Page 1

WAGO-I/O-SYSTEM 750

Manual

750-306

Fieldbus Coupler

Version 2.0.0

DeviceNetTM

125 Kbaud ... 500 Kbaud; digital and analog signals

Page 2

2 WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

© 2015 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Manual

Version 2.0.0

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-306 DeviceNet

TM

Fieldbus Coupler

Table of Contents

1 Notes about this Documentation ................................................................. 7

1.1 Validity of this Documentation ................................................................. 7

1.2 Copyright ................................................................................................... 7

1.3 Symbols ..................................................................................................... 8

1.4 Number Notation ..................................................................................... 10

1.5 Font Conventions .................................................................................... 10

2 Important Notes ......................................................................................... 11

2.1 Legal Bases ............................................................................................. 11

2.1.1 Subject to Changes ............................................................................. 11

2.1.2 Personnel Qualifications ..................................................................... 11

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying

Provisions ........................................................................................... 11

2.1.4 Technical Condition of Specified Devices ......................................... 12

2.2 Safety Advice (Precautions) .................................................................... 13

3 System Description..................................................................................... 15

3.1 Manufacturing Number ........................................................................... 16

3.2 Component Update .................................................................................. 17

3.3 Storage, Assembly and Transport ........................................................... 17

3.4 Assembly Guidelines/Standards .............................................................. 18

3.5 Power Supply .......................................................................................... 19

3.5.1 Isolation .............................................................................................. 19

3.5.2 System Supply .................................................................................... 20

3.5.2.1 Connection ..................................................................................... 20

3.5.2.2 Dimensioning ................................................................................. 21

3.5.3 Field Supply........................................................................................ 24

3.5.3.1 Connection ..................................................................................... 24

3.5.3.2 Fusing ............................................................................................ 26

3.5.4 Supplementary Power Supply Regulations ........................................ 29

3.5.5 Supply Example.................................................................................. 30

3.5.6 Power Supply Unit ............................................................................. 32

3.6 Grounding ............................................................................................... 33

3.6.1 Grounding the DIN Rail ..................................................................... 33

3.6.1.1 Framework Assembly .................................................................... 33

3.6.1.2 Insulated Assembly ........................................................................ 33

3.6.2 Grounding Function............................................................................ 34

3.7 Shielding ................................................................................................. 35

3.7.1 General ............................................................................................... 35

3.7.2 Bus Cables .......................................................................................... 35

3.7.3 Signal Lines ........................................................................................ 36

3.7.4 WAGO Shield Connecting System .................................................... 36

4 Device Description ..................................................................................... 37

4.1 View ........................................................................................................ 38

4.2 Connectors ............................................................................................... 40

4.2.1 Device Supply .................................................................................... 40

4.2.2 Fieldbus Connection ........................................................................... 41

Manual

Version 2.0.0

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

4.3 Display Elements .................................................................................... 42

4.4 Operating Elements ................................................................................. 43

4.4.1 Service Interface ................................................................................. 43

4.4.2 DIP Switch.......................................................................................... 44

4.4.2.1 Baud Rate Setting .......................................................................... 44

4.4.2.2 Station address ............................................................................... 45

4.5 Technical Data ........................................................................................ 46

4.5.1 Device Data ........................................................................................ 46

4.5.2 System Data ........................................................................................ 46

4.5.3 DeviceNetTM Fieldbus ........................................................................ 46

4.5.4 Supply ................................................................................................. 47

4.5.5 Accessories ......................................................................................... 47

4.5.6 Connection Type ................................................................................ 47

4.5.7 Climatic Environmental Conditions ................................................... 48

4.5.8 Mechanical Strength acc. to IEC 61131-2 .......................................... 48

4.6 Approvals ................................................................................................ 49

4.7 Standards and Guidelines ........................................................................ 51

5 Mounting ..................................................................................................... 52

5.1 Installation Position ................................................................................. 52

5.2 Overall Configuration ............................................................................. 52

5.3 Mounting onto Carrier Rail ..................................................................... 54

5.3.1 Carrier Rail Properties ........................................................................ 54

5.3.2 WAGO DIN Rail ................................................................................ 55

5.4 Spacing .................................................................................................... 55

5.5 Mounting Sequence ................................................................................. 56

5.6 Inserting and Removing Devices ............................................................ 57

5.6.1 Inserting the Fieldbus Coupler/Controller .......................................... 58

5.6.2 Removing the Fieldbus Coupler/Controller ....................................... 58

5.6.3 Inserting the I/O Module .................................................................... 59

5.6.4 Removing the I/O Module .................................................................. 60

6 Connect Devices ......................................................................................... 61

6.1 Data Contacts/Internal Bus ..................................................................... 61

6.2 Power Contacts/Field Supply .................................................................. 62

6.3 Connecting a Conductor to the CAGE CLAMP® ................................... 63

7 Function Description ................................................................................. 64

7.1 Operating System .................................................................................... 64

7.2 Process Data Architecture ....................................................................... 65

7.2.1 Basic Setup ......................................................................................... 65

7.3 Data Exchange ........................................................................................ 66

7.3.1 Communication Interfaces .................................................................. 67

7.3.2 Memory Space .................................................................................... 67

7.3.3 Addressing .......................................................................................... 68

7.3.3.1 Fieldbus-Specific Addressin g ........................................................ 68

8 Commissioning ........................................................................................... 71

8.1 Connecting Client PC and Fieldbus Nodes ............................................. 72

8.2 Setting the DeviceNet™ Station Address and Baud Rate ........................ 73

8.3 Configuring Static Assemblies ................................................................ 73

Manual

Version 2.0.0

Page 5

WAGO-I/O-SYSTEM 750 Table of Contents 5

750-306 DeviceNet

TM

Fieldbus Coupler

9 Diagnostics .................................................................................................. 74

9.1 LED Signaling ......................................................................................... 74

9.1.1 Evaluating the Fieldbus Status ........................................................... 75

9.1.2 Evaluating Node Status – I/O LED (Blink Code Table) .................... 76

9.1.3 Evaluating Power Supply Status ........................................................ 83

10 Fieldbus Communication .......................................................................... 84

10.1 DeviceNetTM ............................................................................................ 84

10.1.1 Network Structure .............................................................................. 85

10.1.1.1 Transfer Media ............................................................................... 85

10.1.1.2 Cabling ........................................................................................... 86

10.1.1.3 Topology ........................................................................................ 88

10.1.1.4 Network Grounding ....................................................................... 89

10.1.1.5 Interface Modules .......................................................................... 89

10.1.2 Network Communication ................................................................... 90

10.1.2.1 Objects, Classes, Instances and Attributes .................................... 90

10.1.3 Characteristics of DeviceNetTM Devices ............................................ 91

10.1.3.1 Communication Model .................................................................. 91

10.1.3.1.1 Message Groups ........................................................................ 91

10.1.3.1.2 Message Types .......................................................................... 91

10.1.3.1.2.1 I/O Messages ........................................................................ 91

10.1.3.1.2.2 Explicit Messages ................................................................. 91

10.1.3.2 Data Exchange ............................................................................... 92

10.1.4 Process Data and Diagnostic Status ................................................... 92

10.1.4.1 Process Image ................................................................................ 92

10.1.4.1.1 Assembly Instances ................................................................... 92

10.1.5 Configuration and Parameterization Using the Object Model ........... 94

10.1.5.1 EDS Files ....................................................................................... 94

10.1.5.2 Object Model ................................................................................. 94

10.1.5.2.1 Object Classes ........................................................................... 96

10.1.5.2.1.1 Identity Class (0x01) ............................................................ 96

10.1.5.2.1.2 Message Router (0x02) ........................................................ 97

10.1.5.2.1.3 DeviceNet Object (0x03) ..................................................... 97

10.1.5.2.1.4 Assembly Object (0x04) ....................................................... 98

10.1.5.2.1.5 Connection Object (0x05) .................................................. 103

10.1.5.2.1.6 Acknowledge Handler Object (0x2B) ................................ 108

10.1.5.2.1.7 Coupler Configuration Object (0x64) ................................ 108

10.1.5.2.1.8 Discrete Input Point Object (0x65) .................................... 114

10.1.5.2.1.9 Discrete Output Point Object (0x66) .................................. 115

10.1.5.2.1.10 Analog Input Point Object (0x67) ...................................... 116

10.1.5.2.1.11 Analog Output Point Object (0x68) ................................... 117

10.1.5.2.1.12 Module Configuration Object (0x80) ................................. 118

11 I/O Modules .............................................................................................. 119

11.1 Overview ............................................................................................... 119

11.2 Process Data Architecture for DeviceNetTM ......................................... 120

11.2.1 Digital Input Modules....................................................................... 120

11.2.2 Digital Output Modules .................................................................... 121

11.2.3 Analog Output Modules ................................................................... 123

11.2.4 Specialty Modules ............................................................................ 124

11.2.5 System Modules ............................................................................... 144

Manual

Version 2.0.0

Page 6

6 Table of Contents WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

12 Use in Hazardous Environments ............................................................ 145

12.1 Marking Configuration Examples ......................................................... 146

12.1.1 Marking for Europe According to ATEX and IEC-Ex .................... 146

12.1.2 Marking for America According to NEC 500 .................................. 151

12.2 Installation Regulations ......................................................................... 152

12.2.1 Special Conditions for Safe Use (ATEX Certificate TÜV 07 ATEX

554086 X) ......................................................................................... 153

12.2.2 Special Conditions for Safe Use (ATEX Certificate TÜV 12 ATEX

106032 X) ......................................................................................... 154

12.2.3 Special Conditions for Safe Use (IEC-Ex Certificate TUN 09.0001 X)155

12.2.4 Special Conditions for Safe Use (IEC-Ex Certificate IECEx TUN

12.0039 X) ........................................................................................ 156

12.2.5 Special Conditions for Safe Use According to ANSI/ISA 12.12.01 157

List of Figures .................................................................................................... 158

List of Tables ...................................................................................................... 160

Manual

Version 2.0.0

Page 7

WAGO-I/O-SYST EM 750 Notes about this Documentation 7

750-306 DeviceNet

TM

Fieldbus Coupler

1 Notes about this Documentation

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

1.1 Va lidity of this Documentation

This documentation is only applicable to the “DeviceNetTM Fieldbus Coupler”

(750-306).

The product “DeviceNetTM Fieldbus Coupler” (750-306) shall only be installed

and operated according to the instructions in this manual and the system

description for the WAGO-I/O-SYSTEM 750.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the system

description for the WAGO-I/O-SYSTEM 750, which can be downloaded at

www.wago.com. There, you can obtain important information including

information on electrical isolation, system power and supply specifications.

