Page 1

Pos: 2 /Dokumentation allgemein/Einband/Einband Handbuch - Frontseite 20 15 - mit D ocV ari abl en (S ta ndar d) @ 9\mod_1285229289866_0.docx @ 64941 @ @ 1

WAGO-I/O-SYSTEM 750

Manual

750-658

CAN Gateway

Version 1.2.0, valid from

Version 01/01

Pos: 3 /Alle S erie n (Al lge mei ne M odul e) /Rec htli ch es, Allg emei n es/I mpre ssu m f ür St and ard han dbüc h er - al lg. Ang aben, A nschr iften, Telef onnu mmern un d E-Mail -Adr esse n @ 3\mod_1219151118203_21.docx @ 21060 @ @ 1

FW/HW-

Page 2

2 WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

© 2017 WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

=== Ende der Li st e für Te xtm arke Ei nba nd_ vorn e ===

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-658 CAN Gateway

Pos: 5 /Dok ument ati on allg em ein/ Verz eic hni sse /Inh alts ver zei chni s - Ü bersc hrift oG und Ver zeich nis @ 3\ mod_1219151230875_21.docx @ 21063 @ @ 1

Table of Contents

1 Notes about this Documentation ................................................................. 6

1.1 Validity of this Documentation ................................................................. 6

1.2 Copyright ................................................................................................... 6

1.3 Symbols ..................................................................................................... 7

1.4 Number Notation ....................................................................................... 9

1.5 Font Conventions ...................................................................................... 9

2 Important Notes ......................................................................................... 10

2.1 Legal Bases ............................................................................................. 10

2.1.1 Subject to Changes ............................................................................. 10

2.1.2 Personnel Qualifications ..................................................................... 10

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying

Provisions ........................................................................................... 10

2.1.4 Technical Condition of Specified Devices ......................................... 11

2.2 Safety Advice (Precautions) .................................................................... 12

3 CAN Technology ........................................................................................ 14

4 Device Description ..................................................................................... 15

4.1 View ........................................................................................................ 17

4.2 Connectors ............................................................................................... 18

4.2.1 Data Contacts/Internal Bus ................................................................. 18

4.2.2 Power Jumper Contacts/Field Supply ................................................ 19

4.2.3 CAGE CLAMP® Connectors ............................................................. 21

4.3 Display Elements .................................................................................... 22

4.4 Schematic Diagram ................................................................................. 23

4.5 Technical Data ........................................................................................ 24

4.5.1 Device Data ........................................................................................ 24

4.5.2 Supply ................................................................................................. 24

4.5.3 CAN Communication ......................................................................... 25

4.5.4 Connection Type ................................................................................ 25

4.5.5 Climatic Environmental Conditions ................................................... 25

4.6 Approvals ................................................................................................ 26

4.7 Standards and Guidelines ........................................................................ 27

5 Function Description ................................................................................. 28

5.1 Operating Modes ..................................................................................... 28

5.1.1 Sniffer Mode ....................................................................................... 29

5.1.2 Transparent Mode ............................................................................... 29

5.1.3 Mapped Mode ..................................................................................... 29

5.1.3.1 Map CAN Telegrams in Input Direction ....................................... 29

5.1.3.2 Map CAN Telegrams in Output Direction .................................... 30

5.1.3.2.1 "Content of the CAN telegram" Setting .................................... 30

5.1.3.2.2 "Send on request" Setting ......................................................... 31

5.1.3.2.3 "Send on change" Setting .......................................................... 31

5.1.3.2.4 "Cycle Time" Setting ................................................................ 31

5.1.3.3 Access CAN Telegrams via the Mailbox ...................................... 32

5.2 Filter Settings .......................................................................................... 33

5.2.1 "Overwrite" Setting ............................................................................ 33

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

5.2.2 "Keep All" Setting .............................................................................. 33

6 Process Image ............................................................................................. 34

6.1 Process Image in "Sniffer" Operating Mode ........................................... 35

6.1.1 Mailbox............................................................................................... 35

6.1.2 CAN User Data Range ....................................................................... 35

6.2 Process Image in "Transparent" Operating Mode ................................... 37

6.2.1 Mailbox............................................................................................... 37

6.2.2 CAN User Data Range ....................................................................... 37

6.3 Process Image in the "Mapped" Operating Mode ................................... 38

6.3.1 Mailbox............................................................................................... 38

6.3.2 Toggle Byte ........................................................................................ 38

6.3.3 Mapped Cyclical Data (CAN User Data) ........................................... 38

7 Mounting ..................................................................................................... 39

7.1 Mounting Sequence ................................................................................. 39

7.2 Inserting and Removing Devices ............................................................ 40

7.2.1 Inserting the I/O Module .................................................................... 40

7.2.2 Removing the I/O Module .................................................................. 41

8 Connect Devices ......................................................................................... 42

8.1 Connecting a Conductor to the CAGE CLAMP® ................................... 42

8.2 Connect CAN Bus ................................................................................... 43

9 Configuration and Parameterization ....................................................... 44

9.1 Configuration and Parameterization with WAGO-I/O-CHECK ............ 45

9.1.1 Configuration Dialog .......................................................................... 46

9.1.1.1 Toolbar ........................................................................................... 46

9.1.1.2 Function Area ................................................................................ 50

9.1.1.3 Diagnosis Area ............................................................................... 50

9.1.2 Load Parameters into the Application ................................................ 51

9.1.3 "Configuration" Dialog ...................................................................... 53

9.1.3.1 Set Mailbox Diagnosis ................................................................... 53

9.1.3.2 Set Mailbox Length ....................................................................... 56

9.1.3.3 Setting the Process Image Size ...................................................... 57

9.1.4 Function Area in the "Sniffer Mode" ................................................. 58

9.1.5 Function Area in the "Transparent Mode" ......................................... 59

9.1.6 Function Area in the "Mapped Mode" ............................................... 61

9.1.6.1 "PII" View ...................................................................................... 61

9.1.6.2 "PIO" View .................................................................................... 63

9.1.7 "CAN Parameter" Dialog ................................................................... 66

9.1.7.1 Select CAN Data Format ............................................................... 66

9.1.7.2 Set CAN Baud Rate ....................................................................... 67

9.1.8 "Filter" Dialog .................................................................................... 68

9.2 Configuration and Parameterization with e!COCKPIT .......................... 70

9.3 Startup with WAGO-I/O-PRO ................................................................ 71

10 Appendix ..................................................................................................... 72

10.1 Mailbox 2.0 Transmission Method ......................................................... 72

10.1.1 Message .............................................................................................. 72

10.1.2 Transmission Channel ........................................................................ 73

10.1.2.1 The Handshake Byte ...................................................................... 74

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 5

WAGO-I/O-SYSTEM 750 Table of Contents 5

750-658 CAN Gateway

10.1.3 Communication Phases ...................................................................... 75

10.1.3.1 Synchronization ............................................................................. 75

10.1.3.1.1 Mailbox Commands .................................................................. 75

10.1.3.1.2 Acknowledgement .................................................................... 76

10.1.3.1.3 Signaling ................................................................................... 76

10.1.3.1.4 Finite Automation ..................................................................... 77

10.1.3.2 Data Exchange ............................................................................... 78

10.1.3.2.1 Example .................................................................................... 79

10.2 Protocols Supported by Mailbox 2.0 ....................................................... 80

10.2.1 Protocol 0x80 (Parameter Access) ..................................................... 80

10.2.2 Protocol 0x81 (Diagnostics) ............................................................... 81

10.3 Overview of Parameters .......................................................................... 83

10.3.1 Table 0: Base Register ........................................................................ 83

10.3.2 Tables 50 … 55: Filter Configuration ................................................ 83

10.3.3 Tables 100 … 144: Configuration of Output Direction for "Mapped

Mode" ................................................................................................. 84

