Page 1

Manual

WAGO-ETHERNET-Accessories 852

8 Port 100BASE-TX Industrial Eco Switch

852-112

Assembly, Installation and Handling

Version 1.0.0

Page 2

2 General WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 1.1 /Alle Serien (Allgemeine Module)/Hinweise zur Dokumentation/Impre ssum @ 3\mod_1219151118 203_21.doc @ 21060

General

© 2009 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Pos: 1.2 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Manual

Version 1.0.0

Page 3

WAGO-ETHERNET-Accessories 852 Table of Contents 3

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 1.3 /Dokumentation allgemein/Verzeichni sse/Inhaltsverzeic hnis - Überschrif t 1 @ 3\mod_1219151230875_21.doc @ 21063

Table of Contents

General ................................................................................................................... 2

Table of Contents................................................................................................... 3

1 Important Notes ........................................................................................... 5

1.1 Legal Bases.................................................................................................... 5

1.1.1 Subject to Changes.................................................................................... 5

1.1.2 Personnel Qualification............................................................................. 5

1.1.3 Proper Use of the Industrial Switches....................................................... 5

1.1.4 Technical Condition of Specified Devices................................................ 5

1.2 Standards and Regulations for Operating the Industrial Switches................. 6

1.3 Symbols.......................................................................................................... 7

1.4 Safety Information ......................................................................................... 9

1.5 Font Conventions......................................................................................... 10

1.6 Number Notation ......................................................................................... 10

2 General........................................................................................................ 11

2.1 Package Contents......................................................................................... 11

2.2 Industrial Ethernet Technology.................................................................... 11

2.3 Switching Technology ................................................................................. 11

2.4 Auto Negotiation.......................................................................................... 11

2.5 Switching, Filtering...................................................................................... 11

2.6 Port Speed & Duplex Mode......................................................................... 12

3 Device Description ..................................................................................... 13

3.1 View............................................................................................................. 14

3.1.1 Front View .............................................................................................. 14

3.2 Connectors ................................................................................................... 15

3.2.1 10/100BASE-TX..................................................................................... 15

3.2.2 Power Input (PWR)................................................................................. 15

3.3 Display Elements ......................................................................................... 16

3.3.1 Unit LED................................................................................................. 16

3.3.2 Port LED´s .............................................................................................. 16

4 Assembly..................................................................................................... 17

4.1 Installation site............................................................................................. 17

4.2 Mountable on carrier rail ............................................................................. 17

4.3 Screw fixing................................................................................................. 18

4.4 Connect Devices .......................................................................................... 19

4.4.1 Supply voltage......................................................................................... 19

5 Technical Data............................................................................................ 20

6 Appendix..................................................................................................... 21

6.1 Appendix A.................................................................................................. 21

6.1.1 RJ-45 Cables ........................................................................................... 21

List of Figures ...................................................................................................... 22

List of Tables........................................................................................................ 23

Manual

Version 1.0.0

Page 4

4 Table of Contents WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 1.4 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Manual

Version 1.0.0

Page 5

WAGO-ETHERNET-Accessories 852 Important Notes 5 852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 2.1 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Wichtige Erläuterungen - Überschrift 1 @ 4\ mod_1241428899156_21.doc @ 32170

1 Important Notes

Pos: 2.2 /Alle Serien (Allgemeine Module)/Wic htige Erläuterungen/Ein leitung Wichtige Erläu terungen @ 3\mod_1221059 818031_21.doc @ 21717

This section includes an overall summary of the most important safety requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 2.3 /Alle Serien (Allgemeine Module)/Wic htige Erläuterungen/Recht liche Grundlagen @ 3\mod_1 221060626343_21.doc @ 21726

1.1 Legal Bases

Pos: 2.4 /Alle Serien (Allgemeine Module)/Wic htige Erläuterungen/Änder ungsvorbehalt @ 3\mod_122 1060036484_21.doc @ 21720

1.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 2.5 /Serie 852 (Ethernet-Zubehör)/Wichtige Er läuterungen/Persona lqualifikation @ 3\ mod_1222346340968_21. doc @ 22264

1.1.2 Personnel Qualification

All sequences implemented on Series 852 devices may only be carried out by

electrical specialists with sufficient knowledge in automation. The specialists

must be familiar with the current norms and guidelines for the devices and

automated environments.

