Page 1

Manual

WAGO ETHERNET Accessories 852

852-1305

8/4

Industrial

Slots

Version 1.2.0

-Port 1000BASE-T/1000BASE-SX/LX

-Managed-Switch, 8 Ports 1000BASE-T,4

1000BASE-SX/LX

Page 2

2 WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

© 2019 WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 4 45 55

Fax: +49 (0) 571/8 87 – 84 45 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

WAGO is a registered trademark of WAGO Verwaltungsgesellschaft mbH.

Manual

Version 1.2.0

Page 3

WAGO ETHERNET Accessories 852 Table of Contents 3

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

Table of Contents

1 Notes about this Documentation ........................................................... 10

1.1 Validity of this Documentation............................................................... 10

1.2 Copyright .............................................................................................. 10

1.3 Symbols ............................................................................................... 11

1.4 Number Notation .................................................................................. 13

1.5 Font Conventions ................................................................................. 13

2 Important Notes ...................................................................................... 14

2.1 Legal Bases .......................................................................................... 14

2.1.1 Subject to Changes .......................................................................... 14

2.1.2 Personnel Qualification .................................................................... 14

2.1.3 Proper Use of the Industrial Switches .............................................. 14

2.1.4 Technical Condition of Specified Devices......................................... 15

2.1.5 Standards and Regulations for Operating the Industrial Switches .... 15

2.2 Safety Advice (Precautions) ................................................................. 16

2.3 Special Use Conditions for ETHERNET Devices .................................. 19

3 General .................................................................................................... 20

3.1 Scope of Supply ................................................................................... 20

3.2 Industrial ETHERNET Technology ....................................................... 20

3.3 Switching Technology ........................................................................... 21

4 Device Description .................................................................................. 23

4.1 View ..................................................................................................... 24

4.1.1 Front View ........................................................................................ 24

4.1.2 Top View .......................................................................................... 26

4.2 Connectors ........................................................................................... 27

4.2.1 Power Supply (PWR/RPS) ............................................................... 27

4.2.2 Network Connectors......................................................................... 28

4.2.2.1 RJ-45 Port ................................................................................... 29

4.2.2.2 1000BASE SX/LX Ports .............................................................. 29

4.2.2.3 10/100/1000BASE T Ports ........................................................... 29

4.3 Display Elements .................................................................................. 30

4.3.1 Device LEDs .................................................................................... 30

4.3.2 Port LEDs ........................................................................................ 32

4.4 Operating elements .............................................................................. 33

4.4.1 DIP Switches ................................................................................... 33

4.4.2 Reset Button .................................................................................... 34

4.5 Label .................................................................................................... 35

4.5.1 Hardware and Software Version ...................................................... 35

4.6 Technical Data ..................................................................................... 36

4.6.1 Device Data ..................................................................................... 36

4.6.2 System Data .................................................................................... 36

4.6.3 Power Supply ................................................................................... 36

4.6.4 Communication ................................................................................ 37

4.6.5 Environmental Conditions ................................................................ 37

4.7 Approvals ............................................................................................. 38

5 Mounting .................................................................................................. 39

Manual

Version 1.2.0

Page 4

4 Table of Contents WAG O ETHERN ET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

5.1 Installation Site ..................................................................................... 39

5.2 Installation on a Carrier Rail ................................................................. 39

5.3 Removal from Carrier ail ....................................................................... 39

6 Connect Devices ..................................................................................... 40

6.1 Power Supply ....................................................................................... 40

6.2 External Alarm Contact Port ................................................................. 41

6.3 Console Port Cable Connection ............................................................ 41

6.4 1000Base-SX/LX Port, Fiber Optic ....................................................... 42

6.5 10/100/1000BASE-T Ports ................................................................... 43

7 Enhanced Features ................................................................................. 44

7.1 Default Settings .................................................................................... 44

7.1.1 Jumbo Frame ................................................................................... 44

7.1.2 SNTP ............................................................................................... 44

7.1.3 Management Host ............................................................................ 45

7.1.4 MAC Management ........................................................................... 45

7.1.4.1 Static MAC Settings ..................................................................... 46

7.1.4.2 Refusal MAC Settings ................................................................. 46

7.1.5 Port Mirroring ................................................................................... 47

7.1.6 Port Setting s .................................................................................... 47

7.2 Advanced Settings ................................................................................ 51

7.2.1 Bandwidth Limitation ........................................................................ 51

7.2.1.1 QoS ............................................................................................. 51

7.2.1.2 Rate Limitation ............................................................................ 58

7.2.1.2.1 Storm Control .......................................................................... 58

7.2.1.2.2 Rate Limitation ........................................................................ 58

7.2.2 IGMP Snooping ................................................................................ 59

7.2.2.1 MVR ............................................................................................ 62

7.2.2.2 Multicast Address ........................................................................ 65

7.2.3 VLAN ............................................................................................... 68

7.2.3.1 Port Isolation ............................................................................... 70

7.2.3.2 GARP/GVRP ............................................................................... 71

7.2.3.3 Q-in-Q ......................................................................................... 73

7.2.3.3.1 Port-Based Q-in-Q .................................................................. 75

7.2.3.3.2 Selective Q-in-Q...................................................................... 76

7.2.4 DHCP Relay .................................................................................... 77

7.2.5 DHCP Relay Option 82 .................................................................... 79

7.2.6 Dual Ring ......................................................................................... 81

7.2.7 ERPS ............................................................................................... 82

7.2.8 Dual Homing .................................................................................... 85

7.2.9 Link Aggregation .............................................................................. 86

7.2.9.1 Static Trunk ................................................................................. 86

7.2.9.2 LACP ........................................................................................... 86

7.2.10 LLDP ................................................................................................ 87

7.2.11 Loop Detection ................................................................................. 88

7.2.12 Jet Ring............................................................................................ 89

7.2.13 STP .................................................................................................. 90

7.2.14 Xpres s Ring ..................................................................................... 95

7.3 Security ................................................................................................ 96

7.3.1 IP Source Guard .............................................................................. 96

Manual

Version 1.2.0

Page 5

WAGO ETHERNET Accessories 852 Table of Contents 5

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

7.3.1.1 DHCP Snooping .......................................................................... 97

7.3.1.1.1 Server Screening .................................................................... 99

7.3.1.2 Binding Table .............................................................................. 99

7.3.1.3 ARP Inspection .......................................................................... 100

7.3.1.3.1 Filter Table ............................................................................ 101

7.3.2 Access Control List (ACL) .............................................................. 102

7.3.3 802.1x ............................................................................................ 103

