Page 1

Pos: 2 /Dokumentation allgemein/Einband/Einband Handbuch - Frontseite 2015 - mit Doc Var iabl en ( Sta ndar d) @ 9\ mod_1285229289866_0.docx @ 64941 @ @ 1

WAGO-I/O-SYSTEM 750

Manual

750-493(/xxx-xxx)

3-Phase Power Measurem

ent Module

Version 1.2.0

Pos: 3 /Alle Ser ie n (All ge mein e M odul e) /Hin weis e z ur D oku men tat ion/I mpr es sum für Sta ndar dh and büch er - allg. Anga ben, Ans chrif ten, Tel efo nnummer n und E-M ail- Adres sen @ 3\mod_1219151118203_21.docx @ 21060 @ @ 1

Page 2

2 WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

© 2015 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

=== Ende der Lis te f ür T e xtmar ke E inb and _v orne = ==

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 5 /Dok ume ntati on allg em ein/ Ver zeic hni sse /Inh alts ver zei chni s - Ü bersc hrif t oG und Ver zeich nis @ 3\ mod_1219151230875_21.docx @ 21063 @ @ 1

Table of Contents

1 Notes about this Documentation ................................................................. 6

1.1 Validity of this Documentation ................................................................. 6

1.2 Revision History ........................................................................................ 6

1.3 Copyright ................................................................................................... 7

1.4 Symbols ..................................................................................................... 8

1.5 Number Notation ..................................................................................... 10

1.6 Font Conventions .................................................................................... 10

2 Important Notes ......................................................................................... 11

2.1 Legal Bases ............................................................................................. 11

2.1.1 Subject to Changes ............................................................................. 11

2.1.2 Personnel Qualifications ..................................................................... 11

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying

Provisions ........................................................................................... 11

2.1.4 Technical Condition of Specified Devices ......................................... 12

2.2 Safety Advice (Precautions) .................................................................... 13

3 Device Description ..................................................................................... 15

3.1 View ........................................................................................................ 16

3.2 Connectors ............................................................................................... 17

3.2.1 Data Contacts/Internal Bus ................................................................. 17

3.2.2 Power Jumper Contacts/Field Supply ................................................ 17

3.2.3 CAGE CLAMP® Connectors ............................................................. 18

3.3 Display Elements .................................................................................... 19

3.4 Operating Elements ................................................................................. 19

3.5 Schematic Diagram ................................................................................. 20

3.6 Technical Data ........................................................................................ 21

3.6.1 Dimensions and Weight ..................................................................... 21

3.6.2 Voltage Supply ................................................................................... 21

3.6.3 Measuring Inputs ................................................................................ 21

3.6.4 Measuring Signal Processing ............................................................. 22

3.6.5 Internal Bus Communication .............................................................. 22

3.6.6 Connection Type ................................................................................ 22

3.6.7 Climatic Environmental Conditions ................................................... 23

3.7 Approvals ................................................................................................ 24

3.8 Standards and Guidelines ........................................................................ 25

4 Process Image ............................................................................................. 26

4.1 Input and Output Data ............................................................................. 26

4.2 Simple Process Image ............................................................................. 27

4.3 Flexible Process Image ........................................................................... 28

4.4 Control and Status Bytes ......................................................................... 29

5 Function Description ................................................................................. 35

5.1 Measuring Principle ................................................................................ 35

5.2 Measured Values and Measured Value Calculation ............................... 35

5.3 Representation of the Measured Values in the Process Image (PI) ........ 39

5.4 Measuring Errors and Accuracy .............................................................. 46

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

6 Mounting ..................................................................................................... 47

6.1 Mounting Sequence ................................................................................. 47

6.2 Inserting and Removing Devices ............................................................ 48

6.2.1 Inserting the I/O Module .................................................................... 48

6.2.2 Removing the I/O Module .................................................................. 49

7 Connect Devices ......................................................................................... 50

7.1 Connecting a Conductor to the CAGE CLAMP® ................................... 50

7.2 Voltage Measurement ............................................................................. 51

7.3 Current Measurement .............................................................................. 52

7.3.1 Current Measurement on a Motor ...................................................... 52

7.3.2 Current Transformers ......................................................................... 53

7.3.2.1 Accuracy ........................................................................................ 53

7.3.2.2 Types of Current ............................................................................ 53

7.3.2.3 Overcurrent Limiting Factor FS .................................................... 53

7.3.2.4 Protection against Shock Hazard Voltages .................................... 54

7.3.3 Additional Measuring Instruments in the Current Path ...................... 55

7.4 Power Measurement ................................................................................ 56

7.4.1 Power Measurement on a Machine .................................................... 56

7.4.2 56

8 Commissioning ........................................................................................... 57

8.1 Configuration with WAGO-I/O-CHECK ............................................... 58

8.1.1 "Application" Tab ............................................................................... 61

8.1.2 "Phase L1”, “Phase L2”, “Phase L3” Tabs ........................................ 62

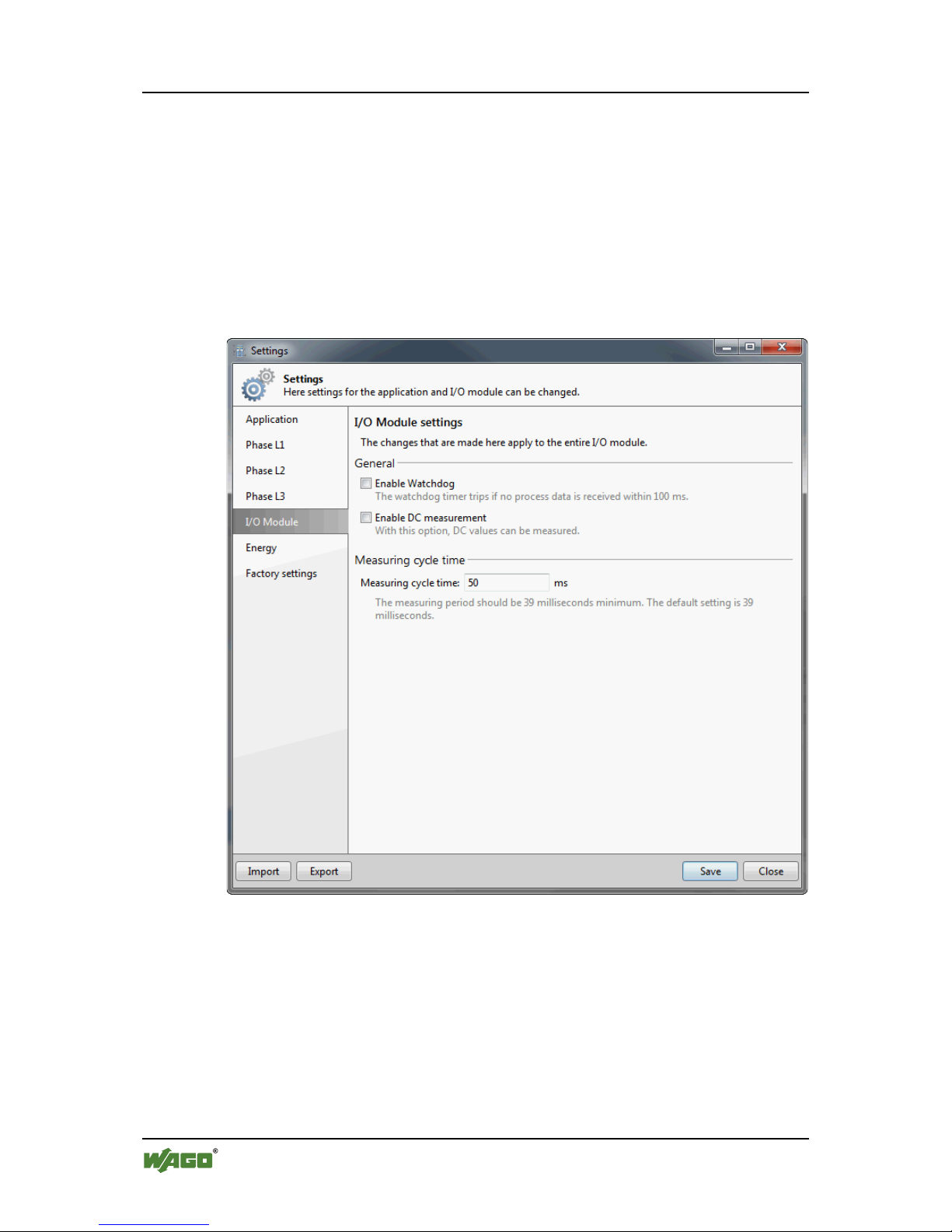

8.1.3 "I/O Module" Tab ............................................................................... 64