All changes to the controller should always be carried out by qualified personnel

with sufficient sufficient skills in PLC programming.

Pos: 2.6 /Serie 852 (Ethernet-Zubehör)/Wichtige Er läuterungen/Bestim mungsgemäße Verwendung @ 3\ mod_1222346110578_2 1.doc @ 22258

1.1.3 Proper Use of the Industrial Switches

The device is designed for the IP30 protection class. It is protected against the

insertion of solid items and solid impurities up to 2.5 mm in diameter, but not

against water penetration. Unless otherwise specified, the device must not be

operated in wet and dusty environments.

Pos: 2.7 /Alle Serien (Allgemeine Module)/Wic htige Erläuterungen/Techni scher Zustand der Gerät e @ 3\mod_1221060446109_2 1.doc @ 21723

1.1.4 Technical Condition of Specified Devices

The components to be supplied Ex Works, are equipped with hardware and

software configurations, which meet the individual application requirements.

Changes in hardware, software and firmware are permitted exclusively within the

framework of the various alternatives that are documented in the specific manuals.

WAGO Kontakttechnik GmbH & Co. KG will be exempted from any liability in

case of changes in hardware or software as well as to non-compliant usage of

components.

Please send your request for modified and new hardware or software configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 2.8 /Serie 852 (Ethernet-Zubehör)/Wichtige Er läuterungen/Normen und Richtlinien @ 3\mod_1222 346239453_21.doc @ 22261

Manual

Version 1.0.0

Page 6

6 Important Notes WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

1.2 Standards and Regulations for Operating the

Industrial Switches

Please observe the standards and regulations that are relevant to installation:

• The data and power lines must be connected and installed in compliance

with the standards to avoid failures on your installation and eliminate any

danger to personnel.

• For installation, startup, maintenance and repair, please observe the accident

prevention regulations of your machine (e.g., BGV A 3, "Electrical

Installations and Equipment").

• Emergency stop functions and equipment must not be deactivated or

otherwise made ineffective. See relevant standards (e.g., DIN EN 418).

• Your installation must be equipped in accordance to the EMC guidelines so

electromagnetic interferences can be eliminated.

Pos: 2.9 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

• Please observe the safety measures against electrostatic discharge according

to DIN EN 61340-5-1/-3. When handling the modules, ensure that

environmental factors (persons, workplace and packing) are well grounded.

• The relevant valid and applicable standards and guidelines regarding the

installation of switch cabinets must be observed.

Manual

Version 1.0.0

Page 7

WAGO-ETHERNET-Accessories 852 Important Notes 7

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 2.10 /Alle Serien (Allgemeine Module)/Hinweise zur Dokumentation/Sy mbole @ 3\mod_12173941975 93_21.doc @ 21010

