Page 1

Pos: 2 /Do kumentation allgemein /Einband/ Einband H andbuch - De ckblatt o hne Varia ntenfeld (S tandard) @ 9\mod_1285229289866_0 .doc @ 64941 @ @ 1

Manual

WAGO-I/O-SYSTEM 750

Channel Relay Ou t put Module AC 230 V, DC 30 V,

2DO 230V AC 2.0A/ Relay 2NO

750-512

2-

non-floating; 2 make contacts

Version 1.2.0

Pos: 3 /Alle Serien (Al lgemeine M odule)/H inweise zur Dokumen tation/Im pressum für St a nd ar d handbüch er - all g . Ang aben, Ansc hr if ten, Telef on n ummern und E-M ail-Adress en @ 3\mod_1219151118203_21.doc @ 21 060 @ @ 1

Page 2

2 WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

© 2013 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

=== Ende der Liste für Textmar ke Einband _vorne ===

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Manual

Version 1.2.0

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 5 /Do kumentation allgemein /Verzeich nisse/Inh altsverzei chnis - Über schrift oG und Verzei chnis @ 3 \mod_1219151230875_21.doc @ 21063 @ @ 1

Table of Contents

1 Notes about this Documentation ................................................................. 5

1.1 Validity of this Documentation ................................................................. 5

1.2 Copyright ................................................................................................... 5

1.3 Symbols ..................................................................................................... 6

1.4 Number Notation ....................................................................................... 8

1.5 Font Conventions ...................................................................................... 8

2 Important Notes ........................................................................................... 9

2.1 Legal Bases ............................................................................................... 9

2.1.1 Subject to Changes ............................................................................... 9

2.1.2 Personnel Qualifications ....................................................................... 9

2.1.3 Use of the 750 Series in Compliance with Underlying Provisions ...... 9

2.1.4 Technical Condition of Specified Devices ......................................... 10

2.2 Safety Advice (Precautions) .................................................................... 11

3 Device Description ..................................................................................... 13

3.1 View ........................................................................................................ 15

3.2 Connectors ............................................................................................... 16

3.2.1 Data Contacts/Internal Bus ................................................................. 16

3.2.2 Power Jumper Contacts/Field Supply ................................................ 17

3.2.3 CAGE CLAMP® Connections ........................................................... 18

3.3 Display Elements .................................................................................... 19

3.4 Operating Elements ................................................................................. 19

3.5 Schematic Diagram ................................................................................. 20

3.6 Technical Data ........................................................................................ 21

3.6.1 Device Data ........................................................................................ 21

3.6.2 Power Supply...................................................................................... 21

3.6.3 Communication .................................................................................. 21

3.6.4 Outputs ............................................................................................... 21

3.7 Approvals ................................................................................................ 22

3.8 Standards and Guidelines ........................................................................ 23

4 Mounting ..................................................................................................... 24

4.1 Mounting Sequence ................................................................................. 24

4.2 Inserting and Removing Devices ............................................................ 25

4.2.1 Inserting I/O Module .......................................................................... 25

4.2.2 Removing the I/O Module .................................................................. 26

5 Connect Devices ......................................................................................... 27

5.1 Connecting a Conductor to the CAGE CLAMP® ................................... 27

5.2 Connection Examples .............................................................................. 28

5.2.1 2-Conductor Connection, ungrounded ............................................... 28

5.2.2 2-Conductor Connection, grounded ................................................... 28

5.2.3 3-Conductor Connection, ungrounded ............................................... 29

5.2.4 3-Conductor Connection, grounded ................................................... 29

6 Process Image ............................................................................................. 30

7 Use in Hazardous Environments .............................................................. 31

Manual

Version 1.2.0

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

7.1 Marking Configuration Examples ........................................................... 32

7.1.1 Marking for Europe according to ATEX and IEC-Ex ........................ 32

7.1.2 Marking for America according to NEC 500 ..................................... 37

7.2 Installation Regulations ........................................................................... 38

7.2.1 Special conditions for safe use (ATEX Certificate TÜV 07 ATEX

554086 X) ........................................................................................... 39

7.2.2 Special conditions for safe use (ATEX Certificate TÜV 12 ATEX

106032 X) ........................................................................................... 40

7.2.3 Special conditions for safe use (IEC-Ex Certificate TUN 09.0001 X)41

7.2.4 Special conditions for safe use (IEC-Ex Certificate IECEx TUN

12.0039 X) .......................................................................................... 42

7.2.5 ANSI/ISA 12.12.01 ............................................................................ 43

List of Figures ...................................................................................................... 44

List of Tables ........................................................................................................ 45

=== Ende der Liste für Textmar ke Verzeich nis_vorne ===

Manual

Version 1.2.0

Page 5

WAGO-I/O-SYSTEM 750 Notes about this Documentation 5

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 7 /Alle Serien (Al lgemeine M odule)/Ü berschrift en für alle Serien/Hi nweis zur Dokument ation/Hinw eise zur D okumentati on - Übersc hrift 1 @ 4 \mod_1237987661750 _21.doc @ 29029 @ 1 @ 1

1 Notes about this Documentation

Pos: 8 /Alle Serien (Allgemeine Module)/Hinweise zur Dokumentation/HinweiseHinweis: Dokument ation aufb ewahren @ 4\mod_1237987339812_21.doc @ 29026 @ @ 1

Keep this documentation!

The operating instructions are part of the product and shall be kept for the entire

lifetime of the device. They shall be transferred to each subsequent owner or user

of the device. Care must also be taken to ensure that any supplement to these

instructions are included, if applicable.

Pos: 9 /Alle Serien (Al lgemeine M odule)/Ü berschrift en für alle Serien/Hi nweis zur Dokument ation/Gülti gkeitsber eich - Über sc hr i f t 2 @ 12\mod_1338912448776_21.doc @ 96469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Ser ie 750 ( WAGO-I/O-SYST EM)/Hin weise zur D okumentatio n/Gültig keitsbereic h Dokume ntation Bus klemme 75 0-xxxx, ohne Varianten angabe @ 14\mod_1358944037947_21.doc @ 109346 @ @ 1

This documentation is only applicable to the I/O module 750-512

(2DO 230V AC 2.0A/ Relay 2NO) of the WAGO-I/O-SYSTEM 750 series.

Pos: 11 /Ser ie 750 ( WAGO-I/O-SYST EM)/Hin weise zur D okumentatio n/Hinweis e/Achtung: Hinweis z ur Dokume ntation B usklemmen 750-xxxx @ 4\mod_1237986979656_21.doc @ 29023 @ @ 1

The I/O module 750-512 shall only be installed and operated according to the

instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos: 12.1 /Al le Serie n (Allgemei ne Module) /Hinweis e zur Doku mentation/ Urhebersc hutz ausfü hrlich @ 4\ mod_1235565145234_21.doc @ 27691 @ 2 @ 1

1.2 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Pos: 12.2 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 12.3 /Al le Serie n (Allgemei ne Module) /Überschr iften für alle Serien /Hinweis z ur Dokum entation/S ymbole - Überschrift 2 @ 13\mod_1351068042408_21.doc @ 105270 @ 2 @ 1