10.3.4 Tables 200 … 244: Configuration of Input Direction for "Mapped

Mode" ................................................................................................. 87

10.4 Register Communication ......................................................................... 89

10.4.1 Control/Status Byte ............................................................................ 90

10.4.2 Register Overview .............................................................................. 91

=== Ende der Li st e für Te xtm arke Ver zeic hni s_v or ne == =

11 Use in Hazardous Environments .............................................................. 92

11.1 Marking Configuration Examples ........................................................... 93

11.1.1 Marking for Europe According to ATEX and IEC-Ex ...................... 93

11.1.2 Marking for America According to NEC 500 .................................... 98

11.2 Installation Regulations ........................................................................... 99

11.2.1 Special Notes Regarding Explosion Protection .................................. 99

11.2.2 Special Notes Regarding ANSI/ISA Ex ........................................... 101

List of Figures .................................................................................................... 102

List of Tables ...................................................................................................... 104

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Pos: 7 /Alle Ser ie n (All ge mein e M odul e) /Üb ersc hri ften/ E ben e 1/Hi nw eis e zu dies er D o kume ntat ion - Üb erschr ift 1 @ 4\mod_1237987661750_21.docx @ 29029 @ 1 @ 1

1 Notes about this Documentation

Pos: 8 /Alle S erie n (Al lge mei ne M odul e) /Sic her hei ts- und sonstige Hinweise/Hinweis /Hi nwei s: D o kume ntat ion auf be wahr en @ 4\mod_1237987339812_21.docx @ 29026 @ @ 1

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

Pos: 9 /Alle S erie n (Al lge mei ne M odul e) /Üb ersc hri ften/ E ben e 2/G ülti g keits berei ch - Üb ersc hrift 2 @ 12\ mod_1338912448776_21.docx @ 96469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/ Gül tigk eits ber eic h/G ültig k eits ber eich Dok um enta tio n Bus kl emme 75 0-x xxx, o hne V aria nten ang abe @ 14\mod_1358944037947_21.docx @ 109346 @ @ 1

This documentation is only applicable to the I/O module 750-658

(CAN Gateway).

Pos: 11 /All e S eri en ( Allg emei n e Mod ule) /R echtl ic hes , Al lgem ei nes/ Gült ig keit sber eic h D oku ment ati on Er gä nzung " ab < FW/H W/ SW- Vers ion> " @ 20\ mod_1407749774742_21.docx @ 161508 @ @ 1

This documentation is only applicable from FW/HW-Version 01/01.

Pos: 12 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/Hi n weis e/Ac ht ung : Hin wei s z ur D oku ment ati on B us kle mme n 75 0-xxxx @ 4\mod_1237986979656_21.docx @ 29023 @ @ 1

The I/O module 750-658 shall only be installed and operated according to the

instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos: 13.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Ur h ebers chut z - Ü bers chrift 2 @ 23\mod_1435647042188_21.docx @ 184808 @ 2 @ 1

1.2 Copyright

Pos: 13.2 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Ur heb ersc hu tz ausf ührl ich @ 4\ mod_1235565145234_21.docx @ 27691 @ @ 1

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Pos: 13.3 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 7

WAGO-I/O-SYSTEM 750 Notes about this Documentation 7

750-658 CAN Gateway

Pos: 13.4 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/S ym bole - Üb erschr if t 2 @ 1 3\mod_1351068042408_21.docx @ 105270 @ 2 @ 1

1.3 Symbols

Pos: 13.5.1 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonstige Hinweise/Gefahr/Gefahr: _Warnung vor Personen schä den allg emei n_ - Erläu terung @ 13\ mod_1343309450020_21.docx @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 13.5.2 /Alle Ser ien ( Al lg emei ne M od ule)/ Sic herh eits - u nd sons tige Hi nweis e/Gef ahr/G efahr : _War nung vor Person ensch äden d urch el ektris chen Str om_ - Erläuterung @ 13\mod_1343309694914_21.docx @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 13.5.3 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/W arn ung/ War nung : _ Warn ung vor P erso nensc h äde n al lgem ei n_ - Er läut eru ng @ 13\mod_1343309877041_21.docx @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 13.5.4 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und so nstig e Hin weise/ Vorsic ht/V orsich t: _War nung vor Pers onensc häd en allge mein_ - Erläuterung @ 13\mod_1343310028762_21.docx @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 13.5.5 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Ac htu ng/ Ach tung : _ War nung vor Sac hsc häd en al lg emei n_ - Erläuterung @ 13\mod_1343310134623_21.docx @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 13.5.6 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonsti ge Hin weise/ Achtu ng/Ac htung : _War nung vor Sachsc häden durc h elektr ostatis che Au fladu ng_ - Erl äut erung @ 13\mod_1343310227702_21.docx @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 13.5.7 /All e Serie n (All gemei ne Mo dul e)/ Sich erh eits- und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Erläuterung @ 13\mod_1343310326906_21.docx @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 13.5.8 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Inf or mati on/I nf orma tio n: _ Wei ter e Inf or mati on allg emei n_ - Erl äuter ung @ 13 \mod_1343310439814_21.docx @ 101051 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 13.6 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 9

