Page 1

Data sheet | Item number:750-8208/025-001

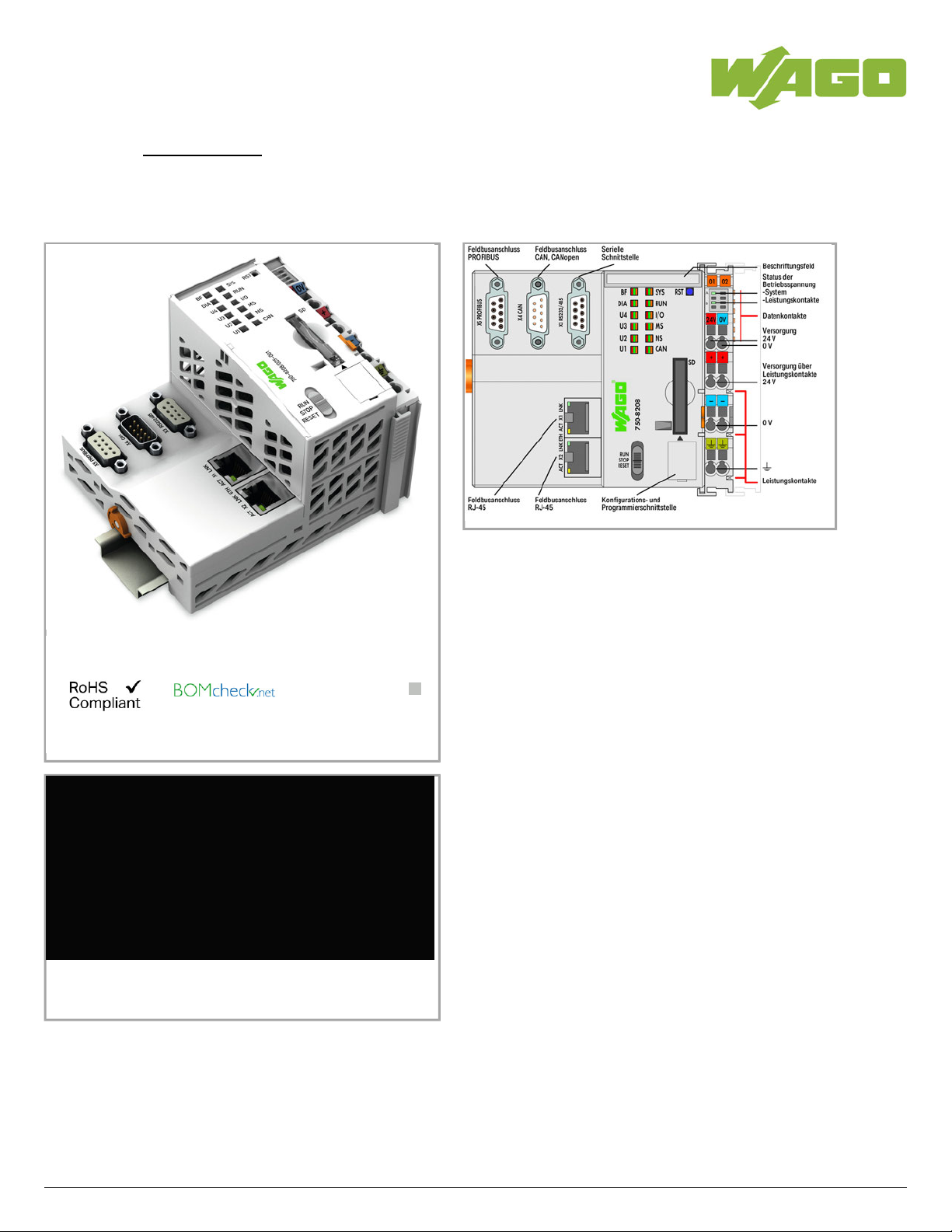

Controller PFC200; 2 x ETHERNET, RS-232/-485, CAN, CANopen, PROFIBUSMaster; Telecontrol technology; Ext. Temperature; light gray

Color:

750-8208_025-001

20.08.2019Page /1 15

Page 2

Data sheet | Item number:750-8208/025-001

Item description

The PFC200 Controller is a compact PLC for the modular WAGO-I/O-SYSTEM. Besides network and fieldbus interfaces, the controller supports all

digital, analog and specialty modules found within the 750/753 Series.

Two ETHERNET interfaces and an integrated switch enable line topology wiring.

