Page 1

Manual

WAGO-I/O-SYSTEM 750

PFC200 DC 2ETH RS CAN

750-8204(/xxx-xxx)

PLC - PFC200 Controller

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 2

2 WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

© 2014 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-8204 PFC200 DC 2ETH RS CAN

Table of Contents

1 Notes about this Documentation ............................................................... 12

1.1 Validity of this Documentation ............................................................... 12

1.2 Copyright ................................................................................................. 12

1.3 Symbols ................................................................................................... 13

1.4 Number Notation ..................................................................................... 15

1.5 Font Conventions .................................................................................... 15

2 Important Notes ......................................................................................... 16

2.1 Legal Bases ............................................................................................. 16

2.1.1 Subject to Changes ............................................................................. 16

2.1.2 Personnel Qualifications ..................................................................... 16

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying

Provisions ........................................................................................... 16

2.1.4 Technical Condition of Specified Devices ......................................... 17

2.2 Safety Advice (Precautions) .................................................................... 18

2.3 Special Use Conditions for ETHERNET Devices .................................. 20

3 Device Description ..................................................................................... 21

3.1 View ........................................................................................................ 24

3.2 Connectors ............................................................................................... 26

3.2.1 Data Contacts/Internal Bus ................................................................. 26

3.2.2 Power Jumper Contacts/Field Supply ................................................ 27

3.2.3 CAGE CLAMP® Connectors ............................................................. 28

3.2.4 Service Interface ................................................................................. 29

3.2.5 Network Connections – X1, X2 ......................................................... 30

3.2.6 RS-232/RS-485 – X3 Communication Connection ........................... 31

3.2.6.1 Operating as an RS-232 Interface .................................................. 32

3.2.6.2 Operating as an RS-485 Interface .................................................. 33

3.2.7 CANopen – X4 Fieldbus Connection ................................................. 34

3.3 Display Elements .................................................................................... 36

3.3.1 Power Supply Indicating Elements .................................................... 36

3.3.2 Fieldbus/System Indicating Elements ................................................ 37

3.3.3 Memory Card Indicating Elements .................................................... 38

3.3.4 Network Indicating Elements ............................................................. 39

3.4 Operating Elements ................................................................................. 40

3.4.1 Operating Mode Switch ...................................................................... 40

3.4.2 Reset Button ....................................................................................... 41

3.5 Slot for Memory Card ............................................................................. 42

3.6 Schematic Diagram ................................................................................. 43

3.7 Technical Data ........................................................................................ 44

3.7.1 Device Data ........................................................................................ 44

3.7.2 System Data ........................................................................................ 44

3.7.3 Power supply ...................................................................................... 44

3.7.4 Clock................................................................................................... 44

3.7.5 Programming ...................................................................................... 45

3.7.6 Internal data bus ................................................................................. 45

3.7.7 ETHERNET ....................................................................................... 45

3.7.8 CANopen ............................................................................................ 45

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

3.7.9 Serial interface .................................................................................... 46

3.7.10 Connection Type ................................................................................ 47

3.7.11 Climatic Environmental Conditions ................................................... 47

3.8 Approvals ................................................................................................ 48

3.9 Standards and Guidelines ........................................................................ 48

4 Function Description ................................................................................. 49

4.1 Network Configuration ........................................................................... 49

4.1.1 Operation in Switch Mode .................................................................. 49

4.1.2 Operation with Separate Network Interfaces ..................................... 49

5 Mounting ..................................................................................................... 50

5.1 Installation Position ................................................................................. 50

5.2 Overall Configuration ............................................................................. 50

5.3 Mounting onto Carrier Rail ..................................................................... 52

5.3.1 Carrier Rail Properties ........................................................................ 52

5.3.2 WAGO DIN Rail ................................................................................ 53

5.4 Spacing .................................................................................................... 53

5.5 Mounting Sequence ................................................................................. 54

5.6 Inserting Devices ..................................................................................... 55

5.6.1 Inserting the Fieldbus Coupler/Controller .......................................... 55

5.6.2 Inserting the I/O Module .................................................................... 56

6 Connect Devices ......................................................................................... 57

6.1 Connecting a Conductor to the CAGE CLAMP® ................................... 57

6.2 Power Supply Concept ............................................................................ 58

6.2.1 Supplementary Power Supply Regulations ........................................ 58

7 Commissioning ........................................................................................... 60

7.1 Switching On the Controller ................................................................... 60

7.2 Determining the IP Address of the Host PC ........................................... 61

7.3 Setting an IP Address .............................................................................. 62

7.3.1 Assigning an IP Address using DHCP ............................................... 63

7.3.2 Changing an IP Address using the “CBM” Configuration Tool via the

Serial Interface.................................................................................... 64

7.3.3 Changing an IP Address using “WAGO Ethernet Settings” .............. 67

7.4 Testing the Network Connection ............................................................ 69

7.5 Shutdown/Restart .................................................................................... 70

7.6 Initiating Reset Functions ....................................................................... 71

7.6.1 Warm Start Reset ................................................................................ 71

7.6.2 Cold Start Reset .................................................................................. 71

7.6.3 Software Reset .................................................................................... 71

7.6.4 Setting a Fixed IP Address ................................................................. 71

7.6.5 Factory Reset ...................................................................................... 72

7.7 Users and Passwords ............................................................................... 73

7.7.1 Services and Users .............................................................................. 73

7.7.2 WBM Group ....................................................................................... 74

7.7.3 Linux User Group ............................................................................... 74

7.7.4 SNMP User Group ............................................................................. 74

7.8 Configuration .......................................................................................... 75

7.8.1 Configuration using Web-Based Management (WBM) ..................... 76

7.8.1.1 WBM User Administration ............................................................ 77

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 5

WAGO-I/O-SYSTEM 750 Table of Contents 5

750-8204 PFC200 DC 2ETH RS CAN

7.8.1.2 General Information about the Page .............................................. 79

7.8.1.3 “Status Information” Page ............................................................. 81

7.8.1.3.1 “Controller Details” Group ....................................................... 81

7.8.1.3.2 “Network Details (Xn)” Group(s) ............................................. 81

7.8.1.4 “CODESYS Configuration” Page ................................................. 82

7.8.1.4.1 “General Configuration” Group ................................................ 82

7.8.1.5 “CODESYS Information” Page ..................................................... 83

7.8.1.5.1 “CODESYS” Group .................................................................. 83

7.8.1.5.2 “Project Details” Group ............................................................ 83

7.8.1.5.3 "Task n" Group(s) ..................................................................... 83

7.8.1.6 “CODESYS WebVisu” Page ......................................................... 85

7.8.1.6.1 “Webserver Configuration” Group ........................................... 85

7.8.1.7 “Configuration of Network Parameters” Page" ............................. 86

7.8.1.7.1 “Hostname” Group .................................................................... 86

7.8.1.7.2 “Domain Name” Group ............................................................ 86

7.8.1.8 “TCP/IP Configuration” Page ........................................................ 87

7.8.1.8.1 “Switch Configuration” Group ................................................. 87

7.8.1.8.2 “IP Address (Xn)” Group(s) ..................................................... 87

7.8.1.8.3 “Default Gateway” Group ......................................................... 88

7.8.1.8.4 “DNS Server” Group ................................................................ 88

7.8.1.9 “Configuration of ETHERNET Parameters” Page ........................ 89

7.8.1.9.1 “Interface Xn” Groups .............................................................. 89

7.8.1.10 “Configuration of Time and Date” Page ....................................... 90

7.8.1.10.1 “Date on Device” Group ........................................................... 90

7.8.1.10.2 “Time on Device” Group .......................................................... 90

7.8.1.10.3 “Time Zone” Group .................................................................. 91

7.8.1.10.4 “TZ String” Group .................................................................... 91

7.8.1.11 “Configuration of the Users for the Web-based Management” Page92

7.8.1.11.1 “Change Password for Selected User” Group ........................... 92

7.8.1.12 “Create Bootable Image” Page ...................................................... 93

7.8.1.12.1 "Create Bootable Image from Active Partition (<Active

Partition>" Group ...................................................................... 93

7.8.1.13 “Configuration of Serial Interface RS232” Page ........................... 94

7.8.1.13.1 “Serial Interface Assigned to” Group ....................................... 94

7.8.1.13.2 “Assign Owner of Serial Interface (Active after Next Controller

Reboot)” Group ......................................................................... 94

7.8.1.14 “Reboot Controller” Page .............................................................. 95

7.8.1.14.1 “Reboot Controller” Group ....................................................... 95

7.8.1.15 “Firmware Back-up” Page ............................................................. 96

7.8.1.16 “Firmware Restore” Page .............................................................. 97

7.8.1.17 “System Partition” Page ................................................................ 98

7.8.1.17.1 “Current Active Partition” Group ............................................. 98

7.8.1.17.2 “Set Inactive Partition Active” Group ...................................... 98