1.2 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Manual

Version 2.0.0

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

1.3 Symbols

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Manual

Version 2.0.0

Page 9

WAGO-I/O-SYST EM 750 Notes about this Documentation 9

750-306 DeviceNet

TM

Fieldbus Coupler

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Manual

Version 2.0.0

Page 10

10 Notes about this Documentation WAGO-I/O-SYSTEM 750

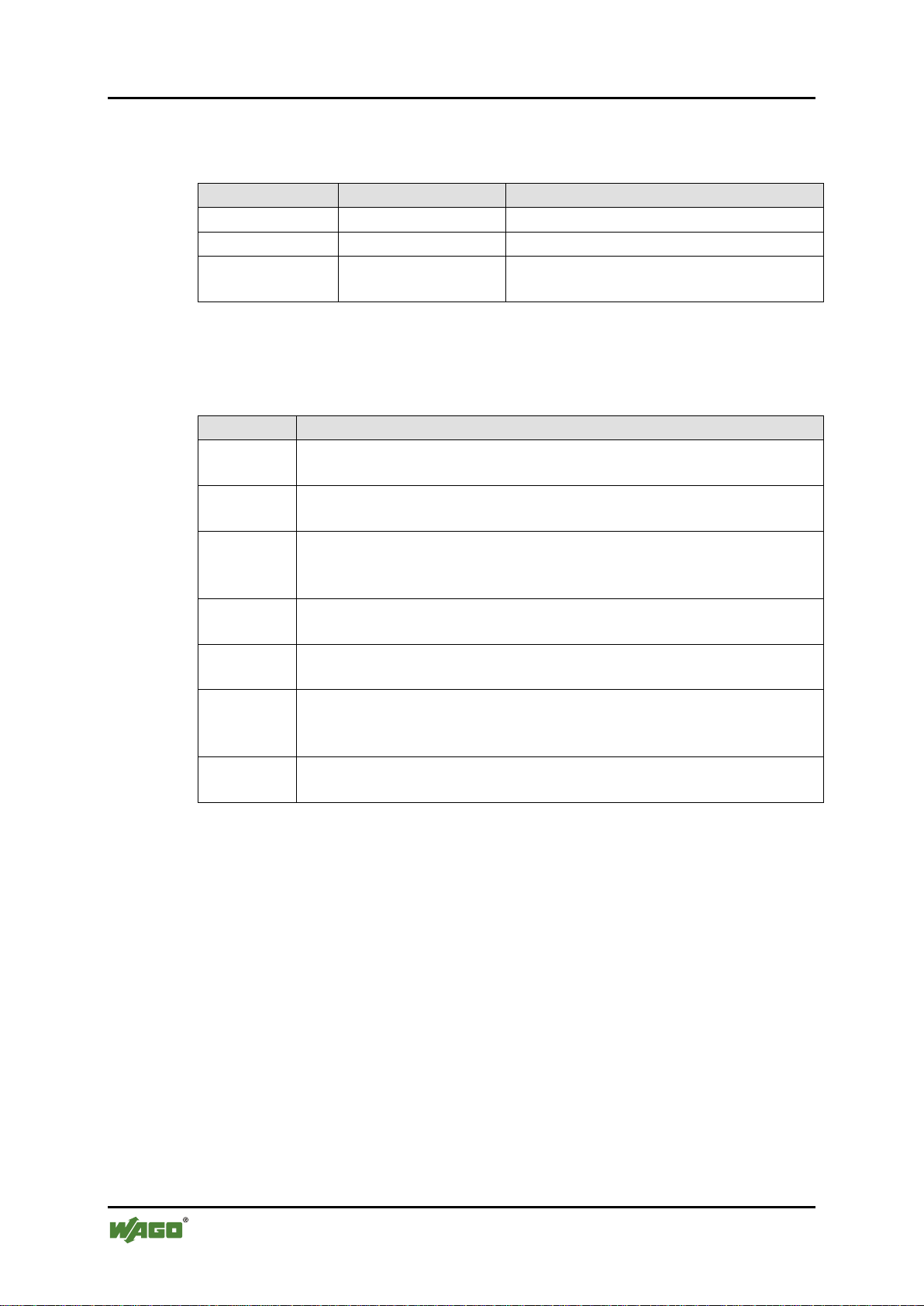

Table 1: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 2: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-306 DeviceNet

TM

Fieldbus Coupler

1.4 Number Notation

1.5 Font Conventions

menu item from a menu.

brackets.

Manual

Version 2.0.0

Page 11

WAGO-I/O-SYST EM 750 Important Notes 11

750-306 DeviceNet

TM

Fieldbus Coupler

2 Important Notes

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

2.1 Legal Bases

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 2.0.0

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

2.1.4 Technical Condition of Spec ified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Manual

Version 2.0.0

Page 13

WAGO-I/O-SYST EM 750 Important Notes 13

750-306 DeviceNet

TM

Fieldbus Coupler

2.2 Safety Advice (Precautions)

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Manual

Version 2.0.0

Page 14

14 Important Notes WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Manual

Version 2.0.0

Page 15

WAGO-I/O-SYST EM 750 System Description 15

750-306 DeviceNet

TM

Fieldbus Coupler

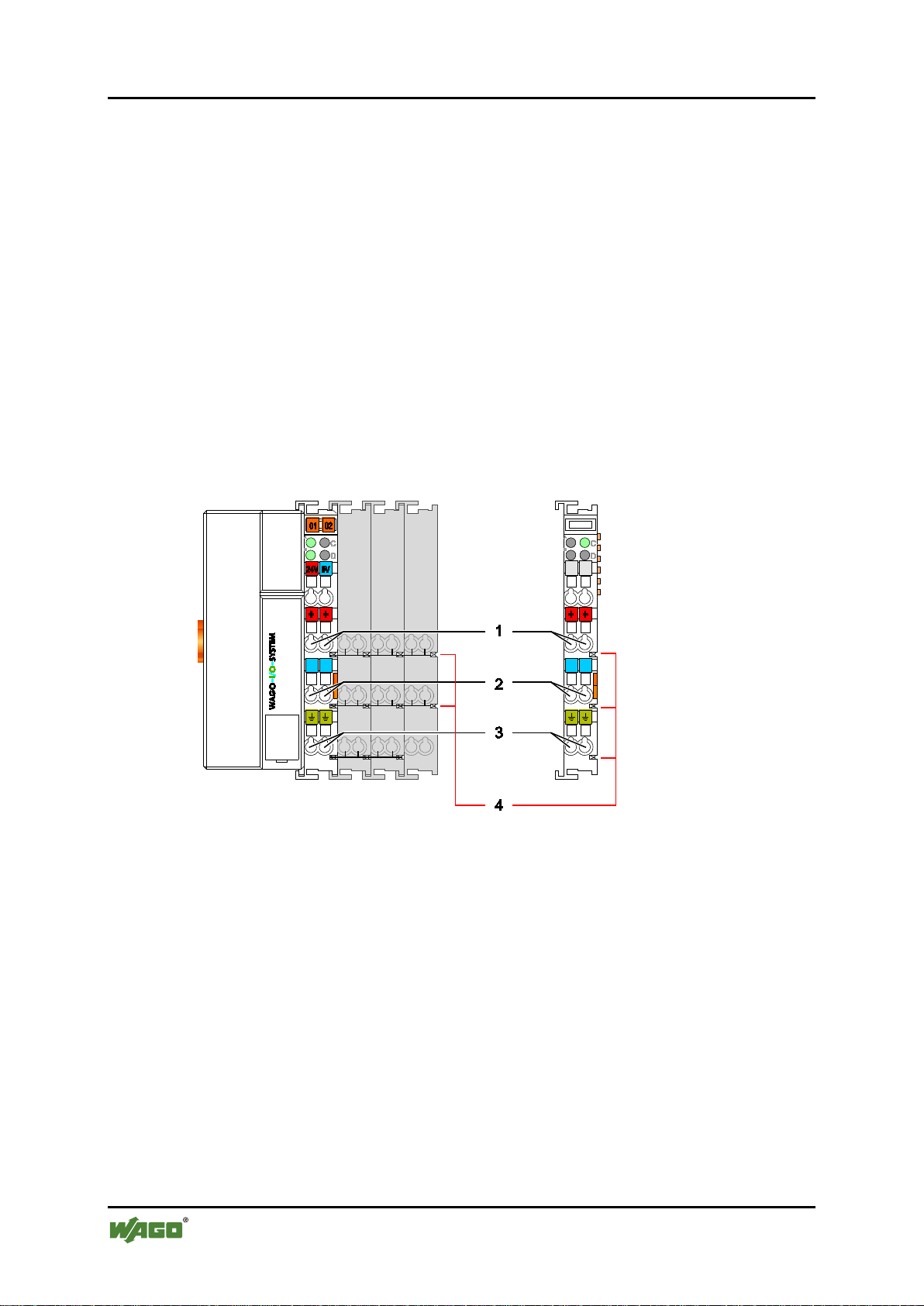

3 System Descrip tion

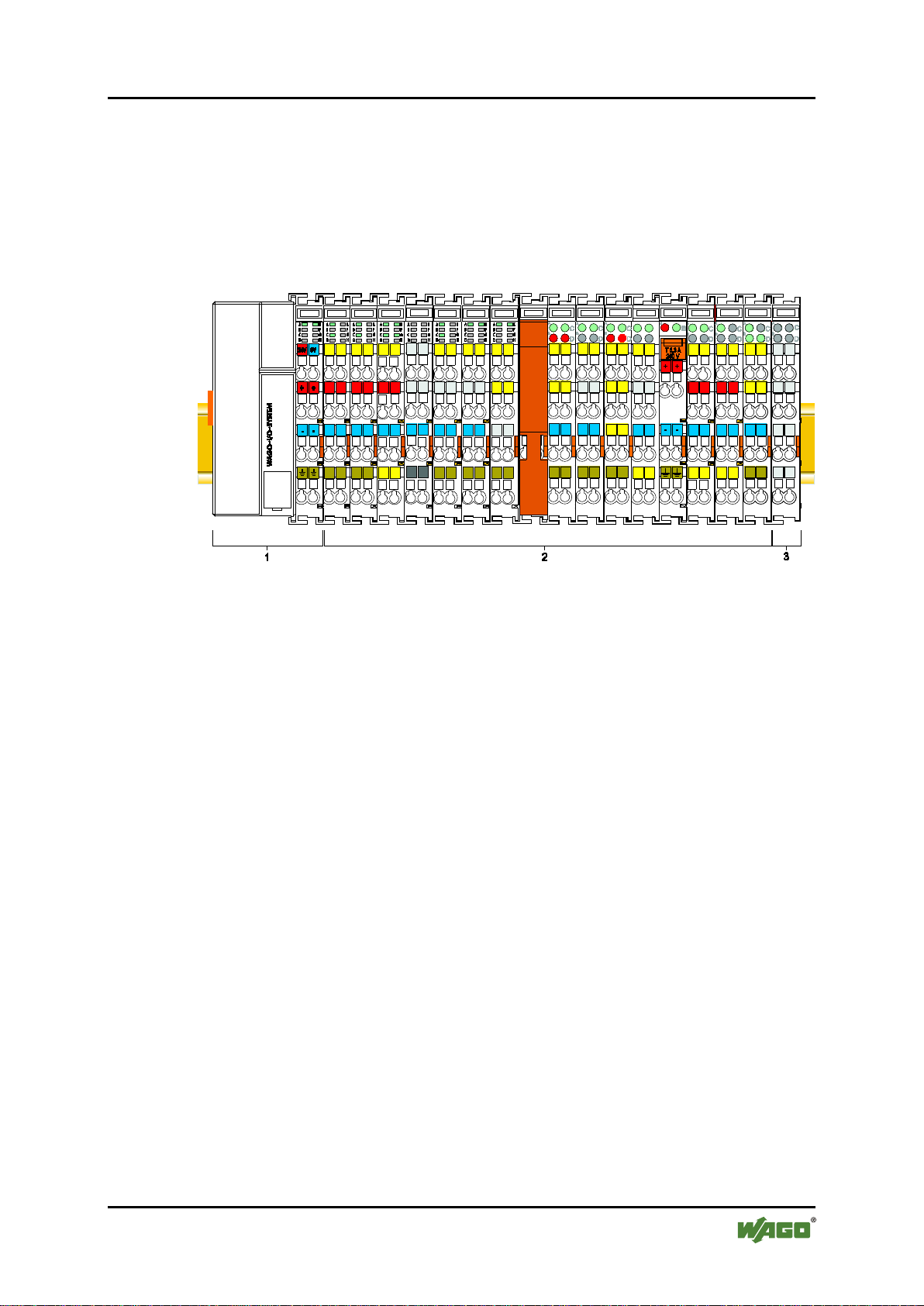

The WAGO-I/O-SYSTEM 750 is a modular, fieldbus-independent input/output

system (I/O system). The configuration described here consists of a fieldbus

coupler/controller (1) and the modular I/O modules (2) for any signal shapes that

form the fieldbus node together. The end module (3) completes the node and is

required for correct operation of the fieldbus node.

Figure 1: Fieldbus Node (Example)

Fieldbus couplers/controllers are available for different fieldbus systems.

The standard fieldbus couplers/controllers contain the fieldbus interface,

electronics and a power supply terminal. The fieldbus interface forms the physical

interface to the relevant fieldbus. The electronics process the data of the I/O

modules and make it available for the fieldbus communication. The 24 V system

supply and the 24 V field supply are fed in via the integrated power supply

terminal.

The fieldbus coupler/controller exchanges process data with the respective control

via the respective fieldbus. The programmable fieldbus controllers (PFC) allow

implementation of additional PLC functions. WAGO-I/O-PRO is used to program

the fieldbus controllers according to IEC 61131-3.

I/O modules for diverse digital and analog I/O signals as well as special functions

can be connected to the fieldbus coupler/controller. The communication between

the fieldbus coupler/controller and the I/O modules is carried out via an internal

bus.

The components of the WAGO-I/O-SYSTEM 750 have clear termination points,

light emitting diodes for status display, plug-in mini WSB tags and group marker

cards for labeling.

