Page 1

Modular I/O System

DeviceNet

750-306, 750-806

Manual

Technical Description,

Installation and

Configuration

Supplement for the Manual 750-135

Version 2002-07-01

Page 2

ii • General

Copyright ã 2002 by WAGO Kontakttechnik GmbH

All rights reserved.

WAGO Kontakttechnik GmbH

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded we would appreciate any information or ideas at any time.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 3

TABLE OF CONTENTS

1 Important Comments.................................................................................4

1.1 Legal Principles......................................................................................4

1.2 Symbols..................................................................................................5

1.3 Font Conventions ...................................................................................6

1.4 Number Notation....................................................................................6

1.5 Safety Notes ...........................................................................................7

1.6 Scope ......................................................................................................8

1.7 Abbreviation...........................................................................................8

2 The WAGO-I/O-SYSTEM 750 .................................................................9

2.1 System Description ................................................................................9

2.2 Technical Data......................................................................................10

2.3 Manufacturing Number........................................................................13

2.4 Storage, Consignment and Transport...................................................14

2.5 Mechanical Setup .................................................................................14

2.6 Power Supply .......................................................................................22

2.7 Grounding.............................................................................................33

2.8 Shielding (screening)............................................................................36

2.9 Assembly Guidelines / Norms .............................................................37

Table of Contents • iii

3 Fieldbus Coupler/Controller...................................................................38

3.1 Fieldbus Coupler 750-306....................................................................38

3.2 Fieldbus Controller 750-806 ................................................................61

4 I/O modules.............................................................................................105

5 DeviceNet.................................................................................................106

5.1 Description .........................................................................................106

5.2 Network Architecture.........................................................................107

5.3 Network Communication ...................................................................112

5.4 Module Characteristics.......................................................................113

5.5 Process data and Diagnostic Status ....................................................114

5.6 Configuration / Parametering with the Object Model........................116

6 Application in Explosive Environments...............................................139

6.1 Foreword ............................................................................................139

6.2 Protective Measures ...........................................................................139

6.3 Classification Meeting CENELEC and IEC ......................................139

6.4 Classifications Meeting the NEC 500 ................................................144

6.5 Identification ......................................................................................146

6.6 Installation Regulations......................................................................148

7 Glossary...................................................................................................150

8 Literature List ........................................................................................151

9 Index ........................................................................................................152

WAGO-I/O-SYSTEM 750

DeviceNet

Page 4

4 • Important Comments

Legal Principles

1 Important Comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanations are

carefully read and abided by.

1.1 Legal Principles

1.1.1 Copyright

This manual is copyrighted, together with all figures and illustrations contained therein. Any use of this manual which infringes the copyright provisions stipulated herein, is not permitted. Reproduction, translation and electronic and photo-technical archiving and amendments require the written consent of WAGO Kontakttechnik GmbH. Non-observance will entail the right of

claims for damages.

WAGO Kontakttechnik GmbH reserves the right to perform modifications

allowed by technical progress. In case of grant of a patent or legal protection

of utility patents all rights are reserved by WAGO Kontakttechnik GmbH.

Products of other manufacturers are always named without referring to patent

rights. The existence of such rights can therefore not be ruled out.

1.1.2 Personnel Qualification

The use of the product detailed in this manual is exclusively geared to specialists having qualifications in PLC programming, electrical specialists or

persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH declines all liability resulting from

improper action and damage to WAGO products and third party products due

to non-observance of the information contained in this manual.

1.1.3 Intended Use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only permitted within the framework of the possibilities documented in the manuals.

All other changes to the hardware and/or software and the non-conforming use

of the components entail the exclusion of liability on part of WAGO Kontakttechnik GmbH.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 5

1.2 Symbols

Important Comments • 5

Symbols

Danger

Always abide by this information to protect persons from injury.

Warning

Always abide by this information to prevent damage to the device.

Attention

Marginal conditions must always be observed to ensure smooth operation.

ESD (Electrostatic Discharge)

Warning of damage to the components by electrostatic discharge. Observe the

precautionary measure for handling components at risk.

Note

Routines or advice for efficient use of the device and software optimization.

More information

References on additional literature, manuals, data sheets and INTERNET

pages

WAGO-I/O-SYSTEM 750

DeviceNet

Page 6

6 • Important Comments

Font Conventions

1.3 Font Conventions

Italic

Italic

\

END

< >

Courier Program code is printed with the font Courier.

1.4 Number Notation

Names of path and files are marked italic

i.e.: C:\programs\WAGO-IO-CHECK

Menu items are marked as bold italic

i.e.: Save

A backslash between two names marks a sequence of

menu items

i.e.: File\New

Press buttons are marked as bold with small capitals

i.e.: ENTER

Keys are marked bold within angle brackets

i.e.: <F5>

i.e.: END_VAR

Number Code Example Note

Decimal 100 normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Within ',

Nibble separated with dots

WAGO-I/O-SYSTEM 750

DeviceNet

Page 7

1.5 Safety Notes

Attention

Switch off the system prior to working on bus modules!

In the event of deformed contacts, the module in question is to be replaced, as

its functionality can no longer be ensured on a long-term basis.

The components are not resistant against materials having seeping and insulating properties. Belonging to this group of materials is: e.g. aerosols, silicones, triglycerides (found in some hand creams).

If it cannot be ruled out that these materials appear in the component environment, then additional measures are to be taken:

- installation of the components into an appropriate housing

- handling of the components only with clean tools and materials.

Attention

Cleaning of soiled contacts may only be done with ethyl alcohol and leather

cloths. Thereby, the ESD information is to be regarded.

Important Comments • 7

Safety Notes

Do not use any contact spray, as in a worst-case scenario; the functioning of

the contact area can be impaired.

The WAGO-I/O-SYSTEM 750 and its components are an open system. It

must only be assembled in housings, cabinets or in electrical operation

rooms. Access must only be given via a key or tool to authorized qualified

personnel.

The relevant valid and applicable standards and guidelines concerning the

installation of switch boxes are to be observed.

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the environment (persons, workplace and packing) is well grounded. Avoid touching

conductive components, e.g. gold contacts.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 8

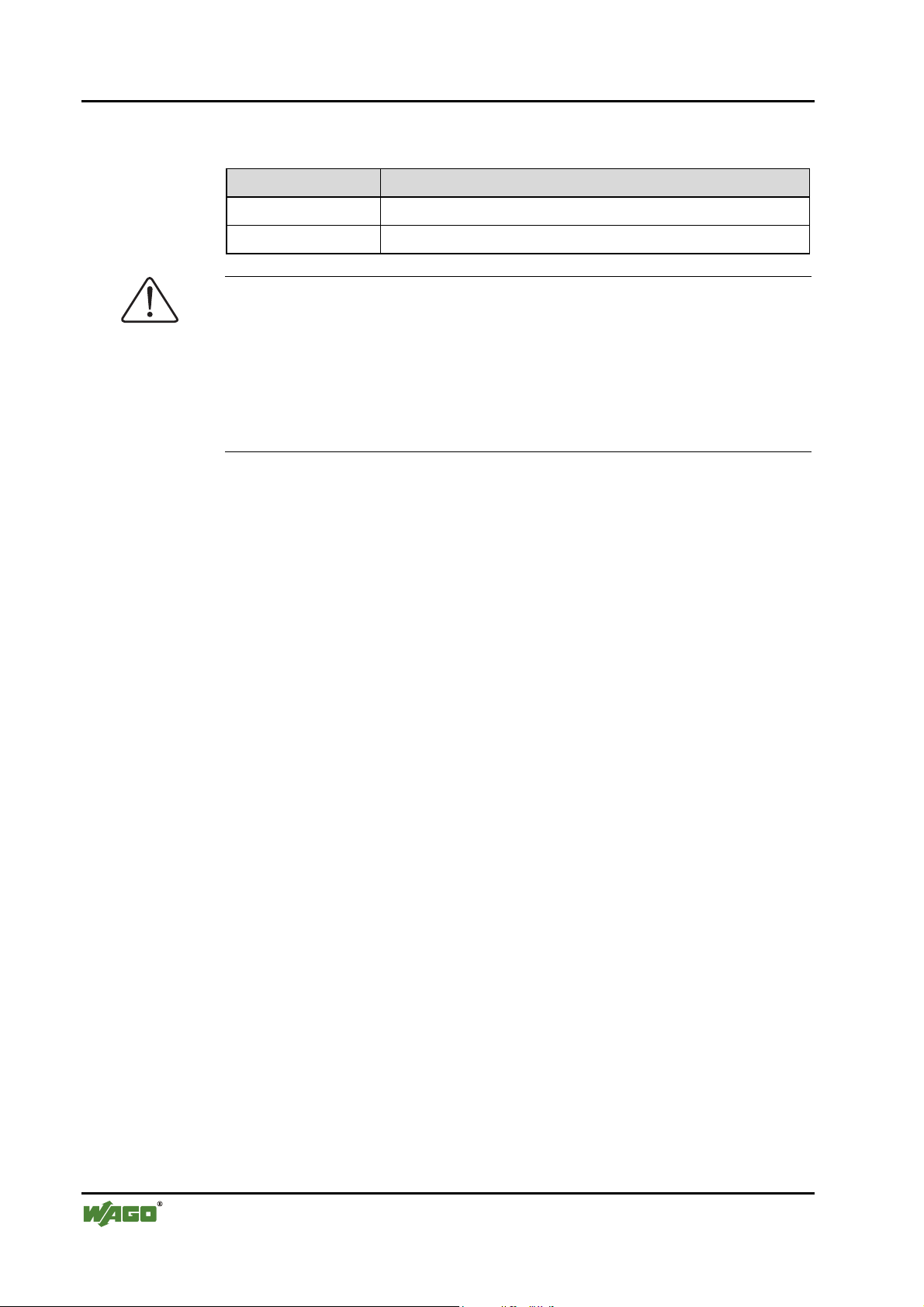

8 • Important Comments

Scope

1.6 Scope

Item no. Description

750-306 fieldbus Coupler DeviceNet; 125 – 500 kBaud

750-806 prog. Fieldbus Controller DeviceNet; 125 – 500 kBaud

Attention

This document is a supplement for the DeviceNet manual.

This manual describes the modular WAGO-I/O-SYSTEM 750 with the fieldbus Coupler for DeviceNet or with the programmable fieldbus Controller for

DeviceNet.

This extract does not contain:

The chapter 3 "I/O modules"

(Description of the field bus independent I/O modules).

1.7 Abbreviation

AI

AO

BC

CAL

CAN

DI

DIP

DO

EDS

I/O

ID

Idx

ISO/ OSI

M

MAC ID

MS

Analog Input

Analog Output

BusCoupler

CAN Application Layer

Controller Area Network

Digital Input

Dual In-line Package

Digital Output

Electronic Data Sheets

Input/Output

Identifier, Identification

Index

International Organization for Standardization / Open Systems Interconnection (model)

Master

Media Access Control Identifier (nodeaddress)

Module Status

NMT

NS

PFC

RO

RW

Network Management

Network Status

Programmable fieldbus Controller

Read Only

Read/Write

WAGO-I/O-SYSTEM 750

DeviceNet

Page 9

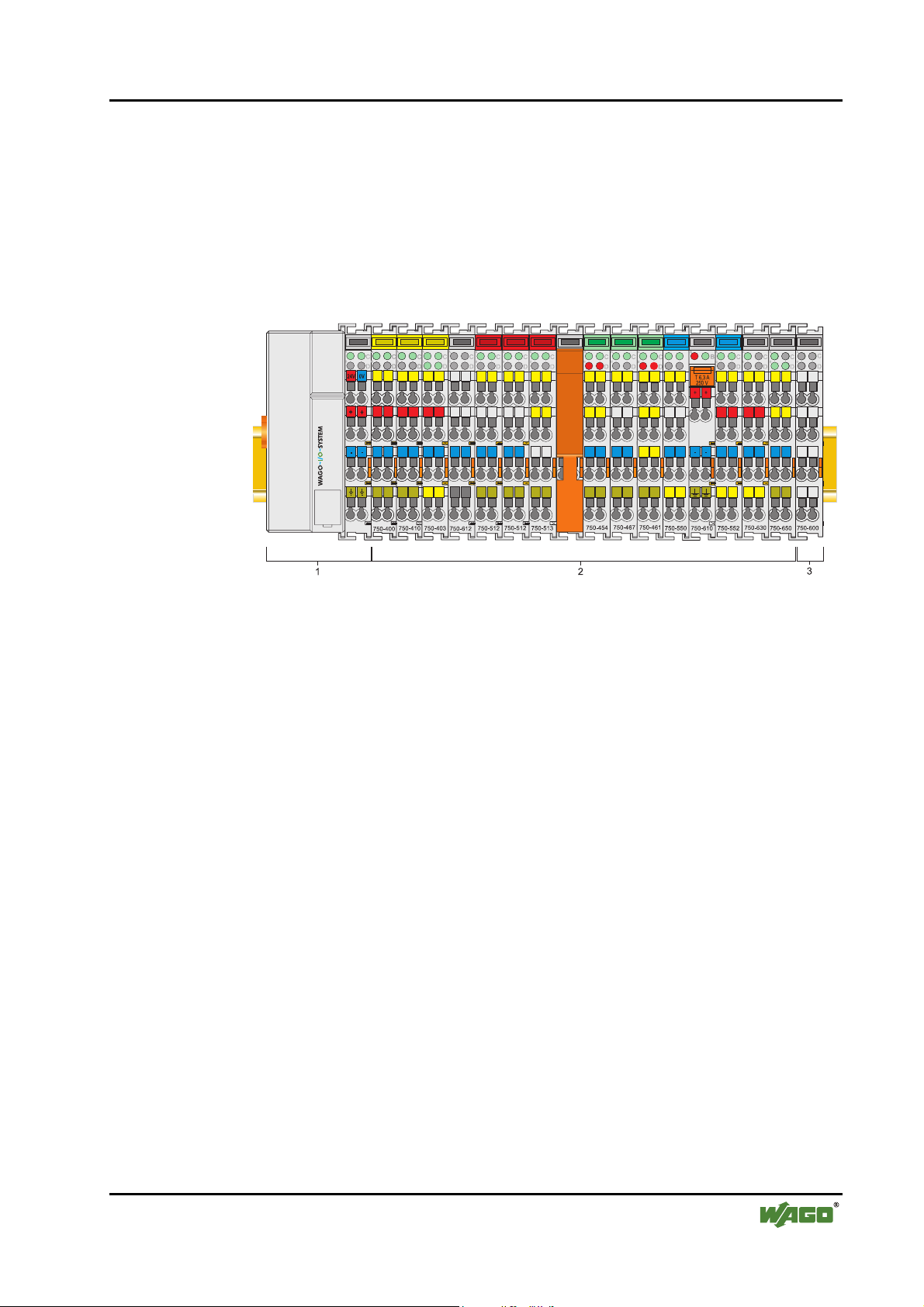

2 The WAGO-I/O-SYSTEM 750

2.1 System Description

The WAGO-I/O-SYSTEM 750 is a modular, fieldbus independent I/O system.

It is comprised of a fieldbus coupler/controller (1) and up to 64 connected

fieldbus modules (2) for any kind of signal. Together, these make up the

fieldbus node. The end module (3) completes the node.

The WAGO-I/O-SYSTEM 750 • 9

System Description

Fig. 2-1: Fieldbus node g0xxx00x

Couplers / controllers for fieldbus systems such as PROFIBUS, INTERBUS,

ETHERNET TCP/IP, CAN (CANopen, DeviceNet, CAL), MODBUS, LON

and others are available.

The coupler / controller contains the fieldbus interface, electronics and a

power supply terminal. The fieldbus interface forms the physical interface to

the relevant fieldbus. The electronics process the data of the bus modules and

make it available for the fieldbus communication. The 24 V system supply and

the 24 V field supply are fed in via the integrated power supply terminal.

The fieldbus coupler communicates via the relevant fieldbus. The programmable fieldbus controller (PFC) enables the implementation of additional PLC

functions. Programming is done with the WAGO-I/O-PRO 32 in accordance

with IEC 61131-3.

Bus modules for diverse digital and analogue I/O functions as well as special

functions can be connected to the coupler / controller. The communication

between the coupler/controller and the bus modules is carried out via an internal bus.

The WAGO-I/O-SYSTEM 750 has a clear port level with LEDs for the status

indication, insertable mini WSB markers and pullout group marker carriers.