8.1.4 "Energy" Tab ...................................................................................... 65

8.1.5 "Factory Settings" Tab ....................................................................... 66

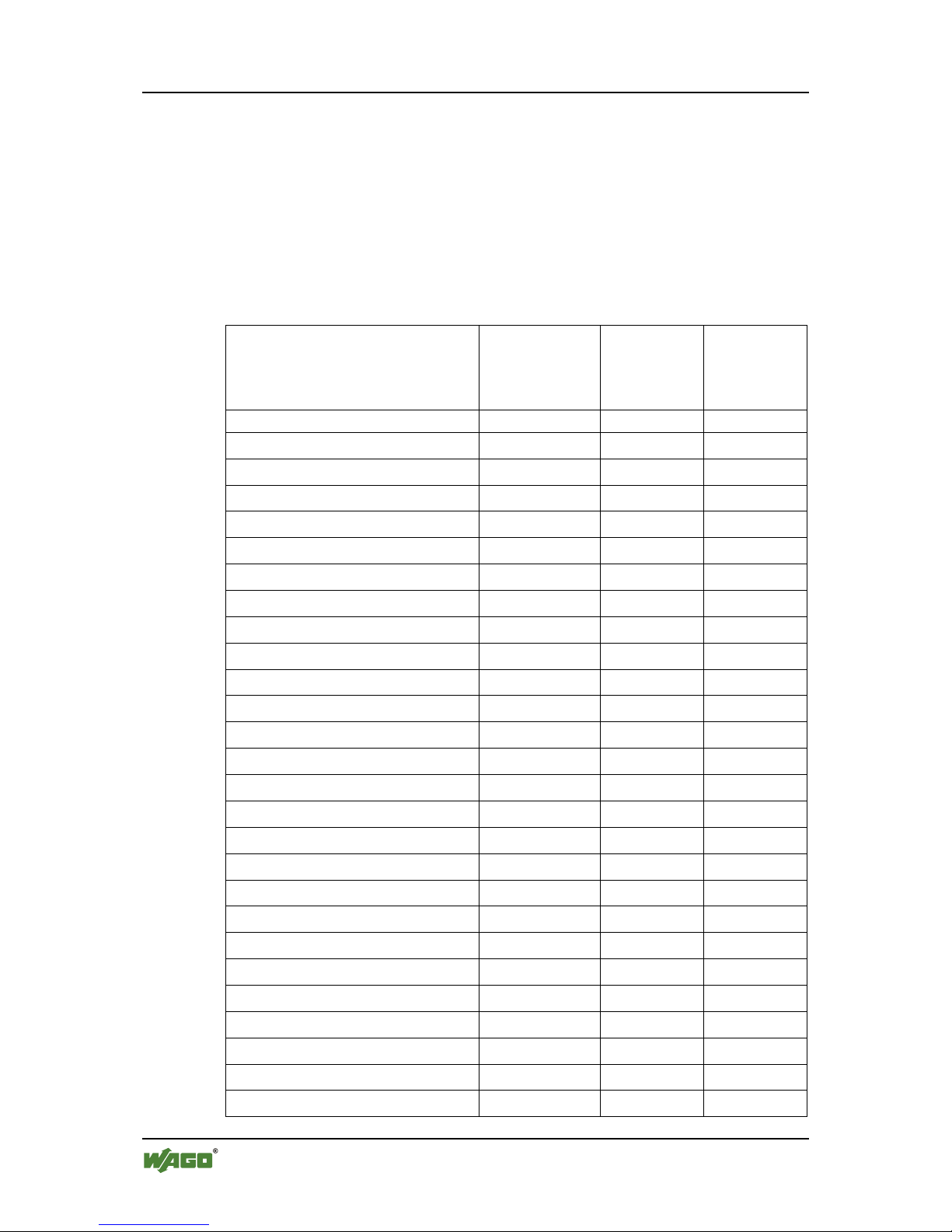

8.1.6 Register Assignment ........................................................................... 67

8.2 Displaying the Measured Values via WAGO-I/O-CHECK .................... 70

9 Diagnostics .................................................................................................. 77

10 Appendix ..................................................................................................... 78

10.1 CSV Data File “Snapshot” ...................................................................... 78

10.2 CSV Data File “Measurement Recording” ............................................. 80

11 Use in Hazardous Environments .............................................................. 81

11.1 Marking Configuration Examples ........................................................... 82

11.1.1 Marking for Europe According to ATEX and IEC-Ex ...................... 82

11.1.2 Marking for America According to NEC 500 .................................... 87

11.2 Installation Regulations ........................................................................... 88

11.2.1 Special Conditions for Safe Use (ATEX Certificate TÜV 07 ATEX

554086 X) ........................................................................................... 89

11.2.2 Special Conditions for Safe Use (ATEX Certificate TÜV 12 ATEX

106032 X) ........................................................................................... 90

11.2.3 Special Conditions for Safe Use (IEC-Ex Certificate TUN 09.0001 X)91

11.2.4 Special Conditions for Safe Use (IEC-Ex Certificate IECEx TUN

12.0039 X) .......................................................................................... 92

11.2.5 Special Conditions for Safe Use According to ANSI/ISA 12.12.01 .. 93

List of Figures ...................................................................................................... 94

Page 5

WAGO-I/O-SYSTEM 750 Table of Contents 5

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

List of Tables ........................................................................................................ 95

=== Ende der Lis te f ür T e xtmar ke V erz eic hni s_vor ne == =

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 7 /Alle Ser ie n (All ge mein e M odul e) /Über sc hri ften für all e S erie n/Hi n weise zur Do ku ment ati on/Hi nw eise zu dies er D o kume ntat ion - Üb ersc hrif t 1 @ 4 \mod_1237987661750_21.docx @ 29029 @ 1 @ 1

1 Notes about this Documentation

Pos: 8 /Alle Ser ie n (All ge mein e M odul e) /Hin weis e z ur D oku men tat ion/H i nweis e/Hi n weis : D okum ent atio n a ufbe wahr e n @ 4 \mod_1237987339812_21.docx @ 29026 @ @ 1

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

Pos: 9 /Alle Ser ie n (All ge mein e M odul e) /Über sc hri ften für all e S erie n/Hi n weise zur Do ku ment ati on/G ülti g keitsb erei ch - Üb ersc hrif t 2 @ 12\mod_1338912448776_21.docx @ 96469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/Hi n weis e zur D okum ent ati on/G ülti gk eits ber eic h/Gül tig kei ts berei ch D ok umen ta tion Bus kle mme 75 0-x xxx, S tan dar dvers i on u nd aufg elis tet e Var ia nte n @ 14\mod_1358944038682_21.docx @ 109354 @ @ 1

This documentation is only applicable to the I/O module 750-493 (3-Phase Power

Measurement Module) and the variants listed in the table below.

Pos: 11 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/Hi n weis e zur D okum ent ati on/G ülti gk eits ber eic h/Var ia nte nlis ten/ Var ia ntenli st e - 7 50-49 3 - Standardversionen 1A+5A und erw.Temp. /025- @ 23\mod_1433851670418_21.docx @ 183628 @ @ 1

Table 1: Variants

Item Number

Description

750-493

3-Phase Power Measurement Module 1 A

750-493/000-001

3-Phase Power Measurement Module 5 A

750-493/025-000

3-Phase Power Measurement Module 1 A,

Operating temperature -20 °C … +60 °C

750-493/025-001

3-Phase Power Measurement Module 5A,

Operating temperature -20 °C … +60 °C

Pos: 12 /All e Ser i en (A llg emei ne M od ule) /Hi nweis e zur D o kume ntat ion /Hi nwei se /Hin weis : G ülti g keit d er Anga ben für aufg el iste te Vari ant en @ 9\mod_1281520778141_21.docx @ 63085 @ @ 1

Documentation Validity for Variants

Unless otherwise indicated, the information given in this documentation applies to

listed variants.

