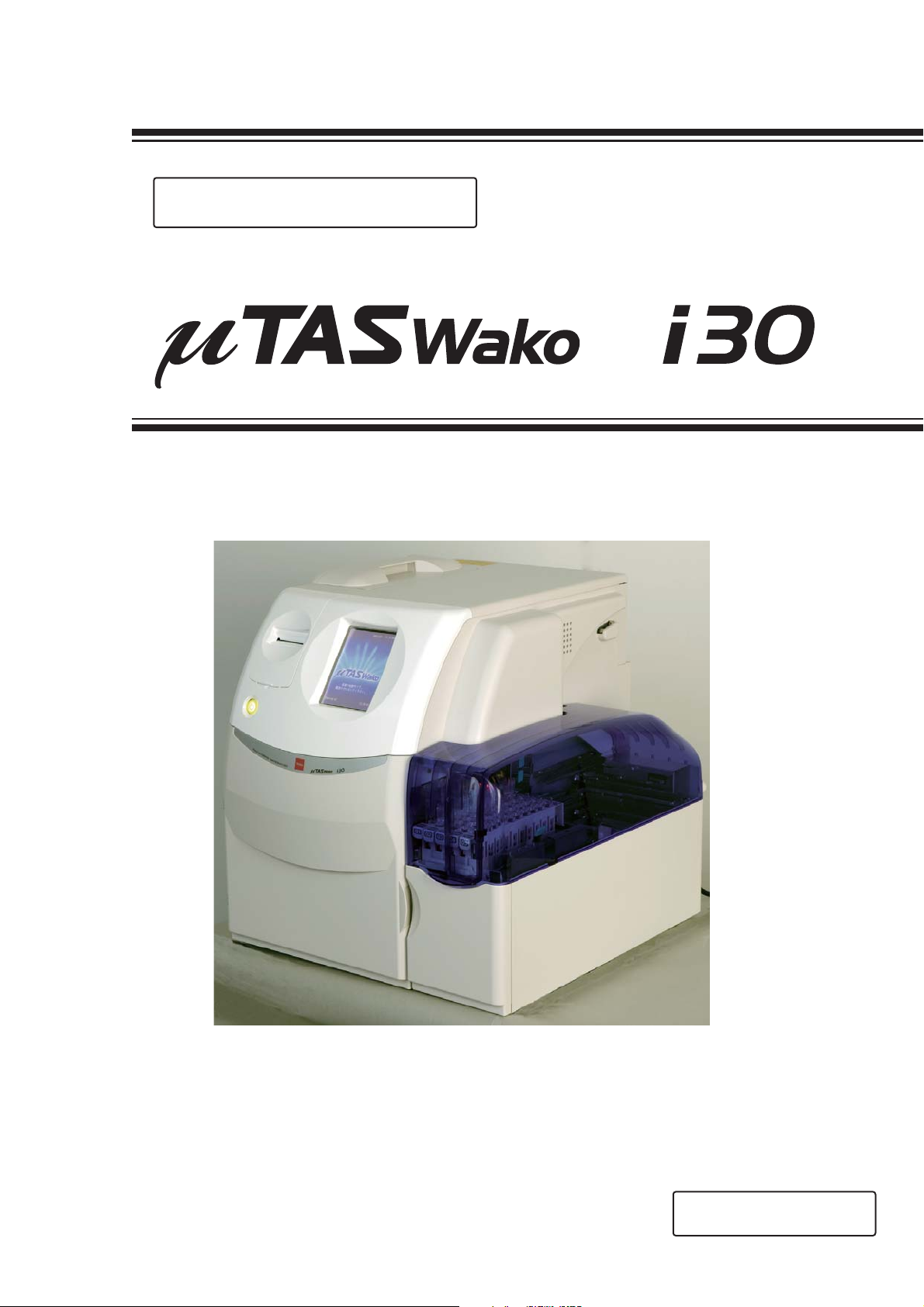

Wako Pure Chemical UTASWAKOI30 User Manual

Instruction ManualInstruction Manual

First Edition

FULLY AUTOMATED IMMUNOANALYZER

December 2009

Wako Pure Chemical Industries, Ltd.