The 1, 2 or 3 wire technology supplemented by a ground wire connection allows

for direct sensor or actuator wiring.

Manual

Version 2.0.0

Page 16

16 System Description WAGO-I/O-SYSTEM 750

01

14

01

01

01

(additional positions)

WW

YY

FW --

HW

FL

-

Calendar

Year

Firmware

Hardware

Firmware

version

Internal info rmation

750-306 DeviceNet

TM

Fieldbus Coupler

3.1 Ma nu fact uri n g Num ber

The serial number indicates the delivery status directly after production. This

number is part of the labeling on the side of each component.

In addition, the serial number is printed on the cover cap of the configuration and

programming interface of the fieldbus coupler/controller, so that it can also be

read when installed.

Figure 2: Marking Area for Serial Numbers

There are two serial numbers in two rows in the side marking. They are left of the

release tab. The first 10 positions in the longer row of the serial numbers contain

version and date identifications.

Example structure of the rows: 0114010101…

week

The row order can vary depending on the production year, only the longer row is

relevant. The back part of this and the shorter row contain internal administration

information from the manufacturer.

version

version

loader

Manual

Version 2.0.0

Page 17

WAGO-I/O-SYST EM 750 System Description 17

Current version data for

1. Update

2. Update

3. Update

Production order no.

NO

only starting fr o m

Date stamp

DS

calendar week 13/2004

Software version

SW

Hardware version

HW

Firmware loader vers.

FWL

only for fieldbus

couplers/controllers

750-306 DeviceNet

TM

Fieldbus Coupler

3.2 Component Update

For the case of an update of one component, the lateral marking on each

component contains a prepared matrix.

This matrix makes columns available for altogether three updates to the entry of

the current update data, like production order number (NO; starting from calendar

week 13/2004), date stamp (DS), software version (SW), hardware version (HW)

and the firmware loader version (FWL, if available).

If the update of a component took place, the current version data are registered

into the columns of the matrix.

Additionally with the update of a fieldbus coupler or controller also the cover of

the configuration and programming interface of the fieldbus coupler or controller

is imprinted with the current production order number.

The original manufacturing information on the device's housing remains

unchanged.

3.3 Storage, Assembly and Transport

Whenever possible, the components are to be stored in their original packaging.

Likewise, the original packaging provides optimal protection during transport.

When assembling or repacking the components, the contacts must not be soiled or

damaged. The components must be stored and transported in appropriate

containers/packaging. Thereby, the ESD information is to be regarded.

Manual

Version 2.0.0

Page 18

18 System Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

3.4 Assem bl y Guidelines/Standar ds

• DIN 60204 Electrical equipping of machines

• DIN EN 50178 Equipping of high-voltage systems with electronic

components (replacement for VDE 0160)

• EN 60439 Low-voltage switchgear and controlgear assemblies

Manual

Version 2.0.0

Page 19

WAGO-I/O-SYST EM 750 System Description 19

750-306 DeviceNet

TM

Fieldbus Coupler

3.5 Power Supply

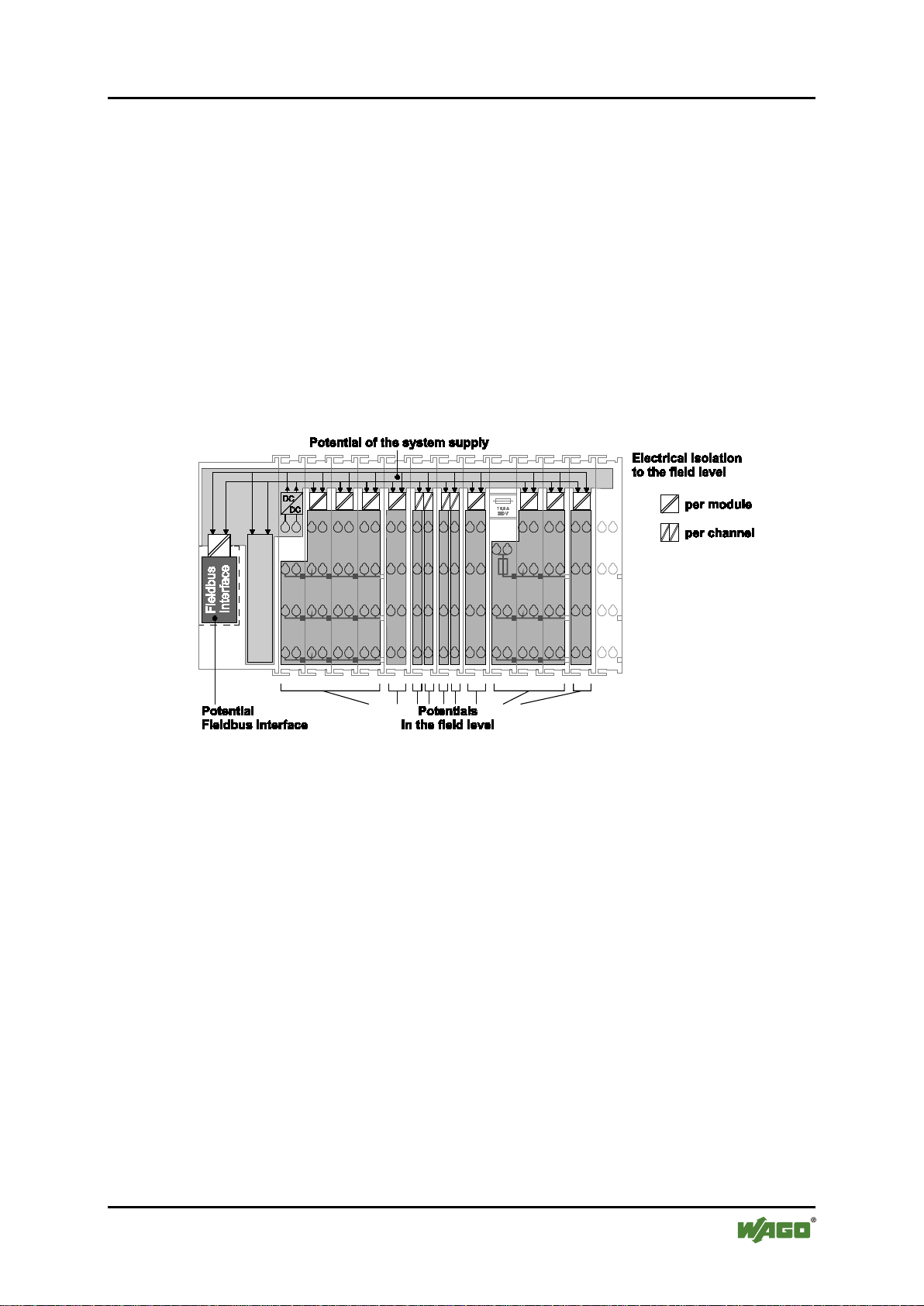

3.5.1 Isolation

Within the fieldbus node, there are three electrically isolated potentials:

• Electrically isolated fieldbus interface via transformer

• Electronics of the fieldbus couplers/controllers and the I/O modules

(internal bus)

• All I/O modules have an electrical isolation between the electronics

(internal bus, logic) and the field electronics. Some digital and analog input

modules have each channel electrically isolated, please see catalog.

Figure 3: Isolatio n for Fieldbus Couplers/Controllers (Example)