Pos: 13 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/Hi n weis e zur D okum ent ati on/Hi n weise /Ac htu ng: Hin weis zur D oku ment ati on B us kle mmen 75 0-xxxx @ 4\ mod_1237986979656_21.docx @ 29023 @ @ 1

The I/O module 750-493 shall only be installed and operated according to the

instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos: 14 /Alle Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/H in weis e z ur D oku ment ati on/ Änd eru ngshi stor ie - Üb erschr ift 2 @ 6\mod_1255513312687_21.docx @ 42790 @ 2 @ 1

1.2 Revision History

Pos: 15 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/Hi n weis e zur D okum ent ati on/Ä nder ung shis tori e/ Buskl em men/ Änder ung shis tori e -493 @ 13\mod_1346246064669_21.docx @ 102093 @ @ 1

Page 7

WAGO-I/O-SYSTEM 750 Notes about this Documentation 7

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Table 2: Revision History

Document

Version

Device Version

Description of Change

Hardware

Software

1.0.1

‒

‒

First issue

1.1.0

≥ 20

≥ 01

Total revision with new layout

1.2.0

≥ 20

≥ 01

Variants

750-493

/025-000 and

750-493

/025-

001 for extended temperature range added.

Pos: 16.1 /Al le Seri en ( All ge mei ne Mo dul e)/H in weis e z ur D oku ment ati on/ Urh eber sc hutz aus führ lic h @ 4\mod_1235565145234_21.docx @ 27691 @ 2 @ 1

1.3 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Pos: 16.2 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 16.3 /Al le Seri en ( All ge mei ne Mo dul e)/Ü bers chr ift en f ür all e S erie n/Hi nwei s e zur Dok um enta tio n/S ymbol e - Ü bers chr ift 2 @ 13\ mod_1351068042408_21.docx @ 105270 @ 2 @ 1

1.4 Symbols

Pos: 16.4.1 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Gefahr/Gefahr: _Warnung vor Personenschäden allgemein_ - Erläuterung @ 13\mod_1343309450020_21.docx @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 16.4.2 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonsti ge Hinw eise/ Gefa hr/Gef ahr: _ Warnu ng vor Per son enschä den durc h elek trisc hen Stro m_ - Erläuterung @ 13\mod_1343309694914_21.docx @ 10103 0 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 16.4.3 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sich erh eits- und sons tig e Hi nwei se/ W arnung / Warn ung: _W arn ung vor P erso nensc h äde n allg em ein_ - Erläuterung @ 13\mod_1343309877041_21.docx @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 16.4.4 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und sons tige Hin weis e/Vorsi cht /Vorsi cht: _ Warnu ng vor Per sone nschä den allg emei n_ - Erläuterung @ 13\mod_1343310028762_21.docx @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 16.4.5 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Achtung/Achtung: _Warnung vor Sachschäden allgemein_ - Erläuterung @ 13\mod_1343310134623_21.docx @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 16.4.6 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Achtung/Achtung: _Warnung vor Sachschäden durch elektrostatische Aufladung_ - Erläuterung @ 13\mod_1343310227702_21.docx @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 16.4.7 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Erläuterung @ 13\mod_1343310326906_21.docx @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 16.4.8 /All e Serie n (Allg emei ne Mod ule)/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nsti ge H inw eis e/I nfor mat ion/I nf or matio n: _W eiter e Inf or mati on allg emei n_ - Erl äuter ung @ 13 \mod_1343310439814_21.docx @ 101051 @ @ 1

Page 9

WAGO-I/O-SYSTEM 750 Notes about this Documentation 9

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 16.5 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 10

10 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 16.6 /Alle Ser ien ( Allge meine Module) /Hin weise z ur Doku ment ation/ Zahle nsyst eme @ 3\mod_1221059454015_21.docx @ 21711 @ 2 @ 1

1.5 Number Notation

Table 3: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Pos: 16.7 /Alle Ser ien ( Allge meine Module) /Hin weise z ur Doku ment ation/ Schri ftko nventi onen @ 3\ mod_1221059521437_21.docx @ 21714 @ 2 @ 1

1.6 Font Conventions

Table 4: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

menu item from a menu.

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

brackets.

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

Pos: 17 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 11

WAGO-I/O-SYSTEM 750 Important Notes 11

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 18 /Alle Seri en (All gemei ne Mod ule)/Ü bers chrif ten für al le Seri en/Wi chtig e Erlä uteru ngen/ Wichti ge Erlä uteru ngen - Üb ersc hrift 1 @ 4\mod_1241428899156_21.docx @ 32170 @ 1 @ 1

2 Important Notes

Pos: 19.1 /Al le Seri en ( All ge mei ne Do ku ment e) ( All ge meine Mo dul e)/ Wic htig e Erl äut eru nge n/Wi cht ige Erl äut eru nge n - Ei nleit ung @ 3\mod_1221059818031_21.docx @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 19.2 /All e Ser i en ( Allg emei ne Mod ule) /Ü bers chri fte n für al le Ser ien/ Wich tig e Er lä uter ung en/R ech tli che Gr u ndl age n - Ü bersc hri ft 2 @ 3\mod_1221060626343_21.docx @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 19.3 /Al le Seri en ( All ge mei ne Do ku ment e) ( All ge meine Mo dul e)/ Wic htige Erläuterungen/Änderungsvorbehalt - Überschrift 3 un d In halt @ 3\ mod_1221060036484_21.docx @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 19.4 /Serie 750 (WAGO-I/O-SYSTEM)/ Wichti ge Erlä uteru ngen/ Pers onalqu alifi katio nPers onalq ualif ikati on 750- xxxx - Über schr ift 3 und Inhalt @ 3\ mod_1224061208046_21.docx @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 19.5 /Serie 750 (WAGO-I/O-SYSTEM)/ Wichti ge Erlä uteru ngen/ Besti mmung sge mäße Ver wend ungBes tim mungsgemäße Verwendung 750-xxxx - Überschrif t 3 un d In hal t @ 3 \mod_1224064151234_21.docx @ 24070 @ 3 @ 1

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with

Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 19.6 /Al le Seri en ( All ge mei ne Do ku ment e) ( All ge meine Mo dul e)/ Wic htig e Erl äut eru nge n/T echni sc her Zus tan d d er G erä te - Ü bers chri ft 3 und Inh alt @ 3\mod_1221060446109_21.docx @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 19.7 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 13

WAGO-I/O-SYSTEM 750 Important Notes 13

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 19.8 /Alle Ser ien ( Allge meine Module) /Übers chri ften für alle S erien/ Wicht ige Erl äuter ungen /Sich erheitshinweise - Üb ersc hrift 2 @ 6\ mod_1260180299987_21.docx @ 46724 @ 2 @ 1

2.2 Safety Advice (Precautions)

Pos: 19.9 /Al le Seri en ( All ge mei ne Do ku ment e) ( All ge meine Mo dul e)/ Wic htig e Erl äut eru nge n/Si ch erhei ts hin weis e/Ei nl eitu ng Sich erh eitshi nweis e Hard ware @ 6\ mod_1260180170493_21.docx @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 19.10 / Ser ie 7 50 ( WAG O-I/ O-SYST EM )/ Wichti g e Erl äut erung en /Sic her hei ts- und s ons tig e Hi nw eise /Gef ahr/ G efahr : B erü hru ngssc hu tz vorse hen 75 0-0 493/04 94/Gef ahr: Berühr ungss chutz vorse hen 750- 0493/0494/0495 @ 15\mod_1366120208015_21.docx @ 117160 @ @ 1

Install protection against electric shock!

All wiring for the measurement system shall be provided with protection against

shock hazard voltages along with the corresponding safety signs!

Pos: 19.11. 1 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /G efahr /G ef ahr: Nich t an G erät en unter Sp ann ung arbei te n! @ 6\ mod_1260180365327_21.docx @ 46727 @ @ 1

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 19.11. 2 /S eri e 75 0 (W AG O-I/O-SY ST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- un d s onsti ge H in wei se/G ef ahr/ Gefa hr: Ei nbau 07 50-x xxx nur i n Gehäus en, Sc hrän ken oder el ektri sche n Betri ebsrä umen! @ 6\mod_1260180556692_21.docx @ 46731 @ @ 1

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 19.11. 3 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /G efahr /G ef ahr: Unfal l verh ütung s vorsc hr ift en b eachten! @ 6\mod_1260180657000_21.docx @ 46735 @ @ 1

Pos: 19.11. 4 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /G efahr /G ef ahr: Auf nor mger ec hte n Ansc hl uss ac hten! @ 6\mod_1260180753479_21.docx @ 46739 @ @ 1

Pos: 19.12 / Ser ie 7 50 ( WAG O-I/ O-SYST EM )/ Wichti g e Erl äut erung en /Sic her hei ts- und s ons tig e Hi nw eise /Ac htu ng/Ac ht ung: Kei n d auer ha fter Ei nga ngsst rom über 1 A bz w. 5A 7 50-0493/0494/Achtung: Kein Eingangsstrom über 1A bzw.5A, 750-0493/0494/0495 @ 15\mod_1366120670473_21.docx @ 117163 @ @ 1

Note the max. continuous measuring current of 1 A resp. 5 A!