Introduction

Thank you for purchasing the μTASWako i30.

The μTASWako i30 is an in vitro diagnostic medical device to analyze blood etc. using the specified

reagents.

Before using this equipment, please read this manual carefully to follow the safety information and the

usage precautions described in the manual.

Keep the manual near the μTASWako i30, so that you can refer to it whenever necessary.

CAUTIONS

1 No part or all of this manual may be reproduced in any form without prior permission.

2 The information contained in this manual may be subject to change without prior notice.

3 Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage result-

ing from installation, relocation, remodeling, maintenance, and repair done by other than

dealers specified by Wako Pure Chemical Industries, Ltd.

4 Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage of

Wako Pure Chemical Industries, Ltd. products due to the use of products of other manufacturers not supplied by Wako Pure Chemical Industries, Ltd.

5 Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage result-

ing from remodeling, maintenance, and repair using repair parts other than those specified

by Wako Pure Chemical Industries, Ltd.

6 Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage result-

ing from negligence of precautions and operating methods contained in this manual.

7 Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage result-

ing from use under environment conditions outside the range of conditions required for

proper use of this product, such as power supply, installation environment, etc. contained in

this manual.

8 Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage result-

ing from natural disasters such as fires, earthquakes, floods, lightning, etc.

Copyright reserved.

Copyright 2009 by Wako Pure Chemical Industries, Ltd.

(i)µTASWako i30 Instruction Manual

INDEX

‣

Safe Usage and Handling Precautions

․

Component Names and Functions

‥

Description of the Assay Principle

…

Operations

‧

Inventory and Maintenance

Troubleshooting

Parameter Setup

Other Functions

Specifications/Consumables

µTASWako i30 Instruction Manual

(iii)

Contents

1. Safe Usage and Handling Precautions............................................................ 1-1

1.1 Definition of Specific Safety Precautions ...........................................................1-1

1.2 Precautions before Operating This Equipment..................................................1-1

1.3 Biohazards and Disposal ...................................................................................1-3

1.4 Laser Warning ...................................................................................................1-4

1.5 High Voltage ......................................................................................................1-4

1.6 Explosive Hazards .............................................................................................1-4

1.7 Electrical Hazards..............................................................................................1-5

1.8 Electromagnetic Compatibility (EMC) ................................................................1-6

1.9 Radio Specification ............................................................................................1-7

1.10 Waste Fluid........................................................................................................1-8

1.11 Installation Site Requirements ...........................................................................1-8

1.12 Action for Malfunction ........................................................................................1-10

1.13 Test Results for Diagnosis.................................................................................1-10

1.14 Quality Control ...................................................................................................1-11

1.15 Reagents ...........................................................................................................1-11

1.16 Handling Calibrators and Controls.....................................................................1-11

1.17 Handling Samples..............................................................................................1-12

1.18 Detergent...........................................................................................................1-12

1.19 Chip and Chip Cassette.....................................................................................1-12

1.20 Recording Paper................................................................................................1-13

1.21 Labels ................................................................................................................1-14

1.22 Periodic Maintenance ........................................................................................1-20

1.23 Product Warranty...............................................................................................1-20

2. Component Names and Functions ..................................................................2-1

2.1 Component Names............................................................................................2-1

2.1.1 External View.........................................................................................................2-1

2.1.2 Bottle Storage and Chip Station

(The front door opened.)........................................................................................2-1

2.1.3 Sample Rack .........................................................................................................2-2

2.1.4 Rear Panel.............................................................................................................2-2

