Page 1

Controllers PFC100/PFC200

General Product Information

PFC100/PFC200:

Maximum Performance in a Minimum

Space

As a member of the WAGO control fam-

ily, the PFC100 and PFC200 Controllers

e!RUNTIME excel with high pro-

with

cessing speed and multiple interfaces

for parallel communication. They oer at

least two ETHERNET connections in all

variants and, depending on the version,

additional interfaces. The CANopen,

PROFIBUS DP, Modbus TCP/UPD/RTU,

PROFINET, EtherNet/IP and EtherCAT

protocols provide a exible connection

to eldbus systems and external input/

output devices. These eldbus systems

can be easily congured directly in WAGO’s easy-to-use e!COCKPIT develop-

ment environment.

The ETHERNET interfaces with an

integrated switch also support all major

IT protocols. In addition to multiple inter-

faces, the PFC100/PFC200 oers ample

memory for your applications thanks to

the internal Flash memory and an inte-

grated interface for memory cards.

Industry 4.0 / IoT

Recording, digitizing and linking data

protably – this is the core concept

behind Industry 4.0. Using a dedicated

library, the WAGO PFC100 and PFC200

Controllers become IoT controllers that

send data from the eld level to the

cloud. Here, they can be aggregated

and used for analysis. This creates true

added value for your company – be it

for increasing the eciency of in-house

production, implementing energy

management in buildings, or developing

further end customer services. Existing

systems also become IoT-ready, making

them sustainable into the future. The

WAGO PFC family of controllers thus

forms the basis for a sustainable corporate world.

Link between Process Data and IT Application

The PF

C100/PFC200 ideally combines

real-time requirements with IT functionality.

It supports both MODBUS/TCP and ETHERNET/IP for use in industrial environments.

TP, SNTP, SNMP, FTP, BootP, DHCP, DNS,

HT

Telnet, SSH and other protocols simplify

integration into IT environments.

Integrated Web pages and Web-based

visualization provide IT applications with

real-time process data. Furthermore, the

750 Series Controllers incorporate library

functions for email, SOAP, ASP, IP conguration, ETHERNET sockets and le system.

Security on Board

The topics of ETHERNET communication

and security are closely linked. To provide

PFC Controller users with a high level of se-

curity, mechanisms for secure connections

such as VPN, int

FTPS, SSH and SSL/TLS are standard.

Demand-Oriented Extensibility

Some controllers oer the option of activating functions that go beyond the standard

via runtime lic

price as needed. This also oers the advantage that with the same exact controller,

dierent functions can be realized and also

combined, which otherwise would only be

replicated via additional variants. The licenses are simply loaded into the controller

together with the project. The additional

licenses available for each controller are

specied by the controller and described in

detail in the “Software” section.

Application Controllers

For some specic solutions, variants of

standard controllers are available that must

be paired with the appropriate solutions.

You will nd these solutions in Section 1.

egrated rewall, HTTPS,

enses, making it possible to

Modular and Expandable

With the WAGO-I/O-SYSTEM 750, the

PFC100/PFC200 can be expanded to almost any input/output interface. A modular,

ail-mount design permits easy instal-

DIN-r

lation, expansion and modication of the I/O

node without t

sign prevents installation errors. In addition,

oven CAGE CLAMP® technology oers

pr

fast, vibration-proof and maintenance-free

connections that are independent of op-

erator skill. Depending on the I/O module’s

gr

anularity, eld levels can be directly wired

using 1-, 2-, 3- or 4-wire technology.

Maximum Reliability and Ruggedness

The PFC100/PFC200 is engineered and

tested for use in the most demanding

environments (e.g., temperature cycling,

shock/vibration loading and ESD) according

to the highest standards. Spring pressure

connection technology guarantees continuous operation. Integrated QA measures in

oduction process and 100% function

the pr

testing ensure consistent quality.

Open-Source Software and Linux®

We unite what belongs together: High-performance WAGO hardware and the

e-ready Linux® operating system. WA-

futur

GO’s controllers oer programming in either

IEC 61131 or directly in Linux® to create

complex tasks. WAGO’s “Embedded Linux”

Controllers impress with base images that

are expandable via open-source packages.