The max. continuous measuring current of the module is 1 A resp. 5 A. If the

used current transformers allow greater secondary currents than 1 A resp. 5 A

install additional transformers with an appropriate transforming ratio!

Pos: 19.13. 1 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg emein e Modul e)/ Wichti ge Erlä uteru ngen/ Sich erheits hin weise/ Achtu ng/Ac htung : Defe kte oder besch ädigt e Gerät e austa usch en! @ 6\mod_1260180857358_21.docx @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 19.13.2 /Alle Serien (Allgemeine Dokumente) (Allgemeine Module)/Wichtige Erläuterungen/Sicherheitshinweise/Achtung/Achtung: Geräte vor krieche nden u nd isoli erend en Sto ffen sch ütze n! @ 6\mod_1260181036216_21.docx @ 46747 @ @ 1

Page 14

14 Important Notes WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 19.13. 3 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /Ac htu ng/ Acht ung : Rei ni gu ng n ur mi t z uläs sig en M at erial ie n! @ 6\mod_1260181203293_21.docx @ 46751 @ @ 1

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 19.13. 4 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /Ac htu ng/ Acht ung : K ein K o nta ktspr ay verw end en! @ 6\mod_1260181290808_21.docx @ 46755 @ @ 1

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 19.13. 5 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /Ac htu ng/ Acht ung : V erp olung v ermei de n! @ 6\mod_1260184045744_21.docx @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 19.13. 6 /Al le Seri en ( Allg em ein e Do ku ment e) (A llg em eine M o dul e)/ Wich tig e Er läut eru ngen /Sic h erh eits hin weise /Ac htu ng/ Acht ung : El ektr ost atis ch e Ent la dung vermei den! @ 6\mod_1260181364729_21.docx @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Pos: 20 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 15

WAGO-I/O-SYSTEM 750 Device Description 15

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 21 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/G erätebeschreibung - Überschrift 1 @ 3\ mod_1233756084656_21.docx @ 27096 @ 1 @ 1

3 Device Description

Pos: 22 /Seri e 7 50 ( WA GO-I/ O-SYST EM) /Ger ät ebesc hrei bu ng/Ei nlei tu ng/A nalog ei nga ngs klemm en/G erä tebe schr eib ung - Einl eit ung 750- 049 3 @ 13\mod_1346315482161_21.docx @ 102130 @ @ 1

The 3-phase power measurement module (also called I/O module) measures the

electrical data in a 3-phase supply network.

The voltages of the three phases are measured via network connection to L1, L2,

L3 and N. The currents are fed to IL1, IL2, IL3 and IN via current transformers.

The μC unit of the I/O module transmits the RMS (root mean square) values into

the process image. Therefore, no high computing power is required from the

controller. For each phase, the active power (P) and the energy consumption (W)

are calculated by the I/O module using the root mean square values of all

measured voltages (V) and currents (I).

For example, both the apparent power (S) and phase shift angle (phi) can easily be

derived from these values.

Thus, the I/O module provides a comprehensive network analysis via the fieldbus.

By means of values such as voltage, current, active and apparent power

consumption or load condition, the operator can regulate the supply to a drive or

machine in the best possible way and protect the installation from damage or

failure.

The I/O modules 750-493 and 750-493/025-000 measure currents up to 1 A and

the modules 750-493/000-001 and 750-493/025-001 measure up to 5 A.

Pos: 23 /Dokum entati on allg emein/ Glie derung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 16

16 Device Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 24 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/A nsic ht - Ü b erschr if t 2 @ 4 \mod_1240984217343_21.docx @ 31958 @ 2 @ 1

3.1 View

Pos: 25 /Seri e 7 50 ( WA GO-I/ O-SYST EM)/ Ger ätebesc hrei bung/A nsic ht/A nalogei nga ngskl emmen/ Ansi cht 750- 0493 - Abb. @ 13 \mod_1346331472304_21.docx @ 102153 @ @ 1

Figure 1: View

Pos: 26 /Seri e 7 50 ( WA GO-I/ O-SYST EM)/ Ger ätebesc hrei bung/A nsic ht/A nsicht C ageCl amp® _Leg ende mit LEDs_ ohne Leis tung skont akte @ 16\mod_1371816091053_21.docx @ 124052 @ @ 1

Table 5: Legend for Figure “View”

Pos.

Description

Details See Section

1

Marking possibility with

Mini-WSB

--2

Status LEDs

“Device Description” > “Display Elements”

3

Data contacts

“Device Description” > “Connectors”

4

CAGE CLAMP® connectors

“Device Description” > “Connectors”

5

Release tab

“Mounting” > ”Inserting and Removing

Devices”

Pos: 27 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 17

WAGO-I/O-SYSTEM 750 Device Description 17

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 28 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/Gerätebeschreibung/Anschlüsse - Überschrift 2 @ 4\mod_1240984262656_21.docx @ 31961 @ 2 @ 1

3.2 Connectors

Pos: 29 /Seri e 7 50 ( WA GO-I/ O-SYST EM) /Ger ät ebesc hrei bu ng/A nsc hlüs se/D ate nko ntakt e/Kl em menbu s - Ü bersc hrift 3 @ 6\mod_1256294684083_21.docx @ 43660 @ 3 @ 1

3.2.1 Data Contacts/Internal Bus

Pos: 30.1 /Serie 750 (WAGO-I/O-SYSTEM)/ Ger äteb eschr eibu ng/A nsc hl üsse/ Date nkon tak te - F eld bus koppl er/-c ont roll er , Ab bild ung und Bes chr ei bung @ 3 \mod_1231771259187_21.docx @ 26002 @ @ 1

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data Contacts

Pos: 30.2 /Serie 750 (WAGO-I/O-SYSTEM)/ Wichti ge Erlä uteru ngen/ Sich erheits - und sonstige Hinweise/Achtung/Achtung: Busklemmen nicht auf Goldfeder kon takt e leg en! @ 7\mod_1266318463636_21.docx @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 30.3 /Serie 750 (WAGO-I/O-SYSTEM)/ Wichti ge Erlä uteru ngen/ Sich erheits - und sonstige Hinweise/Achtung/Achtung: ESD - Auf gute Erdung der U mgebu ng ac hten! @ 7\mod_1266318538667_21.docx @ 50708 @ @ 1

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 31 /Seri e 7 50 ( WA GO-I/ O-SYST EM) /Ger ät ebesc hrei bu ng/A nsc hlüs se/L eist ung sko nta kte/F eld vers orgu ng - Ü bersc hrift 3 @ 6\mod_1256294692864_21.docx @ 43664 @ 3 @ 1

3.2.2 Power Jumper Contacts/Field Supply

Pos: 32 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Ger äteb esc hrei bung /A nschl üs se/L eist u ngs kont akte nic ht vorh and en @ 8\ mod_1281073936319_21.docx @ 62530 @ @ 1

The I/O module 750-493 has no power jumper contacts.

Pos: 33 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 18

18 Device Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 34 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Ger äteb esc hrei bung /A nschl üs se/C AGE CL AMP- Ans chl üsse - Ü b ersc hrif t 3 @ 6 \mod_1256296337770_21.docx @ 43674 @ 3 @ 1

3.2.3 CAGE CLAMP® Connectors

Pos: 35 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Ger äteb esc hrei bung /A nschl üs se/A nal ogei ng ang skle mm en/A nsc hlü sse 75 0-049 3,-0494 CAGE CLAMP @ 14\mod_1363951572599_21.docx @ 115752 @ @ 1

8 CAGE CLAMP® connectors make up the measuring inputs. The 3-phase supply

network and the loads are clamped here. See also section “Connect Devices“.