The 3-wire technology supplemented by a ground wire connection allows the

direct sensor/actuator wiring.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 10

10 • The WAGO-I/O-SYSTEM 750

Technical Data

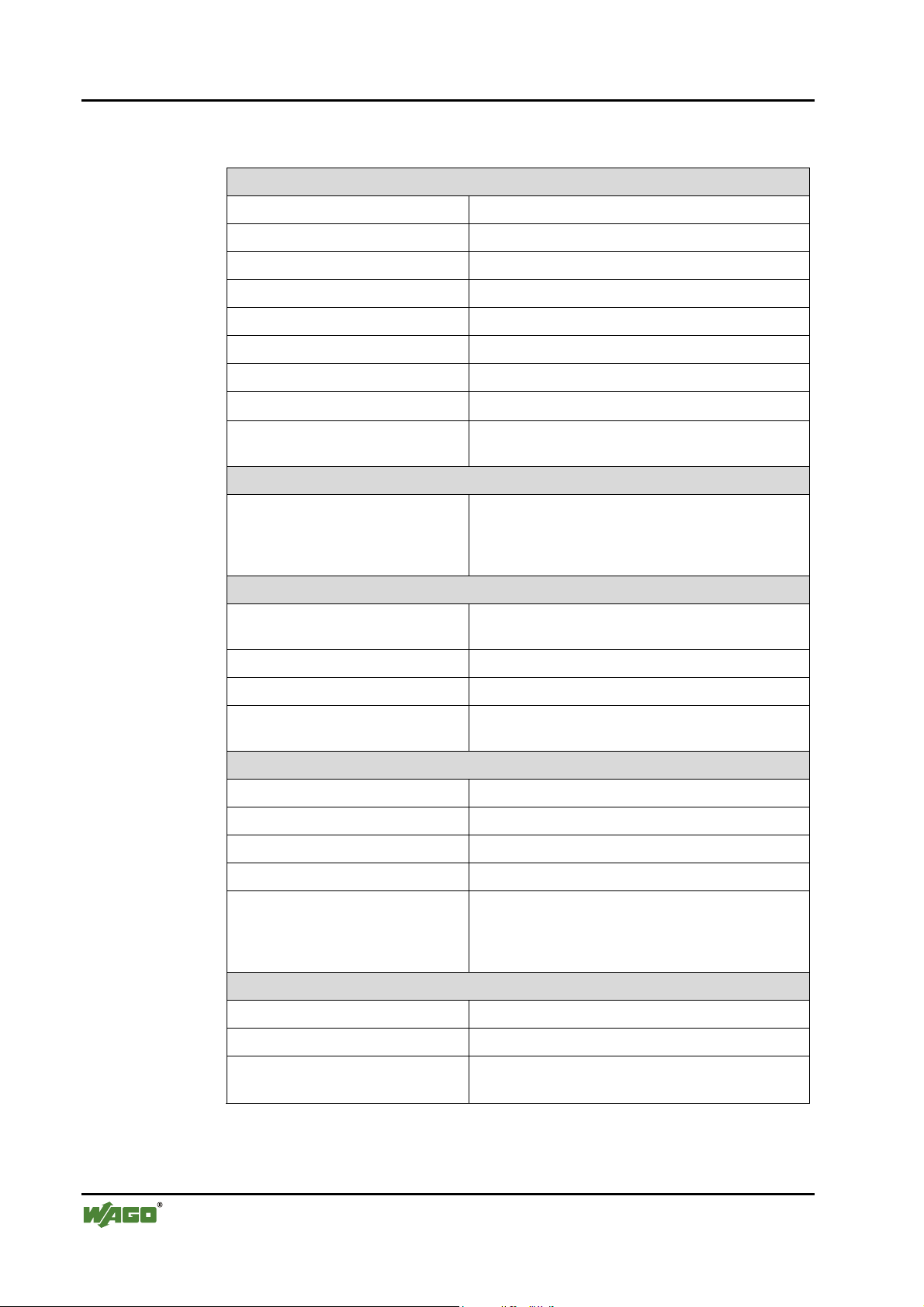

2.2 Technical Data

Mechanic

Material Polycarbonate, Polyamide 6.6

Dimensions Coupler / Controller 51 mm x 65* mm x 100 mm

Dimensions I/O module, single 12 mm x 64* mm x 100 mm

Dimensions I/O module, double 24 mm x 64* mm x 100 mm

Installation on DIN 35 with interlock

modular by double featherkey-dovetail

Mounting position any position

Length of entire node

≤ 831 mm

Marking marking label type 247 and 248

paper marking label 8 x 47 mm

Wire range

Wire range CAGE CLAMP® Connection

0,08 mm² ... 2.5 mm²

AWG 28-14

8 – 9 mm Stripped length

Contacts

Power jumpers contacts blade/spring contact

self-cleaning

Current via power contacts

Voltage drop at I

max

max

10 A

< 1 V/64 modules

Data contacts slide contact, hard gold plated

1,5µ, self-cleaning

Climatic environmental conditions

Operating temperature 0 °C ... 55 °C

Storage temperature -20 °C ... +85 °C

Relative humidity 95 % without condensation

Resistance to harmful substances acc. to IEC 60068-2-42 and IEC 60068-2-43

Special conditions Ensure that additional measures for components are

taken, which are used in an environment involving:

– dust, caustic vapors or gasses

– ionization radiation.

Mechanical strength

Vibration resistance acc. to IEC 60068-2-6

Shock resistance acc. to IEC 60068-2-27

Free fall acc. to IEC 60068-2-32

≤ 1m (module in original packing)

* from upper edge of DIN 35 rail

WAGO-I/O-SYSTEM 750

DeviceNet

Page 11

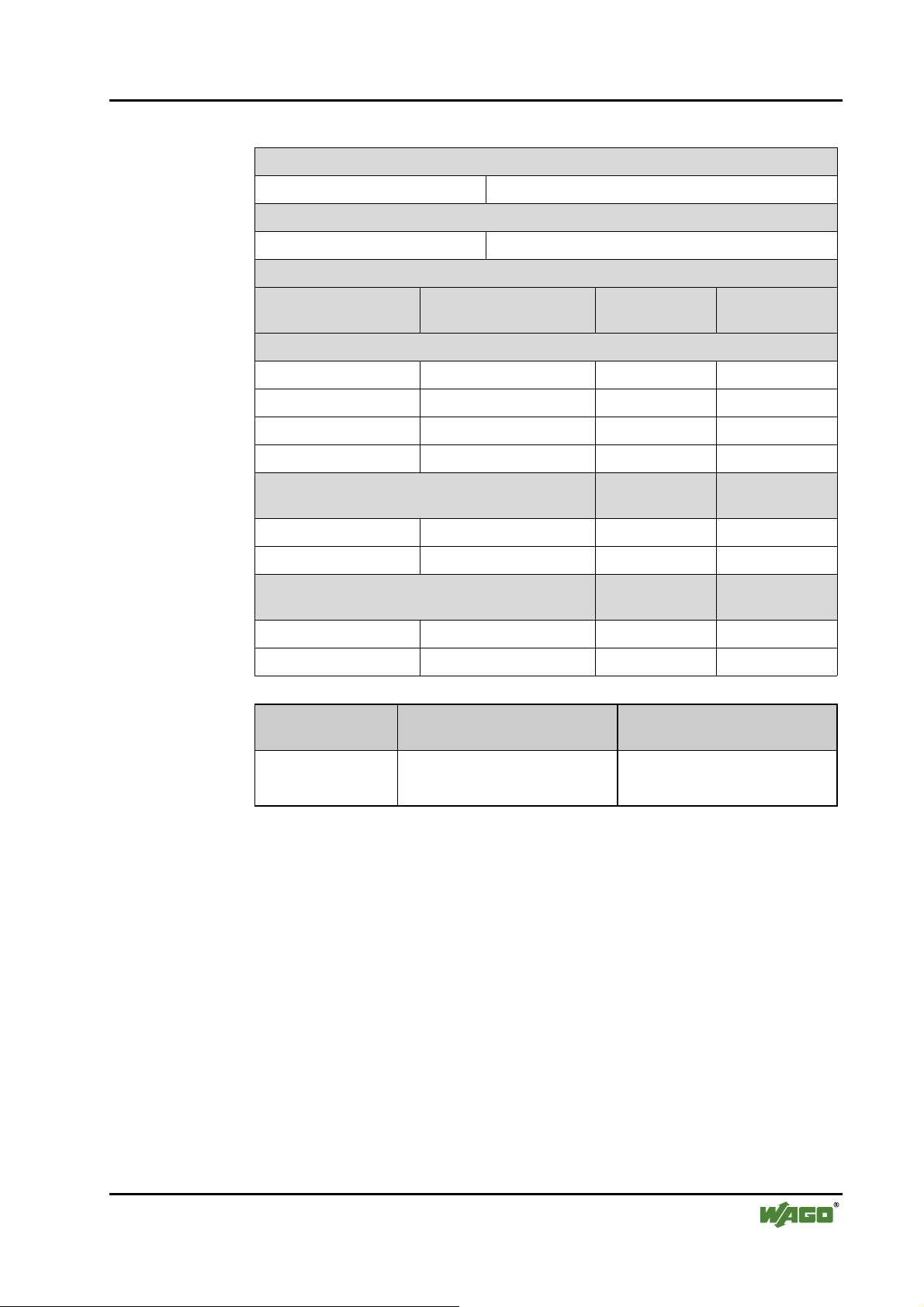

The WAGO-I/O-SYSTEM 750 • 11

Safe electrical isolation

Air and creepage distance acc. to IEC 60664-1

Degree of protection

Degree of protection IP 20

Electromagnetic compatibility*

Technical Data

Directive Test values Strength

class

Immunity to interference acc. to EN 50082-2 (96)

EN 61000-4-2 4kV/8kV (2/4) B

EN 61000-4-3 10V/m 80% AM (3) A

EN 61000-4-4 2kV (3/4) B

EN 61000-4-6 10V/m 80% AM (3) A

Emission of interference acc. to

EN 50081-2 (94)

EN 55011 30 dBµV/m (30m) A

37 dBµV/m

Emission of interference acc. to

EN 50081-1 (93)

EN 55022 30 dBµV/m (10m) B

37 dBµV/m

* Exception: 750-630, 750-631

Range of application

Required specification

emission of interference

Measuring

distance

Measuring

distance

Required specification

immunity to interference

Evaluation

criteria

Class

Class

Industrial areas EN 50081-2 : 1993 EN 50082-2 : 1996

Residential areas EN 50081-1 : 1993*) EN 50082-1 : 1992

*)

WAGO-I/O-SYSTEM 750

DeviceNet

The system meets the requirements on emission of interference in residential areas with

the fieldbus coupler/controller for:

ETHERNET

LonWorks

CANopen

DeviceNet

MODBUS

With a special permit, the system can also be implemented with other fieldbus couplers/controllers in residential areas (housing, commercial and business areas, small-scale

enterprises). The special permit can be obtained from an authority or inspection office. In

Germany, the Federal Office for Post and Telecommunications and its branch offices

issues the permit.

It is possible to use other field bus couplers / controllers under certain boundary conditions. Please contact WAGO Kontakttechnik GmbH.

750-342/-842

750-319/-819

750-337/-837

750-306/-806

750-312/-314/ -315/ -316

750-812/-814/ -815/ -816

Page 12

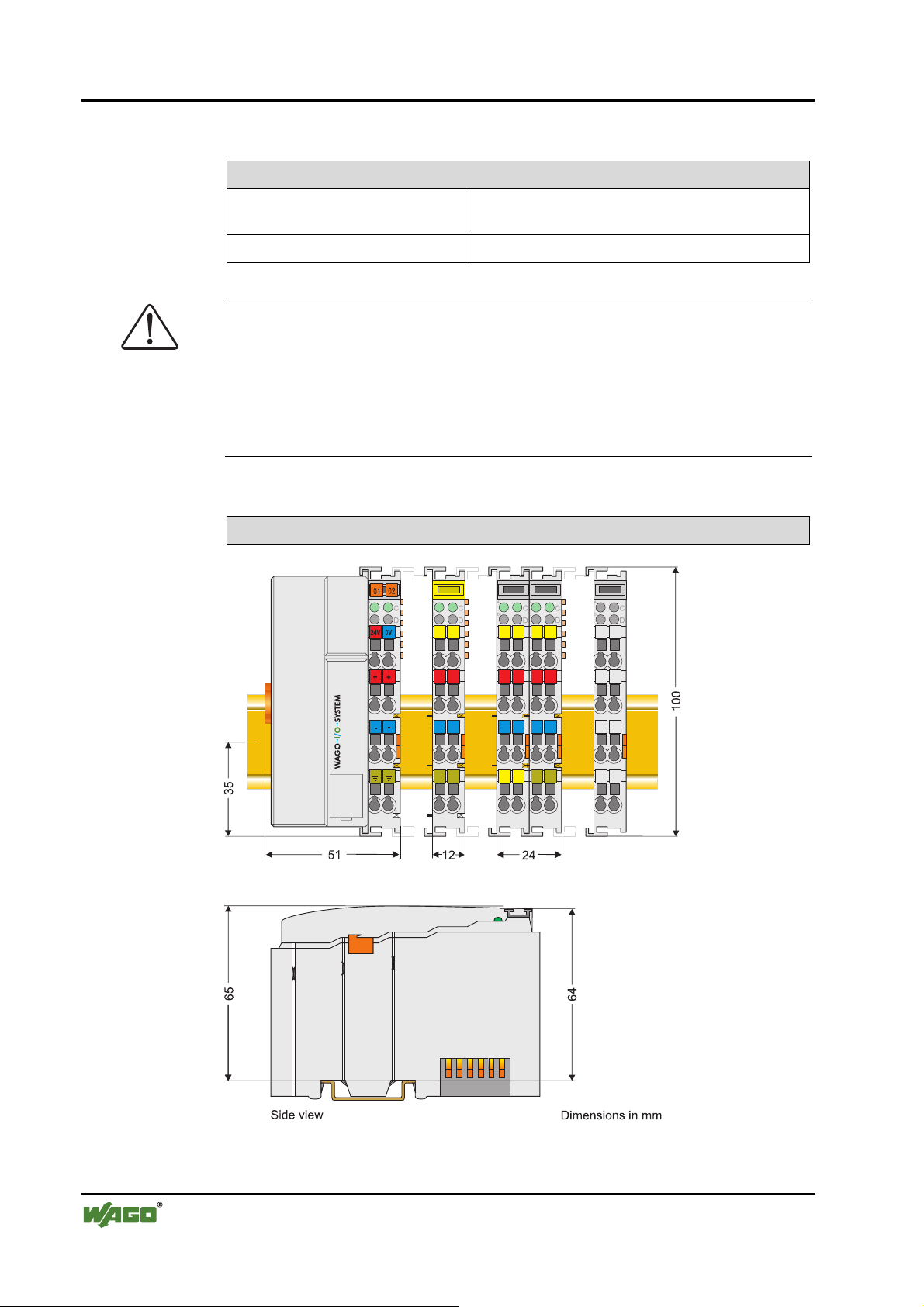

12 • The WAGO-I/O-SYSTEM 750

Technical Data

Maximum power dissipation of the components

Bus modules 0.8 W / bus terminal (total power dissipation, sys-

Fieldbus coupler / controller 2.0 W / coupler / controller

Warning

The power dissipation of all installed components must not exceed the maximal conductible power of the housing (cabinet).

When dimensioning the housing, care is to be taken that even under high external temperatures, the temperature inside the housing does not exceed the

permissible ambient temperature of 55 °C.

tem/field)

Dimensions

Fig. 2-2: Dimensions g01xx05e

WAGO-I/O-SYSTEM 750

DeviceNet

Page 13

2.3 Manufacturing Number

The production number is part of the lateral marking on the component.

Hansastr. 27

D-32423 Minden

The WAGO-I/O-SYSTEM 750 • 13

Manufacturing Number

ITEM-NO.:750-400

2DI 24V DC 3.0ms

2

0.08-2.5mm

24V DC

CL I DIV 2

AWG 28-14

55°C max ambient

Grp. A B C D

op temp code T4A

24246

LISTED 22ZA AND 22XM

0901--02----03

0V 24V DI1

II3G

KEMA 01ATEX1024 X

EEx nA II T4

Di2

PATENTS PENDING

Manufacturing Number

0

9

Calendar

week

1

0

-

Year Software

version

2

0

0

-

Hardware

version

Fig. 2-3: Manufacturing Number g01xx09e

The manufacturing number consists of the production week and year, the

software version (if available), the hardware version of the component, the

firmware loader (if available) and further internal information for

WAGO Kontakttechnik GmbH.