An integrated Webserver provides user configuration options, while displaying PFC200 status information.

Besides the processing industry and building automation, typical applications for the PFC200 include standard machinery and equipment control (e.

g., packaging, bottling and manufacturing systems, as well as textile, metal and wood processing machines).

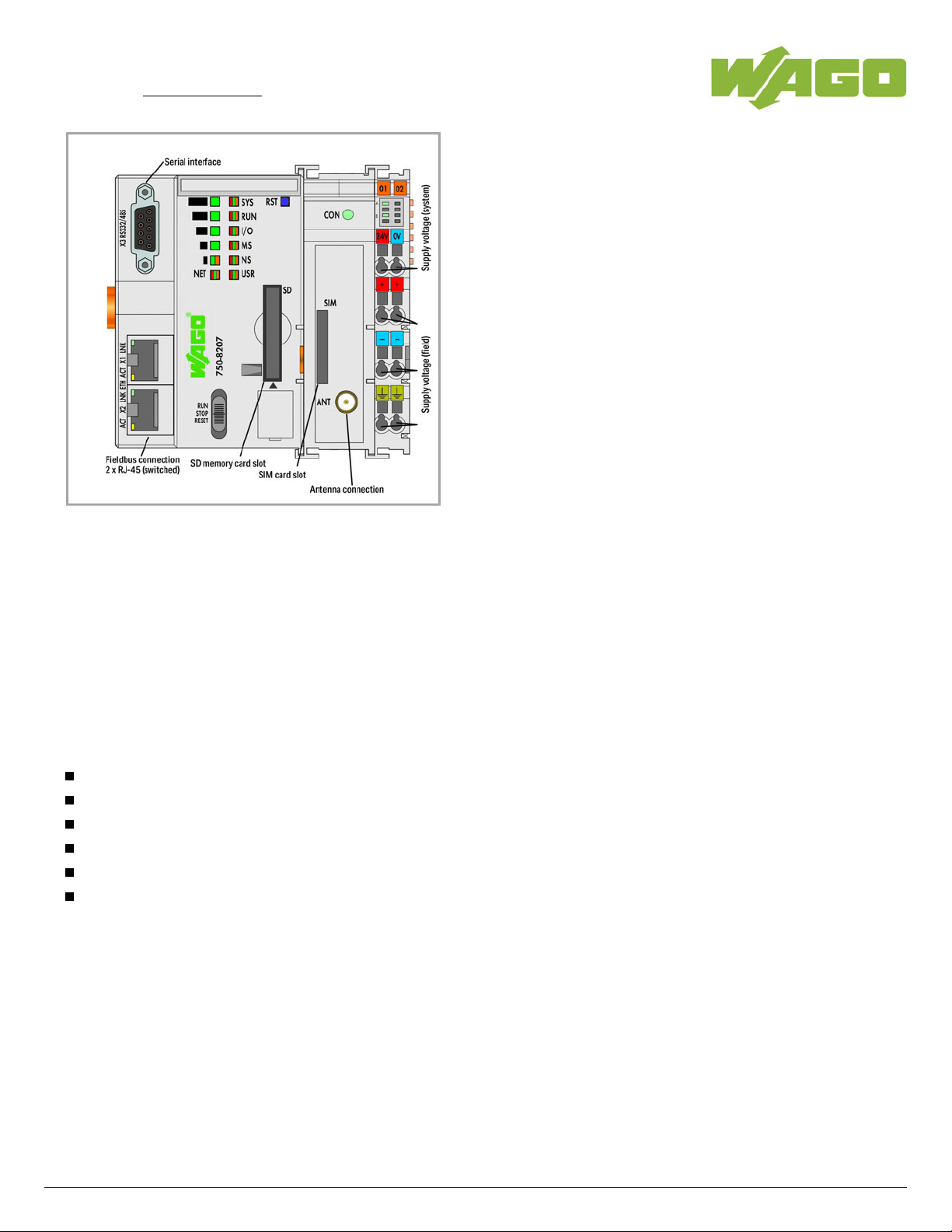

Programming per IEC 61131-3

Programmable via WAGO-I/O-PRO V2.3

Direct connection of WAGO I/O modules

2 x ETHERNET (configurable), RS-232/-485, CAN, CANopen, PROFIBUS DP Master

Linux operating system with RT‐Preempt patch

Configuration via CODESYS or Web-Based Management interface

Maintenance-free

Data

Technical Data

Communication PROFIBUS

CANopen

Modbus (TCP, UDP)