WAGO-I/O-SYSTEM 750 Notes about this Documentation 9

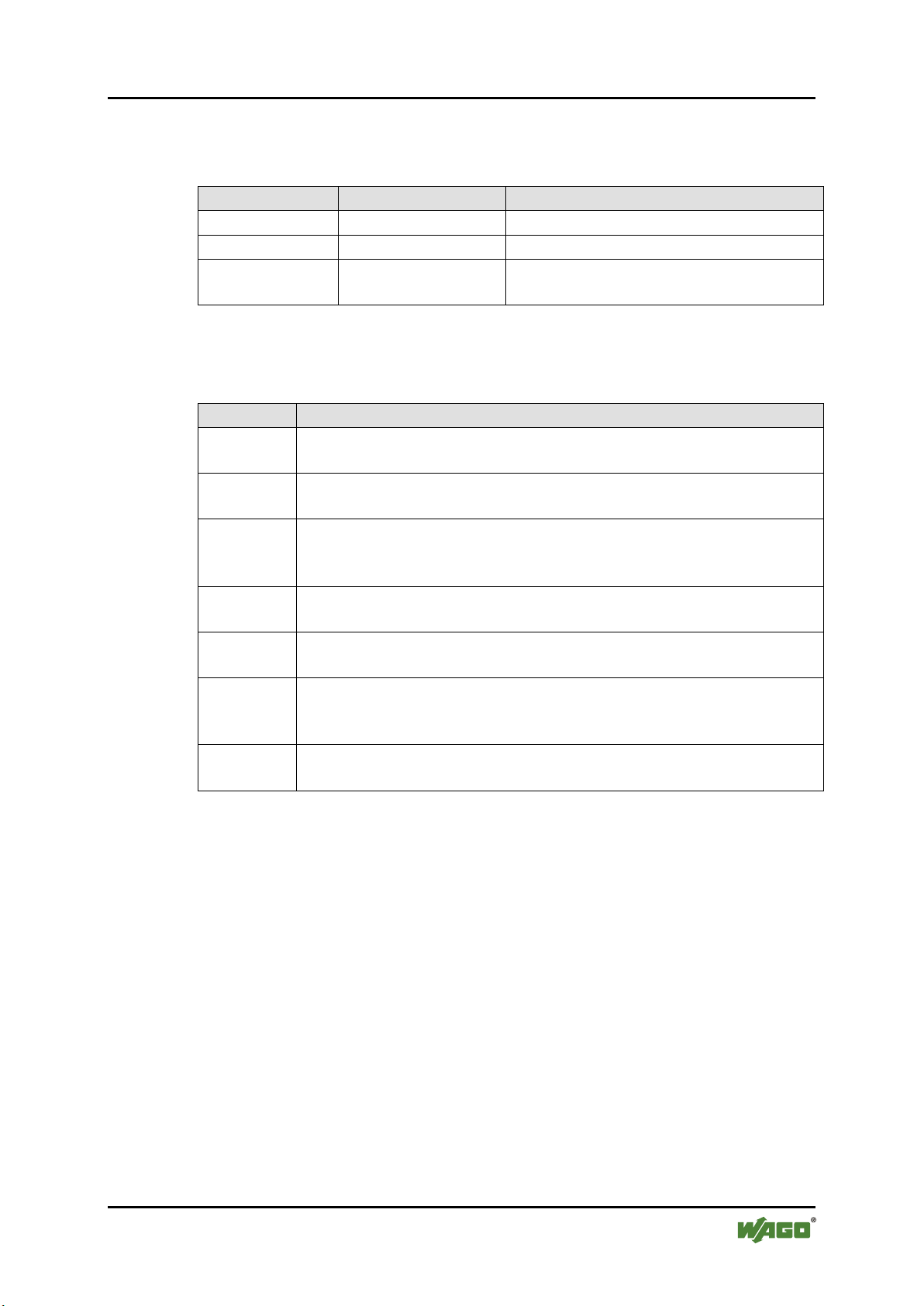

Table 1: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 2: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-658 CAN Gateway

Pos: 13.7 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/D arst ell ung der Z a hle nsys tem e - Ü bers chri ft 2 @ 23\mod_1435647128078_21.docx @ 184811 @ 2 @ 1

1.4 Number Notation

Pos: 13.8 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Za hle nsy st eme @ 3\mod_1221059454015_21.docx @ 21711 @ @ 1

Pos: 13.9 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Sc hr ift kon venti one n - Ü bersc hr ift 2 @ 23\ mod_1435647186005_21.docx @ 184814 @ 2 @ 1

1.5 Font Conventions

Pos: 13.10 / All e S erie n (Al lge mei ne M o dule) /Re cht lich es, All ge mein es/ Schr ift kon venti on en @ 3\mod_1221059521437_21.docx @ 21714 @ @ 1

menu item from a menu.

brackets.

Pos: 14 /Do kum ent atio n all ge mei n/Gl ieder ung s elem ente /---Seit en wechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 10

10 Important Notes WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Pos: 15 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 1/ Wic htig e Er läu ter unge n - Über schri ft 1 @ 4\mod_1241428899156_21.docx @ 32170 @ 1 @ 1

2 Important Notes

Pos: 16.1 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Wi chti g e Erl äuter ung en - Ei nleit u ng @ 3\mod_1221059818031_21.docx @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 16.2 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/R echt lic he G run dlag en - Üb erschr ift 2 @ 3\mod_1221060626343_21.docx @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 16.3 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Ä nder ung sv orbeh alt - Üb ersc hrift 3 un d Inhalt @ 3\mod_1221060036484_21.docx @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 16.4 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Person alqu alifi kation/ Pers onalq ualifi katio n 750- xxxx - Über sc hrift 3 un d In halt @ 3\ mod_1224061208046_21.docx @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 16.5 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Bestim mung sgemäß e Ver wendung /B estim mungsg emäß e Verwe ndung 750-xxxx - Ü bersc hrift 3 u nd Inh alt @ 3\mod_1224064151234_21.docx @ 24070 @ 3 @ 1

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 11

WAGO-I/O-SYSTEM 750 Important Notes 11

750-658 CAN Gateway

Appropriate housing (per 2014/34/EU) is required when operating the WAGOI/O-SYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 16.6 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Te ch nisc her Z us tand der Ger ät e - Ü bersc hr ift 3 u nd I nhal t @ 3\mod_1221060446109_21.docx @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 16.7 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Pos: 16.8 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Si cher hei ts hin weis e - Ü bersc hrift 2 @ 6\mod_1260180299987_21.docx @ 46724 @ 2 @ 1

2.2 Safety Advice (Precautions)

Pos: 16.9 /Al l e Ser ien ( Al lge mei ne M od ule)/ Sic herh eits - u nd s ons tig e Hi nweis e/ Einl eit ung Sic herh eits hin wei se H ar dwar e @ 6\mod_1260180170493_21.docx @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 16.10. 1 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d s onsti ge Hin wei se/G ef ahr/ Gef ahr: Nic ht an G erät en unt er S pann ung ar bei ten! @ 6\mod_1260180365327_21.docx @ 46727 @ @ 1

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 16.10. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Gef ahr/ Gefa hr: Ei nbau 07 50- xxxx nur in Geh äusen, Schrä nken oder ele ktrisc hen Betr iebsräumen! @ 6\mod_1260180556692_21.docx @ 46731 @ @ 1

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 16.10. 3 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d so nstig e H in weis e/G efa hr/G ef ahr: Unf all verh ütung s vorsc hr ift en b each te n! @ 6\mod_1260180657000_21.docx @ 46735 @ @ 1

Pos: 16.10. 4 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d s onsti ge Hin wei se/G ef ahr/ Gef ahr: Auf nor mg erec hte n A nschl us s ac ht en! @ 6\ mod_1260180753479_21.doc x @ 46739 @ @ 1

Pos: 16.11. 1 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d s onsti ge Hin wei se/A cht ung /Ac htu ng: D ef ekt e od er besch ädig te Ger ät e aus taus ch en! @ 6 \mod_1260180857358_21.docx @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 16.11. 2 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d so nsti ge Hin weis e/A cht ung /Ac htu ng: G erä te vor kriec he nde n u nd is oli ere nden Sto ff en sc hüt zen! @ 6\mod_1260181036216_21.docx @ 46747 @ @ 1

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 16.11. 3 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - und sonstige Hinweise/Achtung/Achtung: Reinigung nur mit zulässigen Mat eri alie n! @ 6\mod_1260181203293_21.docx @ 46751 @ @ 1

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 16.11. 4 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - und sonstige Hinweise/Achtung/Achtung: Kein Kontaktspray verwenden! @ 6\mod_1260181290808_21.docx @ 46755 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 13

WAGO-I/O-SYSTEM 750 Important Notes 13

750-658 CAN Gateway

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 16.11. 5 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d s onsti ge Hin wei se/A cht ung /Ac htu ng: V er pol ung en d er D aten- und V ersorg ungs leit ungen vermeid en! @ 6\ mod_1260184045744_21.docx @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 16.11. 6 /A lle Ser ien ( All ge mein e M odul e)/ Sic her heits - un d s onsti ge Hin wei se/A cht ung /Ac htu ng: El e ktros tati sc he Entl adu ng verm ei den! @ 6\ mod _1260181364729_21.docx @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Pos: 17 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 14

14 CAN Technology WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Pos: 18 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/F eld bus komm uni katio n/C AN/C AN-Kommunikation 750-0658 @ 13\mod_1355479155100_21.docx @ 107624 @ 1 @ 1

3 CAN Technology

The CAN bus is a an asynchronous serial bus system for connecting intelligent

actuators and sensors to the control level. CAN standards for "Controller Area

network" and defines a communication standard developed in the mid-1980s for

data transmission in automobiles.

The so-called "Data Link Layer" is defined in the CAN specification. This is the

physical layer and data data link layer. The message format is described in detail.

In addition, the so-called "CAN Application Layer" (CAL) is defined in the CAN

specification. CAL is a general description language for CAN networks and

makes a number of communication services available.

Network management powers up the network in a simplified manner. This

network can be extended by the user as required.

CAN is a so-called "Multi-Master Bus System". Contrary to other fieldbus

systems, the I/O modules connected to the bus are not addressed, but the messages

are identified. The devices are allowed to send messages whenever the bus is

available. Bus conflicts are solved by assigning messages a specific priority. This

priority is defined by the so-called "CAN-ID" (CAN identifier). It is uniquely

assigned to a communication object. The smaller the identifier, the higher the

priority. Thus, communication without bus master module is thus also possible.

