Wahl HEAT-Prober 392EX-S, HEAT-Prober 392E, HEAT-Prober 392EVX, 392M, 392M-S Instruction Manual

...Page 1

HEAT-Prober

®

PLATINUM-RTD

T

HERMOMETERS

Models

392HP,

392E, 392E-S, 392EX, 392EX-S, 392EVX,

392M, 392M-S, 392MX, 392MX-S, 392VX,

360X and 700M

INSTRUCTION MANUAL

©Copyright 2004 Wahl Instruments, Inc. Printed in USA

W-392 (Rev. M)

Page 2

ii

iii

RECEIVING INSPECTION

Check your new Wahl Portable Platinum HEAT-Prober®Thermometer upon

receiving to assure that:

1. It has not been physically damaged in transit.

2. All parts are included.

Then, plug in the probe at top and turn it on to see that it reads room temperature.

If a fault is determined, take the following steps:

1. Notify the Wahl factory of the difficulty. Give number and description. Wahl will issue a Return Merchandise Authorization, and notify our service department to receive the unit.

2. Return the instrument in its shipping container to the factory,

freight prepaid. Repairs will be made under warranty or at regular service

cost.

W

ar

ranty: HEAT-Prober

®

Meters

Wahl Instruments, Inc., hereinafter referred to as Wahl, warrants each instrument of its manufacture to be free from defects in material and workmanship

under normal use and service. Wahl agrees to repair or replace any product

which upon examination is revealed to have been defective due to faulty

workmanship or material if returned to our factory, transportation charges

prepaid, within three years from the date of shipment. This warranty is in lieu

of all other warranties, expressed or implied and of all obligations or liabilities on its part for damages including but not limited to consequential damages, following the use or misuse of instruments sold by Wahl. No agent is

authorized to assume for Wahl any liablility except as set forth above.

W

arranty: Temperature Probes and Meter Accessories

Wahl warrants its Hand-Held Meter Temperature Probes to be free of defects

in workmanship or material. Due to the environmental nature of their use,

probes cannot be replaced without cost unless returned unused within a 30day period. Wahl assumes no liability for damages of any kind, direct or indirect, as a result of installation and/or use of its products; nor any costs

resulting from removing and reinstalling any of its products for replacement

under terms of this warranty.

TABLE OF CONTENTS Page

1.0 INTRODUCTION 1

1.1 Qualification Tests 1

1.2 Hazardous Location Operation 1

2.0 OPERATION 2

2.1 Meter Operation 2

2.2 Automatic Polarity 2

2.3 Digital Display and Accuracy 2

2.4 The Batteries 5

2.4.1 Recharging 5

2.4.2 Continuous Operation 5

3.0 PROBES 6

3.1 Interchangeability 6

3.2 Temperature Sensors in Use 7

4.0 SPECIFICATIONS

Model 392M, 392MX, 392VX,

392E, 392EX, 392EVX, 392HP Platinum Meters 8

5.0 MAINTENANCE/REPAIR 10

6.0 SETUP AND CALIBRATION 11

6.1 Equipment Needed 11

6.2 Voltage Regulator Adjustment 11

6.3 Low Battery Adjustment and Testing 11

6.4 Zero Adjustment Using Wahl Calibrator 12

6.5 Span Adjustment Using Wahl Calibrator 12

6.6 Adjustment Using Decade Resistance Box. 12

6.7 Peak Hold Circuit 13

6.8 Fahrenheit to Centigrade Conversion 16

6.9 Open Probe Display 16

6.9.1 “Help” Display 16

7.0 THERMAL CALIBRATION PROCEDURE 16

8.0 392HP and 392M OPTIONS 17

8.1 392HP 17

8.2 Degree F to C Conversions (Suffix D) 17

Page 3

iv 1

TABLE OF CONTENTS (Continued)

8.3 Intrinsically Safe for Hazardous Location

(-S Versions) 17

8.4 Rate of Change with Hot and Cold

Peak Hold (Option R) 18

9.0 THEORY OF OPERATION 19

9.1 General 19

9.2 Program Flow 19

10.0 392M TROUBLE-SHOOTING AID 22

10.1 Scope 22

10.2 Procedure 22

11.0 ACCESSORIES 25

12.0 CALIBRATION SERVICE 26

13.0 THERMISTOR — .01°C RESOLUTION

HEAT PROBER (700M) 27

13.1 General Discussion 27

13.2 Calibration Procedure 29

13.2.1 Equipment Required 29

13.2.2 Calibration 29

14.0 700M TROUBLE-SHOOTING AID 29

15.0 WARRANTY REGISTRATION 32

16.0 RETURN FOR REPAIR/CALIBRATION 32

1.0 INTRODUCTION

The Digital HEAT-Prober®is a precision instrument for measuring temperature. It uses the latest microprocessor technology to provide conformity to

0.1°F to the IEC751 and ITS90 platinum resistance curve. It provides the certainty of digital display and the precision of 0.1 resolution. It is a complete

instrument with its own rechargeable battery power supply and recharger for

the 392HP, 392E, 392EX, 392M and 392MX, standard 9 volt replaceable battery for the 392EVX and 392VX and a group of interchangeable probes

designed for rapid and accurate temperature measurement.

The probes and meters are individually calibrated and then tested together in

temperature baths before being sent to the user.

The LED display is 0.33" high with high brightness for good readability in all

light conditions. To minimize power drain, the display is multiplexed. The

LCD display is 0.4" high with excellent contrast.

A large portion of the circuit is designed with low power C-MOS components.

The result is a design which provides a low power drain operation, which

allows operation for 8 hours per charge for the 392E, 392EX, 392M, and

392MX meters. Battery life is 50 hours for the replaceable battery used in the

392EVX and 392VX meters. Continuous operation as well as concurrent battery charging is possible by utilizing the recharger.

The instrument contains as a standard, the unique Wahl “Maxi Temp” digital

peak hold circuit which gives the user the option to hold the highest temperature sensed. The peak-hold circuit is achieved by the microprocessor scanning the probe input temperature to determine the peak versus an analog circuit.

1.1 Qualification Tests

This instrument has been extensively tested under temperature environments

from -40 to +140°F, subject to 4-foot drop test, battery life test and running

life tests.

1.2 Hazardous Location Operation

The instrument is Factory Mutual approved for hazardous location operation

and carries the FM label as standard. Factory Mutual approval as intrinsically

safe for hazardous location operations is in the following categories: Class I

and II, Division I, Group D, F, and G when used with battery pack Part

Number 11681-1. A higher level of approval for Group C, D, E, F, and G is

also available as the -S version, and uses a battery pack, Part Number

11681-2, which contains, in addition, a current limiting fusible resistor.

