INSTALLATION & SERVICE INSTRUCTIONS FOR KATES FLOW

CONTROLLERS, MODELS 25FB, 25FS, & 25FZ

IMPORTANT

THE KATES FLOW RATE CONTROLLER IS DESIGNED TO ACCURATELY REGULATE FLOW RATES AND IS PRECISION BUILT WITH

EXACTING TOLERANCES AND FINISHES. TO INSURE SATISFACTORY PERFORMANCE, THE REGULATED FLUID MUST BE CLEAN

AND FREE OF DIRT OR SOLIDS. THE INSTALLATION OF A 10 MICRON FILTER IS RECOMMENDED JUST UPSTREAM OF THE

CONTROLLER.

EQUALLY IMPORTANT: WHEN DIS-ASSEMBLING, SERVICING, OR CLEANING THE CONTROLLER, THE INTERNAL PARTS MUST BE

HANDLED WITH CARE TO PREVENT DAMAGING THE SURFACE FINISH IN ANY WAY.

OPERATION OF A KATES ADJUSTABLE FLOW RATE CONTROLLER THAT IS SUPPLIED BY A POSITIVE DISPLACEMENT PUMP, WILL BE

SATISFACTORY ONLY IF A PRESSURE-RELIEVING VALVE IS CONNECTED BETWEEN THE PUMP AND THE CONTROLLER. THIS IS TO

BYPASS EXCESS FLUID BACK TO THE FLUID SOURCE, OR TO THE INTAKE OF THE PUMP.

INSTALLATION

1. The Kates flow controller is shipped fully assembled, ready for operation, with all parts in place. It is completely self-contained, requires no outside source

of power, no straight piping runs, and is as simple to install as an ordinary ball valve.