Manual

Version 2.0.0

Page 20

20 System Description WAGO-I/O-SYSTEM 750

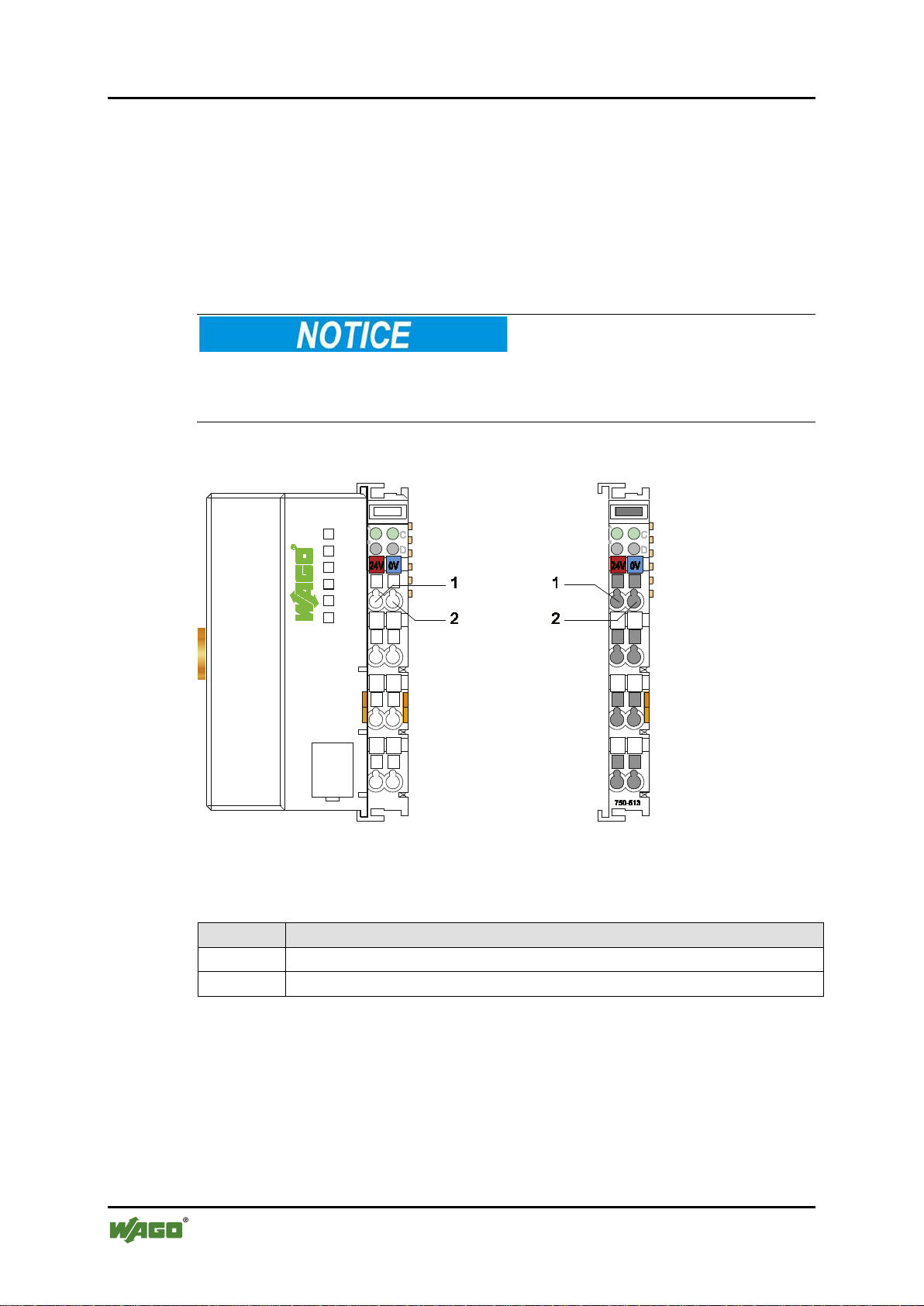

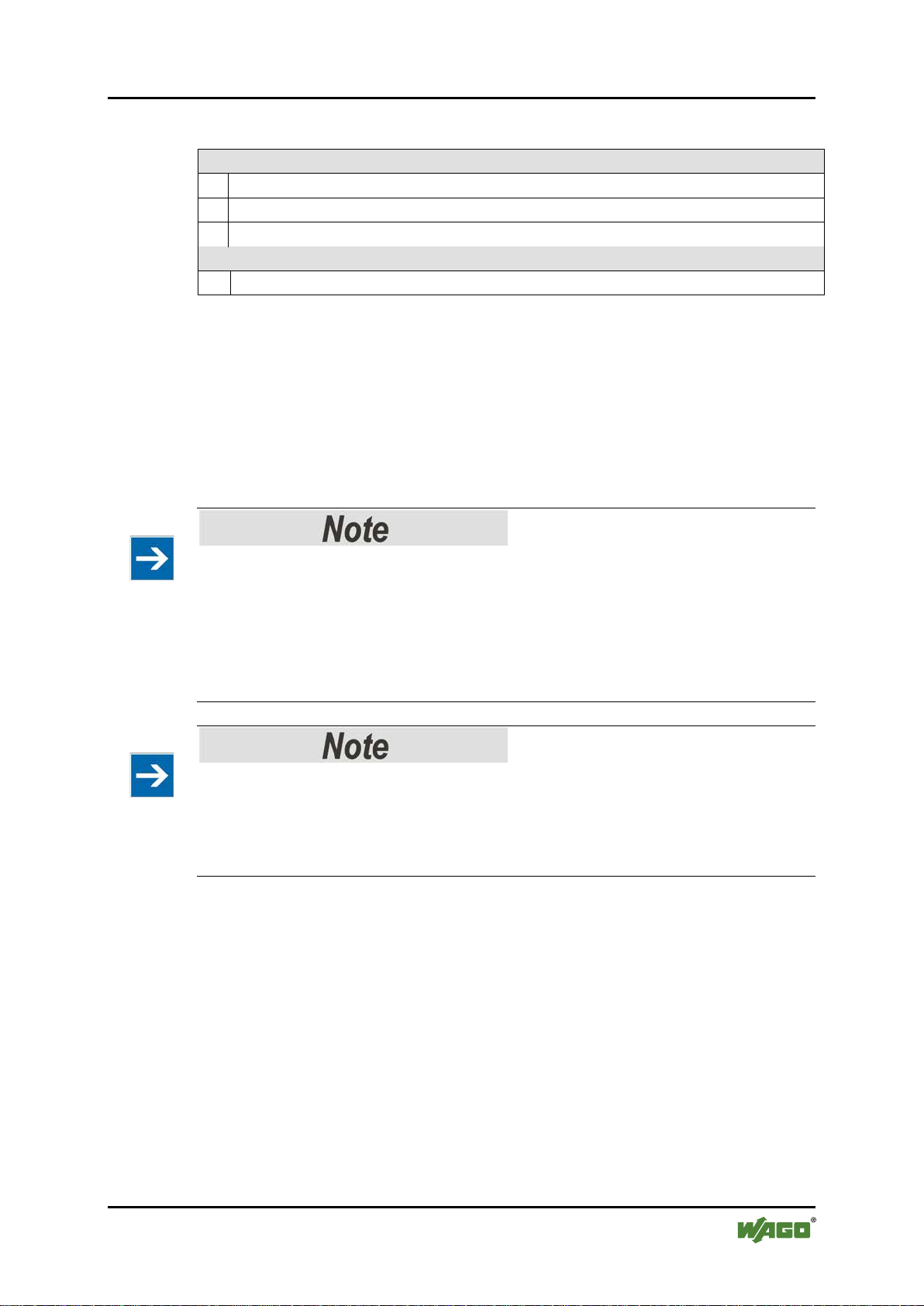

Table 3: Legend for Figure “System Supp ly via Fieldbus Coupler/Controller ( le f t) and via Internal

System Supply Module (right)”

Position

Description

1

System supply DC 24 V (-25 % … +30 %)

2

System supply 0 V

750-306 DeviceNet

TM

Fieldbus Coupler

3.5.2 System Supply

3.5.2.1 Connection

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply.

The power supply is provided via the fieldbus coupler/controller and, if necessary,

in addition via internal system supply modules 750-613. The power supply is

reverse voltage protected.

Do not use an incorrect voltage/frequency!

The use of an incorrect supply voltage or frequency can cause severe damage to

the components.

Figure 4: System Supp ly via Fieldbus Coupler/Controller (left) and via Internal System Supply

Module (right)

The fed DC 24 V supplies all internal system components, e.g. fieldbus

coupler/controller electronics, fieldbus interface and I/O modules via the internal

bus (5 V system voltage). The 5 V system voltage is galvanically connected to the

24 V system supply.

Manual

Version 2.0.0

Page 21

WAGO-I/O-SYST EM 750 System Description 21

Table 4: Alignment

Internal current

consumption*)

Current consumption via system voltage (5 V for electronics

of I/O modules and fieldbus coupler/controller).

Total current

Available current for the I/O modules. Provided by the bus

internal system supply module

*)

See current catalog, manuals, Internet

750-306 DeviceNet

TM

Fieldbus Coupler

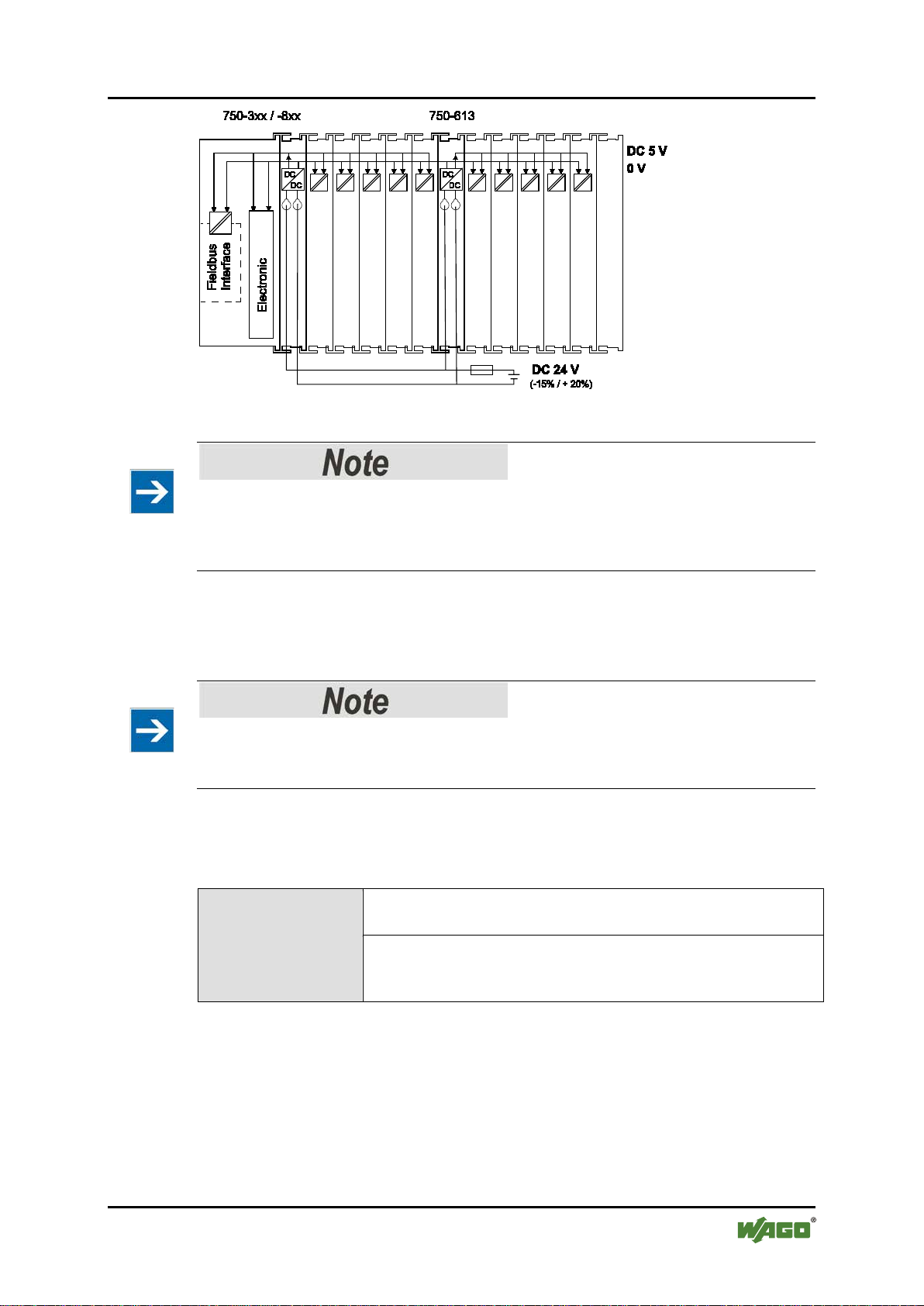

Figure 5: System Voltage for Standard Couplers/Controllers and Extended ECO Couplers

Only reset the system simultaneously for all supply modules!

Reset the system by simultaneously switching the system supply at all supply

modules (fieldbus coupler/controller and potential supply module with bus power

supply) off and on again.

3.5.2.2 Dimensioning

Recommendation

A stable power supply cannot always be assumed. Therefore, you should use

regulated power supplies to ensure the quality of the supply voltage.

The supply capacity of the fieldbus coupler/controller or the internal system

supply module can be taken from the technical data of the components.

for I/O modules*)

power supply unit. See fieldbus coupler/controller and

Manual

Version 2.0.0

Page 22

22 System Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

Example:

Calculating the current consumption on the fieldbus coupler:

Internal current consumption of the coupler 350 mA at 5 V

Total current for I/O modules 1650 mA at 5 V

Sum I

(5 V) total

2000 mA at 5 V

The internal current consumption is indicated in the technical data for each bus

terminal. In order to determine the total requirement, add together the values of all

I/O modules in the node.

Please note the aggregate current for I/O modules. It may be necessary to

supply potential!

When the sum of the internal current consumption for the I/O modules exceeds

their aggregate current, you must use a supply module with bus power supply.

Install it before the position where the permissible aggregate current would be

exceeded.

Example:

Calculating the total current on a standard fieldbus coupler/controller:

A node configuration with 20 relay modules (750-517) and 30 digital input

modules (750-405) should be attached to a fieldbus coupler/controller:

Internal current consumptions 20 × 90 mA = 1800 mA at 5 V

+ 30 × 2 mA = 60 mA at 5 V

Sum of internal current consumptions 1860 mA at 5 V

However, the fieldbus coupler can only provide 1650 mA for the I/O modules.

Consequently, an internal system supply module (750-613), e. g. in the middle of

the node, should be added.

Recommendation

Utilize the smartDESIGNER feature WAGO ProServe® software to configure

fieldbus node assembly. You can test the configuration via the integrated

plausibility check.

The maximum input current of the 24 V system supply is 500 mA. The exact

electrical consumption (I

Manual

Version 2.0.0

) can be determined with the following formulas:

(V)

Page 23

WAGO-I/O-SYST EM 750 System Description 23

Fieldbus coupler or controller

I

=

Sum of all the internal current consumption of the connected

coupler/controller

Internal system supply module

I

=

Sum of all the internal current consumption of the connected

5 V × I

(5 V) total

24 V

η

(87 % Efficiency of the power supply at nominal load 24 V)

750-306 DeviceNet

TM

Fieldbus Coupler

(5 V) total

I/O modules + internal current consumption of the fieldbus

(5 V) total

I/O modules at internal system supply module

Input current I

Activate all outputs when testing the current consumption!

If the electrical consumption of a power supply point for the 24 V system

supply exceeds 500 mA, then the cause may be an improperly dimensioned

node or a defect.

During the test, you must activate all outputs.

(24 V)

=

η = 0.87

Manual

Version 2.0.0

Page 24

24 System Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

3.5.3 Field Supply

3.5.3.1 Connection

Sensors and actuators can be directly connected to the relevant channel of the I/O

module in 1, 2, 3 or 4 conductor connection technology. The I/O module supplies

power to the sensors and actuators. The input and output drivers of some I/O

modules require the field side supply voltage.

The fieldbus coupler/controller provides field side power (DC 24 V). In this case

it is a passive power supply without protection equipment.

Power supply modules with or without fuse holder and diagnostic capability are

available for the power supply of other field potentials (DC 24 V, AC/DC 0 …

230 V, AC 120 V, AC 230 V). The power supply modules can also be used to set

up various potential groups. The connections are connected in pairs to a power

contact.

