Wago 750 Series, 753 Series General Product Information

I/O System – 750 and 753 Series – One System for Every Application

General Product Information

One System for Every Application

The WAGO-I/O-SYSTEM 750/753 is

characterized by its universal application

scope and extensive product portfolio.

With more than 500 dierent modules,

the versatility and exibility is so great

that virtually every requirement in a wide

range of industries is covered.

Industrial Automation

The comprehensive selection of I/O

modules for dierent potentials and

signal types saves time and money

because the sensors/actuators can be

wired directly – even in safety-related

applications.

Building Automation

The broad portfolio enables exible, cellar-to-ceiling solutions with conventional

O modules, standardized industry-spe-

I/

cic eldbus protocols and subsystems

for typical applications in lighting, shading, heating, HVAC andmuchmore.

Marine and Onshor

tion

International approvals coupled with

industry-specic features permit use in

shipbuilding and other harsh sectors.

Addressing requirements inherent in

specic industries and operating environments has enabled use on marine

els and in the EMC-sensitive area of

dies

a vessel’s bridge. Because the requirements are signicantly greater for immunity to interference or emission of interference, along with superior mechanical

performance in these sensitive areas,

the WAGO-I/O-SYSTEM can readily meet

the needs of other industries.

e/Oshore Automa-

Maximum Fieldbus Independence

The system’s modularity is also reected in

its support for numerous eldbus systems

and ETHERNET standards. Depending on

the application, it is possible to choose

between eldbus couplers and communica

tion modules for dierent protocols.

Eas

y to Use

A modular, DIN-rail-mount design permits

easy installation, expansion and modi

cation of the I/O node without tools. The

eamlined design prevents installation

str

errors. In addition, proven CAGE CLAMP®

technology oers fast, vibration-proof and

maintenance-free connections that are

independent of operator skill. Depending on

the I/O module’s granularity, eld peripher

als can be directly wired using 1-, 2-, 3- or

wire technology.

4-

Worldwide Approvals

International approvals for building and

industrial automation, as well as the process

and marine industries, guarantee worldwide

use – even under more rigorous operating

conditions including ATEX, BR-Ex, IECEx,

UL508, UL ANSI/ISA, AEx and numerous

marine certications.

-

-

-

r

Extremely Compact

WAGO’s patented mechanical design leads

to extremely compact I/O nodes. In fact, it

can accommodate up to 16 channels in a

module width of 12mm (1/2″).

• Finely granular I/O modules provide node

customization.

• Space-saving design permits high integration density and direct connection.

Maximum R

The WAGO-I/O-SYSTEM is engineered and

tested for use in the most demanding environments in accordance with the highest

standar

plications. The system is distinguished from

other pr

industrial use because of:

• Greatly increased vibration rating

• Signicantly greater immunity to interfer-

ence (ESD)

• Lower emission of interference

• Larger voltage uctuation range

• Greater durability for continuous operation

in upper temperature ranges

In addition, CAGE CLAMP® spring pressure

connections ensure superior reliability.

Integrated QA measures in the production

process and 100% function testing ensure

consistent quality.

Clear Identication

Module functionality is identied via

integrated or pluggable marker carriers.

Terminal assignment and technical data are

printed onto the side of the I/O module. WA-

GO’s WSB Marking System also allows for

module

eliability and Ruggedness

ds, e.g., those required in marine ap-

oducts that are solely intended for

- and channel-related identication.

Process Automation

Even under the harshest environmental

conditions, use is possible with special

approvals. Potential hazardous area applications include oil and gas production,

the chemic

tion. The WAGO-I/O-SYSTEM can be

installed in Z

safe I/O modules, making it possible to

connect sensors/actuators in Zones

1/21 and 0/20.

al industry and power genera-

one 2/22 with its intrinsically

&

Advantages:

• Fieldbus-independent – support all standard eldbus protocols and ETHERNET

standards

• Flexible platform adapts to diverse applications and environments

• Tested and approved worldwide

• Extensive range of accessories for marking systems and connection technologies

• Vibration-proof, fast and maintenance-free CAGE CLAMP® connections

I/O System – 750 and 753 Series

Variants

Pluggable Connector Functional Safety Use in Hazardous Areas

The pluggable connections of the WAGO-I/O-

SYSTEM 753 allow quick and safe replace

ment. Optional coding pins prevent inserting

the pluggable connector in the wrong I/O

module. Replacing and connecting the I/O

module requires no further action and elimi

nates possible errors – essentially serving as

permanent wiring. Alternatively, eld wiring

is possible via interface modules that can be

connected to the I/O system using a ribbon

cable (see “Types”).