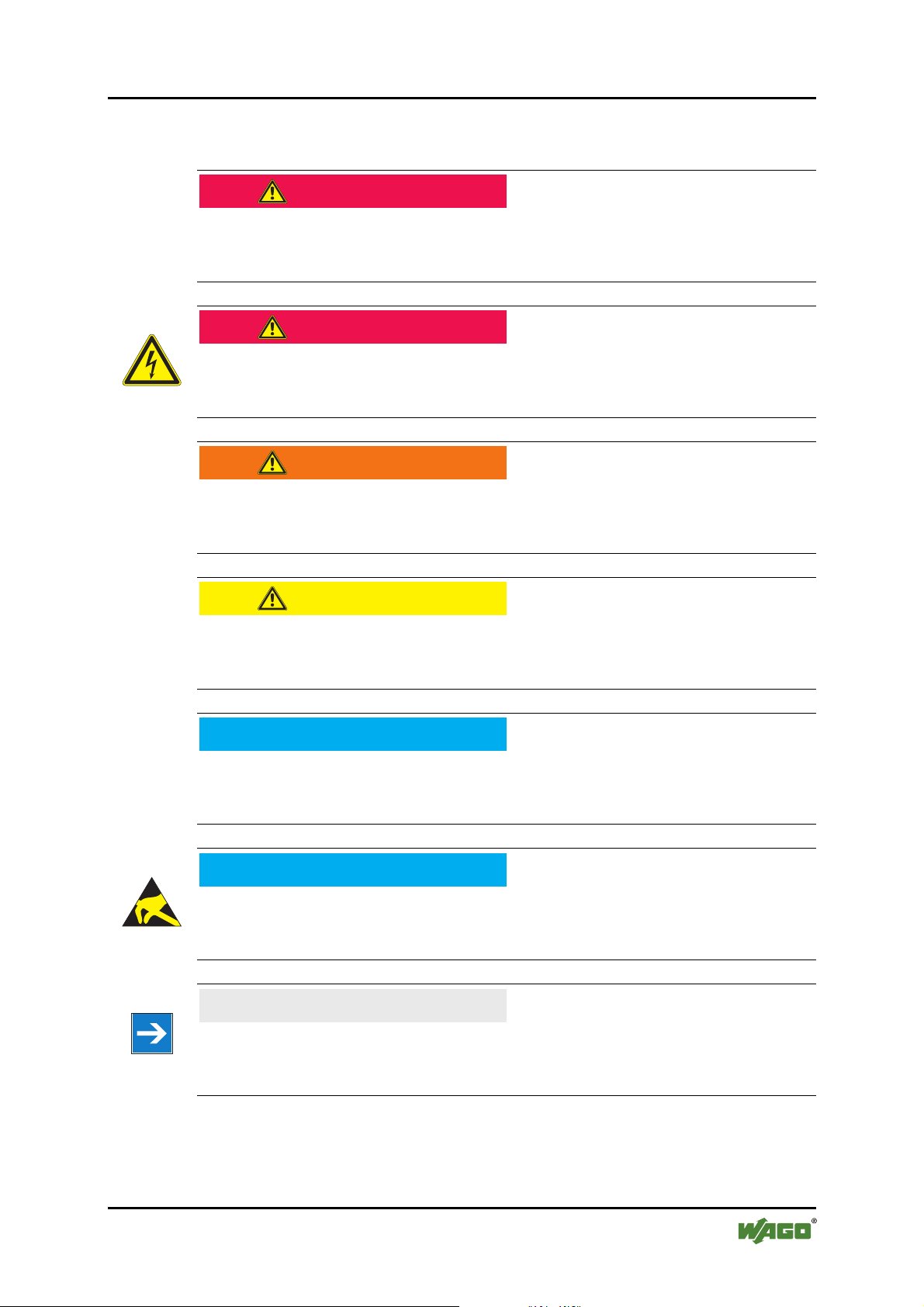

1.3 Symbols

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

DANGER

DANGER

WARNING

CAUTION

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

NOTICE

NOTICE

Note

Manual

Version 1.0.0

Page 8

8 Important Notes WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 2.11 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Information

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Manual

Version 1.0.0

Page 9

WAGO-ETHERNET-Accessories 852 Important Notes 9

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 2.12 /Serie 852 (Ethernet-Zubehör)/Wic htige Erläuterungen/Sic herheitshinweise 852-11 1, 112 @ 4\mod_12367751450 78_21.doc @ 28192

1.4 Safety Information

DANGER

Warning of physical injury

Industrial Eco Switches are exposed operating equipment. They may only be

assembled in housings, cabinets or in electrical operation rooms. Access is only

permitted via a key or tool to authorized qualified personnel.

DANGER

Warning of physical injury

All power sources to the device must always be switched off before performing

any installation, repair or maintenance work.

NOTICE

Warning of damage to equipment

The components are not resistant against materials having seeping and insulating

properties such as: aerosols, silicones, triglycerides (found in some hand creams).

If it cannot be determined that these materials appear in the component

environment, then the components must be installed in an enclosure that is

resistant against the above mentioned materials. Clean tools and materials are

generally required to operate the device/module.

NOTICE

Warning of damage to equipment

Soiled contacts must be cleaned using oil-free compressed air or with ethyl

alcohol and leather cloths.

NOTICE

Warning of damage to equipment

Do not use contact sprays, which could possibly impair contact area functionality.