As of calendar week 43/2000, the production number is also printed on the

cover of the configuration and programming interface of the fieldbus coupler

or controller.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 14

14 • The WAGO-I/O-SYSTEM 750

Storage, Consignment and Transport

2.4 Storage, Consignment and Transport

Wherever possible, the components are to be stored in their original packaging. Likewise, the original packaging provides optimal protection during

transport.

When consigning or repacking the components, the contacts must not be

soiled or damaged. The components must be stored and transported in appropriate containers/packaging. Thereby, the ESD information is to be regarded.

Statically shielded transport bags with metal coatings are to be used for the

transport of open components for which soiling with amine, amide and silicone has been ruled out, e.g. 3M 1900E.

2.5 Mechanical Setup

2.5.1 Installation Position

Along with horizontal and vertical installation, all other installation positions

are allowed.

Attention

In the case of vertical assembly, an end stop has to be mounted as an additional safeguard against slipping.

WAGO item 249-117/002-000 End stop for DIN 35 rail, 10 mm wide

2.5.2 Total Expansion

The maximum total expansion of a node is calculated as follows:

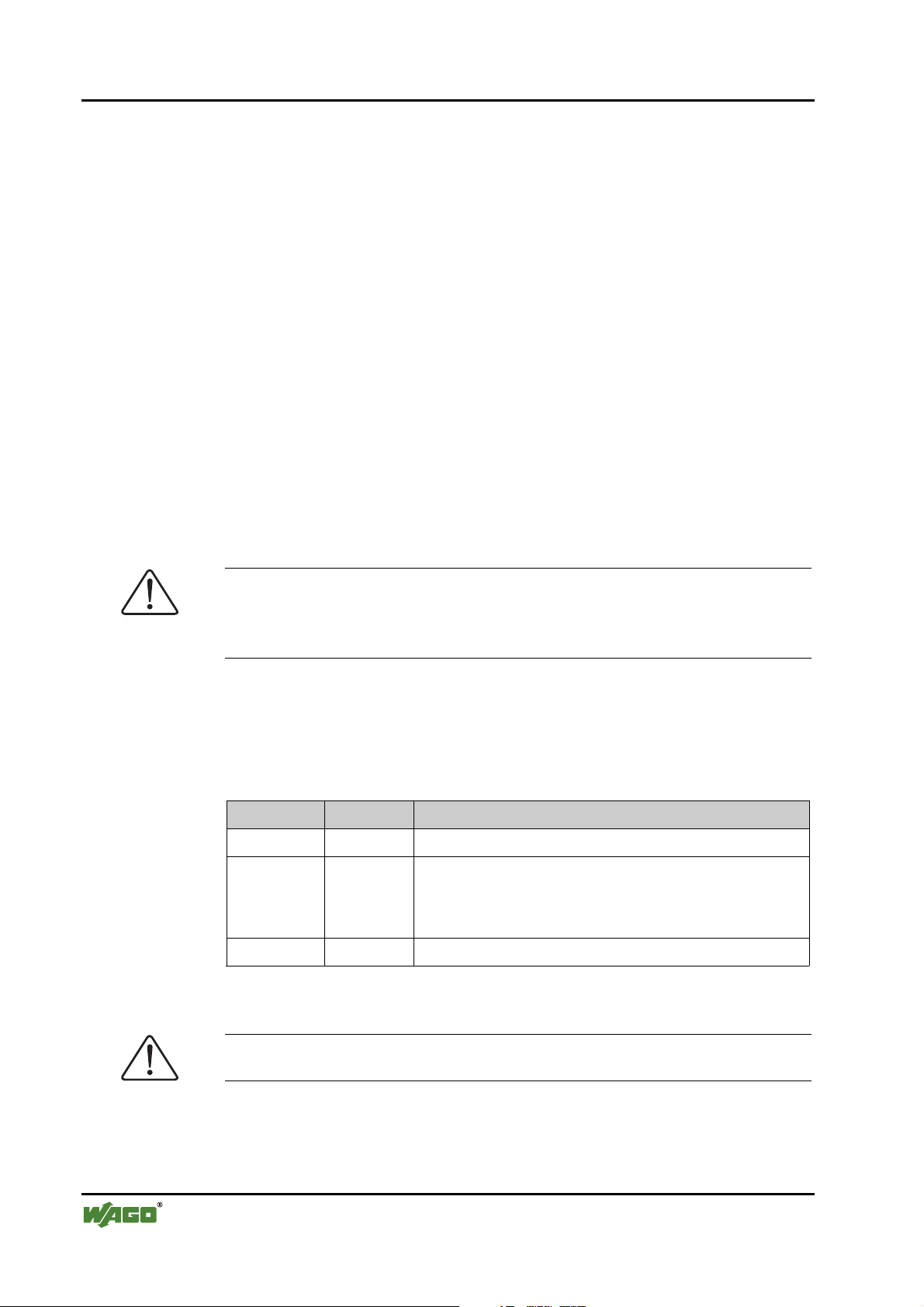

Quantity Width Components

1 51 mm coupler / controller

64 12 mm bus modules

1 12 mm end stop

- inputs / outputs

- power supply modules

- etc.

sum 831 mm

Warning

The maximal total expansion of a node must not exceed 831 mm

WAGO-I/O-SYSTEM 750

DeviceNet

Page 15

The WAGO-I/O-SYSTEM 750 • 15

Mechanical Setup

2.5.3 Assembly onto Carrier Rail

2.5.3.1 Carrier rail properties

All system components can be snapped directly onto a carrier rail in accordance with the European standard EN 50022 (DIN 35).

Warning

WAGO supplies standardized carrier rails that are optimal for use with the

I/O system. If other carrier rails are used, then a technical inspection and approval of the rail by WAGO Kontakttechnik GmbH must take place.

Carrier rails have different mechanical and electrical properties. For the optimal system setup on a carrier rail, certain marginal terms must be observed:

• The material must be non-corrosive.

• Most components have a contact to the carrier rail to ground electro-magnetic disturbances.

In order to avoid corrosion, this tin-plated carrier rail contact must not form a galvanic cell

with the material of the carrier rail which generates a differential voltage above 0.5 V (saline

solution of 0.3% at 20°C) .

• The carrier rail must optimally support the EMC measures integrated into the system and the

shielding of the bus module connections.

• A sufficiently stable carrier rail should be selected and, if necessary, several assembly points

(every 20 cm) should be used in order to prevent bending and twisting (torsion).

• The geometry of the carrier rail must not be altered in order to secure the safe hold of the

components. In particular, when shortening or mounting the carrier rail, it must not be

crushed or bent.

• The base of the components extends into the profile of the carrier rail. For carrier rails with a

height of 7.5 mm, assembly points (screws) are to be riveted under the node in the carrier rail

(slotted head captive screws or blind rivets).

WAGO-I/O-SYSTEM 750

DeviceNet

Page 16

16 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

2.5.3.2 WAGO DIN Rail

WAGO carrier rails meet the electrical and mechanical requirements.

Item Number Description

210-113 /-112 35 x 7.5; 1 mm; steel yellow chromated; slotted/unslotted

210-114 /-197 35 x 15; 1.5 mm; steel yellow chromated; slotted/unslotted

210-118 35 x 15; 2.3 mm; steel yellow chromated; unslotted

210-198 35 x 15; 2.3 mm; copper; unslotted

210-196 35 x 7.5; 1 mm; aluminum; unslotted

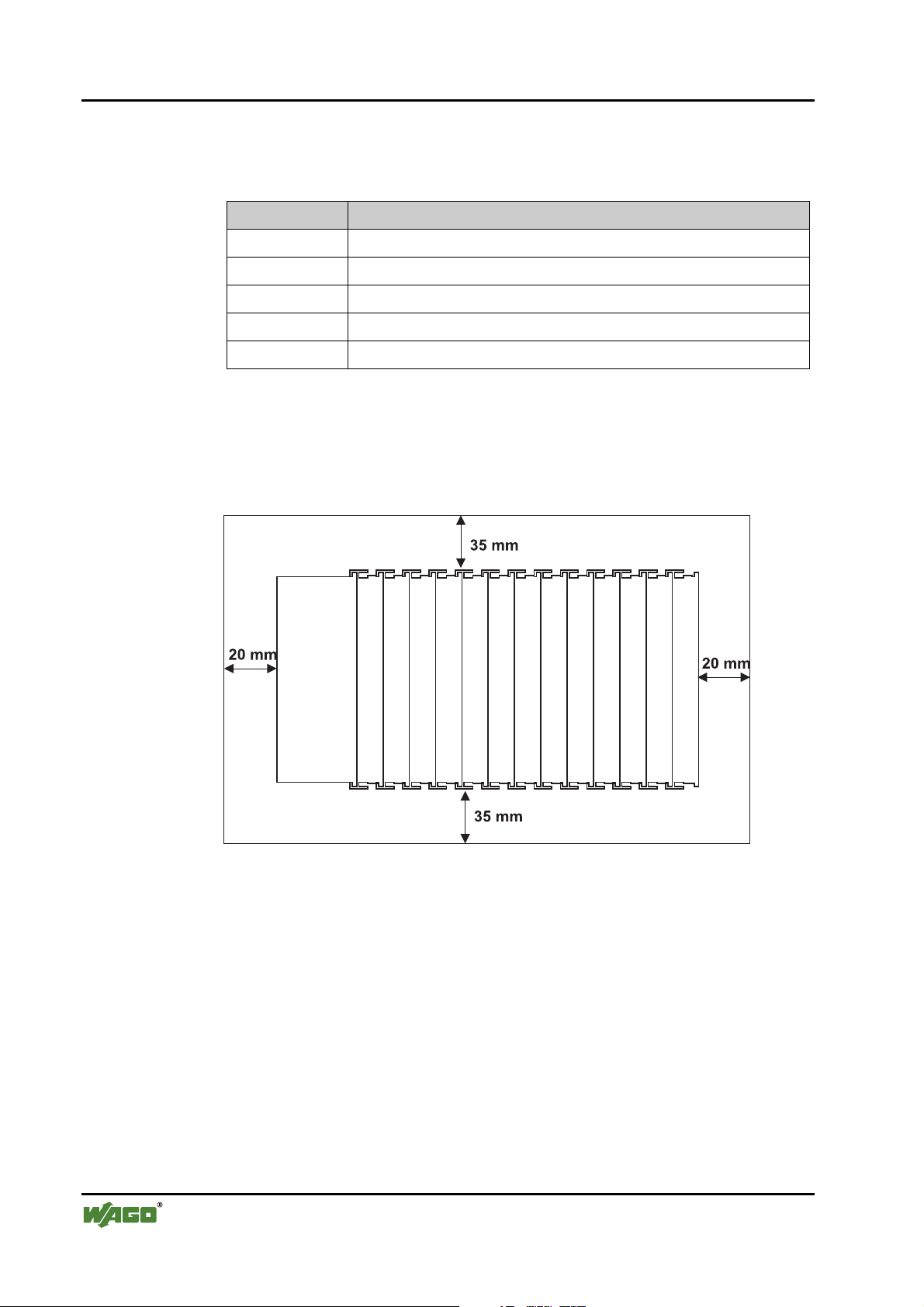

2.5.4 Spacing

The spacing between adjacent components, cable conduits, casing and frame

sides must be maintained for the complete field bus node.

Fig. 2-4: Spacing g01xx13 x

The spacing creates room for heat transfer, installation or wiring. The spacing

to cable conduits also prevents conducted electromagnetic interferences from

influencing the operation.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 17

The WAGO-I/O-SYSTEM 750 • 17

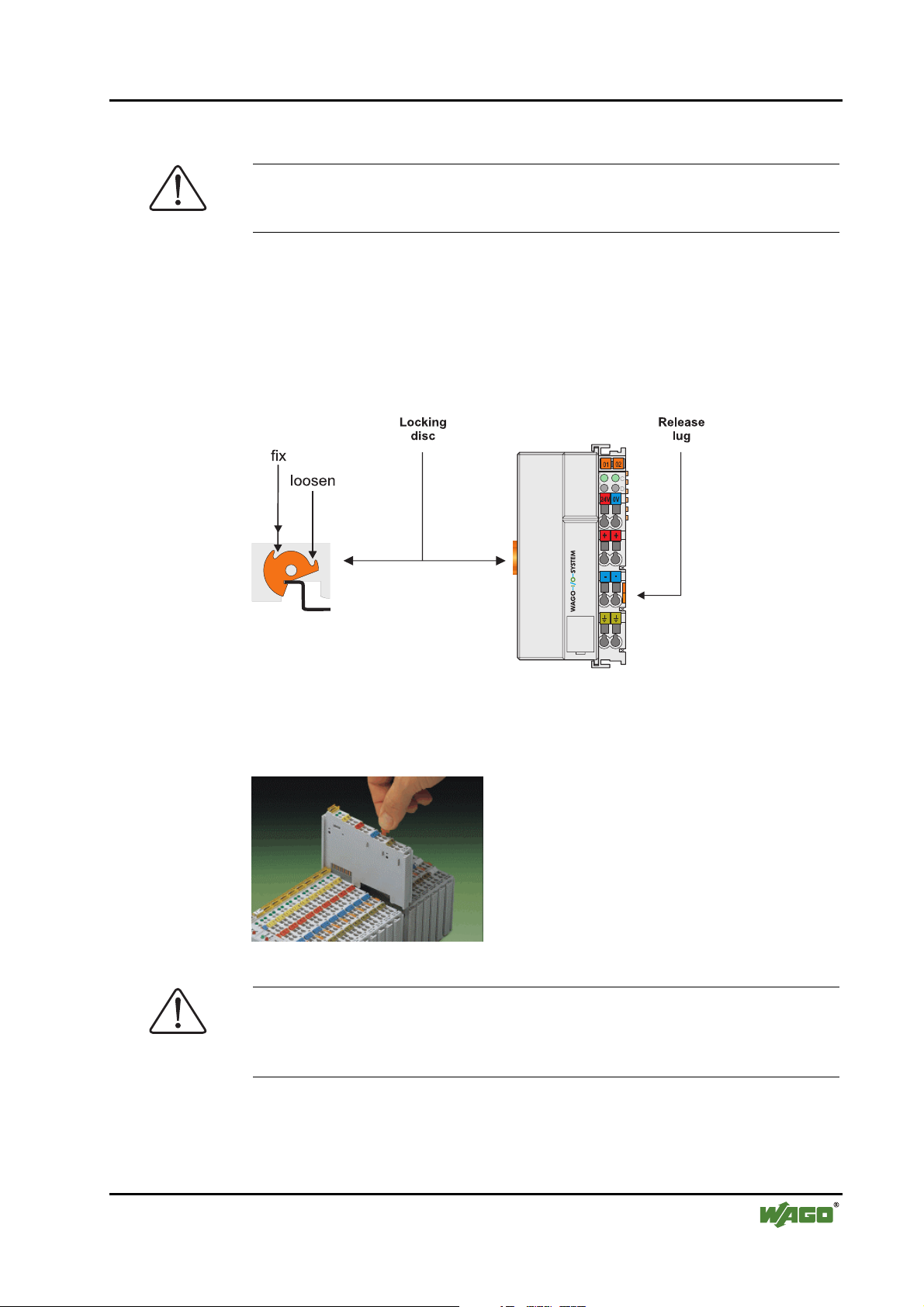

2.5.5 Plugging and Removal of the Components

Warning

Before work is done on the components, the voltage supply must be turned

off.

In order to safeguard the coupler/controller from jamming, it should be fixed

onto the carrier rail with the To do so, push on the upper groove of the locking disc using a screwdriver.

To pull out the fieldbus coupler/controller, release the locking disc by pressing

on the bottom groove with a screwdriver and then pulling the orange colored

unlocking lug.

Mechanical Setup

Fig. 2-5: Coupler/Controller and unlocking lug g01xx12e

It is also possible to release an individual I/O module from the unit by pulling

an unlocking lug.

Fig. 2-6: removing bus terminal p0xxx01x

Danger

Ensure that an interruption of the PE will not result in a condition which

could endanger a person or equipment!

For planning the ring feeding of the ground wire, please see chapter 2.6.3.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 18

18 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

2.5.6 Assembly Sequence

All system components can be snapped directly on a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual components are securely

seated on the rail after installing.

Starting with the coupler/controller, the bus modules are assembled adjacent to

each other according to the project planning. Errors in the planning of the node

in terms of the potential groups (connection via the power contacts) are recognized, as the bus modules with power contacts (male contacts) cannot be

linked to bus modules with fewer power contacts.

Attention

Always link the bus modules with the coupler / controller, always plug from

above.

Warning

Never plug bus modules from the direction of the end terminal. A ground

wire power contact, which is inserted into a terminal without contacts, e.g. a

4-channel digital input module, has a decreased air and creepage distance to

the neighboring contact in the example DI4.

