WAGO 750-626/040-000, 750-602/040-000, 750-624/040-001, WAGO-I/O-SYSTEM 750 XTR Series, 750-612/040-000 User Manual

...Page 1

Pos: 2 /Dokumentation allgemein/Einband/Einband Handbuch - Frontseite 20 15 - mit D ocV ari abl en (S ta ndar d) @ 9\mod_1285229289866_0.docx @ 64941 @ @ 1

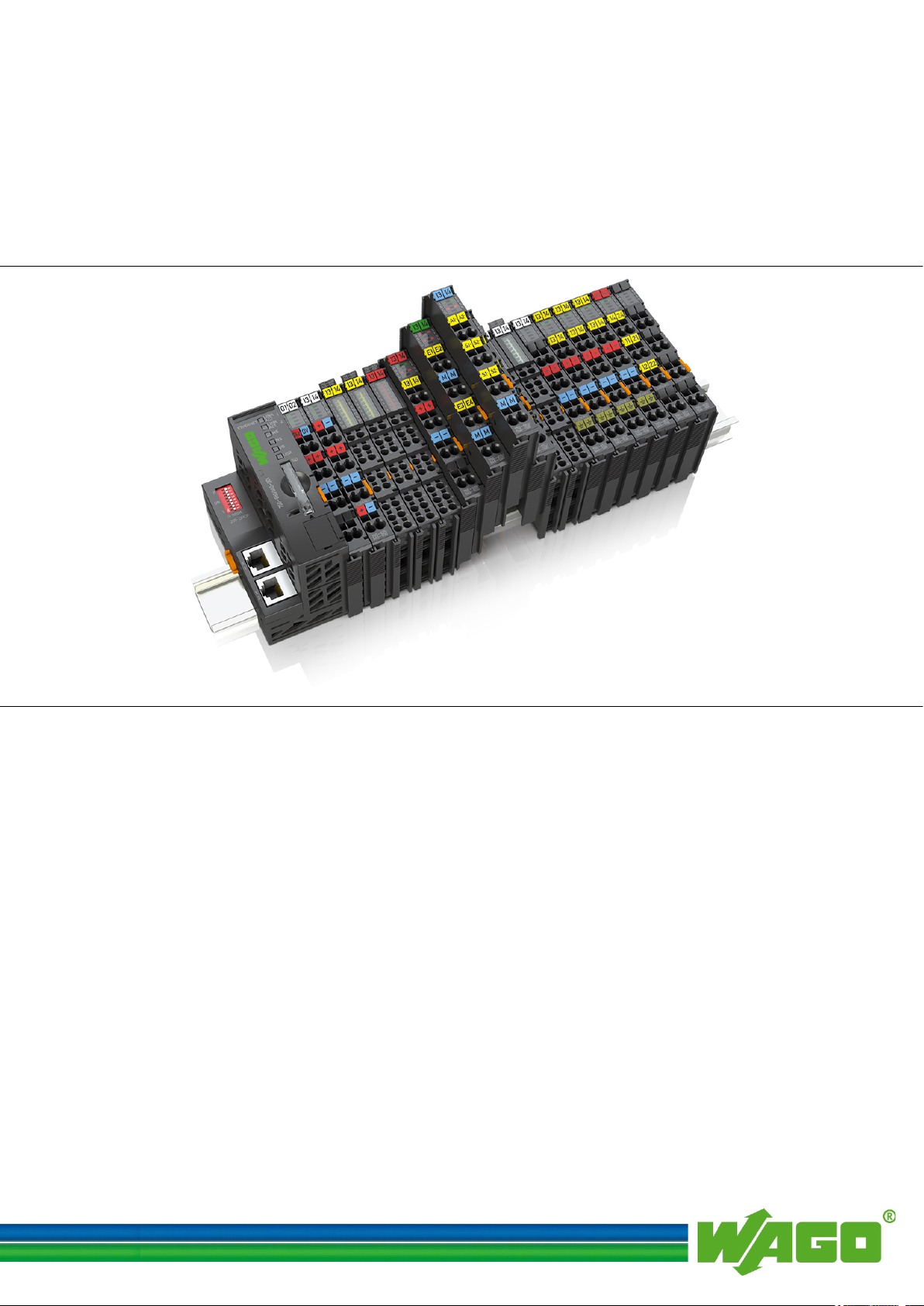

WAGO-I/O-SYSTEM 750 XTR

Manual

750-xxxx/0040-xxxx

Notes /XTR

Guidelines and Recommendations

Version 1.2.0

Pos: 3 /Alle S erie n (Al lge mei ne M odul e) /Rec htli ch es, Allg emei n es/I mpre ssu m f ür St and ard han dbüc h er - al lg. Ang aben, A nschr iften, Telef onnu mmern un d E-Mail -Adr esse n @ 3\mod_1219151118203_21.docx @ 21060 @ @ 1

Design

for Increasing Operational Safety

Page 2

2 WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

© 2016 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

=== Ende der Li st e für Te xtm arke Ei nba nd_ vorn e ===

Manual

Version 1.2.0

Page 3

WAGO-I/O-SYSTEM 750 XTR Table of Contents 3

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 5 /Do kume ntati on allg em ein /Ver zeic hni sse /Inh alts ver z eich nis - Ü ber schrif t oG und Verzei chnis @ 3\mod_1219151230875_21.docx @ 21063 @ @ 1

Table of Contents

1 Notes about this Documentation ................................................................. 5

1.1 Validity of this Documentation ................................................................. 5

1.2 Copyright ................................................................................................... 5

1.3 Symbols ..................................................................................................... 6

1.4 Number Notation ....................................................................................... 8

1.5 Font Conventions ...................................................................................... 8

2 Important Notes ........................................................................................... 9

2.1 Legal Bases ............................................................................................... 9

2.1.1 Subject to Changes ............................................................................... 9

2.1.2 Personnel Qualifications ....................................................................... 9

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with

Underlying Provisions .......................................................................... 9

2.1.4 Technical Condition of Specified Devices ......................................... 10

2.2 Safety Advice (Precautions) .................................................................... 11

3 System Description..................................................................................... 13

3.1 Manufacturing Number ........................................................................... 15

3.2 Component Update .................................................................................. 16

3.3 Storage, Assembly and Transport ........................................................... 16

3.4 Assembly Guidelines/Standards .............................................................. 16

3.5 Technical Data ........................................................................................ 17

3.5.1 Mechanics ........................................................................................... 17

3.5.2 Electrical Safety.................................................................................. 17

3.5.3 Connection Type ................................................................................ 18

3.5.4 Climatic Environmental Conditions ................................................... 18

3.5.5 Residential Use ................................................................................... 19

3.5.6 Example Dimensions .......................................................................... 20

4 Standards and Approvals .......................................................................... 21

5 Assembly ..................................................................................................... 23

5.1 Mounting Position ................................................................................... 23

5.2 Overall Configuration ............................................................................. 23

5.3 Mounting onto Carrier Rail ..................................................................... 24

5.3.1 Carrier Rail Properties ........................................................................ 24

5.3.2 WAGO DIN Rail ................................................................................ 25

5.4 Spacing .................................................................................................... 26

5.5 Mounting Sequence ................................................................................. 27

5.6 Inserting and Removing Devices ............................................................ 29

5.6.1 Inserting the Fieldbus Coupler/Controller .......................................... 29

5.6.2 Removing the Fieldbus Coupler/Controller ....................................... 29

5.6.3 Inserting the I/O Module .................................................................... 30

5.6.4 Removing the I/O Module .................................................................. 31

6 Connect Devices ......................................................................................... 32

6.1 Data Contacts/Internal Bus ..................................................................... 32

6.2 Power Contacts/Field Supply .................................................................. 33

6.3 Connecting a Conductor to the CAGE CLAMP® ................................... 34

Manual

Version 1.2.0

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

6.4 Connecting a Conductor to the Push-in CAGE CLAMP® ...................... 35

6.5 Power Supply .......................................................................................... 36

6.5.1 Isolation .............................................................................................. 36

6.5.2 System Supply .................................................................................... 37

6.5.2.1 Connection ..................................................................................... 37

6.5.2.2 Dimensioning ................................................................................. 38

6.5.3 Field Supply........................................................................................ 41

6.5.3.1 Connection ..................................................................................... 41

6.5.3.2 Fusing ............................................................................................ 42

6.5.4 Power Supply for Mixed Operation ................................................... 44

6.5.5 Supplementary Power Supply Regulations ........................................ 45

6.5.6 Supply Example.................................................................................. 47

6.5.7 Power Supply Units ............................................................................ 49

6.6 Grounding ............................................................................................... 50

6.6.1 Grounding the DIN Rail ..................................................................... 50

6.6.1.1 Framework Assembly .................................................................... 50

6.6.1.2 Insulated Assembly ........................................................................ 50

6.6.2 Grounding Function............................................................................ 51

6.7 Shielding ................................................................................................. 52

6.7.1 General ............................................................................................... 52

6.7.2 Bus Cables .......................................................................................... 52

6.7.3 Signal Lines ........................................................................................ 53

6.7.4 WAGO Shield Connecting System .................................................... 53

List of Figures ...................................................................................................... 54

List of Tables ........................................................................................................ 55

=== Ende der Li st e für Te xtm arke Ver zeic hni s_v or ne == =

Manual

Version 1.2.0

Page 5

WAGO-I/O-SYSTEM 750 XTR Notes about this Documentation 5

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 7 /Alle Ser ie n (All ge mein e M odul e) /Üb ersc hri ften/ Ne ue Ü ber schr ift en/ Ebe ne 1Hin weis e z u di eser D okum ent atio n - Ü ber schri ft 1 @ 4\ mod_1237987661750_21.docx @ 29029 @ 1 @ 1

1 Notes about this Documentation

Pos: 8 /Alle S erie n (Al lge mei ne M odul e) /Sic her hei ts- und sonstige Hinweise/HinweisHinweis: Dokumentation aufbewahren @ 4\mod_1237987339812_21.docx @ 29026 @ @ 1

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

Pos: 9 /Alle S erie n (Al lge mei ne M odul e) /Üb ersc hri ften/ Ne ue Ü ber sc hrift en /Ebe ne 2Gül tig keit sber eic h - Ü ber schr if t 2 @ 12\ mod_1338912448776_21.docx @ 96469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/ Gül tigk eits ber eic h/G ültig k eits ber eich Dok um enta tio n S yste mbesc hr eibu ng 750- xxxx @ 1 4\mod_1358944040650_21.docx @ 109374 @ @ 1

This documentation is only applicable to the WAGO-I/O-SYSTEM 750

XTRseries.

Pos: 11 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/Hi n weis e/Ac ht ung : Hin wei s z ur S yst embes chr ei bung 7 50-xxxx/ 040-000 @ 27\mod_1468507202467_21.docx @ 216916 @ @ 1

The WAGO-I/O-SYSTEM 750 XTR shall only be installed and operated

according to the instructions in this system description and the manuals for the

used fieldbus coupler/controller and I/O modules.