As a “Gold Member” of the Open Source

Automation Development Lab (OSADL),

WAGO supports both nancing and further

development of Linux® in the industrial sector. The controller rmware itself is available

as a “Board Support Package” (BSP).

If you are interested, simply contact our

Technical Support AUTOMATION.

ools. The straightforward de-

elecontrol Technology

T

Standardized telecontrol protocols

according to IEC 60870-5, IEC 61850,

IEC 61400-25 or DNP3 ensure use of the

PFC Controllers in telecontrol technol-

ogy.

tarter Kits

S

For a quick start, WAGO oers every

customer the unique opportunity to purchase a starter kit that already contains

omponents needed to begin

all the c

programming and getting to know the

controllers. For starter kits, see Section

4.5.

Advantages:

• Programming per IEC 61131-3

• Applications with higher-level languages

• Linux® real-time operating system

• Robust and maintenance-free

• Integrated cybersecurity packages

• IoT ready

Page 2

Controllers PFC100/PFC200

Versions

Extended Temperature Range

Industrial automation technology is typically

operated in temperatures ranging from 0°C

to55°C. However, there are applications

like telecontrol technology that require an

extended temperature range. These versions

are available in an extended temperature

range of −20°C to+60°C.

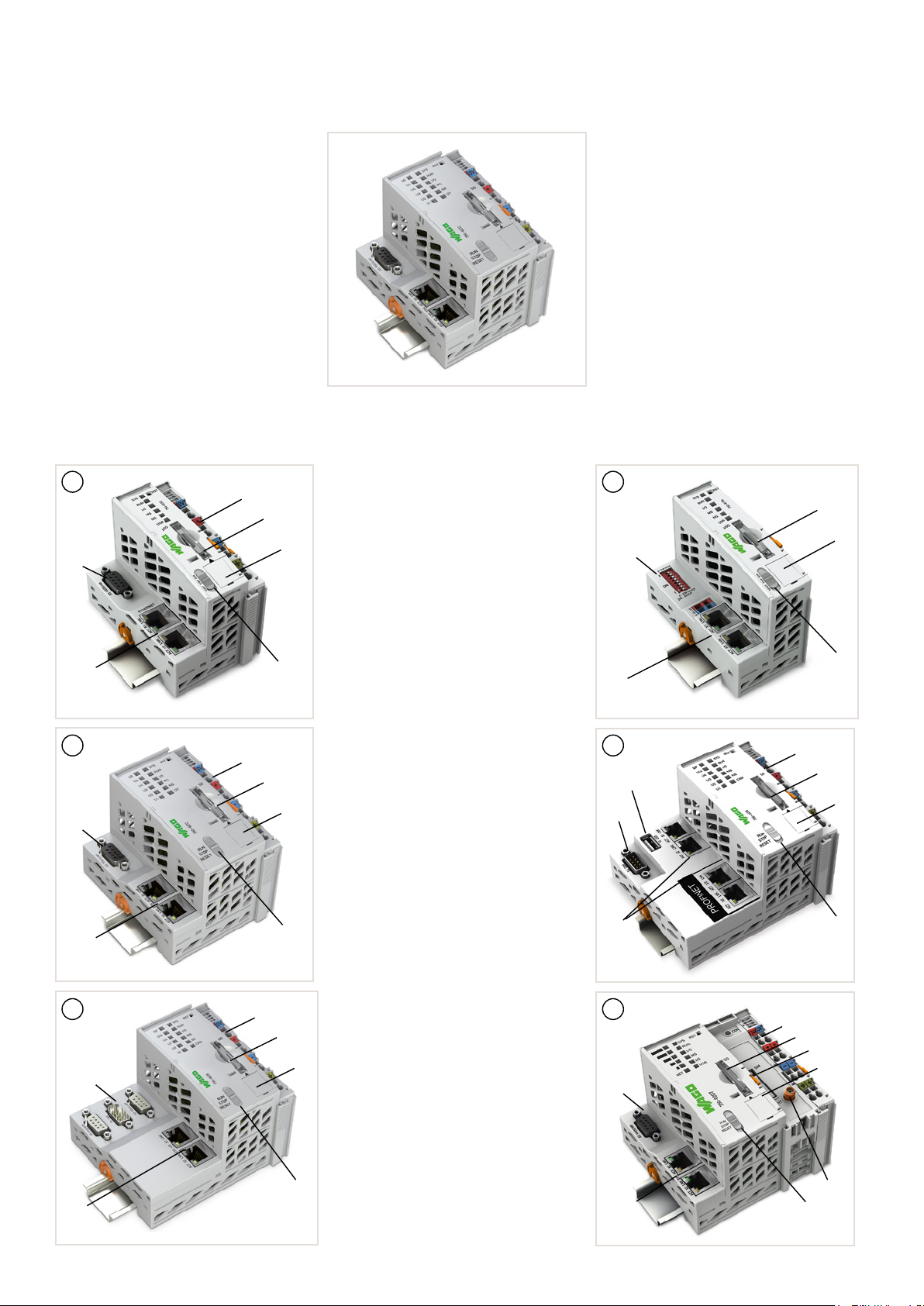

Interfaces and Types

A

b)

c)

C

b)

c)

E

b)

c)

a)

e)

d)

f)

a)

g)

d)

h)

a)

g)

d)

h)

• Including supply module to power downstream I/O

modules (a)

• Technical dierences on the connection level (b)

• ETHERNET 2 x RJ-45 (c)

• Service interface (d)

Housing design (A)

• microSD card slot for external storage media (e)

• Start/stop switch (f)

• W x H x D (mm) 61.5 x 71.9 x 100

• Connection technology (system/eld supply):

CAGE CLAMP®

• Conductor cross section: 0.08 … 2.5 mm²/28 … 14 AWG

Housing design (B)

• microSD card slot for external storage media (e)

• Start/stop switch (f)

• W x H x D (mm) 49.5 x 71.9 x 96.8

• Connection technology (system supply):

CAGE CLAMP®

• Conductor cross section: 0.08 … 1.5 mm²/28 … 16 AWG

Housing design (C)

• SD card slot for external storage media (g)

• Start/stop switch (h)

• W x H x D (mm) 78.6 x 71.9 x 100