2.1.5 Chip, Reagent, Detergent......................................................................................2-3

2.2 Stand-by Switch.................................................................................................2-4

2.2.1 Stand-by Switch and Power Monitor Function.......................................................2-4

2.2.2 Emergency Stop and Action for Recovery.............................................................2-4

2.3 Pipetting and Measuring ....................................................................................2-5

2.4 Operation / Display Panel ..................................................................................2-6

2.4.1 MAIN Dialog ..........................................................................................................2-6

2.4.2 Numeric Keyboard.................................................................................................2-11

2.4.3 PID Keyboard ........................................................................................................2-12

2.5 SID Details.........................................................................................................2-13

2.6 PID Details.........................................................................................................2-13

3. Description of the Assay Principle ..................................................................3-1

µTASWako i30 Instruction Manual

(v)

Contents

4. Operations .......................................................................................................4-1

4.1 Startup Inspection..............................................................................................4-1

4.1.1 Preparation before Turning the Stand-by Switch On.............................................4-2

4.1.2 Turning the Stand-by Switch ON ...........................................................................4-4

4.1.3 When the [Operator ID Function] Is Active ............................................................4-6

4.1.4 Turning off the Analyzer (Shut Down) ...................................................................4-7

4.1.5 Check List for Daily Checks before Use ................................................................4-9

4.1.6 Check List of Daily Checks after Use ....................................................................4-9

4.1.7 Preparation of Sample Rack..................................................................................4-10

4.1.8 Blood Collection Tube for µTASWako i30 .............................................................4-12

4.1.9 Placing Area for Barcode Label.............................................................................4-13

4.1.10 Amount of Sample .................................................................................................4-14

4.2 Calibration Operation.........................................................................................4-15

4.2.1 Calibration Operation Using Barcode Labeled Holder...........................................4-17

4.2.2 Calibration Operation with No Barcode Labeled ...................................................4-21

4.2.3 How to Check the Past Calibration Results...........................................................4-24

4.2.4 How to Calibrate by Selecting Reagent Bottle.......................................................4-25

4.2.5 Calibration Copy ....................................................................................................4-26

4.3 Quality Control Operation ..................................................................................4-27

4.3.1 QC Operation Performed Automatically with Barcode Reading ............................4-27

4.3.2 QC Operation by Selecting Reagent Bottle ...........................................................4-30

4.3.3 QC Operation for Old and New Reagent Bottles...................................................4-33

4.3.4 How to Browse Results of QC Operation (Quality Control Chart) .........................4-34

4.4 Standard Operation ...........................................................................................4-35

4.4.1 Order List Dialog and Sample Rack ......................................................................4-36

4.4.2 Manual Order Operation (Individual) .....................................................................4-37

4.4.3 Manual Order Operation (Batch) ...........................................................................4-38

4.4.4 Auto Request Operation (with Barcode)................................................................4-39

4.4.5 Worksheet Request Operation (with Barcode)......................................................4-40

4.4.6 Worksheet Request Operation (without Barcode).................................................4-41

4.5 Operation Methods ............................................................................................4-42

4.5.1 Details of Manual Order Operation (Individual) .....................................................4-42

4.5.2 Details of Manual Order Operation (Batch) ...........................................................4-46

4.5.3 Editing Batch Order ...............................................................................................4-47

4.5.4 Deleting Orders in Batch .......................................................................................4-48

4.5.5 Details of Auto Request Operation (with Barcode)................................................4-49

4.5.6 Details of Worksheet Request Operation (with Barcode)......................................4-50

4.5.7 Details of Worksheet Request Operation (without Barcode).................................4-52

4.6 Start Operation ..................................................................................................4-55

4.6.1 Sample Loading When Continuously Performing Operation.................................4-58

4.7 Completion of Operations ..................................................................................4-59

4.8 Emergency (STAT) Sample Operation ..............................................................4-61

4.8.1 STAT Operation Order ..........................................................................................4-61

4.9 Additional Sample Loading during Operation ....................................................4-63

4.10 Checking Operation Status................................................................................4-64

4.11 Checking Test Results.......................................................................................4-65

4.11.1 Flow of Checking Results ......................................................................................4-65