Consider power layout of the WAGO-I/O-SYSTEM 750 XTR!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller and I/O modules, which can be downloaded at

www.wago.com. There, you can obtain important information including

information on electrical isolation, system power and supply specifications.

Pos: 12.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Ur h ebers chut z - Ü ber schr ift 2 @ 2 3\mod_1435647042188_21.docx @ 184808 @ 2 @ 1

1.2 Copyright

Pos: 12.2 /Alle S eri en ( Allg emei ne Mo dule) /R echt lich es , Allg em ei nes/ Urh eber sc hutz aus führ lic h @ 4\mod_1235565145234_21.docx @ 27691 @ @ 1

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Pos: 12.3 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 12.4 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2 Sy mbol e - Ü bersc hri ft 2 @ 13\ mod_1351068042408_21.docx @ 105270 @ 2 @ 1

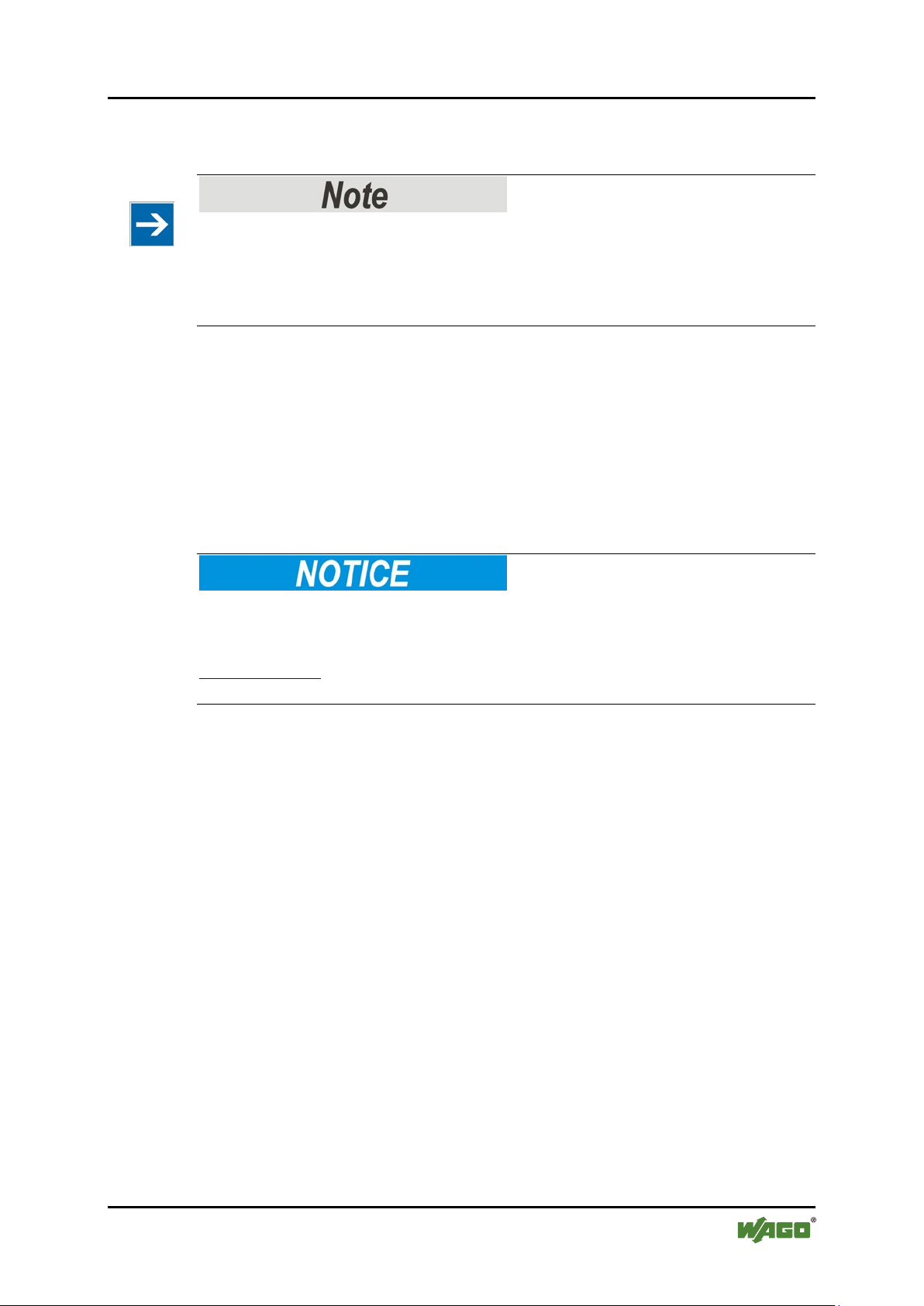

1.3 Symbols

Pos: 12.5.1 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Ge fahr /G efa hr: _War nu ng vor P ers onen sch äde n al lge mei n_ - Erläu terung @ 13\mod_1343309450020_21.docx @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 12.5.2 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonsti ge Hin weise/ Gefahr /Gef ahr: _ Warnu ng vor Per sonen schä den dur ch ele ktrisc hen Stro m_ - Erläuterung @ 13\mod_1343309694914_21.docx @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 12.5.3 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/W arn ung/ War nung : _ Warn ung vor Perso nensc häde n allgem ein_ - Erläuterung @ 13\mod_1343309877041_21.docx @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 12.5.4 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonsti ge Hin weise/ Vorsic ht/V orsich t: _War nung v or Pers onens chäd en allge mein _ - Erläuterung @ 13\mod_1343310028762_21.docx @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 12.5.5 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Ac htu ng/ Ach tung : _ War nung vor Sac hsc häd en al lg emei n_ - Erläuterung @ 13\mod_1343310134623_21.docx @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 12.5.6 /All e Serie n ( All ge meine Mo dul e)/ Sich erh eits- und sonsti ge Hin weise/ Achtu ng/Ac htung : _War nung vor Sachsc häden durc h elektr ostatis che Au fladu ng_ - Erl äuter ung @ 13\ mod_1343310227702_21.docx @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 12.5.7 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Erläut eru ng @ 13\mod_1343310326906_21.docx @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 12.5.8 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Inf or mati on/I nf orma tio n: _ Wei ter e Inf or mati on allg emei n_ - Erl äuter ung @ 13 \mod_1343310439814_21.docx @ 101051 @ @ 1

Manual

Version 1.2.0

Page 7

WAGO-I/O-SYSTEM 750 XTR Notes about this Documentation 7

750-xxxx/0040-xxxx Design Notes /XTR

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 12.6 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750 XTR