Figure 6: Field Supply for Standard Couplers/Controllers and Extended ECO Couplers

Manual

Version 2.0.0

Page 25

WAGO-I/O-SYST EM 750 System Description 25

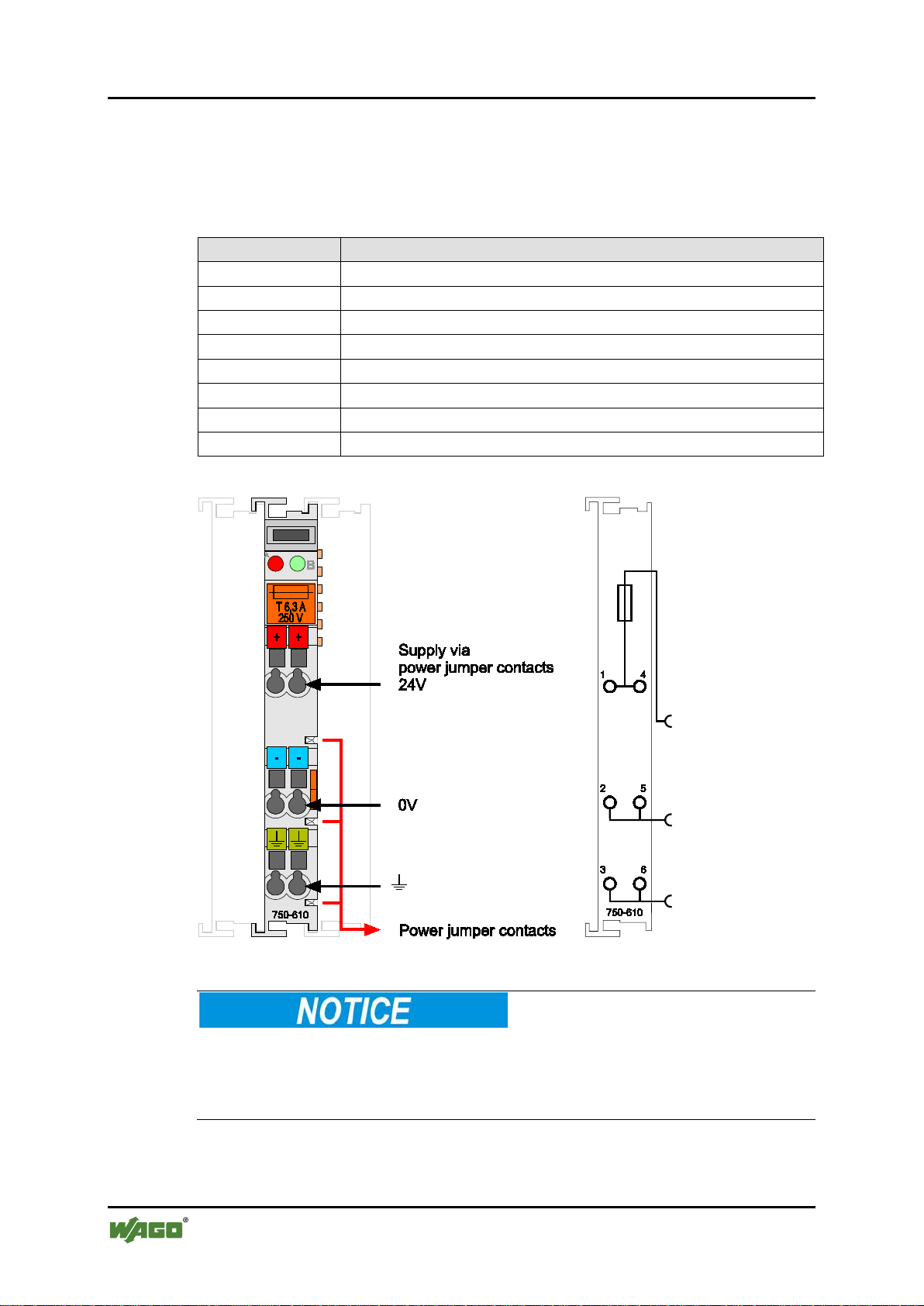

Table 5: Legend for Figure “Field Supply for Standard Couplers/Controllers and Extended ECO

Couplers”

Field supply

1

24 V (-15 % / +20 %)

2

0 V

3

Optional ground potential

Power jumper contacts

4

Potential distribution to adjacent I/O modules

establish the ground connection when the connection to the power jumper

750-306 DeviceNet

TM

Fieldbus Coupler

The field-side power supply is automatically derived from the power jumper

contacts when snapping an I/O module.

The current load of the power contacts must not exceed 10 A on a continual basis.

By inserting an additional power supply module, the field supply via the power

contacts is disrupted. From there a new power supply occurs which may also

contain a new voltage potential.

Recontacts is disrupted!

Some I/O modules have no or very few power contacts (depending on the I/O

function). Due to this, the passing through of the relevant potential is disrupted. If

you require a field supply via power jumper contacts for subsequent I/O modules,

then you have to use a power supply module.

Note the data sheets of the I/O modules.

Use a spacer module when setting up a node with different potentials!

In the case of a node setup with different potentials, e.g. the alteration from

DC 24 V to AC 230 V, you should use a spacer module. The optical separation of

the potentials acts as a warning to heed caution in the case of wiring and

maintenance works. Thus, you can prevent the results of wiring errors.

Manual

Version 2.0.0

Page 26

26 System Description WAGO-I/O-SYSTEM 750

Table 6: Power Supply Modules

Order No.

Field Voltage

750-601

24 V DC, Supply/Fuse

750-609

230 V AC, Supply/Fuse

750-615

120 V AC, Supply/Fuse

750-617

24 V AC, Supply/Fuse

750-610

24 V DC, Supply/Fuse/Diagnosis

750-611

230 V AC, Supply/Fuse/Diagnosis

750-606

Supply Module 24 V DC, 1,0 A, Ex i

750-625/000-001

Supply Module 24 V DC, 1,0 A, Ex i (without diagnostics)

750-306 DeviceNet

TM

Fieldbus Coupler

3.5.3.2 Fusing

Internal fusing of the field supply is possible for various field voltages via an

appropriate power supply module.

Figure 7: Supply Module with Fuse Carrier (Example 750-610)

Observe the maximum power dissipation and, if required, UL requirements!

In the case of power supply modules with fuse holders, you must only use fuses

with a maximum dissipation of 1.6 W (IEC 127).

For UL approved systems only use UL approved fuses.

Manual

Version 2.0.0

Page 27

WAGO-I/O-SYST EM 750 System Description 27

750-306 DeviceNet

TM

Fieldbus Coupler

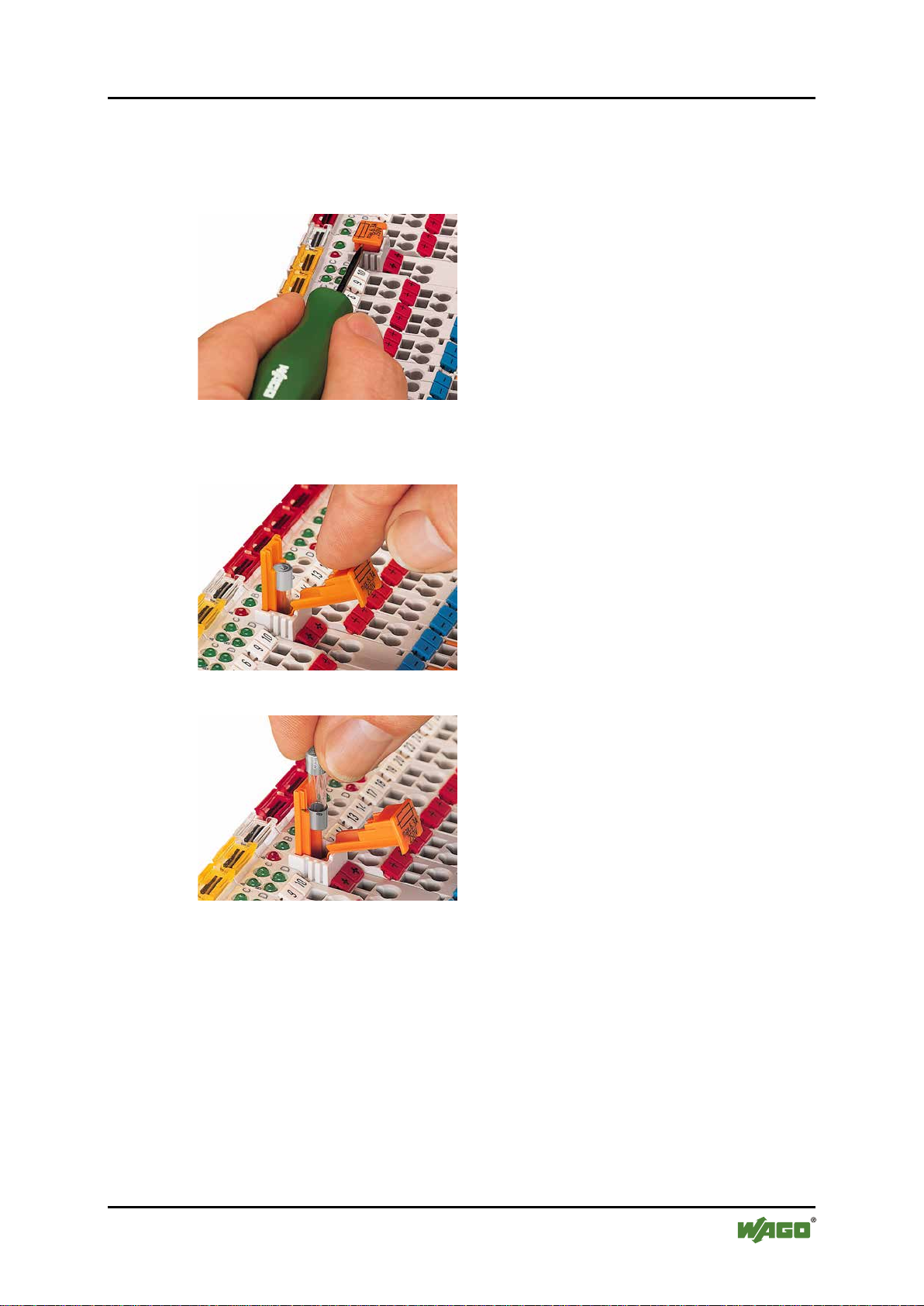

In order to insert or change a fuse, or to switch off the voltage in succeeding I/O

modules, the fuse holder may be pulled out. In order to do this, use a screwdriver

for example, to reach into one of the slits (one on both sides) and pull out the

holder.

Figure 8: Removing the Fuse Carrier

Lifting the cover to the side opens the fuse carrier.

Figure 9: Opening the Fuse Carrier

Figure 10: Cha nging the Fuse

After changing the fuse, the fuse carrier is pushed back into its original position.

Manual

Version 2.0.0

Page 28

28 System Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

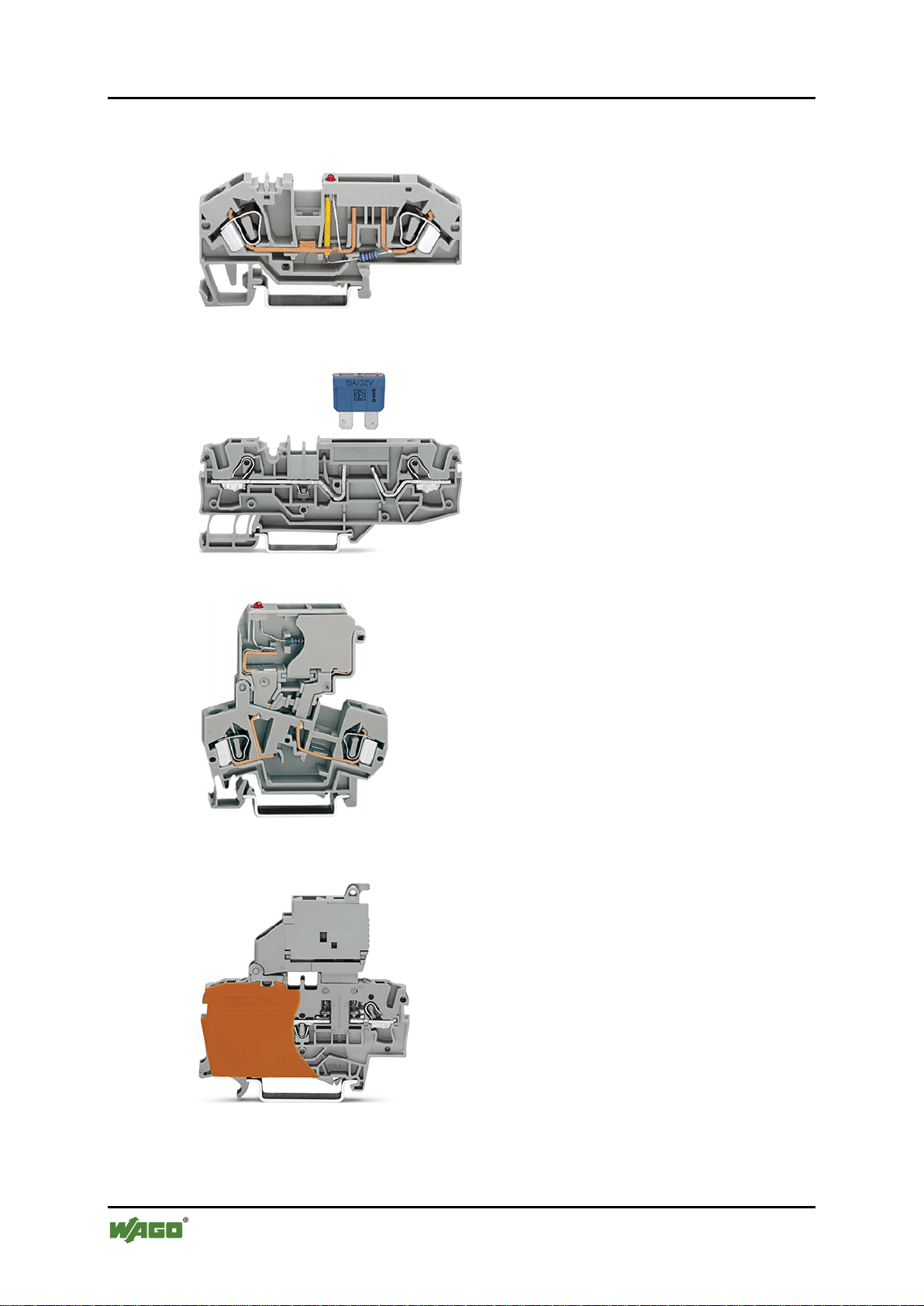

Alternatively, fusing can be done externally. The fuse modules of the WAGO

series 281 and 282 are suitable for this purpose.