7.8.1.18 “Mass Storage” Page ..................................................................... 99

7.8.1.18.1 “<Device Name>” Group(s) ..................................................... 99

7.8.1.18.2 “<Device Name> - FAT Format” Group(s) .............................. 99

7.8.1.19 “Software Uploads” Page ............................................................ 100

7.8.1.19.1 “Upload New Software” Group .............................................. 100

7.8.1.19.2 “Activate New Software” Group ............................................ 100

7.8.1.20 “Configuration of Network Services” Page ................................. 101

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 6

6 Table of Contents WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

7.8.1.20.1 “Telnet” Group ........................................................................ 101

7.8.1.20.2 “FTP” Group ........................................................................... 101

7.8.1.20.3 “FTPS” Group ......................................................................... 101

7.8.1.20.4 “HTTP” Group ........................................................................ 101

7.8.1.20.5 “HTTPS” Group ...................................................................... 101

7.8.1.21 “Configuration of NTP Client” Page ........................................... 102

7.8.1.21.1 “NTP Client” Group................................................................ 102

7.8.1.22 “Configuration of the CODESYS Services” Page ....................... 103

7.8.1.22.1 “CODESYS Webserver” Group ............................................. 103

7.8.1.22.2 “Communication” Group ........................................................ 103

7.8.1.22.3 “Port Authentication” Group .................................................. 103

7.8.1.22.4 “Port Authentication Password” Group .................................. 103

7.8.1.23 “SSH Client Settings” Page ......................................................... 104

7.8.1.23.1 “SSH Client” Group ................................................................ 104

7.8.1.24 “TFTP Server” Page .................................................................... 105

7.8.1.24.1 “TFTP Server” Group ............................................................. 105

7.8.1.25 “Configuration of SNMP parameter” Page ................................. 106

7.8.1.25.1 “General SNMP Configuration” Group .................................. 106

7.8.1.26 “Configuration of SNMP Parameter” Page ................................. 107

7.8.1.26.1 “SNMP v1/v2c Manager Configuration” Group .................... 107

7.8.1.26.2 “Actually Configured Trap Receivers” Group(s) ................... 107

7.8.1.26.3 “Trap Receiver n” Group(s) .................................................... 108

7.8.1.26.4 “Add new Trap Receiver” Group ............................................ 108

7.8.1.27 “Configuration of SNMP v3 Users” Page ................................... 109

7.8.1.27.1 “Actually Configured v3 Users” Group(s) .............................. 109

7.8.1.27.2 “v3 User n” Group(s) .............................................................. 109

7.8.1.27.3 “Add New v3 User” Group ..................................................... 110

7.8.1.28 “Diagnostic Information” Page .................................................... 111

7.8.2 Configuration using a Terminal Program (CBM) ............................ 112

7.8.3 Configuration using “WAGO ETHERNET Settings” ..................... 113

7.8.3.1 Identification Tab ......................................................................... 115

7.8.3.2 Network Tab ................................................................................ 116

7.8.3.3 Protocol Tab ................................................................................. 118

7.8.3.4 Status Tab .................................................................................... 119

8 Run-time System CODESYS 2.3 ............................................................ 120

8.1 Installing the CODESYS 2.3 Programming System ............................. 120

8.2 First Program with CODESYS 2.3 ....................................................... 120

8.2.1 Start the CODESYS Programming System ...................................... 120

8.2.2 Creating a Project and Selecting the Target System ........................ 120

8.2.3 Creating the PLC Configuration ....................................................... 122

8.2.4 Editing the Program Function Block ................................................ 128

8.2.5 Loading and Running the PLC Program in the Fieldbus Controller

(ETHERNET) ................................................................................... 131

8.2.6 Creating a Boot Project .................................................................... 133

8.3 Syntax of Logical Addresses ................................................................. 133

8.4 Creating Tasks ....................................................................................... 134

8.4.1 Cyclic Tasks ..................................................................................... 137

8.4.2 Freewheeling Tasks .......................................................................... 138

8.5 System Events ....................................................................................... 138

8.5.1 Creating an Event Handler ............................................................... 141

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 7

WAGO-I/O-SYSTEM 750 Table of Contents 7

750-8204 PFC200 DC 2ETH RS CAN

8.6 Process Images ...................................................................................... 143

8.6.1 Process Images for I/O Modules Connected to the Controller ......... 145

8.6.2 Process Image for Slaves Connected to the Fieldbus ....................... 146

8.7 Access to Process Images of the Input and Output Data via CODESYS

2.3 .......................................................................................................... 146

8.8 Addressing Example ............................................................................. 148

8.9 Internal Data Bus Synchronization ....................................................... 149

8.9.1 Case 1: CODESYS Task Interval Set Smaller than the I/O Module

Cycle ................................................................................................. 149

8.9.2 Case 2: CODESYS Task Interval Smaller than Twice the Internal

Data Bus Cycle ................................................................................. 151

8.9.3 Case 3: CODESYS Task Interval Greater than Twice the Internal Data

Buc Cycle ......................................................................................... 152

8.9.4 Case 4: CODESYS Task Interval Greater than 10 ms ..................... 153

8.9.5 Internal Data Bus Configuration ...................................................... 154

8.9.5.1 Effect of Update Mode on CODESYS Tasks .............................. 155

8.9.5.1.1 Asynchronous Update Mode ................................................... 155

8.9.5.1.2 Synchronous Update Mode ..................................................... 156

8.10 Memory Settings in CODESYS ............................................................ 156

8.10.1 Program Memory.............................................................................. 156

8.10.2 Data Memory and Function Block Limitation ................................. 157

8.10.3 Remanent Memory ........................................................................... 158

8.11 CODESYS Visualization ...................................................................... 159

8.11.1 Limits of CODESYS Visualization .................................................. 162

8.11.2 Eliminating Errors in CODESYS Web Visualization ...................... 164

8.11.3 FAQs about CODESYS Web Visualization..................................... 165

9 MODBUS .................................................................................................. 167

9.1 General .................................................................................................. 167

9.2 Features ................................................................................................. 167

9.3 Configuration ........................................................................................ 168

9.3.1 MODBUS Settings ........................................................................... 169

9.3.2 MODBUS TCP Settings ................................................................... 170

9.3.3 MODBUS UDP Settings .................................................................. 170

9.3.4 MODBUS RTU Settings .................................................................. 171

9.4 Data Exchange ...................................................................................... 173

9.4.1 Process Image ................................................................................... 174

9.4.2 Flag Area .......................................................................................... 175

9.4.3 MODBUS Registers ......................................................................... 176

9.4.4 MODBUS Mapping.......................................................................... 176

9.4.4.1 MODBUS Mapping for Write Bit Services FC1, FC2 ................ 176

9.4.4.2 MODBUS Mapping for Write Bit Services FC5, FC15 .............. 177

9.4.4.3 MODBUS Mapping for Read Register Services FC3, FC4, FC23178

9.4.4.4 MODBUS Mapping for Write Register Services FC6, FC16, FC22,

FC23 ............................................................................................ 180

9.5 WAGO MODBUS Register .................................................................. 182

9.5.1 Process Image Properties .................................................................. 183

9.5.1.1 Register 0x1022 – Number of Registers in the MODBUS Input

Process Image .............................................................................. 183

9.5.1.2 Register 0x1023 – Number of Registers in the MODBUS Output

Process Image .............................................................................. 183

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 8

8 Table of Contents WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

9.5.1.3 Register 0x1024 – Number of Bits in the MODBUS Input Process

Image ........................................................................................... 183

9.5.1.4 Register 0x1025 – Number of Bits in the MODBUS Output

Process Image .............................................................................. 183

9.5.2 Network Configuration ..................................................................... 184

9.5.2.1 Register 0x1028 – IP Configuration ............................................ 184

9.5.2.2 Register 0x102A – Number of Established TCP Connections .... 184

9.5.2.3 Register 0x1030 – MODBUS TCP Socket Timeout ................... 184

9.5.2.4 Register 0x1031 – MAC Address for ETHERNET-Interface 1

(eth0) ............................................................................................ 184