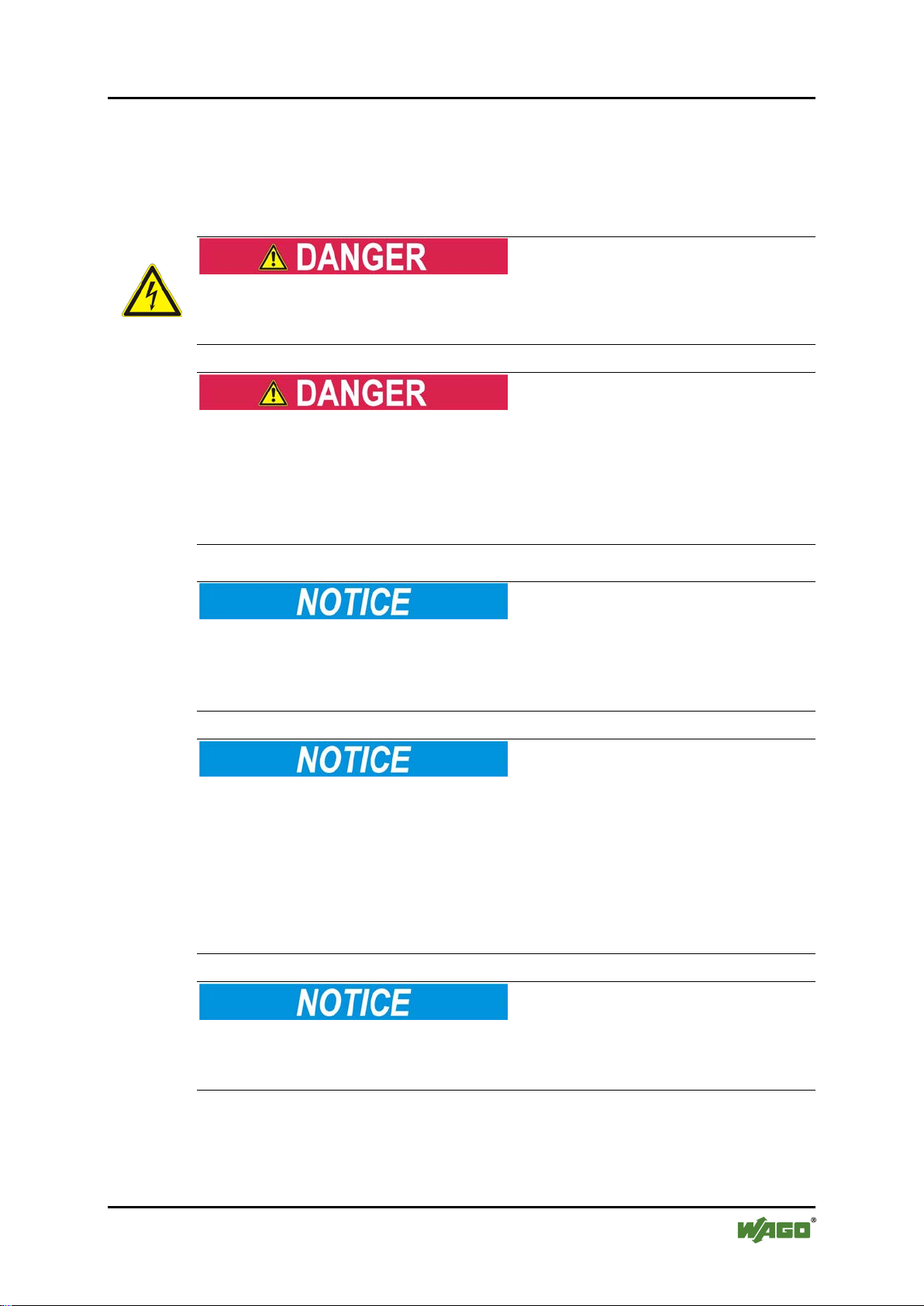

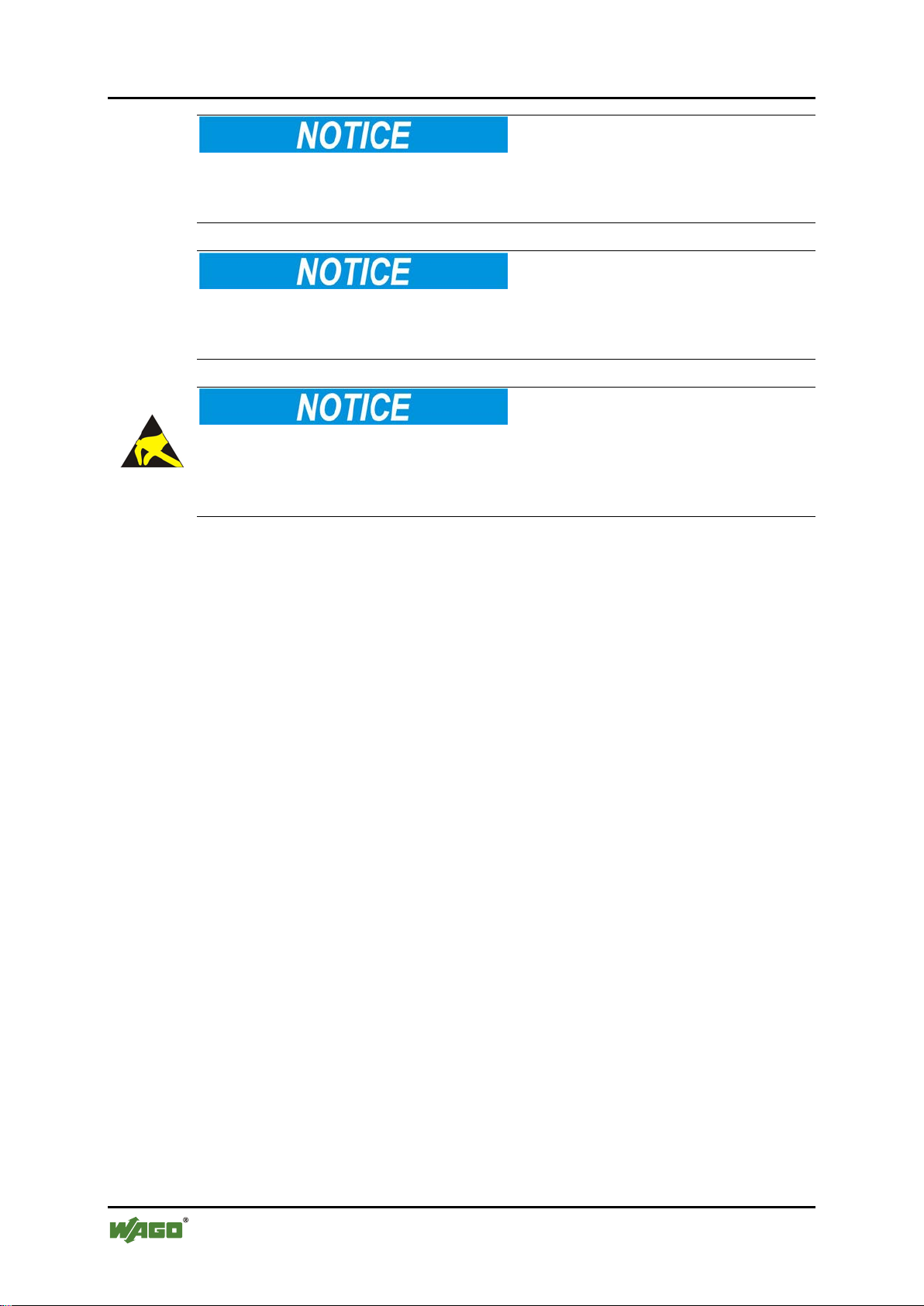

1.3 Symbols

Pos: 12.4.1 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/ Sicherheits - und sonsti ge Hinwei se/Gefahr /Gefahr: _Warnung vor Person enschäden allgemein_ - Erläuterung @ 13\mod_1343309450020_21.doc @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 12.4.2 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/ Si c h er h ei ts - und sonstig e Hinweis e/Gefahr /G ef ahr: _Warn u ng vor Personens ch äden durch el e kt r i sc h e n St r o m _ - Erläuterung @ 13\mod_1343309694914_21.doc @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 12.4.3 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/ Si c h er h ei ts - und sonstig e Hinweis e/Warnung /Warnung: _Warnung vor Perso nenschäd en allgemei n_ - Erläuterung @ 13\mod_1343309877041_21.doc @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 12.4.4 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/ Si c h er h ei ts - und sonstig e Hinweis e/Vorsic ht/Vorsicht : _Warnung vor Pers onenschä den allgemei n_ - Erläu ter ung @ 13\mod_1343310028762_21.do c @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 12.4.5 /Alle Seri en (Allge meine Mod ule)/Wichti ge Erläut erungen/Si cherheits- und sonstige Hinwe ise/Achtung/Achtung: _Warnung vor Sachs chäden allgemein_ - Erläuterung @ 13\mod_1343310134623_21.doc @ 101 041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 12.4.6 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/Sicherheits- und sonstige Hi nweise/Ach tung/Ach tung: _War nung vor S achschäd en durch el ektrostatis che Auflad ung_ - Erläuterung @ 13\mod_1343310227702_21.doc @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 12.4.7 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/ Si c h er h ei ts - und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Eräuterung @ 13\mod_1343310326906_21.doc @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 12.4.8 /All e Serien (All g e meine Modul e) / Wi c htige Erläut erungen/ Si c h er h ei ts - und sonstig e Hinweis e/Infor mation/Infor mation: _Wei tere Infor mation allg em ei n_ - Erläuterung @ 13\mod_1343310439814_21.doc @ 101051 @ @ 1

Manual

Version 1.2.0

Page 7

WAGO-I/O-SYSTEM 750 Notes about this Documentation 7

750-512 2DO 230V AC 2.0A/ Relay 2NO

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 12.5 /Dokumentation allgemein/Gli ederungs elemente/---Sei tenwechs el--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