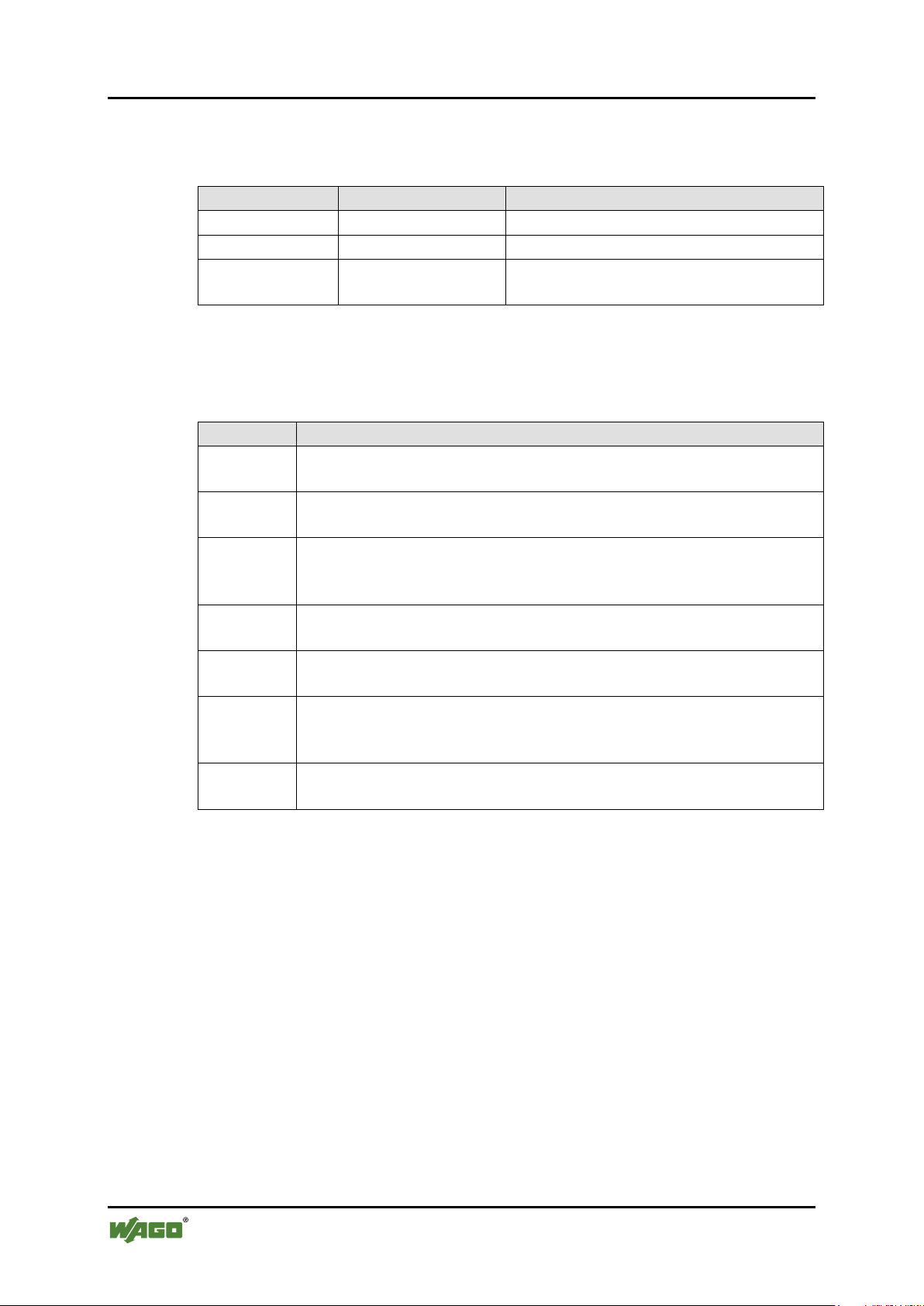

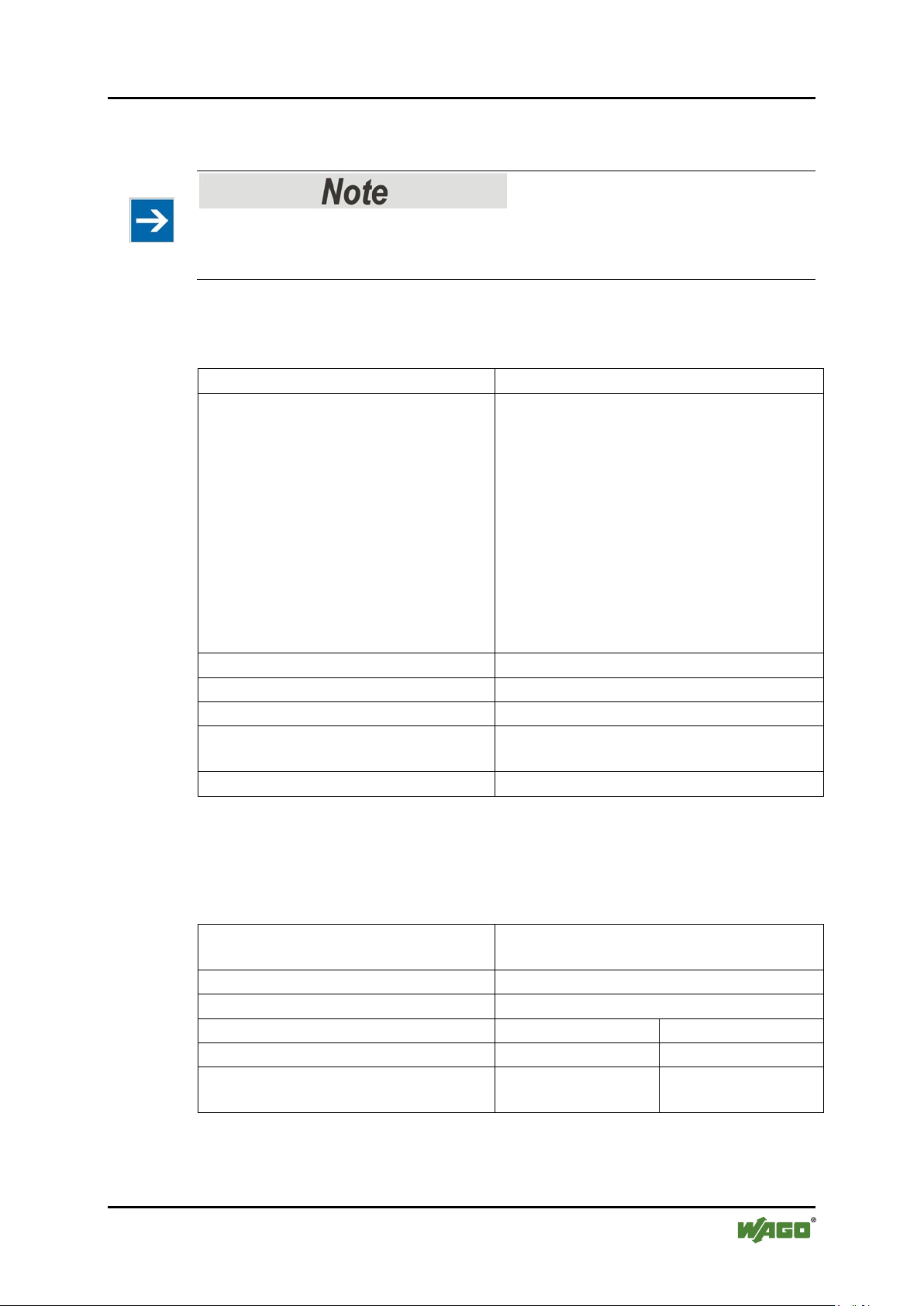

Table 1: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 2: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 12.7 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/D arst ell ung der Z a hle nsys tem e - Ü bers chri ft 2 @ 23\mod_1435647128078_21.docx @ 184811 @ 2 @ 1

1.4 Number Notation

Pos: 12.8 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Za hle nsy st eme @ 3\mod_1221059454015_21.docx @ 21711 @ @ 1

Pos: 12.9 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Sc hr ift kon venti one n - Ü bersc hr ift 2 @ 23\ mod_1435647186005_21.docx @ 184814 @ 2 @ 1

1.5 Font Conventions

Pos: 12.10 / All e S erie n (Al lge mei ne M o dule) /Re cht lich es, All ge mein es/ Schr ift kon venti on en @ 3\mod_1221059521437_21.docx @ 21714 @ @ 1

Pos: 13 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0. docx @ 2 181 0 @ @ 1

menu item from a menu.

brackets.

Manual

Version 1.2.0

Page 9

WAGO-I/O-SYSTEM 750 XTR Important Notes 9

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 14 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 1Wic hti ge Erlä ut erung en - Üb ersc hrif t 1 @ 4 \mod_1241428899156_21.docx @ 32170 @ 1 @ 1

2 Important Notes

Pos: 15.1 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes Wic htig e E rlä uter ung en - Einl eitung @ 3\mod_1221059818031_21.docx @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 15.2 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2R ec htli che Gru ndl age n - Ü bers chri ft 2 @ 3\mo d_1221060626343_21.docx @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 15.3 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes Ä nderu ngs vor beh alt - Ü b erschr if t 3 und I n halt @ 3 \mod_1221060036484_21.docx @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 15.4 /Serie 750 (WAGO-I/O-SYSTEM)/Wi chtig e Erlä uteru ngen/ Person alqu alifi katio n/Pers onalq ualifi katio n 750- xxxx - Über sc hrift 3 un d In halt @ 3\ mod_1224061208046_21.docx @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 15.5 /Serie 750 (WAGO-I/O-SYSTEM)/Wi chtig e Erlä uteru ngen/ Bestim mung sge mäße Ver wendung /B estim mungsg emäß e Verwe ndung 750-xxxx - Ü bersc hrift 3 und Inh alt @ 3\mod_1224064151234_21.docx @ 24070 @ 3 @ 1

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 1.2.0

Page 10

10 Important Notes WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Appropriate housing (per 2014/34/EU) is required when operating the WAGOI/O-SYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 15.6 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes Tec hnis ch er Z ust and der Ger äte - Üb erschr ift 3 und I nhalt @ 3\mod_1221060446109_21.docx @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 15.7 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 11

WAGO-I/O-SYSTEM 750 XTR Important Notes 11

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 15.8 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2 Sich er heits hi nweis e - Ü b erschr if t 2 @ 6 \mod_1260180299987_21.docx @ 46724 @ 2 @ 1

2.2 Safety Advice (Precautions)

Pos: 15.9 /Al l e Ser ien ( Al lge mei ne M od ule)/ Sic herh eits - u nd s ons tig e Hi nweis e/ Einl eit ung Sic herh eits hin wei se H ar dwar e @ 6\mod_1260180170493_21.docx @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 15.10. 1 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Nic ht an G erät en unter Sp ann ung ar beit en! @ 6\ mod_1260180365327_21.docx @ 46727 @ @ 1

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 15.10. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Gef ahr/ Gefa hr: Ei nbau 07 50- xxxx nur in Geh äusen, Schrä nken oder ele ktrisc hen Betr iebsr äume n! @ 6\mod_1260180556692_21.docx @ 46731 @ @ 1

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 15.10. 3 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Un fall verh üt ungs vors chr ift en b each te n! @ 6\mod_1260180657000_21.docx @ 46735 @ @ 1

Pos: 15.10. 4 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Auf nor mg erec hte n Ans chl uss ac hten! @ 6\mod_1260180753479_21.docx @ 46739 @ @ 1

Pos: 15.11 / All e S erie n (Al lge mei ne M o dule) /Sic h erhei ts- und sons tige Hi nwei s e/Gef ahr /Gef ahr: L eit ung en n ur i n spa nnu ngs frei e m Zust a nd a nsc hliess e n od er tr en nen @ 1 6\mod_1372153982130_21.docx @ 124277 @ @ 1

Only connect or disconnect lines when power is safely isolated!

The lines to the device can carry hazardous voltages and currents. Contact with

the lines when live can result in severe injury or death. Therefore, read and

observe the following safety rules before you perform work on the device:

1. Disconnect the respective system component from the power supply.

2. Secure the system component against unintentional restart.

3. Check if the voltage is positively isolated.

Pos: 15.12 / All e S erie n (Al lge mei ne M o dule) /Sic h erhei ts- und s onst ige Hi nwei se/ Vors ic ht/V orsic ht : H eiße Ober fl äc he all ge mein @ 6\mod_1264428115588_21.docx @ 48610 @ @ 1

Hot surface!

The surface of the housing can become hot during operation. If the device was

operated at high ambient temperatures, allow it to cool off before touching it.

Pos: 15.13. 1 /A lle Ser ien ( Allg em ein e D oku ment e) ( Allg em ein e Mo dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weis e/Ac ht ung /Acht u ng: De fe kte oder bes ch ädig te Ger äte aus tausc h en! @ 6\mod_1260180857358_21.docx @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 15.13. 2 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: Ger äte vor kriec hende n und isol iere nden Sto ffen sc hütze n! @ 6\mod_1260181036216_21.docx @ 46747 @ @ 1

Manual

Version 1.2.0

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 15.13. 3 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: R eini gu ng n ur mit z ul ässig en M at eri alie n! @ 6\mod_1260181203293_21.docx @ 46751 @ @ 1

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 15.13.4 /Alle Serien (Allgemeine Dokumente) (Allgemeine Module)/Wich tig e Er läuter u ngen /Sic h erh eits hin weise /Ac htu ng/ Acht ung : K ein K ont a ktspr ay verw end en! @ 6\ mod_1260181290808_21.docx @ 46755 @ @ 1

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 15.13. 5 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: V erp ol ung ver meide n! @ 6\ mod_1260184045744_21.docx @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 15.13. 6 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: El e ktros tati sc he Entl adung vermeid en! @ 6\mod_1260181364729_21.docx @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Pos: 15.14 / Ser ie 750 ( WA GO-I/ O-SYST EM) /Wic htig e Er läu ter ung en/ Sic her heit s- un d s onsti ge Hin wei se/Ac ht ung /Ac htung : XT R - Isolationsprüfungen mit DC durchführen! @ 15\mod_1370843209441_21.docx @ 122210 @ @ 1

Perform insulation tests with direct current (DC)!

Both the supply voltage and control voltage side are capacitively coupled to the

DIN rail. If the modules are mounted on the DIN rail, application of an AC

voltage between the two potentials can lead to the destruction of the device.

Use only direct current (DC) for insulation testing.

To avoid destroying the device, discharge the device completely before applying

the test voltage again.

Manual

Version 1.2.0

Page 13

WAGO-I/O-SYSTEM 750 XTR System Description 13

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 17.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 1 Syst em bes chr eibung - Ü ber sc hrif t 1 @ 3\ mod_1231491805015_21.docx @ 25850 @ 1 @ 1

3 System Description

Pos: 17.2 /Serie 750 (WAGO-I/O-SYSTEM)/S yst embes chr ei bung /Ger ät und Sys tem /Sy ste mbes chr ei bung - Einl eitu ngssa tz XTR @ 27 \mod_1468507555884_21.docx @ 216920 @ @ 1

The 750 XTR Series is part of the WAGO-I/O-SYSTEM 750.