9.5.2.5 Register 0x1037 - MODBUS TCP Response Delay ................... 184

9.5.3 PLC Status Register .......................................................................... 185

9.5.4 MODBUS Watchdog........................................................................ 185

9.5.4.1 Register 0x1100 – Watchdog Command ..................................... 185

9.5.4.2 Register 0x1101 – Watchdog Status ............................................ 187

9.5.4.3 Register 0x1102 – Watchdog Timeout ........................................ 187

9.5.4.4 Register 0x1103 – Watchdog Config .......................................... 188

9.5.5 MODBUS Constants Register .......................................................... 188

9.5.6 Electronic Nameplate ....................................................................... 189

9.5.6.1 Register 0x2010 – Revision (Firmware Index) ........................... 189

9.5.6.2 Register 0x2011 – Series Designator ........................................... 189

9.5.6.3 Register 0x2012 – Device ID ...................................................... 189

9.5.6.4 Register 0x2013 – Major Firmware Version ............................... 189

9.5.6.5 Register 0x2014 – Minor Firmware Version ............................... 189

9.5.6.6 Register 0x2015 – MBS Version ................................................. 189

9.6 Diagnostics ............................................................................................ 190

9.6.1 Diagnostics for the MODBUS Master ............................................. 190

9.6.2 Diagnostics for the Runtime System ................................................ 190

9.6.3 Diagnostics for the Error Server ....................................................... 190

10 CANopen Master and Slave .................................................................... 193

10.1 Object Directory .................................................................................... 193

10.2 Communications Profile ........................................................................ 193

10.2.1 Master Configuration........................................................................ 197

10.3 Data Exchange ...................................................................................... 198

10.3.1 Controller Communication Objects .................................................. 198

10.3.2 Fieldbus-Specific Addressing ........................................................... 199

10.3.3 Examples for the Definition of PFC Fieldbus Variables .................. 203

10.3.3.1 CODESYS Access to PFC Variables .......................................... 203

10.3.3.2 Maximum Indices ........................................................................ 203

10.3.4 CANopen Master Control Configuration ......................................... 205

10.3.4.1 Selecting the Master .................................................................... 205

10.3.4.2 Setting the Master Parameters ..................................................... 206

10.3.4.3 Adding Slaves .............................................................................. 208

10.3.4.4 Configuring the Slave PDOs ....................................................... 214

10.3.4.5 Configuring the Service Data Objects ......................................... 217

10.3.5 CANopen Slave Control Configuration ........................................... 220

10.3.5.1 CANopen Variables Configuration ............................................. 221

10.3.5.2 Configuring of CANopen Parameters ......................................... 222

10.4 Fieldbus Coupler Diagnostics ............................................................... 223

10.4.1 DiagGetBusState() and DiagGetState() ............................................ 223

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 9

WAGO-I/O-SYSTEM 750 Table of Contents 9

750-8204 PFC200 DC 2ETH RS CAN

10.4.2 Creating Diagnostics 7 in CODESYS 2.3 ........................................ 224

10.4.3 Calling Up the Diagnostics Function Block ..................................... 226

10.4.4 Executing a Bus Diagnosis using DiagGetBusState() ...................... 227

10.4.5 Performing Subscriber Diagnostics using DiagGetState() ............... 229

10.4.6 Evaluating the CANopen Diagnosis (Emergency Messages) .......... 231

10.5 Data Exchange between Simple CAN Subscribers and PFC200 in the

CANopen Network ................................................................................ 233

10.6 Data Exchange between CAN Subscribers and the PFC200 in a CAN

Layer2 Network .................................................................................... 235

11 Diagnostics ................................................................................................ 236

11.1 Operating and Status Messages ............................................................. 236

11.1.1 Power Supply Indicating Elements .................................................. 236

11.1.2 Fieldbus/System Indicating Elements .............................................. 237

11.2 Diagnostics Messages (I/O LED) .......................................................... 241

11.2.1 Flashing Sequence ............................................................................ 241

11.2.2 Example of a Diagnostics Message Indicated by a Blink Code ....... 243

11.2.3 Meaning of Blink Codes and Procedures for Troubleshooting ........ 244

12 Service ....................................................................................................... 250

12.1 Inserting and Removing the Memory Card ........................................... 250

12.1.1 Inserting the Memory Card .............................................................. 250

12.1.2 Removing the Memory Card ............................................................ 250

13 Removal .................................................................................................... 252

13.1 Removing Devices ................................................................................ 252

13.1.1 Removing the Fieldbus Coupler/Controller ..................................... 252

13.1.2 Removing the I/O Module ................................................................ 253

14 Appendix ................................................................................................... 254

14.1 Structure of Process Data for the I/O Modules ..................................... 254

14.1.1 Digital Input Modules....................................................................... 255

14.1.1.1 1 Channel Digital Input Module with Diagnostics ...................... 255

14.1.1.2 2 Channel Digital Input Modules ................................................ 255

14.1.1.3 2 Channel Digital Input Module with Diagnostics ...................... 255

14.1.1.4 2 Channel Digital Input Module with Diagnostics and Output

Process Data ................................................................................. 256

14.1.1.5 4 Channel Digital Input Modules ................................................ 256

14.1.1.6 8 Channel Digital Input Modules ................................................ 256

14.1.1.7 8 Channel Digital Input Module PTC with Diagnostics and Output

Process Data ................................................................................. 257

14.1.1.8 16 Channel Digital Input Modules .............................................. 257

14.1.2 Digital Output Modules .................................................................... 258

14.1.2.1 1 Channel Digital Output Module with Input Process Data ........ 258

14.1.2.2 2 Channel Digital Output Modules .............................................. 258

14.1.2.3 2 Channel Digital Input Modules with Diagnostics and Input

Process Data ................................................................................. 259

14.1.2.4 4 Channel Digital Output Modules .............................................. 260

14.1.2.5 4 Channel Digital Output Modules with Diagnostics and Input

Process Data ................................................................................. 260

14.1.2.6 8 Channel Digital Output Module ............................................... 260

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 10

10 Table of Contents WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

14.1.2.7 8 Channel Digital Output Modules with Diagnostics and Input

Process Data ................................................................................. 261

14.1.2.8 16 Channel Digital Output Modules ............................................ 261

14.1.2.9 8 Channel Digital Input/Output Modules .................................... 262

14.1.3 Analog Input Modules ...................................................................... 263

14.1.3.1 1 Channel Analog Input Modules ................................................ 263

14.1.3.2 2 Channel Analog Input Modules ................................................ 263

14.1.3.3 4 Channel Analog Input Modules ................................................ 264

14.1.3.4 3-Phase Power Measurement Module ......................................... 265

14.1.3.5 8 Channel Analog Input Modules ................................................ 265

14.1.4 Analog Output Modules ................................................................... 266

14.1.4.1 2 Channel Analog Output Modules ............................................. 266

14.1.4.2 4 Channel Analog Output Modules ............................................. 266

14.1.5 Specialty Modules ............................................................................ 267

14.1.5.1 Counter Modules ......................................................................... 267

14.1.5.2 Pulse Width Modules ................................................................... 269

14.1.5.3 Serial Interface Modules with alternative Data Format ............... 269

14.1.5.4 Serial Interface Modules with Standard Data Format ................. 270

14.1.5.5 Data Exchange Module ................................................................ 270

14.1.5.6 SSI Transmitter Interface Modules .............................................. 270

14.1.5.7 Incremental Encoder Interface Modules ...................................... 271

14.1.5.8 DC-Drive Controller .................................................................... 273

14.1.5.9 Stepper Controller ........................................................................ 274

14.1.5.10 RTC Module ................................................................................ 275

14.1.5.11 DALI/DSI Master Module ........................................................... 275

14.1.5.12 DALI Multi-Master Module ........................................................ 276

14.1.5.13 LON® FTT Module ...................................................................... 278

14.1.5.14 EnOcean Radio Receiver ............................................................. 278

14.1.5.15 MP Bus Master Module ............................................................... 278

14.1.5.16 Bluetooth® RF-Transceiver .......................................................... 279

14.1.5.17 Vibration Velocity/Bearing Condition Monitoring VIB I/O ....... 280

14.1.5.18 KNX/EIB/TP1 Module ................................................................ 280

14.1.5.19 AS-interface Master Module ....................................................... 281

14.1.6 System Modules ............................................................................... 283

14.1.6.1 System Modules with Diagnostics ............................................... 283

14.1.6.2 Binary Space Module .................................................................. 283

14.2 CODESYS Libraries ............................................................................. 284

14.2.1 General Libraries .............................................................................. 284

14.2.1.1 CODESYS System Libraries ....................................................... 284

14.2.1.2 SysLibCom.lib ............................................................................. 285

14.2.1.3 SysLibFile.lib ............................................................................... 285

14.2.1.4 SysLibFileAsync.lib .................................................................... 286

14.2.1.5 SysLibRtc.lib ............................................................................... 286

14.2.1.6 BusDiag.lib .................................................................................. 287

14.2.1.7 mod_com.lib ................................................................................ 287

14.2.1.8 SerComm.lib ................................................................................ 287

14.2.1.9 WagoConfigToolLIB.lib ............................................................. 288

14.2.1.10 WagoLibCpuUsage.lib ................................................................ 303

14.2.1.11 WagoLibDiagnosticIDs.lib .......................................................... 303

14.2.1.12 WagoLibLed.lib ........................................................................... 304

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 11

WAGO-I/O-SYSTEM 750 Table of Contents 11

750-8204 PFC200 DC 2ETH RS CAN

14.2.1.13 WagoLibNetSnmp.lib .................................................................. 304

14.2.1.14 WagoLibNetSnmpManager.lib .................................................... 304

14.2.1.15 WagoLibSSL.lib .......................................................................... 305

14.2.1.16 WagoLibTerminalDiag.lib ........................................................... 305

14.2.2 Libraries for a CANopen and CANLayer2 Link .............................. 306

14.2.2.1 WagoCANLayer2_02.lib ............................................................. 306

14.2.2.2 WagoCANopen_02.lib ................................................................ 306

List of Figures .................................................................................................... 307

List of Tables ...................................................................................................... 310

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 12

12 Notes about this Documentation WAGO-I/O-SYSTEM 750

Table 1: Variants

Item Number/Variant

Designation

750-8204

PFC200 DC 2ETH RS CAN

750-8204/025-000

PFC200 DC 2ETH RS CAN/T

750-8204 PFC200 DC 2ETH RS CAN

1 Notes about this Documentation

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

1.1 Validity of this Documentation

This documentation is only applicable to the controller “PFC200 DC 2ETH RS

CAN” (750-8204) and the variants listed in the table below.