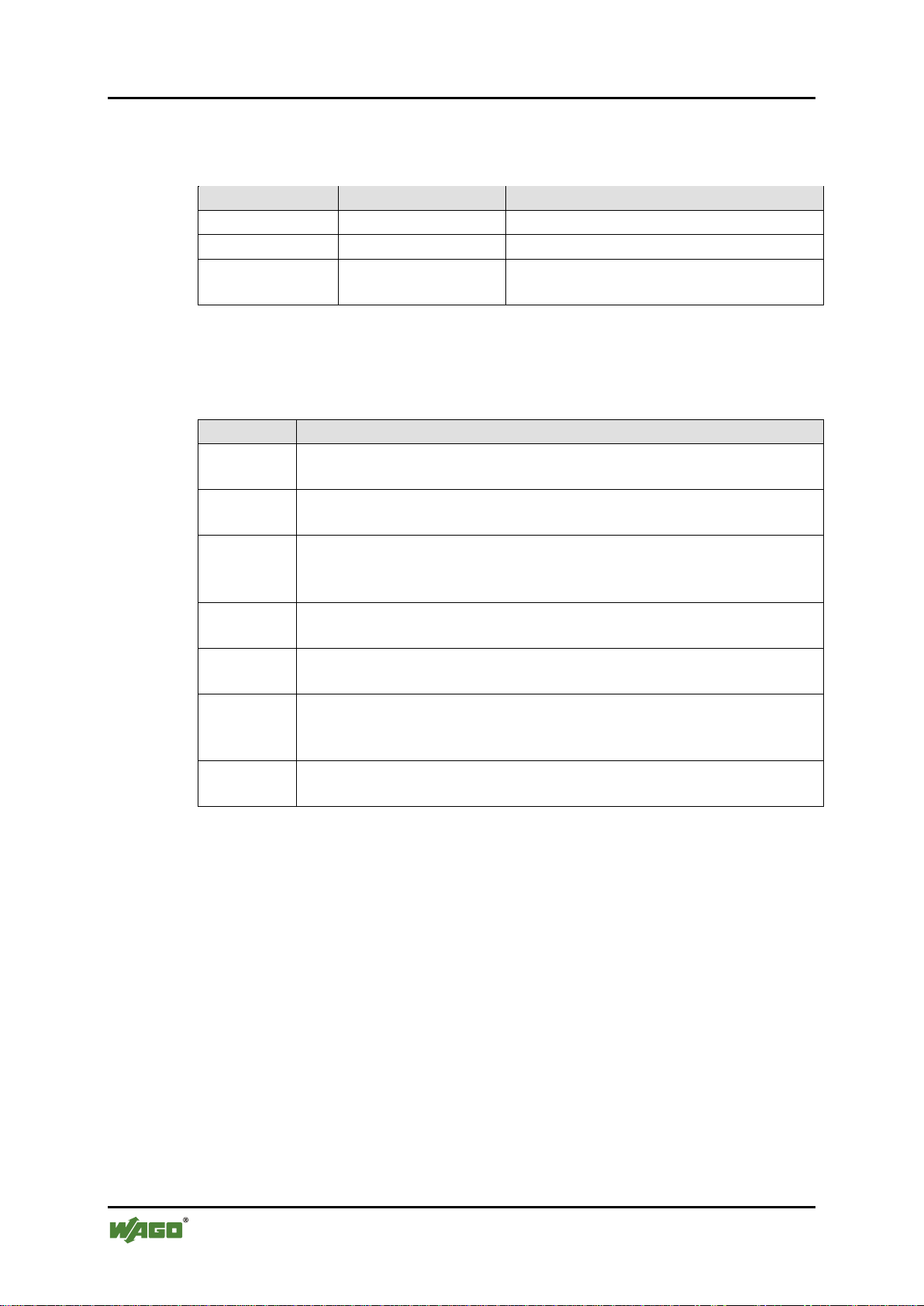

Table 1: Number notation

Number code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 2: Font conventions

Font type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Programme\WAGO-I/O-CHECK

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 12.6 /Al le Serie n (Allgemei ne Module) /Hinweis e zur Doku mentation/ Zahlensys teme @ 3\mod_1221059454015_21.doc @ 21711 @ 2 @ 1

1.4 Number Notation

Pos: 12.7 /Al le Serie n (Allgemei ne Module) /Hinweis e zur Doku mentation/ Schriftko nventione n @ 3\mod_1221059521437_21.d oc @ 21714 @ 2 @ 1

1.5 Font Conventions

Pos: 13 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

menu item from a menu.

brackets.

Manual

Version 1.2.0

Page 9

WAGO-I/O-SYSTEM 750 Important Notes 9

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 14 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/ Wichtige Er läu terungen / Wi c h ti g e Erläuterung en - Übersc hr i ft 1 @ 4\ mod_1241428899156_21.doc @ 32170 @ 1 @ 1

2 Important Notes

Pos: 15.1 /Al le Serie n (Allgemei ne Module) /Wichtig e Erläuteru ngen/Einl eitung Wic htige Erlä uterunge n @ 3\mod_1221059818031_21.d oc @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 15.2 /Al le Serie n (Allgemei ne Module) /Überschr iften für alle Serien /Wichtig e Erläuter ungen/Recht liche Gr undlagen - Ü b er sc hrift 2 @ 3\mod_1221060626343_21.doc @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 15.3 /Al le Serie n (Allgemei ne Module) / Wichtige Er l ä ut er u ngen/Änd er u ngsvorbehal t - Überschr ift 3 und I nhalt @ 3\ mod_1221060036484_21.doc @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 15.4 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/P er s onalquali fi kation 750- xxxx @ 3\mod_1224061208046_21.doc @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on Series 750 devices may only be carried out by

electrical specialists with sufficient knowledge in automation. The specialists

must be familiar with the current norms and guidelines for the devices and

automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 15.5 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/B es timmungs g e mäße Verwen d ung 7 50- xxxx @ 3\mod_1224064151234_21.d oc @ 24070 @ 3 @ 1

2.1.3 Use of the 750 Series in Compli anc e wit h Unde rlying Provisions

Couplers, controllers and I/O modules found in the modular WAGO-I/OSYSTEM 750 receive digital and analog signals from sensors and transmit them

to the actuators or higher-level control systems. Using programmable controllers,

the signals can also be (pre-) processed.

The components have been developed for use in an environment that meets the

IP20 protection class criteria. Protection against finger injury and solid impurities

up to 12.5 mm diameter is assured; protection against water damage is not

ensured. Unless otherwise specified, operation of the components in wet and

dusty environments is prohibited.

Operating 750 Series components in home applications without further measures

is only permitted if they meet the emission limits (emissions of interference)

according to EN 61000-6-3. You will find the relevant information in the section

on "WAGO-I/O-SYSTEM 750" "System Description" "Technical Data" in

the manual for the used fieldbus coupler/controller.

Manual

Version 1.2.0

Page 10

10 Important Notes WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 15.6 /Al le Serie n (Allgemei ne Module) /Wichtig e Erläuteru ngen/Tec hnischer Zu stand der Geräte - Üb erschrift 3 und Inhal t @ 3\mod_1221060446109_21.doc @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Spec ified Devices

The components to be supplied Ex Works, are equipped with hardware and

software configurations, which meet the individual application requirements.

WAGO Kontakttechnik GmbH & Co. KG will be exempted from any liability in

case of changes in hardware or software as well as to non-compliant usage of

components.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 15.7 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 11

WAGO-I/O-SYSTEM 750 Important Notes 11

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 15.8 /All e Ser i e n ( Al l g e mei ne Module)/ Ü berschrift en für alle Ser i en / Wichtige Er l äu ter ungen/Sic herheitshi nweise - Üb er s c hr i f t 2 @ 6\ mod_12601802999 87_21.doc @ 46724 @ 2 @ 1

2.2 Safety Advice (Precautions)

Pos: 15.9 /Al le Serie n (Allgemei ne Module) / Wichtige Erl ä uterunge n/ Si c h er h ei t s- und sonstig e Hinwei se/Einlei tung Sicher heitshin weise Hard ware @ 6\mod_1260180170493_21.doc @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 15.10. 1 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Gefahr/ Gefahr: N icht an Ger äten unter Spannung arbeite n! @ 6\mod_1260180365327_21.d oc @ 46727 @ @ 1

Do not work on components while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 15.10. 2 /Serie 75 0 (WAGO-I/O- SYSTEM)/ Wichtige Er läuterung en/Sicher heits- und sonstige Hinweise/Gefahr/Gefahr: Einbau 07 50-xxxx nur in Gehäusen, Schränken oder elektrischen Betriebsräumen! @ 6\mod_1260180556692_21.doc @ 46731 @ @ 1

Installation only in appropriate housings, cabinets or in electrical operation

rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 15.10. 3 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Gefahr/ Gefahr: U nfallverh ütungsvors c hriften beac ht en! @ 6\mod_1260180657000_21.doc @ 46735 @ @ 1

Pos: 15.10. 4 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Gefahr/ Gefahr: A uf normg erechten Ans chluss ac hten! @ 6\ mod_1260180753479_21.doc @ 46739 @ @ 1

Pos: 15.11. 1 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonstige Hinweis e/Achtung/Achtung: Defekte oder beschädigte Geräte austaus chen! @ 6\mod_1260180857358_21.doc @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 15.11. 2 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Achtu ng/Achtung: Geräte vor krieche nden und is olierend en Stoffen s chützen! @ 6\mod_1260181036216_21.doc @ 46747 @ @ 1

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 15.11. 3 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Achtu ng/Achtung: Reinigu ng nur mit z ulässige n Materiali en! @ 6\mod_1260181203293_21.doc @ 46751 @ @ 1

Cleaning only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 15.11. 4 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Achtu ng/Achtung: Kein Ko ntaktspray verwenden! @ 6\mod_1260181290808_21.doc @ 46755 @ @ 1

Manual

Version 1.2.0

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 15.11. 5 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Achtu ng/Achtung: Verpolung vermeide n! @ 6\mod_1260184045744_21.doc @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 15.11. 6 /Alle Ser ien (Allge meine Mo dule)/Wich tige Erläu terungen/Si cherheits - und sonsti ge Hinwei se/Achtu ng/Achtung: Elektrost atische E ntladung vermeiden! @ 6\mod_1260181364729_21.doc @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that you may destroy by

electrostatic discharge when you touch. Pay attention while handling the devices

to good grounding of the environment (persons, job and packing).

Pos: 16 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 13

WAGO-I/O-SYSTEM 750 Device Description 13

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 17 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Gerätebes chreibung - Ü berschrif t 1 @ 3\mod_1233756084656_21.doc @ 27096 @ 1 @ 1

3 Device Description

Pos: 18.1 /Serie 750 (WAGO-I/O-SYSTEM)/G er ätebeschr ei bung/Einl ei t ung/Anw en du ng /DO/Anw en d ung 750-05xx DO Rel ais @ 5\mod_1246611276875_21 .doc @ 36561 @ @ 1

The 750-512 Digital Output Module transmits binary control signals from the

automation device to the connected actuators (e.g., solenoid valves, contactors,

transmitters, relays or other electrical loads).

Pos: 18.2 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /I/O-Beschr eibung/DO /I/O-Besc hreibung 7 50-05xx 2 DO 3-Leiter (DO, N un d PE) @ 5\mod_1246610806328_21.doc @ 36557 @ @ 1

The module has two output channels. Two actuators with ground (earth) wire may

be directly connected to signal output DO 1, N and PE (earth potential) or signal

Pos: 18.3 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /I/O-Beschr eibung/All gemein/V erweis auf Kapitel " Anschlüss e" @ 8\mod_1276775378035_21.doc @ 57956 @ @ 1

Pos: 18.4 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /I/O-Beschr eibung/All gemein/V erweis auf Kapitel " Geräte ans chließen" > "Anschlus sbeispiel (e)" @ 5\ mod_1246015203281_21.doc @ 36298 @ @ 1

Pos: 18.5 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si c herheits- und sonstige Hinweise/Achtung/Ach tung: DO Induktionsspannungsbegrenzung R elais @ 5\mod_1247031985231_21.doc @ 36766 @ @ 1

output DO 2, N and PE.