There are two CAN standards:

• "2.0A Standard Frame"

• "2.0B Extended Frame"

The "2.0A Standard Frame" makes it possible to address up to 211 different CAN

identifiers. The "2.0B Extended Frame" was later developed to support up to 229

different CAN identifiers.

Each bus node decides by itself when it wants to send data. However, it is also

possible to request other bus nodes to send data. This request happens via the socalled "Remote Frame".

Based on CAN, various protocols have been established on the market at higher

layers. These may include CANopen, DeviceNet and SAE J1939. Support for

these protocols is left to future module variants.

Additional information about the CAN bus!

Additional information about the CAN bus is available on the Internet at

www.can-cia.org.

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 15

WAGO-I/O-SYSTEM 750 Device Description 15

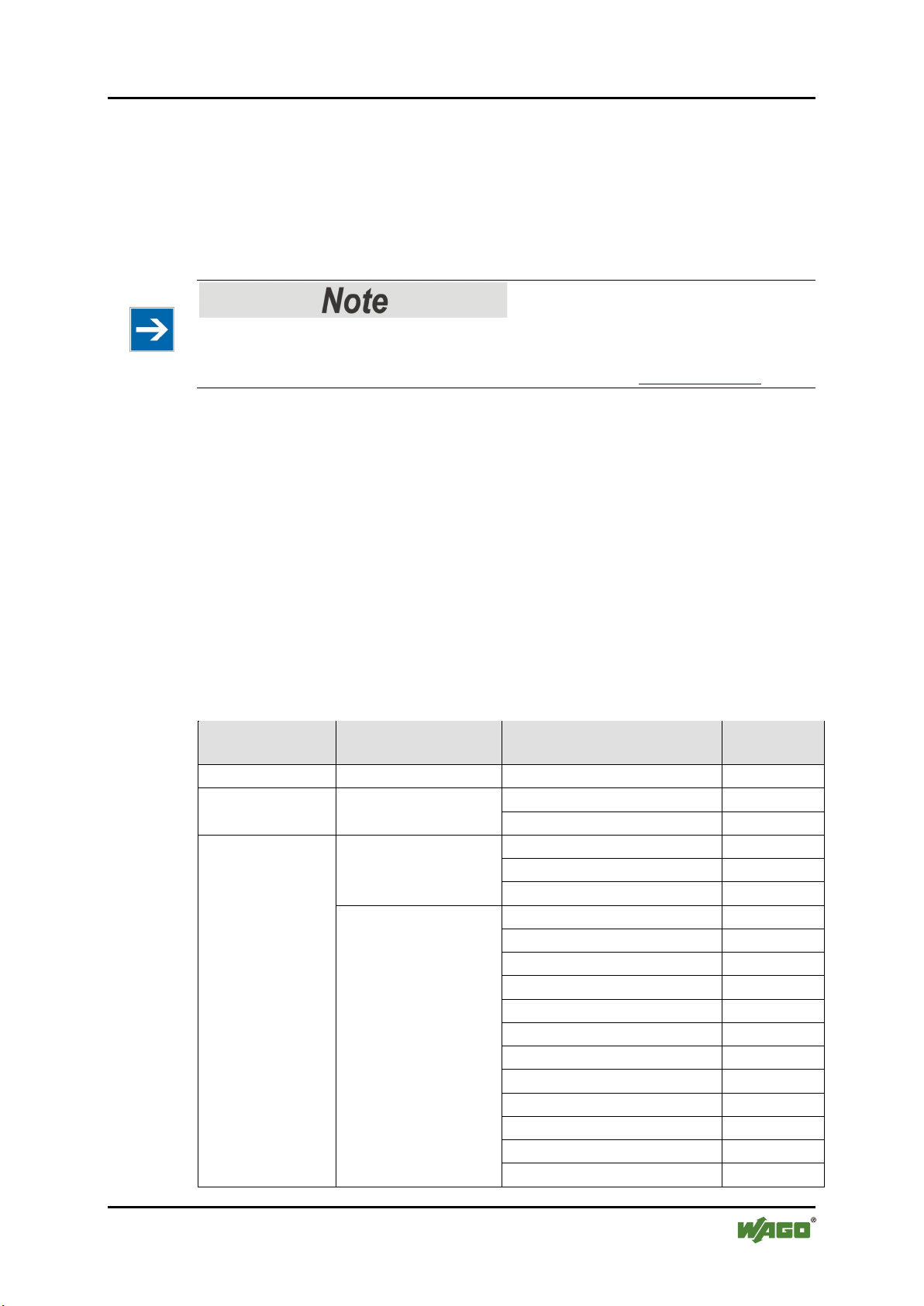

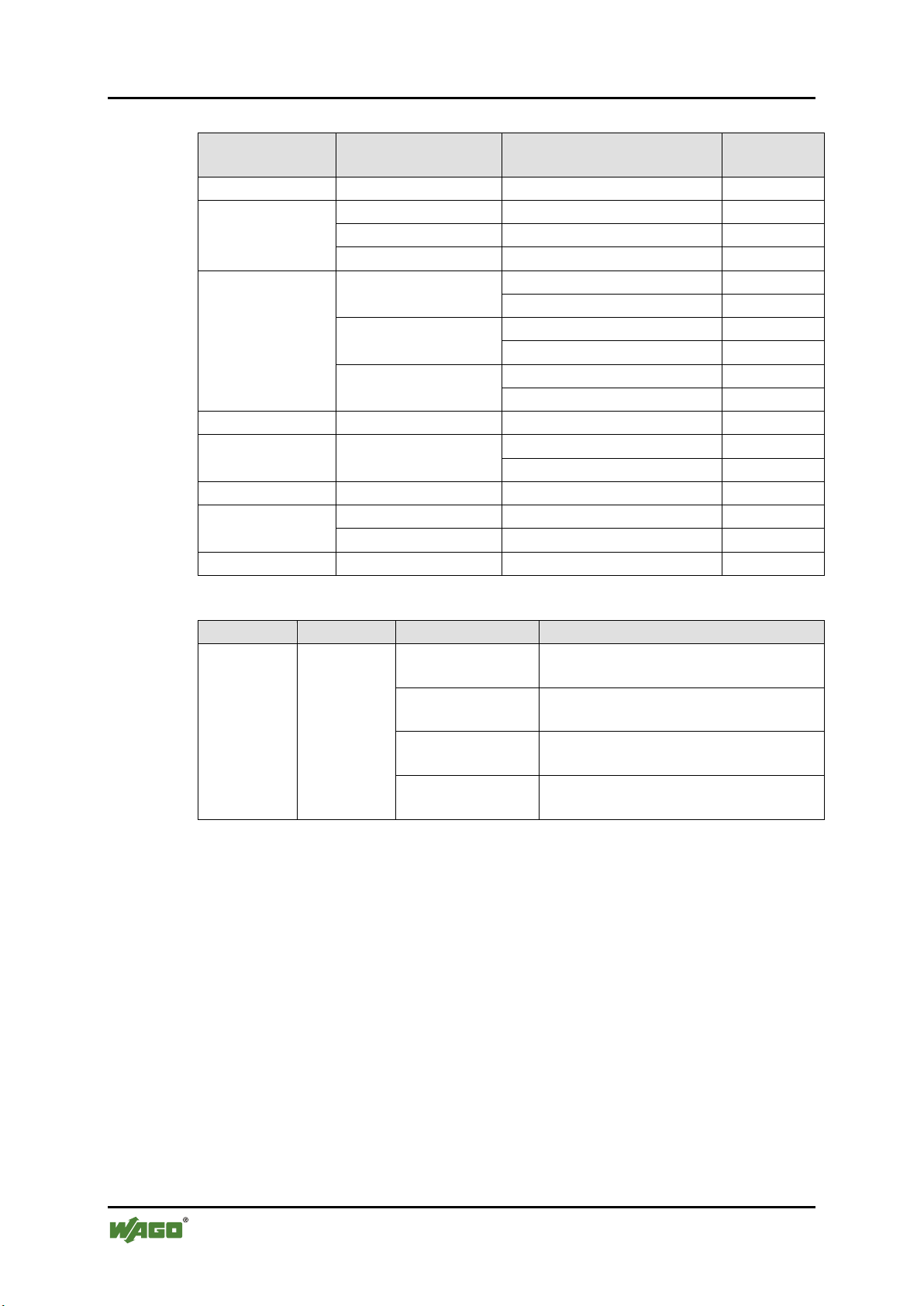

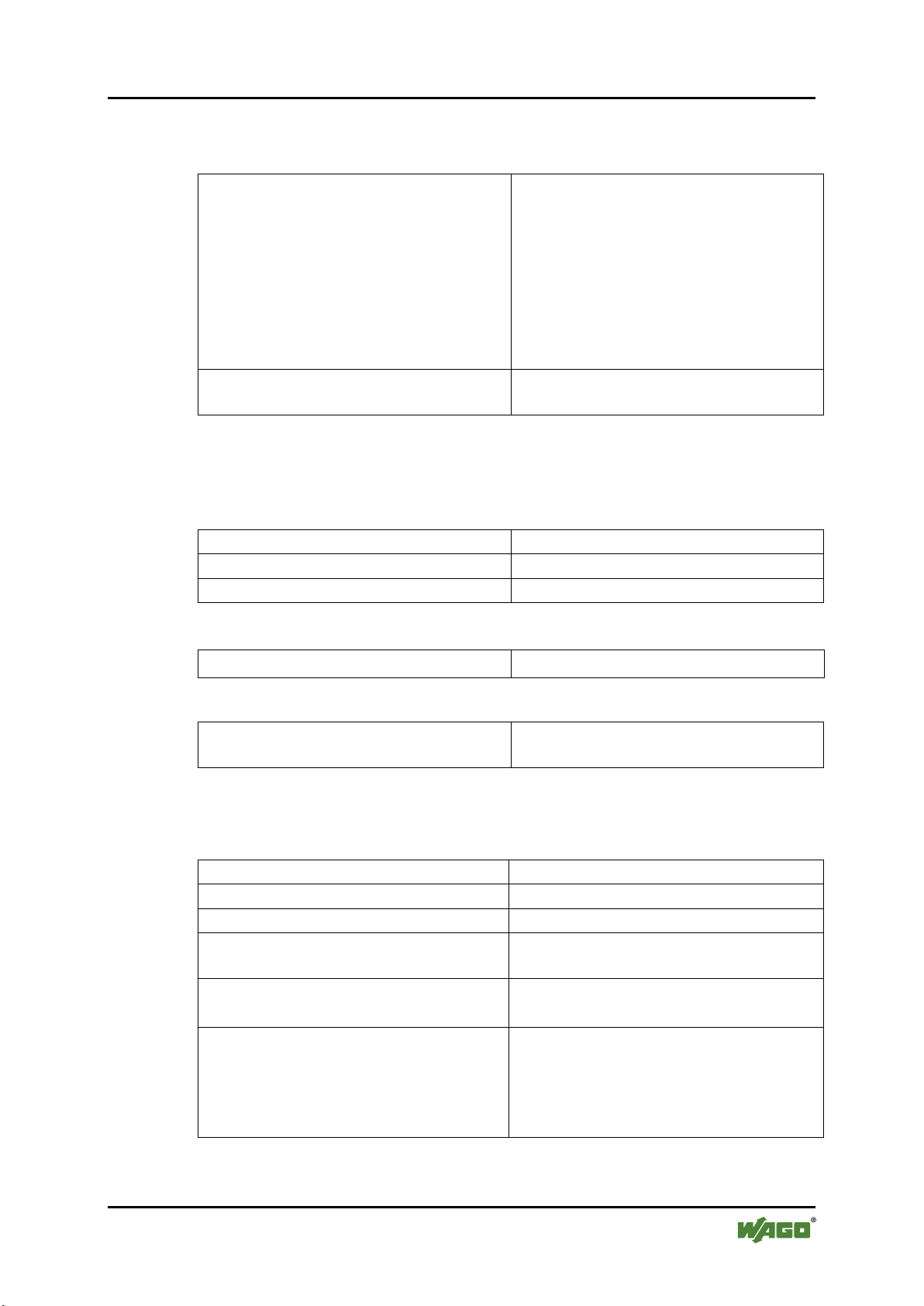

Table 3: 750-658 Compatibility List – Fieldbus Couplers/Controllers

Fieldbus

PROFIBUS

Fieldbus coupler

750-333

17

PROFINET

Fieldbus coupler

750-375

03

750-377

03

ETHERNET

Fieldbus coupler

750-341

08

750-342

17

750-352

02

Fieldbus controller

750-841

19

750-842

18

750-843

02

750-871

07

750-872

03

750-873

05

750-880

03

750-880/0025-0001

03

750-880/0025-0002

03

750-881

03

750-882

02

750-884

03

750-658 CAN Gateway