NOTICE

Warning of damage to equipment

Avoid reverse polarity of data and power lines as this may damage the devices.

NOTICE

Warning of damage to equipment by electrostatic discharge

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched.

Pos: 2.13 /Alle Serien (Allgemeine Module)/Hinweise zur Dokumentation/Sc hriftkonventionen @ 3\ mod_1221059521437_21. doc @ 21714

Manual

Version 1.0.0

Page 10

10 Important Notes WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

1.5 Font Conventions

Table 1: Font Conventions

Font typ:e Indicates:

Names of paths and data files are marked in italic-type.

e.g.: C:\Programme\WAGO-IO-CHECK

Menu items are marked in bold letters.

e.g.: Save

A greater-than sign between two names means the selection of a

menu item from a menu.

e.g.: File > New

Designation of input or optional fields are markeded in bold letters,

e.g.: Start of measurement range

e.g.: Enter the value “4 mA” under Start of measurement range.

Pushbuttons in dialog boxes are marked with bold letters in square

brackets.

e.g.: [Input]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

Pos: 2.14 /Alle Serien (Allgemeine Module)/Hinweise zur Dokumentation/ Zahlensysteme @ 3\mod_122105 9454015_21.doc @ 21711

italic

Menu

>

Input

“Value” Input or selective values are marked in inverted commas.

[Button]

[Key]

1.6 Number Notation

Table 2: Number Notation

Number code Example Note

Decimal 100 Normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Pos: 3 /Dokumentation allgemein/Gliederungsele mente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

In quotation marks, nibble separated with

dots (.)

Manual

Version 1.0.0

Page 11

WAGO-ETHERNET-Accessories 852 General 11 852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 4.1 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Einleitung @ 3\mod_1222 676076609_21.doc @ 22308

2 General

Pos: 4.2 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Paketinhalt 852-11 1, 112 @ 4\mod_12369452887 34_21.doc @ 28399

2.1 Package Contents

• 1 Industrial Eco Switch

• Carrier rail support

Pos: 4.3 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Industrielle Ether net Technologie 852-1 11, 112 @ 4\mod_12369456448 28_21.doc @ 28403

2.2 Industrial Ethernet Technology

The line of switches from WAGO ensure the scalability of your network

infrastructure with outstanding electrical and mechanical characteristics. These

robust devices are designed for industrial use and they are fully compliant with

IEEE802.3, 802.3u.

They have voltage supply with a supply voltage range of 18 … 30 V.

Characteristics such as auto negotiation and auto MDI/MDIX (crossover) on all

10/100 BaseTX ports are realized.

Pos: 4.4 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Switch Technologie @ 3\ mod_1222683606296_21. doc @ 22317

2.3 Switching Technology

Another approach to pushing beyond the limits of Ethernet technology is the

development of switching technology. A switch bridge Ethernet packets at the

MAC address level of the Ethernet protocol transmitting among connected

Ethernet or Fast Ethernet LAN segments.

Switching is a cost-effective way of increasing the total network capacity

available to users on a local area network. A switch increases capacity and

decreases network loading by dividing a local area network into different

segments, which don’t compete with each other for network transmission

capacity.

Pos: 4.5 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Auto Negotiation @ 3\ mod_1222427670250_21. doc @ 22290

2.4 Auto Negotiation

The Industrial Switch’s 10/100Mbps switched RJ-45 ports auto negotiates with

connected devices to determine the fastest data transmission rate supported by

both devices. This helps make the Switch a plug and play device. The Switch’s

RJ-45 ports support full or half duplex, depending on which transmission speed is

supported by the attached device.

Pos: 4.6 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Switching, Filtern @ 3\ mod_1222427760578_21. doc @ 22298

2.5 Switching, Filtering

Packets entering the Industrial Switch with source and destination addresses

belonging to the same port segment will be filtered, limiting those packets to one

port, and relieving the rest of the network from the need to process them. A packet

with a destination address served by another port segment will be forwarded to the

appropriate port, and will not be sent to the other ports where it is not needed.

Packets that are used to maintain network operations (such as the occasional multi

cast packet) are forwarded to all ports.

