Page 1

Manual

WAGO PERSPECTO® 762

762-1121

WP 121 SVGA

PERSPECTO

Version 1.3.1

®

WP - Web Panel

Page 2

2 WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

© 2018 WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

Manual

Version 1.3.1

Page 3

WAGO PERSPECTO® 762 Table of Contents 3

762-1121 WP 121 SVGA

Table of Contents

1 Notes about this Documentation ............................................................. 5

1.1 Scope of Validity ..................................................................................... 5

1.2 Copyright ................................................................................................ 5

1.3 Symbols ................................................................................................. 6

1.4 Number Notation .................................................................................... 8

1.5 Font Conventions ................................................................................... 8

2 Important Notes ........................................................................................ 9

2.1 Legal Bases ............................................................................................ 9

2.1.1 Subject to Changes ............................................................................ 9

2.1.2 Personnel Qualification ...................................................................... 9

2.1.3 Use of the 762 Series in Compliance with Underlying Provisions ....... 9

2.1.4 Technical Condition of Specified Devices........................................... 9

2.2 Safety Advice (Precautions) ................................................................. 11

2.3 Characteristics of the CODESYS Web Visualization ............................. 13

2.3.1 Description of the Function "CookieHandling()" ................................ 14

3 Device Description .................................................................................. 15

3.1 PERSPECTO WP Web Panel .............................................................. 15

3.2 View ..................................................................................................... 16

3.2.1 Front View ........................................................................................ 16

3.2.2 Back View ........................................................................................ 17

3.3 Connectors ........................................................................................... 18

3.3.1 X1 – Supply Voltage ........................................................................ 18

3.3.2 X6 – ETHERNET Interface............................................................... 19

3.3.3 X8/X9 – USB Interfaces ................................................................... 20

3.4 Battery Case ......................................................................................... 21

3.5 Slot for Memory Card ........................................................................... 22

3.6 Operating Elements .............................................................................. 23

3.6.1 Service Button.................................................................................. 23

3.7 Technical Data ..................................................................................... 24

7.1 Housing............................................................................................ 24

3.

3.7.2 Power Supply ................................................................................... 24

3.7.3 Display ............................................................................................. 24

3.7.4 Hardware ......................................................................................... 25

3.7.5 Software........................................................................................... 25

3.7.6 Interfaces ......................................................................................... 25

3.8 Approvals ............................................................................................. 26

3.9 Standards and Guidelines .................................................................... 26

4 Mounting .................................................................................................. 27

4.1 Front Panel Installation ......................................................................... 27

5 Connect Devices ..................................................................................... 28

5.1 Supply voltage ...................................................................................... 28

5.2 Grounding............................................................................................. 28

5.3 Peripheral Devices ............................................................................... 28

6 Commissioning ....................................................................................... 29

Manual

Version 1.3.1

Page 4

4 Table of Contents WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.1 Switch on .............................................................................................. 29

6.2 IP Address of the Device ...................................................................... 30

6.2.1 General ............................................................................................ 30

6.2.2 Setting the IP Address ..................................................................... 30

6.2.3 IP Address ....................................................................................... 31

6.3 The WAGO Control Center ................................................................... 32

6.3.1 Starting the WAGO Control Center .................................................. 32

6.3.2 “General” Tab .................................................................................. 33

6.3.3 “Autostart Applications” Tab ............................................................. 34

6.3.4 “Users” Tab ...................................................................................... 35

6.3.5 “FTP” Tab ........................................................................................ 36

6.3.6 “HTTP” Tab ...................................................................................... 37

6.3.7 “RAS” Tab ........................................................................................ 38

6.3.8 “Backup/Restore” Tab ...................................................................... 39

6.3.9 "Advanced" Tab ............................................................................... 40

6.3.9.1 Read Memory Consumption ........................................................ 40

6.3.10 Saving the Configuration .................................................................. 42

6.4 Optimizing Web Visualization ............................................................... 43

6.4.1 Starting the Java Virtual Machine as an Applet Viewer .................... 43

6.4.2 Starting Internet Explorer in Full-Screen Mode ................................. 43

6.4.3 Adjustments in the WEBVISU.htm of the Controller ......................... 44

7 Service ..................................................................................................... 45

7.1 Battery Maintenance ............................................................................. 45

List of Figures .................................................................................................. 46

List of Tables .................................................................................................... 47

Manual

Version 1.3.1

Page 5

WAGO PERSPECTO® 762 Notes about this Documentation 5

762-1121 WP 121 SVGA

1 Notes about this Documentation

The WP 121 SVGA 762-1121 shall only be installed and operated according to

the instructions in these operating.

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation

is included, if necessary.

1.1 Scope of Validity

This documentation applies to PERSPECTO-Panel 762-1121 (WP 121 SVGA).