7.3.4 Port Security .................................................................................. 106

7.4 Monitor ............................................................................................... 107

7.4.1 Alarm Informa ti o n ........................................................................... 107

7.4.2 Monitor Information ........................................................................ 107

7.4.3 RMON Statistics ............................................................................. 107

7.4.4 SFP ................................................................................................ 107

7.4.4.1 DDM .......................................................................................... 108

7.4.5 Traffic Monitor ................................................................................ 108

7.5 Management ...................................................................................... 109

7.5.1 SNMP ............................................................................................ 109

7.5.2 SNMP Trap .................................................................................... 110

7.5.3 Auto Provision ................................................................................ 110

7.5.4 Mail Alarm ...................................................................................... 112

8 Configuration ........................................................................................ 113

8.1 Overview of Configuration Options ..................................................... 113

8.1.1 Telnet Port ..................................................................................... 114

8.2 Console Port ....................................................................................... 115

9 Configuring in the Web-Based Management System ......................... 116

9.1 System Status .................................................................................... 119

9.1.1 System Informationen .................................................................... 119

9.2 Basic Settings ..................................................................................... 121

9.2.1 General Settings ............................................................................ 121

9.2.1.1 System ...................................................................................... 121

9.2.1.2 Jumbo Frame ............................................................................ 123

9.2.1.3 SNTP......................................................................................... 124

9.2.1.4 Management Host ..................................................................... 127

9.2.2 MAC Management ......................................................................... 128

9.2.2.1 Static MAC Settings ................................................................... 128

9.2.2.2 MAC Table ................................................................................ 130

9.2.2.3 Age Time Setting ....................................................................... 131

9.2.2.4 Refusal MAC Settings ............................................................... 132

9.2.3 Port Mirroring ................................................................................. 133

9.2.4 Port Setting s .................................................................................. 135

9.2.4.1 General Settings ........................................................................ 135

9.2.4.2 Information ................................................................................ 137

9.3 Advanced Settings .............................................................................. 138

9.3.1 Bandwidth Control .......................................................................... 138

9.3.1.1 QoS ........................................................................................... 138

9.3.1.1.1 Port Priority ........................................................................... 138

9.3.1.1.2 IP DiffServ (DSCP) ............................................................... 139

9.3.1.1.3 Priority/Queue Mapping ........................................................ 140

9.3.1.1.4 Schedule Mode ..................................................................... 141

Manual

Version 1.2.0

Page 6

6 Table of Contents WAG O ETHERN ET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

9.3.1.2 Rate Limitation .......................................................................... 143

9.3.1.2.1 Storm Control ........................................................................ 143

9.3.1.2.2 Bandwidth Limitation ............................................................. 145

9.3.2 IGMP Snooping .............................................................................. 146

9.3.2.1 IGMP Snooping ......................................................................... 146

9.3.2.1.1 General Settings ................................................................... 146

9.3.2.1.2 Port Setting s ......................................................................... 148

9.3.2.1.3 Querier Settings .................................................................... 150

9.3.2.2 IGMP Filtering ........................................................................... 151

9.3.2.2.1 General Settings ................................................................... 151

9.3.2.2.2 Group Settings ...................................................................... 152

9.3.2.2.3 Port Setting s ......................................................................... 153

9.3.2.3 MVR .......................................................................................... 154

9.3.2.3.1 MVR Settings ........................................................................ 154

9.3.2.3.2 Group Settings ...................................................................... 156

9.3.2.4 Multicast Address ...................................................................... 157

9.3.2.5 Multicast IP Statistics ................................................................. 158

9.3.3 VLAN ............................................................................................. 159

9.3.3.1 Port Isolation ............................................................................. 159

9.3.3.2 VLAN ......................................................................................... 161

9.3.3.2.1 VLAN Settings ...................................................................... 161

9.3.3.2.2 Tag Settings .......................................................................... 163

9.3.3.2.3 Port Setting s ......................................................................... 164

9.3.3.3 GARP/GVRP ............................................................................. 166

9.3.3.3.1 GVRP ................................................................................... 166

9.3.3.3.2 GARP Timer ......................................................................... 168

9.3.3.4 IP-Subnet-VLAN ........................................................................ 170

9.3.3.5 MAC VLAN ................................................................................ 171

9.3.3.6 Protocol VLAN ........................................................................... 172

9.3.3.7 Q-in-Q ....................................................................................... 173

9.3.3.7.1 VLAN Stacking ...................................................................... 173

9.3.3.7.2 Port-based Q-in-Q ................................................................. 175

9.3.3.7.3 Selective Q-in-Q.................................................................... 176

9.3.4 DHCP Relay .................................................................................. 178

9.3.5 DHCP Options ............................................................................... 179

9.3.5.1 Option 82 ................................................................................... 179

9.3.6 Dual Homing .................................................................................. 180

9.3.7 Dual Ring ....................................................................................... 181

9.3.8 ERPS ............................................................................................. 183

9.3.8.1 Ring Settings ............................................................................. 183

9.3.8.2 Instance Settings ....................................................................... 187

9.3.9 Link Aggregation ............................................................................ 188

9.3.9.1 Static Trunk ............................................................................... 188

9.3.9.2 LACP ......................................................................................... 190

9.3.9.3 LACP Info. ................................................................................. 192

9.3.10 LLDP .............................................................................................. 194

9.3.10.1 Settings ..................................................................................... 194

9.3.10.2 Neighbor .................................................................................... 196

9.3.11 Loop Detection ............................................................................... 197

9.3.12 Jet Ring.......................................................................................... 199

Manual

Version 1.2.0

Page 7

WAGO ETHERNET Accessories 852 Table of Contents 7

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

9.3.13 MODBUS ....................................................................................... 200

9.3.14 STP ................................................................................................ 201

9.3.14.1 General Settings ........................................................................ 201

9.3.14.2 Port Parameters ........................................................................ 203

9.3.14.3 STP Status ................................................................................ 206

9.3.15 Xpres s Ring ................................................................................... 207

9.4 Security .............................................................................................. 209

9.4.1 IP Source Guard ............................................................................ 209

9.4.1.1 DHCP Snooping ........................................................................ 209

9.4.1.1.1 DHCP Snooping ................................................................... 209

9.4.1.1.2 Port Setting s ......................................................................... 211

9.4.1.1.3 Server Screening .................................................................. 212

9.4.1.2 Binding Table ............................................................................ 213

9.4.1.2.1 Static Entry ........................................................................... 213

9.4.1.2.2 Binding Table ........................................................................ 215

9.4.1.3 ARP Inspection .......................................................................... 216

9.4.1.3.1 ARP Inspection ..................................................................... 216

9.4.1.3.2 Filter Table ............................................................................ 218

9.4.2 Access Control List ........................................................................ 219

9.4.3 802.1x ............................................................................................ 223

9.4.3.1 Global Settings .......................................................................... 223

9.4.3.2 Port Setting s .............................................................................. 226

9.4.4 Port Security .................................................................................. 229

9.5 Monitor ............................................................................................... 231

9.5.1 Alarm Informa ti o n ........................................................................... 231

9.5.2 Monitor Information ........................................................................ 232

9.5.3 Port Statistics ................................................................................. 234

9.5.4 Port Utilization ................................................................................ 235

9.5.5 RMON Statistics ............................................................................. 236

9.5.6 SFP Informati on ............................................................................. 239

9.5.7 Traffic Monitor ................................................................................ 241

9.6 Management ...................................................................................... 243

9.6.1 SNMP ............................................................................................ 243

9.6.1.1 SNMP ........................................................................................ 243

9.6.1.1.1 SNMP Settings ..................................................................... 243

9.6.1.1.2 Community Name ................................................................. 244

9.6.1.2 SNMP Trap ............................................................................... 246

9.6.1.2.1 Trap Receiver Settings.......................................................... 246

9.6.1.3 Auto Provision ........................................................................... 247

9.6.1.3.1 Mail Alarm ............................................................................. 248

9.6.1.3.2 Maintenance ......................................................................... 250

9.6.1.3.3 Configuration ........................................................................ 250

9.6.2 Firmware ........................................................................................ 252

9.6.3 Reboot ........................................................................................... 253

9.6.4 Server ............................................................................................ 254

9.6.4.1 System Log ............................................................................... 256

9.6.4.2 User Account ............................................................................. 258

10 Appendix ............................................................................................... 260

10.1 Console Port (RJ-45 to DB9) .............................................................. 260

Manual

Version 1.2.0

Page 8

8 Table of Contents WAG O ETHERN ET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

10.2 RJ-45 Cable ....................................................................................... 261

10.3 Configuring in the Command Line Interface (CLI) ............................... 262

10.3.1 System Status ................................................................................ 262

10.3.1.1 System Information.................................................................... 262

10.3.2 Default Settings .............................................................................. 263

10.3.2.1 System ...................................................................................... 263

10.3.2.2 Jumbo Frame ............................................................................ 263

10.3.2.3 SNTP......................................................................................... 264

10.3.2.4 Management Host ..................................................................... 265

10.3.2.5 MAC Management..................................................................... 265

10.3.2.6 Blackhole MAC .......................................................................... 266

10.3.2.7 Port Mirroring ............................................................................. 266

10.3.2.8 Port Setting s .............................................................................. 267

10.3.3 Advanced Settings ......................................................................... 268

10.3.3.1 Bandwidth Control ..................................................................... 268

10.3.3.2 QoS ........................................................................................... 268

10.3.3.3 Rate Limitation .......................................................................... 268

10.3.3.4 Storm Control ............................................................................ 269

10.3.3.5 IGMP Snooping ......................................................................... 270

10.3.3.6 MVR .......................................................................................... 271

10.3.3.7 Multicast Address ...................................................................... 271

10.3.3.8 VLAN ......................................................................................... 272

10.3.3.8.1 Port Isolation ......................................................................... 272

10.3.3.8.2 VLAN Settings ...................................................................... 273

10.3.3.9 GARP/GVRP ............................................................................. 274

10.3.3.10 Q-in-Q ....................................................................................... 275

10.3.3.10.1 VLAN Stacking ...................................................................... 275

10.3.3.11 DHCP Relay .............................................................................. 276

10.3.3.12 Dual Homing.............................................................................. 277

10.3.3.13 Link Aggregation ....................................................................... 277

10.3.3.14 LACP ......................................................................................... 278

10.3.3.15 LLDP ......................................................................................... 279

10.3.3.16 Loop Detection .......................................................................... 280

10.3.3.17 STP ........................................................................................... 281

10.3.3.18 Xpres s Ring ............................................................................... 282

10.3.4 Security .......................................................................................... 283

10.3.4.1 DHCP Snooping ........................................................................ 283

10.3.4.2 Server Screening ....................................................................... 284

10.3.4.3 Binding Table ............................................................................ 284

10.3.4.4 ARP Inspection .......................................................................... 285

10.3.4.5 Filter Table ................................................................................ 285

10.3.4.6 Access Control List .................................................................... 286

10.3.4.7 802.1x ....................................................................................... 288