Manual

Version 1.0.0

Page 12

12 General WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

The Industrial Switch operates in the store and forward switching mode, which

eliminates bad packets and enables peak performance to be achieved when there is

heavy traffic on the network.

Pos: 4.7 /Serie 852 (Ethernet-Zubehör)/Einleitu ng/Port-Geschwindigk eit und Duplex-Modus @ 3\ mod_1222427724921_21. doc @ 22294

2.6 Port Speed & Duplex Mode

After a cable is plugged into a specific port, the system uses auto negotiation to

determine the transmission mode for the new twisted pair connection:

If the connected device does not support auto negotiation or has auto negotiation

disabled, an auto sensing process is initiated to select the speed and set the duplex

mode to half duplex.

Pos: 5 /Dokumentation allgemein/Gliederungsele mente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Manual

Version 1.0.0

Page 13

WAGO-ETHERNET-Accessories 852 Device Description 13

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 6.1 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Gerätebeschreibung - Überschrift 1 @ 3\mod_12337 56084656_21.doc @ 27096

3 Device Description

Pos: 6.2 /Serie 852 (Ethernet-Zubehör)/Gerätebeschr eibung/Eigenschaf ten allgemein @ 3\mod_122 0960104203_21.doc @ 21260

The Industrial Switch was designed for easy installation in an industrial

environment where vibration, shock, heat, and RF interference may be

commonplace.

The Industrial Switch, with its small, compact size, was specifically designed for

easy DIN rail mounting and can be installed where space is limited.

The Industrial Switch is ideal for deployment with multiple high-speed servers for

shared bandwidth 10 Mbps or 100 Mbps workgroups. With the highest bandwidth

200 Mbps (100 Mbps full duplex mode), any port can provide workstations with a

congestion-free data pipe for simultaneous access to the server.

The Industrial Switch is expandable by cascading two or more switches together

in a ‘daisy-chain’ fashion. As all ports support 200 Mbps, the Industrial Switch

can be cascaded from any port and to any number of switches.

The Industrial Switch combines dynamic memory allocation with store-and

forward switching to ensure that the buffer is effectively allocated for each port,

while controlling the data flow between the transmit and receive nodes to

guarantee against all possible packet loss.

Pos: 6.3 /Serie 852 (Ethernet-Zubehör)/Gerätebeschr eibung/Eigenschaf ten 852-112 @ 4\mod_1243 257266296_21.doc @ 33692

Other key features are:

Pos: 6.4 /Serie 852 (Ethernet-Zubehör)/Gerätebeschr eibung/Gerätebesc hreibung 852-112 @ 4\ mod_1243258009843_21. doc @ 33704

• Eight (8) 10/100Base-TX Ports

• Comprehensive front-panel diagnostic LEDs

• Supports Auto-MDI/MDI-X

• Full/half-duplex transfer modes for each port

• Wide supply voltage range 18 … 30 V

• Store-and-forward switching method

• Integrated address Look-Up Engine, supports 2K absolute MAC addresses

• Supports surge protection

• Power input polarity protection function

• IEEE 802.3x flow control for fullduplex

• Wide operating temperature range 0 °C … 70 °C

• Auto-Negotiation an allen Ports

• Rugged metal-IP30 case

• Vibration/Shock operational

The 852-112 has 8 ports with each port featuring Auto-negotiation and auto

MDI/MDI-X detection. Existing 10 Mbps networks can now be upgraded

effortlessly to higher speed 100Mbps Fast Ethernet networks.

The 852-112 8-port density can be used to create multiple segments to alleviate

client congestion and provide dedicated bandwidth to each user node.

The 852-112 is a cost-effective solution to keep up with the constant demands for

emerging IP-based industry communication needs. The switch can be easily

Manual

Version 1.0.0

Page 14

14 Device Description WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

configured and installed and is also ideally suited for small to medium-sized

networks.