1.2 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Manual

Version 1.3.1

Page 6

6 Notes about this Documentation WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

1.3 Symbols

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Manual

Version 1.3.1

Page 7

WAGO PERSPECTO® 762 Notes about this Documentation 7

762-1121 WP 121 SVGA

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Manual

Version 1.3.1

Page 8

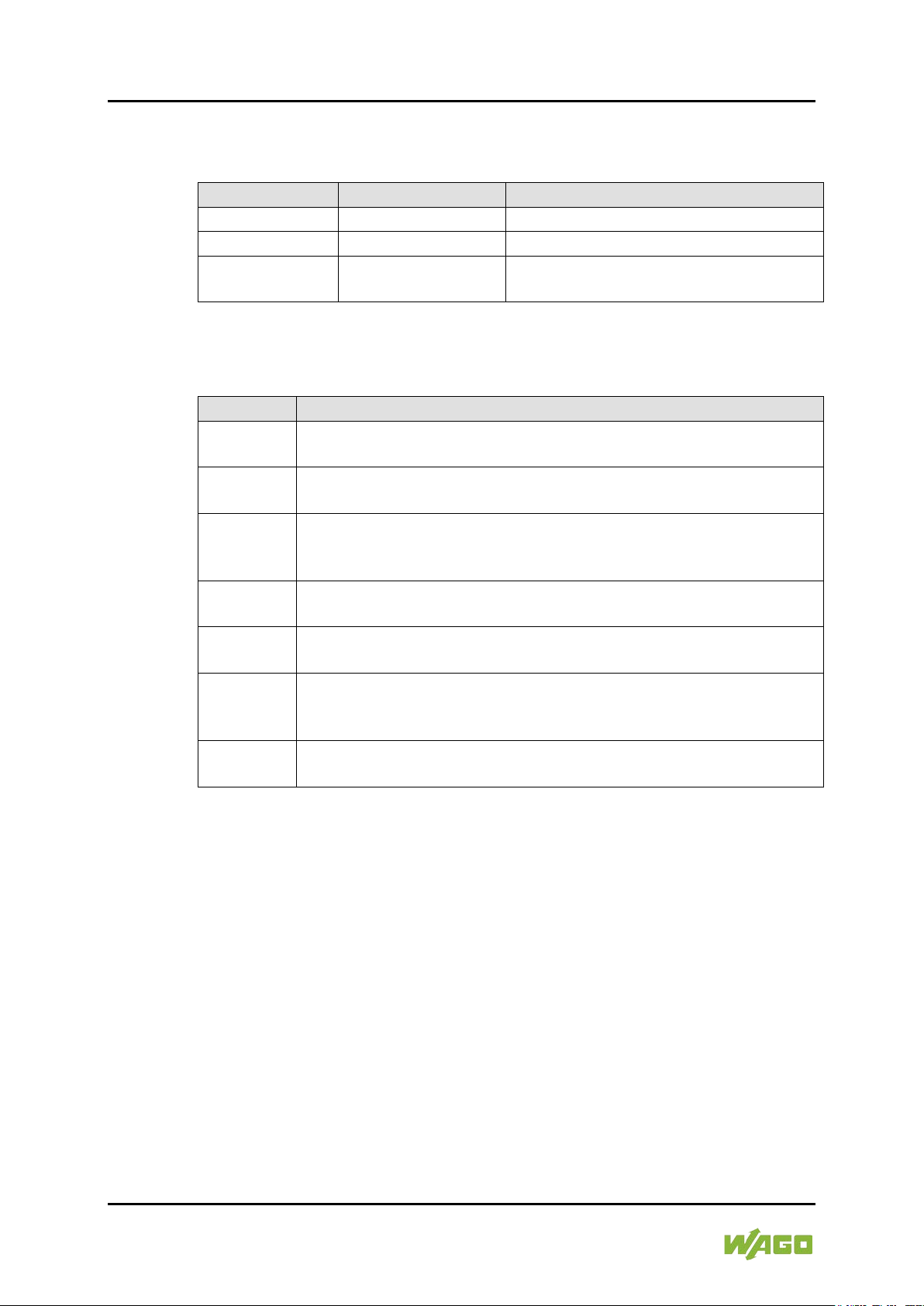

8 Notes about this Documentation WAGO PERSPECTO® 762

Table 1: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated

with dots (.)

Table 2: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

Start of measurement range

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

762-1121 WP 121 SVGA

1.4 Number Notation

1.5 Font Conventions

e.g.: C:\Program Files\WAGO Software

menu item from a menu.

e.g.:

e.g.: Enter the value “4 mA” under

brackets.

.

