out tag-out

power source.

FIG. 26 BELT DEFLECTION MODEL 3510

4. Unbolt and remove the belt/chain cover. Lay to the

side.

5. Use a 7 pound weight to determine the belt deection in a static condition on a new Agri-Vac

®

.

There should be a ¼ inch deection.

6. Adjusting Tension:

a. Loosen the jam nuts on the adjusting bolts.

Loosen hold-down bolts slightly.

b. Turn the adjusting bolt to set the tension.

Maintain pulley alignment.

c. Check the tension again. Overtightening will

cause belt stretching and overload the bearing. Belts that are too loose will slip, tear and

wear rapidly. Check alignment (next page).

d. Tighten jam nuts. Tighten hold-down bolts.

e. Install and secure guards/covers.

Gas

40

Electric

FIG. 27 ADJUSTING BOLTS

7. Pulley Alignment:

a. Lay a straight-edge across the faces of the

two pulleys.

b. If the gap between the pulley and the straight-

edge exceeds 1/16 inch (1.5mm), the pulleys

must be realigned.

c. Measure the distance the pulley needs to

move.

d. Loosen belts.

e. Remove bolts from the pulley which is to be

moved.

f. Install bolts into pulleys’ threaded holes and