Always terminate the fieldbus node with an end module (750-600).

WAGO-I/O-SYSTEM 750

DeviceNet

Page 19

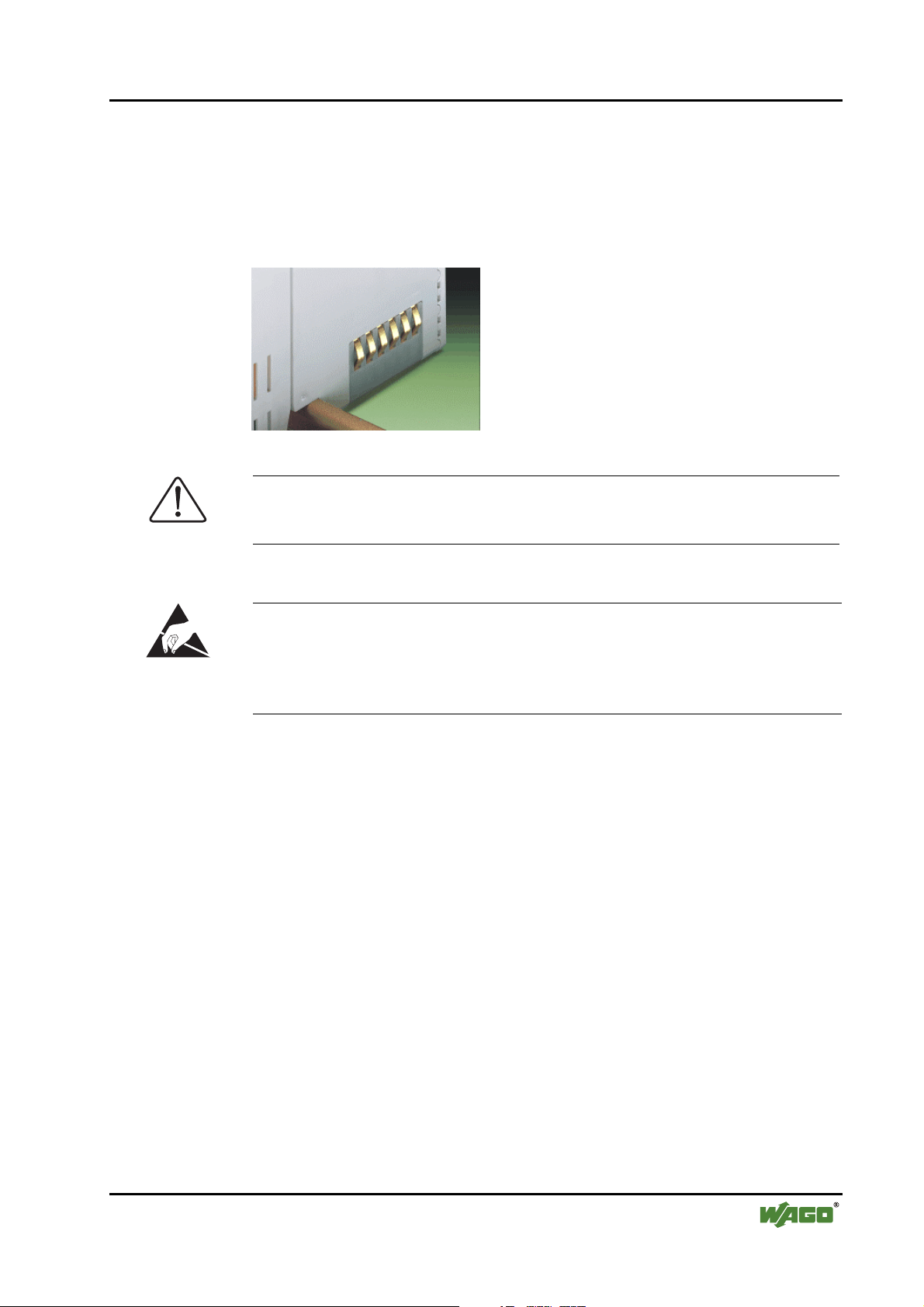

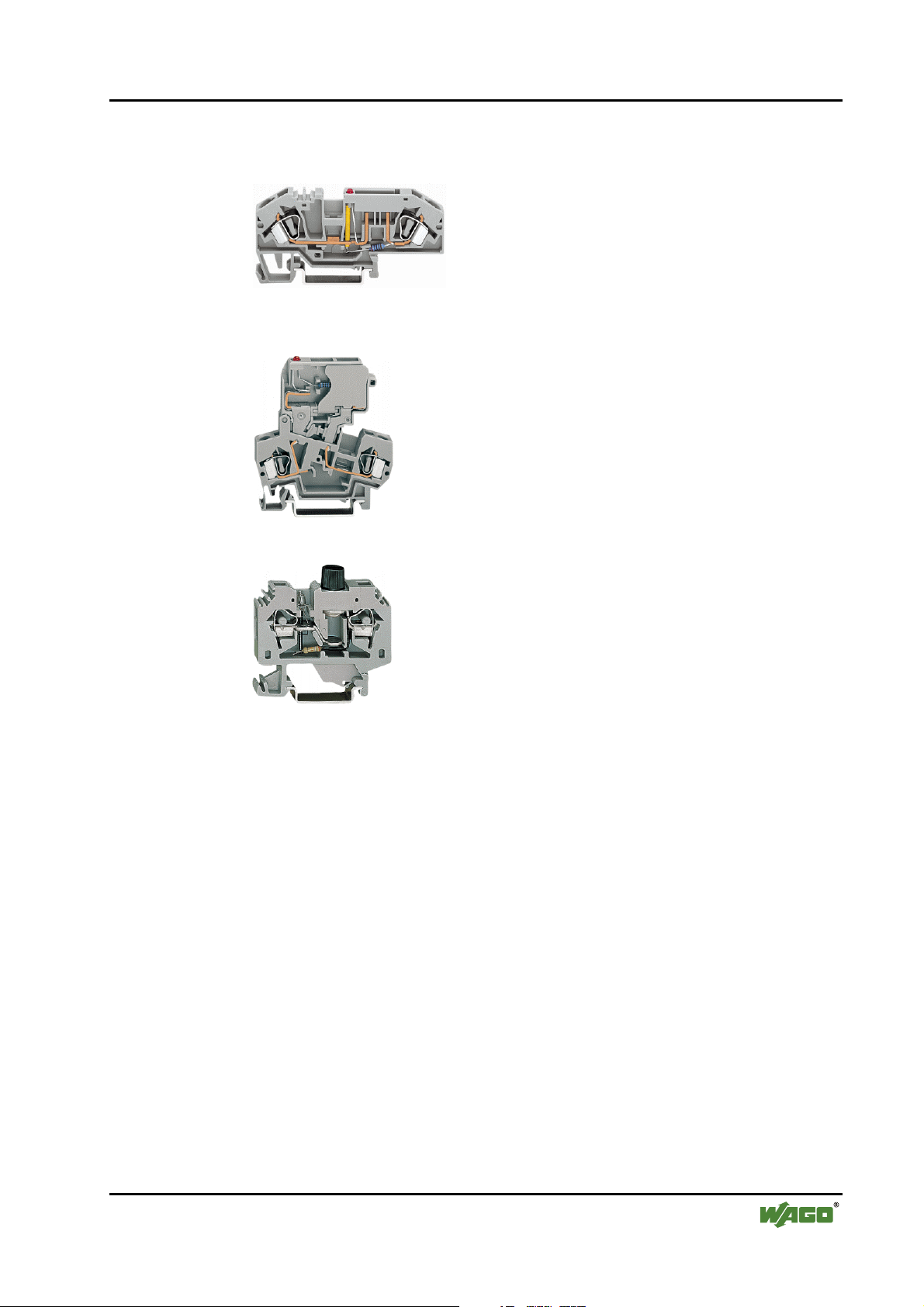

2.5.7 Internal Bus / Data Contacts

Communication between the coupler/controller and the bus modules as well as

the system supply of the bus modules is carried out via the internal bus. It is

comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Fig. 2-7: Data contacts p0xxx07x

Warning

Do not connect the I/O module to gold spring contacts in order to avoid soiling or scratches!

The WAGO-I/O-SYSTEM 750 • 19

Mechanical Setup

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the environment (persons, workplace and packing) is well grounded. Avoid touching

conductive components, e.g. gold contacts.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 20

20 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

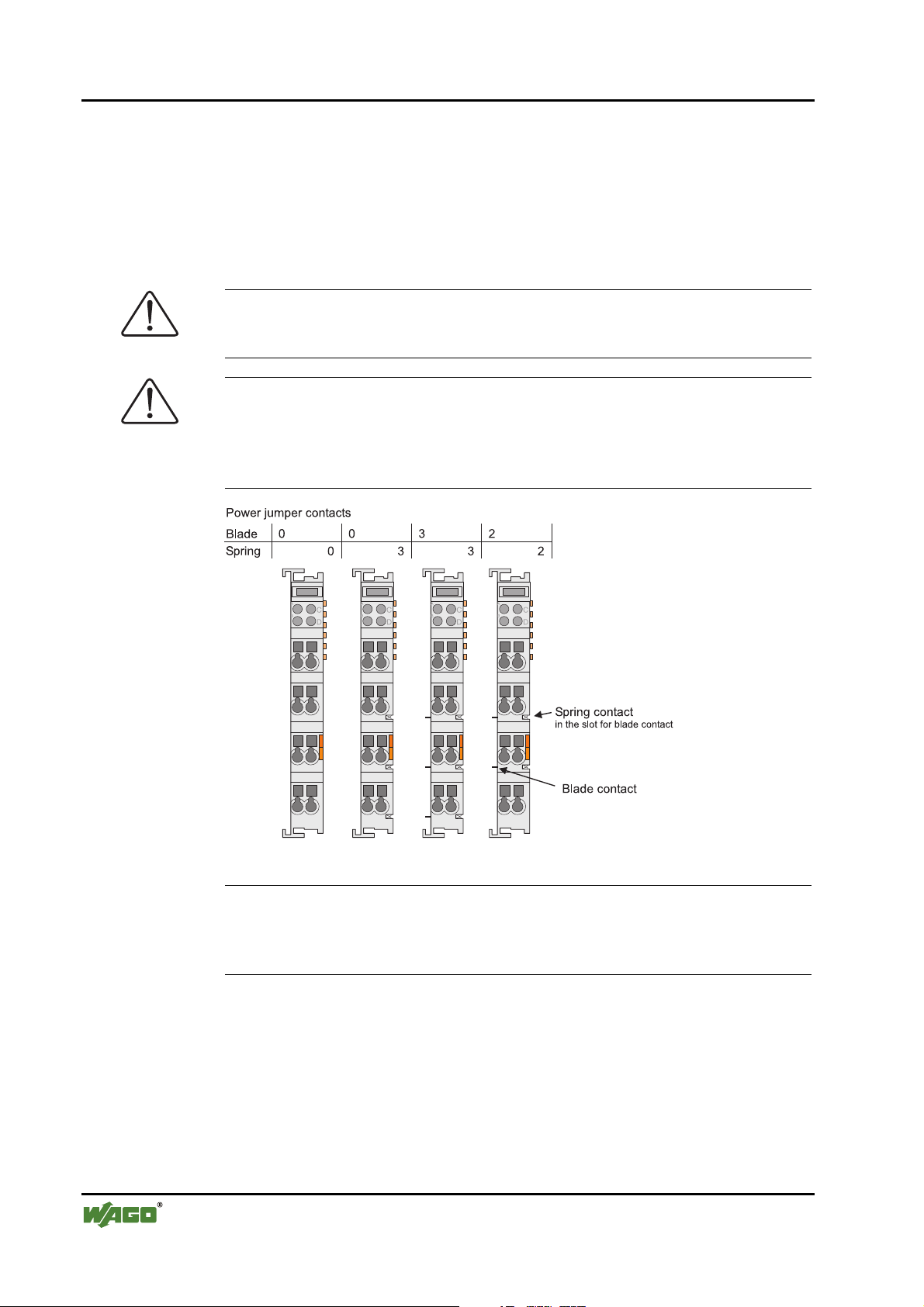

2.5.8 Power Contacts

Self-cleaning power contacts , are situated on the side of the components

which further conduct the supply voltage for the field side. These contacts

come as touchproof spring contacts on the right side of the coupler/controller

and the bus module. As fitting counterparts the module has male contacts on

the left side.

Danger

The power contacts are sharp-edged. Handle the module carefully to prevent

injury.

Attention

Please take into consideration that some bus modules have no or only a few

power jumper contacts. The design of some modules does not allow them to

be physically assembled in rows, as the grooves for the male contacts are

closed at the top.

Fig. 2-8: Example for the arrangement of power contacts g0xxx05e

Recommendation

With the WAGO ProServe® Software smartDESIGNER, the assembly of a

fieldbus node can be configured. The configuration can be tested via the integrated plausibility check.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 21

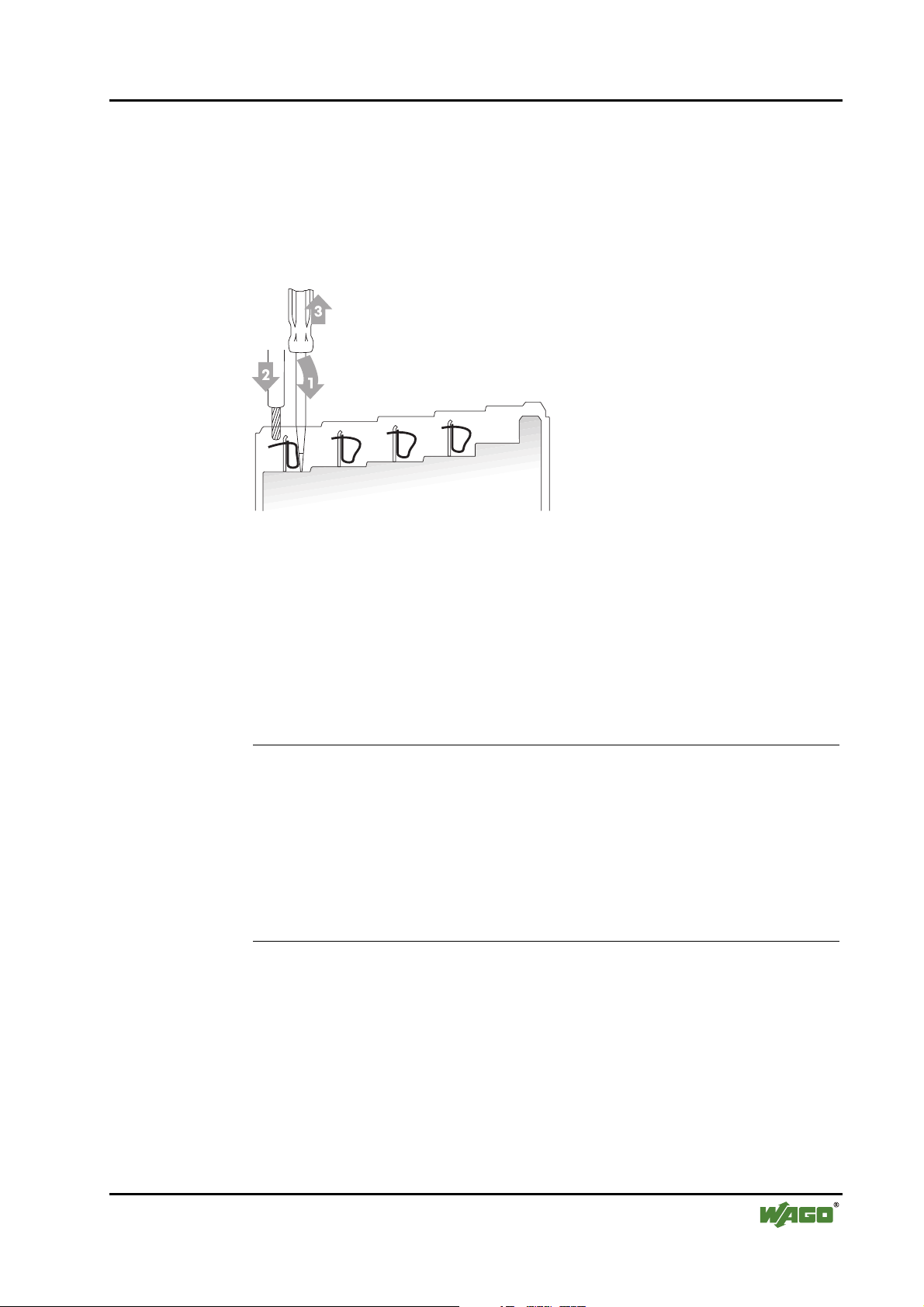

2.5.9 Wire connection

All components have CAGE CLAMP® connections.