Manual

Version 1.3.1

Page 9

WAGO PERSPECTO® 762 Important Notes 9

762-1121 WP 121 SVGA

2 Important Notes

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

2.1 Legal Bases

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications. WAGO Kontakttechnik GmbH & Co. KG owns all

rights arising from the granting of patents or from the legal protection of utility

patents. Third-party products are always mentioned without any reference to

patent rights. Thus, the existence of such rights cannot be excluded.

2.1.2 Personnel Qualification

All sequences implemented on Series 762 devices may only be carried out by

electrical specialists with sufficient knowledge in automation technology. These

specialists must be familiar with the current standards and guidelines for the

devices and the automated environments.

All changes to the controller shall always be performed by qualified personnel

with sufficient skills in PLC programming.

2.1.3 Use of the 762 Series in Compliance with Underlying

Provisions

762 Series modules are suitable for use in the area of time control and

automation. Their use extends beyond residential and commercial areas, as well

as industrial areas. Technical data must be observed for all types of applications.

Radio interference in residential areas

This is a class A device. This device can cause radio interference in residential

areas. In this case, the operator may be required to take appropriate measures.

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. These

modules contain no parts that can be serviced or repaired by the user. The

Manual

Version 1.3.1

Page 10

10 Important Notes WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

following actions will result in the exclusion of liability on the part of WAGO

Kontakttechnik GmbH & Co. KG:

• Repairs,

• Changes to the hardware or software that are not described in the

operating instructions,

• Improper use of the components.

Further details are given in the contractual agreements. Please send your

request for modified and new hardware or software configurations directly to

WAGO Kontakttechnik GmbH & Co. KG.

Pixel error in TFT display

Any pixel errors of the TFT display due to production reasons do not represent

grounds for complaint!

Manual

Version 1.3.1

Page 11

WAGO PERSPECTO® 762 Important Notes 11

762-1121 WP 121 SVGA

2.2 Safety Advice (Precautions)

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Install only in appropriate housings, cabinets or in electrical operation

rooms!

The device is an open unit. As such, install it exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to authorized staff only by

means of specific keys or tools.

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for

handling devices/modules.

Clean only with permitted materials!

Clean housing and soiled contacts with propanol.

Manual

Version 1.3.1

Page 12

12 Important Notes WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Do not use in telecommunication circuits!

Only use devices equipped with ETHERNET or RJ-45 connectors in LANs.

Never connect these devices with telecommunication networks.

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Manual

Version 1.3.1

Page 13

WAGO PERSPECTO® 762 Important Notes 13

762-1121 WP 121 SVGA

2.3 Characteristics of the CODESYS Web Visualization

Depending on the version of CODESYS installed

The functionality of the Web visualization depends on the version of CODESYS

"webvisu.jar" Java applet used.

This file is normally the same version as the CODESYS version installed. The

general function of the file is the responsibility of the company 3S. The version

and function be explicitely checked. Always use the most current CODESYS

version from the WAGO-I/O-PRO-CD released by WAGO Kontakttechnik GmbH

& Co. KG.

Please also observe the chapter "CODESYS Web Visualization" in the

CODESYS online help.

The file "webvisu.htm" is the base HTML page for Web visualization and is

copied when installing the WAGO-IO-PRO or WAGO-AUTOMATION-COCKPIT

to the subdirectory <3S Software Installation Directory>\Visu.

Settings can be made in this file to optimize and adjust Web visualization.

Observe the CODESYS online help, chapter "Editing the 'webvisu.htm' file" and

chapter "Optimization of the Web Visualization" > "Adjustments in the

WEBVISU.htm of the Controller".

Limitations of the CODESYS Web visualization

The CODESYS Web visualization contains some limitations and particularities.

In connection with the Web panel, the following description must be observed for

continuous operation: To use this file with the WAGO Web panel, the call for the

function "CookieHandling()" is disabled.

Depending on the visualization elements and Web server used, memory

requirements may continuously increase in the panel. Please regularly check the

memory requirements of the panel. Observe the chapter "The WAGO Control

Center" > "Advanced Tab".

Manual

Version 1.3.1

Page 14

14 Important Notes WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

Response time depends on the number, type and form of the objects

displayed

This device has been designed for presentation of simple CODESYS Web

visualizations. The device establishes communication with a controller (e.g. from

the series 750-88x or 758-8xx) and displays the visualization pages stored there.

Due to the limitations of the technologies used, the following points should be

observed:

The response time depends on the number, type and form of the objects

displayed. The fewer the objects displayed per page, the faster the device

responds.

More time is required the first time a visualization page is called up than

subsequent calls.

There is a delay the first time a visualization page is displayed because it is first

fully compiled in the working memory.

Should it take more than 1 second to compile, a message appears with the text

"Loading ..." to indicate that background activity is underway. When switching to

another visualization page, a copy of the page remains in the cache and

subsequent calls of the page are much faster. Because the size of the cache is

limited, it may not always be possible to store all pages in memory entirely

depending on the application. As a result, you may experience delays later when

calling up the same page.