Pos: 17.3 /Serie 750 (WAGO-I/O-SYSTEM)/S yst embes chr ei bung /Ger ät und Sys tem /Sy ste mbes chr ei bung - Auf bau Fel dbus kn ot en /X TR @ 18\ mod_1392743431433_21.docx @ 145817 @ @ 1

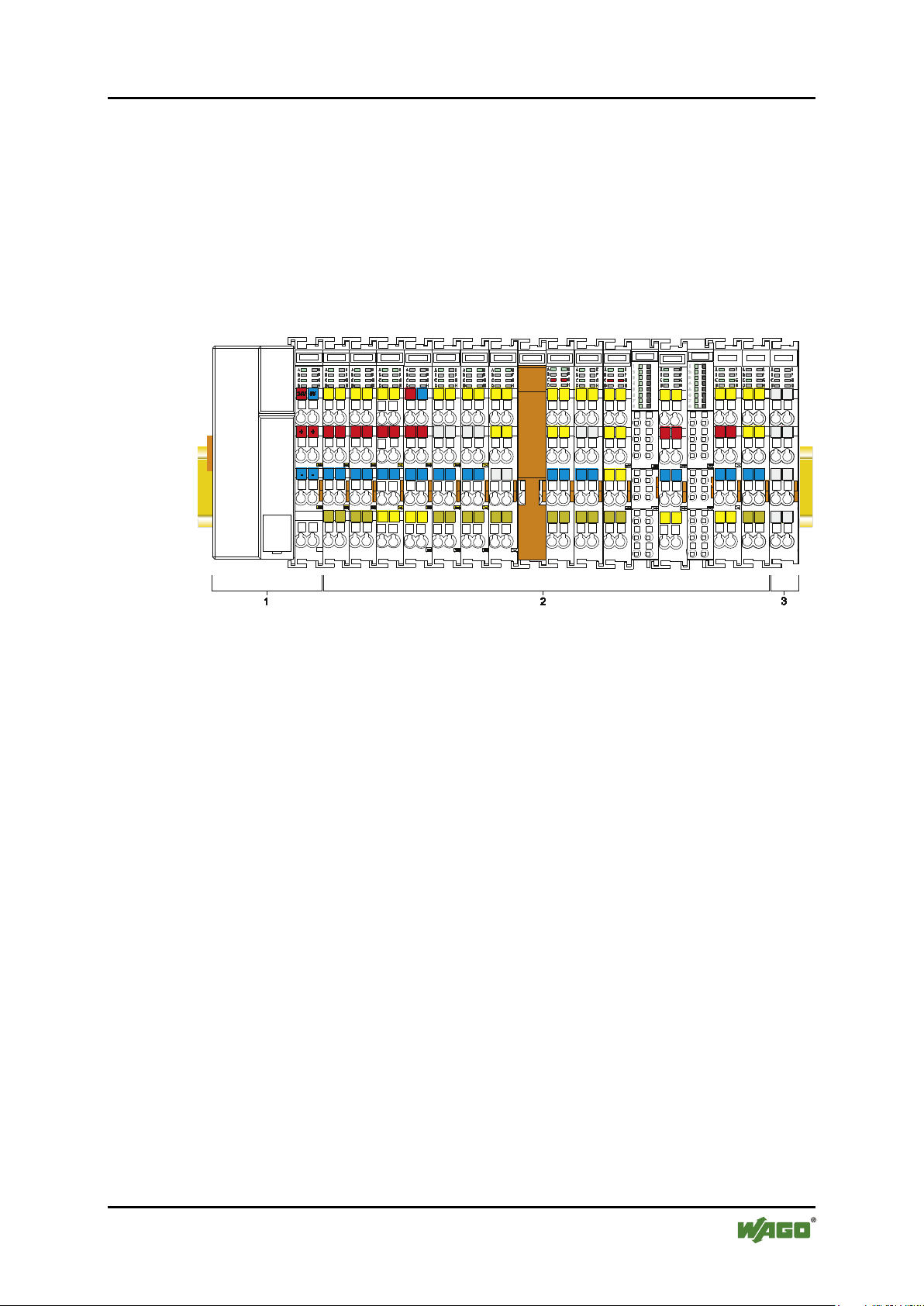

The WAGO-I/O-SYSTEM 750 is a modular, fieldbus-independent input/output

system (I/O system). The configuration described here consists of a fieldbus

coupler/controller (1) and the modular I/O modules (2) for any signal shapes that

form the fieldbus node together. The end module (3) completes the node and is

required for correct operation of the fieldbus node.

Figure 1: Fieldbus Node (Example)

Fieldbus couplers/controllers are available for different fieldbus systems.

Pos: 17.4 /Serie 750 (WAGO-I/O-SYSTEM)/Syste mbes chr ei bung /Ger ät und Sys tem /Sy ste mbes chr ei bung - Besc hr eib ung Auf ba u Fel dbu skn ote n (S tand ard) @ 3\mod_1231493221890_21.docx @ 25870 @ @ 1

The standard fieldbus couplers/controllers contain the fieldbus interface,

electronics and a power supply terminal. The fieldbus interface forms the physical

interface to the relevant fieldbus. The electronics process the data of the I/O

modules and make it available for the fieldbus communication. The 24 V system

supply and the 24 V field supply are fed in via the integrated power supply

terminal.

The fieldbus coupler/controller exchanges process data with the respective control

via the respective fieldbus. The programmable fieldbus controllers (PFC) allow

implementation of additional PLC functions. WAGO-I/O-PRO is used to program

the fieldbus controllers according to IEC 61131-3.

Pos: 17.5 /Serie 750 (WAGO-I/O-SYSTEM)/S yst embes chr ei bung /Ger ät und Sys tem /Sy ste mbes chr ei bung - Ko mmuni kati on Klem menbus , LEDs , 3-Leiter tec h nik @ 3\ mod_1231493520906_21.docx @ 25877 @ @ 1

I/O modules for diverse digital and analog I/O signals as well as special functions

can be connected to the fieldbus coupler/controller. The communication between

the fieldbus coupler/controller and the I/O modules is carried out via an internal

bus.

The components of the WAGO-I/O-SYSTEM 750 have clear termination points,

light emitting diodes for status display, plug-in mini WSB tags and group marker

cards for labeling.

The 1, 2 or 3 wire technology supplemented by a ground wire connection allows

for direct sensor or actuator wiring.

Manual

Version 1.2.0

Page 14

14 System Description WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 17.6 /Serie 750 (WAGO-I/O-SYSTEM)/S yst embes chr ei bung /Ger ät und Sys tem /Sy ste mbes chr ei bung - Ei nführ ung Ser ie 750 XTR @ 27\mod_1468507667008_21.docx @ 216923 @ @ 1

The distinctiveness of the 750 XTR Series lies in its area of application in extreme

environmental conditions. It is extremely temperature-resistant, immune to

interference, as well as insensitive to vibrations and impulse voltages.

The components of the 750 XTR Series are easily recognizable by their dark-gray

housing color.

Pos: 17.7 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 15

WAGO-I/O-SYSTEM 750 XTR System Description 15

01

14

01

01

01

(additional positions)

WW

YY

FW --

HW

FL

-

Calendar

Year

Firmware

Hardware

Firmware

version

Internal information

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 17.8 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schriften/Ebene 2Fertigungsnummer - Überschr ift 2 @ 3\mod_1225444612218_21.docx @ 24889 @ 2 @ 1

3.1 Manufacturing Number

Pos: 17.9.1 /S erie 750 (W AGO- I/O-S YST EM)/G erä te besc hrei bu ng/B edr uc kung /Fer tig ung snu mm er 75 0- xxxx - Einl eit ung FBK/ PFC @ 2 4\mod_1444111422821_21.docx @ 192825 @ @ 1

The serial number indicates the delivery status directly after production. This

number is part of the labeling on the side of each component.

In addition, the serial number is printed on the cover cap of the configuration and

programming interface of the fieldbus coupler/controller, so that it can also be

read when installed.

Pos: 17.9.2 /S erie 750 (W AGO- I/O-S YST EM)/G erä te besc hrei bu ng/B edr uc kung /Fer tig ung snu mm er 75 0- xxxx - Abbil dung und Erlä uteru ng @ 24\mod_1443678328855_21.docx @ 192638 @ @ 1