Figure 11: Fuse Modules for Automotive Fuses, Series 282

Figure 12: Fuse Modules for Automotive Fuses, Series 2006

Figure 13: Fuse Modules with Pivotable Fuse Carrier, Series 281

Figure 14: Fuse Modules with Pivotable Fuse Carrier, Series 2002

Manual

Version 2.0.0

Page 29

WAGO-I/O-SYST EM 750 System Description 29

Table 7: Filter Modules for 24 V Supply

Order No.

Name

Description

750-626

Supply Filter

Filter module for system supply and field supply

bus power supply (750-613)

750-624

Supply Filter

Filter module for the 24 V field supply

(750-602, 750-601, 750-610)

750-306 DeviceNet

TM

Fieldbus Coupler

3.5.4 Supplementar y Power Supply Regulations

The WAGO-I/O-SYSTEM 750 can also be used in shipbuilding or offshore and

onshore areas of work (e. g. working platforms, loading plants). This is

demonstrated by complying with the standards of influential classification

companies such as Germanischer Lloyd and Lloyds Register.

Filter modules for 24 V supply are required for the certified operation of the

system.

(24 V, 0 V), i. e. for fieldbus coupler/controller and

Therefore, the following power supply concept must be absolutely complied with.

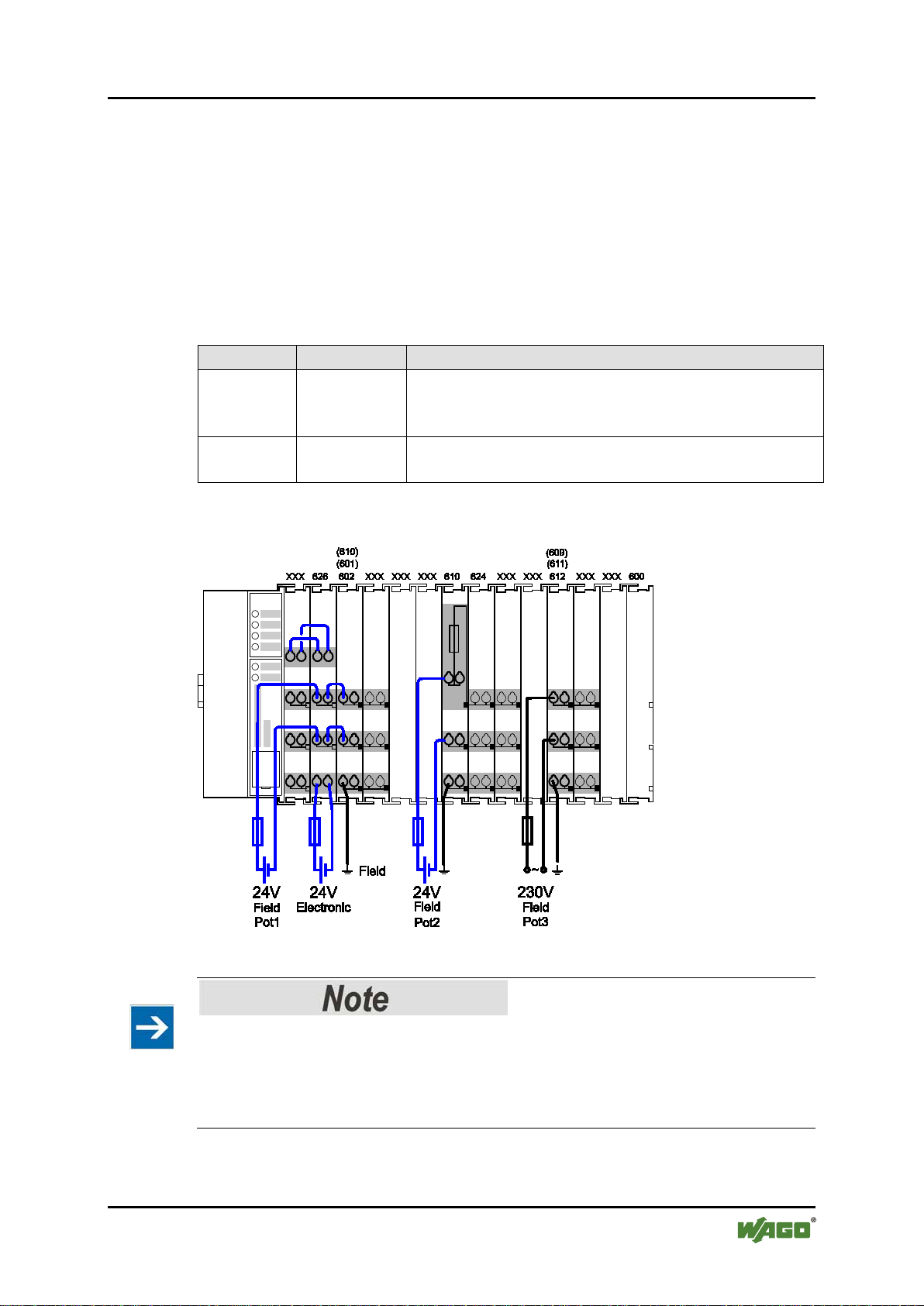

Figure 15: Power Supply Concept

Use a supply module for equipotential bonding!

Use an additional 750-601/ 602/ 610 Supply Module behind the 750-626 Filter

Module if you want to use the lower power jumper contact for equipotential

bonding, e.g., between shielded connections and require an additional tap for this

potential.

Manual

Version 2.0.0

Page 30

30 System Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

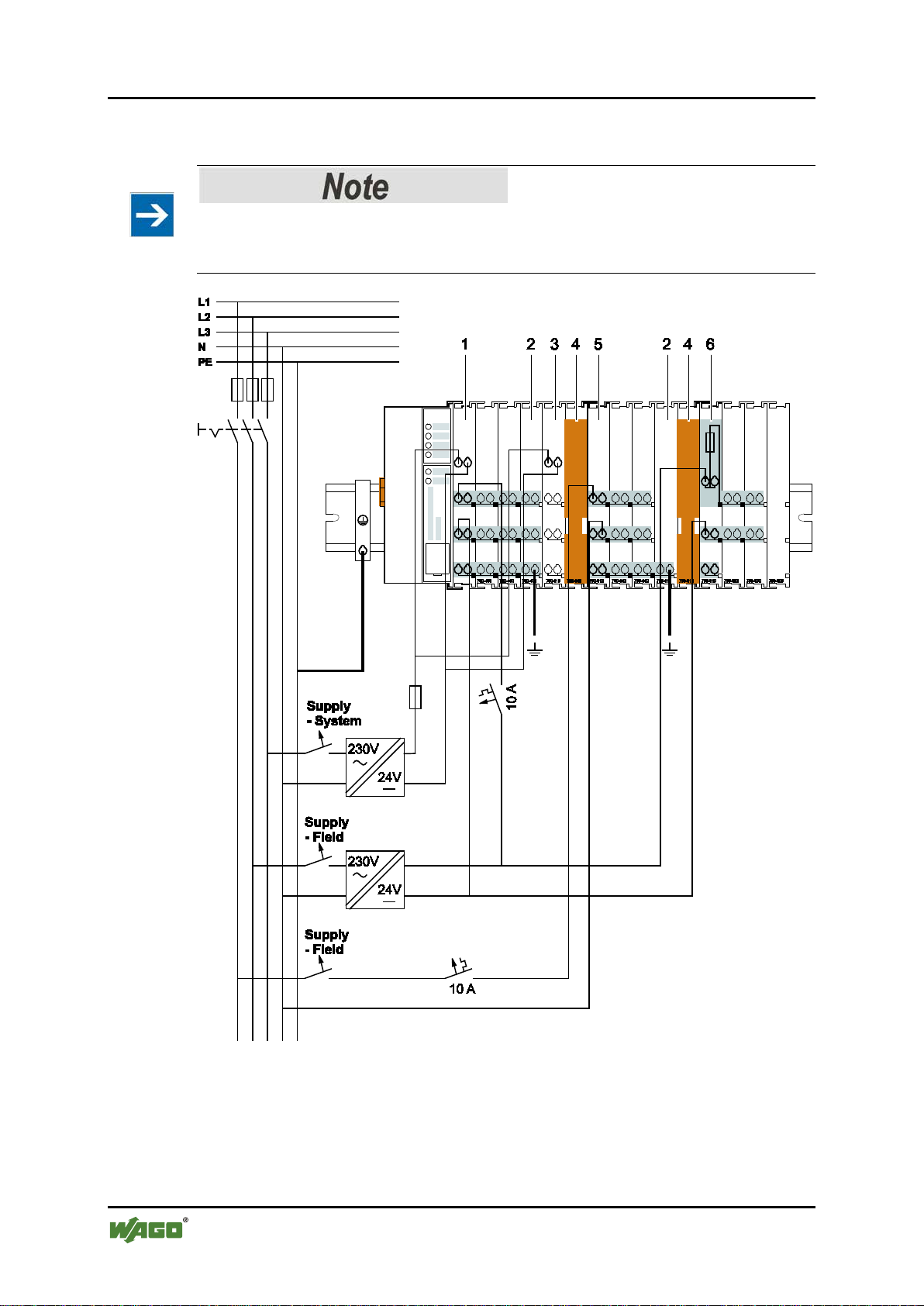

3.5.5 Supply Example

SupplSggggggggggggggggg

The system supply and the field supply shall be separated!

You should separate the system supply and the field supply in order to ensure bus

operation in the event of a short-circuit on the actuator side.

Figure 16: Supply Example for Standard Couplers/Controllers

Manual

Version 2.0.0

Page 31

WAGO-I/O-SYST EM 750 System Description 31

Table 8: Legend for Figure “Supply Example for Fieldbus Coupler/Controller”

Pos.

Description

1

Power Supply on coupler via external Supply Module

2

Power Supply with optional ground

3

Internal System Supply Module

4

Separation module recommended

5

Supply Module passive

6

Supply Module with fuse carrier/diagnostics

750-306 DeviceNet

TM

Fieldbus Coupler

Manual

Version 2.0.0

Page 32

32 System Description WAGO-I/O-SYSTEM 750

Table 9: WAGO Power Supply Units (Selection)

WAGO Power

Supply Unit

Description

787-612

Primary switched mode;

DC 24 V; 2,5 A Input nominal voltage AC 230 V

787-622

Primary switched mode;

DC 24 V; 5 A Input nominal voltage AC 230 V

787-632

Primary switched mode;

DC 24 V; 10 A Input nominal voltage AC 230/115 V

Rail-mounted modules with universal mounting carrier

288-809

AC 115 V/DC 24 V; 0,5 A

288-810

AC 230 V/DC 24 V; 0,5 A

288-812

AC 230 V/DC 24 V; 2 A

288-813

AC 115 V/DC 24 V; 2 A

750-306 DeviceNet

TM

Fieldbus Coupler

3.5.6 Power Supply Unit

The WAGO-I/O-SYSTEM 750 requires a 24 VDC voltage (system supply).