2.3.1 Description of the Function "CookieHandling()"

The use of this Java Script function results in a continuous memory consumption

on the Web panel.

The last set language for dynamic texts is stored by this mechanism and is

automatically reset at the next call-up of the Web visualization.

This function is not possible on the Web panels. The response corresponds with

that of an Internet browser that does not accept cookies.

Manual

Version 1.3.1

Page 15

WAGO PERSPECTO® 762 Device Description 15

762-1121 WP 121 SVGA

3 Device Description

The 762 Series panels are used to operate and visualize the controllers of the

WAGO-I/O-SYSTEM. The integrated WAGO-AUTOMATION COCKPIT

development environment is used to program the panels and controllers.

3.1 PERSPECTO WP Web Panel

Featuring specialized software, the Web Panel functions as Web browser,

connecting a controller with its own Web server.

With the Web Panels, more control units are easy to add.

The display of CODESYS 2.3 Web visualization is optimized for the Web Panel.

The Web Panels are simple display and HMI devices and have no CODESYS

and HMI runtime of their own.

Manual

Version 1.3.1

Page 16

16 Device Description WAGO PERSPECTO® 762

Table 3: Legend for Figure “Front View”

No.

Description

1

Front panel

2

Touch screen display

762-1121 WP 121 SVGA

3.2 View

3.2.1 Front View

Figure 1: Front View

Manual

Version 1.3.1

Page 17

WAGO PERSPECTO® 762 Device Description 17

Table 4: Legend for Figure “Back View”

No.

Designation

Description

1

-

Housing

2

X1

Connection for 24VDC power supply

RS-232 serial interface (COM 3) and RS-485/RS-422

serial interface (COM 2) as D-sub 9 connector

4

X3

RS-232 serial interface (COM 1) as D-sub 9 connector

5

X4

CAN-Bus 1 (CANopen) interface as D-sub 9 connector

6

X5

CAN-Bus 0 (CANopen) interface as RJ45 jack

7

X8/X9

USB host interfaces

8

X6

ETHERNET interface as RJ45 jack

9

Service

Service button

3V Battery

11

X13

Slot for CF memory card

762-1121 WP 121 SVGA

3.2.2 Back View

Figure 2: Back View

3 X2

10

CR1/2AA

Battery case

Manual

Version 1.3.1

Page 18

18 Device Description WAGO PERSPECTO® 762

Table 5: X1 Pin Assignment

Pin

Assignment

Function

1

+24 V

Supply Voltage

2

0 V GND

Reference potential GND

3

FE

Ground conductor

762-1121 WP 121 SVGA

3.3 Connectors

3.3.1 X1 – Supply Voltage

Use the X1 connection for the device power supply. More information about the

power supply and power consumption is available in the "Technical Data"

section.

Figure 3: Connector X1 – Supply Voltage

Manual

Version 1.3.1

Page 19

WAGO PERSPECTO® 762 Device Description 19

Table 6: X6 Pin Assignment

Pin

Assignment

Function

1

TX+

Transmit Data +

2

TX-

Transmit Data -

3

RX+

Receive Data +

4

n.c. - 5

n.c. - 6

RX-

Receive Data -

7

n.c. - 8

n.c.

-

762-1121 WP 121 SVGA

3.3.2 X6 – ETHERNET Interface

An RJ45 jack is used for the ETHERNET interface.

The connections and cables must meet CAT.5 and the guidelines for ETHERNET

interfaces.

If there are more than 2 devices in a network, then they must be connected to

each other by a HUB or SWITCH. A "1:1" cable is used here.

If there are only 2 devices in a network, a crossover cable can be used.

Figure 4: Connector X6 ‒ ETHERNET RJ45

Manual

Version 1.3.1

Page 20

20 Device Description WAGO PERSPECTO® 762

Table 7: X8/X9 Pin Assignment

Pin

Assignment

Function

1

USB_VCC1

USB +5V DC

2

USB_N1

USB data line N1

3

USB_P1

USB data line P1

4

USB_GND

USB GND

762-1121 WP 121 SVGA

3.3.3 X8/X9 – USB Interfaces

The interfaces are designed as USB host interfaces, type A.

The following table and illustration provide information on the pin assignment of

the interfaces. The interface connection meets the USB specification 2.0.

Figure 5: Connectors X8/X9 – USB Interfaces

Manual

Version 1.3.1

Page 21

WAGO PERSPECTO® 762 Device Description 21

762-1121 WP 121 SVGA

3.4 Battery Case

Do not charge, disassemble or burn the battery!

Incorrect use of the lithium battery contained in this device may cause damage

incurred by fire or chemical burns. The battery must not be charged,

disassembled, burned or exposed to temperatures exceeding 100°C (212°F).