Ethernet

Modbus RTU

Telecontrol protocols

RS-232 serial interface

750-8208_025-001

20.08.2019Page /2 15

Page 3

Data sheet | Item number:750-8208/025-001

RS-485 interface

MQTT

Ethernet protocol DHCP

DNS

NTP

FTP

FTPS

SNMP

HTTP

HTTPS

SSH

Telecontrol protocols IEC 60870-5-101/-103/-104

IEC 61400-25

IEC 61850-7

DNP3

Visualization Web-Visu

Operating system Real-time Linux (with RT-Preempt patch)

CPU Cortex A8, 600 MHz

Programming languages per IEC 61131-3 Instruction List (IL)

Ladder Diagram (LD)

Function Block Diagram (FBD), Continuous Function Chart (CFC)

Structured Text (ST)

Sequential Function Chart (SFC)

Programming environment WAGO-I/O-PRO V2.3 (based on CODESYS V2.3)

Configuration options WAGO-I/O-CHECK

Web-based management

Baud rate (communication/fieldbus 1) 10/100Mbit/s

Baud rate ETHERNET:10/100Mbit/s

Transmission medium (communication/fieldbus) ETHERNET:Twisted Pair S-UTP; 100 Ω; Cat. 5; Line length (max.):

100 m

Main memory (RAM) 256 MB

Internal memory (flash) 256 MB

Hardware non-volatile memory 128 Kbytes

Program memory 16MB

Data memory 64MB

Software non-volatile memory 128 Kbytes

Type of memory card SD and SDHC up to 32 GB (All guaranteed properties are only valid

in connection with the WAGO 758-879/000-001 memory card.)

Memory card slot Push-push mechanism, sealable cover lid

Number of modules per node max. 250

Number of I/O modules without bus extension max. 64

Input and output process image (internal) max. 1000Worte/1000Worte

Input and output process image (MODBUS) max. 1000Worte/1000Worte

Input and output process image (PROFIBUS) max. 2500Worte/2500Worte

Input and output process image (CAN) max. 2000Worte/2000Worte

Indicators LED (SYS, RUN, I/O, CAN, BF, DIA, U1 U4) red/green/orange:

750-8208_025-001

20.08.2019Page /3 15

Page 4

Data sheet | Item number:750-8208/025-001

Status system, program, internal data bus, CANopen, PROFIBUS,

PROFIBUS diagnostics, status programmable by user (can be used

via CODESYS library); LED (A, B) green: System power supply status,

field supply

System supply voltage

DC24V(-25 +30%);via wiring level (CAGE CLAMP connection)

®

Input current typ. at rated load (24 V) 670 mA

Total current for system supply 1700 mA

Field supply voltage DC24V(-25 +30%);via power jumper contacts

Current carrying capacity of the power jumper contacts 10 A

Number of outgoing power jumper contacts 3

Isolation 500 V system/supply

Connection data

Connection technology: communication/fieldbus PROFIBUS:1 x D-Sub 9 socket;CANopen:1 x D-Sub 9

connector;Modbus TCP/UDP:2 x RJ-45;Modbus RTU:1 x D-Sub 9

socket;RS-232 serial interface:1 x D-sub 9 socket;RS-485

interface:1 x D-Sub 9 socket;Telecontrol protocols:1 x D-Sub 9

socket;Telecontrol protocol IEC 60870-5-104:1 x

?;Fernwirkprotokoll IEC 61850:1 x RJ-45;Fernwirkprotokoll DNP3:1

x RJ-45 oder Buchse D-Sub 9

Connection technology: system supply

2 x CAGE CLAMP

®

Connection technology: field supply

6 x CAGE CLAMP

®

Connection type (1) System/field supply

Solid conductor 0.08 2.5mm²/ 28 14AWG

Fine-stranded conductor 0.08 2.5mm²/ 28 14AWG

Strip length 8 9mm/ 0.31 0.35inch

Connection technology: Device configuration 1 x 4-pole male connector

Geometrical Data

Width 112mm/ 4.409inch

Height 71.9mm/ 2.831inch

Height from upper-edge of DIN-35 rail 64.7mm/ 2.547inch

Depth 100mm/ 3.937inch

Mechanical data

Weight 263.7 g

Color light gray

Housing material Polycarbonate, polyamide 6.6

Conformity marking CE

750-8208_025-001

20.08.2019Page /4 15

Page 5

Data sheet | Item number:750-8208/025-001

Environmental Requirements

Surrounding air (operating) temperature -20 60°C

Surrounding air (storage) temperature -40 85°C

Protection class IP00*

Degree of pollution (5) 2 per IEC 61131-2

Operating altitude without temperature derating: 0 2000 m; with temperature

derating: 2000 5000 m (0.5 K/100 m); max.: 5000 m

Relative air humidity (no condensation) 95 %

Relative humidity Short-term condensation per Class 3K6/IEC EN 60721-3-3 and E

DIN 40046-721-3, taking a temperature range of −20 +60 °C into

consideration (except wind-driven precipitation, water and ice

formation)