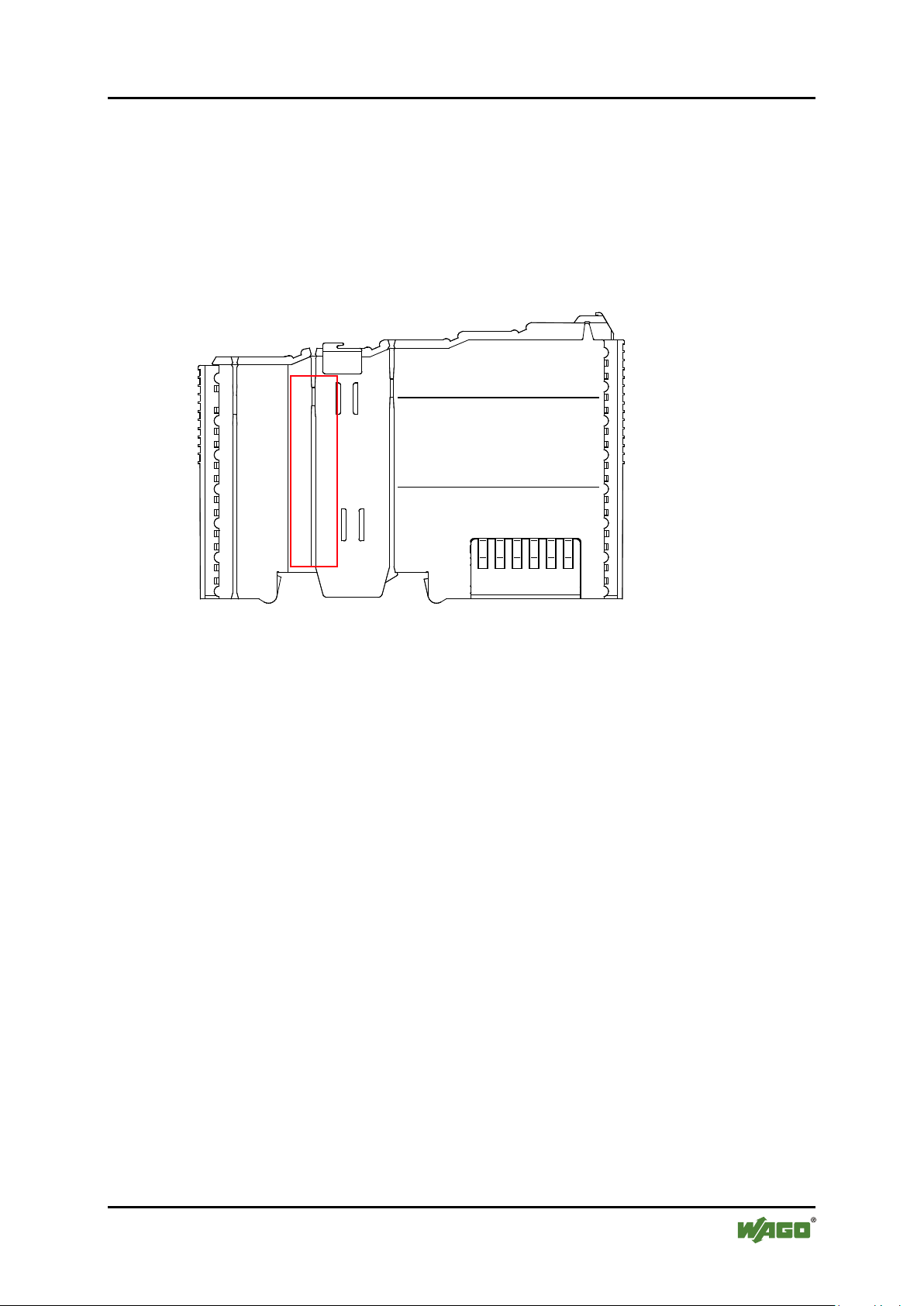

Figure 2: Marking Area for Serial Numbers

There are two serial numbers in two rows in the side marking. They are left of the

release tab. The first 10 positions in the longer row of the serial numbers contain

version and date identifications.

Example structure of the rows: 0114010101…

week

The row order can vary depending on the production year, only the longer row is

relevant. The back part of this and the shorter row contain internal administration

information from the manufacturer.

Pos: 17.10 /D o kum entat io n all ge mei n/Gli ed eru ngsel e ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

version

version

loader

Manual

Version 1.2.0

Page 16

16 System Description WAGO-I/O-SYSTEM 750 XTR

Current Version data for

1. Update

2. Update

3. Update

Production Order

Number

NO

Datestamp

DS

Software index

SW

Hardware index

HW

Firmware loader index

FWL

only for fieldbus

coupler/controller

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 17.11 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Syste mbes chrei bung /Gerä t und Syst em/Ko mpon enten- Upd ate- Matri x a b 20 04 @ 1 6\mod_1373883131873_21.docx @ 126130 @ 2 @ 1

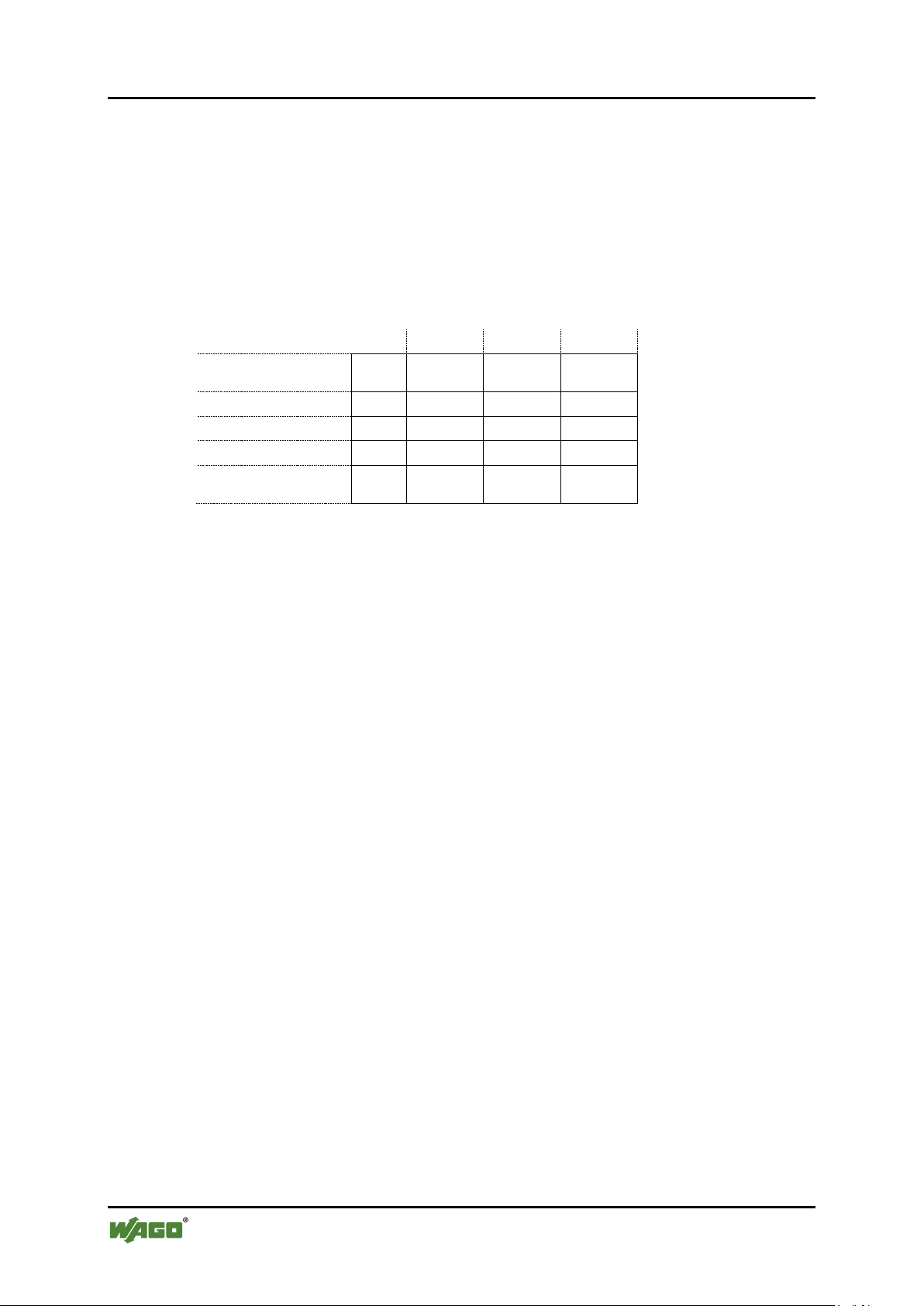

3.2 Component Update

For the case of an update of one component, the lateral marking on each

component contains a prepared matrix.

This matrix makes columns available for altogether three updates to the entry of

the current update data, like production order number (NO), update date (DS),

software version (SW), hardware version (HW) and the firmware loader version

(FWL, if available).

If the update of a component took place, the current version data are registered

into the columns of the matrix.

Additionally with the update of a fieldbus coupler or controller also the cover of

the configuration and programming interface of the fieldbus coupler or fieldbus

controller is printed on with the current manufacturing and production order

number.

The original manufacturing data on the housing of the component remain thereby.

Pos: 17.12 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Syste mbes chrei bung /Gerä t und Syst em/L ageru ng, Kom missi onier ung un d Transp ort @ 3\ mod_1225446600609_21.docx @ 24897 @ 2 @ 1

3.3 Storage, Assembly and Transport

Whenever possible, the components are to be stored in their original packaging.

Likewise, the original packaging provides optimal protection during transport.

When assembling or repacking the components, the contacts must not be soiled or

damaged. The components must be stored and transported in appropriate

containers/packaging. Thereby, the ESD information is to be regarded.

Pos: 17.13 /D o kum entat io n all ge mei n/Gli ed eru ngsel e ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Pos: 17.14 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Syste mbes chrei bung /Gerä t und Syst em/Au fba urichtli nie n und Nor men @ 3\mod_1231311929250_21.docx @ 25820 @ 2 @ 1

3.4 Assembly Guidelines/Standards

• DIN 60204 Electrical equipment of machines

• DIN EN 50178 Electronic equipment for use in power installations

(replacement for VDE 0160)

Pos: 18 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

• EN 60439 Low-voltage switchgear and controlgear assemblies

Page 17

WAGO-I/O-SYSTEM 750 XTR System Description 17

Table 3: Technical Data – Mechanics

Material

Polycarbonate, polyamide

Dimensions W × H*) × D:

Fieldbus coupler/controller (standard)

51 mm × 65*) mm × 100 mm

Fieldbus coupler/controller (ECO)

50 mm × 65*) mm × 100 mm

Fieldbus coupler (expanded ECO)

62 mm × 65*) mm × 100 mm

PLC - Controller (PFC200)

79 mm × 65*) mm × 100 mm

112 mm × 65*) mm × 100 mm

I/O module, single

12 mm × 62*) mm × 100 mm

I/O module, double

24 mm × 62*) mm × 100 mm

I/O module, quadruple

48 mm × 62*) mm × 100 mm

Mounting

On TS 35 with locking

stackable due to

Double slot and key connection

Mounting position

Any

Marking

Standard labels and labels for labeling

holders

Protection type

IP20

*)

From upper-edge of DIN 35 rail

Table 4: Technical Data – Electrical Safety

Clearance/creepage distances

Acc. EN 60255-5, EN 60664-1,

EN 50178, IEEE C37.90

Pollution degree

2

Overvoltage category

III

Rated voltage AC/ DC UB

< 50 V

50 V < UB < 250 V

Test voltage

775 VDC

3.5 kVDC

Rated surge voltage

1 kV (EN 60870-2-1

/ Class VW1)

5 kV (EN 60870-2-1

/ Class VW3)

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 19 /Alle S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 2Tec hni sch e D aten - Ü bersc hrift 2 @ 3\ mod_1232967587687_21.docx @ 26924 @ 2 @ 1

3.5 Technical Data

Pos: 20.1 /Serie 750 (WAGO-I/O-SYSTEM)/G erät eb eschr ei bung /T echni sc he Da te n/S onst ige/ Hi nweis : A kt uell e Wer te den je weil igen Ha ndb ücher n entn ehm en! @ 3\mod_1232967647578_21.docx @ 26960 @ @ 1

Refer to the relevant manuals for current values!

If the technical data of components differ from the values described here, the

technical data shown in the manuals of the respective components shall be valid.

Pos: 20.2 /Serie 750 (WAGO-I/O-SYSTEM)/G eräte beschr eibu ng/T echnisc he Dat en/S onstig e/Mec hani k, Ansc hl., Kont akte , Klim a, Elektr . Sich erheit , IP XTR @ 17\mod_1389346680484_21.docx @ 141078 @ 3333 @ 1

3.5.1 Mechanics

3.5.2 Electrical Safety

Manual

Version 1.2.0

Page 18

18 System Description WAGO-I/O-SYSTEM 750 XTR

Table 5: Technical Data – Field Wiring

Wire connection

CAGE CLAMP® /

Push-in CAGE CLAMP®

Cross section

0.25 mm² … 2.5 mm², AWG 24 … 14 /

0.25 mm² … 1.5 mm², AWG 24 … 16

Stripped lengths

8 mm … 9 mm / 0.33 in

Table 6: Technical Data – Power Jumper Contacts

Power jumper contacts

Blade/spring contact, self-cleaning

Voltage drop at I

max.