The battery compartment holds a 3 V lithium battery, type CR1/2AA or Z3600A,

that supplies the real time clock and the SRAM with power in case of a power

failure.

If you want to change the lithium battery during a power failure, make sure that

you have the new battery ready to hand. For a certain time a gold cap capacitor

provides the required power. The data of the volatile memory (SRAM) is therefore

preserved during a battery exchange.

At room temperature, the battery has a life span of about one year.

Figure 6: Battery Case

Manual

Version 1.3.1

Page 22

22 Device Description WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

3.5 Slot for Memory Card

The panel 762-1121 is equipped with a Flash memory slot on the side for a CF

card. It supports cards with a 2 GB maximum. Supported memory cards (item no.

758-879/000-000) are available from WAGO.

Manual

Version 1.3.1

Page 23

WAGO PERSPECTO® 762 Device Description 23

762-1121 WP 121 SVGA

3.6 Operating Elements

3.6.1 Service Button

The service switch on the back of the device is used to call up the Windows CD

desktop. The WAGO Control Center can be launched, for example, to configure

the device.

Figure 7: Service Button

Manual

Version 1.3.1

Page 24

24 Device Description WAGO PERSPECTO® 762

Table 8: Technical Data ‒ Housing

Front panel

Anodized aluminium, polyester film

Housing material

Varnished sheet steel

Dimensions (W x H x L)

330 x 268 x 47 mm

Panel cutout (B x H)

312 x 250 mm

Fixing means

6 clamping elements

Surrounding air temperature, operation

0 °C ... +50 °C

Surrounding air temperature, storage

-10 °C ... +60 °C

Relative humidity (without

10 % ... 85 %

Weight

2600 g

Degree of protection

Front IP65,

back IP20

Table 9: Technical Data ‒ Power Supply

Voltage supply

DC 24 V (18 ... 30 V)

Max. input current (24 V)

500 mA

Operating power

10 ... 18 W

Buffer battery

CR 1/2 AA

Table 10: Technical Data ‒ Display

Display type

TFT

Screen size (diagonal)

30,7 cm (12,1“)

Display colors

65.536

Graphics resolution

800 x 600 pixels

Contrast ratio

500:1

Angle of view horizontal / vertical

-65° ... 65° / -75° ... 45°

Brightness

400 cd/m²

HBT*

50.000 hrs.

Panel

Touch, analog, resistive

Light transmission

typ.

80 %

Durability

10 Mio. activations with finger

762-1121 WP 121 SVGA

3.7 Technical Data

3.7.1 Housing

condensation)

3.7.2 Power Supply

3.7.3 Display

* HBT (Half Brightness Time) defines the LED chip brightness decrease to

50% original brightness at Ta = 25 ± 2°C and RH = 60 ± 10%.

Manual

Version 1.3.1

Page 25

WAGO PERSPECTO® 762 Device Description 25

Table 11: Technical Data ‒ Hardware

Processor

32 Bit XScale 520 MHz

RAM / Flash / SRAM

64 MB / 32 MB / 1 MB

Memory expansion

CF-Card (max. 2 GB)

Table 12: Technical Data ‒ Software

Operating system

Windows CE 5.0

Software configuration

Internet browser

panel configuration software

Table 13: Technical Data ‒ Interfaces

USB interface

2 x USB2.0 Host (Type A)

Ethernet interface

1 x 10/100 Mbit RJ-45

Maximum length of connecting cables

USB: maximum 3 m

supply

762-1121 WP 121 SVGA

3.7.4 Hardware

3.7.5 Software

Java Virtual Machine

3.7.6 Interfaces

Power supply: maximum 3 m to power

Manual

Version 1.3.1

Page 26

26 Device Description WAGO PERSPECTO® 762

Conformity Marking

762-1121 WP 121 SVGA

3.8 Approvals

The following approvals have been granted to 762-1121 panels:

3.9 Standards and Guidelines

762-1121 panels meet the following requirements on emission and immunity of

interference:

EMC CE-Immunity to interference EN 61000-6-2

EMC CE-Emission of interference EN 61000-6-4

Manual

Version 1.3.1

Page 27

WAGO PERSPECTO® 762 Mounting 27

762-1121 WP 121 SVGA

4 Mounting

4.1 Front Panel Installation

The devices are intended for installation in switch cabinets, for example.

Vertical installation of the panels is recommended.

Note about differing mounting position!

The operating temperature ranges specified in the technical data apply to the

recommended mounting position. If the panel is mounted in a position different

than recommended, cooling can be affected. Contact WAGO Service for more

information.

The PERSPECTO Series panels are used in the panel cutout provided and bolted

down with the included clamping elements from behind (note the following

installation diagram).

Figure 8: Installation of the Clamping Elements

Information on the dimensions of the panel cutout is available in the Technical

Data section.