Page 4

2

3

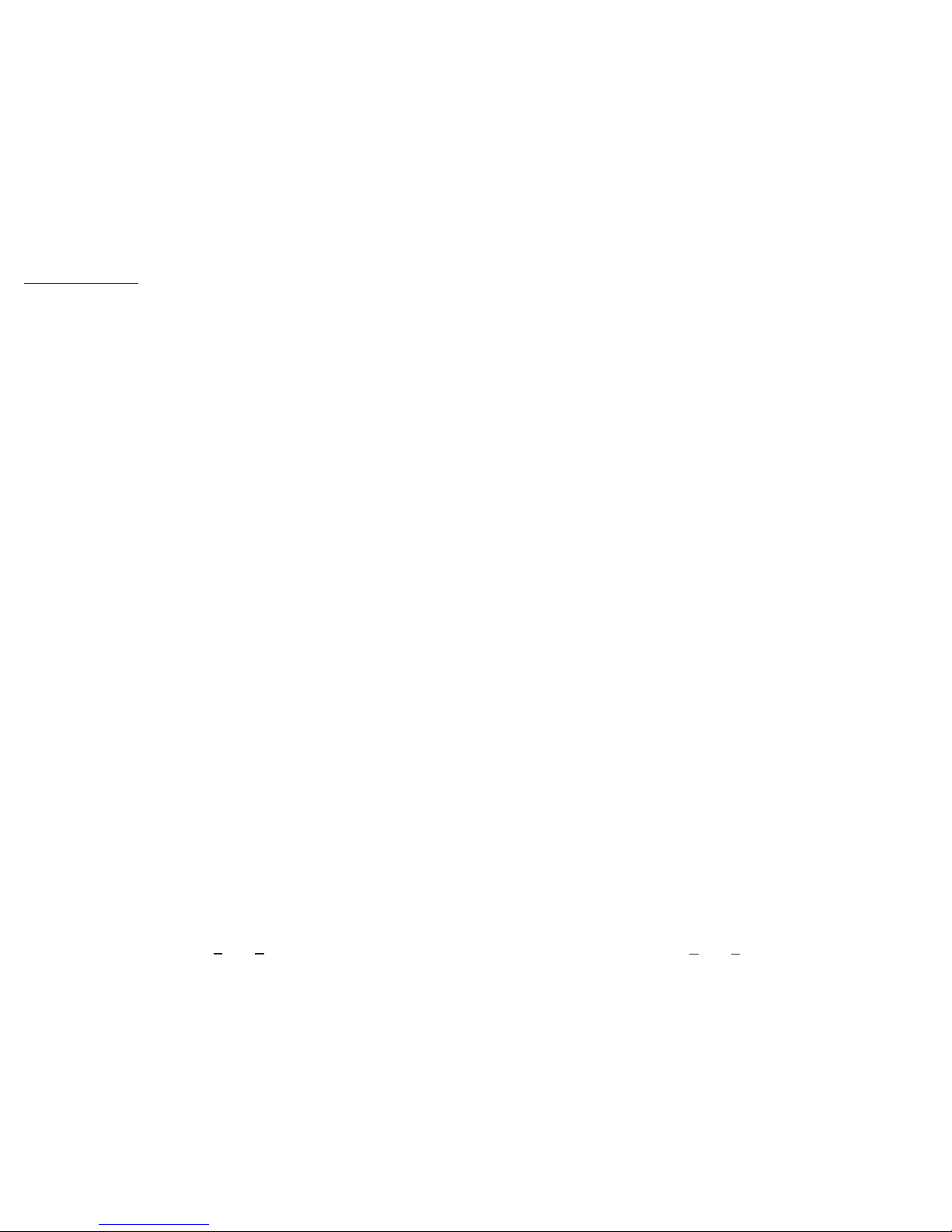

2.0 OPERATION (See Figure 2-1)

Insert probe into jack at top. Turn on the switch at the left. The switch is 3position; the lower detent is marked “N” for normal temperature monitoring,

the middle detent is “OFF” and the upper detent is marked “P” for use of the

“Maxi Temp” Peak hold circuit. This will track temperature and hold the highest attained reading. The room temperature will be displayed in °C or °F as

indicated. If “L” or “Lo Bat” appears or if there is no reading, this indicates

the battery is discharged. Recharge the unit by inserting the recharger in an

appropriate power source, 50-60 Hz wall outlet and plug in the recharger jack

to the receptacle on the left side of the unit, or in the case of the 392EVX or

392VX, replace the battery. For fastest recharging time, turn POWER for the

instrument OFF. Charge for 6-7 hours.

Make measurements with sensor probe as required. Turn off switch when

measurements are complete to conserve battery life.

2.1 Meter Operation

The HEAT-Prober instrument has an accurate measuring range as stated on

the front label. The probes, however, may not be capable of this entire range

of use. Wahl probes are typically capable of -40°C to 500°C (or -40°F to

900°F).

The digital readout will show resolution to 0.1° increments from

-180.0°C to +190°C (or -290°F to 375°F). At approximately 190°C (or 375°F)

the instrument automatically ranges to one degree C or F resolution. When

returning from higher temperatures to below 190°C (or 375°F), the instrument will automatically begin to read in 0.1° increments again.

2.2 Automatic Polarity

When the temperature sensed is below zero, a minus sign will automatically

show on the digital display. Absence of a sign indicates positive temperature.

2.3 Digital Display and Accuracy

The characteristic of digital readouts is a flicker in the least significant digit.

In this instrument, you can expect to see a 1-digit flicker, particularly when

reading 0.1 increments. Variations over 0.1 will be attributable to sensor temperature changes.

Figure 2-1. Digital Heat

Prober Major Features

Page 5

4

5

2.4 The Batteries

The 392HP, 392E, 392EX, 392M, and 392MX HEAT-Prober are powered with

five size AA rechargeable nickel-cadmium batteries, 1.2 volts each. The total

capacity is 650 milliampere hours at 6.0 volts. The display demands the

largest power drain. Depending on the number of digits being displayed, the

batteries can power the instrument for a minimum of 5 hours or for as long

as 8 hours.

The 392EVX and 392VX meter utilizes an LCD type display to conserve battery life. Battery life is in excess of 50 hours of continuous use.

SPECIAL NOTE: Rechargeable batteries should be kept at full charge. On the

shelf, they will gradually discharge, losing about 10% per week. If the battery

fails to respond to recharge, provisions have been made for ease of replacement. Open the back cover, and disconnect from the instrument by means of

the Molex connector. Replace with Wahl Model Number 11681-1 or 11681-2

(See Figure 2-2). Model 392EVX and 392VX incorporates a LCD display and a

standard 9V battery capable of 50 hours continuous operation.

2.4.1 Recharging

To recharge the batteries, use the recharger supplied. Plug in directly to

115VAC, 60 cycle wall plug and insert jack into socket on left side of HEATProber. (For overseas 220-volt lines, use a Franzus converter adapter with the

recharger supplied or request a 220 volt recharger.)

2.4.2 Continuous Operation

The 392HP, 392E, 392EX, 392M, and 392MX, HEAT-Prober can be continuously operated by using a battery recharger to restore or recharge the batteries as rapidly as they are depleted.

NOTE: The instrument cannot rectify AC current. A DC charger with open circuit voltage of 9.0 volts and approximately 120 milliamperes will maintain the

battery charge. This occurs when the switch is on and the instrument is

operating. Do not connect a voltage source to the batteries unless its current

is limited to 120 milliamperes.

The MA-150 recharger will charge the batteries with the switch “OFF”, or

make-up battery drain if the instrument is operating. The recharger supplied

with the instrument will enable continuous operation without draining the

batteries.

Figure 2-2. 9V Battery Compartment (top picture); Rechargeable Battery

Pack Compartment (bottom picture).