The assignment of the connections is described in the "Connections" section.

Connection examples are shown in section "Connecting Devices" "Connection

Examples".

Inductive loads must be dampened!

For the protection of relay coils and contacts, inductive loads must be dampened

with an effective protection circuit!

Examples of protection circuits can be seen in the section "Protective Circuits for

Contacts of Relay Modules".

Pos: 18.6 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /I/O-Beschr eibung/DO /I/O-Besc hreibung 7 50-0512 Schl ieß er-Relais @ 5\mod_1246868974281_21.doc @ 36625 @ @ 1

Each module is equipped with one non-floating make contact relay per channel,

i.e. the fieldside voltage supply (230 V AC or 30 V DC) is connected to each

terminal of the relay and is fed in via the internal power jumper contacts of an

adjacent supply module.

By closing a relay, the field power applied is switched to the second relay

connection of signal output DO1 or DO2.

Pos: 18.7 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /I/O-Beschr eibung/DO /I/O-Besc hreibung 7 50-05xx Ansteuerung der Relais (Interne Systemspannung) @ 5\mod_1246861676649_21 .doc @ 36599 @ @ 1

The internal system voltage is used to trigger the relays.

Pos: 18.8 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /LED-Anzei ge/LED Zu stand Relai s @ 5\mod_1246862048946_21.doc @ 36603 @ @ 1

Pos: 18.9 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/Ei nleitung /LED-Anzei g e/ Verweis auf Ka pi t el "Anzeigeel emente" @ 5\ mod_1246010525000_21.doc @ 36194 @ @ 1

The switching status of the two relays is indicated via green status LEDs.

The meaning of the LEDs is described in the “Display Elements” section.

Pos: 18.10 / Serie 750 ( WAGO-I/O-SY STEM)/Wi chtige Erl äuterung en/Sicherhei ts- und son stige Hin weise/Hin weis/Hinwei s: Einspei seklemme für Versor gung ungl eich 24 V ei nsetzen @ 5\mod_1247032609340_21.doc @ 36784 @ @ 1

Use additional supply module!

Use an additional supply module if I/O modules require a field supply not equal to

24 V DC. Insert the supply module in front of the module that requires the

different supply.

Pos: 18.11 / Serie 750 ( WAGO-I/O-SY STEM)/G er ät e beschreib ung / Einleitung /Versorg u ng /Versorg ung AC 230 V / DC 30 V, 0 V, Er d e üb er Lei s t u ngskonta kt e @ 5\ mod_1246869265656_21.doc @ 36628 @ @ 1

The I/O module receives the AC 230V or DC 30V potential for the field level

from an upstream I/O module or from the fieldbus coupler/controller via the

Manual

Version 1.2.0

Page 14

14 Device Description WAGO-I/O-SYSTEM 75 0

750-512 2DO 230V AC 2.0A/ Relay 2NO

power contacts used as blade contacts. It then provides this potential to

subsequent I/O modules via the power contacts used as spring contacts.

Pos: 18.12 / Serie 750 ( WAGO-I/O-SY STEM)/Wic htige Erläu terungen /Sicherhei ts- und sons tige Hinw eise/Acht ung/Achtung : Maximal er Strom Leistungs kontakte 1 0 A @ 3\mod_1226499143500_21.doc @ 25029 @ @ 1

Do not exceed maximum current via power contacts!

The maximum current to flow through the power contacts is 10 A.

Greater currents can damage the power contacts.

When configuring the system, ensure that this current is not exceeded. If

exceeded, an additional potential feed module must be used.

Pos: 18.13 / Serie 750 ( WAGO-I/O-SY STEM)/G erätebeschr eibung/Ei nleitung/ Versorgung /Anordnu ng unter Ber ücksichti gung der Leistungs kontakte bel iebig @ 3\ mod_1233756233468_21.doc @ 27099 @ @ 1

With consideration of the power jumper contacts, the individual modules can be

arranged in any combination when configuring the fieldbus node. An arrangement

in groups within the group of potentials is not necessary.

Pos: 18.14 / Serie 750 ( WAGO-I/O-SY STEM)/G er ät e beschreib ung / Einleitung /Einsatz b er ei c h/Einsat zb er ei c h 750-xxxx alle Koppl er/Controll er ohne Ei nschrän kung @ 3\mod_1232541691906_21.doc @ 26522 @ @ 1

The I/O module 750-512 can be used with all fieldbus couplers/controllers of the

WAGO-I/O-SYSTEM 750.

Pos: 19 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 15

WAGO-I/O-SYSTEM 750 Device Description 15

Table 1: Caption acc. to figure „Connections““

No.

Designation

Description

Details see chapter

Marking possibility with

Mini-WSB

„Technical manual“ >

„Display elements

„Mounting“ > „Mounting

device“

CAGE CLAMP®-supply DO

V, N and ground.

Power contacts AC 230 V /

DC 30 V

„Technical manual “ >

„Connections“

„Mounting“ > „Mounting

device“

„Technical manual “ >

„Connections “

„Technical manual “ >

„Connections“

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 20 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Ansicht - Ü berschrift 2 @ 4\mod_1240984217343_21.doc @ 31958 @ 2 @ 1

3.1 View

Pos: 21 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansic ht/Digital ausgangs klemmen/A nsicht 750- 0512 @ 10\mod_1298370 459642_21.doc @ 69783 @ @ 1

Figure 1: View

Pos: 22 /Dokumentation allgemein/G li e derungsel e m en te /---Seitenwec hsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

1 ---

2 A, C Status-LEDs

3 --- Data contacts

4 1 … 8

1, DO 2, AC 230 V / DC 30

5 ---

6 --- Interlock links

7 --- Power contacts 0 V

8 --- Power contacts ground

---

„Technical manual “ >

„Connections“

Manual

Version 1.2.0

Page 16

16 Device Description WAGO-I/O-SYSTEM 75 0

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 23 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Anschlüss e - Übersc hr if t 2 @ 4\ mod_12409842626 56_21.doc @ 31961 @ 2 @ 1

3.2 Connectors

Pos: 24 /Ser ie 750 ( WAGO-I/O-SYSTEM)/Gerätebeschreibung/Anschlüsse/Datenkontakte/Klemmenbus - Überschrift 3 @ 6\ mod_1256294684083_21.doc @ 43660 @ 3 @ 1

3.2.1 Data Contacts/Internal Bus

Pos: 25.1 /Serie 750 (WAGO-I/O-SYSTEM)/G erätebesc hreibung/A nschlüsse/Datenkontakte @ 3\mod_1231771259187_21.doc @ 26002 @ @ 1

Communication between the coupler/controller and the I/O modules as well as the

system supply of the I/O modules is carried out via the internal bus. It is

comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data contacts

Pos: 25.2 /Serie 750 (WAGO-I/O-SYSTEM)/Wic hti g e Er l ä ut erungen/Si c herheits- und sonstige Hi n w ei s e/Achtung /Ac htung: Bus kl emmen nicht a uf Gol dfederk on t a kt e leg e n! @ 7\mod_1266318463636_21.doc @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 25.3 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si cherheits - und sonstige Hinweise/Achtung/Achtung: ESD - Auf gute Erdung der Umgebu ng achten! @ 7\mod_1266318538667_21 .doc @ 50708 @ @ 1

Ensure that the environment is well grounded!

The modules are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the modules, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 26 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 17

WAGO-I/O-SYSTEM 750 Device Description 17

Table 3: Power jumper contacts

Connection

Type

Number

Function

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 27 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansc hlüsse/Leis tungskont akte/Feld versorgung - Überschr i ft 3 @ 6\ mod_1256294692864_21.doc @ 43664 @ 3 @ 1

3.2.2 Power Jumper Contacts/ Field Supply

Pos: 28.1 /Serie 750 (WA GO-I/O-SYSTEM ) / Wi c htige Erläut erungen/Si c herheits- und sonstig e Hinweis e/Vorsic ht/Vorsicht : Verletz ungsgefahr durch sch arfkantig e Messerko ntakte! @ 6\mod_1256193279401_21.doc @ 43414 @ @ 1

Risk of injury due to sharp-edged male contacts!

The male contacts are sharp-edged. Handle the module carefully to prevent injury.

Pos: 28.2 /Serie 750 (WAGO-I/O-SYSTEM)/Ger ätebeschr eibung/Ans chlüsse/L eistungs kontakte 3 LK (Messer /Feder) @ 7\mod_1266318232808_21.doc @ 50691 @ @ 1

The I/O module 750-512 has 3 self-cleaning power jumper contacts that supply

and transmit power for the field side. The contacts on the left side of the I/O

module are designed as male contacts and the contacts on the right side as spring

contacts.

Fig 3: Power jumper

contacts

Pos: 28.3 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si c herheits- und sonstige Hinweise/Achtung/Achtung: Maximaler Strom Leistungskontakte 10 A @ 3\mod_1226499143500_21.doc @ 25029 @ @ 1

Do not exceed maximum current via power contacts!

The maximum current to flow through the power contacts is 10 A.

Greater currents can damage the power contacts.

When configuring the system, ensure that this current is not exceeded. If

exceeded, an additional potential feed module must be used.