Documentation Validity for Variants

Unless otherwise indicated, the information given in this documentation applies to

listed variants.

This documentation is only applicable from SW-Version 02.02.12(03).

1.2 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 13

WAGO-I/O-SYSTEM 750 Notes about this Documentation 13

750-8204 PFC200 DC 2ETH RS CAN

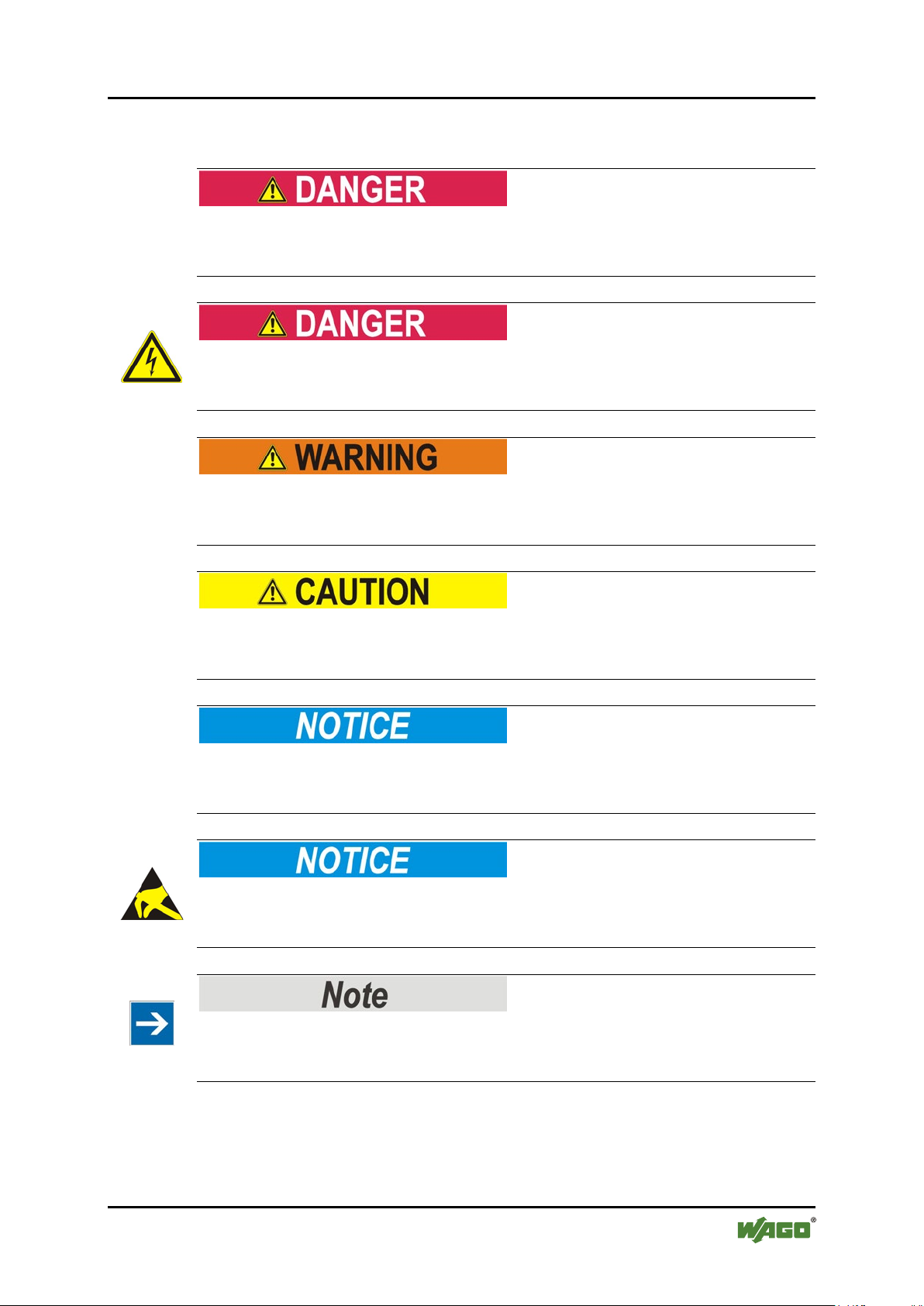

1.3 Symbols

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 14

14 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 15

WAGO-I/O-SYSTEM 750 Notes about this Documentation 15

Table 2: Number Notation

Number code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 3: Font Conventions

Font type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Programme\WAGO-I/O-CHECK

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-8204 PFC200 DC 2ETH RS CAN

1.4 Number Notation

1.5 Font Conventions

menu item from a menu.

brackets.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 16

16 Important Notes WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

2 Important Notes

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

2.1 Legal Bases

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 17

WAGO-I/O-SYSTEM 750 Important Notes 17

750-8204 PFC200 DC 2ETH RS CAN

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 18

18 Important Notes WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

2.2 Safety Advice (Precautions)

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Do not use in telecommunication circuits!

Only use devices equipped with ETHERNET or RJ-45 connectors in LANs.

Never connect these devices with telecommunication networks.

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 19

WAGO-I/O-SYSTEM 750 Important Notes 19

750-8204 PFC200 DC 2ETH RS CAN

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 20

20 Important Notes WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

2.3 Special Use Conditions for ETHERNET Devices

If not otherwise specified, ETHERNET devices are intended for use on local

networks. Please note the following when using ETHERNET devices in your

system:

• Do not connect control components and control networks to an open

network such as the Internet or an office network. WAGO recommends

putting control components and control networks behind a firewall.

• Limit physical and electronic access to all automation components to

authorized personnel only.

• Change the default passwords before first use! This will reduce the risk of

unauthorized access to your system.

• Regularly change the passwords used! This will reduce the risk of

unauthorized access to your system.

• If remote access to control components and control networks is required,

use a Virtual Private Network (VPN).

• Regularly perform threat analyses. You can check whether the measures

taken meet your security requirements.

• Use “defense-in-depth” mechanisms in your system's security configuration

to restrict the access to and control of individual products and networks.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 21

WAGO-I/O-SYSTEM 750 Device Description 21

750-8204 PFC200 DC 2ETH RS CAN

3 Device Description

The controller 750-8204(PFC200 DC 2ETH RS CAN) is an automation device

that can perform control tasks of a PLC. It is suitable for mounting on a DIN rail

and stands out on account of its various interfaces.

This controller can be used for applications in mechanical and systems

engineering, in the processing industry and in building technology.

You can connect all available I/O modules of the WAGO-I/O-SYSTEM 750 (750

and 753 Series) to the controller, enabling it to internally process analog and

digital signals from the automation environment, or to supply these signals to

other devices via one of the available interfaces.

Automation tasks can be executed in all IEC 61131-3-compatible languages with

the programming system CODESYS 2.3 (WAGO-I/O-PRO).

The implementation of the CODESYS task processing is optimized with real-time

extensions in order to provide maximal performance for automation tasks. For

visualization, Web visualization is also available in addition to the development

environment.

The controller provides a physical 256 Mbyte program memory (flash), a 256

Mbyte data memory (RAM) and a 128 kbyte remanent memory (retain,

NVRAM). The memory capacities may not be able to be utilized fully on account

of internal administration.

The file system on the internal memory provides 64 Mbyte for applications. Files

may also be stored on a removable memory card, or on an internal RAM disk.

The controller provides a 16 Mbyte program memory, a 64 Mbyte data memory

and a 128 kbyte remanent memory (retain and flag variables) in an integrated

NVRAM for IEC-61131-3 programming on CODESYS applications.

</dg_

Two ETHERNET interfaces and an integrated, configurable switch enable line

topology wiring for:

• In line topology with a common MAC address and IP address for both

interfaces.

• Two separate networks with a common MAC address and an IP address for

each interface.