4.11.2 Result Dialog .........................................................................................................4-66

(vi)

µTASWako i30 Instruction Manual

Contents

4.11.3 How to Check Printed Test Results.......................................................................4-68

4.11.4 Recalculation Function ..........................................................................................4-70

4.11.5 Retransmission and Reprint ..................................................................................4-72

4.12 Re-run Operation ...............................................................................................4-73

4.12.1 Re-run Range ........................................................................................................4-74

4.12.2 How to Order Re-run Operation ............................................................................4-75

4.13 Power Outage and the Recovery.......................................................................4-79

5. Inventory and Maintenance .............................................................................5-1

5.1 About Inventory Key ..........................................................................................5-1

5.2 Consumables Dialog..........................................................................................5-2

5.2.1 Inventory Dialog.....................................................................................................5-3

5.3 How to Set Reagents and Consumables...........................................................5-4

5.3.1 Reagents ...............................................................................................................5-4

5.3.2 Chips .....................................................................................................................5-8

5.3.3 Detergent...............................................................................................................5-12

5.3.4 Purified Water and Waste Fluid.............................................................................5-14

5.4 Periodic Maintenance ........................................................................................5-18

5.5 Items of User Maintenance................................................................................5-19

5.5.1 Weekly Inspection .................................................................................................5-19

5.5.2 Monthly Inspection.................................................................................................5-20

5.5.3 Quarterly Inspection (once every 3 months)..........................................................5-24

5.5.4 Replacing Recording Paper...................................................................................5-25

5.5.5 Cleaning Outer Covers ..........................................................................................5-26

5.5.6 Liquid Leak Check around Bottles (Purified Water and Waste Fluid) and inside of the

Maintenance Cover ...............................................................................................5-27

5.5.7 Liquid Leak Check When External Water Supply and Drainage Kit (optional parts) In-

stalled ...................................................................................................................5-28

5.6 Maintenance Function .......................................................................................5-29

5.6.1 Error Log................................................................................................................5-30

5.6.2 Condition Monitor ..................................................................................................5-31

5.6.3 Washing Pipetting Probe .......................................................................................5-32

5.6.4 Washing Electrodes...............................................................................................5-33

5.7 Contrast Adjustment of Operation/Display Panel ..............................................5-34

5.8 Procedures before and after Long-term Disuse.................................................5-35

5.8.1 Storage ..................................................................................................................5-35

5.8.2 Re-Start .................................................................................................................5-35

6. Troubleshooting ...............................................................................................6-1

6.1 Error Indications.................................................................................................6-1

6.1.1 Error Indication Format..........................................................................................6-1

6.1.2 Error Level .............................................................................................................6-1

6.2 Error List ............................................................................................................6-2

µTASWako i30 Instruction Manual

(vii)

Contents

6.3 Corrective Action ...............................................................................................6-8

6.3.1 How to Recover from Chip Jamming.....................................................................6-8

6.3.2 How to Recover from Sample Rack Transfer Error ...............................................6-12

6.3.3 When Waste Fluid Filled Detected ........................................................................6-13

6.3.4 No Purified Water Supplied ...................................................................................6-14

6.3.5 When Reagent Surface Is Not Detected ...............................................................6-15

7. Parameter Setup.............................................................................................. 7-1

7.1 Parameter Setup List .........................................................................................7-1

7.2 Administrator Password and Parameter Setup Dialog ......................................7-2

7.3 Parameter Setup Methods.................................................................................7-3

7.3.1 Reference Interval Setup.......................................................................................7-3

7.3.2 Re-run Range Setup..............................................................................................7-5

7.3.3 Correlation Formula Setup ....................................................................................7-8

7.3.4 Date and Time Setup.............................................................................................7-11

7.3.5 Buzzer Setup .........................................................................................................7-12

7.3.6 Printer Setup..........................................................................................................7-13