Page 6

6

7

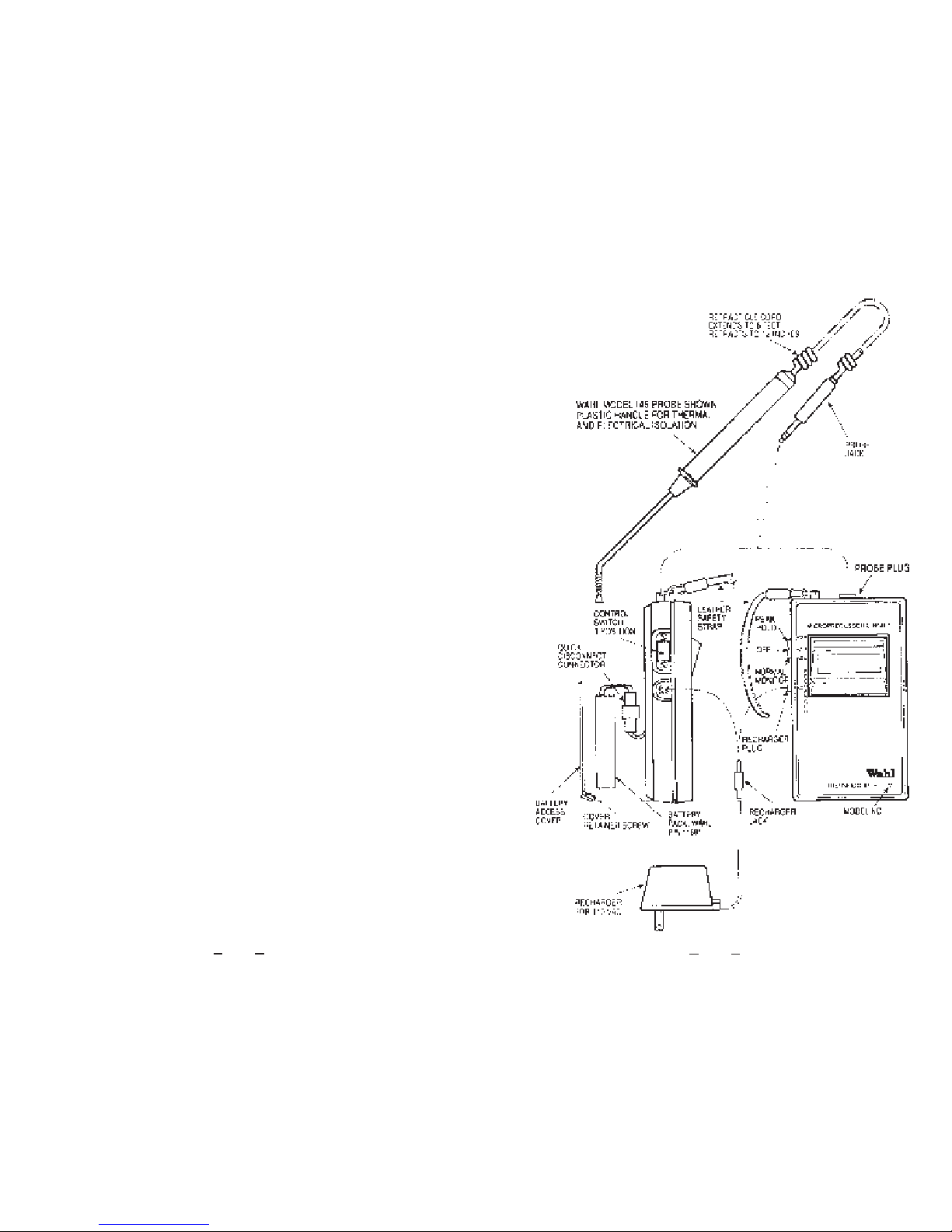

3.0 PROBES

Probes compatible with the 392 HEAT-Prober are constructed utilizing a wire

wound Platinum RTD sensor with an R0 of 100 Ohms wired in a 3-wire configuration to compensate for lead length effects. To provide probe interchangeability at 0 degrees C, a balancing resistor is added to the sensor circuit and trimmed for a total resistance of 100.94 Ohms at 0°C. (See Figure

3-2)

The High Performance HEAT-Prober, Model 392HP, utilizes probes similar to

the 392 but incorporating an additional calibration resistor that provides

probe interchangeability at all temperatures.

3.1 Interchangeability

Probes are individually balanced to 100.94 Ohms at 0°C to compensate for

variations in different probe configurations. This guarantees probe interchangeability at 0°C. In addition, each probe is tested at a minimum of one

higher temperature. This calibration data is recorded on a calibration tag

attached to the probe. (See Figure 3-1)

Probe Interchangeability (Immersion)

Ice Point ±0.3°C (±0.5°F)—(392HP ±0.2°F)

100°C ±0.6°C (+1.0°F)

200°C ±1.1°C (±2.0°F)

Surface probes are tested on surface calibration plates especially built to

replicate the end-use. The variance is somewhat larger as follows:

100°C ±1.1°C (±2.0°F)

200°C ±2.2°C (±4.0°F)

Figure 3-2. Probe Circuit NOTE: Platinum sensor element manufacturers

quote 0.1% tolerance at 0°C, or 0.1 ohms on a 100 ohm sensor. This results

in 0.3°C variance. The tolerance at higher temperatures is greater than 0.1%

in accordance with the following formula as specified by DIN 43760:

Tolerance = ±.3°C + .0054t (°C)

Thus at 200°C, the expected sensor error could be 0.3°C + .0054 (200) =

±1.38°C.

3.2 Temperature Sensors in Use

An understanding of heat-transfer is needed for accurate field use of temperature sensors. The sensor measures its own temperature, therefore, to measure a body temperature it requires good contact with that body, or in the case

of liquids or gases good immersion and mixing.

A portable probe temperature sensor must have the following characteristics:

(a) a low thermal mass (product of its specific heat and weight);

(b) a large area for surface contact to permit heat-transfer between the

object being measured and the probe sensor,

(c) a minimum of heat conduction away from the sensor which will

reduce its temperature below that of the object being measured and create an

inaccuracy.

Surface probes are designed with the above three conditions as criteria, and

also include an insulating handle for your safety and convenience. Each

probe is assembled with a plastic handle made of high quality Delrin

®

which:

(a) Thermally isolates the hand from the probe, preventing hand heat

from reaching the sensor, and sensor heat, in the case of high temperature

measurement, from burning the hand.

(b) Electrically isolating the hand from the metal probes and therefore,

potentially, from a voltage on the surface to be measured.

The handle is attached to a tangle-free retractable cord which extends 6' and

retracts to 12" (See Figure 2-1). Each Probe is labeled with its part number

and type.

For surface measurements, to obtain best time responses and accuracy, two

things are necessary;

(a) Good surface contact with all of the probe surface. Make sure of

this by holding it squarely on the surface. The 121 and 145 surface probes

are specially designed with a spring loaded tip to provide compliance with the

surface.

(b) A rough surface gives poor heat conductance to the measuring

probe. This can be overcome by applying a thin layer of heat conducting silicone paste between the measuring point and the probe tip. The paste shortens response time up to 50%.

In liquids, move the immersion probe around the mix to get good contact. In

air, put the probe in the vicinity of a stream to get good velocity, other wise

move the probe back and forth to induce velocity across the tip.

Page 7

8

9

392 SERIES METER SPECIFICATIONS

Model

392HP

392E

392EX

392E-S

392EX-S

392EVX

Range

-290 to 1450°F

-180 to 788°C

-290 to 1450°F

-180 to 788°C

-290 to 1450°F

-180 to 788°C

Digital Display

Bright 0.33"

LED

392E/392E-S

Bright 0.33" high LED

Red, 0.4" high

LCD

392EX/392EX-S

Red, 0.4" high LCD

Resolution 0.1° below 375°F (190°C). Auto Ranges to 1˚ above 375°F (190°C).