Two connectors each form the three measuring channels:

• L1 and IL1: voltage and current of phase L1

• L2 and IL2: voltage and current of phase L2

• L3 and IL3: voltage and current of phase L3

Figure 3: CAGE CLAMP

®

Connectors

Table 6: Legend for Figure “CAGE CLAMP® Connectors”

Channel

Designation

Connector

Function

1

L1

1

Voltage L1

IL1

5

Current L1

2

L2

2

Voltage L2

IL2

6

Current L2

3

L3

3

Voltage L3

IL3

7

Current L3

−

N 4

Neutral wire for

voltage measurement

IN 8

Neutral wire for

current measurement

Pos: 36 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 19

WAGO-I/O-SYSTEM 750 Device Description 19

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 37 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/A nz eigeel e mente - Üb erschr ift 2 @ 4\mod_1240984390875_21.docx @ 31964 @ 2 @ 1

3.3 Display Elements

Pos: 38 /Seri e 7 50 ( WA GO-I/ O-SYST EM)/ Ger ätebesc hrei bung/A nzei geele mente /Anal ogei ngang skle mmen/A nzei geele mente 7 50-0493 @ 13\mod_1348655994627_21.docx @ 103538 @ @ 1

8 LEDs A … H are used to indicate the operating status and possible errors.

The meaning of these indications is listed in section „Diagnostics“.

Figure 4: LED-indicators

Pos: 39 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/B edi enel eme nte - Üb ersc hrif t 2 @ 4 \mod_1239191655456_21.docx @ 30439 @ 2 @ 1

3.4 Operating Elements

Pos: 40 /Serie 750 (WAGO-I/O-SYSTEM)/Ger äteb esc hrei bung /B edie nel em ente/ Bedi en el ement e Buskl em me 7 50- xxxx nicht vor hande n @ 4\mod_1236322031125_21.docx @ 28063 @ @ 1

The I/O module 750-493 has no operating elements.

Pos: 41 /Do kum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 20

20 Device Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 42 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/Sc h emat isch es Sch altbi ld - Über sc hrift 2 @ 4\ mod_1240984441312_21.docx @ 31967 @ 2 @ 1

3.5 Schematic Diagram

Pos: 43 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Ger äteb esc hrei bung /S che mati sc he Sc hal tbil der/ A nalog eing ang skl em men/ Sc hem atisc hes Sc halt bil d 7 50-0 493 @ 13\mod_1348574311920_21.docx @ 103381 @ @ 1

Figure 5: Schematic Diagram

Function Earth FE!

In order to get a function earth, the connections N and IN are connected to the

mounting rail via a 1 nF capacitor and a spring contact. If the rail is correctly

connected to PE, the immunity to interference is increased.

Page 21

WAGO-I/O-SYSTEM 750 Device Description 21

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 44 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Pos: 45 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/T ech nisc he Date n - Ü ber schr if t 2 @ 3\ mod_1232967587687_21.docx @ 26924 @ 2 @ 1

3.6 Technical Data

Pos: 46.1 /Serie 750 (WAGO-I/O-SYSTEM)/ Ger äteb eschr eibu ng/T ech nisc he Date n/ Anal ogei ng angs kl emme n/T ec hnis che D at en 7 50-0 493 @ 13 \mod_1348667756744_21.docx @ 103558 @ 33333 @ 1

3.6.1 Dimensions and Weight

Table 7: Technical Data ‒ Dimensions and Weight

Width

12 mm

Height (from upper edge of carrier rail)

64 mm

Length

100 mm

Weight

48 g

3.6.2 Voltage Supply

Table 8: Technical Data ‒ Voltage Supply

Voltage

System voltage DC 5 V

(via internal bus)

Current consumption

100 mA

Category of overvoltage

III

Rated voltage impulse

4 kV

Degree of distortion

2

3.6.3 Measuring Inputs

Table 9: Technical Data ‒ Measuring Inputs

Number of inputs

6 (3 voltage inputs, 3 current inputs)

Rated measuring voltage max.

Input resistance typ.

Phase-to-phase voltage Lx - Ly:

480 VAC

Phase voltage Lx - N: 277 VAC/DC

1072 kΩ

Measuring current max.

1 A for 750-493,

5 A for 750-493/000-001

1 A for 750-493,025-000

5 A for 750-493/025-001

Input resistance typ.

22 mΩ for 750-493,

5 mΩ for 750-493/000-001

22 mΩ for 750-493/025-000

5 mΩ for 750-493/025-001

Frequency range

- DC filter activated

- DC filter deactivated

10 … 2000 Hz

0 … 2000 Hz

Max. frequency

7.2 kHz

Signal form

any (in consideration of the frequency

range and max. frequency)

Page 22

22 Device Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

3.6.4 Measuring Signal Processing

Table 10: Technical Data ‒ Measuring Signal Processing

Measuring procedure

Calculation of true RMS for voltages

and currents, sample rate 8 kHz per

channel, resolution 24 bits

Measuring cycle time

Configurable for min. and max. values

Measuring error for current and voltage

For AC max. 0.5 %, for DC max. 1.0 %

(of full-scale value)

Calculated values

Active power and energy, network

frequency and cos phi

3.6.5 Internal Bus Communication

Table 11: Technical Data ‒ Internal Bus Communication

Bit width (internal bus)

Input and output data with 9 bytes each

Pos: 46.2 /Al le Seri en ( All ge mei ne Mo dul e)/Ü bers chr ift en f ür all e S erie n/G erät eb esc hreib ung /Ans chl uss tech ni k - Üb ers chri ft 3 @ 1 7\mod_1380123271324_21.docx @ 132788 @ 3 @ 1

3.6.6 Connection Type

Pos: 46.3 /Serie 750 (WAGO-I/O-SYSTEM )/ Ger äteb esc hrei bu ng/T ech nisc he D ate n/ Ansc hlus stec h nik/T ec hnisc h e Dat en Dat en konta kte @ 1 7\mod_1380123495844_21.docx @ 132794 @ @ 1

Table 12: Technical Data – Data Contacts

Data contacts

Slide contact, hard gold plated, selfcleaning

Pos: 46.4 /Serie 750 (WAGO-I/O-SYSTEM)/ Ger äteb esc hrei bung /T ech nisc he D ate n/A nsc hluss tec hni k/T ec hnisc he D at en V erdr ah tung se ben e CC - 0,0 8 bis 2,5 mm2 @ 17\ mod_1380121238809_21.docx @ 132780 @ @ 1

Table 13: Technical Data – Field Wiring

Wire connection

CAGE CLAMP®

Cross section

0.08 mm² … 2.5 mm², AWG 28 … 14

Stripped lengths

8 mm … 9 mm / 0.33 in

Pos: 46.5 /Serie 750 (WAGO-I/O-SYSTEM)/ Ger äteb esc hrei bung /T ech nisc he D ate n/Kl i matis che U mg eb ungs bedi ng ung en/T ech nisc he Dat en Klimat. Umgebungsbed. mit erw. Temp. -20...+60°C/-40...+8 5°C für /02 5 @ 5 \mod_1247658089120_21.docx @ 37606 @ 3 @ 1

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

3.6.7 Climatic Environmental Conditions

Table 14: Technical Data – Climatic Environmental Conditions

Operating temperature range

0 °C … 55 °C

Operating temperature range for

components with extended

temperature range (750-xxx/025-xxx)

−20 °C … +60 °C

Storage temperature range

−25 °C … +85 °C

Storage temperature range for

components with extended

temperature range (750-xxx/025-xxx)

−40 °C … +85 °C

Relative humidity

Max. 5 % … 95 % without condensation

Resistance to harmful substances

Acc. to IEC 60068-2-42 and

IEC 60068-2-43

Maximum pollutant concentration at

relative humidity < 75 %

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

Ensure that additional measures for

components are taken, which are used in

an environment involving:

– dust, caustic vapors or gases

– ionizing radiation

Pos: 47 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 24

24 Device Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 48 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hreibung/Zulassungen - Überschrift 2 @ 3\mod_1224055364109_21.docx @ 24030 @ 2 @ 1

3.7 Approvals

Pos: 49 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Ger äteb esc hrei bung /Z ulass u nge n/Al lgem ei n/Z ulass ung en B us kle mme 7 50- xxx x All ge mein, St and ardv ersi on un d all e Var i ante n - Ei nlei tung @ 3\mod_1233911570312_21.docx @ 27390 @ @ 1