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded

and fine–stranded conductors. Each clamping unit accommodates one conductor.

The WAGO-I/O-SYSTEM 750 • 21

Mechanical Setup

Fig. 2-9: CAGE CLAMP® Connection g0xxx08x

The operating tool is inserted into the opening above the connection. This

opens the CAGE CLAMP®. Subsequently the conductor can be inserted into

the opening. After removing the operating tool, the conductor is safely

clamped.

More than one conductor per connection is not permissible. If several conductors have to be laid at a connection, then they should be laid in off-course

wiring; e.g. together with WAGO transfer terminals.

Attention

If it is unavoidable to jointly connect 2 conductors, then a ferrule must be

used.

Ferrule:

Length 8 mm

Nominal cross section

max.

1 mm2 for 2 conductors with 0.5 mm

2

each

WAGO Product 216-103

or products with comparable properties

WAGO-I/O-SYSTEM 750

DeviceNet

Page 22

22 • The WAGO-I/O-SYSTEM 750

Power Supply

2.6 Power Supply

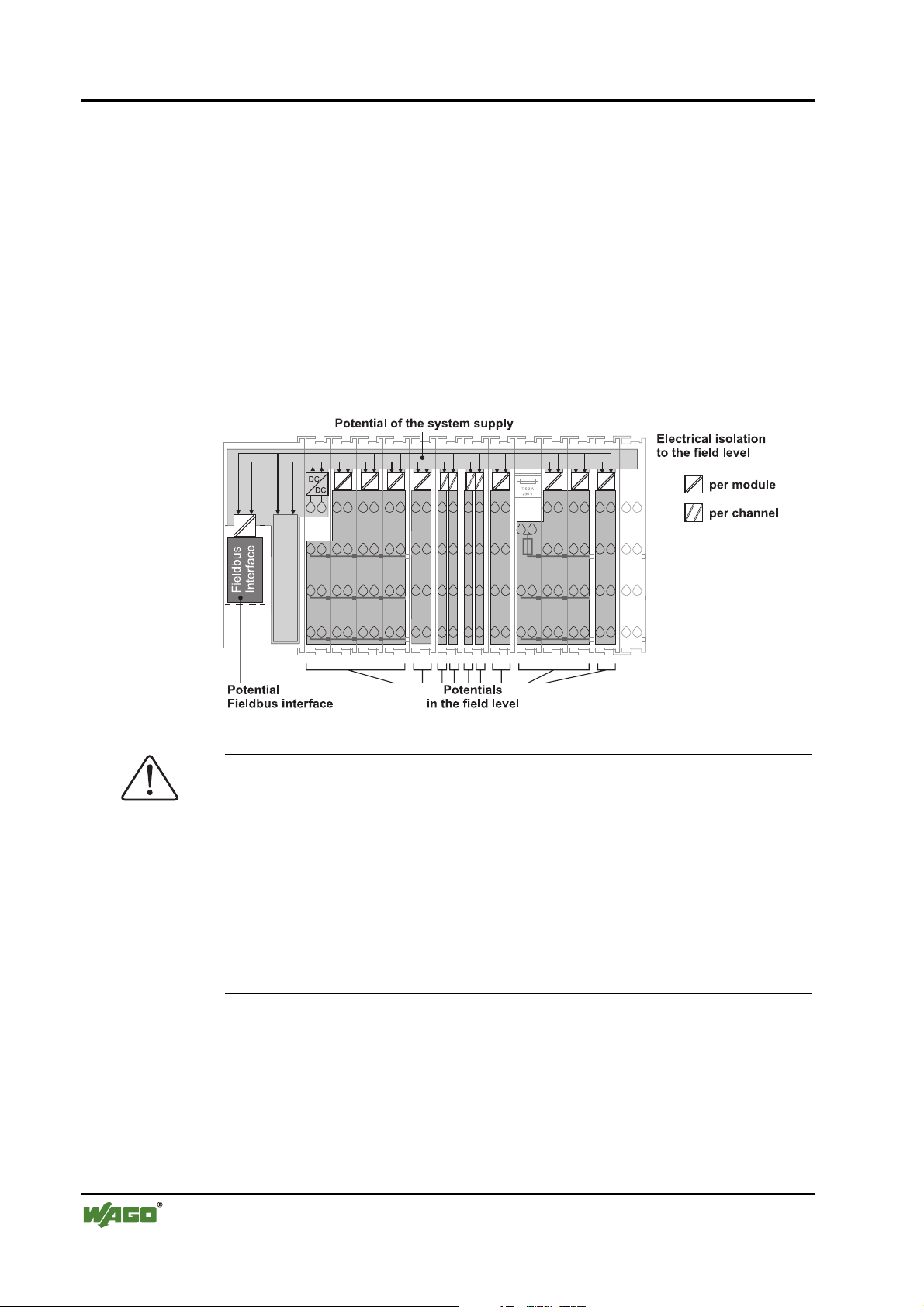

2.6.1 Isolation

Within the fieldbus node, there are three electrically isolated potentials.

• Operational voltage for the fieldbus interface.

• Electronics of the couplers / controllers and the bus modules (internal bus).

• All bus modules have an electrical isolation between the electronics (internal bus, logic) and

the field electronics. Some analogue input modules have each channel electrically isolated,

please see catalogue.

Fig. 2-10: Isolation g0xxx01e

Attention

The ground wire connection must be existent in each group. In order that all

protective conductor functions are maintained under all circumstances, it is

sensible to lay the connection at the beginning and end of a potential group.

(ring format, please see chapter "2.7.3"). Thus, if a bus module comes loose

from a composite during servicing, then the protective conductor connection

is still guaranteed for all connected field devices.

When using a joint power supply unit for the 24 V system supply and the

24 V field supply, the electrical isolation between the internal bus and the

field level is disregarded for the potential group.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 23

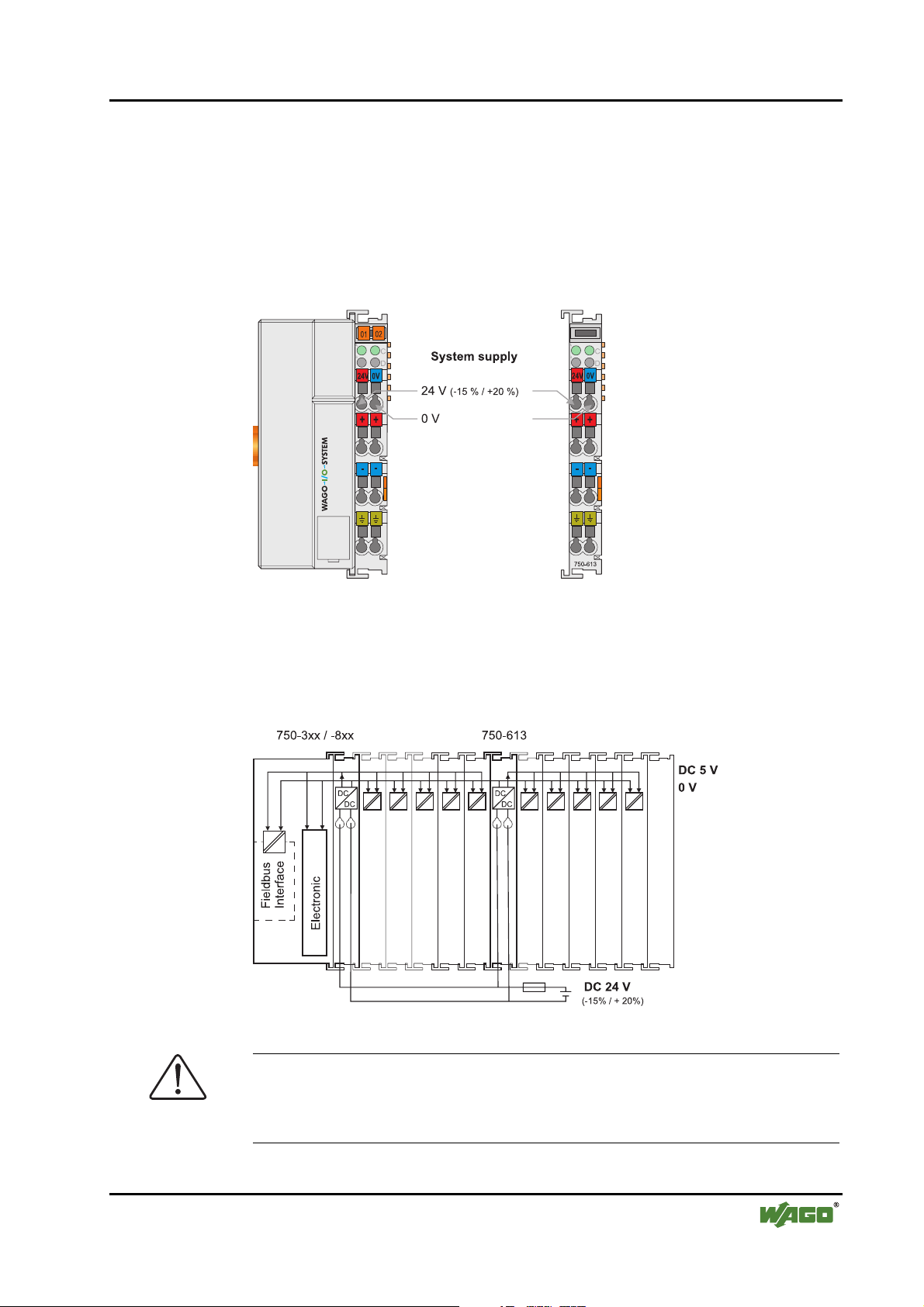

2.6.2 System Supply

2.6.2.1 Connection

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply

(-15% or +20 %). The power supply is provided via the coupler / controller

and, if necessary, in addition via the internal system supply modules

(750-613). The voltage supply is reverse voltage protected.

The WAGO-I/O-SYSTEM 750 • 23

Power Supply

Fig. 2-11: System Supply g0xxx02e

The direct current supplies all internal system components, e.g. coupler/controller electronics, fieldbus interface and bus modules via the internal

bus (5 V system voltage). The 5 V system voltage is electrically connected to

the 24 V system supply.

Fig. 2-12: System Voltage g0xxx06e

Attention

Resetting the system by switching on and off the system supply, must take

place simultaneously for all supply modules (coupler / controller and

750-613).

WAGO-I/O-SYSTEM 750

DeviceNet

Page 24

24 • The WAGO-I/O-SYSTEM 750

Power Supply

2.6.2.2 Alignment

Recommendation

A stable network supply cannot be taken for granted always and everywhere.

Therefore, regulated power supply units should be used in order to guarantee

the quality of the supply voltage.

The supply capacity of the coupler/controller or the internal system supply

module (750-613) can be taken from the technical data of the components.

Internal current consumption*)

Residual current for bus terminals*)

*) cf. catalogue W3 Volume 3, manuals or Internet

Example

Current consumption via system voltage:

5 V for electronics of the bus modules and coupler /

controller

Available current for the bus modules. Provided by

the bus power supply unit. See coupler / controller

and internal system supply module (750-613)

Coupler 750-301:

internal current consumption:350 mA at 5V

residual current for

bus modules: 1650 mA at 5V

sum I(5V) ges: 2000 mA at 5V

The internal current consumption is indicated in the technical data for each bus

terminal. In order to determine the overall requirement, add together the values of all bus modules in the node.

Attention

If the sum of the internal current consumption exceeds the residual current for

bus modules, then an internal system supply module (750-613) must be

placed before the module where the permissible residual current was exceeded.

Example:

A node with a PROFIBUS Coupler 750-333 consists of 20 relay modules (750-517) and 20 digital input modules (750-405).

Current consumption:

20*105 mA = 2100 mA

10* 2 mA = 20 mA

Sum 2120 mA

The coupler can provide 1800 mA for the bus modules. Consequently,

an internal system supply module (750-613), e.g. in the middle of the

node, should be planned.

Recommendation

With the WAGO ProServe® Software smartDESIGNER, the assembly of a

fieldbus node can be configured. The configuration can be tested via the integrated plausibility check.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 25

The WAGO-I/O-SYSTEM 750 • 25

Power Supply

The maximum input current of the 24 V system supply amounts to 500 mA.

The exact electrical consumption (I

) can be determined with the following

(24 V)

formulas:

Coupler/Controller

I(5 V) ges. = Sum of all current consumptions of the connected bus modules

+ internal current consumption coupler / controller

750-613

I(5 V) ges. = Sum of all current consumptions of the connected bus modules

Input current I(24 V) =

5 V / 24 V * I(5 V) ges./ η

η = 0.87 (at nominal load)

Note

If the electrical consumption of the power supply point for the 24 V-system

supply exceeds 500 mA, then the cause may be an improperly aligned node

or a defect.

During the test, all outputs, in particular those of the relay modules, must be

active.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 26

26 • The WAGO-I/O-SYSTEM 750

Power Supply

2.6.3 Field Supply

2.6.3.1 Connection

Sensors and actuators can be directly connected to the relevant channel of the

bus module in 1-/4 conductor connection technology. The bus module supplies

power to the sensors and actuators. The input and output drivers of some bus

modules require the field side supply voltage.

The coupler/controller provides field side power (DC 24V). Power supply

modules are available for other potentials, e.g. AC 230 V. Likewise, with the

aid of the power supply modules, various potentials can be set up. The connections are linked in pairs with a power contact.

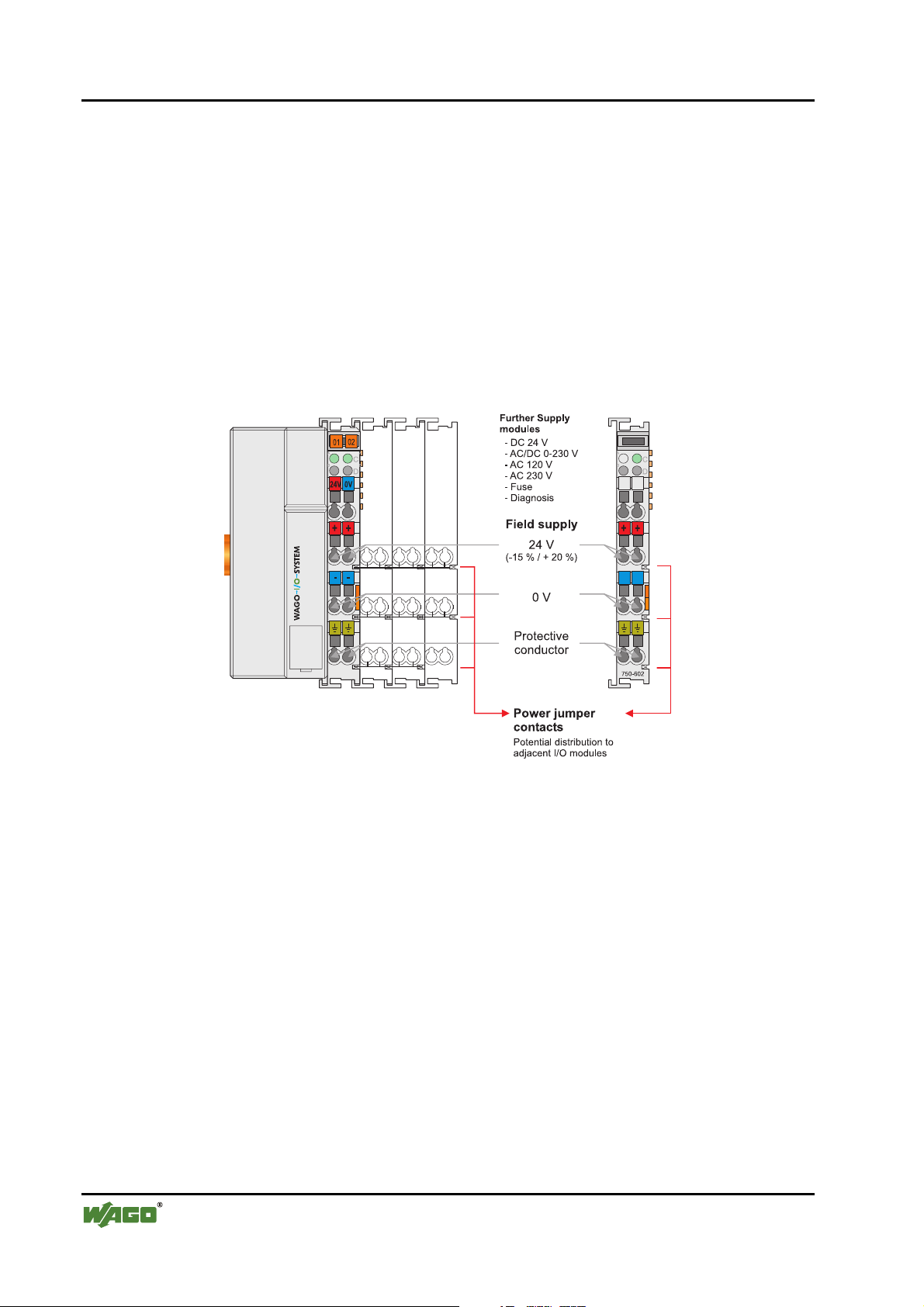

Fig. 2-13: Field Supply (Sensor / Actuator) g0xxx03e

The supply voltage for the field side is automatically passed on via the power

jumper contacts when assembling the bus modules .