Meter Accuracy at 77°F ±0.1°F/C ±1 digit at 32°F (0°C)

System Accuracy

(Meter with 202

immersion probe)

±0.1°F ±1 digit

at ice point,

±0.25% reading

thereafter

±0.3°F at ice point,

±0.5% reading thereafter

Repeatability ±0.2°F

Peak Hold Microcomputer calculated, switch to “P” to activate

Ambient Operating

Range

0 to 130°F (-18 to +55°C)

Temperature

Coefficient

0.01 deg/deg over ambient range

FM (Factory Mutual)

Approved*

Class I & II,

Div. 1, Groups:

D, F, & G

Class I & II,

Div. 1, Groups:

C, D, E, F, & G

Not

Available

Power

11681-1

6.25 V

NiCad Battery

11681-2

6.25 V

NiCad Battery

9V Alkaline

battery

(NEDA 1604A)

Battery Life

4.5 hrs. per

charge

392E/392E-S

10 hrs. per charge

50 hrs.

per charge

Low battery

indication.

392EX/392EX-S

50 hrs. per charge

Low Battery Indicator Yes

Noise Rejection

Greater than 40 dB at 60 Hz increasing at 20 dB per decade.

Spurious noise attenuated by internal 16 Hz filter.

392HP includes special noise rejection program for use in presence

of rampant EMF such as spark ignition engines.

Size 3" W x 6" L x 1.5" D (7.5 cm x 15 cm x 3.75cm)

Weight 12 oz. (340gm) 7 oz. (198gm)

* FM Approval Groups: C (Ethylene Gas), D (Methane, Propane), E (Metal Dust), F (Coal

Dust), and G (Grain Dust)

All 392 Models Available in °F, °C, or Dual Scale, add “F”, “C” or “D” to Model Number. Dual

Scale not available on -S Models.

392 SERIES METER SPECIFICATIONS

Model

392M

392MX

392M-S

392MX-S

392VX

Range

-60 to 752°F

-51 to 400°C

-60 to 752°F

-51 to 400°C

Digital Display

392M/392M-S

Bright 0.33" high LED

Red, 0.4" high LCD

392MX/392MX-S

Red, 0.4" high LCD

Resolution 0.1° below 375°F (190°C). Auto Ranges to 1˚ above 375°F (190°C).

Meter Accuracy at 77°F ±0.1°F/C ±1 digit at 32°F (0°C)

System Accuracy

(Meter with 202

immersion probe)

±0.3°F at ice point,

±0.5% reading thereafter

Repeatability ±0.2°F

Peak Hold Microcomputer calculated, switch to “P” to activate

Ambient Operating

Range

0 to 130°F (-18 to +55°C)

Temperature

Coefficient

0.01 deg/deg over ambient range

FM (Factory Mutual)

Approved*

Class I & II,

Div. 1, Groups:

D, F, & G

Class I & II,

Div. 1, Groups:

C, D, E, F, & G

Not

Available

Power

11681-1

6.25 V

NiCad Battery

11681-2

6.25 V

NiCad Battery

9V Alkaline battery

(NEDA 1604A)

Battery Life

392M/392M-S

10 hrs. per charge

50 hrs.

per charge

392MX/392MX-S

50 hrs. per charge

Low Battery Indicator Yes

Noise Rejection

Greater than 40 dB at 60 Hz increasing at 20 dB per decade.

Spurious noise attenuated by internal 16 Hz filter.

392HP includes special noise rejection program for use in presence

of rampant EMF such as spark ignition engines.

Size 3" W x 6" L x 1.5" D (7.5 cm x 15 cm x 3.75cm)

Weight 12 oz. (340gm) 7 oz. (198gm)

* FM Approval Groups: C (Ethylene Gas), D (Methane, Propane), E (Metal Dust), F (Coal

Dust), and G (Grain Dust)

All 392 Models Available in °F, °C, or Dual Scale, add “F”, “C” or “D” to Model Number. Dual

Scale not available on -S Models.

4.0 SPECIFICATIONS

Page 8

10

11

5.0 MAINTENANCE/REPAIR

The HEAT-Prober instrument may be recalibrated, or adjusted for a particular

probe in the field by following the directions in Section 6.0. However, it is

recommended that calibrations and repair be done at the factory. Return the

HEAT-Prober in its foam package with a description of symptoms, and a

repair estimate will be made for your approval.

The best way to check the functioning and calibration condition of the HEATProber is to use the Wahl accessory Calibrator Models Numbers CAL392HT

or CAL392LT, which plug right into the probe connection and provides five

key calibration points. (See Figure 5-1). The calibrator has a set of precisionwound resistors which are measured at the factory against a NIST traceable

standard. The WAHL calibrator is a convenient instrument to determine

whether a problem is in the probe or the meter. If the meter checks on all 5

calibration points within tolerance, for example, then one will know that the

probes are at fault.

The most common maintenance problem

is battery failure, evidenced by no display. NiCad battery failure and prevention

of this problem are noted in Section 2.4.

If you suspect a dead battery:

1. Plug in the recharger and

allow to recharge for 12 hours. If batteries fail to recharge after this time:

2. Open the battery compartment lid on the bottom of the instrument.

Unplug the battery. Using a DVM, check

voltage with a 16 ohm load. If the voltage

drops rapidly it indicates a fault in the

battery.

3. With the convenient detachable plug, the battery pack Model

Number 11681-1 or 11681-2 can be easily replaced by a new one. For emergencies it is possible to use a 9-volt transistor battery to power the HEAT-Prober (but

one must make a special connection).

Expected continuous running time on 9volt alkaline battery is about 3 hours, for

LED display or 6 hours for LCD display.

Figure 5-1. 392M Platinum Heat

Prober with Wahl Calibrator

Model Number CAL392HT.

6.0 SET-UP AND CALIBRATION

6.1 Equipment Needed

A. Digital voltmeter, Fluke 41/2 digit Model 8600A or equivalent.

B. Wahl Platinum Calibrator (Model Number CAL392HT or CAL392LT) or

General Radio decade box, Model 1433-1 (or equivalent) with standard coil

cord (Model 10434-01 or 10434-02) cable as used with Wahl probes.

C. Power supply — Powermate, Model OPA-1OC or equivalent.

6.2 Voltage Regulator Adjustment (Note: Meters with serial numbers S/N

3445 and higher, or N Series,do not require adjustment of voltage regulator.)

Remove the 4 screws from the bottom of the case, then remove the top

cover. You will note the adjustment points as shown in Figure 6-1.

1. Initially the 392M should be set-up with an external power supply

(rather than a battery) so that the current can be limited to no more than 120

milliamperes.

2. Connect the plus (+) DVM lead to C-10 junction common with Q2.

Connect the minus (-) lead to the cathode lead of CR1.

3. Apply power to the 392M using an external power supply with the

voltage set at 6.5V and current limit set at 120 milliamperes. Connect power

supply (+) to U1-1 and (-) to CR1 - cathode. Adjust R21 for voltage reading

of exactly +5.000 volts on the DVM.