Both of these interfaces support:

• 10Base-T / 100Base-TX

• Full/Half duplex

• Autonegotiation

• Auto-MDI(X)

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 22

22 Device Description WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

The following fieldbus circuits are implemented for exchange of process data:

• MODBUS TCP

• MODBUS UDP

• MODBUS RTU (via RS-232 or RS-485)

• CANopen Master/Slave

In the controller, all input signals from the sensors are combined. After connecting

the controller, all of the I/O modules on the bus node are detected and a local

process image is created from these. Analog and specialty module data is sent via

words and/or bytes; digital data is sent bit by bit.

No direct access from fieldbus to the process image for I/O modules!

Any data that is required from the I/O module process image must be explicitly

mapped in the CODESYS program to the data in the fieldbus process image and

vice versa! Direct access is not possible!

Fieldbus configuration can be performed using the CODESYS 2.3 controller

configuration.

A Web-based management system (WBM) is also available as a configuration aid.

This system includes various dynamic HTML pages from which, among other

things, information about configuration and the status of the controller can be

called up. The WBM is already stored in the device and is presented and operated

using an Internet browser. You can also save your own HTML pages in the

implemented file system, or call up programs directly.

In the controller's initial state, the installed firmware is based on Linux®, with

special real-time extensions of the RT-Preempt patch. In addition, the following

application programs are also installed on the controller, along with a number of

different auxiliary programs:

• a SNMP server/client

• a Telnet server

• a FTP, FTPS server

• a SSH server/client

• a Web server

• a NTP client

• a BootP and DHCP daemon

• a CODESYS Runtime Environment

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

750-8204 PFC200 DC 2ETH RS CAN

Based on IEC-61131-3 programming, data processing takes place on site in the

controller. The logical process results can be output directly to the actuators or

transmitted via a connected fieldbus to the higher level controller.

Memory card is not included in the scope of delivery!

Note, the controller is delivered without memory card.

To use a memory card, you must order one separately. The controller can also be

operated without memory card expansion, the use of a memory card is optional.

</dg_

Only use recommended memory cards!

Use only the SD memory card available from WAGO (item No. 758-879/000-

001) as it is suitable for industrial applications subjected to environmental

extremes and was developed for use in the controller.

Compatibility with other commercially available storage media cannot be

guaranteed.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 24

24 Device Description WAGO-I/O-SYSTEM 750

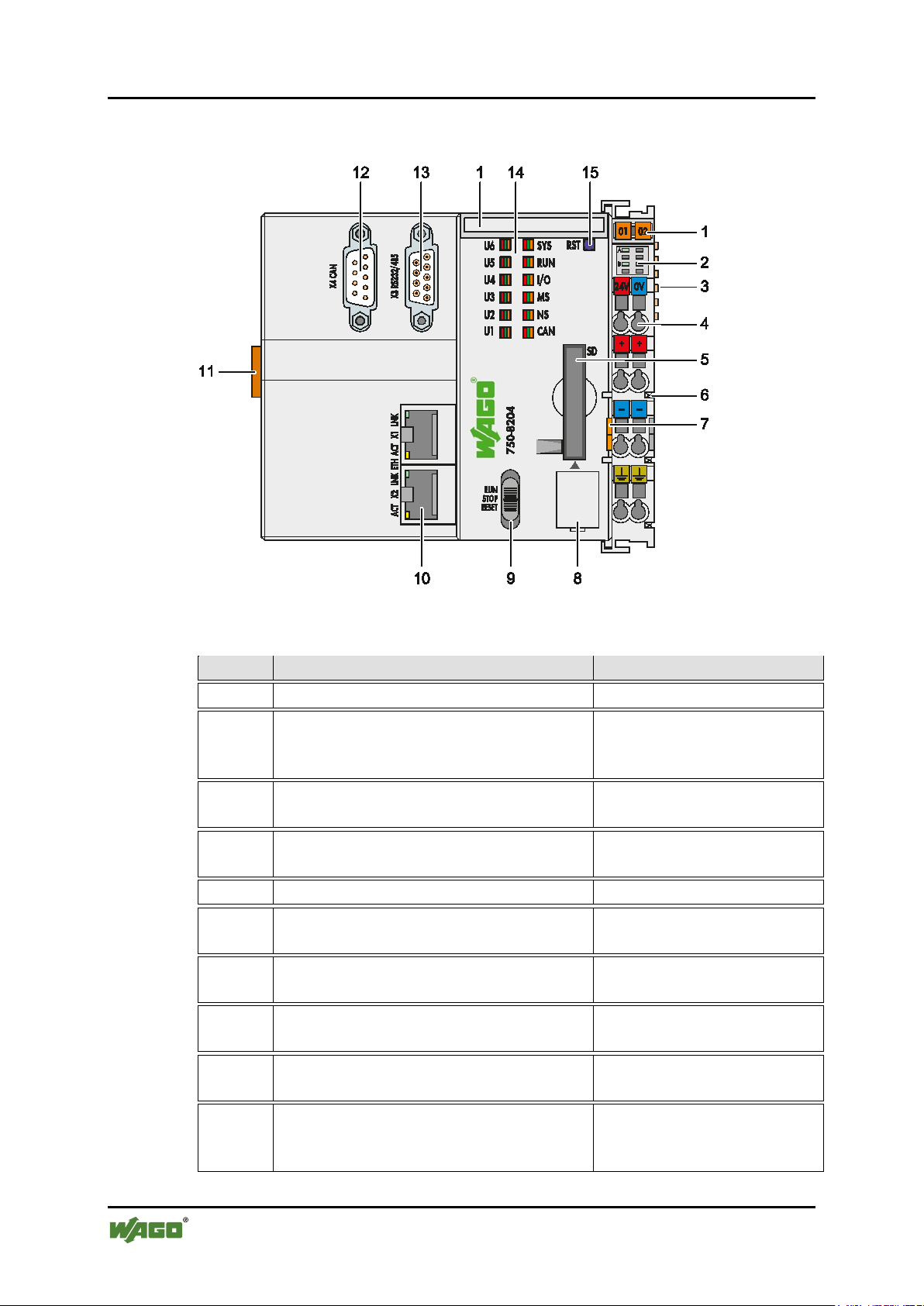

Table 4:Legend for figure “Device view”

Item

Description

See section

1

Marking Options (Mini-WSB)

---

“Indicating elements” >

supply”

“Connections” > “Data

contacts/Internal data bus”

CAGE CLAMP® Connections for Power

Supply

“Connections” > “CAGE

CLAMP® connections”

5

Slot for memory card

“Memory card slot”

Power contacts for power supply of

down-circuit I/O modules

“Connections” > “Power

contacts/ Field-side supply”

“Mounting” > “Inserting and

Removing Device”

“Connections” > “Service

interface”

“Operating elements” >

“Mode selector switch”

“Connections” > “Network

X1, X2”

750-8204 PFC200 DC 2ETH RS CAN

3.1 View

Figure 1: View of device

2 LED Indicators – Power Supply

“Indicating element power

3 Data contacts

4

6

7 Releasing strap

8 Service Interface (behind the flap)

9 Mode selector switch

10 ETHERNET Connections

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

connections ETHERNET –

Page 25

WAGO-I/O-SYSTEM 750 Device Description 25

“Mounting” > “Inserting and

Removing Device”

“Connections” > “CANopen

– X4 Fieldbus Connection”

“Connections” >

232/RS-485 – X3”

“Indicating elements” >

Fieldbus/System”

“Operating elements” >

“Reset button”

750-8204 PFC200 DC 2ETH RS CAN

11 Safe Locking Feature

12 Fieldbus Connection – CANopen

13 Serial interface

14 LED Indicators – System

15 Reset button (in hole)

“Communication port RS-

“Indicating elements

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 26

26 Device Description WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

3.2 Connectors

3.2.1 Data Contacts/Internal Bus

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Communication between the controller and the I/O modules and system power

supply for the I/O modules is provided via the internal data bus, which consists of

6 data contacts designed as self-cleaning gold spring contacts.