The current load of the power contacts must not exceed 10 A on a continual

basis. The current load capacity between two connection terminals is identical

to the load capacity of the connection wires.

By setting an additional power supply module, the field supply via the power

contacts is disrupted. From there a new power supply occurs which also contains a potential alternation.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 27

2.6.3.2 Fusing

The WAGO-I/O-SYSTEM 750 • 27

Power Supply

Attention

Some bus modules have no or very few power contacts (depends on the I/O

function). Due to this, the passing on of the relevant potential is disrupted. If

a field supply is required for subsequent bus modules, then a power supply

module must be used.

Note the data sheets of the bus modules.

In the case of a node setup with different potentials, e.g. the alteration from

DC 24 V to AC 230V, a spacer module should be used. The optical separation of the potentials acts as a warning to heed caution in the case of wiring

and maintenance works. Thus, the results of wiring errors can be prevented.

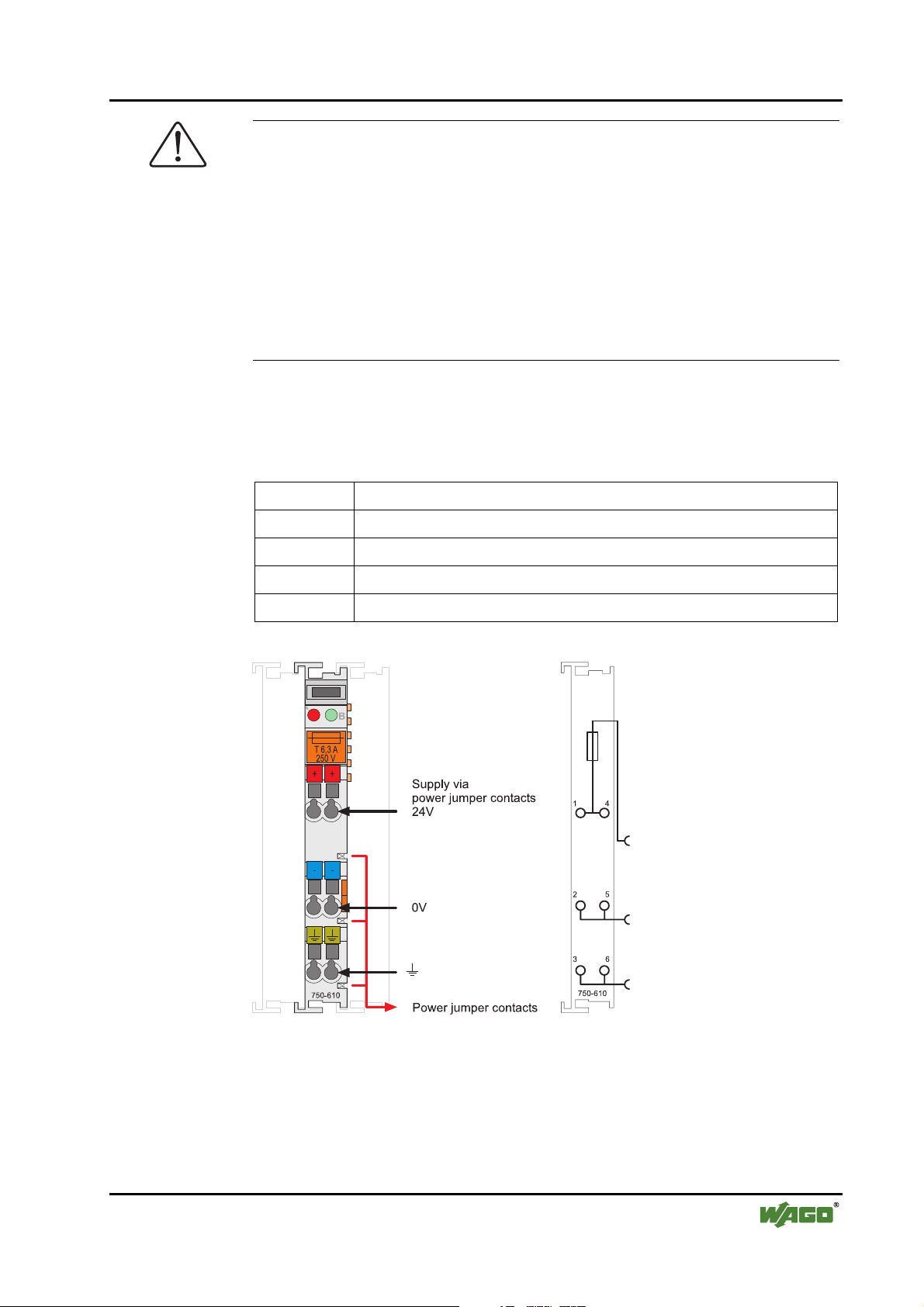

Internal fusing of the field supply is possible for various field voltages via an

appropriate power supply module.

750-601 24 V DC, Supply / Fuse

750-609 230 V AC, Supply / Fuse

750-615 120 V AC, Supply / Fuse

750-610 24 V DC, Supply / Fuse / Diagnosis

750-611 230 V AC, Supply / Fuse / Diagnosis

Fig. 2-14: Supply module with fuse carrier (Example 750-610) g0xxx09x

WAGO-I/O-SYSTEM 750

DeviceNet

Page 28

28 • The WAGO-I/O-SYSTEM 750

Power Supply

Warning

In the case of power supply modules with fuse holders, only fuses with a

maximal dissipation of 1.6 W (IEC 127) must be used.

For UL approved systems only use UL approved fuses.

In order to insert or change a fuse, or to switch off the voltage in succeeding

bus modules, the fuse holder may be pulled out. In order to do this, use a

screwdriver for example, to reach into one of the slits (one on both sides) and

pull out the holder.

Fig. 2-15: Removing the fuse carrier p0xxx05x

Lifting the cover to the side opens the fuse carrier.

Fig. 2-16: Opening the fuse carrier p0xxx03x

Fig. 2-17: Change fuse p0xxx04x

After changing the fuse, the fuse carrier is pushed back into its original position.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 29

The WAGO-I/O-SYSTEM 750 • 29

Power Supply

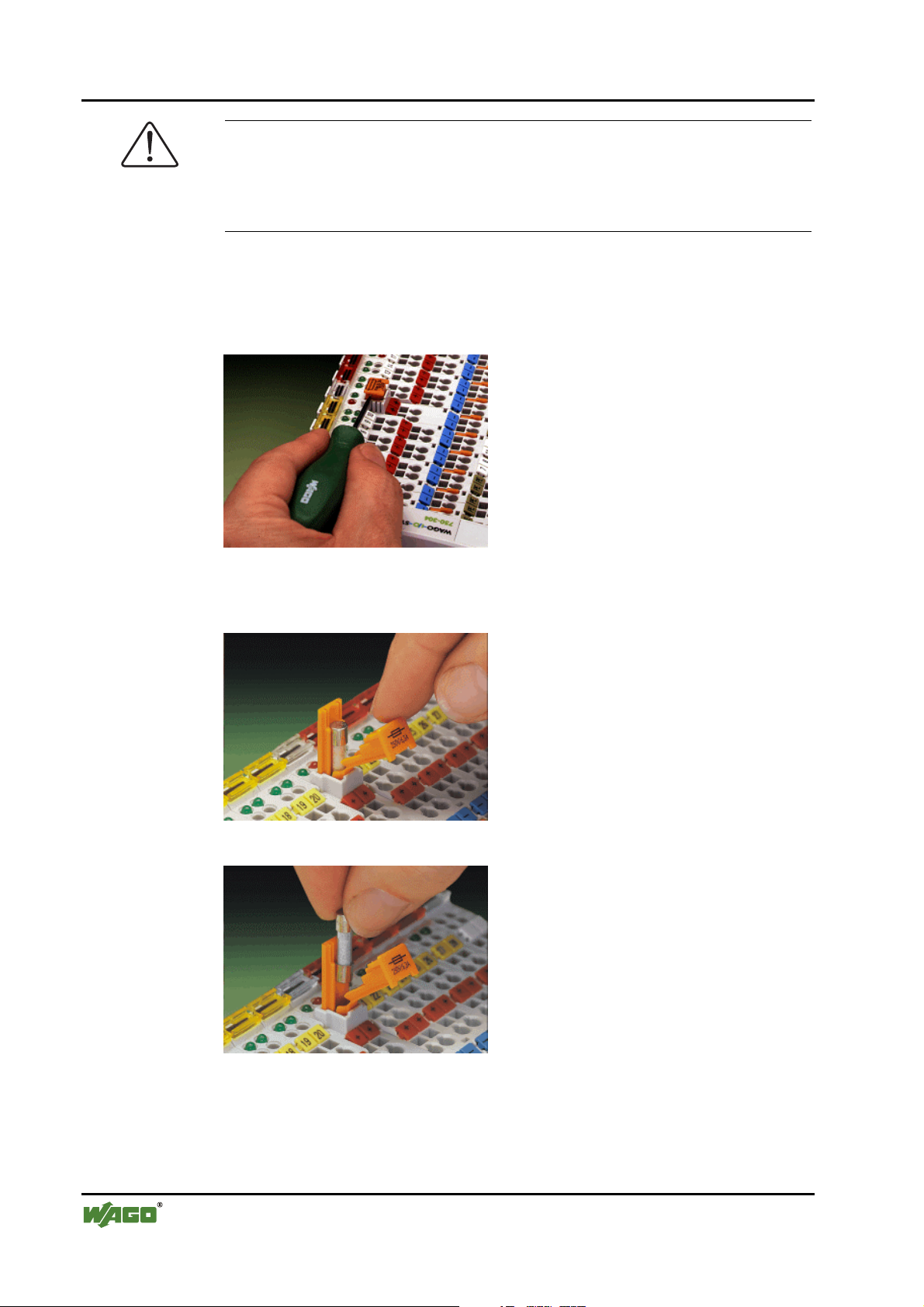

Alternatively, fusing can be done externally. The fuse modules of the WAGO

series 281 and 282 are suitable for this purpose.

Fig. 2-18: Fuse modules for automotive fuses, Series 282 pf66800x

Fig. 2-19: Fuse modules with pivotable fuse carrier, Series 281 pe61100x

Fig. 2-20: Fuse modules, Series 282 pf12400x

WAGO-I/O-SYSTEM 750

DeviceNet

Page 30

30 • The WAGO-I/O-SYSTEM 750

Power Supply

2.6.4 Supplementary power supply regulations

The WAGO-I/O-SYSTEM 750 can also be used in shipbuilding or offshore

and onshore areas of work (e.g. working platforms, loading plants). This is

demonstrated by complying with the standards of influential classification

companies such as Germanischer Lloyd and Lloyds Register.

Filter modules for 24-volt supply are required for the certified operation of the

system.

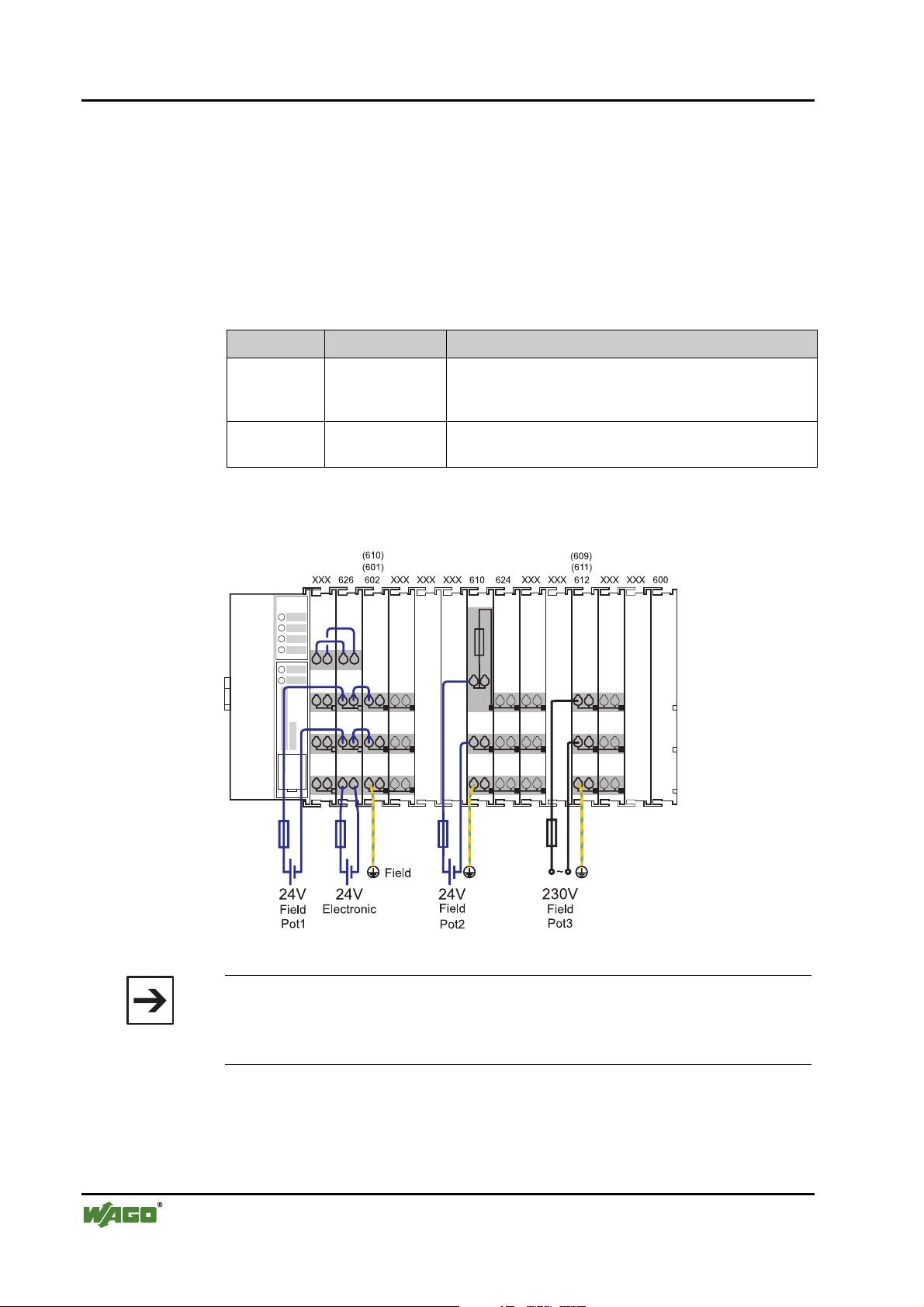

Item No. Name Description

750-626 Supply filter Filter module for system supply and field supply (24 V,

0 V), i.e. for field bus coupler / controller and bus power

supply (750-613)

750-624 Supply filter Filter module for the 24 V- field supply

(750-602, 750-601, 750-610)

Therefore, the following power supply concept must be absolutely complied

with.

Fig. 2-21: Power supply concept g01xx11e

Note

Another potential power terminal 750-601/602/610 must only be used behind

the filter terminal 750-626 if the protective earth conductor is needed on the

lower power contact or if a fuse protection is required.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 31

750-630750-400 750-410 750-401

750-613

750-512 750-512750-616 750-513 750-610 750-552 750-600750-612 750-616

1)

a)

b)

c)

d)

1)

2) 2)

24V

24V

10 A

10 A

L1

L2

L3

N

PE

230V

230V

Main ground bus

Shield (screen) bus

System

Supply

Field

Supply

Field

Supply

1) Separation module

recommended

2) Ring-feeding

recommended

a) Power Supply

on coupler / controller

b) Internal System

Supply Module

c) Supply Module

passive

d)

iagnostics

Supply Module

with fuse carrier/

d

2.6.5 Supply example

Note

The system supply and the field supply should be separated in order to ensure

bus operation in the event of a short-circuit on the actuator side.