4. When the 392M has been mounted in its case and connected to a

5-battery pack, the DVM is connected as described above and the +5.000

adjustment checked and trimmed if necessary.

6.3 Low Battery Adjustment and Testing

1. Connect DVM (-) to CR1 Cathode and (+) to upper side of R24.

2. Adjust R37 clockwise or counterclockwise until DVM reads 2.11 volts.

3. Disconnect DVM.

4. DISCONNECT BATTERY PACK. Low Battery indicator must be performed with an external variable power supply. Start with 6 volts and slowly

decrease the voltage toward 5.8 volts.

When the battery threshold is reached, a small “L” should appear in the most

significant digit position of the 392HP, 392E and 392M display. “Lo Bat”

appears in the display of the 392EX, 392MX, 392EVX and 392MVX. The actual value of the low battery voltage threshold may vary from 5.45 volts to 5.55

volts.

Page 9

12

13

Keep decreasing the supply voltage until 5.5 volts is reached, as measured

with a digital DVM. The meter should maintain correct operation even though

the small “L” or “Lo Bat” is on, indicating a low battery.

Now raise the voltage back up until the small “L” or “Lo Bat” turns off. The

voltage at which this happens should be from 5.50 to 5.55 volts.

Under normal operation, an additional 20 minutes will elapse from the time

the small “L” or “Lo Bat” appears until the battery voltage decreases to 5.5

volts, assuming a normal 5-pack of AA NiCad batteries is being used. Below

5.5 volts, the computer may introduce some errors or not operate the display

at all.

6.4 Zero Adjustment Using Wahl Calibrator

1. Insert the Wahl calibrator and adjust the calibrator to the

32°F/0°C position. Apply power to the meter and make an initial adjustment

at R5 for a reading of 32.0°F or 0.0°C depending on your model.

NOTE: For the version 392HP, which has a 4-wire probe configuration, the

microprocessor averaging process is slightly slower. The moving average for

the 392HP may be made faster by turning the power off and then back on

again, any time an input resistance or pot setting is changed.

2. Make the best adjustment you can at this point, and then proceed

to the span adjustment.

6.5 Span Adjustment Using Wahl Calibrator

1. Set Wahl Calibrator for 284°F/140°C and apply power to the

meter. Adjust R35 (R16 on HP.) clockwise for a display of 284.0°F or

140.0°C.

2. Repeat the zero span adjustment until the meter reads

32.0°F/0.0°C exactly, and reads 212°F/100°C or 284°F/140°C within acceptable limits of error.

Since only one span adjustment covers both low and high scales, any error

that must be tolerated should be pushed to the high scale where percentage

wise it will be less of an error.

6.6 Adjustment Using Decade Resistance Box

Basic Theory: Platinum has a well defined resistance versus temperature

curve. Accordingly, if a decade resistor is put in the place of the probe to

simulate the standard platinum element, a quick and accurate calibration can

be achieved.

6.6.1. Setup and Calculations

The decade resistor box may be used as the source to perform a standard

calibration. A coiled cord cable with connector for the Wahl probe should be

used (Model Number 10434-01). This has an approximate resistance of 0.36

ohms. The actual resistance should be determined for your setup and this

value used in the calculations. The total resistance to be simulated is .94

ohms above the sensor resistance specified in the ITS90 Platinum Resistance

Tables for 100 ohm, .00385 ohm/ohm/degree C sensors. Therefore, the

decade resistance setting should be a table value plus 0.94 ohms minus the

actual cable resistance measured above i.e. the decade box setting for 0°C

should be: 100.00 + 0.94 - 0.36 = 100.58 ohms.

Note: for HP models do not subtract cord resistance in calculation steps. Use

coiled cord Model Number 10434-02.

Step 1: Set the Decade Box for a total resistance (decade box + lead

resistance) for 100.94 ohms and adjust zero control R5 for a display reading

of 0.0°C or 32.0°F, ±0.1°.

Step 2: Set the Decade Box for a total resistance (decade box + lead

resistance) for 154.52 ohms and adjust span control R35 (R16 for HP models) for a display reading of 140.0°C or 284.0°F, ±0.1°.

Step 3: Repeat Steps 1 and 2 as necessary for optimum calibration.

6.7 Peak Hold Circuit

1. To enable the PEAK HOLD mode, depress the forward/ upper

position of the Power Switch. Adjust calibrator or decade box for an upscale

temperature reading allowing the display to stabilize.

2. When display has stabilized to a temperature reading appropriate

for the calibrator/decade box setting, move the calibrator/decade box to the

position or resistance that represents a lower temperature, and verify that the

peak temperature of Step 1 is held.

NOTE: This is a digital peak that is computed by the peak hold circuit, and

as such will not drift up or down as may happen with analog circuits. What

may happen is that the calibrator or decade box can momentarily “go open”

as it is switched between settings. The meter may see this and jump up scale

and retain a higher reading. When this happens, switch meter off and back

on to peak hold setting, and the reading will be restored.

Page 10

14

15

Models 392MX, 392MVX, 392EX, and 392EVX

Models 392HP, 392M and 392E

Use the Circuit Board Diagrams on these pages to locate potentiometer placement of

Zero Adjustment and Span Adjustment. Note that placement varies with Model.

See page 28 for Model 700M Board Layout.

Page 11

16

17

6.8 Fahrenheit to Centigrade Conversion

The HEAT-Prober can be ordered as a °F or °C unit. The 392 will read out in

°F unless a jumper is in place. When jumped to equivalent reading of what

was displayed in °F will be displayed in °C. The computer makes the calculation and there is no adjustment. “D” versions will have a front power switch

for selecting between °F and °C.

6.9 Open Probe Display

Remove the calibrator or decade box from the meter while the power is on.

The display should show -OL-.

If power is turned on while probe is absent, the same display should occur.

6.9.1 “Help” Display (Appears on 392E or 392M only, 392EX or 392MX

does not display “Help”)

The microcomputer is programmed to display “Help” when span adjustment

outside the normal range is attempted. If “Help” continues to be displayed, it

indicates that an incorrect adjustment is being attempted or a faulty meter.

7.0 THERMAL CALIBRATION PROCEDURE

For thermal calibration of temperature, baths are needed for immersion

probes, and surface plates are used for surface probes. However, remember

that calibrating with a specific probe will introduce the error of the probe into

the meter system. Other probes may therefore introduce greater or lesser

error, because the meter is moved away from its nominal curve. DO NOT calibrate a surface probe by immersion. There will be an error because compensation is made at the factory for heat loss in surface probes.

Insert the probe in the unit and into well stirred, controlled ice baths at 0°C.

(Be sure it is well stirred). The temperature can vary 1°C, depending on the

layer of water the probe is in, or proximity to a piece of ice.

With the top cover removed (as explained in Section 6.2) and instrument

open, adjust until the 0.0 reading is obtained.

For span, a 250°C or higher bath, should be used. Adjust R35 until the temperature reading is achieved.

8.0 392M and 392HP OPTIONS

8.1 392HP

The “HP” option allows probes to be calibrated and interchangeable over the

entire temperature range. This also results in superior system accuracies at

all temperatures. The “HP” option utilizes a Noise Rejection program which

minimizes transient noise effects.

In this version a special 4-pin receptacle is installed at the probe connection,

and the four pins are wired to the printed circuit board from the probe connector side as shown in Figure 8-1. A resistor with a nominal value of 5K is

installed in each individual probe via the extra pin. 5K resistance indicates to

the microprocessor that nominal curve values in the memory shall be used.

