Page 1

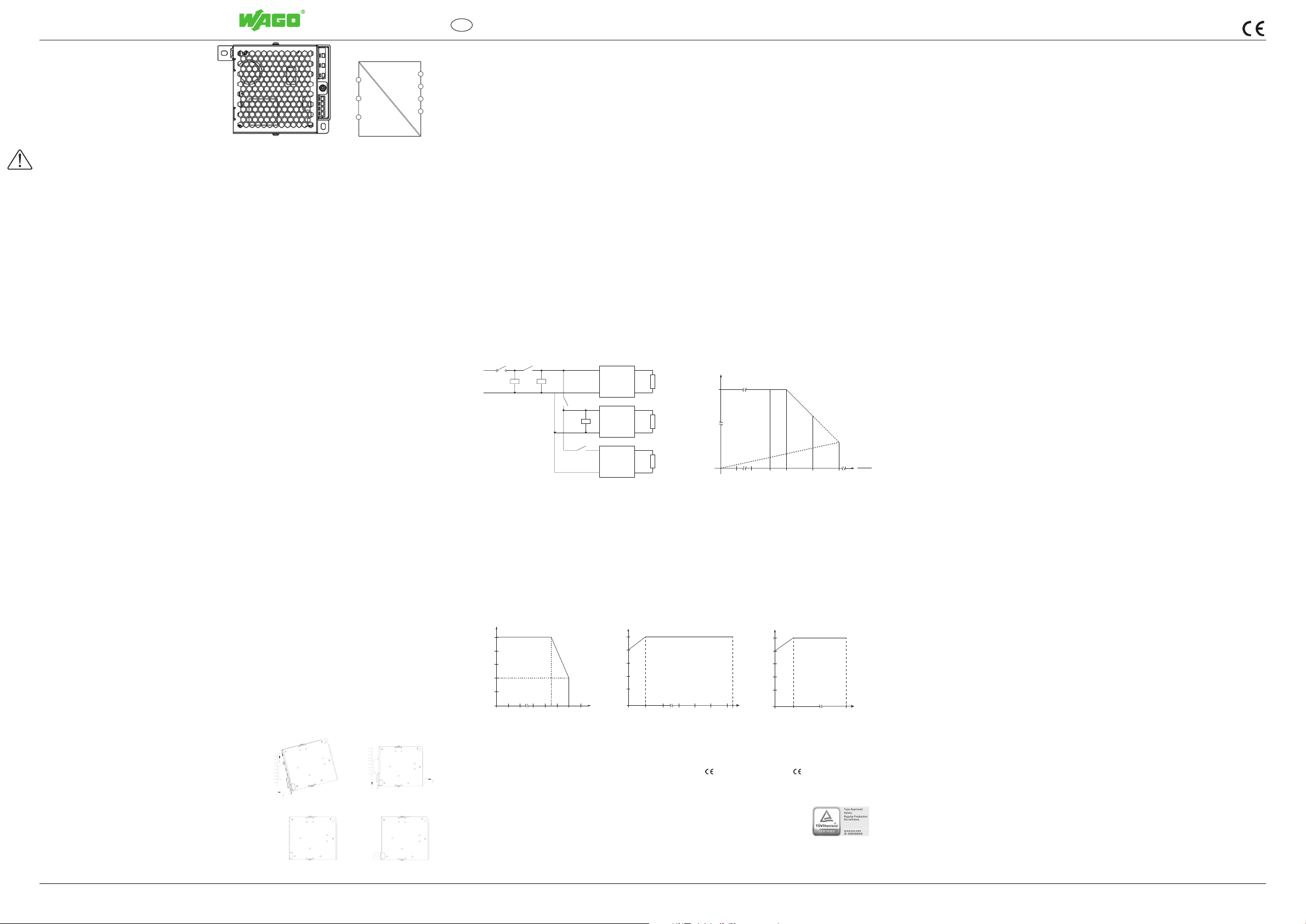

AC Input voltage (V)

Load (%)

DC Input voltage (V)

Load (%)

Temperature (°C)

Load (%)

Operating and Assembly Instructions, Rev. 1.3

9970-0966/0787-1702

Please keep!

EPSITRON® ECO Power 787-1702

Switched-Mode Power Supply

Fig. 1: 787-1702 Switched-Mode Power Supply Unit

1. Safety Information and Application Notes

Congratulations on your purchase of this high-quality product. When used as intended in the described scope of application, it will

provide years of reliable service. As with every technical product, however, risk of personal injury or material damage can arise with

improper use, inappropriate removal of necessary covers or incorrect installation or operation. Follow these operating instructions and

proceed according to the accepted technology standards. All work relating to installation, startup and operation, as well as maintenance, must be performed by qualified specialists (IEC 60364, VDE 0105).

