Page 1

DST600 • DST610 • DST620 Series

Digi-Stem

Thermometer

User Manual

04/12/12

WD1032 Rev G

For use with model:

DST600, DST600R,

DST600I, DST610,

DST611, DST620 &

DST621

Wahl Instruments, Inc.

234 Old Weaverville Road

Asheville, NC 28804

Toll Free 800-421-2853

Phone 828-658-3131

Fax 828-658-0728

www.palmerwahl.com

Page 2

DST600 • DST610 • DST620 Series USER MANUAL

WARRANTY & CALIBRATION

Index

1. Application and Key Features _________________________________________ 2

2. CE Approval _______________________________________________________ 3

3. Installation ________________________________________________________ 3

4. Battery Installation / Replacement / Battery Life ___________________________ 6

5. Operation _________________________________________________________ 7

6. Calibration ________________________________________________________ 9

7. Specifications – DST600 _____________________________________________ 10

8. DST610, DST611, DST620 and DST621 ________________________________ 11

9. Specifications – DST610, DST611, DST620, DST621 ______________________ 15

10. Service ___________________________________________________________ 16

Registration is fast and easy. In about a minute you

can have your product automatically registered for

Warranty Protection and our Calibration Reminder

service. Let Palmer Wahl help you protect your

investment, and maintain product accuracy and

compliance with ISO and other quality standards.

Questions? Call Customer Service

at 1-800-421-2853 or 828-658-3131

Or email: register@palmerwahl.com

REGISTRATION at

www.palmerwahl.com/register

1. Application and Key Features

The Wahl DST600 is designed for temperature monitoring applications,

specifically in the food, dairy and pharmaceutical markets, however it is well

suited for any application requiring a high degree of accuracy and reliability. To

achieve this objective the DST600 incorporates the following features:

• High reliability, 4-wire, 100 ohm, .00385Ω/Ω/°C, thin-film platinum RTD

sensor per DIN EN 60751, Class A.

• High accuracy 24-bit Delta-Sigma Analog/Digital Converter.

• Self-checking Electronic Circuitry: Meter repetitively checks the electronics

accuracy by measurement of on-board ultra-stable, low ppm precision

resistors against embedded firmware values and displays “err” in the event

the electronics is out by more than ±0.5°F (0.3°C). The self-checking

electronic circuit may be tested by rapidly changing the temperature of the

sensor, such as placing from room temperature into ice bath or heated

process. Unit will display “err” occasionally when going through rapid

changes and will return to normal as temperature begins to stabilize (usually

2 of 16

Page 3

DST600 • DST610 • DST620 Series USER MANUAL

within 10° of final temperature). This serves as a test and indicator that the

self-checking circuitry is functioning properly.

• Probe Error checking: Checks for open wire, open sensor, shorted sensor,

incorrect wiring.

• Probe ID feature: Alerts the operator that the probe has been changed and

the calibration may be void. Requires the use of calibration software to

calibrate and associate the new probe with the meter. Available on fixed

stem and remotes less than 25 meters.

• Programmable R0: Allows programming of the sensing probes specific R0

value into the meter for accurate temperature calibration.

2. CE Approval

The DST600 carries CE approval per EN61326: 2006 for Radiated

Electromagnetic Field Immunity, Electrostatic Discharge Immunity and Radiated

Emissions Disturbances. See sections 3.4 and 3.5 for detailed installation

instructions.

3. Installation

Caution! See important information regarding Lithium Batteries on the

enclosed document #WD1053, before proceeding!

Your unit was shipped partially assembled. Installation of the battery by the enduser is necessary as transportation regulations prohibit shipping units with the

battery installed. Units with long probes or remote cables may be shipped

unassembled. After installation of the battery, verify the display is operational

and remove the protective film from the window. In the event the display is not

operational, check that the battery is installed properly by following the battery

installation procedure, section 4.