Other values of this resistor tell the microprocessor to initiate corrections to

the nominal curve.

Close matching with a probe is achieved as follows: The probe is tested at a

specific bath temperature, and a decade box is attached where the R33 resistor would be in the probe. The resistance is adjusted until the 392HP reads

the precise temperature of the bath, for example 100°C, taking out the tolerance of the probe. A value of 4K, for example, may be needed in the decade

box to adjust the reading by 0.2%. The new resistor value of 4K tells the

microprocessor to make an adjustment for that specific probe. The decade

box is removed, and a resistor with the same value as the adjusted box is

potted inside the 4-pin probe connector between pins 3 and 4 (See Figure 8-

2).

8.2 Degree F to C Conversion (Specify Suffix D)

The microprocessor provides true digital conversion for temperature

throughout the whole range of the instrument. This switch is a convenience

where dual measurement scales are needed.

8.3 Intrinsically Safe for Hazardous Operations (Order -S Models)

The standard 392M instrument is Factory Mutual classified for Class I and II,

Division I, Group D (for methane and propane), and Group G (for grain dust).

To achieve the higher level Group C rating (for ethylene gas), Group F (for

coal dust), and Group E rating (for metal dust), the instrument is required to

have an additional current limiting resistor in the NiCad battery pack.

Therefore -S Models use battery pack Model Number 11681-2, which

includes the current limiting resistor. In all other aspects, it is the same as

the standard 392M.

Page 12

18

19

Each HP version probe, therefore, has its specific resistor to indicate to the

microprocessor the correction to be taken.

Figure 8-1. Wiring Diagram for 392HP

Figure 8-2. 4-Pin Probe Connector Expanded View

8.4 Rate of Change with Hot and Cold Peak Hold (Order Option R)

This unit has microprocessor program revision E which can display any one

of four different measurements repeatedly. The four display modes are as follows:

1. Normal Temperature. The temperature as sensed by the attached

probe is displayed with updates 2.5 times per second. (Switch Position “N”).

2. Rate of Change of Temperature. The change in temperature

sensed is updated every six seconds. The rate of change is displayed in

degrees per minute with proper polarity sign.

3. Hot Peak Hold. Continuous display of the hottest temperature

sensed since the last time the unit was turned on. (Switch Position “HP”).

4. Cold Peak Hold. Continuous display of the coldest temperature

since the last time the unit was turned on. (Switch Position “CP”).

If either the cold peak or the hot peak should increase, the display

will be updated to read the new colder or hotter peak. Turning the instrument

off will remove the cold and hot peaks from memory. Upon turn on, the

microprocessor is reset for the input of new data.

9.0 THEORY OF OPERATION

9.1 General

The microcomputer, as directed by this program receives and evaluates data

from the analog-to-digital converter, and delivers the proper temperature values to the display driver. The readings may be in Fahrenheit or Celsius, peak

or current value.

The Flow Chart (Figure 9.1) shows the operation of the program. Details of

the components will be discussed in this section.

9.2 Program Flow

When Power is turned on, the program will start executing instructions from

address 000, the location of the top level program labeled “Main.”

The first routine called is “Initialize”. This is a house-keeping routine which

establishes the starting conditions. The data memory (RAM) is cleared, the

input/output ports are configured, and the display is set up for 0.0 reading.

Next, the routine “Gaincheck” is called. A solid state switch is confirmed to

connect the AID converter to a precision wire-wound resistor of known value.

The resistor reading is compared with the ideal value, stored in memory, and

a factor is calculated and stored to be applied to subsequent readings of the

probe resistance.

Probe and gaincheck readings are maintained in a “Moving Average” (M.A.)

fashion to minimize the effects of random variations. Gaincheck readings following “Initialize” or the detection of a removed probe cause the moving

average to be crammed with the current value. Subsequent passes cause the

moving average to be updated and refined. Gaincheck updates occur alternately with probe readings the first 15 cycles, and then they are performed

only every 20th cycle. This is to allow more computer visibility to the probe

updates with reduced inertia. Settling time is provided to allow analog reference circuits to stabilize when the probe readings are done on the high scale.

The compensation readings are always made on the low scale.

If readings exceed the compensation limits (about 6% is allowed), the program branches to a subroutine which displays “Help” on the second such

excess.

The next routine entered, “Get Probe”, performs as described above for the

compensation readings; however a separate moving average is maintained

Page 13

20

21

for the probe readings. Both use a common subroutine, “Get M.A.”, which

calls “Get ND”. Control and handshaking between the converter and the computer is performed by this latter subroutine. Data is fetched in 2 bytes, first

the low order 8 bits, then the high order 4 bits, the sign and over range bits.

“Get M.A.” uses the converter reading to either cram or update, as directed

by a counter within the computer.

The program then enters “Compensate”. The factor derived from “Gaincheck”

is added to or subtracted from the latest reading.

“Range” then examines the compensated answers to see if we are on the correct scale. The unit always comes in the low range and remains there unless

there is an over range indication which causes the range to be changed to

high. If a negative reading exceeds that which would be lower than -300

degrees, the routine branches to give an over range display indication, If the

unit is in the high range, and over range is indicated (above 1500°F), the over

range condition is displayed (-OL-). If the reading is lower than about 370

degrees, the unit downranges. Any of these conditions cause the program to

return to get a new probe reading with instructions that the moving average

be crammed with new data. Additionally, if over range is displayed indicating

on open probe lead or removed probe, conditions are set for the next entry

into “Gaincheck” to cause the compensation reading to be crammed; and also

that rapid updates to it are to be made on following passes. This is done to

accommodate changes in probes by the user, so that the display will represent the actual probe readings as soon as possible.

If no change to the current range is indicated, a fall-through occurs to “Get

Temp”. This routine essentially looks up the Fahrenheit temperature from

tables. There are separate tables for each range.

The “Display” routine updates the display on every other trip through to limit

possible rapid changes when the probe moving average is being updated in

the fast mode. The answer to be displayed is converted to decimal, and then

transmitted to the display driver in the order of most significant digit first.

Leading zeros are suppressed up to the unit’s digit. The decimal point is suppressed if the routine is called for the purpose of displaying “over range” or

“Help”.

The program is now complete and a jump to “Gaincheck” completes the loop.

Figure 9.1. Flow Chart

Power On

Initialize

Evaluate Compensation

Circuits

Get Probe Reading

Compensate As Required

Range Check

Lookup Temperature

Display Temperature

°F/°C

Monitor/Peak

Main Program Platinum Heat Prober 392M

Changed

Page 14

22

10.0 392M TROUBLE-SHOOTING AID

10.1 Scope

This section describes basic diagnostics to find the majority of the problems

with malfunctioning 392M units.

Equipment Required:

1. Wahl 392M Calibrator (Model Number CAL392-HT)

2. 4- Digit DVM, Fluke 8600A or equivalent.

3. Oscilloscope.

4. Power supply, Power/mate BPA-10c or equivalent.

10.2 Procedure

Make certain that the 392 unit experiencing the problem has been properly

set-up, per Section 6.0, before proceeding to this section.

HOW TO USE TROUBLE-SHOOTING PROCEDURE: Locate the problem on

this table and proceed with the action starting with Step 1. Note, for all DVM

and scope measurements, connect the (-) lead to CR1 Cathode (GND).