Pos: 6.5 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Ansicht - Überschrif t 2 @ 4\mod_1240984217343_21. doc @ 31958

3.1 View

Pos: 6.6 /Serie 852 (Ethernet-Zubehör)/Gerätebeschr eibung/Ansichten 8 52-112 @ 4\mod_124325835 0203_21.doc @ 33708

3.1.1 Front View

Pos: 6.7 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

LNK/ACT

1

5

852-112

8-port 10/100 Industrial Switch

2

6

3

3

+18~30V DC

PWR

7

2

8

1

100

4

+-

654

Figure 1: Front view of Industrial Eco Switch

Pos. Description

1 TX port 100 Mbps LED

2 TX port LNK/ACT LED

3 TX ports (8)

4 Primary Power LED

5 Terminal stripes for connection power supply (PWR)

6 Grounding screw

100

LNK/ACT

3

1

2

Manual

Version 1.0.0

Page 15

WAGO-ETHERNET-Accessories 852 Device Description 15

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 6.8 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Anschlüsse - Überschr ift 2 @ 4\mod_124098426265 6_21.doc @ 31961

3.2 Connectors

Pos: 6.9 /Serie 852 (Ethernet-Zubehör)/Gerätebeschr eibung/10/100BA SE-TX Anschlüsse 852-112 @ 5\mod_1247815970296 _21.doc @ 37869

3.2.1 10/100BASE-TX

LNK/ACT

1

2

3

4

100

Figure 2: 10/100BASE-TX

The 10/100BASE-TX ports support network speeds of either 10 Mbps or

100 Mbps, and can operate in half- and full-duplex transfer modes. The ports also

offer automatic MDI/MDI-X crossover detection that gives true “plug and play”

capability – just plug the network cables into the ports and the ports will adjust

according to the end-node devices. The following are the recommended cables for

the RJ-45 connectors:

• 100 m – Cat 5 or better

Pos: 6.10 /Serie 852 (Ethernet-Zubehör)/Gerätebesc hreibung/Spannung sversorgung 852-112 @ 4\ mod_1243334538609_21. doc @ 33949

3.2.2 Power Input (PWR)

The female connector can easily be connected to the 3-pole male connector

located on the top of the switch.

The male connector shows the following pin assignment:

Table 3: Power Input (PWR)

+18~30V DC

+-

Figure 3: Power input

Name Designation

+ PWR Primary DC input

- PWR Primary DC input

GND Ground

Manual

Version 1.0.0

Page 16

16 Device Description WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

NOTICE

Warning of damage to equipment by electrostatic discharge

DC Powered Industrial Eco Switch: Power is supplied through an external DC

power source. Check the technical specification section for information about the

DC power input voltage. Since the Industrial Eco Switch does not include a power

switch, plugging its power adapter into a power outlet will immediately power it

on.

Pos: 6.11 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Anzeigeelemente - Übersc hrift 2 @ 4\mod_124098439 0875_21.doc @ 31964

3.3 Display Elements

Pos: 6.12 /Serie 852 (Ethernet-Zubehör)/Gerätebesc hreibung/LED-Anzei gen 852-112 @ 4\mod_1243 333639218_21.doc @ 33929

This Industrial Switch is equipped with Unit LEDs to enable you to quickly

determine the status of the Switch, as well as Port LEDs to see what is happening

across your connection.

They are as follows:

3.3.1 Unit LED

Table 4: Unit LED

PWR

Figure 4: Unit LED

3.3.2 Port LED´s

Table 5: Port LED´s

LNK/ACT

1

2

3

4

Pos: 7 /Dokumentation allgemein/Gliederungsele mente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

100

Figure 5: Port LEDs

LED Desig-

Status Description

nation

PWR Primary

Green Industrial Eco Switch uses

Power LED

Aus Primary power off.

LED Desig-

Status Description

nation

100 TX-port

Green Port operating at 100 Mps (1

100 Mbps

LED

LNK/ACT TX port

Off Port operating at below

Green Illuminated when connectors

LNK/

ACT

LED

Flash-

ing

Off No valid link established on

primary power.

LED for each port).

100 Mps.

are attached (1 LED for each

port).

Data traffic passing through

port.

port.

Manual

Version 1.0.0

Page 17

WAGO-ETHERNET-Accessories 852 Assembly 17 852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 8.1 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Montieren - Überschr ift 1 @ 3\mod_1225446744750_21. doc @ 24900

4 Assembly

Pos: 8.2 /Serie 852 (Ethernet-Zubehör)/Montieren/ Montageort 852-111, 112 @ 3\ mod_1221812987484_21. doc @ 21968

4.1 Installation site

The location selected to install the Industrial Switch may greatly affect its

performance. When selecting a site, we recommend considering the following

rules:

• Install the Industrial Switch at an appropriate place. See chapter “Technical

Data“ for the acceptable temperature and humidity operating ranges.