The following approvals have been granted to the basic version and all variants of

750-493 I/O modules:

Pos: 50 /All e Ser i en (A llg emei ne M od ule) /Zul ass ung en/ Stan dar dz ulas sung en/C E ( Ko nfor mi täts ken nzei ch nung ) @ 3\mod_1224494777421_21.docx @ 24276 @ @ 1

Conformity Marking

Pos: 51 /All e Ser i en (A llg emei ne Module)/Zulassungen/Standardzulassungen/cULus (UL508) @ 3\mod_1224055013140_0.docx @ 24020 @ @ 1

CULUS

UL508

Pos: 52 /Seri e 7 50 ( WA GO-I/ O-S YSTEM )/ Ger ät ebesc hrei bu ng/Z ulas su nge n/A llg emei n/Z ulass u nge n Bus kle mme 75 0-x xxx Al lg emei n, S ta ndard ver si on u nd V aria nte 001 - Ei nleit ung @ 20\ mod_1409558703693_21.docx @ 162402 @ @ 1

The following approvals have been granted to the basic version of 750-493 I/O

modules and the variation 750-493/000-001:

Pos: 53 /All e Ser i en (A llg emei ne M od ule) /Zul ass ung en/ Stan dar dz ulas sung en/ KC - Kor ea C er tific ate - AI @ 20\mod_1406533217893_21.docx @ 160376 @ @ 1

Korea Certification MSIP-REM-W43-AIM750

Pos: 54 /Dokum entati on allg emein/ Glie derung sele mente /------Leerz eile------ @ 3\mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 55 /Seri e 7 50 ( WA GO-I/ O-SYST EM)/ Ger ätebesc hrei bung/Z ulass ung en/E x/Zulas sung en Buskl emm e 750-x xxx Ex, Sta ndar dvers ion und al le Var ianten - Einl eitung @ 4\mod_1239099781531_21.docx @ 30158 @ @ 1

The following Ex approvals have been granted to the basic version and all

variants of 750-493 I/O modules:

Pos: 56.1 /Al le Seri en ( All ge mei ne Mo dul e)/Z ula ssu nge n/E x-Zul ass ung en/ TÜV AT EX/T ÜV 0 7 A TEX 554 086 X: I M 2 E x d I M b II 3 G E x nA IIC T4 Gc II 3 D E x tc I IIC T 135°C D c @ 14\mod_1361949753233_0.docx @ 113015 @ @ 1

TÜV 07 ATEX 554086 X

I M2 Ex d I Mb

II 3 G Ex nA IIC T4 Gc

II 3 D Ex tc IIIC T135°C Dc

Pos: 56.2 /Al le Seri en ( All ge mei ne Mo dul e)/Z ula ssu nge n/E x-Zul ass ung en/ IEC Ex ( TÜV N or d) /IEC Ex T UN 09.0 001 X: Ex d I M b E x nA IIC T4 Gc E x tc IIIC T 13 5°C @ 14 \mod_1361950034299_0.docx @ 113019 @ @ 1

IECEx TUN 09.0001 X

Ex d I Mb

Ex nA IIC T4 Gc

Ex tc IIIC T135°C Dc

Pos: 56.3 /Al le Seri en ( All ge mei ne Mo dul e)/Z ula ssu nge n/E x-Zul ass ung en/ cU Lus/c U Lus ( AN SI/IS A 12.1 2.01) Cl ass I, D i v2 ABC D T 4 @ 3\mod_1224054791812_0.docx @ 24014 @ @ 1

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

Pos: 56.4 /Dokumentation allgemein/Gliederungselemente/------Leerzeile------ @ 3\mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 57 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 25

WAGO-I/O-SYSTEM 750 Device Description 25

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 58 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/G erä teb esc hrei bu ng/N orm en u nd R ic htli nien - Üb erschr ift 2 @ 4\mod_1242804031875_21.docx @ 33646 @ 2 @ 1

3.8 Standards and Guidelines

Pos: 59 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Ger äteb esc hrei bung /N orm en u nd Ri cht lini e n/Nor men un d Ri chtl ini en B us kle mme 7 50- xxxx, o hne Var iant enang ab e - Einl eitung @ 7\mod _1274278887584_21.docx @ 56645 @ @ 1

750-493 I/O modules meet the following standards and guidelines:

Pos: 60 /All e Ser i en (A llg emei ne M od ule) /Nor me n un d Ric htl ini en/ Ex( i)-N orm en/ Expl osi ons fähi ge Atm osph äre EN 600 79-0 @ 14 \mod_1360841627885_21.docx @ 111880 @ @ 1

Explosive atmosphere EN 60079-0

Devices – General requirements

Pos: 61 /All e Ser i en (A llg emei ne M od ule) /Nor me n un d Ric htl ini en/ Ex( i)-N orm en/ Expl osi ons fähi ge Atm osph äre EN 600 79-15 @ 13\mod_1351072320086_21.docx @ 105289 @ @ 1

Explosive atmosphere EN 60079-15

Equipment protection by type of protection "n"

Pos: 62 /All e Ser i en (A llg emei ne M od ule) /Nor me n un d Ric htl ini en/ Ex( i)-N orm en/ Expl osi ons fähi ge Atm osph äre EN 600 79-31 @ 13\mod_1351072407879_21.docx @ 105292 @ @ 1

Explosive atmosphere EN 60079-31

Equipment dust ignition protection by enclosure "t"

Pos: 63 /All e Ser i en (A llg emei ne M od ule) /Nor me n un d Ric htl ini en/ EMV- Nor men - Stan dar d/E MV C E- Störf estig keit EN 6 1000-6-2 @ 4\mod_1242797655625_21.docx @ 33591 @ @ 1

EMC CE-Immunity to interference acc. to EN 61000-6-2

Pos: 64 /All e Ser i en (A llg emei ne M od ule) /Nor me n un d Ric htl ini en/ EMV- Nor men - Stan dar d/E MV C E- Störaussendung EN 61000-6-4 @ 4\mod_1242798273984_21.docx @ 33602 @ @ 1

EMC CE-Emission of interference acc. to EN 61000-6-4

Pos: 65 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 26

26 Process Image WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 66 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/ __ n oc h nic ht ei ns orti ert e Üb ers chri fte n m üss en n och eins orti er t w erden __/ Pr ozess a bbil d - Ü bersc hri ft 1 @ 4\mod_1240983067828_21.docx @ 31942 @ 1 @ 1

4 Process Image

Pos: 67 /Seri e 7 50 ( WA GO-I/ O-SYST EM )/ Proz ess abbi ld Kl e mme nbus /An alog ei nga ngs klem men /Pr ozes sab bil d 7 50-04 93 @ 5\mod_1251702231515_21.docx @ 41084 @ 2222 @ 1

The 750-493 I/O module provides, on 3 logical channels, a maximum of 9 bytes

input and 9 bytes output process data to a fieldbus coupler/controller. The data to

be sent and received will be stored in up to 6 input and output bytes (D0 ... D5),

i.e. in 3 data words. This means 3 process data are sent.

3 control bytes (C0 ... C2) and 3 status bytes (S0 … S2) are used for selecting

process data and for setting parameters.

Notice that the process data image depends on the used fieldbus coupler/

controller!

Mapping the process data into the process image is specific for the fieldbus

coupler/controller used. You will find both this information and the specific

configuration of the relevant control/status bytes in the manual of the

coupler/controller, section "Fieldbus Specific Configuration of Process Data"

which describes the process image.

4.1 Input and Output Data

Table 15: Input and Output Data

9 Bytes Input Data

9 Bytes Output Data

S0

Status byte 0

C0

Control byte 0

D0

Input data word 1 (LSB)

D0

Output data word 1 (LSB)

D1

Input data word 1 (MSB)

D1

Output data word 1 (MSB)

S1

Status byte 1

C1

Control byte 1

D2

Input data word 2 (LSB)

D2

Output data word 2 (LSB)

D3

Input data word 2 (MSB)

D3

Output data word 2 (MSB)

S2

Status byte 2

C2

Control byte 2

D4

Input data word 3 (LSB)

D4

Output data word 3 (LSB)

D5

Input data word 3 (MSB)

D5

Output data word 3 (MSB)

Page 27

WAGO-I/O-SYSTEM 750 Process Image 27

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

4.2 Simple Process Image

Each input data word in a simple process image is assigned to one channel and

can only read measured values from this channel.