392 SERIES TROUBLE SHOOTING PROCEDURE

Step Problem Action to be Performed If Correct If Incorrect

1.

Blank

Display*

Measure voltage at U6-19 with

DVM. It should be at +4.3 ±.2V.

Proceed to

Step 3.

Proceed to

Step 2.

2. *

Repeat above measurement, but

with (+) lead at Q4 emitter.

Check for

open trace

between Q4

emitter and

U6-19.

Go to Step 4.

3.

Check U4-25 with an oscilloscope.

It should be a 3.58MHz square

wave with levels from 0 to 5 volts.

Replace U6. If

still no display,

go to Step 9.

Replace U4. If

still no display, go to

Step 7.

4. *

Check voltage at Q4 collector. It

should be equal to the battery

voltage or applied voltage from

test power supply.

Proceed to

next step.

Check for

open trace

from Pin

5 to Q4 (C).

5.

Check voltage on junction of R30

and CR5 cathode. Should be

+5.000 ± .005V.

Proceed to

next step.

Go to Step 8.

6. *

Check voltage on junction of R30

and Q4 base. It should be between

+4.7 and +4.9 volts.

Replace Q4. Replace R30.

7.

Replace Yl crystal and repeat Step3.Done. Go to Step 16.

8.

No +5000

volts or

incorrect

Measure voltage at U2-2. It should

be +2.5 volts ± 0.1V.

Go to Step 11. Proceed to

next step.

9.

Measure voltage at pin 5 of wire

harness. It should be equal to the

battery or power supply voltage.

Proceed to

next step.

Check wire

harness for

broken wires.

10.

Check voltage at U7-2. It should

be +2.5 volts ± 0.1V.

Proceed to

next step.

Replace U7.

11.

Check voltage at Q2 between base

and emitter, there should be

approx. a 0.7V drop.

Replace

Q2. If still

incorrect go to

Step 16.

Replace U2

and check

CR3, CR4,

R19, R20 &

R22.

12.

Unit constantly

reads OL-

Measure voltage at U4-28 with

DVM. It should be -4.3 ± 0.1V.

Proceed to

next step.

Proceed to

Step 14.

23

Page 15

24

25

392 SERIES TROUBLE SHOOTING PROCEDURE

Step Problem Action to be Performed If Correct If Incorrect

13.

Set the Wahl Calibrator to 212°F

and insert into the T/C connector.

Use DVM to measure the following voltages U3-12 should be .255

to .275V U3-13 should be .071 to

.079V

*U3-1 should be .580 to .620V

*U3-3 should be .660 to .710V

Proceed to

next measurement.

If any voltage is

incorrect, check

R1-R17, R35,

R36, CR6 and

CR7. Also check

wires from connector to circuit

board.

*U34 should be .660 to .710V

U3-14 should be .017 to .079V

U3-15 should be .580 to .620V

Proceed to

next step.

Replace U3 and

if problem is not

corrected, go to

Step 16.

14.

Check the output of U1-4 for a 0

to 6 volt square wave of approx.

10 kHz æ 2 kHz.

Replace CR1

and CR2.

Proceed to next

step.

15.

Check for a sawtooth wave at U1-

1. It should have a voltage level of

1.8 to +4.2 volts.

Replace U1.

If display

still reads

-OL-replace

U4.

Replace C67 and

recheck

U1-1. If problem

is not corrected

go to step 16.

16.

Return unit to factory for repair.

*NOTE: Does not apply to 392MX and 392M with Serial Numbers before N120

11.0 ACCESSORIES

392 SERIES CALIBRATORS

Model Number Usable With Meter Calibration Points

CAL392-HT

392E, 392EX, 392EVX,

392M, 392MX, 392VX

and 700M

-58°F, 32°F, 212°F, 284°F, 752°F

-50°C, 0°C, 100°C, 140°, 400°C

CAL392HP-HT 392HP only

CAL392-LT

392E, 392EX, 392EVX,

392M, 392MX, 392VX

Ice Point to Boil

Calibrator

32°F, 68°F, 104°F, 140°F, 212°

0°C, 20°C, 40°C, 60°C, 100°C

CAL392HP-LT

392HP only

Ice Point to Boil

Calibrator

392 SERIES METER ACCESSORIES

Model Number Description

DA-4 Silicone Paste

DA-6 Belt-Clip Meter Case with Hand Strap

DA-10 Nylon Safety Wrist Strap

DA-60 Shock-Proof attache-style Instrument Case

11681-1 Spare NiCad Battery Pack

11681-2 Spare NiCad Pack for -S Models

MN1604 Standard 9V Alkaline Battery

MA150 Battery Recharger, 120V AC 50/60Hz

MA150E Battery Recharger, 220V AC 50/60Hz, European

METER OPTIONS

392NIST

Certificate with 3 Standard Calibration Points between 32°F (0°C)

& 500°F (250°C) Meter calibration includes one probe.

392NIST-1

Certificate with 3 User-specified Calibration Points between -40°F

(-40°C) & 600°F (315°C) Meter calibration includes one probe.

Page 16

26

27

12.0 CALIBRATION SERVICE

Recalibration service can be provided at a nominal cost, if desired. Special

thermal calibration traceable to NIST is available. Standard temperature

points are: 0°C, 94°C, and 250°C. Custom points are available upon request.

13.0 700M THERMISTOR .01°C/F RESOLUTION HEAT PROBER

13.1 General Discussion

The Wahl Thermistor unit measures temperature over a range of -1.00°C to

60.99°C (30.20°F to 141.78°F) with .01°C resolution. The sensing element in

the probes is a highly stable thermistor, with .1°C interchangeability, the output being processed and linearized before display. The accuracy of the meter

is .02°C. With probe installed, the accuracy is .04°C.

The signal conditioning circuitry is completely chopper stabilized and associated resistive components have a very low temperature coefficient. This combination yields essentially drift free operation.

The linearization of the Thermistor sensor is accomplished in two steps for

best utilization of the available analog-to-digital converter range. A resistive

network accomplishes a portion of the linearization while a look-up” table in

the microprocessor completes the balance.

All operations of the instrument are controlled by the microprocessor including the drive for the display and peak reading computation and retention.

Another important feature of the instrument is the use of dual power regulators and dual grounding systems to provide the ultimate in isolation between

sensitive signal conditioning circuits and the high level digital processing and

display circuits.

The power source of the 700M is the same as the 392M, which is a rechargeable nickel-cadmium battery pack composed of five AA size cells with a combined voltage of 6.0 volts and capacity rating of .65 amp-hours. The unit is

supplied with a recharger which can be plugged in at any time to maintain

the charge of the battery pack. Low battery condition is displayed as “L” in

the left-hand side of the display. The 700M is available only with LED display.

Should the temperature being measured extend beyond the limits of the

instrument, or in the event the probe is removed from the unit or becomes

defective and opens, an indication of -OL- will be displayed on the LED display. Correcting the over/under range condition or inserting a functioning

probe will again bring the instrument to a proper indicating condition.