< 1 V/64 modules

Current over power jumper contacts

max.

10 A

Table 7: Technical Data – Internal Bus

Data contacts

Slide contact, hard gold plated,

self-cleaning

Table 8: Technical Data – Climatic Environmental Conditions

Operating temperature range

−40 °C … +70 °C

Storage temperature range

−40 °C … +85 °C

Relative humidity

1)

95 %

Elevation above sea level

max.

5000 m

Stress due to contaminants

Acc. IEC 60068-2-42 and IEC 60068-2-43

Max. contaminant concentration at a

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

The components may not be used without

radiation can occur.

1)

Short-term condensation acc. class 3K7 / IEC EN 60721-3-3 (except wind-driven precipitation,

water and ice formation) permitted

750-xxxx/0040-xxxx Design Notes /XTR

3.5.3 Connection Type

3.5.4 Climatic Environmental Conditions

without temperature derating

with temperature derating

0 m … 2000 m

2000 m … 5000 m: 0.5 K per 100 m

relative humidity < 75%

Pos: 20.3 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

additional measures at locations in which

dust, corrosive fumes, gases or ionized

Page 19

WAGO-I/O-SYSTEM 750 XTR System Description 19

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 20.4 /Serie 750 (WAGO-I/O-SYSTEM)/G erät eb eschr ei bung /T echni sc he Da te n/EM V/Ei ns atz ber eich XTR (In dustr ie, Woh nber eich) @ 17 \mod_1389356140919_21.docx @ 141147 @ 3 @ 1

3.5.5 Residential Use

The system with the fieldbus coupler/controller meets the requirements for

interference emissions in residential areas:

• ETHERNET 750-352/040-000

750-880/040-000

750-880/040-001

750-8202/040-000

750-8202/040-001

750-8206/040-000

750-8206/040-001

• CANopen 750-338/040-000

750-838/040-000

With individual approval, the system can also be used for residential use

(residential, business and commercial areas, small business) with other fieldbus

couplers/controllers. The individual approval can be obtained from a

governmental or testing agency. In Germany, the Federal Office for Post and

Telecommunications and its extensions issue the individual approval.

Use of other fieldbus couplers/controllers is possible under certain conditions.

Please contact WAGO Kontakttechnik GmbH & Co. KG.

Pos: 20.5 /Serie 750 (WAGO-I/O-SYSTEM)/G erät eb eschr ei bung /T echni sc he Da te n/A bmess u nge n/Ab mess ung en XTR (sc hmal ) @ 18\ mod _1392189220217_21.docx @ 145161 @ 3 @ 1

Manual

Version 1.2.0

Page 20

20 System Description WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

3.5.6 Example Dimensions

Figure 3: Dimensions – Nodes with Fieldbus Coupler/Controller (Example)

Pos: 21 /D okum ent atio n al lge mein/ Gli eder ungs ele me nte/---Sei te nwec hsel--- @ 3\ mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 21

WAGO-I/O-SYSTEM 750 XTR Standards and Approvals 21

Table 9: Climatic and Mechanical Environmental Conditions

Range

Acc. Standard

Title

Environmental testing

EN 61131-2

Programmable logic controller, testing

EN 60721-3-1

Environmental conditions – long-term

storage

EN 60721-3-3

Environmental conditions – stationary

use, weather-protected

EN 60870-2-2

Telecontrol equipment – environmental

conditions

EN 61850-3

Communication networks and systems

in stations

IEEE 1613

Environmental and Testing

Requirements in Power Substations

Shipbuilding

Systems for maritime shipping

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 22 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 1N or men und Z ul ass unge n - Ü bersc hrift 1 @ 15\mod_1366723683236_21.docx @ 117687 @ 1 @ 1

4 Standards and Approvals

Pos: 23.1 /Serie 750 (WAGO-I/O-SYSTEM)/G erät eb eschr ei bung /N ormen un d Ri chtl ini en/ Nor men un d Ric htl ini en 7 5x- xxx Systembesc hreibung @ 18\mod_1393329414685_21.docx @ 146305 @ @ 1

The WAGO-I/O-SYSTEM 750 XTR series was tested according to the following

standards and guidelines. The test values are available in the manual of the

respective I/O module or fieldbus coupler/controller:

Pos: 23.2 /Serie 750 (WAGO-I/O-SYSTEM)/G erät eb eschr ei bung /N ormen un d Ri chtl ini en/ Nor men un d Ric htl ini en XT R - Mech anik un d Klim a Syste mbesc hreib ung @ 18\ mod_1394618852600_21.docx @ 147748 @ @ 1

Pos: 23.3 /Al l e Ser ien ( Al lge mei ne M od ule)/N or me n un d Ric htli ni en/N or men und R ic htli nie n XT R - EMV - S yste mb esc hrei bung @ 16\mod_1378286378361_21.docx @ 130729 @ @ 1

Compliance with the standards is component-dependent

Depending on the selected components, there may be limitations in the

performance of individual EMC standards.

Therefore, observe the section “Standards and Guidelines” in the manual of your

I/O modules or fieldbus coupler/controller!

Manual

Version 1.2.0

Page 22

22 Standards and Approvals WAGO-I/O-SYSTEM 750 XTR

Table 10: EMC

Range

acc. standard

Title

EMC immunity to

EN 61000-6-1

EMC – Generic Standard – Immunity

for residential environments

EN 61000-6-2

EMC – Generic Standard – Immunity

for industrial environments

EN 61131-2

Programmable logic controller – testing

Shipbuilding

Systems for maritime shipping

EN 50121-3-2

EMC – Railway applications –

Apparatus

EN 50121-4

Railway applications – EMC –

Emission and immunity

EN 50121-5

Railway applications – EMC –

Emission and immunity

EN 60255-26

Measuring relays and protection

equipment – EMC

EN 60870-2-1

Telecontrol equipment – EMC

EN 61850-3

Communication networks and systems

in stations – General requirements

IEC 61000-6-5

Immunity for power station and

substation environments

IEEE 1613

Environmental and Testing

Requirements in Power Substations

VDEW: 1994

Digital station technology –

Recommendations

EMC emission of

EN 61000-6-3

EMC – Generic standard – Emission

standard for residential environments

EN 61000-6-4

EMC – Generic standard – Emission

standard for industrial environments

EN 61131-2

Programmable logic controller – testing

Shipbuilding

Systems for maritime shipping

EN 50121-3-2

EMC – Railway applications –

Apparatus

EN 50121-4

Railway applications – EMC –

Emission and immunity

EN 50121-5

Railway applications – EMC –

Emission and immunity

EN 60255-26

Measuring relays and protection

equipment – EMC

EN 60870-2-1

Telecontrol equipment – EMC

EN 61850-3

Communication networks and systems

in stations – General requirements

750-xxxx/0040-xxxx Design Notes /XTR

interference

Pos: 24 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

interference

Manual

Version 1.2.0

Page 23

WAGO-I/O-SYSTEM 750 XTR Assembly 23

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 25 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 1M on tag e - Ü bersc hri ft 1 @ 1 5\mod_1366723611709_21.docx @ 117655 @ 1 @ 1

5 Assembly

Pos: 26.1 /Serie 750 (WAGO-I/O-SYSTEM)/Montieren/Demontieren/Einbaulage XTR @ 16\mod_1373976754254_21.docx @ 126292 @ 2 @ 1

5.1 Mounting Position

The following mounting positions are approved:

• Lying horizontal

• Standing horizontal

• Vertical

Use an end stop in the case of vertical installation!

When installed vertically, also mount an end stop below the fieldbus node to

protect the fieldbus node against sliding.

WAGO item number 249-116 end stop for TS 35, 6 mm wide

WAGO item number 249-117 end stop for TS 35, 10 mm wide

Pos: 26.2 /Serie 750 (WAGO-I/O-SYSTEM)/Mon tiere n/De monti eren/ Gesam taus bau XTR @ 16 \mod_1373976975062_21.docx @ 126295 @ 2 @ 1

5.2 Overall Configuration

The maximum total length of a fieldbus node without fieldbus coupler/controller

is 780 mm including end module. The width of the end module is 12 mm. When

assembled, the I/O modules have a maximum length of 768 mm.

Examples:

• 64 I/O modules with a 12 mm width can be connected to a fieldbus

coupler/controller.

• 32 I/O modules with a 24 mm width can be connected to a fieldbus

coupler/controller.

Exception:

The number of connected I/O modules also depends on the type of fieldbus

coupler/controller is used. For example, the maximum number of stackable I/O

modules on one PROFIBUS DP/V1 fieldbus coupler/controller is 63 with no

passive I/O modules and end module.

Observe maximum total length of a fieldbus node!

The maximum total length of a fieldbus node without fieldbus coupler/controller

may not exceed 780 mm.

Also note the limitations of individual fieldbus couplers/controllers.

Pos: 26.3 /Serie 750 (WAGO-I/O-SYSTEM )/M on tiere n/D em onti ere n/M ont age auf T r agsc hien e ( XTR) @ 2 4\mod_1444997402760_21.docx @ 193805 @ 233 @ 1

Manual

Version 1.2.0

Page 24

24 Assembly WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

5.3 Mounting onto Carrier Rail

5.3.1 Carrier Rail Properties

All system components can be snapped directly onto a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

Do not use any third-party carrier rails without approval by WAGO!

WAGO Kontakttechnik GmbH & Co. KG supplies standardized carrier rails that

are optimal for use with the I/O system. If other carrier rails are used, then a

technical inspection and approval of the rail by WAGO Kontakttechnik GmbH &

Co. KG should take place.

Carrier rails have different mechanical and electrical properties. For the optimal

system setup on a carrier rail, certain guidelines must be observed:

• The material must be non-corrosive.

• Most components have a contact to the carrier rail to ground electro-

magnetic disturbances. In order to avoid corrosion, this tin-plated carrier rail

contact must not form a galvanic cell with the material of the carrier rail

which generates a differential voltage above 0.5 V (saline solution of 0.3 %

at 20°C).

• The carrier rail must optimally support the EMC measures integrated into

the system and the shielding of the I/O module connections.

• A sufficiently stable carrier rail should be selected and, if necessary, several

mounting points (every 20 cm) should be used in order to prevent bending

and twisting (torsion).

• The geometry of the carrier rail must not be altered in order to secure the

safe hold of the components. In particular, when shortening or mounting the

carrier rail, it must not be crushed or bent.

• The base of the I/O components extends into the profile of the carrier rail.