Mounting position any

Type of mounting DIN-35 rail

Vibration resistance acc. to IEC 60068-2-6

Shock resistance 15g per IEC 60068-2-27

EMC immunity to interference acc. to EN 61000-6-2, marine applications

EMC emission of interference acc. to EN 61000-6-3, marine applications

Exposure to pollutants Per IEC 60068-2-42 and IEC 60068-2-43

Fire load 0.886 MJ

Permissible H S contaminant concentration at a relative humidity 75

2

%

10 ppm

Permissible SO contaminant concentration at a relative humidity 75

2

%

25 ppm

Commercial data

Country of origin DE

GTIN 4055143624862

Customs Tariff No. 85371091990

Approvals / Certificates

Ex-Approvals

Logo Approval Additional Approval Text Certificate name

ATEX

TUEV Nord Cert GmbH

EN 60079 TUEV_14_ATEX_148929_X

ATEX

TUEV Nord Cert GmbH

IEC 60079-0 IECEx_TUN_14.0035_X

750-8208_025-001

20.08.2019Page /5 15

Page 6

Data sheet | Item number:750-8208/025-001

Country specific Approvals

Logo Approval Additional Approval Text

Certificate

name

KC

National Radio Research Agency

Article 58-2, Clause 3 MSIP-

REM-W43PFC750

Ship Approvals

Logo Approval Additional Approval Text

Certificate

name

ABS

American Bureau of Shipping

- 19HG1821812PDA

DNV GL

Det Norske Veritas, Germanischer Lloyd

- TAA00001J4

PRS

Polski Rejestr Statków

- TE/2237

/880590/19

Compatible products

system box

Item no.: 850-804

IP65 enclosure; Stainless steel; WxHxD (400x123x200 mm); 4 x M20, 16 x M16, 28 x M12 cable grip

850-804

Item no.: 850-804/000-001

IP65 enclosure; Stainless steel; WxHxD (400x123x200 mm); 2 x M20, 13 x M16, 32 x M12 cable grip

850-804

/000-001

Item no.: 850-805

IP65 enclosure; Stainless steel; WxHxD (600x123x200 mm); 4 x M20, 19 x M16, 67 x M12 cable grip

850-805

Item no.: 850-814/002-000

IP65 enclosure; Sheet steel (RAL 7035); WxHxD (200x120x200 mm); without flange plate

850-814

/002-000

750-8208_025-001

20.08.2019Page /6 15

Page 7

Data sheet | Item number:750-8208/025-001

Item no.: 850-815/002-000

IP65 enclosure; Sheet steel (RAL 7035); WxHxD (300x120x200 mm); without flange plate

850-815

/002-000

Item no.: 850-816/002-000

IP65 enclosure; Sheet steel (RAL 7035); WxHxD (400x120x200 mm); without flange plate

850-816

/002-000

Item no.: 850-817/002-000

IP65 enclosure; Sheet steel (RAL 7035); WxHxD (600x120x200 mm); without flange plate

850-817

/002-000

Item no.: 850-825

IP65 enclosure; Aluminium (RAL 7032); WxHxD (160x100x160 mm); 9 x M12, 4 x M20

850-825

Item no.: 850-826

IP65 enclosure; Aluminium (RAL 7032); WxHxD (240x100x160 mm); 4 x M20, 4 x M16, 14 x M12 cable

grip

850-826

Item no.: 850-826/002-000

IP65 enclosure; Aluminium (RAL 7035); WxHxD (240x100x160 mm); 4 x M20, 4 x M16, 14 x M12 cable

grip

850-826

/002-000

Item no.: 850-827

IP65 enclosure; Aluminium (RAL 7032); WxHxD (320x100x160 mm); 4 x M20, 8 x M16, 17 x M12 cable