10.3.4.8 Port Security .............................................................................. 289

10.3.5 Monitor ........................................................................................... 290

10.3.5.1 Alarm ......................................................................................... 290

10.3.5.2 Monitor Information.................................................................... 290

10.3.5.3 RMON Statistics ........................................................................ 290

10.3.5.4 SFP Informati on ........................................................................ 290

10.3.5.5 Traffic Monitor ........................................................................... 291

Manual

Version 1.2.0

Page 9

WAGO ETHERNET Accessories 852 Table of Contents 9

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

10.3.6 Management .................................................................................. 292

10.3.6.1 SNMP ........................................................................................ 292

10.3.6.2 Auto Provision ........................................................................... 293

10.3.6.3 Mail Alarm ................................................................................. 293

10.3.6.4 Maintenance .............................................................................. 294

10.3.6.5 System Log ............................................................................... 294

10.3.6.6 User Account ............................................................................. 295

10.4 MODBUS/TCP Tables ........................................................................ 296

10.4.1 Data Format and Function Code .................................................... 296

10.4.2 MODBUS Registers ....................................................................... 296

List of Figures ................................................................................................ 308

List of Tables .................................................................................................. 311

Manual

Version 1.2.0

Page 10

10 Not es about this Documentation WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

1 Notes about this Documentation

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation

is included, if necessary.

1.1 Validity of this Docu me nta tion

This documentation is only applicable to WAGO ETHERNET accessory products

“8/4-Port 1000BASE-T/1000BASE-SX/LX” (852-1305).

1.2 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Manual

Version 1.2.0

Page 11

WAGO ETHERNET Accessories 852 Notes about this Documentation 11

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

1.3 Symbols

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Manual

Version 1.2.0

Page 12

12 Not es about this Documentation WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Manual

Version 1.2.0

Page 13

WAGO ETHERNET Accessories 852 Notes about this Documentation 13

Table 1: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated

with dots (.)

Table 2: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

Start of measurement range

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

1.4 Number Notation

1.5 Font Conventions

e.g.: C:\Program Files\WAGO Software

menu item from a menu.

e.g.:

e.g.: Enter the value “4 mA” under

brackets.

.

Manual

Version 1.2.0

Page 14

14 Important Notes WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

2 Important Notes

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

2.1 Legal Bases

2.1.1 Subject t o Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications. WAGO Kontakttechnik GmbH & Co. KG owns all

rights arising from the granting of patents or from the legal protection of utility

patents. Third-party products are always mentioned without any reference to

patent rights. Thus, the existence of such rights cannot be excluded.

2.1.2 Personnel Qualification

All sequences implemented on Series 852 devices may only be carried out by

electrical specialists with sufficient knowledge in automation. The specialists must

be familiar with the current norms and guidelines for the devices and automated

environments.

All changes to the controller should always be carried out by qualified personnel

with sufficient sufficient skills in PLC programming.

2.1.3 Proper Use of the Industrial Switches

The device is designed for the IP30 protection class. It is protected against the

insertion of solid items and solid impurities up to 2.5 mm in diameter, but not

against water penetration. Unless otherwise specified, the device must not be

operated in wet and dusty environments.

Manual

Version 1.2.0

Page 15

WAGO ETHERNET Accessories 852 Important Notes 15

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. These

modules contain no parts that can be serviced or repaired by the user. The

following actions will result in the exclusion of liability on the part of WAGO

Kontakttechnik GmbH & Co. KG:

• Repairs,

• Changes to the hardware or software that are not described in the

operating instructions,

• Improper use of the components.

Further details are given in the contractual agreements. Please send your

request for modified and new hardware or software configurations directly to

WAGO Kontakttechnik GmbH & Co. KG.

2.1.5 Standards and Regul a t ions for Operating the Industrial Switches

Please observe the standards and regulations that are relevant to installation:

• The data and power lines must be connected and installed in compliance

with the standards to avoid failures on your installation and eliminate any

danger to personnel.

• For installation, startup, maintenance and repair, please observe the

accident prevention regulations of your machine (e.g., DGUV Regulation

“Electrical Installations and Equipment”).

• Emergency stop functions and equipment must not be deactivated or

otherwise made ineffective. See relevant standards (e.g., DIN EN 418).

• Your installation must be equipped in accordance to the EMC guidelines so

electromagnetic interferences can be eliminated.

• Please observe the safety measures against electrostatic discharge

according to DIN EN 61340-5-1/-3. When handling the modules, ensure

that environmental factors (persons, workplace and packing) are well

grounded.

• The relevant valid and applicable standards and guidelines regarding the

installation of switch cabinets must be observed.

Manual

Version 1.2.0

Page 16

16 Important Notes WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

2.2 Safety Advice (Precautions)

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Only install in appropriate housings, cabinets or electrical operation

rooms!

WAGO's 852 Series ETHERNET Switches are considered exposed operating

components. Therefore, only install these switches in lockable housings, cabinets

or electrical operation rooms. Access must be limited to authorized, qualified staff

having the appropriate key or tool.

Ensure a standard connection!

To minimize any hazardous situations resulting in personal injury or to avoid

failures in your system, the data and power supply lines shall be installed

according to standards, with careful attention given to ensuring the correct

terminal assignment. Always adhere to the EMC directives applicable to your

application.

Do not use in telecommunication circuits!

Only use devices equipped with ETHERNET or RJ-45 connectors in LANs.

Never connect these devices with telecommunication networks.

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Manual

Version 1.2.0

Page 17

WAGO ETHERNET Accessories 852 Important Notes 17

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for

handling devices/modules.

Clean only with permitted materials!

Clean housing and soiled contacts with propanol.

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Laser radiation warning!

Do not stare into openings of the connections when no cable is connected, so as

not to expose the radiation.

It can emit invisible radiation.

It concerns here a laser class 1 according EN 60825-1.

Manual

Version 1.2.0

Page 18

18 Important Notes WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

Radio interference in residential areas

This is a Class A device. This device can cause radio interference in residential

areas; in this case, the operator can be required to take appropriate measures to

prevent such interference.

Manual

Version 1.2.0

Page 19

WAGO ETHERNET Accessories 852 Important Notes 19

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

2.3 Special Use Conditions for ETHERNET Devices

If not otherwise specified, ETHERNET devices are intended for use on local

networks. Please note the following when using ETHERNET devices in your

system:

• Do not connect control components and control networks to an open

network such as the Internet or an office network. WAGO recommends

putting control components and control networks behind a firewall.

• Limit physical and electronic access to all automation components to

authorized personnel only.

• Change the default passwords before first use! This will reduce the risk of

unauthorized access to your system.

• Regularly change the passwords used! This will reduce the risk of

unauthorized access to your system.

• If remote access to control components and control networks is required,

use a Virtual Private Network (VPN).

• Regularly perform threat analyses. You can check whether the measures

taken meet your security requirements.

• Use “defense-in-depth” mechanisms in your system's security configuration

to restrict the access to and control of individual products and networks.

Manual

Version 1.2.0

Page 20

20 General WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

3 General

3.1 Scope of Supply

• 1 Industrial managed switch with multipoint connector

• Protective covers for unused ports

• Data cable RS-232 for CLI

3.2 Industrial ETHERNET Technology

The ra nge of WAGO switches ensures scalability of your network infrastructure

with outstanding electrical and mechanical characteristics. These robust devices

are designed for industrial use and they are fully compliant with IEEE 802.3,

802.3u, 802.3w, 802.3z, 802.3x, 802.3ab, 802.3ad, 802.1d, 802.1q, 802.1p and

802.1x standards.

They have voltage supply with a supply voltage range of 12 … 60 V.

Characteristics such as auto-negotiation and auto-MDI/MDIX (crossover) on all

10/100/1000BASE-T ports are also realized.

Manual

Version 1.2.0

Page 21

WAGO ETHERNET Accessories 852 General 21

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

3.3 Switching Technology

Industrial ETHERNET primarily uses switching technology. This technology

allows any network subscriber to send at any time because the subscriber always

has an open peer-to-peer connection to the next switch. The connection is

bidirectional, i.e., the subscriber can send and receive at the same time (full

duplex).

The targeted use of switching technology can increase real-time capability

because the peer-to-peer connection prevents collisions in network

communication.

The Industrial Managed Switch was developed for easy installation in a

manufacturing environment where vibration, shock, heat and radio frequency

interference are common.