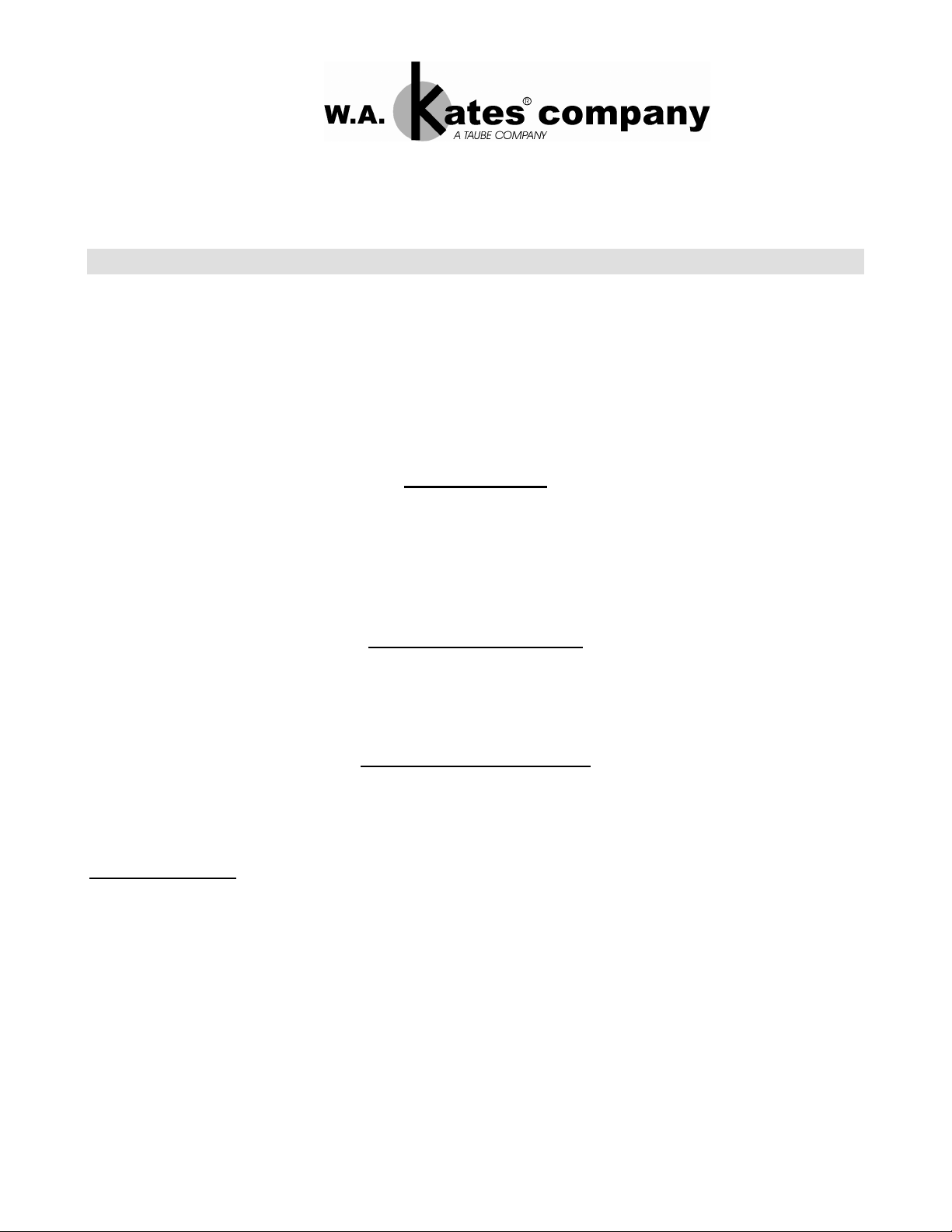

2. Upstream and downstream shutoff valves and a bypass valve should be installed (see Fig. 1) so that the controller may be opened for inspection and cleaning

without requiring complete system shutdown.

3. Before installing the controller be sure to flush out the piping system to remove any foreign material such as dirt, scale, chips, etc.

4. The controller should be installed at a point in the pipe where it will be completely filled with liquid under all conditions of operation. On threaded

connections, apply pipe thread compound sparingly to male threads only so that surplus will not get inside the controller and cause “sticking” or prevent

operation.

START UP PRODEDURE

1. Place controller “on stream” by opening upstream and downstream shutoff valves and slowly closing the bypass valve around the controller.

The controller will now regulate the flow rate at the set value.

2. When normal fluid temperature is above room temperature, especially with viscous fluids, there may be a “warming up” period until the controller reaches the

same temperature as the fluid. During this warming up period, the controller may be somewhat sluggish in action. If desired, this warming up period may be

eliminated by the use of a heating coil or jacket.

SERVICE INSTRUCTIONS

The Kates Flow Rate Controller has only one moving element, and is designed so that there are no complex linkages, delicate bearings, or any failure-prone

components. Therefore, occasional cleaning may be the only servicing the controller will require.

CAUTION: MAKE SURE THAT THE CONTROLLER IS RELIEVED OF PRESSURE BEFORE ATTEMPTING TO SERVICE OR CLEAN.

TO CLEAN CONTROLLER

CAUTION: in all cleaning operations, be very careful not to scratch, nick or mark any surfaces or edges.

1. It is necessary to remove the controller from the line to clean. If installation includes proper shutoff and bypass valves, operate these and take the controller

off stream or control. (See fig. 1)

2. Arrange a clean area where internal trim parts can be placed and kept free of lint or grit.

3. Do not remove the adjuster from the body. If the adjuster is moved rotationally, then the flow rate will be altered from the factory set point.