grip

850-827

Item no.: 850-827/002-000

IP65 enclosure; Aluminium (RAL 7035); WxHxD (320x100x160 mm); 4 x M20, 8 x M16, 17 x M12 cable

grip

850-827

/002-000

Item no.: 850-828

IP65 enclosure; Aluminium (RAL 7032); WxHxD (480x100x160 mm); 4 x M20, 10 x M16, 35 x M12 cable

grip

850-828

Item no.: 850-828/002-000

IP65 enclosure; Aluminium (RAL 7035); WxHxD (480x100x160 mm); 4 x M20, 10 x M16, 35 x M12 cable

grip

850-828

/002-000

Item no.: 850-834

IP65 enclosure; Polyester (RAL 7032); WxHxD (164x100x164 mm); 9 x M12, 4 x M20

850-834

Item no.: 850-835

IP65 enclosure; Polyester (RAL 7032); WxHxD (244x100x164 mm); 4 x M20, 4 x M16, 14 x M12 cable

grip

850-835

Item no.: 850-836

IP65 enclosure; Polyester (RAL 7032); WxHxD (324x100x164 mm); 4 x M20, 8 x M16, 17 x M12 cable

grip

850-836

memory card

Item no.: 758-879/000-001

Memory Card SD; SLC-NAND; 2 GByte; Temperature from -40 to 90 °C

758-879

/000-001

shield connection

Item no.: 790-108

Shield clamping saddle; 11 mm wide; diameter of compatible conductor

790-108

Item no.: 790-116

Shield clamping saddle; 19 mm wide; diameter of compatible conductor; 7 ... 16 mm

790-116

750-8208_025-001

20.08.2019Page /7 15

Page 8

Data sheet | Item number:750-8208/025-001

Item no.: 790-124

Shield clamping saddle; 27 mm wide; diameter of compatible conductor; 6 ... 24 mm

790-124

Item no.: 790-140

Shield clamping saddle; diameter of compatible conductor

790-140

Item no.: 790-208

Shield clamping saddle; 12.4 mm wide; 3 ... 8 mm

790-208

Item no.: 790-216

Shield clamping saddle; 21.8 mm wide; 6 ... 16 mm

790-216

Item no.: 790-220

Shield clamping saddle; 30 mm wide; 6 ... 20 mm

790-220

software

Item no.: 759-333

WAGO-I/O-PRO

759-333

Item no.: 759-333/000-923

WAGO-I/O-PRO; USB-Set

759-333

/000-923

Item no.: 759-911

WAGO-I/O-PRO; CD

759-911

Carrier rail

Item no.: 210-112

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; slotted; according to EN 60715; "Hole width 25 mm

210-112

Item no.: 210-113

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; unslotted; according to EN 60715

210-113

Item no.: 210-114

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; unslotted; similar to EN 60715

210-114

Item no.: 210-115

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; slotted; according to EN 60715; "Hole width 18 mm

210-115

Item no.: 210-118

Steel carrier rail; 35 x 15 mm; 2.3 mm thick; 2 m long; unslotted; according to EN 60715

210-118

Item no.: 210-196

Aluminum carrier rail; 35 x 8.2 mm; 1.6 mm thick; 2 m long; unslotted; similar to EN 60715; silver-colored

210-196

Item no.: 210-197

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; slotted; similar to EN 60715

210-197

Item no.: 210-198

Copper carrier rail; 35 x 15 mm; 2.3 mm thick; 2 m long; unslotted; according to EN 60715; coppercolored

210-198

Item no.: 210-504

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; slotted; galvanized; according to EN 60715

210-504

Item no.: 210-505

Steel carrier rail; 35 x 7.5 mm; 1 mm thick; 2 m long; unslotted; galvanized; according to EN 60715

210-505

Item no.: 210-506

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; unslotted; galvanized; similar to EN 60715

210-506

750-8208_025-001

20.08.2019Page /8 15

Page 9

Data sheet | Item number:750-8208/025-001

Item no.: 210-508

Steel carrier rail; 35 x 15 mm; 1.5 mm thick; 2 m long; slotted; galvanized; similar to EN 60715

210-508

General accessories

Item no.: 750-921

Bluetooth® Adapter; light gray

750-921

Item no.: 750-923

Configuration cable; USB connector; Length: 2.5 m; black

750-923

Item no.: 750-923/000-001

Configuration cable; USB connector; Length: 5 m

750-923

/000-001

wiring and connectors

Item no.: 750-960

Fieldbus Connector PROFIBUS; with D-sub male connector; 9-pole; light gray

750-960

Item no.: 750-963

Fieldbus Connector CANopen; with D-sub female connector; 9-pole; light gray

750-963

Item no.: 750-975

ETHERNET RJ-45 connector, IP20; ETHERNET 10/100 Mbit/s; for field assembly; light gray