• Connection technology (system/eld supply):

CAGE CLAMP®

• Conductor cross section: 0.08 … 2.5 mm²/28 … 14 AWG

Housing design (D)

• SD card slot for external storage media (g)

• Start/stop switch (h)

• ETHERNET 4 x RJ-45 (i)

• USB interface (j)

• W x H x D (mm) 112 x 71.9 x 100

• Connection technology (system/eld supply):

CAGE CLAMP®

• Conductor cross section: 0.08 … 2.5 mm²/28 … 14 AWG

Housing design (E)

• SD card slot for external storage media (g)

• Start/stop switch (h)

• W x H x D (mm) 112 x 71.9 x 100

• Connection technology (system/eld supply):

CAGE CLAMP®

• Conductor cross section: 0.08 … 2.5 mm²/28 … 14 AWG

Housing design (F)

• SD card slot for external storage media (g)

• Start/stop switch (h)

• GSM antenna connection(k)

• SIM card slot (l)

• W x H x D (mm) 102.5 x 71.9 x 100

• Connection technology (system/eld supply):

CAGE CLAMP®

• Conductor cross section: 0.08 … 2.5 mm²/28 … 14 AWG

Eco

The Eco version of the PFC200 limits the

number of stackable I/O modules to four.

Telecontrol Technology

The telecontrol technology versions of the

PFC200 are distinguished by their integrated,

standardized telecontrol technology:

• IEC 60870-5

• IEC 61850

• IEC 61400-25

• DNP3

B

e)

d)

b)

f)

c)

D

a)

g)

j)

d)

b)

i)

F

a)

h)

g)

l)

d)

b)

k)

c)

h)

Page 3

Controllers PFC100/PFC200

Installation Instructions

Power Supply

The internal electronics are powered by the

controller. The power supply to the eld-side

supply is electrically isolated. The division

enables a separate supply for sensors

and actuators. Snapping the I/O modules

together automatically routes the supply

voltages. Supply modules with diagnostics

enable additional monitoring of the power

supply. This conguration ensures a exible,

user-specic supply design for a station. The

current supply to the electronics is limited by

a maximum value. If the sum of the internal

current demand of all the I/O modules should

exceed this value, an additional system sup

ply module is necessary. Even in this case,

power supply to the eld-side supply of 10A

may not be exceeded. However, dierent

power supply modules allow a new power

supply, formation of potential groups and the

implementation of emergency stops.