1.1 Packaging

Please inspect the equipment promptly for transport damages such as deformation and loose parts. Please report damages to the

transport company immediately, even if the outer packaging is undamaged.

1.2 Storage

Admissible storage temperature: -25 °C to +70 °C

Admissible air humidity: 10% to 95% relative air humidity; no condensation

For long-term storage: At storage temperature +25°C, equipment with built-in condensers

must be attached to the system voltage for at least 5 minutes every 2 years.

1.3 Instructions for Installation and Operation

Protect equipment from inappropriate stress. Particularly during transport and handling, ensure that no parts are bent and that electrical

spacing remains constant. Avoid touching the electrical components and contacts. Keep sufficient distance from adjacent parts so as to

avoid interfering with the cooling! During operation, the equipment (pursuant to the degree of protection) can have hot surfaces. Never

assemble and wire the equipment when the power is connected. Observe the product description and the technical information in our

main catalog, as well as the labels on the equipment and on the type plate. Perform the installation according to the local conditions,

applicable regulations (e.g., VDE 0100), national accident prevention specifications (e.g., UVV-VBG4 or BGV A2) and accepted

technical regulations. This electrical equipment is intended to be installed in electrical systems or machines and fulfills requirements of

the low voltage directive (2006/95/EG). When installing in machines, normal operation must not commence until it is determined the

machine complies with the requirements of the machinery directive (2006/42/EG); EN 60204 shall be observed. Commencement of

normal operation is only allowed under compliance of the EMC directive (2004/108/EG). The manufacturer of the system or machine

is responsible to ensure compliance with the limit values required by EMC legislation.

1.4 Maintenance and Assembly

Electrical equipment does not typically require special maintenance; however, depending on the degree of protection, it must be protected from dust accumulation, moisture, radiation and aggressive chemicals. Repairs shall only be undertaken within the scope of the

measures outlined in these operating instructions. If an equipment failure does occur, please send the equipment to us to be repaired.

Please provide the following information: type of failure, attendant circumstances (operating conditions, wiring), assumptions about the

cause of failure, previous uncommon occurrences, etc.

1.5 Disposal

Please observe current regulations and dispose of equipment according to material composition; e.g., electronic scrap (circuit boards),

plastic, sheet metal, copper, etc.

1.6 Modifications

The product documentation has been prepared and checked with great care. However, no guarantee can be made regarding

completeness and absence of failure. Any transfer of specifications to the respective application should be checked. The technical data

describes the product characteristics but does not guarantee them. We reserve the right to make changes that further the technical

progress.

2. Application Area

This equipment is a primary switched-mode power supply unit. It is a mounting component used to supply energy to industrial electric

and electronic users of information technology, automation, plant construction, process engineering, control engineering and building

automation. Without additional measures, this equipment shall not be used:

- in places with a high concentration of ionizing radiation

- in places with difficult operating conditions;

e.g. dust formation, caustic vapors or gases, Strong electric or magnetic fields

- in facilities which require special monitoring;

e.g. elevators, electrical equipment in particularly dangerous places

An “additional measure“ can be installing this equipment in a cabinet or a box.

3. Special Conditions for Safe Use

This power supply unit shall only be operated in dry conditions and shall be mounted on a DIN 35 rail (acc. to EN 60715).

The power supply unit is intended to be installed within a tool-accessible IP54 enclosure.

The power supply unit shall be used in an environment of not more than pollution degree 2.

Use copper conductors, only, rated to at least 105°C. A minimum 2.5 mm² earthing conductor must be used.

Output side ( - ) shall be earthed due to EN 62368-1 and EN 60204-1.

Provision shall be made to prevent the rated voltage being exceeded by transient disturbances of more than 140% of the peak rated

voltage.

Acc. to EN 60335-1, disconnection from the mains supply must be possible after installation. Therefore a switch for all poles shall be

incorporated in the fixed wiring in accordance with the wiring rules.

Refer to derating curves for load and ambient conditions (chapter 11). Surrounding air temperature range T

The cooling of this power supply unit shall not be impaired. For consistent heat dissipation, mount horizontally (air inlet below, outlet

above). Other mounting positions: At user‘s risk. We recommend in that case max. 50% power output and max. +45°C surrounding air

temperature Ta. The minimum distances to adjacent parts need to be obeyed.

Depending on the operating mode, audible noise may develop.

According to EN 60335-1, the appliance is not to be used by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction. Children being supervised not

to play with the appliance. Cleaning and user mainenance shall not be made by children without supervision.

4.1 Assembly (on DIN rail)

The hook on the reverse side connects the power supply unit to the uppershank of the DIN 35 rail (see Fig. 2a). The power supply unit then snaps in

place by pressing it down in the direction of the rail and by simultaneously

pulling the latch on the underside.