Due to its compact size, the Industrial Managed Switch makes mounting on the

DIN rail particularly sim p le a n d in s tallation possible in environments with limited

space.

Two or more switches can be added in series to the Industrial Managed Switch.

Since all ports support 100 Mbit/, this series connection is possible for the

industrial managed switch from every port and with any number of switches.

The Industrial Managed Switch is also equipped with a variety of management

functions that let you configure communication parameters as you desire to

monitor network behavior in different ways. In addition, the Industrial Managed

Switch is built with dual redundant power inputs for maximum reliability and

network availability. Other integrated features of the switch such as Autonegotiation, Rate limitation, Port isolation, etc. optimize your network

performance and provide a secure network, offering a cost-effective solution in a

small but powerful package.

The 1000BASE SX/LX ports are designed to connect Gigabit SFP modules that

support network speeds of 100/1000 Mbit/s.

Manual

Version 1.2.0

Page 22

22 General WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

Other key features are:

• Eight (8) 10/100/1000BASE-T, four (4) 1000BASE-SX/LX (SFP type fiber

transceivers) and one (1) Console port (RJ-45)

• Diagnostic LEDs on the front

• Web-based/SNMP Management

• Redundant DC power supply

• Large voltage range: 12 … 60 V

• DIP switches to set alarm functions

• Full compliance with IEEE 802.3, 802.3u, 802.3z, 802.3x, 802.3ad,

802.3ab, 802.1d, 802.1q, 802.1p, 802.1w, 802.1x standards

• Implemented functions:

- Dual ring

- ERPS

- Jet ring

- Xpress Ring (redundant ring) with less than 50 ms recovery time

• Non-blocking, store-and-forward switching, rapid spanning tree protocol

(RSTP)

• Auto-negotiation on all 10/100/1000Base-T ports

• Auto-MDI/MDIX (crossover) on all 10/100/1000BASE-T ports

• VLAN (802.1q) VID

• IGMP snooping for multicast filtering

• Port configuration status and statistics

• Port trunking

• SNMP v1/v2 and RMON

• Rugged IP30 metal housing

• Operable in vibration / shock

Manual

Version 1.2.0

Page 23

WAGO ETHERNET Accessories 852 Device Description 23

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4 Device Description

The 852-1305 is an indust rial ETHERNET switch with 8 10/100/1000BASE-T

ports, with autonegotiation and auto-MDI-/MDI-X detection at every port.

Using the Industrial Managed Switch's 8 ports, several segments can be set up

for reducing network load and a dedicated bandwidth assigned to each user

node.

In addition, the 852-1305 Industrial Managed Switch has 4 ports with SFP

1000BASE-SX/LX to connect multi-mode or single-mode fiber optic cables for

wave lengths of 850 nm (SX), 1310 nm (LX) and 1550 nm (ZX).

The 852-1305 is a cost-effect solution to keep up with the constant demands of

IP-based, industrial communication needs.

The Industrial Managed Switch is easy to configure and install and is best suited

for small to medium-sized networks.