7.3.7 Cal/QC Repeat Number ........................................................................................7-14

7.3.8 Inventory Warning Level Setup .............................................................................7-15

7.3.9 Operator ID Setup .................................................................................................7-16

7.3.10 Accumulative Test Counts.....................................................................................7-18

7.3.11 Data Communication & Barcode Setup.................................................................7-19

7.3.12 Data Export............................................................................................................7-26

7.3.13 Software Version ...................................................................................................7-28

7.3.14 Program Update ....................................................................................................7-29

7.3.15 Maximum Rack Number Setup..............................................................................7-31

7.3.16 Repeat Number for CV Setup................................................................................7-31

7.3.17 Pump Priming ........................................................................................................7-32

7.3.18 Options Setup........................................................................................................7-33

7.3.19 AFP Peak Setting ..................................................................................................7-34

8. Other Functions ...............................................................................................8-1

8.1 External Water Supply and Drainage Kit ...........................................................8-1

9. Specifications/Consumables............................................................................ 9-1

9.1 Specifications.....................................................................................................9-1

9.2 Standard Accessary List ....................................................................................9-2

9.3 Consumables.....................................................................................................9-2

9.4 Periodical Replacement Parts ...........................................................................9-3

9.5 Optional Parts ....................................................................................................9-3

(viii)

µTASWako i30 Instruction Manual

1 Safe Usage and Handling Precautions

WARNING

CAUTION

IMPORTANT

CAUTION

CAUTION

CAUTION

CAUTION

1 Safe Usage and Handling Precautions

This section contains safety precautions which must be followed for the safe operation of the

μTASWako i30. Before using this equipment, please read this chapter carefully and follow the precautions given, so that you can operate it correctly.

1.1 Definition of Specific Safety Precautions

Specific safety precautions are noted by the terms WARNING, CAUTION, IMPORTANT, and additional

information by NOTE. The respective meanings are as follows:

Indicates hazardous situations that may lead to serious injury, even death or the transmission of

infectious agents if the precaution is not followed.

Indicates hazardous situations that may lead to minor or moderate injury or physical damage if

the caution is not followed.

1

Indicates improper handling that could have an adverse effect on the accuracy of the measurement values if the precaution is not followed.

NOTE: Indicates procedures requiring special attention, instructions that must be followed,

supplementary explanations, etc.

1.2 Precautions before Operating This Equipment

Before using this equipment, please read this Instruction Manual carefully so that you can

operate the equipment correctly.

Whenever you operate this equipment, be sure to observe the precautions described in this

manual. Failure to do so may subject you to injuries, cause property damage, or produce

incorrect test results.

This equipment is an in vitro diagnostic medical device using in vitro diagnostic agents.

Do not use the equipment for other purposes.

This equipment is classified as an in vitro diagnostic medical device under DIRECTIVE 98/79/

EC.

This equipment is only to be operated by personnel appropriately trained for its intended use and

correct operation. Patients do not come into direct contact with the equipment.

1-1µTASWako i30 Instruction Manual

1

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

1 Safe Usage and Handling Precautions

Wako Pure Chemical Industries, Ltd. shall not be liable for malfunction and damage resulting

from connection with other devices or use of software not supplied by Wako Pure Chemical

Industries, Ltd.

The accessories (for example, AC power cable, etc.) are specified only for this equipment. Do

not use the specified accessories for other equipment.

Do not place cups or containers with liquids on the equipment. If liquids spill over the equipment,

fire or electrical shock may occur.

Do not place heavy objects on the equipment, and do not apply force on the equipment. This

may results damage and/or malfunction on the equipment.

Do not have an impact shock on the equipment. Otherwise, malfunction and/or damage on the

equipment may occur.

Do not strike or scratch the operation/display panel using a sharp-pointed instrument

(mechanical pencil or ballpoint pen, etc.). This may results damage and/or malfunction on the

equipment.