4.2 Disassembly (from DIN rail)

By pulling the latch on the underside, the rail support release is activated.

By tilting the power supply unit forward, it can come unhinged from the rail

(see Fig. 2b).

4.3 Other mounting options

The DIN rail mounting adaptor can be fastened on the side of the power

supply, too. Please use the screws delivered with the DIN rail adaptor, only

(see Fig. 2c).

The power supply unit can also be fastenend with screws (M4) to a mounting plate. Please use screw mount adaptor (see Fig. 2d).

Fig. 2a: Assembly Fig. 2b: Disassembly

Fig. 2c: Side mounting Fig. 2d: Screw mounting

WAGO Kontakttechnik GmbH & Co. KG

Hansastr. 27, 32423 Minden, Germany

www.wago.com

3

N

L

L

N

-

+

+

3

: -20°C ≤ Ta ≤ +60°C.

a

DC+

DC+

DC-

DC-

GB

5.1 Connections

Check the appropriate operating voltage before connecting the equipment (see type plate).

5.2 Terminal Strips

Connecting the supply lines is performed on the input and output sides via securely soldered WAGO 236 Series Terminal Strips with

CAGE CLAMP

On the input side, the black clamping points are intended for the L, N and PE connections.

On the output side, four blue clamping points are available: two for “+“ and two for “-“ (see Fig.1).

Output side ( - ) can be earthed due to EN 62368-1 and EN 60204-1.

5.3 Connecting Cables

The WAGO 236 Series Terminal Strips with CAGE CLAMP

AWG 12 (solid or fine-stranded). With respect to conductor cross-section dimensions, note the possible output current with a measurement of approx. 1.6 x I

6. LED

A green LED [DC OK] serves as an output voltage indicator (U

7. Setting up the output voltage

The frontal trim-pot [Adjust] can be used to externally set up the output voltage of DC 22 V to 26 V (see Fig. 1).

8. Parallel Connection (on the output side)

In parallel operation, set the output voltage of the devices which are to be connected in parallel to precisely the same value, if possible.

Additionally, the wire resistance from the power supply unit to the load must be nearly identical. Only devices of the same type shall be

used for connecting in parallel.

Notes:

Please use external rail-mounted terminal blocks when connecting in parallel. A parallel connection directly on the output side of the

terminal strips of the device is not allowed. When decoupling the outputs in parallel mode, the use of diodes in the positive path is

recommended. These diodes must be configured for the device‘s maximum output current.

9. Inrush Current

If several devices are supplied on the input side using the same electric current, higher inrush currents can result. In this case, the use of

auxiliary relays, which cause a time delay in start-up, is recommended (see Fig. 4).

The number of devices connected to a circuit using the same electric current arises from the amount of leakage current. Acc. to

EN 62368-1, this shall not exceed a maximum of 3.5 mA.

L

N

Fig. 4: Time delay in start-up of power supply units Fig. 5: Output characteristics

10. Overload or Short Circuit

The equipment‘s output is electronically protected from overload and short circuits. If the output current I

l

out,nom

In case of short circuit (I

The device will turn on the output voltage periodically and test the output circuit for short circuit.

After eliminating the overload or short circuit, the power supply unit automatically supplies the output voltage as indicated.

11. Derating

The maximal load is dependent on the surrounding air temperature and the input voltage.

Equipment evaluated with the following rated values:

U

in,nom

If equipment is used outside these ratings, additional derating has to be considered:

A derating of -4.0 %/K shall be taken into account for surrounding air temperature T

An additional derating of -2 %/V shall be taken into account for input voltages U

100

Fig. 6: Temperature derating curve Fig. 7: Input voltage derating curve

12. Standards and Approvals

Electrical safety and EMC (electromagnetic compatibility) is provided through the equipment configuration in accordance with the cited

standards. The equipment conforms to the legal stipulations and standards for conformity and bears the and the TÜV mark.

®

connection technology. The clamping points can be opened with a tool (e.g. WAGO 210-657 or 210-658).

®

connection technology are suited for single conductors of up to 2.5 mm² ,

.

out,nom

> DC 21 V), (see Fig. 1).

out

K1S

K2K1

L

+

787-17xx

N

K2

L

K3

K3

787-17xx

N

L

787-17xx

N

R

L1

–

+

RL2

–

+

RL3

–

DC 24V

(see Fig. 5), the SMPS will be in overload. The output voltage will be reduced.