Figure 2: Data contacts

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 27

WAGO-I/O-SYSTEM 750 Device Description 27

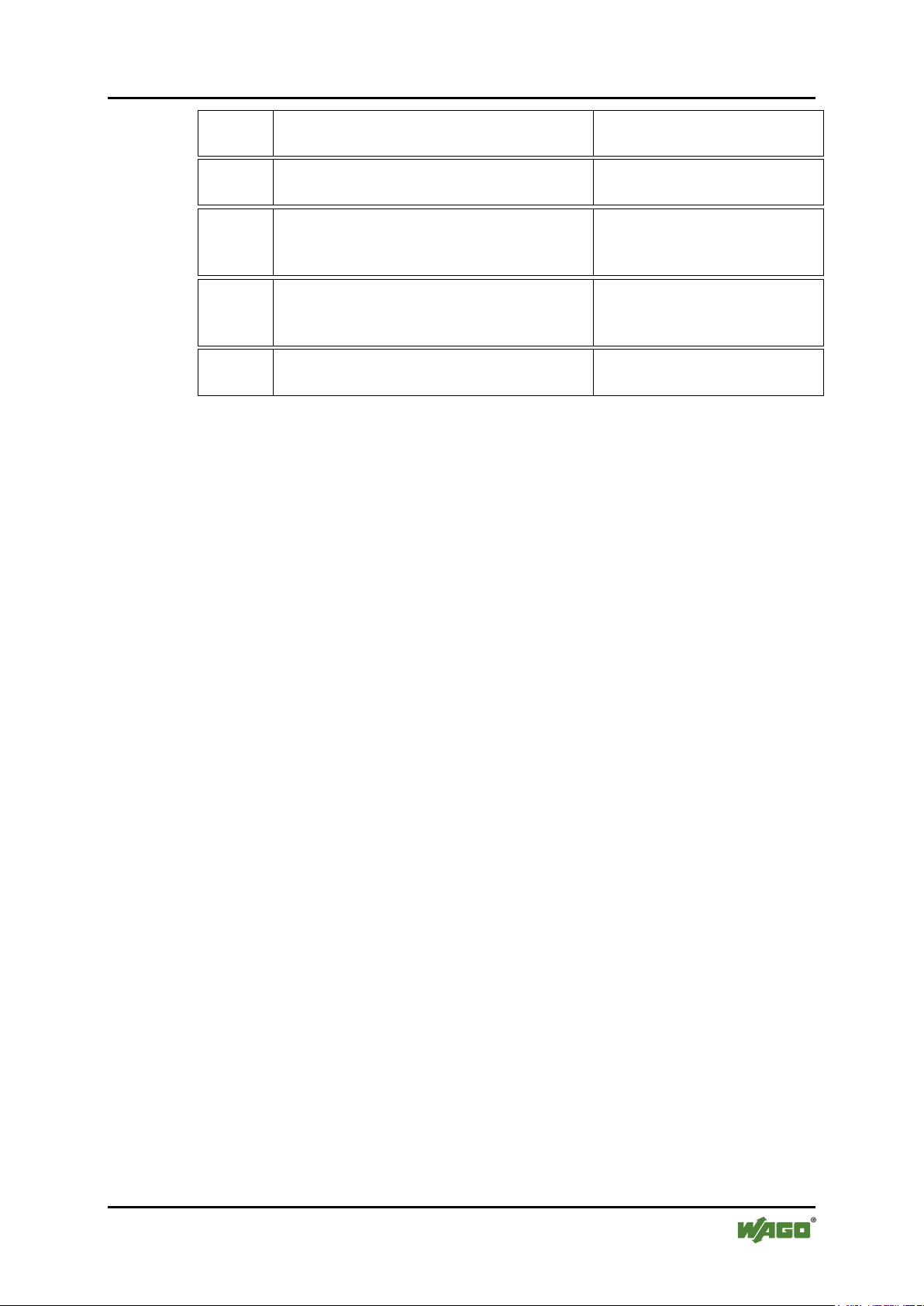

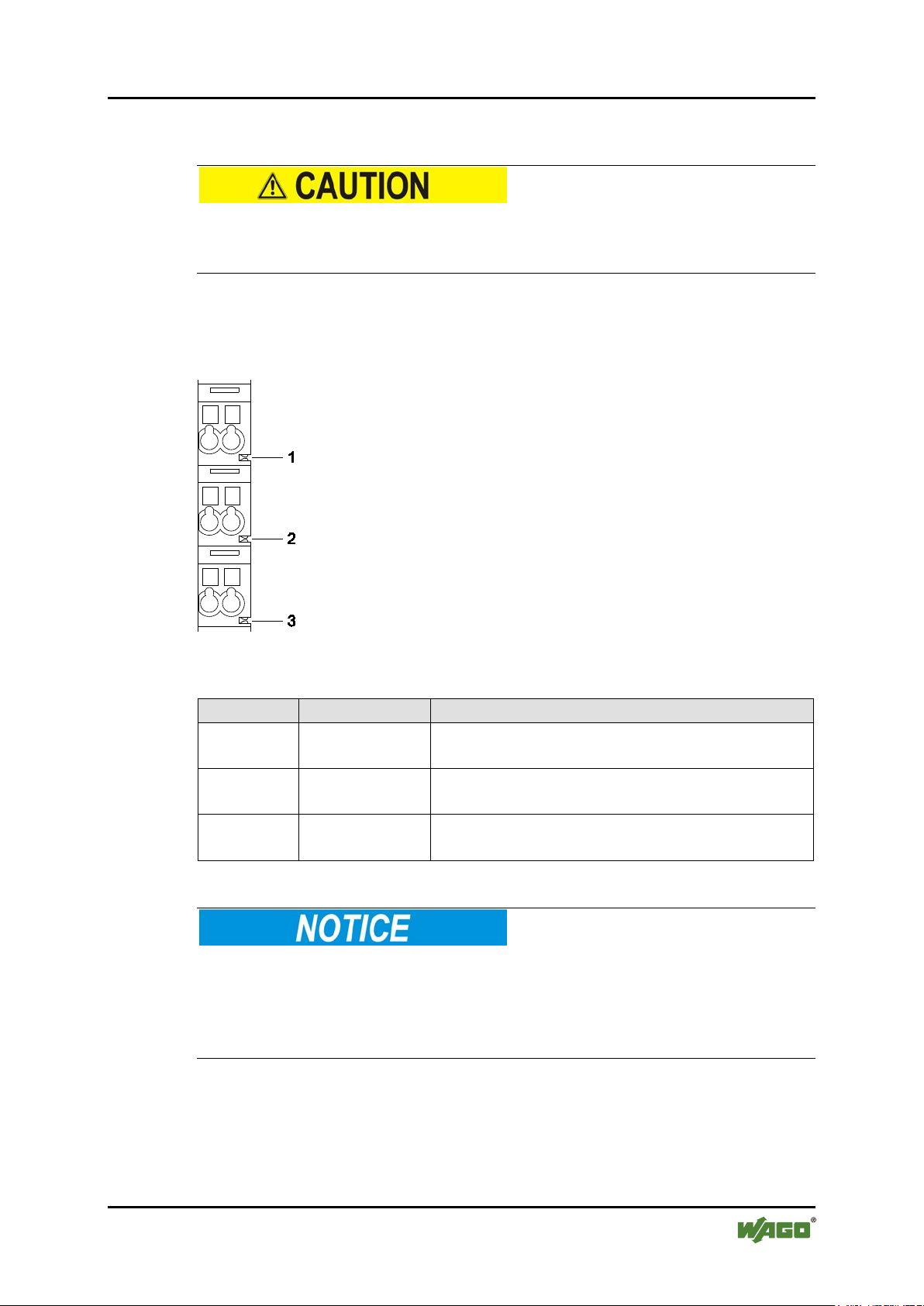

Table 5: Legend for Figure “Power Jumper Contacts”

Contact

Type

Function

Potential transmission (UV)

for field supply

Potential transmission (0 V)

for field supply

Potential transmission (ground)

for field supply

750-8204 PFC200 DC 2ETH RS CAN

3.2.2 Power Jumper Contacts/Field Supply

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

The controller 750-8204is equipped with 3 self-cleaning power contacts for

transferring of the field-side power supply to down-circuit I/O modules. These

contacts are designed as spring contacts.

Figure 3: Power Jumper Contacts

1 Spring contact

2 Spring contact

3 Spring contact

Do not exceed maximum current via power jumper contacts!

The maximum current to flow through the power jumper contacts is 10 A.

Greater currents can damage the contacts.