The settings described in Chapter 7 include important settings, which affect test results such as

correlation formula. The settings must be operated only by the administrators who have the

responsibility for the use of the equipment. Inputting a password allows the administrators to

operate the administrator tools.

Do not remodel the µTASWako i30.

The durability period for this equipment is 6 years after installation at your site.

(This period is valid as long as the precautions for use are followed and regular periodic

maintenance is performed correctly.)

As the concerns for safety or performance will increase when this period of 6 years expires,

please consult your customer support for advice.

µTASWako i30 Instruction Manual1-2

1 Safe Usage and Handling Precautions

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

Whenever you operate or touch the parts labeled, be sure to observe the precautions

described in Sec. 1.21 (P1-14) “Labels”.

Keep ethanol away from fire as it is highly flammable, when using it for disinfection or cleaning.

1.3 Biohazards and Disposal

As used (contaminated) consumables (e.g., used chips, sample tubes, blood collection tubes,

reagents, calibrators, Controls, or detergent’s cups) and contaminated swabs or cloths used for

cleaning the equipment are infectious waste, process the waste correctly in compliance with any

applicable regulations in your country, such as by incineration, melting, sterilization or disinfection. Even if you entrust a dealer with the disposal, ensure to process the waste correctly in compliance with any applicable regulations.

When discarding the equipment that may be contaminated with blood samples, be sure to process it correctly in compliance with any applicable regulations in your country because it is infectious waste.

1

When handling blood samples and performing maintenance (cleaning the analyzer), always follow biohazard procedures (e.g., wearing gloves, lab coat, and safety goggles), referring to the

sample handling rules of your facility. If any part of the body comes in contact with samples,

immediately rinse the contaminated body part thoroughly under running water and then disinfect

the body part using ethanol for disinfection. Seek medical assistance if necessary.

Do not touch used chips and sample tubes with bare hands as these are contaminated with

blood sample. If any part of the body comes in contact with contaminated consumables, immediately rinse the contaminated body part thoroughly under running water and then disinfect the

body part using ethanol for disinfection. Seek medical assistance if necessary.

When samples come in contact with the equipment’s components, immediately clean and disinfect the components using soft cloth moistened with ethanol for disinfection.

The LCD display lamps in this product contain mercury, which must be recycled or disposed of in

accordance with local, state, or federal laws.

1-3µTASWako i30 Instruction Manual

1

WARNING

CAUTION

WARNING

WARNING

1 Safe Usage and Handling Precautions

1.4 Laser Warning

<Embedded laser>

The μTASWako i30 has a built-in laser [class 3B, 638nm, maximum 45 mW (CW)].

<Safety standard>

This equipment complies with FDA performance standards for laser products except for deviations pursuant to Laser Notice No.50, dated (June 24, 2007).

This equipment is a Class 1 laser product (designed according to IEC60825-1:2001).

<Laser safety>

As above, this equipment conforms to the FDA performance standards (Laser Notice No.50), so the

laser radiation is designed to be safety. As long as the users operate the equipment correctly, so that

the safety is fully guaranteed.

<Covers of the equipment>

The covers of the equipment are secured using screws.

If the screws are loosened or the covers are removed, the laser beam may be leaked.

Be sure not to loosen the screws and not to remove the covers, except for by technicians specially

trained.

Do not remove the covers secured by screws.

As the equipment has a built-in laser source, the laser radiation may expose to users to harm

their eyes. If the equipment is possible to be abnormal, please contact your customer support for

assistance.

Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposure.

1.5 High Voltage

This equipment uses high voltage.

As long as the users operate the equipment correctly (including user maintenance), there are no risks

to touch the high voltage at all.

Do not remove the covers secured by screws.

Otherwise, electrical shock may occur as the equipment includes high voltage inside.

1.6 Explosive Hazards

As this equipment is not explosion-proof, be sure not to use flammable and explosive gas

around the equipment.

µTASWako i30 Instruction Manual1-4

Loading...

Loading...