Pos: 19 /Dokum entati on allg emei n/ Glie derung s elem ente /---Seit en wechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Pos: 20 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 1/ Ger äte bes chr eib ung - Ü ber schr if t 1 @ 3\ mod_1233756084656_21.doc x @ 27096 @ 1 @ 1

4 Device Description

Pos: 21.1 /Serie 750 (WAGO-I/O-SYSTEM)/Gerätebeschreibung/Einleitung/Anwendung/SO/Anwendung 750- 0658 @ 14\mod_1358947377666_21.docx @ 109393 @ @ 1

The I/O module 750-658 is used to connect a CAN bus network to a PLC

independent of the fieldbus.

The I/O module supports the physical layer and data link layer by default.

Pos: 21.2 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Hi nwei s/Hi n weis : H öher e Pr ot okol lschi cht e n unt erst ütz en @ 14\ mod_1360327953696_21.docx @ 111249 @ @ 1

Support higher protocol layers!

Use IEC-61131-compliant function blocks to support the I/O module of higher

protocol layers. The function blocks can be downloaded at www.wago.com.

Pos: 21.3 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nlei tung /I/ O-Besc hrei bu ng/ SO/I/ O-Beschreibung 750-0658 @ 14\mod_1358948130403_21.docx @ 109442 @ @ 1

The I/O module can be configured and parameterized via:

• WAGO-I/O-CHECK

• e!COCKPIT,

• PROFIBUS GSD or

• Function blocks

Pos: 22 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/Ei nlei tu ng/E ins atz ber eich /Ei ns atzber ei ch 7 50- xxx x nur Koppl er/C ontrol ler a us Kompa tibili tätsli ste @ 4\ mod_1242389440265_21.docx @ 33262 @ @ 1

The 750-658 module can be used with the fieldbus couplers and controllers of the

WAGO-I/O-SYSTEM 750 of the specified version or higher listed in the

“Compatibility list” table.