Manual

Version 1.3.1

Page 28

28 Connect Devices WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

5 Connect Devices

5.1 Supply voltage

Connect the supply voltage to contact 1 (24 VDC) and contact 2 (GND) of the

included 734-103 female connector. Use an appropriate operating tool to open

the CAGE CLAMP

cross section of max. 1.5 mm² into the connections and remove the operating

tool.

5.2 Grounding

Connect the functional earth to the grounding screws or lugs on the housing and

to contact 3 (FE) of the included female connector as described in the previous

section. Plug the female connector onto the X1 male connector (power) and then

verify that the clamping connection is secured.

®

connections. Feed the 7 mm stripped conductors with a

5.3 Peripheral Devices

The interfaces to the back of the device are used to connect the peripheral

devices electrically. The number and arrangement of the interfaces depend on

the design (note the information in the "Technical Data" chapter or “Connection”

chapter).

The Ethernet interface is used for connection to a LAN.

The USB master interfaces are used for connecting to a keyboard, mouse or

USB stick. Because there are a large number of USB devices on the market, no

guarantee can be made about the function of individual devices.

Manual

Version 1.3.1

Page 29

WAGO PERSPECTO® 762 Commissioning 29

762-1121 WP 121 SVGA

6 Commissioning

6.1 Switch on

After applying the power supply, the device switches on automatically.

After the boot and self-test phase that lasts about 10 seconds, the programs set

in the WAGO Control Center (e.g. HMI runtime) are launched automatically.

To stop the programs and Windows CE desktop for configuring the panels from

launching automatically, the touch screen must be touched within a adjustable

time period (default setting 3 s) after the boot & self-test phase.

The service switch on the back of the device can be used to launch the Windows

CE desktop at any time.

The WAGO Control Center can be used to change the start behavior of the

device.

Time window for launching the Windows CE desktop!

The WAGO Control Center can be used to set the time window for launching the

Windows CE desktop after the boot and self-test phase.

If the time is set to 0, the Windows CE desktop can only be launched by the

service switch.

Manual

Version 1.3.1

Page 30

30 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.2 IP Address of the Device

6.2.1 General

The Web panels communicate with the Web server via the TCP/IP protocol.

Therefore, a TCP/IP connection is required. An IP address must be assigned to

the device after switching it on for the first time.

The WAGO Control Center installed on the device is used to assign the IP

address by default (observe "Setting the IP Address" section).

The device can either draw its IP address from a DHCP server on the network or

the device can be assigned a fixed IP address.

The current IP address can be queried by double-clicking on the network icon in

the system tray in the task bar.

DHCP / fixed IP address

The device must be connected to a network to change the IP address from

DHCP to a fixed IP address.

6.2.2 Setting the IP Address

The WAGO Control Center is used to set the IP address. Call up the WAGO

Control Center from the Start menu:

Start > Programs > Utilities > WAGO Control Center

1. Click the Advanced tab and then on the [LAN] button.

2. In the "Adapter Settings", click on the IP Address tab.

3. Enter the desired IP address and click [OK] to confirm.

Manual

Version 1.3.1

Page 31

WAGO PERSPECTO® 762 Commissioning 31

762-1121 WP 121 SVGA

Figure 9: IP Address

6.2.3 IP Address

When using a crossover cable to connect between the panel and configuring PC

directly, it is recommended that both devices have fixed IP addresses with an open

address in the range 192.168.1.xxx.

In this case, the subnet mask is automatically set to 255.255.255.0. There is no

default gateway.

IP Address

The devices must be set to different IP addresses.

Manual

Version 1.3.1

Page 32

32 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.3 The WAGO Control Center

The WAGO Control Center can be used to configure the device. Settings for the

Autostart programs, uses, FTP/HTTP and RAS access can be made. General

device settings can also be checked and modified.

6.3.1 Starting the WAGO Control Center

The WAGO Control Center is launched from the Start menu:

Start > Programs > Utilities > WAGO Control Center

The tabs of the WAGO Control Center are explained on the following pages.

Manual

Version 1.3.1

Page 33

WAGO PERSPECTO® 762 Commissioning 33

762-1121 WP 121 SVGA

6.3.2 “General” Tab

Figure 10: “General” Tab

Device Information

Information about the device is found here. This information is important, for

example, for support cases.

General

Watchdog:

A watchdog can be configured here, which can restart the device if it

crashes after a set time.

Don’t start Windows CE Shell:

If the checkbox is enabled, the Windows CE desktop can no longer be

launched. The task bar is no longer displayed.

Simple Network Time protocol:

If there is an Internet connection, the system clock of the device can be

synchronized via an SNTP server.

Client Only

If the checkbox is enabled, the internal SNTP server is disabled.