Table 16: Simple Process Image

Controlbyte

Input Data Word

Channel 1

C0

Input data word 1

D1

D0

Channel 2

C1

Input data word 2

D3

D2

Channel 3

C2

Input data word 3

D5

D4

When entering a process data index into a control byte in the process data mode,

the process data is returned in the associated process data word.

The process data indices are listed below in section “Control and Status Bytes”.

The channel index has no significance in the simple process image.

The simple process image is the default (factory) setting.

1st Example:

Reading out the voltages (rms value) of phases L1, L2 and L3

Enter 0x01 (process data index = 1) into the control bytes C0, C1 and C2.

The voltage (rms value) of phase L1 is returned in process data word 1 (D0, D1),

the voltage (rms value) of phase L2 is returned in process data word 2 (D2, D3)

and the voltage (rms value) of phase L3 is returned in process data word 3 (D4,

D5).

2nd Example:

Reading out the voltage (rms value) of phase L1, the current (rms value) of

phase L2 and the active power of phase L3

Enter 0x01 (channel index = 0, process data index = 1) into control byte C0,

0x00 (channel index = 0, process data index = 0) into control byte C1 and

0x02 (channel index = 0, process data index = 2) into control byte C2.

The voltage (rms value) of phase L1 is returned in input data word 1 (D0, D1),

the current (rms value) of phase L2 is returned in input data word 2 (D2, D3) and

the active power of phase L3 is returned in input data word 3 (D4, D5).

Page 28

28 Process Image WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

4.3 Flexible Process Image

An input data word in a flexible process image can read measured values from

any channel.

The flexible process image is enabled via WAGO-I/O-CHECK on the „Phase L1“,

„Phase L2“ and „Phase L3“ tabs.

1st Example:

Reading out the current (rms value), voltage (rms value) and active power of

phase L2

Enter 0x10 (channel index 1, process data index 0) into control byte C0,

0x11 (channel index 1, process data index 1) into control byte C1 and

0x12 (channel index 1, process data index 2) into control byte C2.

The current (rms value) of phase L2 is returned in input data word 1 (D0, D1),

the voltage (rms value) of phase L2 is returned in input data word 2 (D2, D3) and

the active power of phase L2 is returned in input data word 3 (D4, D5).

2nd Example:

Reading out the current (rms value) and voltage (rms value) of phase L1 and

the voltage (rms value) of phase L2

Enter 0x00 (channel index 0, process data index 0) into control byte C0,

0x01 (channel index 0, process data index 1) into control byte C1 and

0x11 (channel index 1, process data index 1) into control byte C2.

The current (rms value) of phase L1 is returned in input data word 1 (D0, D1),

the voltage (rms value) of phase L1 is returned in input data word 2 (D2, D3) and

the voltage (rms value) of phase L2 is returned in input data word 3 (D4, D5).

Page 29

WAGO-I/O-SYSTEM 750 Process Image 29

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

4.4 Control and Status Bytes

Table 17: Control Byte C0

Control Byte C0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reg_Com

Reserved

Channel_ID

ProcDat_ID

ProcDat_

ID

Here, enter the process data index for the physical variable you wish to read out

using input data word 1.

0:

Current (rms)

1:

Voltage (rms)

2:

Active power

3:

Power factor

4:

Active energy

5:

Max. current

6:

Max. voltage

7:

Max. active power

8:

Frequency

9:

Min. current

10:

Min. voltage

11:

Min. active power

12 .... 15:

Reserved

Channel_

ID

Simple

process

image

Always 0

(With the simple process image the channel index has no significance.)

Flexible

process

image

Here, enter the channel index for the channel from which you wish to

read out a measured value using input data word 1.

0:

Channel 1

1:

Channel 2

2:

Channel 3

3:

Calibration mode active

Reg_Com

0:

Process data communication

1:

Register communication

Page 30

30 Process Image WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Table 18: Status Byte S0

Status Byte S0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reg_Com

Err_L1

Channel_ID

ProcDat_ID

ProcDat_

ID

Process data index for the physical variable which was read out using input data

word 1.

Channel_

ID

Simple

process

image

Always 0

(With the simple process image the channel index has no significance.)

Flexible

process

image

Channel index for the channel from which a measured value was read

out using input data word 1

Err_L1

0:

The voltage between L1 and N is greater than the set undervoltage

threshold.

1:

The voltage between L1 and N is less than the set undervoltage

threshold. The LED „B“ lights up.

Reg_Com

0:

Process data communication

1:

Register communication

Page 31

WAGO-I/O-SYSTEM 750 Process Image 31

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Table 19: Control Byte C1

Control Byte C1

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reg_Com

Reserved

Channel_ID

ProcDat_ID

ProcDat_

ID

Here, enter the process data index for the physical variable you wish to read out

using input data word 2.

0:

Current (rms)

1:

Voltage (rms)

2:

Active power

3:

Power factor

4:

Active energy

5:

Max. current

6:

Max. voltage

7:

Max. active power

8:

Frequency

9:

Min. current

10:

Min. voltage

11:

Min. active power

12 .... 15:

Reserved

Channel_

ID

Simple

process

image

Always 0

(With the simple process image the channel index has no significance.)

Flexible

process

image

Here, enter the channel index for the channel from which you wish to

read out a measured value using input data word 2.

0:

Channel 1

1:

Channel 2

2:

Channel 3

3:

Calibration mode active

Reg_Com

0:

Process data communication

1:

Register communication

Page 32

32 Process Image WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Table 20: Status Byte S1

Status Byte S1

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reg_Com

Err_L2

Channel_ID

ProcDat_ID

ProcDat_

ID

Process data index for the physical variable which was read out using input data

word 2.

Channel_

ID

Simple

process

image

Always 0

(With the simple process image the channel index has no significance.)

Flexible

process

image

Channel index for the channel from which a measured value was read

out using input data word 2

Err_L2

0:

The voltage between L2 and N is greater than the set undervoltage

threshold.

1:

The voltage between L2 and N is less than the set undervoltage

threshold. The LED „E“ lights up.

Reg_Com

0:

Process data communication

1:

Register communication

Page 33

WAGO-I/O-SYSTEM 750 Process Image 33

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Table 21: Control Byte C2

Control Byte C2

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reg_Com

Reserved

Channel_ID

ProcDat_ID

ProcDat_

ID

Here, enter the process data index for the physical variable you wish to read out

using input data word 3.

0:

Current (rms)

1:

Voltage (rms)

2:

Active power

3:

Power factor

4:

Active energy

5:

Max. current

6:

Max. voltage

7:

Max. active power

8:

Frequency

9:

Min. current

10:

Min. voltage

11:

Min. active power

12 .... 15:

Reserved

Channel_

ID

Simple

process

image

Always 0

(With the simple process image the channel index has no significance.)

Flexible

process

image

Here, enter the channel index for the channel from which you wish to

read out a measured value using input data word 3.

0:

Channel 1

1:

Channel 2

2:

Channel 3

3:

Calibration mode active

Reg_Com

0:

Process data communication

1:

Register communication

Page 34

34 Process Image WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Table 22: Status Byte S2

Status Byte S2

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Reg_Com

Err_L3

Channel_ID

ProcDat_ID

ProcDat_

ID

Process data index for the physical variable which was read out using input data

word 3.

Channel_

ID

Simple

process

image

Always 0

(With the simple process image the channel index has no significance.)

Flexible

process

image

Channel index for the channel from which a measured value was read

out using input data word 3

Err_L3

0:

The voltage between L3 and N is greater than the set undervoltage

threshold.

1:

The voltage between L3 and N is less than the set undervoltage

threshold. The LED „F“ lights up.

Reg_Com

0:

Process data communication

1:

Register communication

Pos: 68 /Dokum entati on allg emein/ Glie derung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Page 35

WAGO-I/O-SYSTEM 750 Function Description 35

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Pos: 69 /All e Ser i en (A llg emei ne M od ule) /Üb ers chri fte n für al le S eri en/F un ktio ns beschr ei bung Fun kti ons bes chr eib ung - Über schr ift 1 @ 4\mod_1239025975389_21.docx @ 30003 @ 1 @ 1

5 Function Description

Pos: 70 /Seri e 750 (WAGO-I/O-SYST EM)/ Funk tions beschr eibu ng/Fu nktio nsbesc hrei bung 75 0-0493 @ 14\mod_1361260872587_21.docx @ 112240 @ 2222 @ 1

0493 @ 14\mod_1361260872587_21.docx @ 112240 @ 2222 @ 4

5.1 Measuring Principle

The 3-phase power measurement module operates using 6 analog/digital

converters for acquiring the current and voltage levels in all three phases. The 3

phases are connected to the current measuring channels of the I/O module in

"single-ended" measurement topology. Each of the 6 measurement inputs is

scanned at a frequency of 8 kHz. The input filters on the measuring channels have

a limit frequency of 7.2 kHz. The analog measured values are quantized with 24

bits and further processed digitally.