Infeed of the field

1 Blade cont act 3

supply voltage

(UV, 0 V and earth)

Forwarding of the

2 Spring contact 3

field supply voltage

(UV, 0 V and earth)

Pos: 29 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 18

18 Device Description WAGO-I/O-SYSTEM 75 0

Table 4: Connectors

Designati

on

Output DO 1: Field supply

DC 30 V

Power

contacts

Power

contacts

Power

contacts

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 30 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansc hlüsse/CA GE CLAMP-An schlüsse - Ü berschrift 3 @ 6\mod_1256296337770_21.doc @ 43674 @ 3 @ 1

3.2.3 CAGE CLAMP® Connections

Pos: 31 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansc hlüsse/Dig italausgang sklemme n/ Anschlüss e 75 0-0512 @ 10\mod_1298374547434_21.doc @ 69887 @ @ 1

Pos: 32 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Figure 4: Connectors

Connector Channel

Function

1 1 DO 1 Output DO 1: Signal vo lta ge

5 2 DO 2 Output DO 2: Signal vo lta ge

6 2

AC 230 V

DC 30 V

AC 230 V

7 2 N Output DO 2: N

8 2 Earth Output DO 2: Earth

jumper

jumper

jumper

- +24 V Field supply 24 V

- 0 V Field supply 0 V

- Earth Field supply Earth

Manual

Version 1.2.0

Page 19

WAGO-I/O-SYSTEM 750 Device Description 19

Table 5: Display elements

Designation

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 33 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Anzeigeel emente - Üb erschrift 2 @ 4\mod_1240984390875_21.doc @ 31964 @ 2 @ 1

3.3 Display Elements

Pos: 34 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschreibung/Anzeigeelemente/Digitalausgangsklemm en/Anzeigeelemente 750-0512 @ 10\mod_1298371006175_21.doc @ 69835 @ @ 1

LED Channel

A 1

Figure 5: Displa y

elements

Pos: 35 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Bedienel emente - Über schrift 2 @ 4\mod_1239191655456_21.doc @ 30439 @ 2 @ 1

C 2

3.4 Operating Elements

Pos: 36 /Ser ie 750 ( WAGO-I/O-SYST EM)/Ger ätebeschrei bung/Bedi enelement e/Bedienel emente B usklemme 7 50-xxxx nic ht vorhand en @ 4\mod_1236322031125_21.doc @ 28063 @ @ 1

The I/O module 750-512 has no operating elements.

Pos: 37 /Dokumentation allgemein/Gliederungs elemente/---Sei tenwechs el--- @ 3\mod_1221108045078_ 0.doc @ 21810 @ @ 1

State Function

off Output DO 1: Signal volta ge (0)

Status

DO 1

green Output DO 1: Signal voltage (1)

off Output DO 2: Signal voltage ( 0)

Status

DO 2

green Output DO 2: Signal voltage (1)

Manual

Version 1.2.0

Page 20

20 Device Description WAGO-I/O-SYSTEM 75 0

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 38 /Alle Seri en (Allge mei ne Module)/Ü ber s chriften für al l e S erien/Gerä tebeschr ei b u ng / Sc hematisch es Schaltbil d - Überschri f t 2 @ 4\mod_1240984441312_21.doc @ 31967 @ 2 @ 1

3.5 Schematic Diagram

Pos: 39 /Ser ie 750 ( WAGO-I/O-SYST EM ) / Gerätebes c hr ei bung/Sch e matische Sc hal tbilder/Di g i t alausgang s klemmen/Sc hematisch es Schaltbil d 750-0512 @ 10\mod_1298371082616_21.doc @ 69847 @ @ 1

Figure 6: Schematic d iagram

Pos: 40 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 21

WAGO-I/O-SYSTEM 750 Device Description 21

Table 6: Technical data device

Width

12 mm

Height (from upper edge of 35 DIN rail)

64 mm

Depth

100 mm

Weight

ca. 55 g

Table 7: Technical data power supply

Current consumption

max.

(internal)

100 mA

Table 8: Technical data communication

Internal bit width

2 bits

Table 9: Technical data inputs

Number of outputs

2 make contacts

Switching voltage

(max.)

AC 250 V/DC 30 V

Switching power

500 VA/60 W

cosφ

max

= 0,4; L/R

max

= 7 ms

Switching current

(max.)

AC/DC 2 A

Switching current

(min.)

10 mA / 5 V DC

Switching rate

(max.)

30/min (at nominal load)

Pull-in time

(max.)

10 ms

Bounce time

typ.

1,2 ms

Drop-out time

max.

10 ms

Contact material

Silver alloy

Mechanical life

max.

2x107 switching operations

Electrical life

min.

3x105 (AC 2 A/250 V) or (DC 2 A/30V)

Isolation

1,5 kV

(field/system)*

Overvoltage category III

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 41 /Alle Ser i en (Allge mei ne Module)/Ü ber s chriften für al l e S erien/Gerä tebeschr ei b u ng / Tec hnische Dat en - Überschr ift 2 @ 3\ mod_1232967587687_21.doc @ 26924 @ 2 @ 1

3.6 Technical Data

Pos: 42 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Tech nische Date n/Digitalausgangsklemmen/Technische Dat en 750-0512 @ 10\mod_1298385334380_21.doc @ 699 79 @ 3333 @ 1

3.6.1 Device Data

3.6.2 Power Supply

3.6.3 Communication

3.6.4 Outputs

eff.

*2,5 kV rated surge voltage;

Pos: 43 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 22

22 Device Description WAGO-I/O-SYSTEM 75 0

Conformity Marking

TÜV 07 ATEX 554086 X

I M2 Ex d I Mb

II 3 D Ex tc IIIC T135°C Dc

Ambient temperature range:

0 °C ≤ T

a

≤ +60 °C

IECEx TUN 09.0001 X

Ex d I Mb

Ex tc IIIC T135°C Dc

Ambient temperature range:

0 °C ≤ T

a

≤ +60 °C

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 44 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Zulassung en - Übersc hr i ft 2 @ 3\ mod_1224055364109_21.doc @ 24030 @ 2 @ 1

3.7 Approvals

Pos: 45 /Ser ie 750 ( WAGO-I/O-SYST EM ) / Gerätebes c hr ei bung/Zul as s u ngen/Infor m at i on: Weiter e Inf ormatione n z u Zul assungen 750- xxxx @ 3\mod_1227190967156_21.doc @ 25221 @ @ 1

More Information about Approvals

Detailed references to the approvals are listed in the document "Overview

Approvals WAGO-I/O-SYSTEM 750", which you can find on the DVD

“AUTOMATION Tools and Docs” (order no. 0888-0412) or via the internet

under: www.wago.com Documentation WAGO-I/O-SYSTEM 750

System Description.

Pos: 46 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Zulass ungen/All gemein/Zul assungen Busklem me 750-xxxx Al l g e mein, ohne Var i an tenangab e - Ei nleitung @ 4\ mod_1237460656921_21.doc @ 28643 @ @ 1

The following approvals have been granted to 750-512 I/O modules:

Pos: 47.1 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Stan dardzulass ungen/CE ( Konformit ätskennzei chnung) @ 3\mod_1224494777421_21.doc @ 24276 @ @ 1

Pos: 47.2 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Stan dardzulass ungen/cULus (UL508) @ 3\mod_1224 055013140_0.doc @ 24020 @ @ 1

Pos: 47.3 /Dokumentation allgemein/Gliederungselemente/------Leerzeile------ @ 3\mod_1224662755687_0.doc @ 24460 @ @ 1

Pos: 48 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Zulass ungen/Ex /Zulassu ngen Buskl emme 750- xxxx Ex, ohne Vari antenangabe - Einleitung @ 4\mod_1237191218000_21.doc @ 28423 @ @ 1

The following Ex approvals have been granted to 750-512 I/O modules:

Pos: 49.1 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Ex-Zul assungen /TÜV ATEX/ TÜV 07 AT EX 554086 X: I M2 Ex d I Mb II 3 G Ex nA nC I IC T4 Gc I I 3 D Ex tc IIIC T135 °C Dc @ 14 \ mod_1362133489555_0.doc @ 113428 @ @ 1

Pos: 49.2 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Ex-Zul assungen /Ergänzung Zulässig er Umgebung stemper aturbereic h 0 °C <= Ta <= +60 °C @ 9\mod_1295605895541_21. doc @ 68610 @ @ 1

Pos: 49.3 /Alle Serien (Allgemeine Module)/Zu lassungen/Ex-Zulassungen/IEC E x (TÜ V N or d) /IECEx TUN 09. 0001 X: Ex d I Mb E x nA nC IIC T4 Gc Ex tc IIIC T13 5°C @ 14 \mod_1362133668858 _0.doc @ 113432 @ @ 1

CULUS

II 3 G Ex nA nC IIC T4 Gc

UL508

Ex nA nC IIC T4 Gc

Pos: 49.4 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Ex-Zul assungen /Ergänzung Zulässig er Umgebung stemper aturbereic h 0 °C <= Ta <= +60 °C @ 9\mod_1295605895541_21. doc @ 68610 @ @ 1

Pos: 49.5 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Ex-Zul assungen /cULus/cUL us (ANSI/I SA 12.12. 01) Class I, Div2 ABC D T4 @ 3\ mod_1224054791812_0.doc @ 24014 @ @ 1

Pos: 49.6 /Dokumentation allgemein/Gliederungselemente/------Leerzeile------ @ 3\mod_1224662755687_0.doc @ 24460 @ @ 1

Pos: 50 /Ser ie 750 ( WAGO-I/O-SYST EM ) / Gerätebes c hr ei bung/Zul as s u ngen/Schif f/Zulassu ngen Buskle mme 750-xxx x Schiff, ohne Variant enangabe - Einleitu ng @ 4\mod_1237190918453_21.doc @ 28420 @ @ 1

Pos: 51.1 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/ABS ( American Bureau of Shipping) @ 3\mod_1224055151062_0.doc @ 24023 @ @ 1

Pos: 51.2 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/BSH ( Bundesam t für Seesc hifffahrt und Hydrog raphie) @ 5\mod_1246341825156_21.doc @ 36334 @ @ 1

Pos: 51.3 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/BV (B ureau Veri tas) @ 3\mod_1224492116171 _0.doc @ 2 4220 @ @ 1