> 1.4 x I

out

AC 110-240V, P

80

60

40

20

-20 -10 03040506070

out,nom

30W, Ta +45°C and U

), the green LED [DC O.K.] will turn off, and output voltage U

out, nom

AC 100-240V, P

in,nom

100

80

60

40

20

90 100 110 230

U

out

Constant

Power

Mode

0 105%100% 160%140%

is greater than 1.05 to 1.4 x

out

will be turned off.

out

24W, Ta +45°C.

out,nom

> +45°C (see Fig. 6).

a

< AC 100 V (see Fig. 7).

in

100

80

60

40

20

264

125 140

Electrical safety acc. to EN 62368-1: 2014 + A11: 2017 and EN 60335-1: 2012

EMC Emission of interference acc. to EN 61204-3: 2000

EMC Immunity to interference acc. to EN 61204-3: 2000

1

Y

UL 60950

E255815

r

UL 508

E255817

13. Technical Data

Input (AC IN)

Rated input voltage U

Input voltage range: AC 90 V to 264 V (see Fig. 7),

: AC 100 V to 240 V; DC 140 V to 340 V

in,nom

DC 125 V to 375 V

(external fuse necessary for DC supply)

Frequency: 50 Hz to 60 Hz

Frequency range: 47 Hz to 63 Hz

Input current Iin: < 0.7 A (at AC 100 V and nominal load)

Peak input current: < 18 A (at AC 230 V)

Discharge current: < 3.5 mA (at AC 230V)

Power factor: > 0.45 (at AC 230 V and nominal load)

Mains failure hold-up time: > 10 ms (at AC 230 V)

Output (DC OUT)

Rated output voltage U

Output voltage range: DC 22 V to 26 V; adjustable

: DC 24 V (default setting), SELV

out,nom

Adjustment accuracy: 1%

Residual ripple: < 200 mVpp

Nominal Load Pout,nom: 30 W (AC 110-240 V); 24 W (AC 100-240 V)

Output current I

1.0 A (at AC 100-240 V and DC 24 V)

: 1.25 A (at AC 110-240 V and DC 24 V)

out,nom

Efficiency/power losses

Efficiency: typ. 80% (at AC 230 V and nominal load)

Power loss: typ. 6 W (at AC 230 V, DC 24 V, 1.25 A)

Fuse protection

Internal protection: 1 A / 250 V

Recommended backup fusing: Wire breaking 6 A or 10 A, B characteristic

Transient overvoltage protection: Varistor

Connection

Connection technology: CAGE CLAMP

Type of wire: Solid or stranded wire

®

(WAGO Series 236)

Cross section: 0.08 mm² to 2.5 mm² / AWG 28 to12 (Series 236)

Stripped lengths: 5 to 6 mm / 0.20 to 0.24 in (Series 236)

Input side: 3-pole, black, for L, N and PE (Series 236)

Output side: 4-pole, blue, for 2x + und 2x – (Series 236)

Dimensions and weight

Dimensions (mm) W x H x L 30 x 90 x 99 (Length L from upper-edge of DIN 35 rail)

Weight: 0.25 kg

I

out

I

out,nom

Environmental requirements

Storage temperature: -25°C to +70°C

Surrounding air temperature range T

Relative humidity (without condensation): 10 % to 95 %

: -20°C ≤ Ta ≤ +60°C

a

Climatic class: 3K3 (acc. to EN 60721)

Load Derating: Equipment evaluated with the following rated values:

U

U

If equipment is used outside these ratings, additional derating

(see chapter 11) has to be considered:

-4.0 %/K for +45°C < T

-2.0 %/V for U

Pollution degree: 2 (acc. to EN 50178)

Temperature coefficient: < +/- 0.05%/K for -10°C ≤ T

MTBF: > 100'000 h (acc. to MIL-HDBK-217)

AC 110-240V, P

in,nom

AC 100-240V, P

in,nom

< AC 100 V

in

30W, Ta +45°C and

out,nom

24W, Ta +45°C

out,nom

≤ +60°C

a

≤ +50°C

a

Cooling

During operation, some inner components can heat up to more than +100°C. The enclosure surface can heat up to more

than +60°C, Recommended minimum distance from adjacent parts in case of natural convection and surrounding air temperature +60°C, U

left/right: 15 mm

AC 230 V, P

in

out

12 W:

above/below: 70 mm

Safety and protection

Protection class: prepared for protection class I

Degree of protection: IP20 acc. to EN 60529

Overload protection: Reduction of output voltage (see chapter 10) if l

Short-circuit protected: yes

> 1.05 to 1.4 x l

out

out,nom

Idling-proof: yes

375

Feedback voltage: max. 30 V

Parallel operation: yes, max. 2 power supply units for increased power (see chapter 8)

Serial operation: yes, max. 4 power supply units

Vibration stress: 0.7 g (acc. to EN 60068-2-6)

Shock stress: 15 g (acc. to EN 60068-2-27)

Isolation voltages: AC 1.5 kV for input side and PE

AC 3.0 kV for input and output sides

AC 0.5 kV for output side and PE

SELV: acc. to EN 60335-1

Subject to design changes

Loading...

Loading...