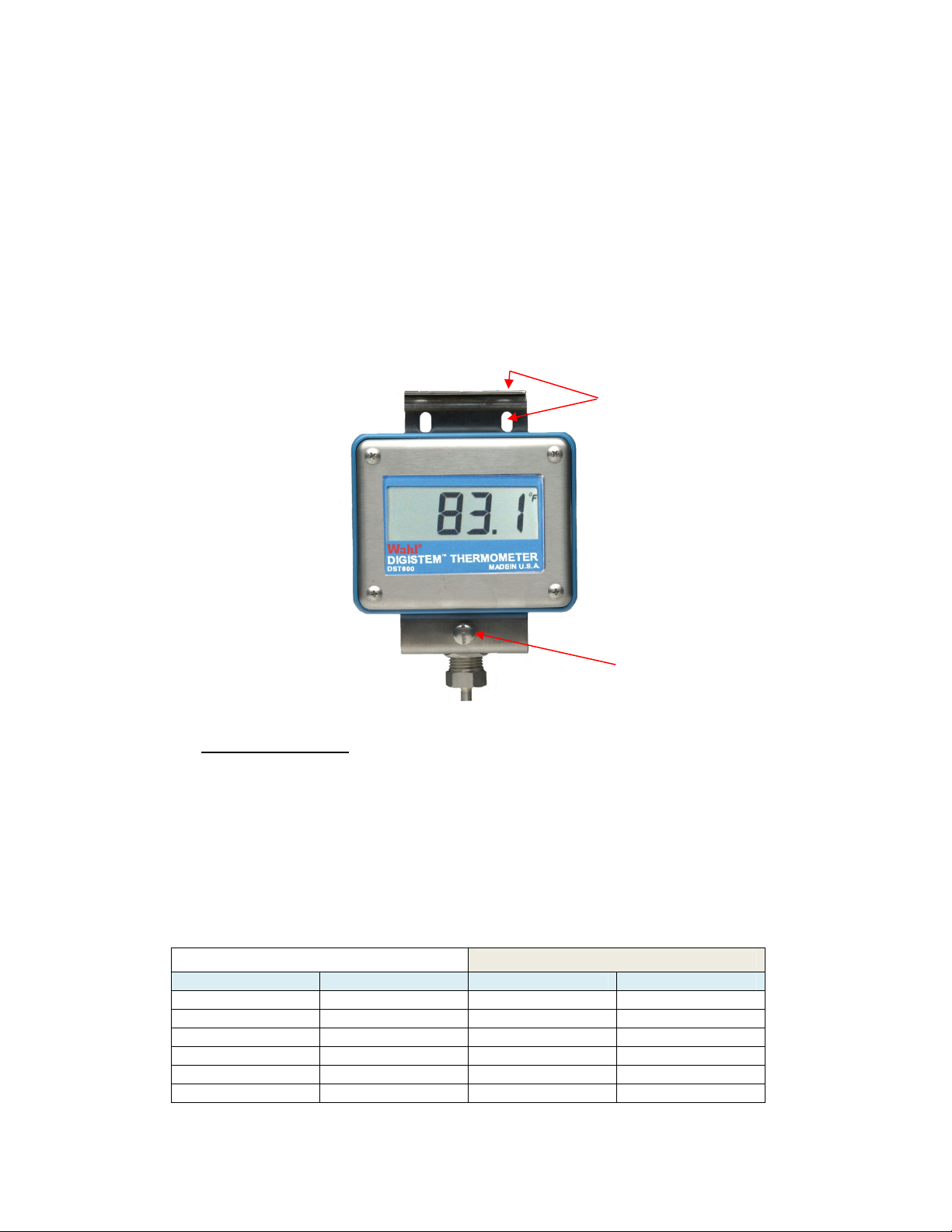

3.1. Meter Mounting – Fixed Probe

Fixed probes may be mounted by the threaded fitting or sanitary clamp into

the process. Apply thread sealing compound or Teflon tape to the threaded

fitting as required. Units with swivel nut fittings or adjustable angle stems

may be adjusted after installation for best viewing angle.

Caution! Do not rotate Digi-Stems with adjustable angles more than 360° in

one direction as wire breakage may occur. See 3.7 for adjustment procedure.

Caution! Do not use the Digi-Stem enclosure to tighten meter. Use a wrench

on the coupling nut for tightening.

3.2. Meter Mounting – Remote Probe

An optional mounting bracket is available for mounting remote meters to

walls, panels, pipes, etc. The mounting bracket may be attached by the top

or rear surface with user provided mounting screws, clamps, etc. The

mounting bracket is available in 2 styles, p/n DSA3030, without ground lug

and DSA3031, which includes a grounding lug for grounding of the meter

when the probe will not be grounded.