Manual

Version 1.3.1

Page 34

34 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.3.3 “Autostart Applications” Tab

You can enter programs here that should launch automatically after booting. The

HMI runtime is entered here by default.

The time window for launching the programs after the boot and self-test phase of

the device can also be set here.

Figure 11: “Autostart Applications” Tab

Enter the program to be called in the "Application:" line and the parameters to be

passed in the "Arguments" line.

Example:

Application: Flashdisk\CrEme\bin\CrEme.exe

Arguments: -cf Flashdisk\creme.cfg 'http://192.168.1.1/plc/webvisu.htm'

Manual

Version 1.3.1

Page 35

WAGO PERSPECTO® 762 Commissioning 35

762-1121 WP 121 SVGA

6.3.4 “Users” Tab

You can create FTP users, grant rights and assign directories. The menu is

generally self-explanatory.

Figure 12: “Users” Tab

User/Virtual Roots:

A directory from another (protected) tree, for example, can be put in the user's

home directory. By doing so, you gain access to this and subsequent directories.

FTP Home Directory/HTTP directory path:

The user starts downwards from this menu. The use cannot get to higher-level

directories.

Rights:

Access rights assigned to users are displayed here.

Access Rights

If no home directory is set for a user, the user gets FULL ACCESS to the panel

despite disabled write access. Enter at least on \ in the home directory.

Manual

Version 1.3.1

Page 36

36 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.3.5 “FTP” Tab

You can configure the FTP server of the device here.

More information about creating users is available in the "Users Tab" section.

Figure 13: “FTP” Tab

Manual

Version 1.3.1

Page 37

WAGO PERSPECTO® 762 Commissioning 37

762-1121 WP 121 SVGA

6.3.6 “HTTP” Tab

You can configure the Web server of the device here.

Figure 14: “HTTP” Tab

Application example:

An \httptest directory with the /test alias was created on the flash disk.

A Web page index.htm was created in this directory.

The page can be used in a Web browser to access the following address:

http://[IP address of the device]/test

Manual

Version 1.3.1

Page 38

38 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.3.7 “RAS” Tab

The Remote Access Service (RAS) is a service for remote access to a Windows

CE device.

Figure 15: “RAS” Tab

Both RAS functions, server and client, are supported.

The connection between a RAS client and the RAS server can be established via

a modem, VPM or direct connection.

For more information about the Remote Access Service (RAS) of the device,

please contact WAGO Support.

Manual

Version 1.3.1

Page 39

WAGO PERSPECTO® 762 Commissioning 39

762-1121 WP 121 SVGA

6.3.8 “Backup/Restore” Tab

You can save and restore the device configuration and project data, for example,

on a memory card.

Figure 16 “Backup/Restore” Tab

The [Backup] button is used to save the parameters defined in the

backup_restore.cfg and entries on the target data carrier.

The [Restore] button is used to restore the parameters defined in the

backup_restore.cfg and entries on the device.

Create backup!

It is recommended that you create a backup after commissioning the device and

to keep the backup in a safe place.

Operating system update!

There is no operating system update for the device.

Manual

Version 1.3.1

Page 40

40 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.3.9 "Advanced" Tab

You can perform advanced settings for the device. The menu is generally selfexplanatory.

Figure 17: "Advanced" Tab

6.3.9.1 Read Memory Consumption

Click the [System …] button and select the [Memory] tab.

Manual

Version 1.3.1

Page 41

WAGO PERSPECTO® 762 Commissioning 41

762-1121 WP 121 SVGA

Figure 18: Memory Consumption

A progress bar displays the memory consumption.

Manual

Version 1.3.1

Page 42

42 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.3.10 Saving the Configuration

After configuring the panel, the settings must be permanently saved in the

registry. Call up the following utility program:

Start -> Programs -> Utilities -> Save Registry

Fail-safe saving of the configuration!

If the settings are not saved as described, they are lost when the device is

restarted.

Manual

Version 1.3.1

Page 43

WAGO PERSPECTO® 762 Commissioning 43

762-1121 WP 121 SVGA

6.4 Optimizing Web Visualization

The following settings have been made to optimize visualization.

6.4.1 Starting the Java Virtual Machine as an Applet Viewer

The following call is enabled by default in the Autostart Applications tab.

Application: Flashdisk\CrEme\bin\CrEme.exe

Arguments: -cf Flashdisk\creme.cfg 'http://192.168.1.1/plc/webvisu.htm'

Change the IP address based on your application.

To connect an IPC to the Web panel, please use the following syntax for the

URL: "http://192.168.1.1:8080/webvisu.htm".

To keep the call line short and simple, most settings are saved to a configuration

file.

The name of the configuration file with path is passed to the application by the -cf

parameter.

Recommended start version

This start version is recommended in connection with CODESYS.