Pos: 51.4 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/DNV ( Det Nors ke Veritas) C lass B @ 3 \mod_1224492540562_0.doc @ 24224 @ @ 1

Manual

Version 1.2.0

The following ship approvals have been granted to 750-512 I/O modules:

ABS (American Bureau of Shipping)

Federal Maritime and Hydrographic Agency

BV (Bureau Veritas)

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

750-512 2DO 230V AC 2.0A/ Relay 2NO

DNV (Det Norske Veritas) Class B

Pos: 51.5 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/GL (G ermanisch er Lloyd) C at. A, B, C , D (EMC 1) @ 3\mod_1224492724484_0.doc @ 24228 @ @ 1

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1)

Pos: 51.6 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/KR (K orean Reg ister of S hipping) @ 3\mod_1224492806109_0.doc @ 24232 @ @ 1

KR (Korean Register of Shipping)

Pos: 51.7 /Al le Serie n (Allgemei ne Module) /Zulassu ngen/Schi ffszulassu ngen/LR ( Lloyd’s Reg ister) En v. 1, 2, 3, 4 @ 3\mod_1224492890453_0.doc @ 24236 @ @ 1

LR (Lloyd’s Register) Env. 1, 2, 3, 4

Pos: 51.8 /Alle Serien (Allgemeine Module)/Zulassungen/Schiffszulassungen/NKK (Nippon Kaiji Kyokai) @ 3\mod_1224493002656_0.doc @ 24240 @ @ 1

NKK (Nippon Kaiji Kyokai)

Pos: 51.9 /Al le Serie n (Allgemei ne Module) /Zulassungen/Schiffszulassungen/PRS (Polski Re j estr Statków) @ 3\mod_1224497273250_0.do c @ 24295 @ @ 1

PRS (Polski Rejestr Statków)

Pos: 51.10 / Alle Serie n (Allgemei ne Modul e)/Zulassu ngen/Schif fszulassu ngen/RINA (Registro Italiano N avale) @ 3\mod_1224493078359_0.doc @ 24244 @ @ 1

RINA (Registro Italiano Navale)

Pos: 51.11 /D okument ation allge mein/Gli ederungsel emente/------Leerz eile------ @ 3\mod_1224662755687_0.doc @ 24460 @ @ 1

Pos: 52 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/G erätebesc hreibung /Normen und Richtlini en - Übersc hrift 2 @ 4\mod_1242804031875_21.doc @ 33646 @ 2 @ 1

3.8 Standards and Guidelines

Pos: 53 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Norm en und Ric htlinien/EM V-Normen Busklemme 750-xxxx, ohne Variantenangabe - Einleitung @ 4\mod_12428039 44015_21.doc @ 33642 @ @ 1

750-512 I/O modules meet the following requirements on emission and immunity

of interference:

Pos: 54 /All e Serien ( Allgemeine Module)/N ormen un d Richtlini en/EMV CE- Störaussendung EN 61000-6-4: 2007 @ 4\mod_1242798273984_21.doc @ 33602 @ @ 1

EMC CE-Emission of interference acc. to EN 61000-6-4: 2007

Pos: 55 /All e Serien ( Allgemeine Module)/N ormen un d Richtlini en/EMV CE- Störfesti g k eit EN 61 0 00- 6-2: 2005 @ 4\mod_1242797655625_21.doc @ 33591 @ @ 1

EMC CE-Immunity to interference acc. to EN 61000-6-2: 2005

Pos: 56 /All e Serien ( Allgemeine Module)/N ormen un d Richtlini en/EMV Sc hiffbau-Stör aussendu ng Germani scher Ll oyd (2003) @ 4\mod_1242798400546_21 .doc @ 33606 @ @ 1

EMC marine applications-Emission

of interference acc. to Germanischer Lloyd (2003)

Pos: 57 /All e Serien ( Allgemeine Module)/N ormen un d Richtlini en/EMV Sc hiffbau-Stör festigkei t G ermanisch er Ll o yd (2003) @ 4\mod_1242798409640_21.doc @ 33610 @ @ 1

EMC marine applications-Immunity

to interference acc. to Germanischer Lloyd (2003)

Pos: 58 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 24

24 Mounting WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 59 /All e Serien ( Allgemeine Module)/Ü berschrift en für all e S erien/Monti eren - Demo ntieren/M ontieren - Üb erschrift 1 @ 3\ mod_1225446744750_21.doc @ 24900 @ 1 @ 1

4 Mounting

Pos: 60.1 /Serie 750 (WAGO-I/O-SYSTEM)/M ontieren/M ontagerei henfolge @ 3\ mod_1231770210031_21.doc @ 25992 @ 2 @ 1

4.1 Mounting Sequence

All system components can be snapped directly on a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual components are securely

seated on the rail after installation.

Starting with the coupler/controller, the I/O modules are mounted adjacent to each

other according to the project design. Errors in the design of the node in terms of

the potential groups (connection via the power contacts) are recognized, as the I/O

modules with power contacts (male contacts) cannot be linked to I/O modules

with fewer power contacts.

Pos: 60.2 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si c herheits- und sonstig e Hinweis e/Vorsicht /Vorsicht : Verletz ungsgefahr durch sch arfkantig e Messerko ntakte! @ 6\mod_1256193279401_21.doc @ 43414 @ @ 1

Risk of injury due to sharp-edged male contacts!

The male contacts are sharp-edged. Handle the module carefully to prevent injury.

Pos: 60.3 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si c herheits- und sonstige Hinweise/Achtung/Ach tung: Busklemmen in vor gegebener Reihenfolge stecken! @ 6\mod_1256194177073_21.doc @ 43429 @ @ 1

Connect the I/O modules in the required order!

Never plug I/O modules from the direction of the end terminal. A ground wire

power contact, which is inserted into a terminal without contacts, e.g. a 4-channel

digital input module, has a decreased air and creepage distance to the neighboring

contact in the example DI4.

Pos: 60.4 /Serie 750 (WAGO-I/O-SYSTEM)/Wichti g e Erläuteru ng en/Sicher h ei t s- und sonsti ge Hinwei se/Achtung /Achtung : Aneinand erreihen von Buskle mmen nur b ei offener N ut! @ 6\mod_1256193351448_21.doc @ 43417 @ @ 1

Assemble the I/O modules in rows only if the grooves are open!

Please take into consideration that some I/O modules have no or only a few power

jumper contacts. The design of some modules does not allow them to be

physically assembled in rows, as the grooves for the male contacts are closed at

the top.

Pos: 60.5 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si c herheits- und sonstige Hinweise/Hinweis/Hinweis: Busabschluss nicht verges sen! @ 6\ mod_1256194225557_21.doc @ 43432 @ @ 1

Don't forget the end module!

Always plug an end module 750-600 onto the end of the fieldbus node! You must

always use an end module at all fieldbus nodes with the WAGO I/O System 750

fieldbus couplers/controllers to guarantee proper data transfer.

Pos: 60.6 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.do c @ 21810 @ @ 1

Manual

Version 1.2.0

Page 25

WAGO-I/O-SYSTEM 750 Mounting 25

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 60.7 /Serie 750 (WAGO-I/O-SYSTEM)/M ontieren/ Ger äte einfüge n und entfer ne n - Ü berschrif t 2 @ 3\mod_1231768483250_21.doc @ 25950 @ 2 @ 1

4.2 Inserting and Removing Devices

Pos: 60.8 /Serie 750 (WAGO-I/O-SYSTEM)/ Wi c ht i g e Er l ä ut erungen/Si c herheits- und sonstig e Hinweis e/Gefahr/G efahr: Vor sicht bei der Unter brechung v on FE! @ 6\ mod_1256193919214_21.doc @ 43423 @ @ 1

Use caution when interrupting the PE!

Make sure that people or equipment are not placed at risk when removing an I/ O

module and the associated PE interruption. To prevent interruptions, provide ring

feeding of the ground conductor, see section "Grounding/Ground Conductor" in

manual "System Description WAGO-I/O-SYSTEM 750".

Pos: 60.9 /Al le Serie n (Allgemei ne Module) / Wichtige Er l ä ut er u ngen/Sich er h eits- und so nst ig e Hinweis e/ Achtung/A c h tu ng : Arbeiten a n Ger äten nur spa n nu ng sfrei durch f ü hr e n! @ 6\mod_1256193963573_21.doc @ 43426 @ @ 1

Perform work on devices only if the system is de-energized!

Working on devices when the system is energized can damage the devices.

Therefore, turn off the power supply before working on the devices.

Pos: 60.10 /S erie 750 ( WAGO-I/O-SYST EM)/Monti eren/Bus kl e mme einfüge n @ 3\ mod_1231769726703_21.doc @ 25989 @ 3 @ 1

4.2.1 Inserting I/O Module

1. Position the I/O module so that the tongue and groove joints to the fieldbus

coupler/controller or to the previous or possibly subsequent I/O module are

engaged.

Figure 7: Insert I/O module

2. Press the I/O module into the assembly until the I/O module snaps into the

carrier rail.

Manual

Version 1.2.0

Page 26

26 Mounting WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Figure 8: Snap the I/O mo dule into place

With the I/O module snapped in place, the electrical connections for the data

contacts and power contacts (if any) to the fieldbus coupler/controller or to the

previous or possibly subsequent I/O module are established.

Pos: 60.11 / Serie 750 ( WAGO-I/O-SY STEM)/Mo nti eren/Bus kl e mme entfer ne n @ 4\ mod_1239169375203_21.doc @ 30334 @ 3 @ 1

4.2.2 Removing the I/O Module

Pos: 61 /Dokum e nt a ti o n al l g e mein/Glie der ungselemente/---Seiten wechsel--- @ 3\mod_1221108045078_0.do c @ 21810 @ @ 1

1. Remove the I/O module from the assembly by pulling the release tab.

Figure 9: Removing the I /O module

Electrical connections for data or power contacts are disconnected when removing

the I/O module.