Recommendation

A stable power supply cannot always be assumed everywhere. Therefore, you

should use regulated power supplies to ensure the quality of the supply voltage

(see also table “WAGO power supply units”).

For brief voltage dips, a buffer (200 µF per 1 A load current) must be provided.

Power failure time not acc. IEC 61131-2!

Note that the power failure time of 10 ms acc. IEC 61131-2 is not maintained in a

maximum configuration.

The power demand must be determined individually depending on the entry point

of the field supply. All loads through field devices and I/O modules must be taken

into account. The field supply also impacts the I/O modules because the input and

output drivers of some I/O modules require the voltage of the field supply.

System and field supply must be isolated!

The system supply and field supply must be isolated to ensure bus operation in the

event of short circuits on the actuator side.

Manual

Version 2.0.0

Page 33

WAGO-I/O-SYST EM 750 System Description 33

Table 10: WAGO Ground Wire Termi nals

Order No.

Description

283-609

1-conductor ground (earth) terminal block make an automatic contact

Note: Also order the end and intermediate plate (283-320).

750-306 DeviceNet

TM

Fieldbus Coupler

3.6 Grounding

3.6.1 Grounding the DIN Rail

3.6.1.1 Framework Assembly

When setting up the framework, the carrier rail must be screwed together with the

electrically conducting cabinet or housing frame. The framework or the housing

must be grounded. The electrical connection is established via the screw. Thus,

the carrier rail is grounded.

Ensure sufficient grounding is provided!

You must take care to ensure the flawless electrical connection between the

carrier rail and the frame or housing in order to guarantee sufficient grounding.

3.6.1.2 Insulated Assembly

Insulated assembly has been achieved when there is constructively no direct

ohmic contact between the cabinet frame or machine parts and the carrier rail.

Here, the earth ground must be set up via an electrical conductor in accordance

with valid national safety regulations.

Recommendation

The optimal setup is a metallic assembly plate with grounding connection which

is electrically conductive linked to the carrier rail.

The separate grounding of the carrier rail can be easily set up with the aid of the

WAGO ground wire terminals.

to the carrier rail; conductor cross section: 0.2 mm² … 16 mm2

Manual

Version 2.0.0

Page 34

34 System Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

3.6.2 Grounding Function

The grounding function increases the resistance against electro-magnetic

interferences. Some components in the I/O system have a carrier rail contact that

dissipates electro-magnetic interferences to the carrier rail.

Figure 17: Carrier Rail Co ntact (Example)

Ensure sufficient grounding is provided!

You must take care to ensure the direct electrical connection between the carrier

rail contact and the carrier rail.

The carrier rail must be grounded.

For information on carrier rail properties, see section “Mounting” > … > “Carrier

Rail Properties”.

The bottom CAGE CLAMP

connection of a field-side functional ground. This potential is made available to

the I/O module arranged on the right through the spring-loaded contact of the

three power contacts. Some I/O modules are equipped with a knife-edge contact

that taps this potential. This forms a potential group with regard to functional

ground with the I/O module arranged on the left.

®

connectors of the supply modules enable optional

Manual

Version 2.0.0

Page 35

WAGO-I/O-SYST EM 750 System Description 35

750-306 DeviceNet

TM

Fieldbus Coupler

3.7 Shielding

3.7.1 General

Use of shielded cables reduces electromagnetic interference and thus increases

signal quality. Measurement errors, data transmission errors and interference due

to excessive voltage can be prevented.

Connect the cable shield to the ground potential!

Integrated shielding is mandatory to meet the technical specifications in regards to

measuring accuracy. Connect the cable shield and ground potential at the inlet to

the cabinet or housing. This allows induced interference to dissipate and to be

kept away from devices in the cabinet or housing.

Figure 18: Cable Shield at Ground Potential

Improve shielding performance by placing the shield over a large area!

Higher shielding performance is achieved via low-impedance connection between

shield and ground. For this purpose, connect the shield over a large surface area,

e.g., WAGO shield connecting system. This is especially recommended for largescale systems where equalizing current or high impulse-type currents caused by

atmospheric discharge may occur.

Keep data and signal lines away from sources of interference!

Route data and signal lines separately from all high voltage cables and other

sources of high electromagnetic emission (e.g., frequency converter or drives).

3.7.2 Bus Cables

The shielding of the bus line is described in the respective configuration

guidelines and standards of the bus system.

Manual

Version 2.0.0

Page 36

36 System Description WAGO-I/O-SYSTEM 750

Figure 19: Examples of the WAGO Shield Connecting System

750-306 DeviceNet

TM

Fieldbus Coupler

3.7.3 Signal Lines

I/O modules for analog signals and some interface I/O modules are equipped with

shield clamps.

Use shielded signal lines!

Only use shielded signal lines for analog signals and I/O modules which are

equipped with shield clamps. Only then can you ensure that the accuracy and

interference immunity specified for the respective I/O module can be achieved

even in the presence of interference acting on the signal cable.

3.7.4 WAGO Shield Connecting System

The WAGO shield connecting system consists of shield clamping saddles,

busbars and various mounting carriers. These components can be used to achieve

many different configurations.

Figure 20: Application of the WAGO Shield Connecting System

Manual

Version 2.0.0

Page 37

WAGO-I/O-SYST EM 750 Device Description 37

750-306 DeviceNet

TM

Fieldbus Coupler

4 Device Description

The DeviceNetTM Fieldbus Coupler 750-306 links the WAGO-I/O-SYSTEM 750

as a slave to the DeviceNetTM fieldbus system.

This fieldbus coupler can be used for applications in mechanical and systems

engineering, as well as in the processing industry.

The fieldbus connection is made via 231 series 5-pin plug connector of the WAGO

MULTI CONNECTION SYSTEM (MCS).

The DIP switch can be used to specify baud rate and station address of the

fieldbus coupler.

In the Fieldbus Coupler, all input signals from the sensors are combined. After

connecting the Fieldbus Coupler, the Fieldbus Coupler determines which I/O

modules are on the node and creates a local process image from these. Analog and

specialty module data is sent via words and/or bytes; digital data is grouped bitby-bit.

The local process image is divided into two data zones containing the data

received and the data to be sent.

The process data is sent via the DeviceNetTM fieldbus to a control system for

further processing. The process output data is sent via the DeviceNetTM fieldbus.

The data of the analog modules is mapped first into the process image. The

modules are mapped in the order of their physical position after the Coupler.

The bits of the digital modules are combined into bytes and then mapped after the

analog ones in the process image. If the number of digital I/Os is greater than 8

bits, the Fieldbus Coupler automatically begins a new byte.

The fieldbus coupler supports the DeviceNetTM “Bit Strobe” function where the

function is limited to the extent that only the status byte is supplied.

Manual

Version 2.0.0

Page 38

38 Device Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

4.1 View

The view below shows the three parts of the device:

• The left side shows the fieldbus connection and a DIP switch to set both the

node ID and baud rate.

• LEDs for operation status, bus communication, error messages and

diagnostics, as well as the service interface are in the middle area.

• The right side shows the power supply unit for the system supply and for the

field supply of the attached I/O modules via power jumper contacts.

LEDs show the status of the operating voltage for the system and field

supply (jumper contacts).

Figure 21: View DeviceNet

TM

Fieldbus Coupler

Manual

Version 2.0.0

Page 39

WAGO-I/O-SYST EM 750 Device Description 39

Table 11: Legend for Figure “View DeviceNetTM Fieldbus Coupler”

Designation

OVERFL,

CONNECT

Group marking carrier (retractable) with

WSB markers

“Device Description” >

“Display Elements”

“Connect Devices” > “Data

Contacts/I nternal Bus”

“Connect Devices” >

the CAGE CLAMP®”

“Connect Devices” >

the CAGE CLAMP®”

“Connect Devices” >

Field Supply”

“Mounting” >

Devices”

“Connect Devices” >

the CAGE CLAMP®”

“Connect Devices” >

Field Supply”

“Connect Devices” >

the CAGE CLAMP®”

“Connect Devices” >

Field Supply”

“Device Description” >

“Operating Elements”

“Device Description” >

“Operating Elements”

“Mounting” > “Inserti ng

and Removing Devices”

Fieldbus Data contacts connection, 231 Series

(MCS)

“Device Description“ >

“Connectors“

750-306 DeviceNet

TM

Fieldbus Coupler

Pos.

RUN,

1

BUS OFF,

2 ---

Status LEDs Fieldbus

additional marking possibility on two miniature

Meaning Details see Section

“Device Description” >

“Display Elements”

---

3 A, B or C Status LED’s System/Field Supply

4 --- Data Contacts

5 24 V, 0 V CAGE CLAMP® Connections System Supply

®

6 +

CAGE CLAMP

24 VDC

Connections Field Supply

7 --- Power Jumper Contact 24 VDC

8 --- Unlockin g Lu g

“Connecting a conductor to

“Connecting a conductor to

“Power Contacts/

“Inserting and Removi ng

9 - CAGE CLAMP® Connections Field Supply 0 V

10 --- Po wer Jumper Contact 0 V

11 (Ground)

12 --- Power Jumper Contact (Ground)

13 --- Service Interface (open flap)

16 --- DIP Switch

15 --- Locking Disc

16 ---

CAGE CLAMP

(Ground)

®

Connections Field Supply

“Connecting a conductor to

“Power Contacts/

“Connecting a conductor to

“Power Contacts/

Manual

Version 2.0.0

Page 40

40 Device Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

4.2 Connectors

4.2.1 Device Supply

The device is powered via terminal blocks with CAGE CLAMP® connections.

The device supply generates the necessary voltage to power the electronics of the

device and the internal electronics of the connected I/O modules.

The fieldbus interface is galvanically separated to the electrical potential of the

device.

Figure 22: Device Supply

Manual

Version 2.0.0

Page 41

WAGO-I/O-SYST EM 750 Device Description 41

Table 12: Pin Assignment for the Fieldbus Connection, Series 231 (MCS)

PIN

Signal

Code*

Description

5

V+

red

11 V … 25 V

4

CAN_H

white

CAN Signal

High

3

Drain shield

Shield termination

2

CAN_L

blue

CAN Signal

Low

1

V-

black

0 V

*

according to DeviceNetTM specification, identical to the conductors of the

DeviceNetTM cable

750-306 DeviceNet

TM

Fieldbus Coupler

4.2.2 Fieldbus Connection

The fieldbus connection for DeviceNetTM is made via Series 231 5-pin plug

connector from the MULTI CONNECTION SYSTEM (MCS). A connector

(OpenStyle) is the counterpart. The 231-305/010-000/050-000 connector is

included.

Figure 23: Fieldbus Connections, Series 231 (MCS)

To connect small conductor cross-sections, an insulation stop of series 231-670

(white), 231-671 (light gray) or 231-672 (dark gray) should be used due to their

flexibility. The insulating stop prevents the conductor from deforming when

pushed against the conductor stop. As a result, the conductor insulation may be

clamped, causing intermittent contact or no contact at all. The marking of the

connector, as well as housing parts, test plugs with cable and male connectors for

cable extensions are available.

The connection point is lowered for mounting into an 80 mm-high switchgear

cabinet after connector attachment.

DC/DC converters and optocouplers in the fieldbus interface electrically isolate

the fieldbus system and the electronics.

Manual

Version 2.0.0

Page 42

42 Device Description WAGO-I/O-SYSTEM 750

Table 13: Display Elements Fieldbus Status

LED

Color

Meaning

OVERFL

red

Indicates an error or defect on the fieldbus coupler

RUN

green

Indicates that the fieldbus coupler is operational

BUS OFF

red

Indicates an error or malfunction in the network

CONNEC

T

green

Indicates that the fieldbus coupler is ready for network

communication

Table 14: Display Elements Node Status

LED

Color

Meaning

I/O

red/green/

orange

Indicates the operation of the node and signals via a blink code faults

encountered.

Table 15: Display Elements Supply Voltage

LED

Color

Meaning

A

green

indicates the status of the operating voltage – system

B

green

indicates the status of the operating voltage – power jumper contacts

750-306 DeviceNet

TM

Fieldbus Coupler

4.3 Display Elements

The operating condition of the fieldbus coupler or the node is displayed with the

help of illuminated indicators in the form of light-emitting diodes (LEDs).