Pos: 23 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/Ei nlei tung /Eins atz bereich /Ko mpatibi lit ätslist en/K ompati bilit ätsli ste 750- 0658 @ 14\mod_1361526228651_21.docx @ 112733 @ @ 1

Bus System

Couplers/Controllers

Item Number Firmware

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 16

16 Device Description WAGO-I/O-SYSTEM 750

Table 3: 750-658 Compatibility List – Fieldbus Couplers/Controllers

Fieldbus

Couplers/Controllers

750-885

04

DeviceNet

Fieldbus coupler

750-306

4K

ECO fieldbus coupler

750-346

10

Fieldbus controller

750-806

10

CANopen

Fieldbus coupler

750-337

19

750-338

19

ECO fieldbus coupler

750-347

08

750-348

08

Fieldbus controller

750-837

16

750-838

16

EtherCAT

Fieldbus coupler

750-354

01

KNX

Fieldbus controller

750-849

05

750-889

07

BACnet

Fieldbus controller

750-830

03

LONWORKS

Fieldbus coupler

750-319

05

Fieldbus controller

750-819

09

Various

PFC200

750-820x

02

Table 4: 750-658 Compatibility List – IPC

Bus System

IPC

Item Number

Description

WAGO-IPC

IPC

758-0870/0000-0010

Firmware revision 2.4.31 / 0111

758-0870/0000-0111

Firmware revision 01.01.26(05)

758-0875/0000-0111

Firmware revision 01.01.26(05)

758-0876/0000-0112

Firmware revision 01.01.26(05)

750-658 CAN Gateway

Bus System

Item Number Firmware

Pos: 24 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Internal data bus FW revision 01.02.10(12)

Internal data bus FW revision 01.02.10(12)

Internal data bus FW revision 01.02.10(12)

Internal data bus FW revision 01.02.10(12)

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 17

WAGO-I/O-SYSTEM 750 Device Description 17

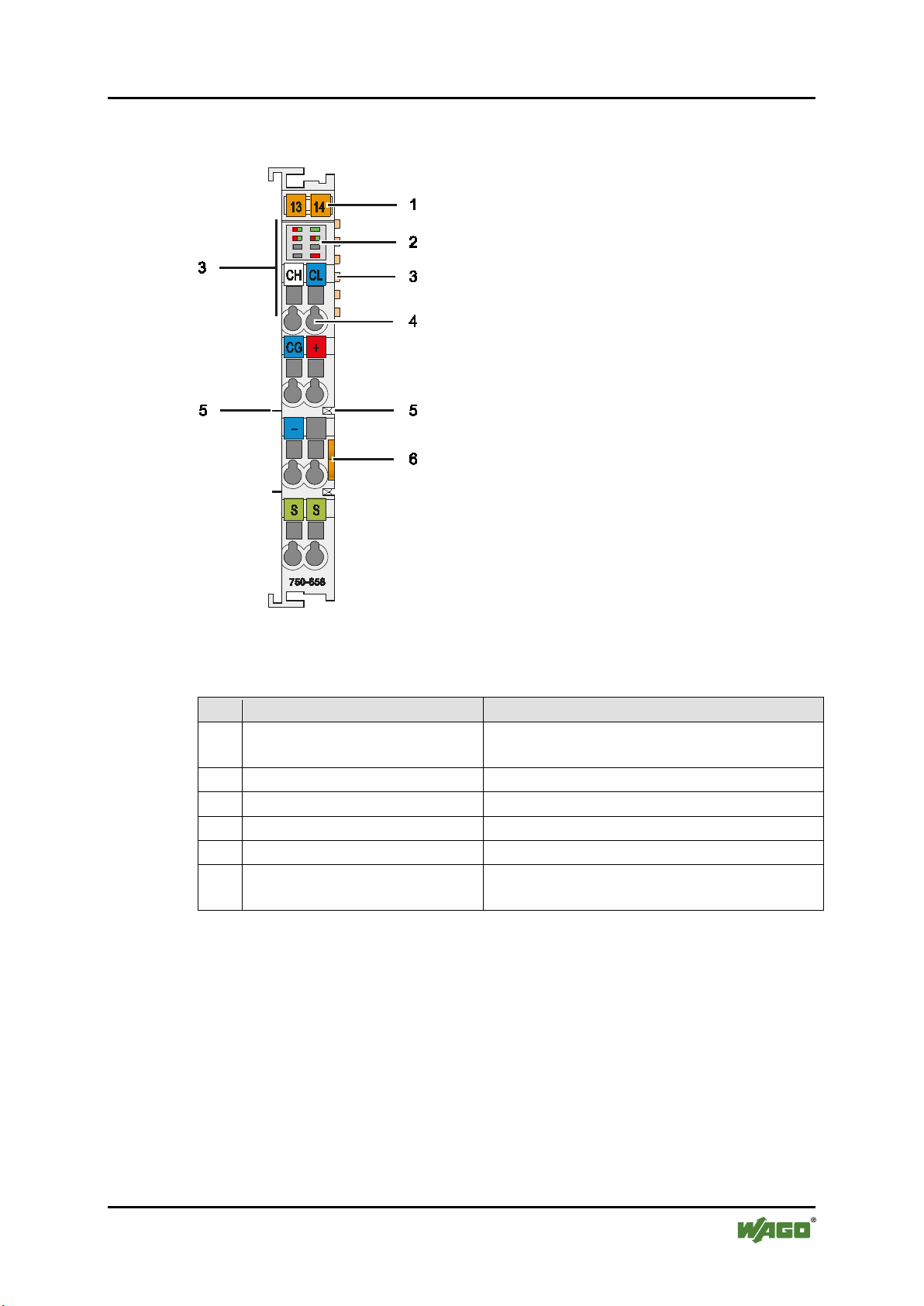

Table 5: Legend for Figure “View”

Pos.

Description

Details See Section

1

Marking possibility with MiniWSB

--2

Status LEDs

“Device Description” > “Display Elements”

3

Data contacts

“Device Description” > “Connectors”

4

CAGE CLAMP® connectors

“Device Description” > “Connectors”

5

Power jumper contacts

“Device Description” > “Connectors”

6

Release tab

“Mounting” > “Inserting and Removing

Devices”

750-658 CAN Gateway

Pos: 25 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Ans ic ht - Ü bers chri ft 2 @ 4\mod_1240984217343_21.docx @ 31958 @ 2 @ 1

4.1 View

Pos: 26 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Ger ätebes chrei bung /Ansic ht/S onder klem men/A nsicht 750-06 58 - A bb. @ 14\ mod_1358344956644_21.docx @ 108848 @ @ 1

Figure 1: View

Pos: 27 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/A nsic ht /Ans ic ht C ageCl a mp®_ Leg ende mi t LED s, mit 1 E ntri eg elung sl asch e @ 15\ mod_1370867188922_21.docx @ 122225 @ @ 1

Pos: 28 /D okum ent atio n al lge mein/ Gli eder ungs ele me nte/---Sei te nwec hsel--- @ 3\ mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 18

18 Device Description WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Pos: 29 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Ans chl üss e - Üb ersc hrift 2 @ 4\ mod_1240984262656_21.docx @ 31961 @ 2 @ 1

4.2 Connectors

Pos: 30 /Serie 750 (WAGO-I/O-SYST EM) /Ger ät ebesc hrei bung /A nschl üss e/Da ten kont akt e/Kl em menbu s - Ü bersc hrift 3 @ 6\ mod_1256294684083_21.docx @ 43660 @ 3 @ 1