TOLERANCE (PROBE INTERCHANGEABILITY)

Temp °C -250 -220 -200 -100 0 100 200 300 400 500

Tolerance

±°C

5.8 1.8 1.2 0.7 0.3 0.5 1.1 1.7 2.3 3.0

±: 1.0 0.7 0.5 0.3 0.1 0.2 0.4 0.6 0.8 1.0

TOLERANCE (PROBE INTERCHANGEABILITY)

°F 0 -20 -40 -60 -80 -100 -120 -140 -160 -180 -200

0 93.03 88.65 84.26 79.85 75.42 70.98 66.52 64.04 57.54

°F 0 20 40 60 80 100 120 140 160 180 200

0 93.03 97.39 101.74 106.07 110.38 114.68 118.97 123.24 127.50 131.74 135.97

200 135.97 140.18 144.38 148.57 152.74 156.90 161.04 165.17 169.28 173.28 177.47

400 177.47 181.54 185.60 189.64 193.67 197.69 201.69 205.68 209.65 213.61 217.55

600 217.55 221.49 225.40 229.31 233.20 237.07 240.93 244.78 248.61 252.43 265.23

800 256.23 260.02 263.80 267.56 271.31 275.04 278.76 282.46 286.15 289.83 293.49

TOLERANCE (PROBE INTERCHANGEABILITY)

Temp

°C

-420 -400 -350 -300 -200 -100 0 32 100 200 300 400 500 600 700 800 900

Tolerance

±°C

10.4 8.3 3.3 1.9 1.5 1.1 0.7 0.6 0.7 0.9 1.5 2.0 2.7 3.3 3.9 4.5 5.4

±: 1.0 0.9 0.7 0.5 0.4 0.3 0.2 0.1 0.2 0.2 0.3 0.4 0.6 0.7 0.8 0.9 1.0

Page 17

28

29

13.2 Calibration Procedure (See Figure 13-1)

13.2.1 Equipment Required

1. Digital Voltmeter, Fluke 8600 41/2 digit or equivalent.

2. Decade resistance box with a range to 30K and resolution to one

ohm. Accuracy required can be determined by using the thermistor slope at

60°C where an error of 1 ohm is equivalent to .01°C.

13.2.2 Calibration

1. Connect DVM(+) to TP2 and (-) to TP1. Turn on power switch and

adjust R15 for a DVM reading of 2.110 ±.002 volts. This sets the low battery

indication point at a battery voltage of 5.5 Volts.

2. Connect the decade resistance box to the unit to be calibrated by

using a cable length of approximately five feet of 22AWG wire and a

Switchcraft #250 plug connector.

3. Set resistance to 29,490 ohms and adjust R5 for a display reading of 0.00°C (32°F).

4. Set the decade box to a resistance of 2760 ohms and adjust R13

for a display reading of 60.00°C (140.00°F).

5. Set the decade box to a resistance of 12,260 ohms and check the

unit for a correct display reading of 20.00°C or 68.00°F.

6. Repeat steps 3, 4 and 5 as necessary for best calibration.

14.0 392M TROUBLE-SHOOTING AID

14.1 Scope

This section describes basic diagnostics to find the majority of the problems

with malfunctioning 700M units.

Equipment Required:

1. Decade Resistance Box

2. 4- Digit DVM, Fluke 8600A or equivalent.

3. Oscilloscope.

4. Power supply, Power/mate BPA-10c or equivalent.

14.2 Procedure

Make certain that the 700M unit experiencing the problem has been properly

set-up, per Section 13.0, before proceeding to this section.

Figure 13.1. 700M Circuit Board Layout

Page 18

30 31

HOW TO USE TROUBLE-SHOOTING PROCEDURE: Locate the problem on

this table and proceed with the action starting with Step 1. Note, for all DVM

and scope measurements, connect the (-) lead to TP1 (GND).

14.0 700M TROUBLE-SHOOTING AID

700M TROUBLE SHOOTING PROCEDURE

Step Problem Action to be Performed If Correct If Incorrect

1.

Blank

Display*

Measure voltage at U6-19 with

DVM. It should be at +5.0 ±0.25V.

Proceed to

Step 4.

Proceed to

Next Step.

2.

Measure voltage at Q3 output

lead. (The output is the lead nearest to the edge of the circuit

board).

Check for open

trace between

Q3 and U6-19.

Proceed to

Next Step.

3.

Measure voltage at input of Q3. It

should be 6.5V ±.1V.

Replace Q3. Go to step 8.

4.

Check voltage at TP3. It should be

+5.0V ±0.25V.

Proceed to

next step.

Go to Step 7.

5.

Check Check U4-25 with a scope.

It should be a 3.58MHz square

wave with levels from 0 to 5 volts.

Replace U6. If

still exists, go

to Step 19.

Replace U4. If

still no display, go to

next step.

6.

Replace Y1 crystal and repeat

Step 5.

Done. Go to Step 19.

7.

No +5

volts or

incorrect

Measure the voltage at Q1 output.

It should be +5.0V ±0.25V. (The

output is the lead nearest to U6).

Check for open

trace on circuit

board.

Proceed to

next step.

8.

Measure voltage at pin 6 of wire

harness. It should be equal to the

battery or power supply voltage.

Proceed to

next step.

Check wire

harness for

broken wires.

9.

Replace Q1 and repeat Step 7. Done. Go to Step 19.

10.

Unit constantly

read -OL-

Measure voltage at U4-28 with

DVM. It should be -4.3 ±0.2V

Go to step 12. Proceed to

next step.

11.

Check voltage at U3-8. It should

be +5.0V ±0.25V.

Replace

U3.

Go to Step 7.

12.

Connect a decade box to the input

and set to 28150 ohms. Measure

voltage at U1-10. It should be

+0.561V ±0.005V.

Go to

Step 14.

Proceed to

next step.

700M TROUBLE SHOOTING PROCEDURE

Step Problem Action to be Performed If Correct If Incorrect

13.

Check voltage at U1-5. It should

be +0.561V ±0.005V.

Replace U1. Go to Step 16.

14.

Check voltage at U2-10. It should

be +1.458 ±0.005V.

Go to Step 19. Proceed to

next step.

15.

Check voltage at U2-5. It should

be +0.578V ±0.005V.

Replace U2. Proceed to

next step.

16.

Check voltage at wire harness at

pin 3 on circuit board. It should

be +0.460V ±0.005V.

Proceed to

next step.

Go to Step 19.

17.

Check voltage at wire harness at

pin 1 on circuit board. It should

be +0.578V ±0.005V.

Go to Step 19. Proceed to

Next Step.

18.

Check for +5 volts, check R1

through R6, R12 and R13. Also

check harness for loose or broken

wires.

Proceed to

next step.

Replace bad

component. If

problem still

exists, proceed to next

step.

19.

Return unit to factory for repair.

Page 19

32

234 Old Weaverville Road • Asheville, North Carolina • 28804-1228

Phone 800-421-2853 • 828-658-3131 • Fax 828-658-0728 • Email: info@palmerwahl.com

www.palmerwahl.com

15.0 WARRANTY REGISTRATION

Fill out the Warranty Registration Form included in this manual and return to

Wahl. We will send you follow-up reminders about recalibration dates.

16.0 RETURN FOR REPAIR/CALIBRATION SERVICE

Warranty Repair Information

Please contact Wahl Customer Service at (800) 421-2853 for a

Return Merchandise Authorization number (RMA) before returning your

instrument to the factory.

Shipping

Material being returned should be packed well, preferably in the original foam

shipping container.

Ship to: WAHL INSTRUMENTS, INC.

234 OLD WEAVERVILLE ROAD

ASHEVILLE, NC 28804-1228

(800) 421-2853

W-392 (Rev. M) 11/04

Loading...

Loading...