When configuring your system, ensure that this current is not exceeded. If

exceeded, insert an additional supply module.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 28

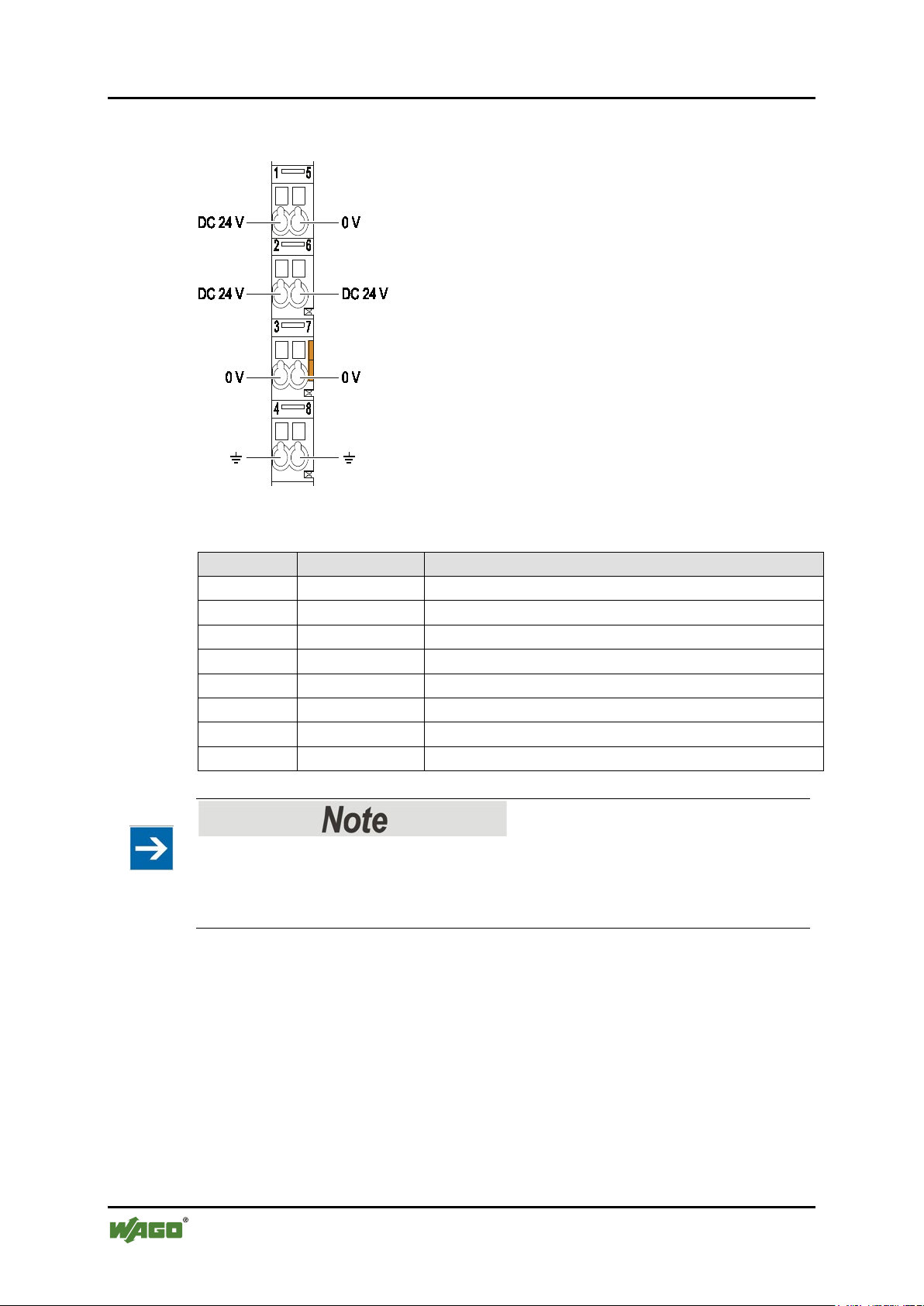

28 Device Description WAGO-I/O-SYSTEM 750

Table 6: Legend for figure “CAGE CLAMP® connections”

Contact

Description

Description

1

24 V

System power supply voltage +24 V

2

+

Field-side power supply voltage UV

3

-

Field-side power supply voltage 0 V

4

Ground

Field-side power supply voltage, ground

5

0 V

System power supply voltage 0 V

6

+

Field-side power supply voltage UV

7

-

Field-side power supply voltage 0 V

8

Ground

Field-side power supply voltage, ground

750-8204 PFC200 DC 2ETH RS CAN

3.2.3 CAGE CLAMP® Connectors

Figure 4: CAGE CLAMP

®

connections

</dg_

Observe supplementary power supply regulations for use in shipbuilding!

Observe supplementary power supply regulations for shipbuilding and the supply

voltage in Section “Connect Devices” > … > “Supplementary Power Supply

Regulations”!

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 29

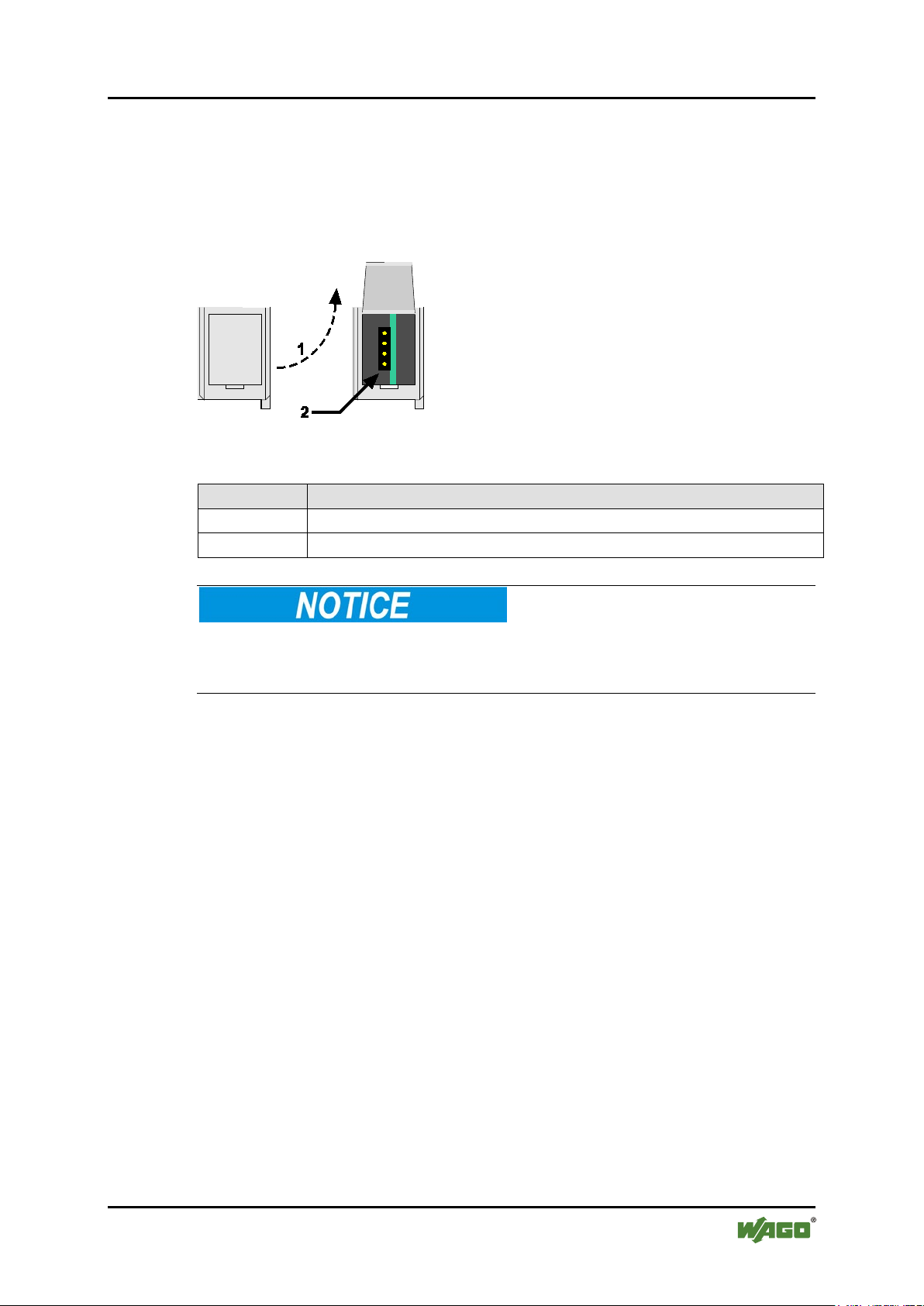

WAGO-I/O-SYSTEM 750 Device Description 29

Table 7: Service interface

Number

Description

1

Open flap

2

Service interface

750-8204 PFC200 DC 2ETH RS CAN

3.2.4 Service Interface

The service interface is located behind the flap.

The Service interface is used for communication with WAGO-I/O-CHECK and

WAGO-I/O-PRO and for firmware download.

Figure 5: Service interface, (closed and open flap)

Device must be de-energized!

To prevent damage to the device, unplug and plug in the communication cable

only when the device is de-energized!

The connection to the 4-pin header under the cover flap can be realized via the

communication cables with the item numbers750-920 and 750-923 or via the

WAGO radio adapter with the item number 750-921.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 30

30 Device Description WAGO-I/O-SYSTEM 750

Table 8: Legend for Figure "Network Connections – X1, X2"

Contact

Signal

Description

1

TD +

Transmit Data +

2

TD -

Transmit Data -

3

RD +

Receive Data +

4

NC

Not assigned

5

NC

Not assigned

6

RD -

Receive Data -

7

NC

Not assigned

8

NC

Not assigned

750-8204 PFC200 DC 2ETH RS CAN

3.2.5 Network Connections – X1, X2

Figure 6: Network connections – X1, X2

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 31

WAGO-I/O-SYSTEM 750 Device Description 31

Table 9: Key for the “RS-232/RS-485 – X3 communication connection” figure

RS-232

RS-485

Signal

Description

Signal

Description

1

NC

Not assigned

NC

Not assigned

2

RxD

Receive Data

NC

Not assigned

3

TxD

Transmit Data

RxD/TxD-P

Receive/transmit data +

4

NC

Not assigned

NC

Not assigned

5

FB_GND

Ground

FB_GND

Ground

6

NC

Not assigned

FB_5V

Power Supply

7

RTS

Request to send

NC

Not assigned

8

CTS

Clear to send

RxD/TxD-N

Receive/transmit data -

9

NC

Not assigned

NC

Not assigned

Enclosure

Shield

Shielding

Shield

Shielding

750-8204 PFC200 DC 2ETH RS CAN

Kommunikati ons ansc hlus s

3.2.6 RS-232/RS-485 – X3 Communication Connection

Figure 7: RS-232/RS-485 – X3 communication connection

Contact

Incorrect parameterization can damage the communication partners!