3 of 16

Page 4

DST600 • DST610 • DST620 Series USER MANUAL

P1 Pin

Signal Name

Fixed Probe

Remote Probe

1 Excite +

White

Brown

2 RTD +

White

White

3 RTD

- Black

Blue

4 Excite

- Black

Black

5 Probe ID Ground

Brown

Gray

6 Probe ID Signal

Orange

Pink

3.2.1. For remote mounting: Mount the bracket with the Digi-Stem

mounting screw towards the bottom (Fig. 1). The Digi-Stem’s

coupling nut should be inserted from the top, with the display facing

out and secured with the Digi-Stem mounting screw. Loosen or

remove the Digi-Stem mounting screw.

3.2.2. For remote cables, thread the cable through the slotted sections of

the mounting bracket holes, so the cable moves freely. Insert the

meter’s coupling nut through the top hole of the mounting bracket and

secure with the large slotted Digi-Stem mounting screw.

Bracket Mounting

Holes

Fig. 1

Digi-Stem

Mounting Screw

3.3. Wire Connections – In the event that your probe was shipped

disconnected from the meter, the following describes the probe wiring and

installation process.

3.3.1. Loosen the four phillips head screws in the front cover until the

cover is removed. Note: The screws are held captive by retaining

washers and should not be removed completely.

3.3.2. Remove the 6 pin pluggable terminal strip connector (J1) from the

PCB mating connector and connect probe wires per the following

table and as shown in Fig. 4.

Probe Connection Wiring Wire Color

4 of 16

Page 5

DST600 • DST610 • DST620 Series USER MANUAL

3.3.3. Connect pluggable terminal strip to PCB connector J1.

3.3.4. Install battery with polarity as indicated on battery holder.

3.3.5. Replace cover on Digi-Stem enclosure and secure with four screws

tightened to a force of 4 to 5 in-lbs. of torque.