Manual

Version 1.2.0

Page 24

24 De vice De s c ription W AGO ETHERNET Accessories 852

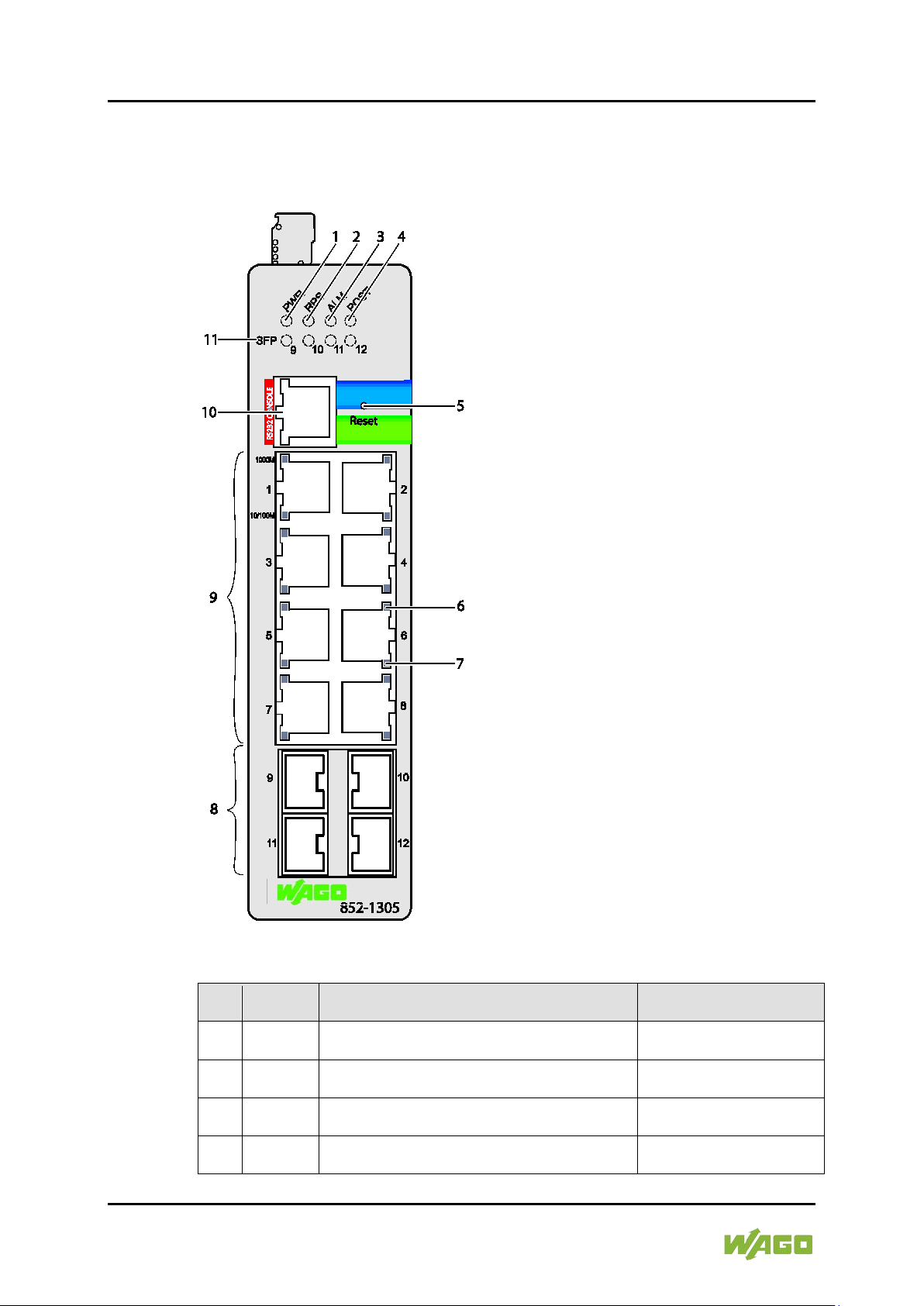

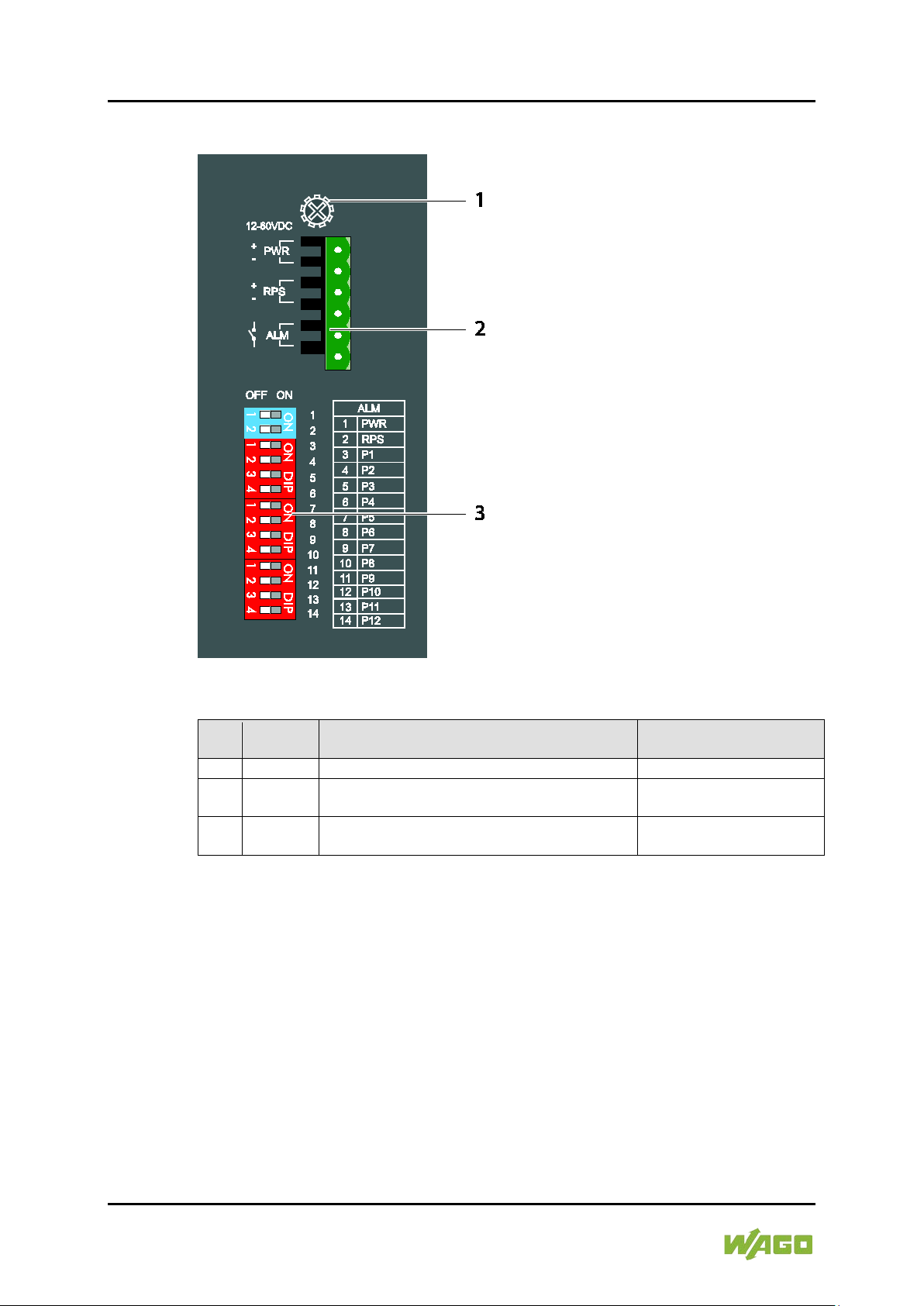

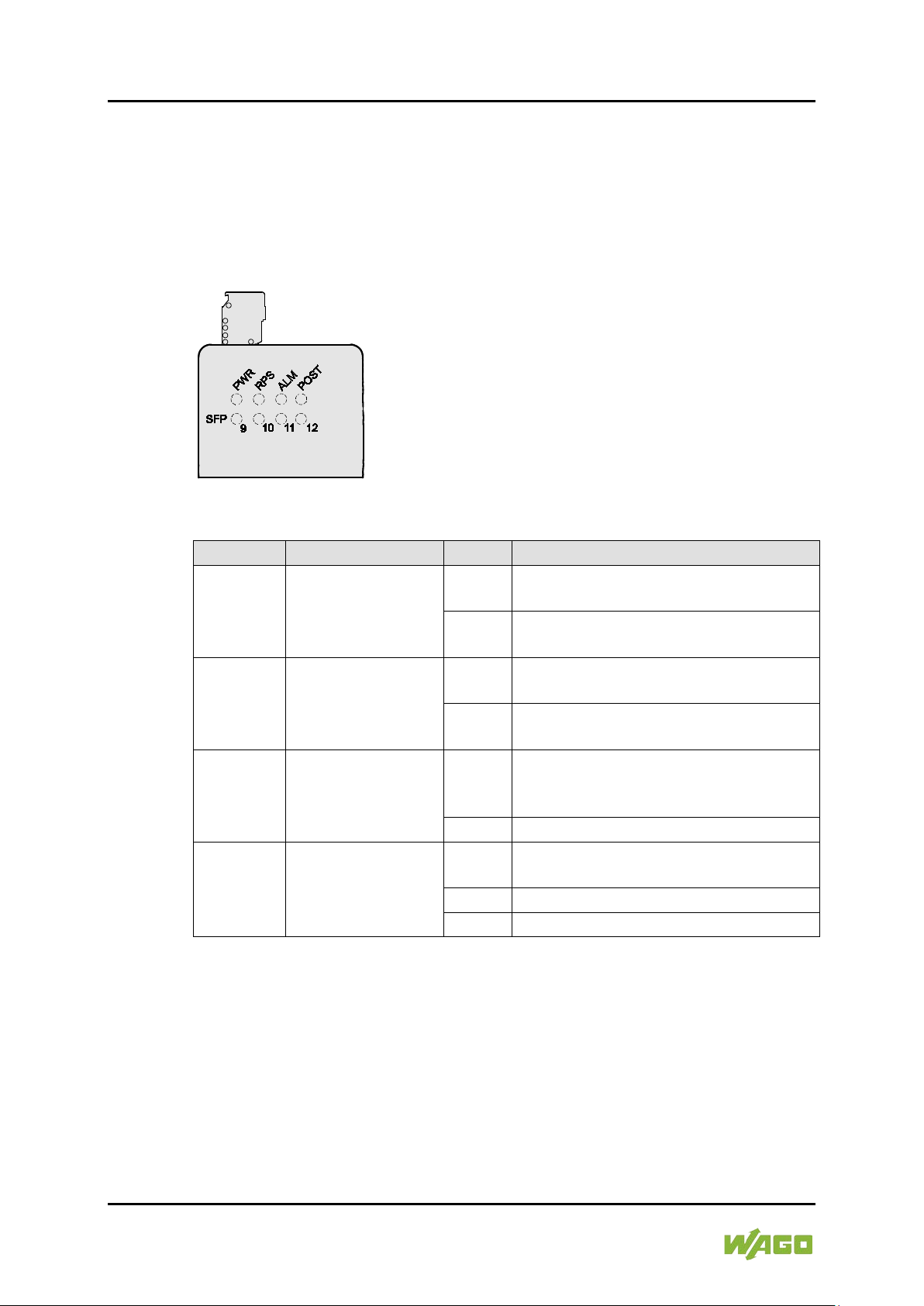

Table 3: Legend for the Figure “Front View of the Industrial Managed Switch”

Descrip-

tion

“Device Description” >

“Display Elements”

“Device Description” >

“Display Elements”

“Device Description” >

“Display Elements”

“Device Description” >

“Display Elements”

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.1 View

4.1.1 Front View

Figure 1: Front View of the Industrial Managed Switch

No.

1 PWR Status LED, supply voltage

2 RPS Status LED, redundant, supply voltage

3 ALM Status LED, alarm

4 POST Status LED, POST

Meaning For Details see Section

Manual

Version 1.2.0

Page 25

WAGO ETHERNET Accessories 852 Device Description 25

Table 3: Legend for the Figure “Front View of the Industrial Managed Switch”

Descrip-

tion

"Device Description" >

Status LED TX Port 1000 Mbit/s

(1 LED for each port)

“Device Description” >

“Display Elements”

Status LED TX Port 10/100 Mbit/s

(1 LED for each port)

“Device Description” >

“Display Elements”

"Device Description" >

"Device Description" >

"Connections"

"Device Description" >

"Connections"

“Device Description” >

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

No.

5 Reset R eset butto n

6 -

7 -

8 - Port 4 x SFP (1000BASE-SX/LX, fiber optic)

9 - Port 8 x RJ-45 (10/100/1000BASE-T ports)

10 - Port 1 x RJ-45 (RS-232 port switch)

11 SFP Status LED SFP port LNK/ACT (4)

Meaning For Details see Section

"Operating Elements"

"Connections"

“Display Elements”

Manual

Version 1.2.0

Page 26

26 De vice De s c ription W AGO ETHERNET Accessories 852

Table 4: Legend for the Figure “Front View of the Industrial Managed Switch”

Descrip-

tion

1 - Grounding lug

-

Connector (male) for power consumption

(PWR/RPS/ALM) and potential-free alarm contact

"Device Description" >

"Connections"

"Device Description" >

"Operating Elements"

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.1.2 Top View

Figure 2: Top View of the industrial ECO switch

No.