• Fix the provided brackets at the back of the Industrial Switch to a DIN rail

to protect the switch from falling.

Pos: 8.3 /Serie 852 (Ethernet-Zubehör)/Montieren/ Montieren 852-112 @ 4\mod_12 42809603015_21.doc @ 33663

4.2 Mountable on carrier rail

1 Rest the Industrial Eco Switch on the carrier rail.

Parallel and perpendicular mounting is possible.

Figure 6: Assembly on carrier rail 1

Manual

Version 1.0.0

Page 18

18 Assembly WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

Figure 7: Assembly on carrier rail 2

4.3 Screw fixing

1 Unscrew the carrier rail mounting on the back of the Eco Switches from the

mounting plate.

2 The switch can be mounted in the boreholes on the mounting plate directly.

Use the drilling template to mark the boreholes.

Figure 8: Drilling template

Manual

Version 1.0.0

Page 19

WAGO-ETHERNET-Accessories 852 Assembly 19

852-112 8 Port 100BASE-TX Industrial Eco Switch

The Industrial Eco Switch can be mounted as follows:

• The surface must be able to bear at least 1.5 kg for the Industrial Switch.

• Conduct a visual inspection of the DC adapter and make sure that it is

connected to the power supply.

• Make sure that the heat output from the Industrial Switch and ventilation

around it is adequate. Do not place any heavy objects on the Industrial

Switch.

• The carrier rail must optimally support the EMC measures integrated into

the system and the shielding of the internal data bus connections.

Note

Important Note!

The ground for the Industrial Switch prevents electromagnetic interference from

electromagnetic radiation.

Observe the corresponding standards for EMC-compatible installations as well.

Pos: 8.4 /Alle Serien (Allgemeine Module)/Übersc hriften für alle Serien/ Geräte anschließen - Überschrift 2 @ 3\mod_1234172 889468_21.doc @ 27460

4.4 Connect Devices

Pos: 8.5 /Serie 852 (Ethernet-Zubehör)/Montieren/ Anschluss Spannungs versorgung 852-111, 112 @ 4\ mod_1236929741531_21. doc @ 28363

4.4.1 Supply voltage

The Industrial Eco Switch uses a DC power supply of 18 … 30 V DC.

The primary power connection is provided via a terminal block located at the top

of the Industrial Eco Switch.

The terminal block is composed of three contact pins and can be inserted and

removed easily by hand to connect to the three pin terminal block (male contacts

located on the body of the Switch).

1 Check the front panel LEDs as the device is powered on to verify that the

Power LED is lit. If not, check that the power cable is correctly and securely

plugged in.

2 PWR +/- conductors:

To connect or disconnect the conductors, actuate the spring directly in the

female connector using a screwdriver or an operating tool and insert or

remove the conductor.

3 If the terminal block is not already inserted into the block receptor of the

Switch, do so now.

Pos: 9 /Dokumentation allgemein/Gliederungsele mente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Manual

Version 1.0.0

Page 20

20 Technical Data WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 10 /Serie 852 (Ethernet-Zubehör)/Technische Da ten/Technische Daten 85 2-112 @ 4\mod_1243342727 734_21.doc @ 33968

5 Technical Data

Table 6: Technical Data

Technical Data

Ports 8 x 10/100Base-TX (RJ-45)

Standards IEEE 802.3 10Base-T;

IEEE 802.3u 100Base-TX/FX ;