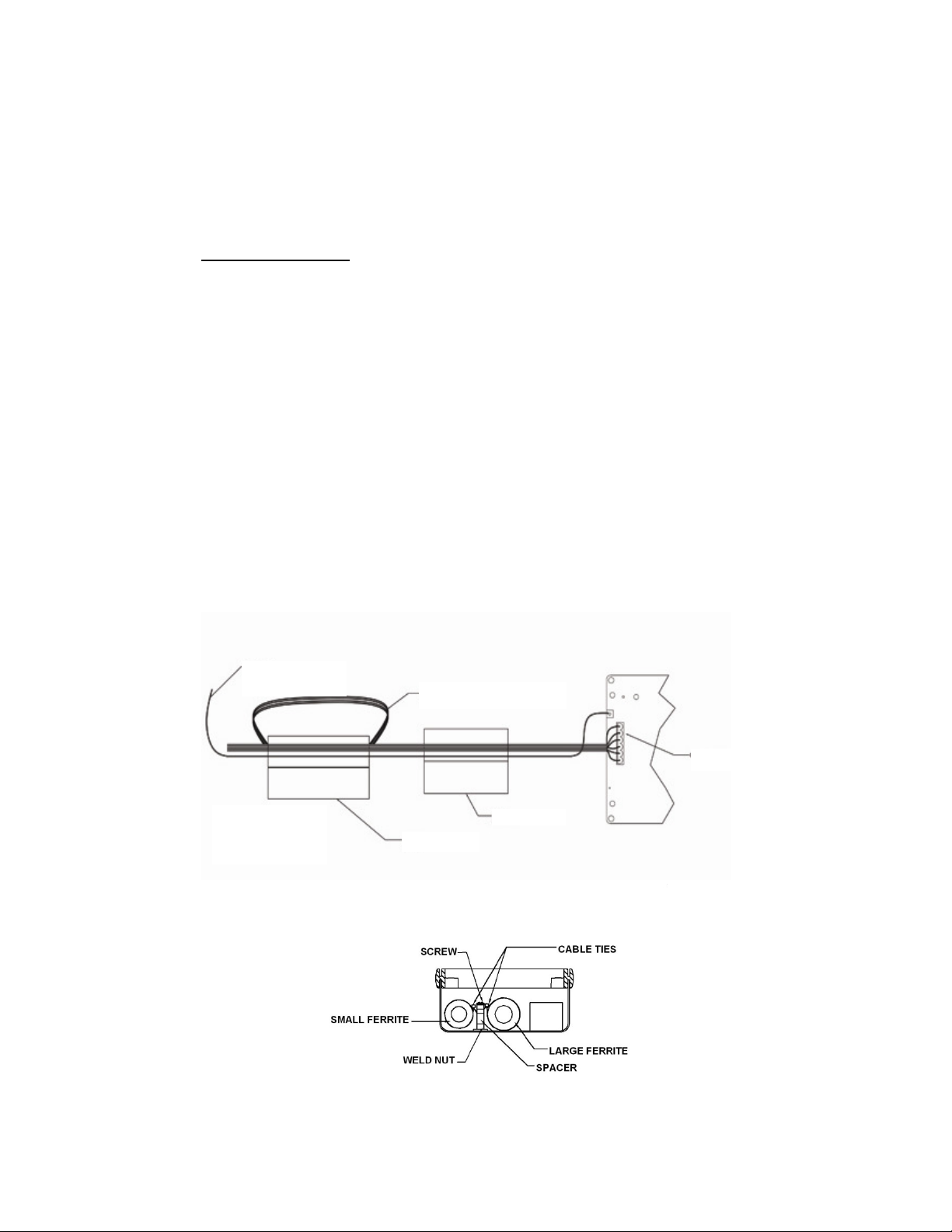

3.4. Ferrite Installation

The Wahl DST600 CE compliance requires installation of 2 clamp-on

ferrites around the internal wiring. These are normally installed when the

system is delivered, however on units with extremely long probes or when

meters are shipped without a probe, these may need to be installed by the

end-user.

There is 1 large ferrite and 1 small ferrite that are required to comply with

the CE directive. See Fig. 2 for reference. The wires coming from the

probe should be passed through the large ferrite, looped around once and

passed through again. Also, route the green/yellow PCB ground lead

through the ferrite once, with the Faston connector toward the probe end

of the ferrite. The large ferrite can then be snapped closed, making sure

that the wires are not pinched. The small ferrite is then installed on the

remaining length of all wires, toward the connector with it passing through

the ferrite only once. The wire does not have to loop through the small

ferrite. The small ferrite can then be snapped closed, making sure that the

wires are not pinched. Cable clamps can then be installed as shown (Fig.

3) to secure the ferrites in place.

Ground Wire Not

Looped

Probe Wire Loop 1 Time

Note:

Ferrites Shown

Open

Large Ferrite

Small Ferrite

Connector P1

Fig. 2

Fig. 3

5 of 16

Page 6

DST600 • DST610 • DST620 Series USER MANUAL

3.5. Grounding

3.5.1. The DST600 should be grounded for CE compliance and optimum

noise immunity.

3.5.2. Grounding on DST600’s with rigid probes is accomplished by

grounding the probe shank. Typically, the equipment that the probe

shank is installed in will be grounded, which will also ground the

DST600 meter assembly.

3.5.3. Grounding on most DST600’s with remote probes is accomplished

in the same manner as the rigid probes. If the remote probe is not

grounded, optional meter mounting bracket, DSA3031, should be

used. This mounting bracket includes a ground lug that allows the

connection of a ground wire for grounding the unit for CE compliance

and optimum noise immunity.

3.5.4. Be certain the PCB ground wire is connected to the housing’s

ground lug, after servicing.

3.6. Ventilation

3.6.1. The DST600 should be installed in an area of adequate air

exchange so that the specified ambient conditions are not exceeded.

3.7. Adjustable Angle Probe – Adjustment

3.7.1. For rotational adjustment, loosen the two long phillips head screws

on the ends of the bracket and rotate the bracket around the coupling

nuts. Tighten screws when position is set to the desired location.

Caution! Do not rotate Digi-Stems with adjustable angles more than

360° in one direction as wire breakage may occur.

3.7.2. Angular adjustment, loosen the two short phillips head screws in

the center slots and pivot the bracket to the desired angle. Tighten

screws.