2 -

3 - DIP Switches

Meaning For Details see Section

Manual

Version 1.2.0

Page 27

WAGO ETHERNET Accessories 852 Device Description 27

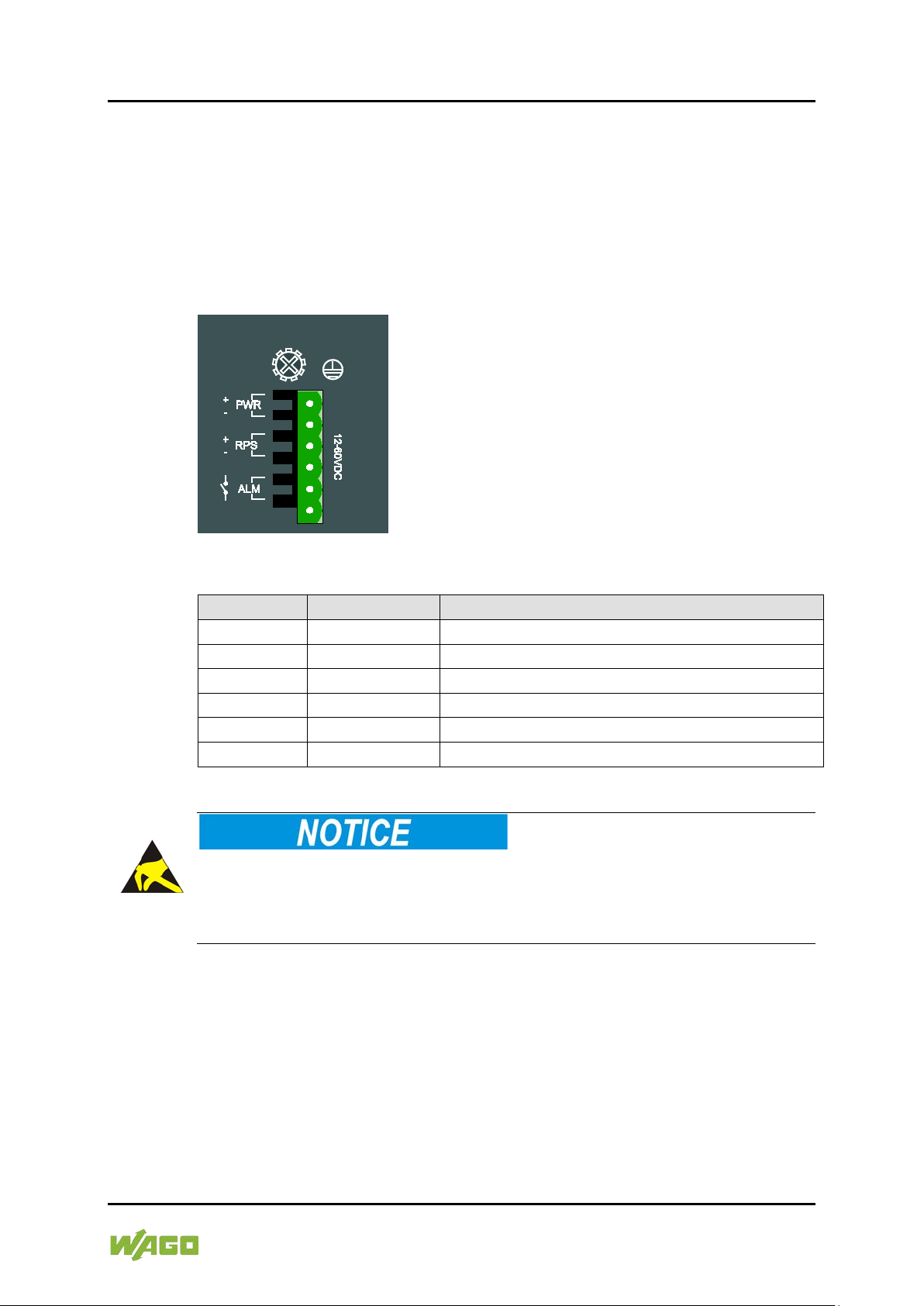

Table 5: Legend for Figure “Power Supply (PWR/RPS)”

Connection

Description

Description

+

PWR

Primary DC input

-

PWR

Primary DC input

+

RPS

Secondary DC input

-

RPS

Secondary DC input

ALM

Contact for external alarm

ALM

Contact for external alarm

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.2 Connectors

4.2.1 Power Supply (PWR/RPS)

The female connector (Item No. 2231-106/026-000) can easily be connected to

the 6-pole male connector located on the top of the switch.

The male connector shows the following pin assignment:

Figure 3: Power Supply (PWR/RPS)

Warning: Damage to property caused by electrostatic discharge (ESD)!

DC Powered Switch: Power is supplied through an external DC power source.

Since the switch does not include a power switch, plugging its power adapter into

a power outlet will immediately power it on.

Manual

Version 1.2.0

Page 28

28 De vice De s c ription W AGO ETHERNET Accessories 852

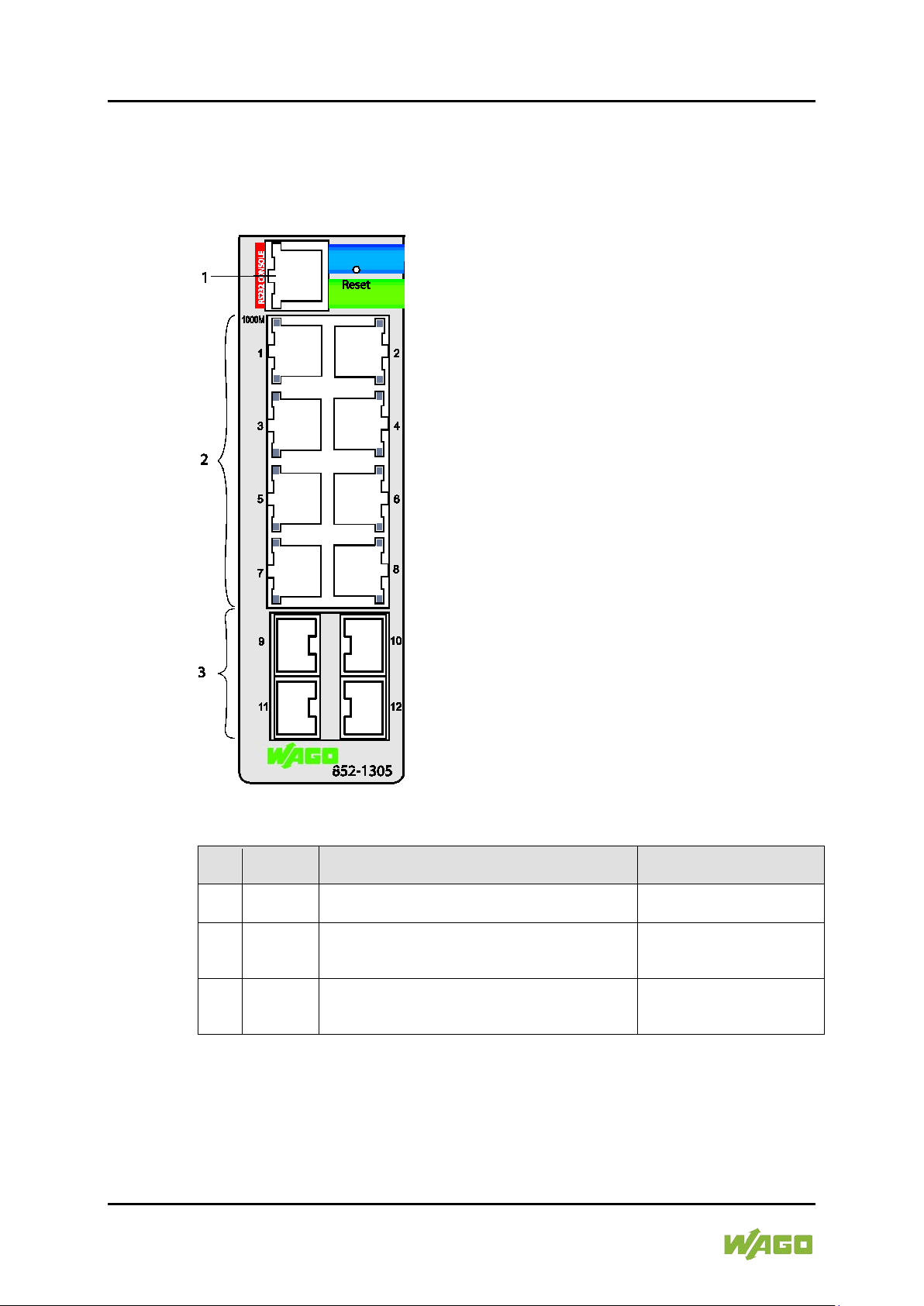

Table 6: Legend for Figure “Network Connections”

Descrip-

tion

“Device Description”

“Device Description”

“Device Description

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.2.2 Network Connectors

This Industrial Managed Switch utilizes ports with fiber or copper port connectors

functioning under ETHERNET and/or Fast ETHERNET protocols.

Figure 4: Network connectors

No.