The WAGO-I/O-SYSTEM 750 • 31

Power Supply

Fig. 2-22: Supply example g0xxx04e

WAGO-I/O-SYSTEM 750

DeviceNet

Page 32

32 • The WAGO-I/O-SYSTEM 750

Power Supply

2.6.6 Power Supply Unit

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply

with a maximum deviation of -15% or +20 %.

Recommendation

A stable network supply cannot be taken for granted always and everywhere.

Therefore, regulated power supply units should be used in order to guarantee

the quality of the supply voltage.

A buffer (200 µF per 1 A current load) should be provided for brief voltage

dips. The I/O system buffers for ca. 1 ms.

The electrical requirement for the field supply is to be determined individually

for each power supply point. Thereby all loads through the field devices and

bus modules should be considered. The field supply as well influences the bus

modules, as the inputs and outputs of some bus modules require the voltage of

the field supply.

Note

The system supply and the field supply should be isolated from the power

supplies in order to ensure bus operation in the event of short circuits on the

actuator side.

WAGO products

Article No.

787-903 Primary switched - mode, DC 24 V, 5 A

787-904 Primary switched - mode, DC 24 V, 10 A

787-912 Primary switched - mode, DC 24 V, 2 A

288-809

288-810

288-812

288-813

Description

wide input voltage range AC 85-264 V

PFC (Power Factor Correction)

wide input voltage range AC 85-264 V

PFC (Power Factor Correction)

wide input voltage range AC 85-264 V

PFC (Power Factor Correction)

Rail-mounted modules with universal mounting carrier

AC 115 V / DC 24 V; 0,5 A

AC 230 V / DC 24 V; 0,5 A

AC 230 V / DC 24 V; 2 A

AC 115 V / DC 24 V; 2 A

WAGO-I/O-SYSTEM 750

DeviceNet

Page 33

2.7 Grounding

2.7.1 Grounding the DIN Rail

2.7.1.1 Framework Assembly

When setting up the framework, the carrier rail must be screwed together with

the electrically conducting cabinet or housing frame. The framework or the

housing must be grounded. The electronic connection is established via the

screw. Thus, the carrier rail is grounded.

Attention

Care must be taken to ensure the flawless electrical connection between the

carrier rail and the frame or housing in order to guarantee sufficient grounding.

2.7.1.2 Insulated Assembly

The WAGO-I/O-SYSTEM 750 • 33

Grounding

Insulated assembly has been achieved when there is constructively no direct

conduction connection between the cabinet frame or machine parts and the

carrier rail. Here the earth must be set up via an electrical conductor.

The connected grounding conductor should have a cross section of at least

4 mm2.

Recommendation

The optimal insulated setup is a metallic assembly plate with grounding connection with an electrical conductive link with the carrier rail.

The separate grounding of the carrier rail can be easily set up with the aid of

the WAGO ground wire terminals.

Article No. Description

283-609 Single-conductor ground (earth) terminal block make an automatic

contact to the carrier rail; conductor cross section: 0.2 -16 mm2

Note: Also order the end and intermediate plate (283-320)

WAGO-I/O-SYSTEM 750

DeviceNet

Page 34

34 • The WAGO-I/O-SYSTEM 750

Grounding

2.7.2 Function Earth

The function earth increases the resistance capacity against disturbances from

electro-mechanical influences. Some components in the I/O system have a carrier rail contact that dissipates electro-magnetic disturbances to the carrier rail.

Fig. 2-23: Carrier rail contact g0xxx10e

Attention

Care must be taken to ensure the flawless electrical connection between the

carrier rail contact and the carrier rail.

The carrier rail must be grounded.

For information on carrier rail properties, please see chapter 2.5.3.2.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 35

2.7.3 Protective Earth

For the field level, the ground wire is placed onto the lower connection terminals of the power supply terminals and further reached through the lower

power contacts to the neighboring bus terminals. If the bus terminal has the

lower power contact, then the ground wire connection of the field devices can

be directly connected to the lower connection terminals of the bus terminals.

Attention

If the connection of the power contacts for the ground wire within the node is

disrupted, e.g. due to a 4-channel bus terminal, then the potential has to be resupplied.

The ring feeding of the earth potential can increase the system security. In the

event that a bus terminal is ripped out of the potential group, the earth potential is still maintained.

During the ring feeding, the ground wire is connected at the beginning and end

of the potential group.

The WAGO-I/O-SYSTEM 750 • 35

Grounding

Fig. 2-24: Ring-feeding g0xxx07e

WAGO-I/O-SYSTEM 750

DeviceNet

Page 36

36 • The WAGO-I/O-SYSTEM 750

Shielding (screening)

2.8 Shielding (screening)

2.8.1 General

The shielding of the data and signal conductors reduces the electromagnetic

influences thereby increasing the signal quality. Measurement errors, data

transmission errors and even disturbances caused by overvoltage can thus be

avoided.

Attention

Constant shielding is absolutely required in order to ensure the technical

specifications in terms of the measurement accuracy.

The data and signal conductors should be laid separately from all highvoltage cables.

The cable shield is to be laid over a large-scale surface onto the earth potential. With this, incoming disturbances can be easily diverted.

The shielding should be placed over the entrance of the cabinet or housing in

order to already repel disturbances at the entrance.

2.8.2 Bus Conductors

The shielding of the bus conductor is described in the relevant assembly

guideline of the bus system.

2.8.3 Signal Conductors

The bus terminals for analogue signals as well as some interface bus terminals

possess connection terminals for the shield.

Note

Improved shielding can be achieved if the shield is previously placed over a

large-scale surface. For this, we recommend the use of the WAGO shield

connecting system for example.

This is particularly recommendable for systems with large-scale expansions

where it cannot be ruled out that differential currents are flowing or high

pulse currents, i. e. activated by atmospheric discharge, may appear.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 37

The WAGO-I/O-SYSTEM 750 • 37

Assembly Guidelines / Norms

2.8.4 WAGO Shield (Screen) Connecting System

The WAGO shield connecting system is comprised of shield terminal frames,

busbars and diverse assembly feet in order to realize a multitude of constructions. Please see catalogue W3 volume 3 chapter 7.

Fig. 2-25: WAGO Shield (Screen) Connecting System p0xxx08x, p0xxx09x, and p0xxx10x

Fig. 2-26: Application of the WAGO Shield (Screen) Connecting System p0xxx11x

2.9 Assembly Guidelines / Norms

DIN 60204, Electrical equipping of machines

DIN EN 50178 Equipping of high-voltage systems with electronic

components (replacement for VDE 0160)

EN 60439 Low voltage – switch box combinations

WAGO-I/O-SYSTEM 750

DeviceNet

Page 38

38 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3 Fieldbus Coupler/Controller

3.1 Fieldbus Coupler 750-306

This chapter includes:

3.1.1 Description......................................................................................39

3.1.2 Hardware.........................................................................................40

3.1.2.1 View .........................................................................................40

3.1.2.2 Device Supply ..........................................................................41

3.1.2.3 Fieldbus Connection.................................................................42

3.1.2.4 Display Elements......................................................................43

3.1.2.5 Configuration Interface ............................................................44

3.1.2.6 Hardware Address (MAC ID) ..................................................44

3.1.2.7 Setting the Baud Rate...............................................................45

3.1.3 Operating System............................................................................45

3.1.4 Process Image .................................................................................46

3.1.5 Data Exchange ................................................................................47

3.1.5.1 Communication Interfaces .......................................................48

3.1.5.2 Memory Areas..........................................................................48

3.1.5.3 Addressing................................................................................49

3.1.6 Configuration Software...................................................................51

3.1.7 Starting up DeviceNet Fieldbus Nodes...........................................51

3.1.7.1 Connecting the PC and Fieldbus Node ....................................51

3.1.7.2 Setting the MAC ID and Baud Rate.........................................51

3.1.7.3 Configuration with Static Assembly ........................................52

3.1.8 LED Display ...................................................................................56

3.1.8.1 Node Status ..............................................................................57

3.1.8.2 Blink Code................................................................................58

3.1.8.3 Fault Message via the Blink Code of the I/O LED ..................58

3.1.8.4 Supply Voltage Status..............................................................59

3.1.9 Technical Data ................................................................................60

WAGO-I/O-SYSTEM 750

DeviceNet

Page 39

3.1.1 Description

The fieldbus Coupler 750-306 displays the peripheral data of all I/O modules

in the WAGO-I/O-SYSTEM 750 on DeviceNet Feldbus. The data is transmitted with objects.

The bus Coupler determines the physical structure of the node and creates a

process image from this with all inputs and outputs. This could involve a

mixed arrangement of analog (word by word data exchange) and digital (byte

by byte data exchange) modules.

The local process image is subdivided into an input and output data area. The

process data can be read in via the DeviceNet bus and further processed in a

control system. The process output data is sent via the DeviceNet bus.

The data of the analog modules are mapped into the automatical created process image according to the order of their position downstream of the bus Coupler. The bits of the digital modules are compiled to form bytes and also

mapped into the process image attached to the data of the analog modules.

Should the number of digital I/Os exceed 8 bits, the Coupler automatically

starts another byte.

Fieldbus Coupler/Controller • 39

Fieldbus Coupler 750-306

The fieldbus Coupler supports the DeviceNet function Bit-Strobe, whereby the

function is insofar restricted, that only the status byte will be delivered.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 40

40 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3.1.2 Hardware

3.1.2.1 View

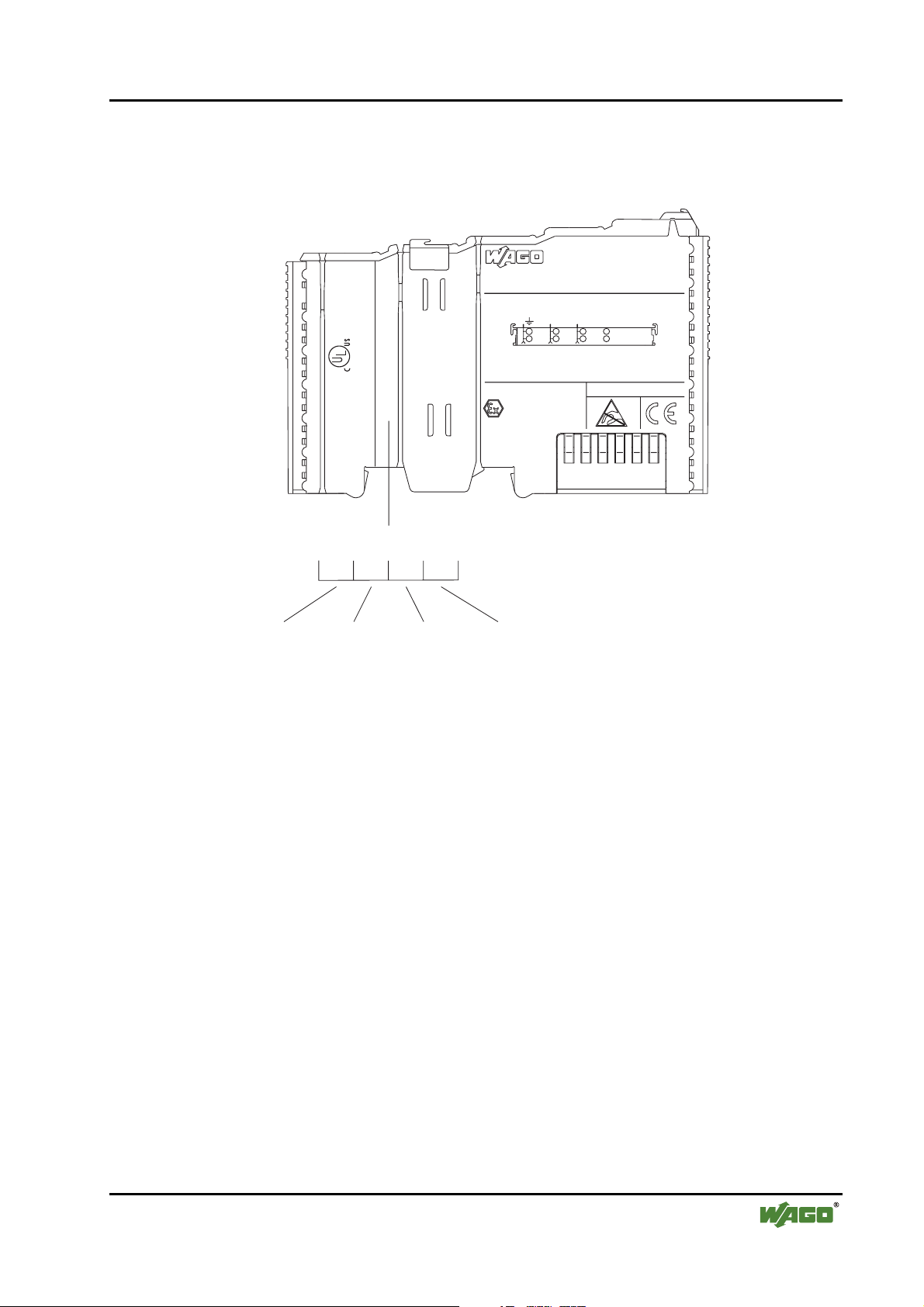

Fieldbus

connection

Series 231

(MCS)

DIP switch

for MAC ID

and baud rate

DeviceNet

OVERFL

MS

RUN

BUS OFF

NS

CONNECT

I/O

12345678

ON

750-306

01 02

A

B

24V

+

Ñ

PE PE

0V

Ñ

Status

voltage supply

-Power jumper

C

D

contacts

-System

Data contacts

Supply

24V

0V

+

Supply via

power jumper

contacts

24V

0V

Power jumper

Configuration

contacts

interface

flap

opened

Fig. 3-1: Fieldbus Coupler 750-306 DeviceNet g030600e

The fieldbus Coupler comprises of:

• Supply module with Internal system supply module for the system supply

as well as power jumper contacts for the field supply via I/O module assemblies.

• Fieldbus interface with the bus connection

• DIP switch for baud rate and MAC ID

• Display elements (LED's) for status display of the operation, the bus com-

munication, the operating voltages as well as for fault messages and diagnosis

• Configuration interface

• Electronics for communication with the I/O modules (internal bus) and the

fieldbus interface

WAGO-I/O-SYSTEM 750

DeviceNet

Page 41

3.1.2.2 Device Supply

The supply is made via terminal blocks with CAGE CLAMP® connection.

The device supply is intended both for the system and the field units.

Fieldbus Coupler/Controller • 41

Fieldbus Coupler 750-306

1

5

24V/0V

10nF

DC

DC

Bus

modules

0V

24V

2

6

FIELDBUS INTERFACE

3

7

4

ELECTRONICS

8

750-306

24V

0V

24V

0V

10nF

ELECTRONICS

FIELDBUS

INTERFACE

1) 2)

1) 1M

2) 10nF/500V

Fig. 3-2: Device supply g030601e

The integrated internal system supply module generates the necessary voltage

to supply the electronics and the connected I/O modules.

The fieldbus interface is supplied with electrically isolated voltage from the

internal system supply module.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 42

42 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3.1.2.3 Fieldbus Connection

For the field bus connection, the DeviceNet interface is equipped with a 5 pole

header, its counter-piece being a plug connector (Open Style Connector).

The scope of delivery includes the plug connector 231-305/010-000/050-000

from the WAGO MULTI CONNECTION SYSTEM. The connector has gold

plated contacts and has the signal designations printed at its clamping units.

The table shows the connection diagram, the colours resulting in accordance

with the DeviceNet specification and are identical to the conductor colours of

the DeviceNet cables.

Fieldbus connection

Series 231

(MCS)

V+

CAN_High

drain

CAN_Low

V-

Pin Signal Code Description

5 V+ red 11 ... 25 V

4 CAN_H white CAN Signal

3 Shield Shield connection

2 CAN_L blue CAN Signal

1 V- black 0 V

High

Low

Fig. 3-3: Fieldbus connection, MCS g012500e

For the connection of small conductor cross sections, we recommend to insert

an insulation stop from series 231-670 (white), 231-671 (light grey) or 231672 (dark grey) due to the low kink resistance. This insulation stop prevents a

conductor from kinking when it hits the conductor contact point, and as such

the conductor insulation from being also entered into and clamped in the connection point. Connector marking, housing components, test connectors including cables and header connectors for cable extensions are available.

The connection point is lowered in such a way that after a connector is inserted, installation in an 80 mm high switchbox is possible.

The electrical isolation between the fieldbus system and the electronics is

made via the DC/DC converter and the optoCoupler in the fieldbus.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 43

3.1.2.4 Display Elements

The operating condition of the fieldbus Coupler or node is signalled via light

diodes (LED).