-

PFC200

with

Supply Module

24 V

Electronics

Field potential 1

24 V

Bus Module

Supply Module

230 V

Field potential 2

24 V

Field potential 3

End Module

Item Number Key

Explanation of the components of an item

number key

Notes

Additional steps must be implemented based

on where the I/O system is installed:

Additionally, both a supply module and a

eld-side power supply lter are recom

mended when operating intrinsically safe Ex

Specic power and eld-side power supply

lters (750-624 or 750-626) are required for

marine and onshore/oshore applications.

A specic supply module (750-606) is

required to operate intrinsically safe Ex i

modules.

i modules for marine and onshore/oshore

applications.

As part of operating safety-related I/O modules, PELV/SELV power supply units must be

used for 24 VDC supply of electronics and

eld. In addition, specic power and eldside power supply lters must be provided

(750-626).

Please refer to the manual for details about

the power supply’s design.

Item No.: 750-81xx = PFC100

00: 2 x ETHERNET, Eco

01: 2 x ETHERNET

02: 2 x ETHERNET, RS-232/-485

Item No.: 750-82xy = PFC200

0y: Generation 1

1y: Generation 2

x2: 2 x ETHERNET, RS-232/-485

x3: 2 x ETHERNET, CAN

x4: 2 x ETHERNET, RS-232/-485, CAN

x5: 4 x ETHERNET, CAN, CANopen, USB

x6: 2 x ETHERNET, RS-232/-485, CAN, PROFIBUS-DP slave

x7: 2 x ETHERNET, RS-232/-485, mobile radio module

x8: 2 x ETHERNET, RS-232/-485, CAN, CANopen, PROFIBUS master

-

.../025-yyy: Extended temperature range of −20 ... +60°C

000: Standard

001: Telecontrol technology

002: Telecontrol Eco

Page 4

Controllers PFC100/PFC200

Standards and Rated Conditions

General Specications

Supply voltage (system) 24VDC (−25 … +30%)*;

Isolation 500 V (system/supply)

Surrounding air temperature (operation) 0 … +55 °C

Surrounding air temperature (operation) for

versions with an extended temperature range

Surrounding air temperature (storage) −40 … +85°C

Relative humidity 95% (non condensing)

Relative humidity for versions with an extended

temperature range

Operating altitude 0 … 2000 m

Pollution degree 2 per IEC 61131-2

Vibration resistance 0.5g (4g for all marine-certied controllers) per

Shock resistance 15g per IEC 60068-2-27

EMC immunity to interference Per EN 61000-6-2

EMC emission of interference Per EN 61000-6-3

Protection type IP20

Mounting type DIN-35 rail

Housing material Polycarbonate; polyamid 6.6

Exposure to pollutants Per IEC 60068-2-42 and IEC 60068-2-43

Permissible SO

a relative humidity < 75 %

Permissible H

a relative humidity < 75 %

Connection technology CAGE CLAMP®

Conductor cross sections; strip length

Standard PFC100/200

Conductor cross sections; strip length

PFC100 Eco

ent carrying capacity (power jumper

Curr

contacts)

contaminant concentration at

2

S contaminant concentration at

2

*for all marine-certied controllers

−20 … +60 °C

Max. 95 %, short-term condensation per Class

3K6 / IEC EN 60721-3-3 and E DIN 40046-721-3,

taking a temperature range of −20…+60 °C into

consideration (except wind-driven precipitation,

water and ice formation)

IEC 60068-2-6

25ppm

10ppm

0.08 … 2.5 mm²/28 … 14 A

8 … 9 mm / 0.31 … 0.35 inch

0.08 … 1.5 mm²/28 … 16 AWG;

5 … 6 mm / 0.2 … 0.24 inch

10 A

WG;

r

&

Loading...

Loading...