4. Battery Installation / Replacement / Battery Life

The DST600 uses a single 3.6V C-cell Lithium Thionyl Chloride battery, Wahl

Catalog # DSA3060. The DST600I uses a single 3.6V AA-cell Lithium Thionyl

Chloride battery, Wahl part number 12234-03. Low battery is indicated by “LOW

BATT” displaying in the lower right corner of the display. This indicates

approximately 2-6 weeks of battery life left. Actual time will vary dependent on

Display Update Rate Setting. See section 5.2 for additional information on

update rate and battery life.

4.1. Procedure

4.1.1. For installation or replacement, loosen the four phillips-head screws

in the front cover until the cover is removed. Note: The screws are

held captive by retaining washers and should not be removed

completely.

4.1.2. Remove old battery and dispose of in accordance with local, state

and federal regulations.

6 of 16

Page 7

DST600 • DST610 • DST620 Series USER MANUAL

4.1.3. Insert new battery with polarity as indicated on battery holder.

Positive terminal should be at the top of the PCB.

4.1.4. Replace cover on Digi-Stem enclosure and secure with four screws

tightened to a force of 4 to 5 in-lbs. of torque.

4.2. Battery Life – Battery life is a function of the display update rate and may

be changed to fit the user’s needs. See section 5.3 for details on display

update rate. The following table shows approximate battery life for a

given display update rate.

Display update

rate in seconds

DST600 w/ DSA3060 battery

approximate life in months

DST600I w/ 12234-03 battery

approximate life in months

1 15.7 5.2

2 32.2 10.7

4 60.7 20.2

5 73.8 24.6

10 129.3 43.1

Fig. 4

5. Operation

5.1. Scale Selection °F/°C - Temperature scale is user selectable via jumper

J8 (Fig. 5) on the Printed Circuit Board (PCB). The scale is indicated in

the upper right corner of the display (Fig. 4).

5.2. Resolution Selection – DST600R offers the user the capability of

changing the displayed resolution by selecting either 0.1° or 1° resolution.

Resolution is selectable via jumper J7 (fig. 5) on the PCB, located to the

left of the F/C selection jumper. Selecting 1° will display the truncated

value, so a temperature of 255.9°F would display as 255°F. NOTE: If

using this feature, it is advised to set the meter to 0.1° resolution for doing

calibration measurements, as using 1° can add up to 0.9° of error to the

displayed reading.

5.3. Making measurements and display update rate - With the batteries

installed and probe connected the meter automatically updates the

display with the most recent measurement. Factory default for display

update rate is once every 2 seconds. Display update rate is settable from

.25 seconds to 10 seconds in .25 second increments, using optional

DSTPROG or DSTCAL software.

7 of 16

Page 8

DST600 • DST610 • DST620 Series USER MANUAL

Pin 1

Exc-

RTD

-

J1

5.4. Error Codes - During normal operation, the DST600 continually performs

diagnostic testing on the sensor lines. Errors are indicated by the

following error codes:

Error Code Description

HI Reading is above meters usable range

LO Reading is below meters usable range or sensor is shorted

CbL1 Indicates cable 1 is open (J1 pin 1)

CbL2 Indicates cable 2 is open (J1 pin 2)

CbL3 Indicates cable 3 is open (J1 pin 3)

CbL4 Indicates cable 4 is open (J1 pin 4), or open sensor

err Indicates accuracy error detected. Will also display during rapid

changes of temperature to the RTD sensor.

Prb Indicates probe ID does not match probe ID programmed in meter

- - - Indicates Low Battery Shutdown Mode

Battery Positive

Terminal

1°/0.1°Jumper

J7 DST600R

Only

°F/°C Jumper

J8

Calibration

Port

Ground Wire

PCB

Probe ID

Signal

Probe ID

Ground

RTD +.

Exc+

Fig. 5 (DST600R Shown)

8 of 16

Page 9

DST600 • DST610 • DST620 Series USER MANUAL

6. Calibration

As with all electronic RTD thermometers, there are two main components to the

system. The first component is the electronics, which measures the resistance of

the sensing element and then converts this resistance value to a temperature

indication. The second component is the probe, also referred to as the sensor.