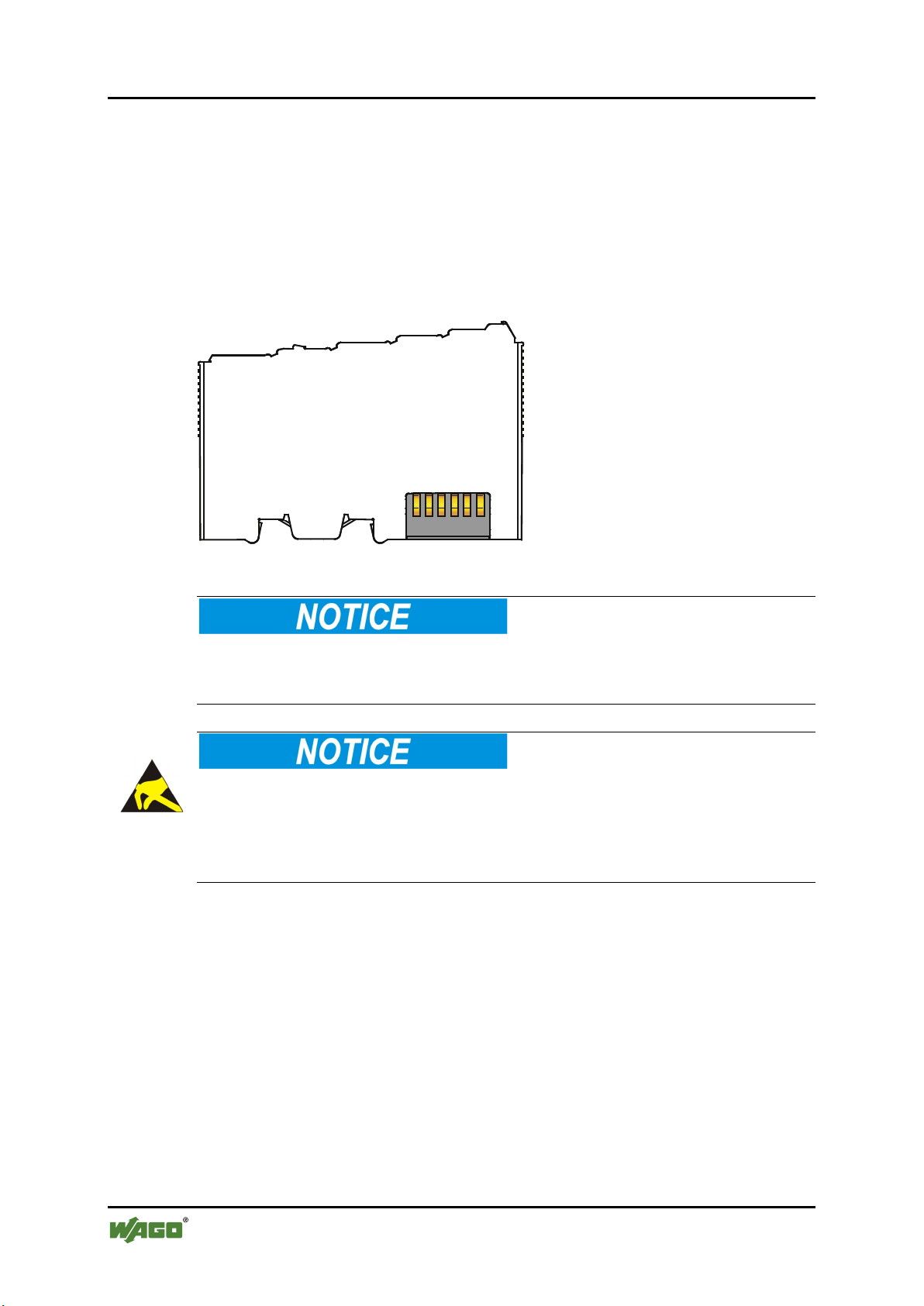

4.2.1 Data Contacts/Internal Bus

Pos: 31.1 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ans chl üsse /Da ten konta kt e - Fel dbu skop pler/ -con trol l er, A bbil dung u nd B esc hrei bung @ 3\mod_1231771259187_21.docx @ 26002 @ @ 1

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data Contacts

Pos: 31.2 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Ac htu ng/A ch tung : Bus kl em men nic ht a uf G oldf eder kon ta kte l eg en! @ 7 \mod_1266318463636_21.docx @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 31.3 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Achtung/Achtung: ESD - Auf gute Erdung der U mg ebu ng ac ht en! @ 7\ mod_1266318538667_21.docx @ 50708 @ @ 1

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 32 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 19

WAGO-I/O-SYSTEM 750 Device Description 19

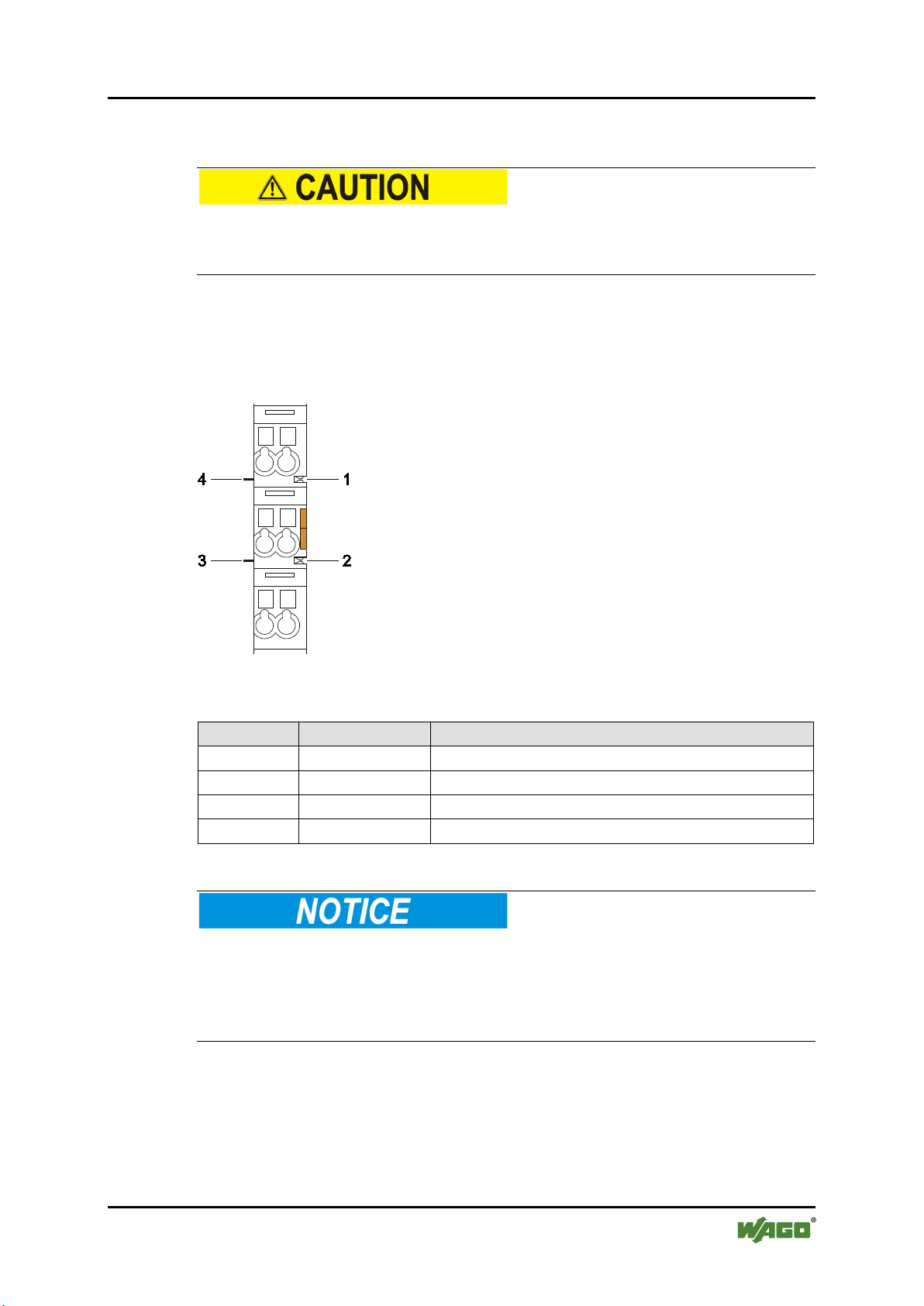

Table 6: Legend for Figure “Power Jumper Contacts”

Contact

Type

Function

1

Spring contact

Potential transmission (Uv) for field supply

2

Spring contact

Potential transmission (0 V) for field supply

3

Blade contact

Potential feed-in (0 V) for field supply

4

Blade contact

Potential feed-in (Uv) for field supply

750-658 CAN Gateway

Pos: 33 /Serie 750 (WAGO-I/O-SYST EM) /Ger ät ebesc hrei bung /A nschl üss e/L eist ungs kont akt e/Fel d versor gu ng - Üb ersc hrift 3 @ 6\ mod_1256294692864_21.docx @ 43664 @ 3 @ 1

4.2.2 Power Jumper Contacts/Field Supply

Pos: 34.1 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Vor sic ht/ Vor sic ht: Verl etz ungs ge fahr dur ch s ch arf kant ige M ess er kont akt e! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Pos: 34.2 /Serie 750 (WAGO-I/O-S YSTEM )/Ger äteb eschr eibu ng/Ans chl üsse/L eistu ngs kontakt e 2 LK (Mess er/F eder) - Einlei tung @ 1 5\mod_1371721641099_21.docx @ 123714 @ @ 1

The I/O module 750-658 has 2 self-cleaning power jumper contacts that supply

and transmit power for the field side. The contacts on the left side of the I/O

module are designed as blade contacts and those on the right side as spring

contacts.