1 - Connection 1 x RJ-45 (RS-232 port)

3 -

2 - Connections 8 x RJ-45 (10/100Base-T ports)

Manual

Version 1.2.0

Meaning For Details see Section

Connection 4 x SFP (1000Base-SX/LX, fiber

optic)

> … > “RJ-45 Port”

> … > “1000BASE SX/LX

Ports”

”> … > “10/100BASE T

Ports”

Page 29

WAGO ETHERNET Accessories 852 Device Description 29

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.2.2.1 RJ-45 Port

The connection to ETHERNET-based fieldbuses is made via the RJ-45

connector (also called “Western plugs”), which are connected to the fieldbus

controller via an integrated switch.

The integrated switch works in store-and-forward mode and for each port,

supports transmission speeds 10/100 Mbit/s as well as the full and half-duplex

transmission modes.

The RJ-45 socket is wired in accordance with 100Base TX requirements.

It is mandatory to use a Category 5e twisted-pair cable from the ETHERNET

standard as a connecting cable. Cable types S-UTP (Screened Unshielded

Twisted Pair) and STP (Shielded Twisted Pair) with a maximum segment length

of 100 m can be used.

The connection point is designed for mounting into an 80 mm-high switchgear

cabinet after connector attachment.

4.2.2.2 1000BASE SX/LX Ports

The 1000BASE SX/LX ports are designed to connect Fast ETHERNET or gigabit

SFP modules that support network speeds of 1000 Mbit/s.

4.2.2.3 10/100/1000BASE T Ports

The 10/100/1000BASE T ports support network speeds of 10 Mbit/s and

1000 Mbit/s and can be operated in half and full-duplex transmission modes.

These ports also provide automatic crossover detection (Auto-MDI/MDI-X) with

plug&play capabilities. Simply plug the network cables into the ports; they then

adapt to the end node devices. We recommend the following cables for the RJ45 ports.

• 10 m – Cat 3 or higher / 100 m – Cat 5e or higher

Manual

Version 1.2.0

Page 30

30 De vice De s c ription W AGO ETHERNET Accessories 852

Table 7: Legend for Figure “Device LEDs”

LED

Name

Status

Description

PWR

Primary Power

Green

The industrial managed switch uses

the primary power supply.

OFF

The primary power supply has been

RPS

Redundant Power

Green

The industrial managed switch uses

the redundant power supply.

OFF

The redundant power supply has been

switched off or a fault has occurred.

ALM

Alarm LED

Red

Lights up in the event of network,

OFF

No alarm to report.

POST

Power On Self Test

Flashe

s

Green

The Switch is operational.

OFF

The Switch is not operational.

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.3 Display Elements

The industrial managed switch is equipped with device LEDs and port LEDs. You

can see the status of the switch at a quick glance of the device LEDs, while the

port LEDs provide information about connection actions.

4.3.1 Device LEDs

Figure 5: Device LEDs

LED

System LED

LED

switched off or a fault has occurred.

connection or ring errors (for Arbiter

nodes).

The Self Test is running.

Manual

Version 1.2.0

Page 31

WAGO ETHERNET Accessories 852 Device Description 31

Table 7: Legend for Figure “Device LEDs”

LED

Name

Status

Description

SFP Port LNK/ACT

Green

Lights up when the port is linked.

Flashe

Off

No proper link established at the port.

SFP Port LNK/ACT

Green

Lights up when the port is linked.

Flashe

s

Off

No proper link established at the port.

SFP Port LNK/ACT

Green

Lights up when the port is linked.

Flashe

s

Off

No proper link established at the port.

SFP Port LNK/ACT

Green

Lights up when the port is linked.

Flashe

Off

No proper link established at the port.

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

LED

9

Data traffic being routed via the port.

s

LED

10

Data traffic being routed via the port.

SFP

LED

11

Data traffic being routed via the port.

LED

12

Data traffic being routed via the port.

s

Manual

Version 1.2.0

Page 32

32 De vice De s c ription W AGO ETHERNET Accessories 852

Table 8: Legend for Figure “Port LEDs”

LED

Name

Status

Description

1000M

1000BASE T Ports

Green

Port in operation at 1000 Mbit/s.

Flashes

Data traffic being routed over the port.

Connection in operation at less than

100 Mbit/s.

10/100BASE T Ports

Green

Lights up when the ports are linked.

Flashes

Data traffic being routed over the port.

OFF

No proper link established at the port.

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.3.2 Port LEDs

Figure 6: Port LEDs

LED

(1 LED for each port)

10/100

LED

(1 LED for each port)

OFF

Manual

Version 1.2.0

Page 33

WAGO ETHERNET Accessories 852 Device Description 33

Table 9: Legend for Figure “DIP Switches

No.

Name

Status

Description

1

PWR

ON

The alarm reporting function for the primary power supply

is activated.

OFF

The alarm reporting function for the primary power supply

2

RPS

ON

The alarm reporting function for the secondary power

supply is activated.

OFF

The alarm reporting function for the secondary power

supply is deactivated.

3 …

P1 …

ON

The alarm reporting function for the port x connection is

activated.

OFF

The alarm reporting function for the port x connection is

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.4 Operating elements

4.4.1 DIP Switc hes

On the top side of the industrial switch there are DIP switches to configure th e

alarm and arbiter configurations.

The meaning of the DIP switch settings are described below:

Figure 7: DIP Switches

14

P12

is deactivated.

deactivated.

Manual

Version 1.2.0

Page 34

34 De vice De s c ription W AGO ETHERNET Accessories 852

Table 10: Legend for Figure “Reset Button”

Name

Status

Description

Reset

Press the Reset button for 2

seconds and release.

The system is restarted.

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

DIP switches let the user manually turn ON/OFF any port, the external alarm, or

the redundant power supply.

The DIP switch must be “ON” to activate the port alarm function. The default

setting is “OFF”.

The following is the recommended procedure for configuring and setting DIP

switches during initial installation:

1 Turn all DIP switches to “OFF”.

2 Install the industrial managed switch in your network.

3 Select the port(s) to be monitored or the alarm to be activated.

4 Set the DIP switch of the corresponding port to “ON”.

5 Turn the industrial managed switch ON.

4.4.2 Reset Button

Figure 8: Reset Button

Important Note!

Use a suitable object, e.g., ballpoint pen or straightened paper clip, to press the

Reset button.

Manual

Version 1.2.0

Page 35

WAGO ETHERNET Accessories 852 Device Description 35

Table 11: Legend for Figure “Label”

No.

“Serial NO” Description

02

Firmware version

01

Hardware version

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.5 Label

4.5.1 Hardware and Software Version

There is a label with the “MAC Address” and “Serial NO” on the back of the

industrial managed switch.

Figure 9: Label (Example)

Manual

Version 1.2.0

Page 36

36 De vice De s c ription W AGO ETHERNET Accessories 852

Table 12: Technical Data – Device Data

Width

Carrier rail mounting

50 mm

Height

Carrier rail mounting

120 mm (from the top edge of the

Depth

Carrier rail mounting

162 mm

Weight

910 g

Degree of protection

IP30

Table 13: Technical Data – System Data

MAC table

Up to 16000 addresses

VLAN

Port based and tag based (4094 VIDs)

Jumbo Frame Size

10240 bytes

Wavelength optical fibers

Depends on SFP module

Maximum lengths

10/100/

RS-232: 15 m

Table 14: Technical Data – Power Supply

Supply voltage

12 … 60 VDC

Power consumption, max.

18 W

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.6 Technical Data

4.6.1 Device Data

carrier rail)

4.6.2 System Data

4.6.3 Power Supply

1000BASE-TX: 100 m;

Fiber optic: 2 km to 80 km

Manual

Version 1.2.0

Page 37

WAGO ETHERNET Accessories 852 Device Description 37

Table 15: Technical Data – Communication

Ports

8 x 10/100/1000BASE-T (RJ-45);

1 x RS-232 (RJ-45)

Standards

IEEE 802.3u 100BASE-TX/FX;

IEEE 802.1x Port Authentication

Topology

Ring and star

Table 16: Technical Data ‒ Environmental Conditions

Surrounding air temperature, operation

-40 °C … +7 0 °C

Surrounding air temperature, operation,

DNV GL (Temperature class D)

-25 °C … +7 0 °C

Surrounding air temperature, stor age

-40 °C … +80 °C

Relative humidity (without

condensation)

95 %

Vibration resistance

Acc. IEC 60068-2-6

Shock resistance

Acc. IEC 60068-2-27

EMC-1 immunity to interference

Acc. EN 61000-6-2

EMC-1 Emission of interference

Acc. EN 61000-6-4

Standard Compass Safe Distance 0.3

Degree deflection

Steering, Standby, Emergency

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.6.4 Communication

4 x SFP 1000BASE-SX/LX, fiber optic;

IEEE 802.3ad Link Aggregation;