For carrier rails with a height of 7.5 mm, mounting points are to be riveted

under the node in the carrier rail (slotted head captive screws or blind

rivets).

• The medal springs on the bottom of the housing must have low-impedance

contact with the DIN rail (wide contact surface is possible).

Manual

Version 1.2.0

Page 25

WAGO-I/O-SYSTEM 750 XTR Assembly 25

Table 11: WAGO DIN Rail

Order number

Description

210-112 /-113

35 × 7.5;

1 mm;

steel yellow chromated; slotted/unslotted

210-197 /-114

35 × 15;

1.5 mm;

steel yellow chromated; slotted/unslotted

210-118

35 × 15;

2.3 mm;

steel yellow chromated; unslotted

210-198

35 × 15;

2.3 mm;

copper; unslotted

210-196

35 × 8.2;

1.6 mm;

aluminum; unslotted

Table 12: Permissible WAGO Carrier Rails When Using XTR PFC200

Item Number

750-8202/040-00x

750-8206/040-00x

210-113 × –

210-114 × –

210-197 × –

210-118 × ×

750-xxxx/0040-xxxx Design Notes /XTR

5.3.2 WAGO DIN Rail

WAGO carrier rails meet the electrical and mechanical requirements shown in the

table below.

Pos: 26.4 /Serie 750 (WAGO-I/O-SYSTEM)/Montieren/Demontieren/Busklemmen 750xxxx/0040xxxx 4g-5g @ 15\mod_1367558844291_21.docx @ 118470 @ @ 1

For vibration loads > 4g, observe the following installation instructions:

• Use pan-head screws or blind rivets at least every 60 mm (12 mm pin

spacing) to secure the DIN rail.

• Make the open conductor length between strain relief and wire connection

as short as possible.

Pos: 26.5 /Serie 750 (WAGO-I/O-SYSTEM)/M onti ere n/D em ontier en/ A uswa hl d er T rag schi ene für XTR- PFC @ 23\mod_1435150387049_21.docx @ 184498 @ @ 1

• Use the reinforced end stop 249-197.

• When using the PFC200 CS 2ETH RS/XTR (750-8202/040-00x), carrier

rails without an oblong hole must also be used. Alternatively, a material

thickness of min. 1.5 mm must be maintained.

• When using the PFC200 CS 2ETH RS CAN DPS/XTR

(750-8206/040-00x), carrier rails without an oblong hole with a material

thickness of min. 2.3 mm must also be used.

Pos: 26.6 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 26

26 Assembly WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 26.7 /Serie 750 (WAGO-I/O-SYSTEM)/M onti ere n/D emon tier en/ Abs tän de @ 3\ mod_1225448283750_21.docx @ 24920 @ 2 @ 1

5.4 Spacing

The spacing between adjacent components, cable conduits, casing and frame sides

must be maintained for the complete fieldbus node.

Figure 4: Spacing

The spacing creates room for heat transfer, installation or wiring. The spacing to

cable conduits also prevents conducted electromagnetic interferences from

influencing the operation.

Pos: 26.8 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 27

WAGO-I/O-SYSTEM 750 XTR Assembly 27

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 26.9 /Serie 750 (WAGO-I/O-SYSTEM)/M ontier en/D emont ieren/M ont agerei henf olge @ 3\ mod_1231770210031_21.docx @ 25992 @ 2 @ 1

5.5 Mounting Sequence

Fieldbus couplers/controllers and I/O modules of the WAGO-I/O-SYSTEM

750/753 are snapped directly on a carrier rail in accordance with the European

standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual devices are securely seated

on the rail after installation.

Starting with the fieldbus coupler/controller, the I/O modules are mounted

adjacent to each other according to the project design. Errors in the design of the

node in terms of the potential groups (connection via the power contacts) are

recognized, as the I/O modules with power contacts (blade contacts) cannot be

linked to I/O modules with fewer power contacts.

Pos: 26.10 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Vor sic ht/ Vors ic ht: V erl etzungsgefahr durch scharfkantige Messerkontakte! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Pos: 26.11 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Ac htu ng/Ac ht ung: Bus kl em men nur i n v orges e hen er Rei he nfol ge stec ken! @ 6\mod_1256194177073_21.docx @ 43429 @ @ 1

Insert I/O modules only from the proper direction!

All I/O modules feature grooves for power jumper contacts on the right side. For

some I/O modules, the grooves are closed on the top. Therefore, I/O modules

featuring a power jumper contact on the left side cannot be snapped from the top.

This mechanical coding helps to avoid configuration errors, which may destroy

the I/O modules. Therefore, insert I/O modules only from the right and from the

top.

Pos: 26.12 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Ac htu ng/Ac ht ung: XTR -Ab schni tte aus schli eßlic h mit XTR- Eins peis e kle mmen begi nn en @ 27\ mod_1468396316258_21.docx @ 216628 @ @ 1

XTR sections begin with XTR supply modules exclusively!

The power jumper contacts of XTR products use a contact material different than

other WAGO-I/O-SYSTEM 750 products.

Connecting power jumper contacts of XTR products to power jumper contacts of

non-XTR products leads to irreversible deterioration in contact characteristics in

the long run.

Therefore, start sections of XTR I/O modules with an XTR supply module.

Only connect XTR I/O modules after XTR supply modules, never otherwise.

Pos: 26.13 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Hi nwei s/Hi n weis : Bus a bsc hluss XTR nic ht verg ess en! @ 15\mod_1368426836647_21.docx @ 119458 @ @ 1

Manual

Version 1.2.0

Page 28

28 Assembly WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Don't forget the bus end module!

Always plug a bus end module 750-600/040-000 onto the end of the fieldbus

node! You must always use this bus end module at all fieldbus nodes with the

WAGO I/O System 750 XTR fieldbus couplers/controllers to guarantee proper

data transfer.

Pos: 26.14 /D o kum entat io n all gem ei n/Gli eder ungs ele ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 29

WAGO-I/O-SYSTEM 750 XTR Assembly 29

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 26.15 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Monti ere n/De montier en/G erät e einfüge n und ent fern en - Übers chr ift 2 @ 3\mod_1231768483250_21.docx @ 25950 @ 2 @ 1

5.6 Inserting and Removing Devices

Pos: 26.16 / All e S erie n (Al lge mei ne M o dule) /Sic h erhei ts- und sonstige Hinweise/Achtung/Achtung: Arbeiten an Geräten nur spannungsfrei durchführen! @ 6\mod_1256193963573_21.docx @ 43426 @ @ 1

Perform work on devices only if they are de-energized!

Working on energized devices can damage them. Therefore, turn off the power

supply before working on the devices.

Pos: 26.17 / Ser ie 750 ( WA GO-I/ O-SY STEM )/M onti ere n/De monti ere n/F eldb us koppl er/-c ontr oll er ei nf üge n @ 3\mod_1234168173031_21.docx @ 27456 @ 3 @ 1

5.6.1 Inserting the Fieldbus Coupler/Controller

1. When replacing the fieldbus coupler/controller for an already available

fieldbus coupler/controller, position the new fieldbus coupler/controller so

that the tongue and groove joints to the subsequent I/O module are engaged.

2. Snap the fieldbus coupler/controller onto the carrier rail.

3. Use a screwdriver blade to turn the locking disc until the nose of the locking

disc engages behind the carrier rail (see the following figure). This prevents

the fieldbus coupler/controller from canting on the carrier rail.

With the fieldbus coupler/controller snapped in place, the electrical connections

for the data contacts and power contacts (if any) to the possible subsequent I/O

module are established.

Pos: 26.18 / Ser ie 750 ( WA GO-I/ O-SY STEM )/M onti ere n/De monti ere n/V erri egel ung - Bil d (S tand ar d) @ 3\mod_1231768944875_21.docx @ 25953 @ @ 1

Figure 5: Release Tab Standard Fieldbus Coupler/Controller (Example)

Pos: 26.19 / Ser ie 750 ( WA GO-I/ O-SY STEM )/M onti ere n/De monti ere n/F eldb us koppl er/-c ontrol ler ent fer nen @ 4\mod_1239169358453_21.docx @ 30330 @ 3 @ 1

5.6.2 Removing the Fieldbus Coupler/Controller

1. Use a screwdriver blade to turn the locking disc until the nose of the locking

disc no longer engages behind the carrier rail.

2. Remove the fieldbus coupler/controller from the assembly by pulling the

release tab.

Electrical connections for data or power contacts to adjacent I/O modules are

disconnected when removing the fieldbus coupler/controller.

Pos: 26.20 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Monti ere n/De montier en/Bus kle mme einf ügen @ 3\mod_1231769726703_21.docx @ 25989 @ 3 @ 1

Manual

Version 1.2.0

Page 30

30 Assembly WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

5.6.3 Inserting the I/O Module

1. Position the I/O module so that the tongue and groove joints to the fieldbus

coupler/controller or to the previous or possibly subsequent I/O module are

engaged.

Figure 6: Insert I/O Module (Example)

2. Press the I/O module into the assembly until the I/O module snaps into the

carrier rail.

Figure 7: Snap the I/O Module into Place (Example)

With the I/O module snapped in place, the electrical connections for the data

contacts and power jumper contacts (if any) to the fieldbus coupler/controller or to

the previous or possibly subsequent I/O module are established.

Pos: 26.21 /D o kum entat io n all ge mei n/Gli ed eru ngsel e ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 31

WAGO-I/O-SYSTEM 750 XTR Assembly 31

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 26.22 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Monti ere n/De montier en/Bus kle mme ent ferne n @ 4\mod_1239169375203_21.docx @ 30334 @ 3 @ 1

5.6.4 Removing the I/O Module

1. Remove the I/O module from the assembly by pulling the release tab.

Figure 8: Removing the I/O Module (Example)

Electrical connections for data or power jumper contacts are disconnected when

removing the I/O module.

Pos: 26.23 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /G efahr /G efahr : V ors ich t bei d er Un ter brec hung v on F E! - XTR @ 18 \mod_1389853538533_21.docx @ 142058 @ @ 1

Use caution when interrupting the FE!

With I/O modules for 220/230 VAC, make sure that people or equipment are not

placed at risk when removing an I/O module and the associated FE interruption

(function grounding). To prevent interruptions, provide ring feeding of the ground

conductor, see section “Grounding”.

Pos: 27 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 32

32 Connect Devices WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 28 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 1Ger ät e an schl ieß en - Ü b erschr if t 1 @ 3 \mod_1234172889468_21.docx @ 27460 @ 1 @ 1

6 Connect Devices

Pos: 29 /All e S eri en ( Allg emei n e Mod ule)/ Sic her heits- und s onsti ge H in weis e/G efa hr/ Gefa hr: Lei tung en nur i n s pan nung sfr eie m Z usta nd ans chli esse n o der tre nne n @ 16\mod_1372153982130_21.docx @ 124277 @ @ 1

Only connect or disconnect lines when power is safely isolated!