The probes sensor resistance changes as its temperature changes. This change

is in conformance to the DIN EN 60751 Class A standard. As in all manufactured

goods, there are slight variations in the finished parts. A key variable of an RTD

sensor is its resistance at 0°C, referred to as “R0” value. Once this value is

measured, it may be programmed into the meter to correct the temperature

conversion algorithm. Programming and/or calibration require the use of the

DSTPROG or DSTCAL software package. These packages include the USB

cable, USB/DST Interface Box and DST calibration cable. DSTPROG

programming software includes the ability to set the Sample Rate, R0 and

associate a new probe with the meter. DSTCAL includes the DSTPROG

capability plus calibration of the meter and/or calibration of the system (probe

with meter). The DST600 uses the following techniques for calibration. For

details of the calibration, see the DSTCAL software manual.

6.1. Ohm Meter calibration – Ohm Meter calibration is a 2-point calibration,

which calibrates the DST600’s electronics. It requires a NIST traceable

precision resistance source with a known accuracy of ± 0.03 ohms at 90

and 194.1 ohms. Resistors used should have a temperature coefficient

of <5.0-ppm.

6.2. Probe (system) calibration - Probe calibration is a single point calibration

that is performed by placing the probe into an ice bath and following the

on screen prompts of the DSTCAL software. The DST600 and software

will measure the probes R0 value and program it into the DST600’s

memory. The system is then calibrated. After system calibration is

completed, the calibration should be checked at the temperatures of

interest to the end user, using calibrated measuring equipment and

calibration baths. If traceability to a National Standard, such as NIST is

required, this check should be performed using traceable instruments,

performed and documented in compliance to documented procedures.

9 of 16

Page 10

DST600 • DST610 • DST620 Series USER MANUAL

7. Specifications – DST600

10 of 16

Page 11

DST600 • DST610 • DST620 Series USER MANUAL

8. DST610, DST611, DST620 and DST621

Models DST610, DST611, DST620 and DST621 are variations of the DST600

that include an isolated secondary sensor housed in the same probe shank. This

enables the user to have an independent signal from the same probe for use by

a controller or recorder.

8.1. DST610 – Consists of DST600 meter with an isolated secondary sensor

and terminal block. The DST610 provides an isolated secondary RTD for

independent external use allowing the user to have an additional

measuring circuit located in the same probe shank. This reduces the

number of penetrations made into the process and reduces error due to

non-uniformity of the process.

8.1.1. Connection is made via a 4-circuit terminal strip (see Fig. 4). A ½”

NPT female fitting on the side of the enclosure allows access to

connections. This connection should be sealed to prevent moisture,

water or dust entry. We recommend using a liquid-tight conduit fitting

or cable gland for wire entry. User may use in a 2, 3 or 4 wire

configuration as shown in Figure A1.

8.1.2. Secondary RTD specifications are as follows:

R0 100 ohms per DIN EN 60751

Accuracy Class A per DIN EN 60751

Temperature coefficient TCR = 3850 ppm/K

Connection Factory wired for 4-wire, user selectable 2,

3, or 4-wire connection

Self-heating 0.4 K/mW at 0°C

Measuring current 0.3 to 1.0 mA, self-heating must be

considered

Terminal Block type Euro style

Maximum wire size 10 AWG

Fig. 6 – DST610 Terminal Block Wiring

11 of 16

Page 12

DST600 • DST610 • DST620 Series USER MANUAL

8.2. DST611 - All the features of the DST610, and includes a pre-wired Turck

4-pin connector mounted in the side enclosure fitting. This allows

convenient user connection/disconnection. This option requires the use

of a connecting cable or connector (ordered separately). Connector

wiring are shown in Figure A2.

8.2.1. Optional IP68 rated field wireable connectors and cables:

Wahl P/N Description

12075-07 Straight field wireable connector, 4-6 mm cable gland

12075-08 Straight field wireable connector, 6-8 mm cable gland

12075-09 Right angle field wireable connector, 4-6 mm cable gland

12075-10 Right angle field wireable connector, 6-8 mm cable gland

Cable assemblies are single-ended and feature a molded IP68 rated

connector. Opposite end is left un-stripped. Insulation is PVC and rated

to 105°C.