IEEE 802.3 10BASE-T;

IEEE 802.1d Spanning Tree Protocol;

IEEE 802.3x Flow Control;

IEEE 802.1p CoS Prioritization;

IEEE 802.1q VLAN Tagging;

IEEE 802.3ab LLDP;

IEEE 802.3ab 1000BASE-T;

IEEE 802.3w RSTP;

IEEE 802.3z 1000BASE-SX/LX;

4.6.5 Environmenta l Conditions

Compass Safe Distance 1.0 Degree

deflection

750 mm

500 mm

Manual

Version 1.2.0

Page 38

38 De vice De s c ription W AGO ETHERNET Accessories 852

Conformity Marking

DNV GL

Enclosure: A]

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

4.7 Approvals

The following approvals have been granted for the WAGO ETHERNET

accessory product “8/4-Port 1000BASE-T/1000BASE-SX/LX” (852-1305):

The following approvals are pending for WAGO ETHERNET accessory products

“8/4-Port 1000BASE-T/1000BASE-SX/LX” (852-1305):

Ordinary

Locations

The following ship approvals have been granted for the WAGO ETHERNET

accessory product “8/4-Port 1000BASE-T/1000BASE-SX/LX” (852-1305):

UL61010-2-201

[Temperature: D, Humidity: B, Vibration: C, EMC: B,

Manual

Version 1.2.0

Page 39

WAGO ETHERNET Accessories 852 Mounting 39

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

5 Mounting

5.1 Installation Site

The location selected to install the industrial managed switch may greatly affect

its performance. When selecting a site, we recommend considering the following

rules:

• Install the industrial managed switch at an appropriate place. See section

“Device Description” > … > “Technical Data“ for the acceptable

temperature and humidity operating ranges.

Make sure that the heat output from the industrial managed switch and ventilation

around it is adequate. Do not place any heavy objects on the industrial managed

switch.

5.2 Installation on a Carrier Rail

The carrier rail must optimally support the EMC measures integrated into the

system and the shielding of the internal data bus connections.

Place the industrial managed switch onto the DIN rail from the top and snap it

into position.

5.3 Removal from Carrier ail

To remove the industrial managed switch from the carrier rail, insert a suitable

tool into the metal tab under the switch and deflect the metal tab downward.

You can then release the switch down from the carrier rail and remove it

upwards.

Manual

Version 1.2.0

Page 40

40 Connect Devices WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

6 Connect Devices

6.1 Power Supply

The industrial managed switch uses direct current power supply for 12 … 60 V.

The primary and secondary network link is established via a 6-pin plug-in

connection located on the top of the industrial managed switch.

The female connector is composed of six connecting terminals and can be

inserted and removed easily by hand to connect to the 6-pin plug connector

located on the top of the switch.

The power supply for the industrial managed switch automatically adjusts to the

local power source and can also be switched On if no or not all patch cables are

connected.

1 Check whether the power LED on the front lights up when the device is

switched ON. If not, check that the power cable is correctly and securely

plugged in.

2 If a secondary power supply is connected, the RPS LED lights up.

3 PWR +/- conductors:

To connect or disconnect the conductors, actuate the spring in the female

connector directly using a screwdriver or an operating tool and insert or

remove the conductor.

4 For the backup DC connection, follow the same procedure as above.

Attach power wires to the female connector (in the position marked “RPS

+/-”).

5 Plug the female connector into the male connector of the switch if it has not

already been plugged in.

6 Check whether the power LED on the top of the device lights up when

power is supplied to the device. If not, check to ensure that the power cable

is plugged in correctly and fits securely.

Manual

Version 1.2.0

Page 41

WAGO ETHERNET Accessories 852 Connect Devices 41

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

6.2 External Alarm Contact Port

The industrial managed switch has an alarm contact connection on the top panel.

For detailed instructions on how to connect the alarm contact power wires to the

two ALM contacts of the 6-pin female connector, please refer to section “Power

Supply (PWR/RPS)” (it is the same procedure).

You can connect the alarm circuit to any warning device already installed in the

user's control room or factory floor. When a fault occurs, the industrial switch

sends a signal through the alarm contact to activate the external alarm. The

alarm contact has two ports that form a fault circuit for connecting to alarm

systems.

An alarm is signaled in the following cases:

1 Link failure (e.g., cable disconnected, device breakdown, etc.)

2 PWR/RPS:

a Power failure (power cord is disconnected, power supply malfunction,

etc.)

b Input power falls outside specification

(12 … 60 V)

3 Failure in jet ring or ERPS ring (Enhancement mode).

6.3 Console Port Cable Connection

The console port (RJ-45) provides the local management facility.

1. Insert the RJ-45 side of the (8 pin RJ-45 to DB9) cable into the RJ-45

console port on the Industrial Managed Switch and the other end into the

COM port of the computer.

2. Configure the Hyper Terminal settings as mentioned in chapter

“Configuration“ > … > “Console Port”.

For console port (8 pin RJ-45) pin assignment, please see in the chapter

“Appendix“ > …> “Console Port (RJ-45 to DB9)”.

Manual

Version 1.2.0

Page 42

42 Connect Devices WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

6.4 1000Base-SX/LX Port, Fiber Optic

When connecting a fiber optic cable to a 1000Base-SX/LX port on the industrial

managed switch, make sure to use the right connector type (LC) and SFP

module.

There are various types of multi-mode, single mode or WDM SFP modules.

Follow the steps below to connect the fiber optic cable properly:

Rubber covers

Remove and safely store the rubber covers of the fiber optic port (LC).

If no fiber optic cable is connected, the rubber cover should be installed to protect

the fiber optics.

1 Insert the respective SFP modules.

2 Ensure that the fiber optic ports are clean. You can clean the cable

connectors by wiping them with a clean cloth or a cotton ball soaked with a

little ethanol. Dirty fiber optic cables affect the quality of the light transmitted

via the cable and leads to reduced performance at the port.

3 Connect one end of the fiber optic cable to the LC port of the industrial

managed switch and the other end to the fiber optic port of the other

device.

Proper connection of the fiber optic cable to the SFP module

For a proper connection, snap the connector of the fiber optic cable into the SFP

module audibly.

4 Check the respective port LED on the industrial managed switch that the

connection is established (see section “Device Description” > … > “Display

Elements”).

Manual

Version 1.2.0

Page 43

WAGO ETHERNET Accessories 852 Connect Devices 43

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

6.5 10/100/1000BASE-T Ports

The 10/100BASE-T ports (RJ-45 ETHERNET ports) of the industrial managed

switch support both autosensing and autonegotiation.

1 Connect one end of the twisted pair cable of the type Category 3/4/5/5e to

an available RJ-45 port on the industrial managed switch and the other end

to the port of the selected network node.

2 Check the respective port LED on the industrial managed switch that the

connection is established.

(see section “Display Elements” > … > “Port LEDs”).

Manual

Version 1.2.0

Page 44

44 Enhanced Features WAGO ETHERNET Accessories 852

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

7 Enhanced Features

7.1 Default Settings

7.1.1 Jumbo Frame

“Jumbo Frames” are ETHERNET frames with a size of more than 1500 bytes.

Jumbo frames can increase data transmission efficiency in a network. The bigger

the “Jumbo Frame”, the better the network performance.

“Jumbo Frame” settings

The “Jumbo Frame” settings apply to all ports.

If the size of a packet exceeds the size of the “Jumbo Frame”, the packet is

dropped.

7.1.2 SNTP

SNTP (“Simple Network Time Protocol”) is a protocol for synchronizing clocks in

computer systems. It is a less complex implementation of an NTP (“Network Time

Protocol”).

SNTP uses “Coordinated Universal Time” (French: “Temps Universel

Coordonné”). No information on time zones or daylight savings time is

transmitted. This information falls outside the protocol range and must be

obtained separately.

The SNTP port is 123.

1. T he SNTP server always replies the current UTC time.

2. If t he switch receives the SNTP reply time, it adjusts the time to the time

zone configuration and configures the time for the switch accordingly.

3. If the time server's IP address is not configured, the switch does not send

an SNTP request packet.

4. If t he switch does not receive an SNTP reply packet, it repeats the

challenge indefinitely every ten seconds.

5. If t he switch receives an SNTP reply, it repeats the time request from the

NTP server every hour.

6. If t he time zone and NTP server changes, the switch repeats the request

process.

7. No default SNTP server.

Manual

Version 1.2.0

Page 45

WAGO ETHERNET Accessories 852 Enhanced Features 45

852-1305 8/4-Port 1000BASE-T/1000BASE-SX/LX

7.1.3 Manageme nt Host

The management host limits the number of hosts that the switch can manage.