750-975

Item no.: 750-977/000-011

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568A; AWG 22

750-977

/000-011

Item no.: 750-977/000-012

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568B; AWG 22

750-977

/000-012

Item no.: 750-977/000-021

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568A; AWG 24

750-977

/000-021

Item no.: 750-977/000-022

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568B; AWG 24

750-977

/000-022

Item no.: 750-978/000-011

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568A; AWG 22; Strain relief

750-978

/000-011

Item no.: 750-978/000-012

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568B; AWG 22; Strain relief

750-978

/000-012

Item no.: 750-978/000-021

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568A; AWG 24; Strain relief

750-978

/000-021

Item no.: 750-978/000-022

Connector ETHERNET; RJ-45; Cat. 6A; straight; Code T568B; AWG 24; Strain relief

750-978

/000-022

750-8208_025-001

20.08.2019Page /9 15

Page 10

Data sheet | Item number:750-8208/025-001

Item no.: 750-979/000-011

Connector ETHERNET; RJ-45; Cat. 6A; angled; Code T568A; AWG 22; Strain relief

750-979

/000-011

Item no.: 750-979/000-012

Connector ETHERNET; RJ-45; Cat. 6A; angled; Code T568B; AWG 22; Strain relief

750-979

/000-012

Item no.: 750-979/000-021

Connector ETHERNET; RJ-45; Cat. 6A; angled; Code T568A; AWG 24; Strain relief

750-979

/000-021

Item no.: 750-979/000-022

Connector ETHERNET; RJ-45; Cat. 6A; angled; Code T568B; AWG 24; Strain relief

750-979

/000-022

Marking accessories

Item no.: 2009-145

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; white

2009-145

Item no.: 2009-145/000-002

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; yellow

2009-145

/000-002

Item no.: 2009-145/000-005

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; red

2009-145

/000-005

Item no.: 2009-145/000-006

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; blue

2009-145

/000-006

Item no.: 2009-145/000-007

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; gray

2009-145

/000-007

Item no.: 2009-145/000-012

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; orange

2009-145

/000-012

Item no.: 2009-145/000-023

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; green

2009-145

/000-023

Item no.: 2009-145/000-024

Mini-WSB Inline; for Smart Printer; on reel; stretchable 5 - 5.2 mm; plain; snap-on type; violet

2009-145

/000-024

Item no.: 248-501

Miniature WSB Quick marking system; plain; Marker width 5 mm; 10 strips with 10 markers per card

248-501

Item no.: 248-501/000-002

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; yellow

248-501

/000-002

Item no.: 248-501/000-005

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-005

750-8208_025-001

20.08.2019Page /10 15

Page 11

Data sheet | Item number:750-8208/025-001

Item no.: 248-501/000-006

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-006

Item no.: 248-501/000-007

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-007

Item no.: 248-501/000-012

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-012

Item no.: 248-501/000-017

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-017

Item no.: 248-501/000-023

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-023

Item no.: 248-501/000-024

Mini-WSB marking card; as card; not stretchable; plain; snap-on type; white

248-501

/000-024

Item no.: 750-103

Group marker carrier

750-103

Item no.: 750-107

Group marker carrier

750-107

Downloads

Documentation

Manual

WAGO-I/O-SYSTEM 750

DNP3 Solution

V 1.5.0 pdf

4.3 MB

Download

PFC200 CS 2ETH RS CAN DPM Telecontrol/T

PLC - PFC200 Controller

V 1.3.0

Jul 24, 2019

pdf

6.1 MB

Download

Cyber Security for Controller PFC100 / PFC200 V 1.2.0 pdf

8.3 MB

Download

WAGO-I/O-SYSTEM 750

IEC-61850 Solution

V 1.8.0 pdf

19.7 MB

Download

WAGO-I/O-SYSTEM 750

IEC-60870 Solution

V 1.8.0 pdf

6.0 MB

Download

WAGO MODBUS Master Configurator

for configuration of MODBUS networks in WAGO-I/O-PRO (CODESYS)