Acquisition and processing of the measured values of all three phases is

performed simultaneously in the very same way.

5.2 Measured Values and Measured Value Calculation

The 3-phase power measurement module makes the following AC measured

values available per phase (Lx = L1, L2 or L3):

Voltage:

• RMS value voltage Lx – N

• Maximum RMS value voltage Lx – N

• Minimum RMS value voltage Lx – N

Current:

• RMS value current Lx

• Maximum RMS value current Lx

• Minimum RMS value current Lx

Power:

• Active power Lx

• Maximum value active power Lx

• Minimum value active power Lx

Energy:

• Active energy Lx

Frequency:

• Supply network frequency Lx

Power factor:

• cos phi Lx

Limit value:

• Undervoltage Lx: Threshold value undershot

Alternatively, the following DC measured values are available if DC

measurement has been activated in the I/O module. See section "Commissioning"

> "Configuration with WAGO-I/O-CHECK".

Voltage:

• DC voltage Lx – N

Current:

• DC current Lx

Power:

• Power (DC current) Lx

Page 36

36 Function Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Calculating the RMS Values for Current and Voltage

The I/O module measures the true RMS of the voltages and currents applied to the

measurement inputs per period. See figure below.

∑

=

=

N-1

0k

2

k

N

1

eff

iI

∑

=

=

N-1

0k

2

k

N

1

eff

uU

ik:

Scan value of the current

I

eff

:

RMS value of the current

uk:

Scan value of the voltage

U

eff

:

RMS value of the voltage

N:

No. of scan values

Figure 6: RMS Value Calculation (Example, Not to Scale)

In a 50-Hz-supply network, the RMS value can be read with the specified

measuring accuracy with every second period via the process image. Therefore,

the default setting of the measuring cycle time is 39 ms.

For applications where voltage and current drops have to be evened out, a mean of

the RMS values for current and voltage can be generated by the measuring cycle

time setting. If a time of 40 ms is set in WAGO-I/O-CHECK, there is averaging of

2 RMS values, a value of 500 ms is set, there is averaging of 13 RMS values

(500/39 = 12.82).

The maximum measuring cycle time can be 24375 ms. The update rate in the

process image corresponds to the time set.

Page 37

WAGO-I/O-SYSTEM 750 Function Description 37

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Calculating Power and Energy

The individual time-synchronous scan values for currents and voltages are used to

calculate active power (P). Phase shifts between currents and voltages are taken

into account when calculating power.

The time integration of power yields the energy per phase.

Determining the Frequency

Phase frequencies are determined by zero-crossing detection of the scanned

signals.

Calculating the Power Factor cos phi

The power factor cos phi is calculated from the phase shift between current and

voltage of the fundamental wave of the respective phase.

The I/O module can be configured, so that the cos phi is output with or without

sign (see section "Commissioning" > "Configuration with WAGO-I/O-CHECK").

If a sign is put out, it is not the information acquisition (+) or delivery (-) of active

power (P), but a statement on the load on the network:

• A positive (+) sign of the cos phi means inductive load

• A negative (-) sign of the cos phi means capacitive load

Together with the sign of the active power, you can determine the quadrants in the

4-quadrant display for an AC network:

Figure 7: 4-Quadrant Display of Active and Reactive Power

Page 38

38 Function Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Apparent Power and Reactive Power

Not all loads are purely resistive in real supply networks. Phase shifting therefore

occurs between the current and the voltage. However, this does not affect the

method for determining the RMS values for current and voltage previously

described. They can both be obtained as measured values from the I/O module.

The apparent power (S) can be calculated from these measured values using the

following equation:

S = U · I

The reactive power (Q) can then be calculated using the following equation:

22

PS

Q −=

Page 39

WAGO-I/O-SYSTEM 750 Function Description 39

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

5.3 Representation of the Measured Values in the

Process Image (PI)

The I/O module records and calculates numerous measured values. Up to 3

measured values can be represented in the process image (PI). The selection of

these ones is made with the process data indices in control bytes C0, C1 and C2 in

the output data.

The following table lists the available measured values:

Table

23: Measured Values in the Process Image (PI)

Measured Value

Data

Type

PI

Scaling Factor PI

750-493

750-493/

025-000

(1A)

750-493/000

-001

750-493/025

-001

(5A)

Voltage

RMS value voltage L1 - N UInt16 0.1V / LSB 0.1V / LSB

RMS value voltage L2 - N

UInt16

0.1V / LSB

0.1V / LSB

RMS value voltage L3 - N UInt16 0.1V / LSB 0.1V / LSB

Maximum RMS value voltage L1 - N

UInt16

0.1V / LSB

0.1V / LSB

Maximum RMS value voltage L2 - N UInt16 0.1V / LSB 0.1V / LSB

Maximum RMS value voltage L3 - N

UInt16

0.1V / LSB

0.1V / LSB

Minimum RMS value voltage L1 - N UInt16 0.1V / LSB 0.1V / LSB

Minimum RMS value voltage L2 - N

UInt16

0.1V / LSB

0.1V / LSB

Minimum RMS value voltage L3 - N UInt16 0.1V / LSB 0.1V / LSB

Current

RMS value current L1 UInt16 0.001A / LSB 0.005A / LSB

RMS value current L2 UInt16 0.001A / LSB 0.005A / LSB

RMS value current L3 UInt16 0.001A / LSB 0.005A / LSB

Maximum RMS value current L1 UInt16 0.001A / LSB 0.005A / LSB

Maximum RMS value current L2 UInt16 0.001A / LSB 0.005A / LSB

Maximum RMS value current L3 UInt16 0.001A / LSB 0.005A / LSB

Minimum RMS value current L1 UInt16 0.001A / LSB 0.005A / LSB

Minimum RMS value current L2 UInt16 0.001A / LSB 0.005A / LSB

Minimum RMS value current L3 UInt16 0.001A / LSB 0.005A / LSB

Power

Active power L1

Int16

0.1W / LSB

0.5W / LSB

Active power L2 Int16 0.1W / LSB 0.5W / LSB

Active power L3

Int16

0.1W / LSB

0.5W / LSB

Maximum value active power L1 Int16 0.1W / LSB 0.5W / LSB

Maximum value active power L2

Int16

0.1W / LSB

0.5W / LSB

Maximum value active power L3 Int16 0.1W / LSB 0.5W / LSB

Minimum value active power L1

Int16

0.1W / LSB

0.5W / LSB

Page 40

40 Function Description WAGO-I/O-SYSTEM 750

750-493 3-Phase Power Measurement Module

Manual

Version 1.2.0

Minimum value active power L2 Int16 0.1W / LSB 0.5W / LSB

Minimum value active power L3 Int16 0.1W / LSB 0.5W / LSB

Energy

Active energy L1 UInt16

Setup with WAGO-I/O-CHECK

or in Register 35

Active energy L2 UInt16

Setup with WAGO-I/O-CHECK

or in Register 35

Active energy L3 UInt16

Setup with WAGO-I/O-CHECK

or in Register 35

Frequency

Supply network frequency L1 UInt16 0.1Hz / LSB 0.1Hz / LSB

Supply network frequency L2 UInt16 0.1Hz / LSB 0.1Hz / LSB

Supply network frequency L3 UInt16 0.1Hz / LSB 0.1Hz / LSB

Power factor

cos phi L1

Int16

0.01

0.01

cos phi L2 Int16 0.01 0.01

cos phi L3

Int16

0.01

0.01

DC measured values

DC voltage L1 - N UInt16 0.1V / LSB 0.1V / LSB

DC voltage L2 - N UInt16 0.1V / LSB 0.1V / LSB

DC voltage L3 - N UInt16 0.1V / LSB 0.1V / LSB

DC current L1 UInt16 0.001A / LSB 0.005A / LSB