IEEE 802.3x Flow Control

Topology Star

LED Each device: 1 x Power (PWR), green

Each port: 1 x Link/Activity

(LNK/ACT), green

1 x Speed (100 Mbps),

green

Supply voltage DC 18 V … 30 V

Energy consumption max. 3 W

Operating temperature 0 °C ... +60 °C

Storage temperature -20 °C ... +80 °C

Relative air humidity (no condensation) 95 %

Dimensions (mm) W x H x L 109,2* x 23,4 x 73,8

* Height from upper-edge of DIN 35

rail

Mounting DIN 35 rail

Weight 165 g

Vibration resistance acc. IEC 60068-2-6

Shock resistance acc. IEC 60068-2-27

Degree of protection IP 30

EMV 1-Immunity to Interference acc. EN 61000-6-2: 2005

EMV 1-Emission to Interference acc. EN 61000-6-4: 2001

Pos: 11 /Dokumentation allgemein/Gliederungsele mente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Manual

Version 1.0.0

Page 21

WAGO-ETHERNET-Accessories 852 Appendix 21 852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 12.1 /Alle Serien (Allgemeine Module)/Überschr iften für alle Serien/ Anhang - Überschrif t 1 @ 4\mod_1239874070437_21.doc @ 30560

6 Appendix

Pos: 12.2 /Serie 852 (Ethernet-Zubehör)/Anhang/An hang A 852-111,112 @ 4\mod_12369 31584406_21.doc @ 28371

6.1 Appendix A

6.1.1 RJ-45 Cables

When connecting your network devices, use a standard Category 5 cable for a

10Base-T configuration for 100Base-TX. The pin assignments are as follows:

Table 7: RJ-45 Cables

Pin Pair Colours

1 TD+ Pair 2 White/Orange

2 TD- Pair 2 Orange/White

3 RX+ Pair 3 White/Green

4 N/A Pair 1 Blue/White

5 N/A Pair 1 White/Blue

6 RX- Pair 3 Green/White

7 N/A Pair 4 Brown/White

8 N/A Pair 4 Brown/White

Pos: 13.1 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Table 8: Configuration

Application Cable Type Application

Switch

to

Switch

or

Network Adapter

Straight through

Cable

Switch Hub

End

1 1

2 2

3 3

6 6

Switch Converter

Converter

to

Switch

Cross Over

Cable

End #1 End #2

1 1

2 2

3 3

6 6

Remark

The Switch features automatic MDI/MDI-X and NWay on RJ-45 port.

Manual

Version 1.0.0

Page 22

22 List of Figures WAGO-ETHERNET-Accessories 852

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 13.2 /Dokumentation allgemein/Verzeichni sse/Abbildungsver zeichnis - Überschri ft 1 @ 3\mod_1219222916765_2 1.doc @ 21080

List of Figures

Figure 1: Front view of Industrial Eco Switch...................................................... 14

Figure 2: 10/100BASE-TX ................................................................................... 15

Figure 3: Power input............................................................................................ 15

Figure 4: Unit LED................................................................................................ 16

Figure 5: Port LEDs ..............................................................................................16

Figure 6: Assembly on carrier rail 1...................................................................... 17

Figure 7: Assembly on carrier rail 2...................................................................... 18

Figure 8: Drilling template.................................................................................... 18

Pos: 13.3 /Dokumentation allgemein/Gliederungse lemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.doc @ 21810

Manual

Version 1.0.0

Page 23

WAGO-ETHERNET-Accessories 852 List of Tables 23

852-112 8 Port 100BASE-TX Industrial Eco Switch

Pos: 13.4 /Dokumentation allgemein/Verzeichni sse/Tabellenverzeic hnis - Überschrif t 1 @ 3\mod_1219222958703_21. doc @ 21084

List of Tables

Table 1: Font Conventions .................................................................................... 10

Table 2: Number Notation..................................................................................... 10

Table 3: Power Input (PWR).................................................................................15

Table 4: Unit LED................................................................................................. 16

Table 5: Port LED´s .............................................................................................. 16

Table 6: Technical Data ........................................................................................20

Table 7: RJ-45 Cables ...........................................................................................21

Table 8: Configuration ..........................................................................................21

===== Ende der Stückliste =====

Manual

Version 1.0.0

Page 24

WAGO Kontakttechnik GmbH & Co. KG

Postfach 2880 • D-32385 Minden

Hansastraße 27 • D-32423 Minden

Phone: +49/5 71/8 87 – 0

Fax: +49/5 71/8 87 – 1 69

E-Mail: info@wago.com

Internet: http://www.wago.com

Loading...

Loading...