V 1.1.0 pdf

1.8 MB

Download

750-8208_025-001

20.08.2019Page /11 15

Page 12

Data sheet | Item number:750-8208/025-001

Con igu e DN 3 / IEC 608 0 wit telecont ol con igu ato and e!COCK I

V 2.0.0 pdf

7.7 MB

Download

Quick-Start Guide

WAGO-I/O-SYSTEM 750

DNP3 Solution

V 1.5.0 pdf

4.3 MB

Download

WAGO-I/O-SYSTEM 750

IEC-61850 Solution

V 1.8.0 pdf

19.7 MB

Download

WAGO-I/O-SYSTEM 750

IEC-60870 Solution

V 1.8.0 pdf

6.0 MB

Download

Bid Text

750-8208/025-001 doc

37.4 kB

Download

Tutorial

Set IP address with Ethernet Settings

In this video we are demonstrating how you can set a IP address with Ethernet

Settings. Content: 00:27 – Chapter #1 Download and install software; 00:56 – Chapter

#2 Open Ethernet Settings; 01:10 – Chapter #3 Establish serial Connection; 01:34 –

Chapter #4 Set IP address; 02:10 – Chapter #5 Check IP address

3.0

Dec 18, 2017

mp4

88.3 MB

Download

WAGO IEC 61400-25 solution (Windmill) 1.0

Jun 1, 2012

wmv

20.4 MB

Download

WAGO IEC 61850 solution (Transformer) 1.0

Jun 1, 2012

wmv

20.0 MB

Download

Establish connection to a controller using SSH

In this video we are demonstrating how to establish a SSH connec-tion with a

controller using for example PuTTY to be able to work with the LINUX console.

Contents: 0:21 Download and install the SSH client; 0:40 Establish the SSH

connection; 0:50 Log on to the Controller

1.0

Aug 5, 2017

mp4

29.0 MB

Download

Tutorial WAGO IEC 61850 / 61400 solution 1.0

Jun 1, 2012

wmv

45.4 MB

Download

Additional Information

Disposal; Electrical and electronic equipment, Packaging V 1.0.0 pdf

265.8 kB

Download

System Description

Design Notes

Basic conditions and recommendations for higher operational safety

V 2.0.0 pdf

1.5 MB

Download

750-8208_025-001

20.08.2019Page /12 15

Page 13

Data sheet | Item number:750-8208/025-001

Overview on WAGO-I/O-SYSTEM 750 approvals

pdf

780.2 kB

Download

Controller PFC100/200, General Product Information pdf

591.2 kB

Download

Application Notes

Application Note CoDeSys 2.3

Application note Cloud Connectivity

This application note explains how the WAGO controllers PFC100 and PFC200 can

communicate with cloud services like Microsoft Azure (WAGO Cloud), Amazon AWS

and IBM Bluemix. Data could be send to the cloud and commands could receive from

the cloud. The libraries WagoLibCloud for WAGO-I/O-PRO V2.3 and WagoAppCloud

for e!COCKPIT are used.

2019-07-17

Jul 17, 2019

zip

4.1 MB

Download

e!COCKPIT application note WagoLibCloud

This application note explains how the WAGO controllers PFC100 and PFC200 can

communicate with cloud services like Microsoft Azure (WAGO Cloud), Amazon AWS

and IBM Bluemix. Data could be send to the cloud and commands could receive from

the cloud. The libraries WagoLibCloud for WAGO-I/O-PRO V2.3 and WagoAppCloud

for e!COCKPIT are used.

2019-07-17

Jul 17, 2019

zip

4.0 MB

Download

HART Tool Routing via PROFIBUS with 750-833 and 750-333 (a116140)

This application note describes how to set up asset management systems, which

facilitate simple, efficient configuration of HART field devices.

Using the Cerabar PMC51 (Endress+Hauser) as an example, connecting any HART

sensor to a WAGO PROFIBUS controller and a WAGO PROFIBUS Coupler is

explained. The cyclic PROFIBUS Master (750-8208) realizes the data exchange. As an

acyclic master, a TH LINK PROFIBUS provides access for the plant asset

management applications WAGOframe, PACTware and FieldCare.

1.0.0

Mar 22, 2019

pdf

5.3 MB

Download

HART Tool Routing via ETHERNET with

750-820x/750-88x and CODESYS 2.3 (a116120)

This application note describes how to set up asset management systems, which

facilitate simple, efficient configuration of HART field devices.