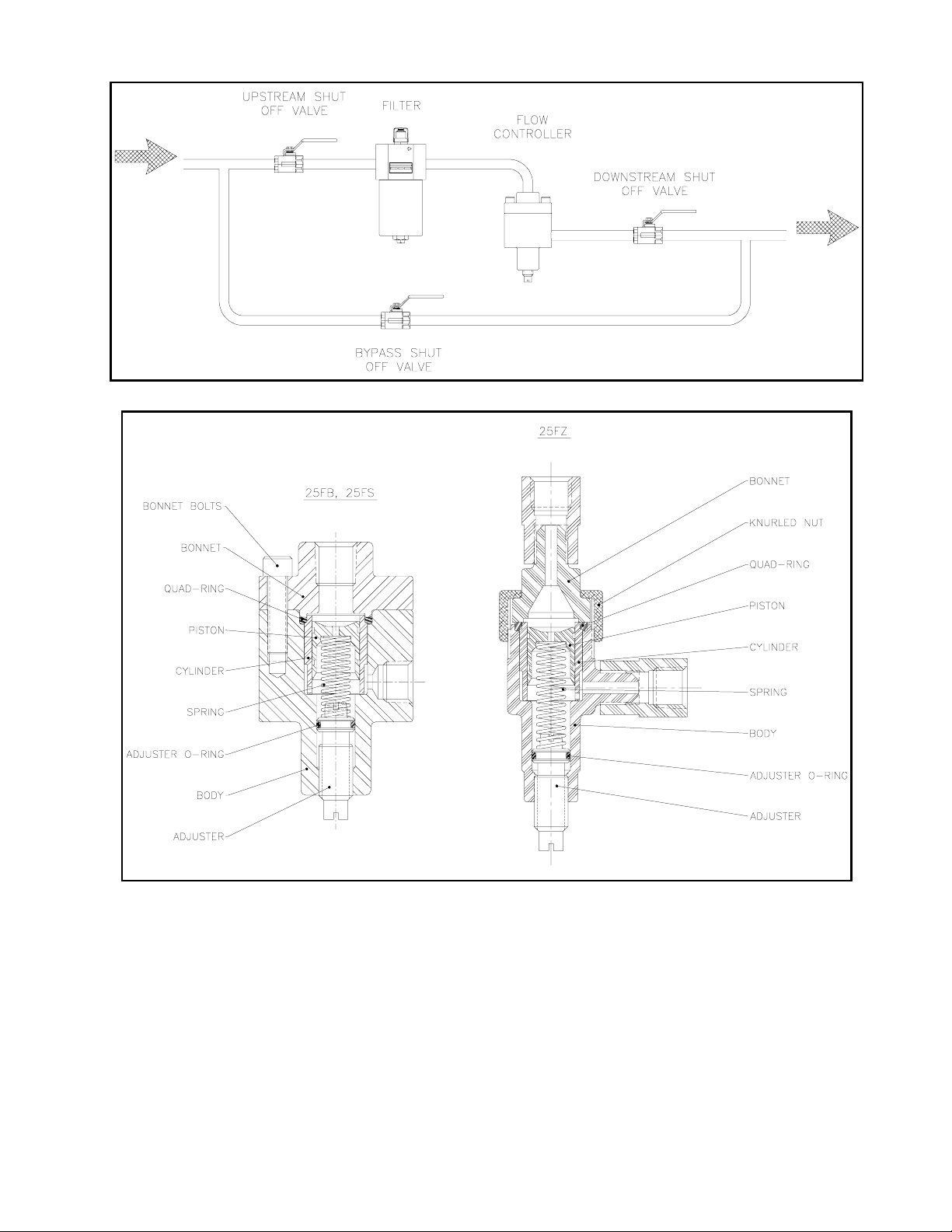

4. Remove bonnet bolts (or knurled nut), lift bonnet straight up, and place in the clean area.

5. Carefully tip body upside down so that the piston and spring slide out, and place both in the clean area.

6. Remove the Quad-ring, and inspect for damage. Replace if necessary, and place in the clean area.

7. Remove the cylinder and place in the clean area.

8. Thoroughly clean all the parts that have been removed from the controller by immersing them in a suitable solvent. Thoroughly clean and flush inside of

controller body with the solvent, and drain. Because of the closely fitted parts, it is VERY IMPORTANT that all parts and surfaces, including valve ports,

be COMPLETELY CLEAN. Any dirt, sediment, coating or gummy residue must be completely removed. Wipe all parts and surfaces dry with a clean, lintfree cloth. CAUTION: in all cleaning operations, be very careful not to scratch, nick or mark any surfaces or edges.

9. Insert the cylinder, the spring, and the piston.

10. Push the piston down inside the cylinder to check if the parts move freely. If the parts do not move freely repeat the cleaning and then continue. If the parts

do not move freely after several cleanings, a replacement controller maybe required.

11. Replace quad-ring, bonnet, bonnet bolts (or knurled nut) and tighten. Reinstall controller in system and place in service by following Steps 1-2 listed under

the heading “START UP PROCEDURE”.

BLT 587 - 02

Figure 1

Figure 2

PRODUCT WARRANTY

The W.A. KATES COMPANY guarantees every piece of equipment manufactured by it t o be inspected, tested, and free from defects in workmanship or material when shipped from its factory.

No warranty of corrosion resistance of any parts or assembly is expressed or implied.

This guarantee is valid for one year from date of shipment from its plant. Within that time, the W.A. KATES COMPANY will replace free of charge any equipment returned, with shipping

charges prepaid, found to have been defective at time of shipment.

This warranty does not apply to : (a) damage resulting from misuse or inadequate handling; (b) damage resulting from continued use after defect is apparent; (c) any other damage, loss or

liability; or (d) any piece of equipment that is changed, modified or altered in any way after it leaves the factory.

The liability of the W.A. KATES COMPANY shall be limited to the replacement, f.o.b. our factory, of any equipment found to have been defective at time of shipment with duplicate or similar

equipment of equal performance rating, but such liability shall in no event exceed the contract price for said equipment.

W.A. KATES CO. 1363 Anderson, Clawson, Michigan 48017

(248) 435-8225 - Fax (248) 435-8255

E-mail info@wakates.com

WWW http://www.wakates.com

BLT 587 - 02

Loading...

Loading...