Walinga 510, 614 Maintenance Manual

BLOWER REPAIR & MAINTENANCE

MANUAL FOR CHROME BLOWERS

MODELS: 510 & 614

2

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

3

Dear Customer,

Thank you for choosing WALINGA TRANSPORTATION EQUIPMENT. For your convenience, should you

require any information related to Parts, Service or Technical Engineering, please contact one of the

following Walinga Personnel in Guelph at 1-888 925-4642 unless noted*

TECHNICAL - ENGINEERING:

Tom Linde (ext 5) thl@walinga.com

Ken Swaving *519 787-8227 (ext:100) cms@walinga.com

WARRANTY CLAIMS:

For Customers in Canada:

Gary Nijenhuis (ext:258) gary.nijenhuis@walinga.com

For Customers in USA:

Jonathan Medemblik * (800) 466-1197 (ext 8) jtm@walinga.com

SERVICE MANAGER:

Chris Ecclestone *(519) 787-8227 (ext:106) chris.ecclestone@walinga.com

Duane Swaving 226 979-8227 duane.swaving@walinga.com

ORIGINAL PARTS SALES:

For Customers in Canada:

Jack Lodder (ext: 224)

jel@walinga.com arts Department

Fax: (519) 824-0367

For Customers in USA:

John VanMiddlekoop * (800) 466-1197 (ext 3) jvm@walinga.com

___________________________________________________________________________________

CORPORATE HEAD OFFICE:

RR#5 Guelph, Ontario,N1H 6J2

PHONE (519) 824-8520 FAX (519) 824-5651

walinga.com

AGRI-VAC MANUFACTURING FACILITY:

938 Glengarry Cres. Fergus, Ontario Canada N1M 2W7

Tel: (519) 787-8227 Fax: (519) 787-8210

FACTORY DISTRIBUTION AND SERVICE CENTRES:

1190 Electric Ave. Wayland, MI.USA 49348

Tel (800) 466-1197 Fax (616) 877-3474

70 3rd Ave. N.E. Box 1790 Carman, Manitoba Canada R0G 0J0

Tel (204) 745-2951 Fax (204) 745-6309

220 Frontage Rd. Davidson, Saskatchewan Canada S0G 1A0

Tel: (306) 567-3031 Fax: (306) 567-3039

Blower Repair & Maintenance Manual

for 510 & 614 Blowers

#34-05198-6 v1.2 11.2014

Printed In Canada

Issue Date: November, 2015

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

4

LONG-LIFE SERVICE

Although WALINGA blowers are sturdy, precision-engineered machines, there are several relatively

simple but basic installation and maintenance procedures that must be observed to assure optimum

performance.

It is the purpose of this manual to help you properly install, maintain and service your WALINGA blower;

follow the instructions carefully and you will be rewarded with long-life service.

TABLE OF CONTENTS

Special Features Of Walinga Blowers 7

Section One

Lubrication 9

Section Two:

Maintenance-Retiming 10

Disassembly Of Blower 14

Assembly Of Blower 15

Assembly Of Blower (Con’t) 16

Section Three:

Repair And Replacement 18

Timing Gear And Hub Removal 18

Bearing And Gear Replacement On Gear Head Units 21

Parts Description 22

Trouble Shooting 24

Blower Startup Checklist 26

Instructions For Remounting Blowers 28

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

5

LONG LIFE DESIGN

WALINGA Rotary Positive Displacement Blowers are designed to give the user the most compact unit

possible. The drive shaft is extended for direct coupling or to accommodate a multiple V-belt drive.

The following standard blowers are available from Walinga:

WALINGA 510 & 614

These high performance blowers offer 700 to 1800 CFM at pressures up to 12 psi continuously.

Gears and bearings are splash lubricated.