With the Cerabar PMC51 (Endress+Hauser) as an example, a connection is

established from any HART sensor to a WAGO PROFIBUS Controller and a WAGO

ETHERNET Fieldbus Coupler. The configuration is made with the asset management

software WAGOframe, PACTware und FieldCare.

1.0.0

Mar 22, 2019

pdf

3.9 MB

Download

Using the web visualization with Java™ runtime environment (JRE, JVM) 7 update 51

(7u51) (a500690)

Oracle announced an update (7u51) for their Java™ runtime environment for the 14th

of January 2014 which might have an impact on the use of the WAGO web

visualization with Controller, PERSPECTO CP devices and WAGO-IO-IPCs. For more

details please have a look into our application note.

Download

Application note for installing a MySQL-Server on a PFC-Controller

V 1.0.4

May 16, 2019

zip

4.5 MB

Download

750-8208_025-001

20.08.2019Page /13 15

Page 14

Data sheet | Item number:750-8208/025-001

This Application Note explains how a MySQL-Server can be set up and used on a PFC

200. The Application shows how measurement values of the 3-Phase Power

Measurement Module can be written into a database.

Application Note e!COCKPIT

HART Tool Routing via ETHERNET with 750-820x and e!RUNTIME (a116130)

This application note describes how to set up asset management systems, which

facilitate simple, efficient configuration of HART field devices.

With the Cerabar PMC51 (Endress+Hauser) as an example, a connection is

established from any HART sensor to a WAGO PROFIBUS Controller and a WAGO

ETHERNET fieldbus coupler. The configuration is made with the asset management

software WAGOframe, PACTware und FieldCare.

1.0.0

Mar 22, 2019

pdf

2.9 MB

Download

e!COCKPIT application note WagoLibCloud

This application note explains how the WAGO controllers PFC100 and PFC200 can

communicate with cloud services like Microsoft Azure (WAGO Cloud), Amazon AWS

and IBM Bluemix. Data could be send to the cloud and commands could receive from

the cloud. The libraries WagoLibCloud for WAGO-I/O-PRO V2.3 and WagoAppCloud

for e!COCKPIT are used.

2019-07-17

Jul 17, 2019

zip

4.0 MB

Download

SNMP Communication (a500850)

This application note explains how the WAGO controllers PFC100 andPFC200 can

communicate via SNMP: Sending traps / inform notifications, creating an MIB and

using the controller as an SNMP agent. To do so, the SNMP-specific libraries for

WAGO-I/O-PRO V2.3 and e!COCKPIT are used.

V1.1.0

Aug 19, 2019

zip

4.0 MB

Download

eCOCKPIT application note installation MySQL-Server

This Application Note explains how a MySQL-Server can be set up and used on a PFC

200. The Application shows how measurement values of the 3-Phase Power

Measurement Module can be written into a database.

2019-07-10

Jul 10, 2019

pdf

1.9 MB

Download

Libraries

Library

Library WagoLibCloud_02.lib

Die Bibliothek dient zur Kommunikation des WAGO Controller PFC100 und PFC200

mit Cloud Diensten wie Microsoft Azure (WAGO Cloud), Amazon AWS and IBM

Bluemix. Daten können zur Cloud gesendet und Kommandos von der Cloud

empfangen werden.

V2.2.3

Apr 29, 2019

zip

57.1 kB

Download

Engineering-Software

Configuration and Commissioning Software

WAGO-IO-PRO Demo-Version (759-912) / Serie 750, 758 und 762 2.3.9.55

Jul 3, 2015

zip

108.3 MB

Download

750-8208_025-001

20.08.2019Page /14 15

Page 15

Data sheet | Item number:750-8208/025-001

Runtime Software

Firmware

Firmware: 750-8208/025-001 Controller PFC200; 2 x ETHERNET, RS-232/-485, CAN,

CANopen, PROFIBUS-Master; Telecontrol technology; Ext. Temperature; light gray

13

Jul 11, 2019

zip

83.4 MB

Download

CAD/CAE - Smart Data

CAD data

3D Download 750-8208/025-001 URL Download

EPLAN

EPLAN Data Portal Download

Device Files

Device Description File

750-914; EDS file for CANopen / 750, 752 and 767 Series XR

Jul 30, 2019

zip

1.7 MB

Download

Device Driver

750-914; EDS file for CANopen / 750, 752 and 767 Series XR

Jul 30, 2019

zip

1.7 MB

Download

Product family

Controller 750

Show all products from the family

750-8208_025-001

Subject to changes.

20.08.2019Page /15 15

Loading...

Loading...