Extended Temperature Range

-

-

In the European Union, the machinery direc-

tive denes the requirements for machine

and system safety. This ensures a uniform

standard for the protection of “life and limb”

for people within a machine’s operating area.

The required risk assessment is based

on harmonized standards (e.g., EN 13849)

that identify existing risks and required risk

reduction (SIL or PL quality). Based on the

risk assessment, safety functionality can be

implemented, e.g., by presence detection

or protection zone violations using secure

switches or light arrays to immediately shut

down the “risk.” For this purpose, the safety

signals are detected by the “yellow” safety

modules and transmitted via “PROFIsafe” to

the fail-safe PLC for further processing. The

result is then executed via safe actuator (e.g.,

output module or controller).

The uniquely characteristic safety values

of the WAGO modules facilitate calculation

of the nal safety function up to Cat. 4/PLe

according to EN 13849, or SIL3 according to

EN 62061 or IEC 61511.

In many plants across the chemical and

petrochemical industries, as well as in the

production and process automation sectors,

installations are operated that process explosive gas- or dust-air mixtures. This is why

electrical equipment must be explosion-proof

in order to avoid injuries to personnel and

damage to facilities.

The modules within the WAGO-I/O-SYSTEM

750 are designed for use in both non-hazardous and hazardous areas.

The direct application of eldbus technology

in hazardous areas is typically resource-intensive. When used in hazardous areas of

Zone 2/22, the WAGO-I/O-SYSTEM 750 offers a safe, easy and economical connection

to the sensors and actuators of Zones 0/20

and 1/21. The “blue” Ex i I/O modules were

specially developed for this purpose. They

form an intrinsically safe section that can

be integrated into a standard eldbus node,

oering all the advantages of state-of-the-art

eldbus technology. The WAGO-I/O-SYSTEM

750 is also approved for mining applications.

Industrial automation technology is typically

operated in temperatures ranging from 0 °C

to 55 °C. However, there are applications that

require an extended temperature range.

For these applications, WAGO oers a line of

WAGO-I/O-SYSTEM 750 products for tem

peratures ranging from −20°C to +60°C.

For extreme applications, where even this

extended temperature range is not sucient,

the WAGO-I/O-SYSTEM 750 XTR is available.

-

The mixed operation of safe and conventional

I/O modules streamlines system conguration. For increased electromagnetic immu-

nity (EMC standard), WAGO oers compact

power supply lter modules. Specic power

supply features must be considered, which

are described in detail in the corresponding

manuals.