NOTES

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

6

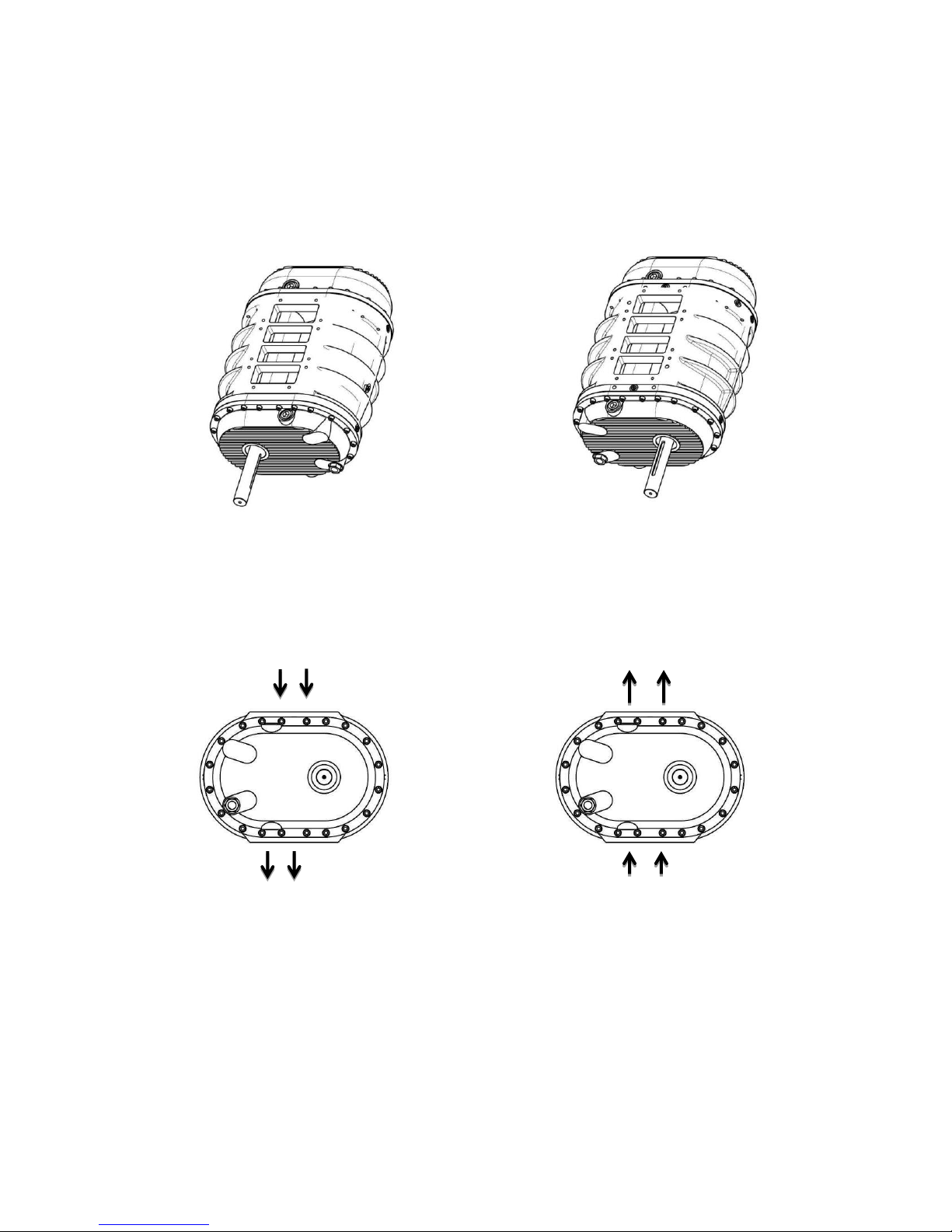

Walinga Chrome Blowers

Right-Hand-Drive Option

The standard shaft position on Walinga Super Chrome Blowers is at the left-hand side when viewed from

the drive end. A right hand drive conversion is available to suit specific applications. Walinga or a trained

dealer must be consulted prior to installation or perform this conversion to ensure that the warranty

coverage is not voided. Note that direction of air-flow through the blower will be the reverse of a standard

blower.