Manual

Version 1.2.0

Page 27

WAGO-I/O-SYSTEM 750 Connect Devices 27

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 62 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/A nschließ en/Geräte a nschließ en - Überschr ift 1 @ 3\ mod_1234172889468_21.doc @ 27460 @ 1 @ 1

5 Connect Devices

Pos: 63 /Serie 750 (WAGO-I/O-SYSTEM)/Anschl ießen/Lei ter an CAG E CLAMP anschließe n - Überschri ft 2 und T ext @ 3\mod_1225448660171_21.doc @ 24928 @ 2 @ 1

5.1 Connecting a Conductor to the CAGE CLAMP®

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded and

finely stranded conductors.

Only connect one conductor to each CAGE CLAMP® connection!

Only one conductor may be connected to each CAGE CLAMP® connection.

Do not connect more than one conductor at one single connection!

If more than one conductor must be routed to one connection, these must be

connected in an up-circuit wiring assembly, for example using WAGO feedthrough terminals.

Exception:

If it is unavoidable to jointly connect 2 conductors, then you must use a ferrule to

join the wires together. The following ferrules can be used:

Length 8 mm

Nominal cross section

WAGO Product 216-103 or products with comparable properties.

1. To open the CAGE CLAMP® insert the actuating tool into the opening

above the connection.

1 mm2 for 2 conductors with 0.5 mm2 each

max.

Pos: 64 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

2. Insert the conductor into the corresponding connection opening.

3. To close the CAGE CLAMP® simply remove the tool - the conductor is

then clamped firmly in place.

Figure 10: Connecting a conductor to a CAGE CLAMP

®

Manual

Version 1.2.0

Page 28

28 Connect Devices WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 65 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/A nschließ en/Anschl ussbeispiel e - Überschr ift 2 @ 4\ mod_1240996036328_21.doc @ 32010 @ 2 @ 1

5.2 Connection Examples

Pos: 66 /Ser ie 750 ( WAGO-I/O-SYST EM)/Anschli eßen/Anschl ussbeispi ele/Digit alausgang s klemmen/A ns c hlussbeis piele 750-05 12 @ 10\mod_1298558832537_21.doc @ 70220 @ 3333 @ 1

5.2.1 2-Conductor Connection, ungrounded

Figure 11: Conne cting diagram 2-conductor conne ction, ungrounded

5.2.2 2-Conductor Connection, grounde d

Figure 12: Conne cting diagram 2-conductor conne ction, gr ounded

Manual

Version 1.2.0

Page 29

WAGO-I/O-SYSTEM 750 Connect Devices 29

750-512 2DO 230V AC 2.0A/ Relay 2NO

5.2.3 3-Conductor Connection, ungrounded

Figure 3: Connecting diagram 3-conductor connection, ungrounded

5.2.4 3-Conductor Connection, grounde d

Figure 4: Connecting di agram 3-conductor co nnection, grounded

Pos: 67 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 30

30 Process Image WAGO-I/O-SYSTEM 750

Table 10: Output bits

Bit 1

Bit 0

DO 2

DO 1

DO 1

Signal state DO 1 – Digital output channel 1

DO 2

Signal state DO 2 – Digital output channel 2

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 68 /All e Serien ( Allgemeine Module)/Ü berschrift en für al le Serien/P rozessab bild - Übers c hrift 1 @ 4\mod_1240983067828_21.doc @ 31942 @ 1 @ 1

6 Process Image

Pos: 69 /Ser ie 750 ( WAGO-I/O-SYSTEM)/Prozessabbild Klemmenbus/Hinweis: Prozessabbildmapping abhängig von FBK/PFC, ohne Status-/Controlbyte @ 6\mod_1256126797251_21.doc @ 43340 @ @ 1

Mapping of process data in the process image of fieldbus systems

The representation of the process data of some I/O modules or their variations in

the process image depends on the fieldbus coupler/controller used. Please take

this information from the section "Fieldbus Specific Design of the Process Data"

included in the description concerning the process image of the corresponding

coupler/controller.

Pos: 70 /Ser ie 750 ( WAGO-I/O-SYST EM)/Proz essabbild Kl emmenbus /Digitala usgangskl emmen/Proz essabbild 750-x5xx 02 DO @ 4\mod_1236259966765_21.doc @ 28040 @ @ 1

Pos: 71 /Dokum e nt a ti o n al l g e mein/Glie der ungselem en te/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 31

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 31

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.1 /Al le Serie n (Allgemei ne Module) /Einsatz in Ex-Berei c h e n/ Ei nsatz in expl osi onsgefä hr d eten Bereic he n - Ü berschrif t 1 @ 3\mod_1224075191281_21.doc @ 24084 @ 1 @ 1

7 Use in Hazardou s E nvironments

Pos: 72.2 /Serie 750 (WAGO-I/O-SYSTEM)/Eins atz in Ex-B ereichen/Ei nsatzber eich Serie 750 @ 3\mod_1234272230203_21.doc @ 2750 0 @ @ 1

The WAGO-I/O-SYSTEM 750 (electrical equipment) is designed for use in

Zone 2 hazardous areas.

The following sections include both the general identification of components

(devices) and the installation regulations to be observed. The individual

subsections of the "Installation Regulations" section must be taken into account if

the I/O module has the required approval or is subject to the range of application

of the ATEX directive.

Pos: 72.3 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.do c @ 21810 @ @ 1

Manual

Version 1.2.0

Page 32

32 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.4 /Serie 750 (WAGO-I/O-SYSTEM)/Eins atz in Ex-B ereichen/B eispielha fter Aufba u der Kennz eichnung - Ü berschrif t 2 @ 3\mod_1224157499140_21.doc @ 24182 @ 2 @ 1

7.1 Marking Configuration Examples

Pos: 72.5 /Serie 750 (WAGO-I/O-SYSTEM)/Eins atz in Ex-B ereichen/K ennzeichn ung für Eur opa gemäß ATEX und IEC-EX - Über schrift 3 @ 3\mod_1224157620203_21.d oc @ 24185 @ 3 @ 1

7.1.1 Marking for Europe according to ATEX and IEC-Ex

Pos: 72.6 /Serie 750 (WAGO-I/O-SYSTEM)/Eins atz in Ex-B ereichen/B eispielbe druckung d er ATEX- un d IE C- Ex-zugelassenen Busklemmen gemäß CENELEC und IEC_2013 @ 14\mod_1360569228625_21.doc @ 111294 @ @ 1

Figure 13: Side marking example for approved I/O modules according to ATEX and IECEx

Figure 14: Printing Text d e ta il – Marking example for approved I/O modules according to ATEX

and IECEx.

Manual

Version 1.2.0

Page 33

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 33

Table 11: Description of marking example for approved I/O modules according to ATEX and

IECEx

Printing on Text

Description

TÜV 07 ATEX 554086 X

IECEx TUN 09.0001 X

Approving authority and certificate numbers

Dust

II

Equipment group: All except mining

3D

Category 3 (Zone 22)

Ex

Explosion protection mark

tc Dc

Type of protection and equipment protection

level (EPL):protection by enclosure

IIIC

Explosion group of dust

T 135°C

Max. surface temperature of the enclosure

(without a dust layer)

Mining

I

Equipment group: Mining

M2

Category: High level of protection

Ex

Explosion protection mark

d Mb

Type of protection and equipment protection

level (EPL): Flameproof enclosure

I

Explosion group for electrical equipment for

mines susceptible to firedamp

Gases

II

Equipment group: All except mining

3G

Category 3 (Zone 2)

Ex

Explosion protection mark

nA Gc

Type of protection and equipment protection

level (EPL): Non-sparking equipment

nC Gc

Type of protection and equipment protection

interior

IIC

Explosion group of gas and vapours

T4

Temperature class: Max. surface temperature

135°C

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.7 /Dokumentation allgem ein/Gliederungsel em ente/---Seitenwechsel--- @ 3\ mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

level (EPL): Sparking apparatus with protected

contacts. A device which is so constructed that

the external atmosphere cannot gain access to the

Page 34

34 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.8 /Serie 750 (WAGO-I/O-SYSTEM)/Eins atz in Ex-B ereichen/B eispielbe druckung d er Ex-i- und IEC-Ex-i-zugelass enen Bus klemmen ge mäß CENELEC und IEC_2013 @ 14\mod_1360569320118_21.doc @ 111298 @ @ 1

Figure 15: Side marking example for approved Ex i I/O modules according to ATEX and IECEx.

Figure 16: Text de ta il – Marking example for approved Ex i I/O modules according to ATEX and

IECEx.