The lines to the device can carry hazardous voltages and currents. Contact with

the lines when live can result in severe injury or death. Therefore, read and

observe the following safety rules before you perform work on the device:

1. Disconnect the respective system component from the power supply.

2. Secure the system component against unintentional restart.

3. Check if the voltage is positively isolated.

Pos: 30.1 /Serie 750 (WAGO-I/O-SYSTEM)/Ans chl ieß en/D aten ko nta kte/Kl em menb us - Ü ber schr ift 2 @ 7\ mod_1266320620183_21.docx @ 50 718 @ 2 @ 1

6.1 Data Contacts/Internal Bus

Pos: 30.2 /Serie 750 (WAGO-I/O-SYSTEM)/G eräte bes chr eibu ng/A nsc hlüs se/D ate nkon takt e - F eldbu s koppler /-c ontr oll er, A b bild ung und Besc hr eibu ng @ 3 \mod_1231771259187_21.docx @ 26002 @ @ 1

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 9: Data Contacts

Pos: 30.3 /Serie 750 (WAGO-I/O-SYSTEM)/Wicht ige Erl äuter unge n/Sich erhei ts- u nd so nstig e H in weis e/ Acht ung /Ach tu ng: Buskl em men nic ht a uf Gol dfe der konta kt e leg en! @ 7 \mod_1266318463636_21.docx @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 30.4 /Serie 750 (WAGO-I/O-SYST EM)/ Wichti ge Erl äuter unge n/Sich erhei ts- und sonstige Hinweise/Achtung/Achtung: ESD - Auf gute Erdung der Umg ebu ng ac ht en! @ 7\ mod_1266318538667_21.docx @ 50708 @ @ 1

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 30.5 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 33

WAGO-I/O-SYSTEM 750 XTR Connect Devices 33

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 30.6 /Serie 750 (WAGO-I/O-SYSTEM)/Ans chl ieß en/ Leis tung skon tak te/F eld versor gu ng - Ü bers chr ift 2 @ 7\mod_1266320656354_21.docx @ 50722 @ 2 @ 1

6.2 Power Contacts/Field Supply

Pos: 30.7 /Serie 750 (WAGO-I/O-SYSTEM)/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/V orsic ht/ Vor sic ht: Verl etz ungs ge fahr dur ch s ch arf kan tige M es ser kont a kte! @ 6\ mod_1256193279401_21.docx @ 43414 @ @ 1

Pos: 30.8 /Serie 750 (WAGO-I/O-SYSTEM)/G eräte beschr eibu ng/Ans chl üsse/L eistu ngs kontakt e allge mein @ 3\ mod_1231828902046_21.docx @ 26017 @ @ 1

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Self-cleaning power jumper contacts used to supply the field side are located on

the right side of most of the fieldbus couplers/controllers and on some of the I/O

modules. These contacts come as touch-proof spring contacts. As fitting

counterparts the I/O modules have male contacts on the left side.

Figure 10: Example for the Arrangement of Power Contacts

Pos: 30.9 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 34

34 Connect Devices WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 30.10 / Ser ie 750 ( WA GO-I/ O-SY STEM )/A nsc hli eße n/Lei ter an CA GE C LAM P a nsc hließ en (all ge mein) - Üb ers chrif t 2 un d Te xt @ 3\mod_1225448660171_21.docx @ 24928 @ 2 @ 1

6.3 Connecting a Conductor to the CAGE CLAMP®

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded and

finely stranded conductors.

Only connect one conductor to each CAGE CLAMP®!

Only one conductor may be connected to each CAGE CLAMP®.

Do not connect more than one conductor at one single connection!

If more than one conductor must be routed to one connection, these must be

connected in an up-circuit wiring assembly, for example using WAGO feedthrough terminals.

1. For opening the CAGE CLAMP® insert the actuating tool into the opening

above the connection.

2. Insert the conductor into the corresponding connection opening.

3. For closing the CAGE CLAMP® simply remove the tool. The conductor is

now clamped firmly in place.

Figure 11: Connecting a Conductor to a CAGE CLAMP

Pos: 31 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

®

Manual

Version 1.2.0

Page 35

WAGO-I/O-SYSTEM 750 XTR Connect Devices 35

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 32 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Ans chließ en/L eiter a n Push-in CAGE CL AMP® anschließen - Über sc hrift 2 u nd T e xt @ 6\mod_1258964749000_21.docx @ 44640 @ 2 @ 1

6.4 Connecting a Conductor to the Push-in CAGE

®

CLAMP

The Push-in CAGE CLAMP® connection is appropriate for solid, stranded and

finely stranded conductors.

Only connect one conductor to each Push-in CAGE CLAMP® connection!

Only one conductor may be connected to each Push-in CAGE CLAMP®

connection.

Do not connect more than one conductor at one single connection!

If more than one conductor must be routed to one connection, these must be

connected in an up-circuit wiring assembly, for example using WAGO feedthrough terminals.

Terminate both solid and stranded or ferruled conductors by simply pushing them

in - no tool required. For all other types of conductors, Push-in CAGE CLAMP®

must be opened for connection with an operating tool with a 2.5 mm blade (order

no. 210-719).

1. To open the Push-in CAGE CLAMP® insert the actuating tool into the

opening above the connection.

2. Insert the conductor into the corresponding connection opening.

3. To close the Push-in CAGE CLAMP® simply remove the tool - the

conductor is then clamped firmly in place.

Figure 12: Connecting a Conductor to a Push-in CAGE CLAMP

®

Pos: 33 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 36

36 Connect Devices WAGO-I/O-SYSTEM 750 XTR

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 34.1 /Serie 750 (WAGO-I/O-SYSTEM)/S yste mbesc hrei b ung/ Vers orgu ng/S pan nung sv ersor gung - Üb erschr ift 2 @ 3\mod_1232950078953_21.docx @ 26680 @ 2 @ 1

6.5 Power Supply

Pos: 34.2 /Serie 750 (WAGO-I/O-SYSTEM)/Syst embes chrei bung /Vers orgu ng/Pot enti altren nung @ 3\mod_1232950094125_21.docx @ 26732 @ 3 @ 1

6.5.1 Isolation

Within the fieldbus node, there are three electrically isolated potentials:

• Electrically isolated fieldbus interface via transformer

• Electronics of the fieldbus couplers/controllers and the I/O modules

(internal bus)

• All I/O modules have an electrical isolation between the electronics

(internal bus, logic) and the field electronics. Some digital and analog input

modules have each channel electrically isolated, please see catalog.

Pos: 34.3 /Serie 750 (WAGO-I/O-SYSTEM)/S yste mbesc hrei b ung/ Vers orgu ng/P ot ential tr ennung - Bi ld (St and ard + er weit ert er E CO) @ 3\mod_1232950095187_21.docx @ 26740 @ @ 1

Figure 13: Isolation for Fieldbus Couplers/Controllers (Example)

Pos: 34.4 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 37

WAGO-I/O-SYSTEM 750 XTR Connect Devices 37

Table 13: Legend for Figure “System Voltage for Fieldbus Couplers/Controllers”

Position

Description

1

System supply DC 24 V

2

System supply 0 V

750-xxxx/0040-xxxx Design Notes /XTR

Pos: 34.5 /Serie 750 (WAGO-I/O-SYST EM) /S yste mbesc hrei bung /Ver sor gu ng/S yste mver sor gung - Üb ersc hrif t 3 @ 3 \mod_1232950096265_21.docx @ 26748 @ 3 @ 1

6.5.2 System Supply

Pos: 34.6 /Serie 750 (WAGO-I/O-SYSTEM)/S yste mbesc hrei b ung/ Vers orgu ng/S yste mver sor gung - A nsc hluss @ 3\mod_1232950096796_21.docx @ 26752 @ 4 @ 1

6.5.2.1 Connection

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply.

The power supply is provided via the fieldbus coupler/controller and, if necessary,

in addition via internal system supply modules 750-613. The power supply is

reverse voltage protected.

Do not use an incorrect voltage/frequency!

The use of an incorrect supply voltage or frequency can cause severe damage to

the components.

Pos: 34.7 /Serie 750 (WAGO-I/O-SYSTEM)/S yste mbeschr eib ung/Ver sorg ung/S ystem vers orgung XTR - Ans chl uss - S yst em vers org ung (St and ard + er wei ter ter ECO) mi t LW L-Anz eige @ 16\mod_1373884059484_21.docx @ 126140 @ @ 1

Figure 14: System Voltage for Fieldbus Couplers/Controllers (Example)

Pos: 34.8 /Serie 750 (WAGO-I/O-SYSTEM)/S yste mbesc hrei b ung/ Vers orgu ng/S yste mver sor gung - A nsc hluss - Die eing es peis te 2 4 V- Glei chsp annung versor gt... @ 3\mod_1232950097328_21.docx @ 26756 @ @ 1

The fed DC 24 V supplies all internal system components, e.g. fieldbus

coupler/controller electronics, fieldbus interface and I/O modules via the internal

bus (5 V system voltage). The 5 V system voltage is galvanically connected to the

24 V system supply.

Pos: 34.9 /Serie 750 (WAGO-I/O-SYSTEM)/S yste mbeschr eib ung/Ver sorg ung/S ystem vers orgung XTR - Ans chl uss - S yst ems pa nnu ng (S tan dar d + er w eiter ter ECO ) o B @ 16\mod_1373884429295_21.docx @ 126143 @ @ 1

Manual

Version 1.2.0

Page 38

38 Connect Devices WAGO-I/O-SYSTEM 750 XTR

Table 14: Alignment

Internal current

consumption*)

Current consumption via system voltage (5 V for electronics

of I/O modules and fieldbus coupler/controller).

Total current

Available current for the I/O modules. Provided by the bus

internal system supply module

*)

See current catalog, manuals, Internet

750-xxxx/0040-xxxx Design Notes /XTR

Figure 15: System Supply for Fieldbus Coupler/Controller

Pos: 34.10 / Ser ie 750 ( WA GO-I/ O-SY STEM )/S yste mbes chr eibu ng/V ers org ung/ Syst em versor gu ng - Ans chl uss - H i nwei s: Gleic hz. Rü ckse tz en al ler Ver sorg ung s modul e @ 3\mod_1232950097906_21.docx @ 26760 @ @ 1

Only reset the system simultaneously for all supply modules!

Reset the system by switching the system supply simultaneously at all supply

modules (fieldbus coupler/controller and potential supply module with bus power

supply) off and on again.

Pos: 34.11 / Ser ie 750 ( WA GO-I/ O-SY STEM )/S yste mbes chr eibu ng/V ers org ung/ Systemversorgung - Auslegung @ 3\mod_1232950104812_21.docx @ 26780 @ 4 @ 1

6.5.2.2 Dimensioning

Recommendation

A stable power supply cannot always be assumed. Therefore, you should use