LEFT HAND DRIVE

(STANDARD)

RIGHT HAND DRIVE

(OPTION)

AIR IN

AIR OUT

AIR OUT

AIR IN

Walinga Blowers feature in-house internal chrome hardened

components to increase blower life by up to three times!

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

7

SPECIAL FEATURES OF WALINGA BLOWERS

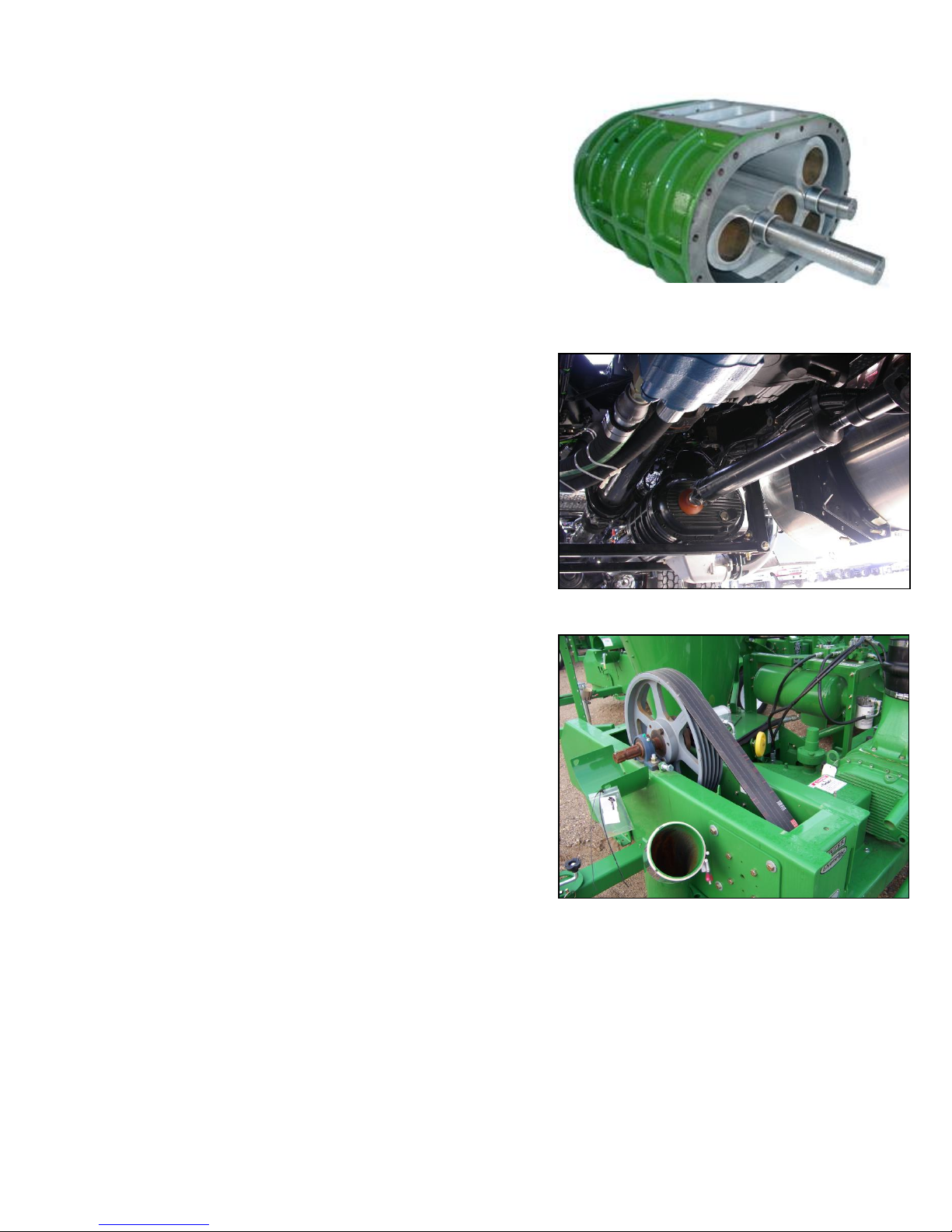

Fig. 1

Fig. 3

Fig. 2

OPERATION

Refer to Figure 1. Rotary positive displacement design

incorporates the use of two figure eight impellers which

rotate in opposite directions to deliver a metered volume

of air. The impellers are separated by minute clearances

which are designed into the unit. These clearances are

maintained by timing gears.