I/O System – 750 and 753 Series

Interfaces and Types

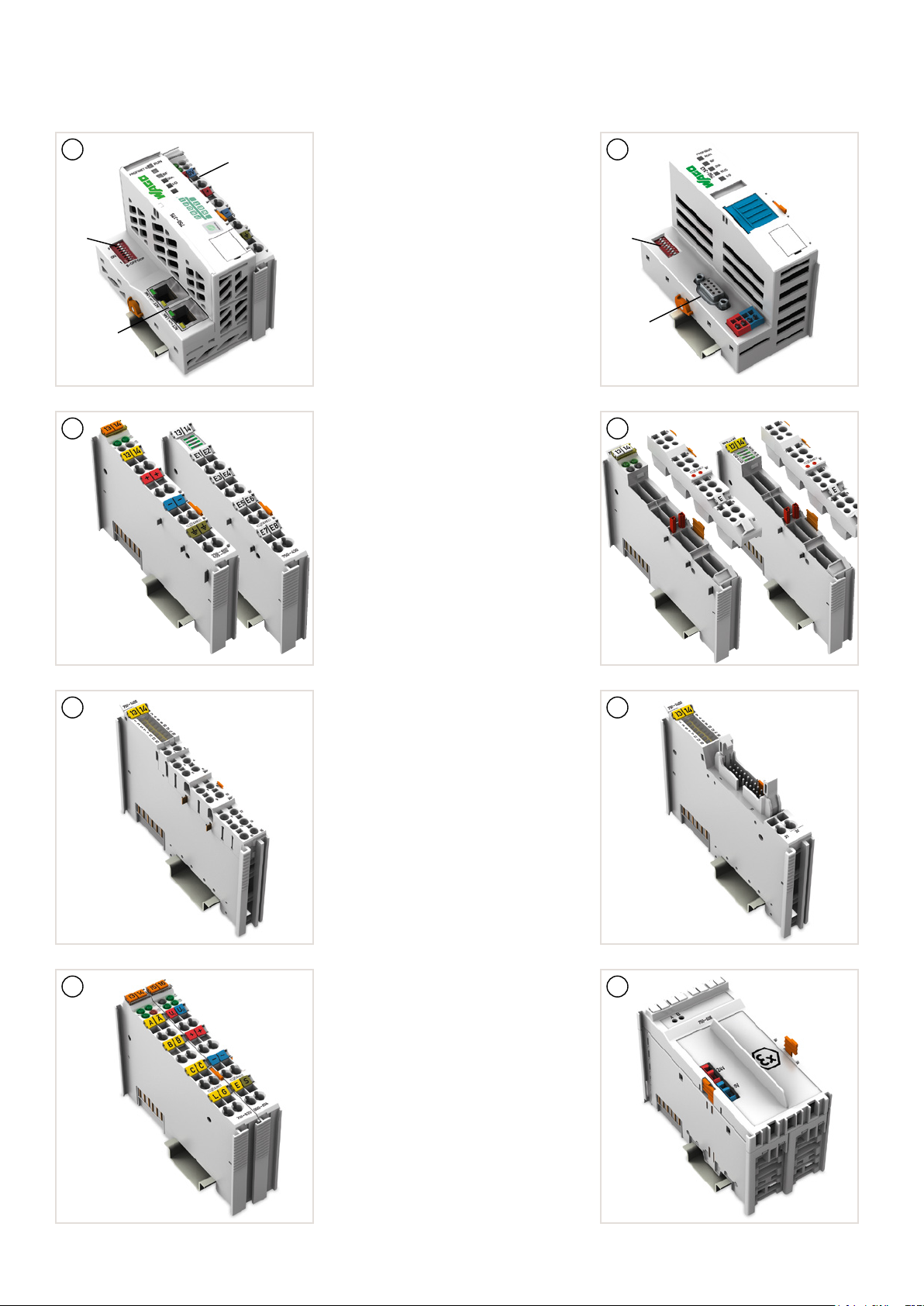

A

b)

c)

C

a)

Housing design: eldbus coupler (A)

• Including supply module (a) to power down

stream I/O modules

• Technical dierences on the connection

level; optional addressing switch (b) and

eldbus interface (c)

• W x H x D (mm) 50.5 x 71.1 x 100 or

• W x H x D (mm) 61.5 x 71.9 x 100

Housing design: eldbus coupler ECO (B)

• Restriction on power supply and data width

• W x H x D (mm) 49.5 x 71.9 x 96.8

Housing design: 750 (C)

• 8 connection points (CAGE CLAMP®)

• W x H x D (mm) 12 x 69.8 x 100 (4 LEDs)

• W x H x D (mm) 12 x 67.8 x 100 (8 LEDs)

Housing design: 753 (D)

• Pluggable Connector

• 8 connection points (CAGE CLAMP®)

• W x H x D (mm) 12 x 69.8 x 100 (4 LEDs)

• W x H x D (mm) 12 x 69 x 100 (8 LEDs)

• Pluggable connectors and coding ngers

are not included.

B

-

b)

c)

D

E

G

Housing design: 750 (E)

• 16 connection points (Push-in CAGE

CLAMP®)

• W x H x D (mm) 12 x 69 x 100

Housing design (F)

• For time-saving wiring between I/O system

and interface modules

• Ribbon cable connection to interface

modules (289 and 704 Series) and interface

adapter

• W x H x D (mm) 12 x 74.1 x 100

Housing design: double width (G)

• Some modules are integrated into a double

housing to address specic technological

needs. Despite utilizing the same standard

ized housing, these modules are twice as

wide.

• W x H x D (mm) 24 x 69.8 x 100

Special housing design (H)

• Some modules are integrated into a spe

cialized housing with a specic width and

pluggable connectors. The dimensions are

specied on the respective catalog page.

-

F

H

-

Loading...

Loading...