Wahl P/N Description

12361-xxx xxx denotes length in meters, i.e. 12361-010 is 10-meter

cable, 12361-120 is 120-meter length.

Connections for 12361 cable for DST611 are as follows:

Wire Color Connection Signal

Brown Pin 1 Excite +

White Pin 2 RTD +

Blue Pin 3 RTD -

Black Pin 4 Excite -

Non-insulated Coupling nut Shield*

*Shield lead should not be terminated if either meter housing or

probe shank is grounded, to avoid ground loops.

Fig. 7 – DST611 connector wiring

12 of 16

Page 13

DST600 • DST610 • DST620 Series USER MANUAL

Fig. 8 –

DST620

transmitter connection

8.3. DST620 – Consists of DST600 meter with an isolated secondary sensor

and 4-20 mA programmable transmitter. Transmitters are programmed at

the factory. The DST620 provides an isolated current output from the

same probe shank. This reduces the number of penetrations made into

the process and reduces error due to non-uniformity of the process.

8.3.1. Connection is made by hardwiring to the transmitter power supply

terminals as shown in Figure A3. A ½” NPT female fitting on the side

of the enclosure allows access to connections. This connection

should be sealed to prevent moisture, water or dust entry. We

recommend using a liquid-tight conduit fitting or cable gland for wire

entry.

8.3.2. Secondary RTD/transmitter specifications are as follows:

R0 100 ohms per DIN EN 60751

Accuracy Class A per DIN EN 60751

Temperature coefficient TCR = 3850 ppm/K

Connection 4-wire

Programming PC programming (optional cable required)

Power Supply Req. 10 to 35 VDC

Range

Accuracy

-58°F to 500°F (-50 to 260°C)

Greater of ±0.4°F or .1% ± (0.2°C or .1%)

Fault monitoring Programmable Hi (>21.6 mA) or Low (<3.5 mA)

Programming

Port

OR

RTD Input

8.4. DST621 - All the features of the DST620, and includes a Turck 4-pin

connector mounted in the side enclosure fitting that is pre-wired to the

transmitter. This allows convenient user connection/disconnection. This

option requires the use of a connecting cable or connector (ordered

separately). Connector wiring and cable wiring are shown in Figure A4.

See below for connectors and cables:

13 of 16

I OUT -

I OUT +

Page 14

DST600 • DST610 • DST620 Series USER MANUAL

Figure 9

– DST621

8.4.1. Optional IP68 rated field wireable connectors and cables:

Wahl P/N Description

12075-07 straight field wireable connector, 4-6 mm cable gland

12075-08 straight field wireable connector, 6-8 mm cable gland

12075-09 right angle field wireable connector, 4-6 mm cable gland

12075-10 right angle field wireable connector, 6-8 mm cable gland

Cable assemblies are single-ended and feature a molded IP68 rated

connector. Opposite end is left un-stripped. Insulation is PVC and rated

to 105°C.

Wahl P/N Description

12361-xxx xxx denotes length in meters, i.e. 12361-010 is 10-meter

cable, 12361-120 is 120-meter length.

Connections for 12361 cable for DST621 are as follows:

Wire Color Connection Signal

Brown Pin 1 Current out + (+Vdc)

White Pin 2 Current out – (-Vdc)

Blue Pin 3 N/C

Black Pin 4 N/C

Non-insulated Coupling nut Shield*

*Shield lead should not be terminated if meter housing or probe shank is

grounded, to avoid ground loops.

14 of 16

Page 15

DST600 • DST610 • DST620 Series USER MANUAL

9. Specifications – DST610, DST611, DST620, DST621

15 of 16

Page 16

DST600 • DST610 • DST620 Series USER MANUAL

234 Old Weaverville Road, Asheville, NC 28804

10. Service

For calibration, service or technical support, contact:

Wahl Instruments, Inc.

234 Old Weaverville Road

Asheville, NC 28804

Ph.: 800-421-2853 (US only)

828.658.3131

Fax: 828.658.0728

Web: www.palmerwahl.com

800-421-2853 • 828-658-3131 • 828-658-0728

www.palmerwahl.com

info@palmerwahl.com

16 of 16

Loading...

Loading...