Example: Content of the configuration file "Flashdisk\creme.cfg"

(with comments not included in the file)

-x800 Width of the display in pixels

-y600 Height of the display in pixels

-ntb Disables the window header line, full screen mode

-ml 20000 Set memory limit to 20000 KB

-aa 1 Anti Aliasing Level (from 0 (no anti-aliasing)) to 5 (best quality))

-av Start Java Virtual Machine (JVM) as an applet viewer

6.4.2 Starting Internet Explorer in Full-Screen Mode

Internet Explorer can also be started in full-screen mode. The "iesimple.exe" file

is launched.

Make the following settings:

Enter the following command in the Autostart Applications tab for starting

Internet Explorer:

Application: \FlashDisk\SysExtras\Tools\iesimple.exe

Arguments: IP address of the page to be displayed

Manual

Version 1.3.1

Page 44

44 Commissioning WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

6.4.3 Adjustments in the WEBVISU.htm of the Controller

In CODESYS version 2.3.9.28, changes have been made to the "webvisu.jar"

java applet for the Web visualization.

To optimize performance of the PERSPECTO panel, the following two

parameters have been adjusted in the "WebVisu.htm" and "WebVisu_wago.htm"

files:

<param name="UPDATETIME" value="100">

<param name="USEURLCONNECTION" value="False">

After installation of the WAGO-CODESYS application, the htm files and jar file

are located in the CODESYS installation directory.

Example path: C:\Program Files\WAGO Software\CODESYS V2.3\visu

Manual

Version 1.3.1

Page 45

WAGO PERSPECTO® 762 Service 45

762-1121 WP 121 SVGA

7 Service

7.1 Battery Maintenance

Do not charge, disassemble or burn the battery!

Incorrect use of the lithium battery contained in this device may cause damage

incurred by fire or chemical burns. The battery must not be charged,

disassembled, burned or exposed to temperatures exceeding 100°C (212°F).

Replace the battery only with an identical one!

Only replace the lithium battery with an identical one. Use of another type of

lithium battery may present a risk of fire or explosion.

Data loss!

If the device is switched off when the battery has failed or has reached its

capacity without replacing the battery, any settings not saved are lost.

The battery in the device control buffers the adjustable parameters and the time

for a power failure or switched off device.

Replace the battery as follows:

1. Make sure that the device has been on for at least 10 minutes before

replacing the battery, allowing the buffer capacitors to load.

2. Switch off the power supply.

3. Remove the buffer battery and install a new one.

4. Restore the power supply.

5. Dispose the discharged battery immediately in a proper manner.

Manual

Version 1.3.1

Page 46

46 List of Figures WAGO PERSPECTO® 762

762-1121 WP 121 SVGA

List of Figures

Figure 1: Front View ...........................................................................................16

Figure 2: Back View ...........................................................................................17

Figure 3: Connector X1 – Supply Voltage ...........................................................18

Figure 4: Connector X6 ‒ ETHERNET RJ45 ......................................................19

Figure 5: Connectors X8/X9 – USB Interfaces ...................................................20

Figure 6: Battery Case .......................................................................................21

Figure 7: Service Button .....................................................................................23

Figure 8: Installation of the Clamping Elements ..................................................27

Figure 9: IP Address ..........................................................................................31

Figure 10: “General” Tab ....................................................................................33

Figure 11: “Autostart Applications” Tab ..............................................................34

Figure 12: “Users” Tab .......................................................................................35

Figure 13: “FTP” Tab ..........................................................................................36

Figure 14: “HTTP” Tab .......................................................................................37

Figure 15: “RAS” Tab .........................................................................................38

Figure 16 “Backup/Restore” Tab ........................................................................39

Figure 17: "Advanced" Tab.................................................................................40

Figure 18: Memory Consumption .......................................................................41

Manual

Version 1.3.1

Page 47

WAGO PERSPECTO® 762 List of Tables 47

762-1121 WP 121 SVGA

List of Tables

Table 1: Number Notation ................................................................................... 8

Table 2: Font Conventions .................................................................................. 8

Table 3: Legend for Figure “Front View” .............................................................16

Table 4: Legend for Figure “Back View” .............................................................17

Table 5: X1 Pin Assignment ...............................................................................18

Table 6: X6 Pin Assignment ...............................................................................19

Table 7: X8/X9 Pin Assignment ..........................................................................20

Table 8: Technical Data ‒ Housing.....................................................................24

Table 9: Technical Data ‒ Power Supply ............................................................24

Table 10: Technical Data ‒ Display ....................................................................24

Table 11: Technical Data ‒ Hardware ................................................................25

Table 12: Technical Data ‒ Software ..................................................................25

Table 13: Technical Data ‒ Interfaces ................................................................25

Manual

Version 1.3.1

Page 48

Loading...

Loading...