The LED information is routed to the top of the case by light guides. In some

cases, the LEDs are multi-colored (red, green or orange).

Figure 24: Display Elements

+

For the diagnostics of the different domains fieldbus, node and supply voltage, the

LEDs can be divided into three groups:

+

+

More information about the LED Signaling

Read the detailed description for the evaluation of the displayed LED state in the

section “Diagnostics” > … > “LED Signaling”.

Manual

Version 2.0.0

Page 43

WAGO-I/O-SYST EM 750 Device Description 43

Table 16: Legend for Figure “Service Interface (Closed and Opened Flap)”

Number

Description

1

Open closed

2

View Service Interface

750-306 DeviceNet

TM

Fieldbus Coupler

4.4 Operating Elements

4.4.1 Service Interface

The service interface is located behind the flap.

It is used for the communication with the WAGO-I/O-CHECK and for

downloading the firmware updates.

Figure 25: Service Interface (Closed and Opened Flap)

Device must be de-energized!

To prevent damage to the device, unplug and plug in the communication cable

only when the device is de-energized!

The connection to the 4-pin header under the cover flap can be realized via the

communication cables with the item numbers750-920 and 750-923 or via the

WAGO radio adapter with the item number 750-921.

Manual

Version 2.0.0

Page 44

44 Device Description WAGO-I/O-SYSTEM 750

Table 17: Setting the Baud Rate via DIP S witch

Baud rate

Slide switch 7

Slide switch 8

125 kBaud (default)

OFF

OFF

250 kBaud

ON

OFF

500 kBaud

OFF

ON

not permitted

ON

ON

- ON

- OFF

Figure 27: Example with Baud rate Sent to 250 kBaud

750-306 DeviceNet

TM

Fieldbus Coupler

4.4.2 DIP Switch

Figure 26: DIP Switch

The DIP switch is used to set the baud rate of the fieldbus coupler and to set the

DeviceNetTM station address (relating to DeviceNetTM, also called “MAC ID”).

Settings are made by moving the slide switches to “ON” or “OFF”.

The position of the individual slide switches is only evaluated when turning on the

fieldbus coupler, i.e., changes are applied when the power supply for the fieldbus

coupler is turned OFF then ON again.

4.4.2.1 Baud Rate Setting

The baud rate is set using slide switches 7 and 8 of the DIP switch. 3 different

baud rates are supported.

Example:

Setting the baud rate to 250 kBaud

Manual

Version 2.0.0

Page 45

WAGO-I/O-SYST EM 750 Device Description 45

- ON 20 = 1

- OFF

- OFF

- ON 23 = 8

- ON 24 = 16

- OFF

Figure 28: Example with Station Address Set to 25

750-306 DeviceNet

TM

Fieldbus Coupler

4.4.2.2 Station address

The station address is set using slide switches 1 to 6.

The binary significance of the individual slide switches increases in the direction

of the slide switch numbers. Slide switch 1 is used to set the lowest bit with a

significance of 20 and slide switch 6 to set the highest bit with a significance of 25.

If slide switch 1 is set to “ON”, “MAC ID” 1 is set, if slide switch 1 and 4 are set

to “ON”, “MAC ID” 9 is set ((20 + 23).

Station addresses in the range of 0 (all slide switches set to “OFF”) to 63 (all slide

switches set to “ON”) can be set for the DeviceNetTM fieldbus nodes. The station

address is set to 1 when delivered.

Example:

Setting the station address to 25.

Manual

Version 2.0.0

Page 46

46 Device Description WAGO-I/O-SYSTEM 750

Table 18: Technical Data, Device Data

Width

51 mm

Height (from upper-edge of DIN35 rail)

65 mm

Depth

100 mm

Weight

approx. 195 g

Degree of protection

IP20

Table 19: Technical Data, System Data

Number of I/O modules

64 with scanner

Number of I/O points

approx. 6000 (master/slave dependent)

Transmission medium

Shielded Cu cable

Drop cable: 2 x 0.2 mm2 + 2 x 0.32 mm2

Bus segment length

100 m ... 500 m

(depending on baud rate/cable)

Network length

acc. specification IEEE 802.3,

stub line length for all baud rates 6 m

Baud rate

125 kBaud, 250 kBaud, 500 kBaud

Buscoupler connection

5-pin male connector, Series 231 (MCS)

Protocols

DeviceNetTM

Number of I/O modules

64

Input process image

max

512 bytes

Output process image

max

512 bytes

Configuration

via PC or PLC

Table 20: Technical Data, DeviceNet

TM

fieldbus

DeviceNetTM characteristics

“Polled I/O Message Connection”,

“Group 2 only Slave”

750-306 DeviceNet

TM

Fieldbus Coupler

4.5 Technical Data

4.5.1 Device Data

4.5.2 System Data

max

max

4.5.3 DeviceNetTM Fieldbus

Remote bus cable: 2 x 0.82 mm2 + 2 x 1.7

mm2

Manual

Version 2.0.0

“Strobed I/O Message Connection”,

“Change of State”/“Cyclic Message Connection”,

Page 47

WAGO-I/O-SYST EM 750 Device Description 47

Table 21: Technical Data, Power Supply

Voltage via power jumper contacts

24 VDC (-15% ... +20%)

Current via power jumper contacts

max.

10 ADC

Power supply efficiency

at nominal

load

87%

Internal current consumption

350 mA at 5 V

Current consumption via

- CAN interface

< 120 mA at 11 V

Total current for I/O modules

1650 mA at 5 V

Electrical isolation

500 V system/supply

Table 22: Technical Data, Accessories

Pluggable connectors

Plug connectors 231-305/010-000/050-000 for

MCS male connector (included)

Marking

Miniature WSB Quick marking system

EDS Files

Download via http://www.wago.com

Table 23: Technical Data – Field Wiring

Wire connection

CAGE CLAMP®

Cross section

0.08 mm² … 2.5 mm², AWG 28 … 14

Stripped lengths

8 mm … 9 mm / 0.33 in

Table 24: Technical Data – Power Jumper Contacts

Power jumper contacts

Spring contact, self-cleaning

Voltage drop at I

max.

< 1 V/64 modules

Table 25: Technical Data – Data Contacts

Data contacts

Slide contact, hard gold plated, selfcleaning

750-306 DeviceNet

TM

Fieldbus Coupler

4.5.4 Supply

typ.

- Power supply

4.5.5 Accessories

4.5.6 Connection Type

< 500 mA at 24 V

Manual

Version 2.0.0

Page 48

48 Device Description WAGO-I/O-SYSTEM 750

Table 26: Technical Data – Climatic Environ mental Conditions

Operating temperature range

0 °C … 55 °C

Operating temperature r a nge for

temperature range (750-xxx/025-xxx)

−20 °C … +60 °C

Storage temperature range

−25 °C … +85 °C

Storage temperature range for

temperature range (750-xxx/025-xxx)

−40 °C … +85 °C

Relative humidity

Max. 5 % … 95 % without condensation

Resistance to harmful substances

Acc. to IEC 60068-2-42 and

IEC 60068-2-43

Maximum pollutant concentration at

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

Ensure that additional measures for

– ionizing radiation

Table 27: Technical Data – Mechanical Strength acc. to IEC 61131-2

Test specification

Frequency range

Limit value

IEC 60068-2-6 vibration

5 Hz ≤ f < 9 Hz

1.75 mm amplitude (permanent)

3.5 mm amplitude (short term)

9 Hz ≤ f < 150 Hz

0.5 g (permanent)

1 g (short term)

Note on vibration test:

a)

Frequency change: max. 1 octave/minute

b)

Vibration direction: 3 axes

IEC 60068-2-27 shock

15 g

Note on shock test:

a)

A Type of shock: half sine

b)

Shock duration: 11 ms

c)

Shock direction: 3x in positive and 3x in negative

direction for each of the three mutually

perpendicular axes of the test specimen

IEC 60068-2-32 free fall

1 m (module in original packing)

750-306 DeviceNet

TM

Fieldbus Coupler

4.5.7 Climatic Environment a l Conditions

components with extended

components with extended

relative humidity < 75 %

components are taken, which are used in

an environment involving:

– dust, caustic vapors or gases

4.5.8 Mechanical Strength acc. to IEC 61131-2

Manual

Version 2.0.0

Page 49

WAGO-I/O-SYST EM 750 Device Description 49

Conformity Marking

ODVA

“Open DeviceNet Vendors Association” certified

TÜV 07 ATEX 554086 X

I M2 Ex d I Mb

II 3 D Ex tc IIIC T135°C Dc

IECEx TUN 09.0001 X

Ex d I Mb

Ex tc IIIC T135°C Dc

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

TUEV 12.1297 X

Ex nA IIC T4 Gc

750-306 DeviceNet

TM

Fieldbus Coupler

4.6 Approvals

More information about approvals.

Detailed references to the approvals are listed in the document “Overview

Approvals WAGO-I/O-SYSTEM 750”, which you can find via the internet

under: www.wago.com > SERVICES > DOWNLOADS > Additional

documentation and information on automation products > WAGO-I/O-SYSTEM

750 > System Description.

The following approvals have been granted to 750-306 fieldbus

coupler/controller:

CULUS

UL508

The following Ex approvals have been granted to 750-306 fieldbus

coupler/controller:

II 3 G Ex nA IIC T4 Gc

Ex nA IIC T4 Gc

Korea Certification MSIP-REM-W43-FBC750

Brasilian-

Ex

Manual

Version 2.0.0

Page 50

50 Device Description WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

The following ship approvals have been granted to 750-306 fieldbus

coupler/controller:

ABS (American Bureau of Shipping)

Federal Maritime and Hydrographic Agency

BV (Bureau Veritas)

DNV (Det Norske Veritas) Class B

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1)

KR (Korean Register of Shipping)

LR (Lloyd’s Register) Env. 1, 2, 3, 4

NKK (Nippon Kaiji Kyokai)

PRS (Polski Rejestr Statków)

RINA (Registro Italiano Navale)

Manual

Version 2.0.0

Page 51

WAGO-I/O-SYST EM 750 Device Description 51

750-306 DeviceNet

TM

Fieldbus Coupler

4.7 Standards and Guidelines

750-306 meets the following requirements on emission and immunity of

interference:

EMC CE-Immunity to interference acc. to EN 61000-6-2

EMC CE-Emission of interference acc. to EN 61000-6-3

EMC marine applications-Immunity

to interference acc. to Germanischer Llo yd

EMC marine applications-Emission

of interference acc. to Germanischer Lloyd

Manual

Version 2.0.0

Page 52

52 Mounting WAGO-I/O-SYSTEM 750

750-306 DeviceNet

TM

Fieldbus Coupler

5 Mounting

5.1 Installation Position

Along with horizontal and vertical installation, all other installation positions are

allowed.

Use an end stop in the case of vertical mounting!

In the case of vertical assembly, an end stop has to be mounted as an additional

safeguard against slipping.

WAGO order no. 249-116 End stop for DIN 35 rail, 6 mm wide

WAGO order no. 249-117 End stop for DIN 35 rail, 10 mm wide

5.2 O verall Configur ation

The maximum total length of a fieldbus node without fieldbus coupler/controller

is 780 mm including end module. The width of the end module is 12 mm. When

assembled, the I/O modules have a maximum length of 768 mm.

Examples:

• 64 I/O modules with a 12 mm width can be connected to a fieldbus

coupler/controller.

• 32 I/O modules with a 24 mm width can be connected to a fieldbus

coupler/controller.

Exception:

The number of connected I/O modules also depends on the type of fieldbus

coupler/controller is used. For example, the maximum number of stackable I/O

modules on one PROFIBUS DP/V1 fieldbus coupler/controller is 63 with no

passive I/O modules and end module.

Observe maximum total length of a fieldbus node!

The maximum total length of a fieldbus node without fieldbus coupler/controller

and without using a 750-628 I/O Module (coupler module for internal data bus

extension) may not exceed 780 mm.

Also note the limitations of individual fieldbus couplers/controllers.

Manual

Version 2.0.0

Page 53

WAGO-I/O-SYST EM 750 Mounting 53

750-306 DeviceNet

TM

Fieldbus Coupler

Increase the total length using a coupler module for internal data bus

extension!

You can increase the total length of a fieldbus node by using a 750-628 I/O

Module (coupler module for internal data bus extension). For such a

configuration, attach a 750-627 I/O Module (end module for internal data bus

extension) after the last I/O module of a module assembly. Use an RJ-45 patch