The voltage levels are -12 V and +12 V for RS-232, and -5 V and +5 V for RS-

485.

If the controller interfaces differ from those of the communication partners (RS232 <> RS-485 or RS-485 <> RS-232), this may damage the interface of the

communication partner.

Therefore, always ensure that the controller interface matches those of its

communication partners when configuring these items!

DC/DC converters and optocouplers in the fieldbus interface electrically isolate

the fieldbus system and the electronics.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 32

32 Device Description WAGO-I/O-SYSTEM 750

Table 10: Function of RS-232 signals for DTE/DCE

Data Direction

DTE

DCE

2

RxD

Input

Output

3

TxD

Output

Input

5

FB_GND

---

---

7

RTS

Output

Input

8

CTS

Input

Output

750-8204 PFC200 DC 2ETH RS CAN

3.2.6.1 Operating as an RS-232 Interface

Depending on the device type DTE (e.g., PC) or DCE (e.g., PFC, modem), the

RS-232 signals have different data directions.

Contact Signal

For a DTE-to-DCE connection, the signals are connected directly (1:1).

Figure 8: Termination with DTE-DCE connection (1:1)

For a DTE-to-DTE connection, the signal connections are crossed.

Figure 9: Termination with DTE-DTE connection (cross-over)

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 33

WAGO-I/O-SYSTEM 750 Device Description 33

750-8204 PFC200 DC 2ETH RS CAN

3.2.6.2 Operating as an RS-485 Interface

To minimize reflection at the end of the line, the RS-485 line must be terminated

at both ends by a cable termination. If required, one pull-up or pull-down resistor

may be used. These resistors ensure a defined level on the bus when no subscriber

is active, i.e., when all subscribers are in “Tri-state”.

Attention — bus termination!

The RS-485 MODBUS bus segment must be terminated at both ends!

No more than two terminations per bus segment may be used!

Terminations may not be used in stub and branch lines!

Operation without proper termination of the RS-485 MODBUS network may

result in transmission errors.

Figure 10: RS-485 bus termination

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 34

34 Device Description WAGO-I/O-SYSTEM 750

Table 11: Legend for Figure “CANopen – X4 Fieldbus Connection”

Contact

Signal

Description

1

-

Not used

2

CAN_L

CAN Signal Low

3

GND

Ground

4

-

Not used

5

Drain Shield

Shield termination

6

-

Not used

7

CAN_H

CAN Signal High

8

-

Not used

9

CAN_V+

Not used

750-8204 PFC200 DC 2ETH RS CAN

3.2.7 CANopen – X4 Fieldbus Connection

Figure 11: CANopen – X4 fieldbus connection

DC/DC converters and optocouplers in the fieldbus interface provide electrical

isolation between the CANopen bus system and the electronics.

The cable shield must be applied to the CAN shield. This is terminated to ground

in devices with 1 MΩ (DIN rail contact). A low-impedance connection of the

shielding to ground is possible only from the outside (e.g., by a supply module).

We recommend using central ground contacts for the entire CANopen bus line

shielding.

To minimize reflection at the end of the line, the CANopen line must be

terminated at both ends by a cable termination.

Attention - bus termination!

The CANopen bus segment must be terminated at both ends!

No more than 2 terminations per bus segment may be used!

Terminations may not be used in stub and branch lines!

Operation without proper termination of the CANopen network may result in

transmission errors.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 35

WAGO-I/O-SYSTEM 750 Device Description 35

750-8204 PFC200 DC 2ETH RS CAN

Observe permissible resistor power loss!

For normal operation, 1/4Watt resistors are sufficient. In the event of a short

circuit (24V power supply to a bus line), the resistor is subjected to a power loss

of (short-circuit output current from transceiver * power supply voltage). The

resistor must be designed to withstand this power loss level.

Figure 12: CANopen standard bus termination

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 36

36 Device Description WAGO-I/O-SYSTEM 750

Table 12: Legend for Figure “Power Supply Indicating Elements”"

Description

Color

Description

A

Green/off

Status of system power supply voltage

B

Green/off

Status of field-side power supply voltage

750-8204 PFC200 DC 2ETH RS CAN

3.3 Display Elements

3.3.1 Power Supply Indicating Elements

Figure 13: Power supply indicating elements

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 37

WAGO-I/O-SYSTEM 750 Device Description 37

Table 13: Legend for figure “Fieldbus/System Indicating Elements”

Description

Color

Description

Red/Green/

Orange/Off

Red/Green/

Orange/Off

Red/Green/

Orange/Off

CG

Without function

NS

Without function

Red/Green/

Orange/Off

User LED 6,

“WagoLibLed.lib” library.

User LED 5,

“WagoLibLed.lib” library.

User LED 4,

“WagoLibLed.lib” library.

User LED 3,

“WagoLibLed.lib” library.

User LED 2,

“WagoLibLed.lib” library.

User LED 1,

“WagoLibLed.lib” library.

750-8204 PFC200 DC 2ETH RS CAN

3.3.2 Fieldbus/System Indicating Elements

Figure 14: Indicating elements for fieldbus/system

SYS

RUN

I/O

CAN

U6

U5

U4

Green/Red/

Orange/Off

Green/Red/

Orange/Off

Red/Green/

Orange/Off

System status

PLC program status

Internal data bus status

CANopen status

programmable using the function blocks of the

programmable using the function blocks of the

programmable using the function blocks of the

U3

U2

U1

Red/Green/

Orange/Off

Red/Green/

Orange/Off

Red/Green/

Orange/Off

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

programmable using the function blocks of the

programmable using the function blocks of the

programmable using the function blocks of the

Page 38

38 Device Description WAGO-I/O-SYSTEM 750

Table 14: Legend for figure “Indicating Elements, memory card slot”

Description

Color

Description

SD

Yellow/Off

Memory card status

750-8204 PFC200 DC 2ETH RS CAN

3.3.3 Memory Card Indicating Elements

Figure 15: Indicating elements, memory card slot

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 39

WAGO-I/O-SYSTEM 750 Device Description 39

Table 15: Legend for figure “Indicating elements, RJ-45 jacks”

Description

Color

Description

LNK

Green/Off

ETHERNET connection status

ACT

Yellow/Off

ETHERNET data exchange

750-8204 PFC200 DC 2ETH RS CAN

3.3.4 Network Indicating Elements

Figure 16: Indicating elements, RJ-45 jacks

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 40

40 Device Description WAGO-I/O-SYSTEM 750

Table 16: Mode selector switch

Item

Activation

Function

Normal mode

CODESYS 2 application runs.

Stop

CODESYS 2 application stopped.

Reset warm start or

“Starting” > “Initiating Reset Functions”)

750-8204 PFC200 DC 2ETH RS CAN

3.4 Operating Elements

3.4.1 Operating Mode Switch

Figure 17: Mode selector switch

</dg_

RUN Latching

STOP Latching

RESET Spring-return

</dg_

Other functions can also be initiated using the reset button.

Reset cold start

(based on the duration of activation, see Section

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 41

WAGO-I/O-SYSTEM 750 Device Description 41

750-8204 PFC200 DC 2ETH RS CAN

3.4.2 Reset Button

Figure 18: Reset button

The Reset button can be actuated using a suitable object (e.g., pen) through a hole

in the enclosure.

Depending on the position of the mode selector switch, the Reset button can be

used to initiate different functions: Software reset, factory reset or fixed IP

address.

Information about these functions are given in the Section “Starting” > “Initiating

Reset Functions”.

Manual

Version 1.1.0, valid from SW-Version 02.02.12(03)

Page 42

42 Device Description WAGO-I/O-SYSTEM 750

750-8204 PFC200 DC 2ETH RS CAN

3.5 Slot for Memory Card

Figure 19: Memory card slot

The memory card is locked in the enclosure by a push/push mechanism. Inserting

and removing the card is described in the Section “Service” > “Inserting and

Removing the Memory Card”.

The memory card is protected by a cover flap, which can also be sealed.

Memory card is not included in the scope of delivery!

Note, the controller is delivered without memory card.