Manual

Version 1.2.0

Page 35

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 35

Table 12: Description of marking example for approved Ex i I/O modules according to ATEX and

IECEx

Inscription text

Description

TÜV 07 ATEX 554086 X

IECEx TUN 12.0039 X

Approving authority and certificate numbers

Dust

II

Equipment group: All except mining

3(1)D

Category 3 (Zone 22) equipment containing a safety

device for a category 1 (Zone 20) equipment

3(2)D

Category 3 (Zone 22) equipment containing a safety

device for a category 2 (Zone 21) equipment

Ex

Explosion protection mark

tc Dc

Type of protection and equipment protection level

(EPL): protection by enclosure

[ia Da]

Type of protection and equipment protection level

circuits for use in Zone 20

[ib Db]

Type of protection and equipment protection level

circuits for use in Zone 21

IIIC

Explosion group of dust

T 135°C

Max. surface temperature of the enclosure (without a

dust layer)

Mining

I

Equipment Group: Mining

M2 (M1)

Category: High level of protection with electrical

circuits which present a very high level of protection

Ex d Mb

Explosion protection mark with Type of protection

enclosure

[ia Ma]

Type of protection and equipment protection level

electrical circuits

I Explosion group for electrical equipment for mines

susceptible to firedamp

750-512 2DO 230V AC 2.0A/ Relay 2NO

IECEx TUN 09.0001X

TÜV 12 ATEX 106032 X

(EPL): associated apparatus with intrinsic safety

(EPL): associated apparatus with intrinsic safety

and equipment protection level (EPL): Flameproof

(EPL): associated apparatus with intrinsic safety

Manual

Version 1.2.0

Page 36

36 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

Table 12: Description of marking example for approved Ex i I/O modules according to ATEX and

IECEx

Gases

II

Equipment group: All except mining

3(1)G

Category 3 (Zone 2) equipment containing a safety

device for a category 1 (Zone 0) equipment

3(2)G

Category 3 (Zone 2) equipment containing a safety

device for a category 2 (Zone 1) equipment

Ex

Explosion protection mark

nA Gc

Type of protection and equipment protection level

(EPL): Non-sparking equipment

[ia Ga]

Type of protection and equipment protection level

circuits for use in Zone 0

[ia Gb]

Type of protection and equipment protection level

circuits for use in Zone 1

IIC

Explosion group of gas and vapours

T4

Temperature class: Max. surface temperature 135°C

750-512 2DO 230V AC 2.0A/ Relay 2NO

(EPL): associated apparatus with intrinsic safety

(EPL): associated apparatus with intrinsic safety

Pos: 72.9 /Doku mentatio n all g emein/Gli e der ungsele m ente/---Seiten wechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 37

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 37

Table 13: Description of marking example for approved I/O modules according to NEC 500

Printing on Text

Description

CL I

Explosion protection group (condition of use

category)

DIV 2

Area of application

Grp. ABCD

Explosion group (gas group)

Op temp code T4

Temperature class

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.10 / Serie 750 ( WAGO-I/O-SY STEM)/Einsa tz in Ex-Ber eichen/K ennzeichn ung für Amer ika gemäß N EC 500 - Überschrif t 3 @ 3\ mod_12241584231 87_21.doc @ 24188 @ 3 @ 1

7.1.2 Marking for America according to NEC 500

Pos: 72.11 / Serie 750 ( WAGO-I/O-SY STEM)/Einsa tz in Ex-Ber eichen/B eispielbedr uckung g emäß NEC 5 00_2013 @ 1 4\mod_1360580302684_21.doc @ 111353 @ @ 1

Figure 17: Side marking example for I/O modules according to NEC 500

Pos: 72.12 /D okument ation allge mein/Gli ederungsel emente/---Seit enwechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Figure 18: Text detail – Marking example for approved I/O modules according to NEC 500

Manual

Version 1.2.0

Page 38

38 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.13 / Alle Seri en (Allgem eine Modul e)/Einsatz in Ex-Berei chen/Err ichtungsb estimmung en @ 3\mod_1232453624234_21.doc @ 26370 @ 2 @ 1

7.2 Installation Regulations

Pos: 72.14 / Alle Seri en (Allgem eine Modul e)/Einsatz in Ex-Bereichen/Errichtungsbestimmungen Ei nleitung _2013 @ 1 4\mod_1360582328318_21.doc @ 111371 @ @ 1

For the installation and operation of electrical equipment in hazardous areas, the

valid national and international rules and regulations which are applicable at the

installation location must be carefully followed.

Pos: 72.15 /D okument ation allge mein/Gli ederungsel emente/---Seit enwechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 39

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 39

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.16 / Serie 750 ( WAGO-I/O-SY STEM)/Einsa tz in Ex-Ber ei c hen/Beso n der e Bedingung e n f ür d en sic h er en Ex-Betrieb g em. ATEX-Zer ti fi kat TÜV 07 ATE X 554086_X _2 01 3 @ 14 \ mod_1360582650801_21.doc @ 111375 @ 3 @ 1

7.2.1 Special conditions for safe use (ATEX Certificate TÜV 07 ATEX 554086 X)

1. For use as Gc- or Dc-apparatus (in zone 2 or 22) the Field bus Independent

I/O Modules WAGO-I/O-SYSTEM 750-*** shall be erected in an

enclosure that fulfils the requirements of the applicable standards (see the

marking) EN 60079-0, EN 60079-11, EN 60079-15 and EN 60079-31.

For use as group I electrical apparatu s M2 the apparatus shall be erected in

an enclosure that ensures a sufficient protection according to EN 60079-0

and EN 60079-1 and the degree of protection IP64.

The compliance of these requirements and the correct installation into an

enclosure or a control cabinet of the devices shall be certified by an ExNB.

2. Measures have to be taken outside of the device that the rating voltage is not

being exceeded of more than 40 % because of transient disturbances.

3. Dip-switches, binary-switches and potentiometers, connected to the module

may only be actuated when explosive atmosphere can be excluded.

4. The connecting and disconnecting of the non-intrinsically safe circuits is

only permitted during installation, for maintenance or for repair purposes.

The temporal coincidence of explosion hazardous atmosphere and

installation, maintenance resp. repair purposes shall be excluded.

This is although and in particular valid for the interfaces “Memory-Card”,

“USB”, “Fieldbus connection”, “Configuration and programming interface”,

“antenna socket”, “D-Sub”, “DVI-port” and the “Ethernet interface”. These

interfaces are not energy limited or intrinsically safe circuits. An operating

of those circuits is in the behalf of the operator.

5. For the types 750-606, 750-625/000-001, 750-487/003-000, 750-484, 750-

633 the following shall be considered: The Interface circuits shall be limited

to overvoltage category I/II/III (non mains/mains circuits) as defined in EN

60664-1.

6. For replaceable fuses the following shall be considered: Do not remove or

replace the fuse when the apparatus is energized.

7. The following warnings shall be placed nearby the unit:

WARNING – DO NOT REMOVE OR REPLACE FUSE WHEN

ENERGIZED

WARNING – DO NOT SEPARATE WHEN ENERGIZED

WARNING – SEPARATE ONLY IN A NON-HAZARDOUS AREA

Pos: 72.17 /D okument ation allge mein/Gli ederungsel emente/---Seit enwechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 40

40 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.18 / Serie 750 ( WAGO-I/O-SY STEM)/Einsa tz in Ex-Ber ei c hen/Beso n der e Bedingung e n f ür d en sic h er en Ex-Betri eb gem. ATEX-Z ertifikat TÜ V 12 ATEX 1060 3 2 x @ 14 \ mod_1360742619838_21.doc @ 111760 @ 3 @ 1

7.2.2 Special conditions for safe use (ATEX Certificate TÜV 12 ATEX 106032 X)

1. For use as Gc- or Dc-apparatus (in zone 2 or 22) the Field bus Independent

I/O Modules WAGO-I/O-SYSTEM 750-*** Ex i shall be erected in an

enclosure that fulfils the requirements of the applicable standards (see the

marking) EN 60079-0, EN 60079-11, EN 60079-15 and EN 60079-31.

For use as group I electrical apparatus M2 the apparatus shall be erected in

an enclosure that ensures a sufficient protection according to EN 60079-0

and EN 60079-1 and the degree of protection IP64.

The compliance of these requirements and the correct installation into an

enclosure or a control cabinet of the devices shall be certified by an ExNB.

2. Measures have to be taken outside of the device that the rating voltage is not

being exceeded of more than 40 % because of transient disturbances.

3. The connecting and disconnecting of the non-intrinsically safe circuits is

only permitted during installation, for maintenance or for repair purposes.

The temporal coincidence of explosion hazardous atmosphere and

installation, maintenance resp. repair purposes shall be excluded.

4. For the type 750-633/000-003 the following shall be considered: The

Interface circuits shall be limited to overvoltage category I/II/III (non

mains/mains circuits) as defined in EN 60664-1.

Pos: 72.19 /D okument ation allge mein/Gli ederungsel emente/---Seit enwechsel--- @ 3\mod_1221108045078_0.doc @ 21810 @ @ 1

Manual

Version 1.2.0

Page 41

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 41

750-512 2DO 230V AC 2.0A/ Relay 2NO

Pos: 72.20 / Serie 750 ( WAGO-I/O-SY STEM)/Einsa tz in Ex-Ber ei c hen/Beso n der e Bedingung e n f ür d en sic h er en Ex-Betrieb gem. IEC-Ex-Zertifikat TUN 09.0001 X_2013 @ 14\mod_1360585996322_21.doc @ 111379 @ 3 @ 1

7.2.3 Special conditions for s af e use (I E C-Ex Cert ificate TUN

09.0001 X)

1. For use as Gc- or Dc-apparatus (in zone 2 or 22) the Field bus Independent

I/O Modules WAGO-I/O-SYSTEM 750-*** shall be erected in an

enclosure that fulfils the requirements of the applicable standards (see the

marking) IEC 60079-0, IEC 60079-11, IEC 60079-15 and IEC 60079-31.

For use as group I electrical apparatus M2 the apparatus shall be erected in

an enclosure that ensures a sufficient protection according to IEC 60079-0

and IEC 60079-1 and the degree of protection IP64.

The compliance of these requirements and the correct installation into an

enclosure or a control cabinet of the devices shall be certified by an ExCB.

2. Measures have to be taken outside of the device that the rating voltage is not

being exceeded of more than 40 % because of transient disturbances.

3. DIP-switches, binary-switches and potentiometers, connected to the module

may only be actuated when explosive atmosphere can be excluded.

4. The connecting and disconnecting of the non-intrinsically safe circuits is

only permitted during installation, for maintenance or for repair purposes.

The temporal coincidence of explosion hazardous atmosphere and

installation, maintenance resp. repair purposes shall be excluded.

This is although and in particular valid for the interfaces “Memory-Card”,