CONSTRUCTION

Walinga blowers are ruggedly built for long life. Impellers

are dynamically balanced to operate without vibration.

Large alloy steel shafts are ground and polished.

Bearings are heavy duty anti-friction type which enable

the blower to maintain its original factory clearances.

Bearings are protected from dirt and contamination by oil

seals. Precision, steel, helical gears are oil lubricated by

a completely self-contained splash system which

atomizes the oil. Breathers are provided to prevent the

air from being contaminated by the blower lubricant.

TYPES OF DRIVE

Direct: Locked bearings on both impeller shafts enable

the blowers to be direct connected. The entire line is

also available with flange adaptors and couplings for

direct connection to internal combustion engines as used

on WALINGA Trailers and Transfer Units. (See Figure

2). In addition, WALINGA blowers are available as

power take off (PTO) units with gear heads in a selection

of ratios to approximately 2.25:1.

V-belt: Walinga blowers can be V-belt driven to permit

changes of speed to accommodate variations in

operation requirements. (See Figure 3)

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

8

SPECIAL FEATURES OF WALINGA BLOWERS - CONT’D

Fig. 4

RELIEF VALVES

VACUUM RELIEF VALVE, spring loaded type.

Built in 1-1/2”, 3”, 4”, and 6” sizes (Figure 4).

Fig. 5

PRESSURE RELIEF VALVE, spring loaded type (Figure 5).

Both valves are supplied as standard equipment.

Fig. 6

TIMING GEARS

Walinga units are fitted with precision steel helical gears and the

exclusive WALINGA TIMING HUB which enables the user to

easily retime the unit in the field and has great shock absorbing

qualities (Figure 6).

Fig. 7

MUFFLER

To minimize sound level with little pressure drop, space and

weight saving packaged-type mufflers are supplied

(Figure 7).

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

9

SECTION ONE:

BLOWER MODEL #

FRONT

REAR

510

1.14 (1.20)

1.40 (1.50)

614

1.40 (1.50)

2.50 (2.60)

LUBRICATION

Anti-friction bearings and precision, steel helical gears are oil lubricated by a completely self-contained splash

system which atomizes the oil. No external oil feed systems or coolers are required.

Units are shipped with oil in the gear case or bearing housing. Do not operate before checking lubrication. The

vent and oil level plug arrangement are shown in figure 8. Remove the oil fill plug from the fill hole at the top of the

cover and the plug from the oil level hole located at the side of the headplate. Fill the housings until oil drips out of

the oil level hole. Do not overfill. * Replace both plugs. Use Walinga Super Duty Blower Oil (Walinga Part# 98-

13813-5) In most cases, operating temperature of the blower will be in the 100-250 Deg. F. range. Normally the

gear case should be drained, flushed, and refilled every 100 hours or annually. If inspection indicated it is

necessary, do at shorter intervals. The oil level should be checked daily.

Fig.8 Blower Schematics

* On units equipped with sight glass, check to be sure that oil levels registers a quarter of the sight glass.

Table 1

OIL CAPACITY LITERS (US QUARTS)

SPECIAL NOTE: As a result of blower operating temperatures, condensation can occur and result in water formation

in the lubricating oil reservoir. It is important that any water accumulation be eliminated, in order to ensure proper

lubrication and long life.

Allow blower to cool down before driving away to prevent condensation and freeze up in cold weather.

Blower Repair & Maintenance Manual #34-05198-6 v1.2 11.2014

Loading...

Loading...