Four LEDs, specific for DeviceNet (OVERFL, RUN, BUSOFF, CONNECT),

indicate the module status (MS) and the network status (NS).

Fieldbus Coupler/Controller • 43

Fieldbus Coupler 750-306

DeviceNet

OVERFL

MS

RUN

BUS OFF

NS

CONNECT

I/O

01

A

B

24V

02

0V

C

D

C

A

Fig. 3-4: Display elements 750-306 g030602x

LED Color Meaning

OVERFL red Errors or faults at the fieldbus Coupler.

RUN green Fieldbus Coupler is ready for operation.

BUS OFF red Error or malfunction at network

CONNECT green Fieldbus Coupler is ready for network communication.

I/O red/

green/

The ‚I/O‘-LED indicates the operation of the node and signals faults

encountered.

orange

A green Status of the operating voltage system

C green Status of the operating voltage – power jumper contacts

WAGO-I/O-SYSTEM 750

DeviceNet

Page 44

44 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3.1.2.5 Configuration Interface

The configuration interface used for the communication with

WAGO-I/O-CHECK or for firmware transfer is located behind the cover flap.

open

flap

Configuration interface

Fig. 3-5: Configuration interface g01xx06e

The communication cable (750-920) is connected to the 4-pole header.

3.1.2.6 Hardware Address (MAC ID)

The DIP switch is used both for parametrizing (setting the baud rate) of the

fieldbus Coupler and for setting the MAC ID.

The MAC-ID (node address) is set with the DIP switches 1 to 6 by 'sliding' the

desired DIP switch to 'ON'.

The binary significance of the individual DIP switches increases according to

the switch number. DIP switch 1 being the lowest bit with the value 20 and

switch 6 the highest bit with the value 25. Therefore the MAC ID 1 is set with

DIP1 = ON, the MAC ID 8 with DIP4 = ON, etc.

For the DeviceNet fieldbus nodes, the node address can be set within the range

from 0 to 63.

ON

12

1

2

345

3

4

5

67

6

7

8

8

Fig. 3-6: Example: Setting of station (node) address MAC ID 1 (DIP 1 = ON) g012540x

ON

The configuration is only read during the power up sequence. Changing the

switch position during operation does not change the configuration of the

buscoupler. Turn off and on the power supply for the fieldbus coupler to accept the DIP switch change.

The default setting is MAC ID 1.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 45

3.1.2.7 Setting the Baud Rate

The fieldbus coupler supports 3 different Baud rates, 125 kBaud, 250 kBaud

and 500 kBaud. DIP switches 7 and 8 are used to set the baud rate.

ON

12

1

2

345

3

4

5

67

6

7

8

8

Fig. 3-7: Example: Setting the baud

rate 250 kBaud (DIP 7 = ON) on a

station (node) with the address MAC

ID 1.

ON

The configuration is only read during the power up sequence. Changing the

switch position during operation does not change the configuration of the

buscoupler. Turn off and on the power supply for the fieldbus Coupler to accept the DIP switch change.

g012541x

Fieldbus Coupler/Controller • 45

Fieldbus Coupler 750-306

Baud rate DIP7 DIP8

125 kBaud

250 kBaud ON OFF

500 kBaud OFF ON

not allowed ON ON

*)

Presetting

*)

OFF OFF

The default setting is Baud rate 125 kB.

3.1.3 Operating System

Following is the configuration of the master activation and the electrical installation of the fieldbus station.

After switching on the supply voltage, the Coupler performs a self-test of all

functions of its devices, the I/O module and the fieldbus interface. Following

this, the I/O modules and the present configuration is determined, whereby an

external, not visible list is generated.

In the event of a fault, the Coupler changes to the "Stop" condition. The "I/O"

LED flashes red. After clearing the fault and cycling power, the Coupler

changes to the "Fieldbus start" status and the "I/O" LED lights up green.

Fig. 3-8: Operating system 750-306 g012113d

WAGO-I/O-SYSTEM 750

DeviceNet

Page 46

46 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3.1.4 Process Image

After powering up, the Coupler recognizes all I/O modules plugged into the

node which supply or wait for data (data width/bit width > 0). In the nodes,

analog and digital I/O modules can be mixed.

The Coupler produces an internal process image from the data width and the

type of I/O module as well as the position of the I/O modules in the node. It is

divided into an input and an output data area.

The data of the digital I/O modules is bit orientated, i.e. the data exchange is

made bit for bit. The analog I/O modules are all byte orientated I/O modules,

i.e. modules where the data exchange is made byte for byte. These I/O modules include, for example, the counter modules, I/O modules for angle and

path measurement as well as the communication modules.

Note

For the number of input and output bits or bytes of the individual I/O modules, please refer to the corresponding I/O module description.

The data of the I/O modules is separated for the local input and output process

image in the sequence of their position after the Coupler in the individual process image.

In the respective I/O area, analog modules are mapped first, then all digital

modules, even if the order of the connected analog and digital modules does

not comply with this order. The digital channels are grouped, each of these

groups having a data width of 1 byte. Should the number of digital I/Os exceed 8 bits, the Coupler automatically starts another byte.

Note

A process image restructuring may result if a node is changed or extended. In

this case, the process data addresses also change in comparison with earlier

ones. In the event of adding a module, take the process data of all previous

modules into account.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 47

3.1.5 Data Exchange

With DeviceNet, the transmission and exchange of data is made using objects.

For a network access on the single objects of the Coupler, it is necessary to

create a connection between the desired participants and to allocate connection

objects.

For an easy and quick set-up of a connection, the DeviceNet fieldbus Coupler

750-306 uses the "Predefined Master/Slave Connection Set", which contains 4

pre-defined connections. For the access on the Coupler the connections only

need to be allocated. The "Predefined Master/Slave Connection Set" confines

itself to pure Master/Slave relationships.

The DeviceNet fieldbus Coupler 750-306 can only communicate via its assigned client and it is a so-called "Group 2 Only Server". The Group 2 Only

Server communicating is only possible via the Group 2 Only Unconnected

Explicit Message Port. These slaves exclusively receive messages defined in

message group 2.

Fieldbus Coupler/Controller • 47

Fieldbus Coupler 750-306

The object configuration for the data transmission is defined by an Assembly

Object. The Assembly Object can be used to group data (e.g. I/O data) into

blocks (mapping) and send this data via one single communication connection.

This mapping results in a reduced number of accesses to the network.

A differentiation is made between "Input-Assemblies" and "OutputAssemblies".

An Input-Assembly reads in data from the application via the network or produces data on the network respectively.

An Output-Assembly writes data to the application or consumes data from the

network respectively.

Various Assembly instances are permanently programmed (static assembly) in

the fieldbus Coupler.

Further information

The Assembly instances for the static assembly are described in chapter

5.5.1.1 "Assembly Instance".

WAGO-I/O-SYSTEM 750

DeviceNet

Page 48

48 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3.1.5.1 Communication Interfaces

For a data exchange, the DeviceNet fieldbus Coupler is equipped with two interfaces:

• the interface to fieldbus (-master) and

• the interface to the bus modules.

Data exchange takes place between the fieldbus master and the bus modules.

Access from the fieldbus side is fieldbus specific.

3.1.5.2 Memory Areas

The Coupler uses a memory space of 256 words (word 0 ... 255) for the physical input and output data.

The division of the memory spaces is identical with all WAGO fieldbus Couplers.

fieldbus coupler

fieldbus

memory area

for input data

word 0

input

modules

word 255

memory area

for output data

word 0

output

modules

word 255

1

2

I/O modules

I

O

Fig. 3-9: Memory areas and data exchange for a fieldbus Coupler g012433e

The Coupler process image contains the physical data of the bus modules in a

storage area for input data and in a storage area for output data (word 0 ... 255

each).

1 The input module data can be read from the fieldbus side.

2 In the same manner, writing to the output modules is possible from the

fieldbus side.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 49

3.1.5.3 Addressing

3.1.5.3.1 Fieldbus Specific

Once the supply voltage is applied, the Assembly Object maps data from the

process image. As soon as a connection is established, a DeviceNet-Master

(Scanner) can address and access the data by "Class", "Instance" and "Attribute".

Data mapping depends on the selected Assembly Instance of the static Assembly.

Further information

The Assembly Instances of the static Assembly are described in chapter

5.5.1.1 "Assembly Instance".

Fieldbus Coupler/Controller • 49

Fieldbus Coupler 750-306

Fieldbus coupler

memory area

for input data

word 0

1

I/O modules

input

modules

word 255

memory area

for output data

word 0

output

modules

word 255

2

I

O

fieldbus

master

Connection

Object

Producer

Consumer

Assembly

Object

Input-

Assemly

Output-

Assemly

Application

Object

Fig. 3-1: Fieldbus specific data exchange for a DeviceNet fieldbus Coupler g012531e

Note

For the number of input and output bits or bytes of the individual I/O modules,

please refer to the corresponding I/O module description.

Note

A process image restructuring may result if a node is changed or extended. In

this case the process data addresses also change in comparison with earlier

ones. In the event of adding a module, take the process data of all previous

modules into account.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 50

50 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

Example for static assembly (default assembly):

The default assembly is:

Output1 (I/O Assembly Instance 1)

Input1 (I/O Assembly Instance 4)

In this example, the fieldbus node arrangement looks like this:

1) 1 fieldbus coupler DeviceNet (750-306),

2) 1 digital 4-channel input module (i. e. 750-402),

3) 1 digital 4- channel output module (i. e. 750-504),

4) 1 analog 2- channel output module with 2 bytes per channel (i. e. 750-552),

5) 1 analog 2- channel input module with 2 bytes per channel (i. e. 750-456),

6) 1 End module (750-600).

Input process image:

Default process data, input image (Assembly Class, Instance 4)

Byte .7 .6 .5 .4 .3 .2 .1 .0

0

1

2

3

4

5

1)

DI = Digital Input

2)

DS = Diagnostic Status

DS08 2)DS07 2)DS06 2)DS05 2)DS04 2)DS03 2)DS02 2)DS01

not used DI041)DI031)DI021)DI01

low byte channel 1

high byte channel 1

low byte channel 2

high byte channel 2

Output process image:

Default process data, output image (Assembly Class, Instance 1)

Byte .7 .6 .5 .4 .3 .2 .1 .0

0

1

2

low byte channel 1

high byte channel 1

low byte channel 2

1)

2)

3

4

1)

DO = Digital Output

high byte channel 2

not used DO04

1)

DO031)DO021)DO01

WAGO-I/O-SYSTEM 750

1)

DeviceNet

Page 51

3.1.6 Configuration Software

To enable a connection between the PLC and the fieldbus devices, the interface modules have to be configured with the individual station data.

To this effect, the scope of delivery of WAGO-I/O-SYSTEM 758 includes the

WAGO NETCON software intended for design and configuration, start-up and

diagnosis.

Further configuration software of different manufacturers include, for instance, RSNetWorx.

3.1.7 Starting up DeviceNet Fieldbus Nodes

This chapter shows the step-by-step procedure for starting up a

WAGO DeviceNet fieldbus node.

Attention

This description is given as an example and is limited to the execution of a

local start-up of an individual DeviceNet fieldbus node.

Fieldbus Coupler/Controller • 51

Fieldbus Coupler 750-306

The procedure contains the following steps:

1. Connecting the PC and fieldbus node

2. Setting the MAC ID and baud rate

3. Configuration with static Assembly

3.1.7.1 Connecting the PC and Fieldbus Node

1. Connect the fitted DeviceNet fieldbus node to the DeviceNet fieldbus

PCB in your PC via a fieldbus cable.

The 24 V field bus supply is fed by an external fieldbus network power

supply over the connections V+, V- of the 5-pin fieldbus connector (MCS

Series 231).

2. Start your PC.

3.1.7.2 Setting the MAC ID and Baud Rate

1. Use the DIP switches 1...6 to set the desired node address (MAC ID). The

binary significance of the individual DIP switches increases according to

the switch number.

ON

12

345

67

8

g012443x

Fig. 3-10: Example: Setting the

MAC ID 4 (DIP 3 = ON).

DIP switch Value

0

1

2

3

4

5

6

2

1

2

2

2

3

2

4

2

5

2

WAGO-I/O-SYSTEM 750

DeviceNet

Page 52

52 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

2. DIP switches 7 and 8 are used to set the desired baud rate.

ON

12

1

2

345

3

4

5

6

7

8

67

8

ON

g012541x

Fig. 3-11: Example: Setting the baud

rate 250 kBaud (DIP 7 = ON) of the

station with MAC ID 1.

3. Then switch on the Coupler supply voltage.

3.1.7.3 Configuration with Static Assembly

In this example, the software WAGO NETCON is used for the configuration.

Baud rate DIP7 DIP8

125 kBaud

*)

OFF OFF

250 kBaud ON OFF

500 kBaud OFF ON

not allowed ON ON

*)

Presetting

The node in the example consists of the following I/O modules:

1234 5 678

AI AI

516 467

AO AO

550 600

750-306

DI DI DI DI

402

402 516

DODO

DODO DODO

516

Fig. 3-12: Example for a fieldbus node g012552x

1. Starting Software and EDS file load

1. Start the configuration software WAGO NETCON.

2. Load an EDS file for the fieldbus Coupler in WAGO NETCON, i. e.

"4.EDS".

For this click on "File/ Copy EDS" and choose the EDS-file to load.

Note

You can download the EDS files for the fieldbus Coupler from the Internet under: www.wago.com.

Upon downloading the EDS file into WAGO NETCON, you can create a

new project and start configuring your network.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 53

Fieldbus Coupler/Controller • 53

Fieldbus Coupler 750-306

2. Create a new project

1. Enter the "File" menu and click on menu point "New".

2. Select "DeviceNet" as the fieldbus system and confirm your selection by

clicking on the "OK" button.

Fig. 3-13: Select fieldbus p112501d

3. Enter Master

1. Enter a fieldbus master on the surface by clicking on the „Master“ menu

point in the "Insert" menu.

A dialog window opens in which you can select the DeviceNet fieldbus card

in your PC.

Fig. 3-14: Select the DeviceNet fieldbus PCB / Insert Master p1x2602d

2. For the DeviceNet Master interface card, click in the left-hand selection

window on the corresponding entry to mark it.

3. Take the Master into the right-hand window by clicking on the "Add" but-

WAGO-I/O-SYSTEM 750

DeviceNet

ton and confirm by clicking on the "OK" button.

Now the fieldbus master is shown on the surface as a graphic.

Page 54

54 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

4. Add a slave

1. Enter a fieldbus slave on the surface by clicking on the “Device” menu

point in the "Insert" menu.

The mouse pointer changes to the letter D with an arrow.

2. Move this mouse pointer to the graphic display of the fieldbus, then click

on the left-hand mouse key.

A dialog window opens permitting you to select a DeviceNet device.

Fig. 3-15: Insert slave p012501d

3. For the fieldbus Coupler 750-306 click in the left-hand selection window

on the corresponding entry to mark it.

4. Take this into the right-hand window by clicking on the "Add" button and

confirm by clicking on the "OK" button.

The configuration is displayed on the surface as a graphic.

Fig. 3-16: Configuration p012502d

WAGO-I/O-SYSTEM 750

DeviceNet

Page 55

Fieldbus Coupler/Controller • 55

Fieldbus Coupler 750-306

5. Device configuration

1. To configure the device, click on its graphic to mark it, then click on the

menu point “Device configuration” in the "Settings" menu.

A dialog window opens permitting you to proceed with the desired settings.

Fig. 3-17: Device Configuration p112505d

6. Load configuration

1. To load the set configuration in the interface card, click on the master’s

graphic to mark it, then click on the “Download” menu point in the "Online" menu.

WAGO-I/O-SYSTEM 750

DeviceNet

Page 56

56 • Fieldbus Coupler/Controller

Fieldbus Coupler 750-306

3.1.8 LED Display

The Coupler possesses several LEDs for on site display of the Coupler operating status or the complete node.

DeviceNet

OVERFL

MS

RUN

BUS OFF

NS

CONNECT

I/O

01

A

B

24V

02

0V

C

D

C

A

Fig. 3-18: Display elements 750-306 g030602x

The module status (MS) and the network status (NS) can be displayed by the

top 4 LED’s. They react as described in the table.

Module status (MS)

OVERFL

(red)

off off no power No power supply to the device.

off on device operational The device operates correctly.

off blinking device in standby The device needs to be configured or has been partly

blinking off minor fault A minor fault has occurred. It exists a diagnostics.

on off unrecoverable fault The device is defective, needs to be serviced or