Pos: 34.3 /Serie 750 (WAGO-I/O-S YST EM)/ Geräte besc hrei bung/A nschl üsse /Leist ungs konta kte 2 LK (M esser/ Feder ) - Abbi ldu ng, ei nf ac he Br eit e - S tan dar d @ 1 5\mod_1367500700037_21.docx @ 118396 @ @ 1

Figure 3: Power Jumper Contacts

Pos: 34.4 /Serie 750 (WAGO-I/O-S YSTEM )/Ger äteb eschr eibu ng/Ans chl üsse/L eistu ngs kontakt e 2 LK (Mess er/F eder) - Legen de @ 15\ mod_1371721352500_21.docx @ 123710 @ @ 1

Pos: 34.5 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstig e Hinw eise/ Achtu ng/Ac htung : Maxi maler S trom Lei stung skon takte 10 A @ 3\mod_1226499143500_21.docx @ 25029 @ @ 1

Do not exceed maximum current via power jumper contacts!

The maximum current to flow through the power jumper contacts is 10 A.

Greater currents can damage the contacts.

When configuring your system, ensure that this current is not exceeded.

If exceeded, insert an additional supply module.

Pos: 34.6 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Hi nwei s/Hi n weis : Po tent ial ei nspei se kle mme für Erd e ei nse tze n! ( kei ne L K für Er de) @ 3 \mod_1226499037468_21.docx @ 25023 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 20

20 Device Description WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Use supply modules for ground (earth)!

The I/O module has no power jumper contacts for receiving and transmitting the

earth potential. Use a supply module when an earth potential is needed for the

subsequent I/O modules.

Pos: 35 /D okum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 21

WAGO-I/O-SYSTEM 750 Device Description 21

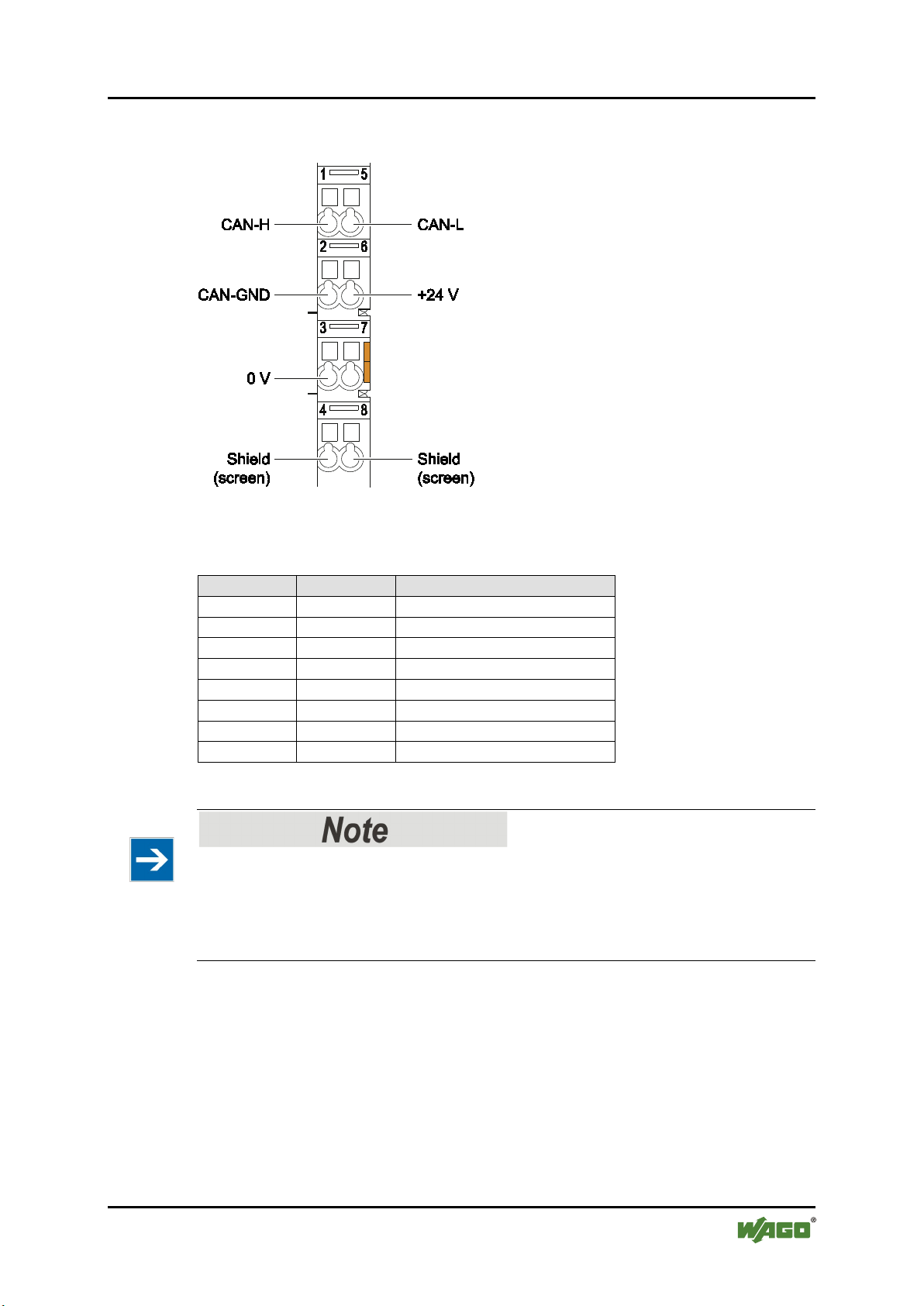

Table 7: Legend for Figure “CAGE CLAMP® Connectors”

Connection

Designation

Function

1

CAN-H

CAN High

2

CAN-GND

CAN Ground

3

0 V

Supply voltage 0 V

4

Shield

Shield (screen)

5

CAN-L

CAN Low

6

+24 V

Supply voltage + 24 V

7

N.C.

-not connected-

8

Shield

Shield (screen)

750-658 CAN Gateway

Pos: 36 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/A nsc hlüs se/ CAG E CL AMP- An schl üss e - Üb ersc hrif t 3 @ 6 \mod_1256296337770_21.docx @ 43674 @ 3 @ 1

4.2.3 CAGE CLAMP® Connectors

Pos: 37 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/A nsc hlüs se/ So nder kle mme n/A nschl üs se C C 75 0-0658 @ 14\mod_1358431143982_21.docx @ 108895 @ @ 1

Figure 4: CAGE CLAMP

®

Connectors

Pos: 38 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Wic htige Er läut erunge n/Si cherh eits- u nd sonstige Hinweise/Hinweis/Hinweis: Geschirmte Signal leit ung en ver wend en! @ 7 \mod_1265723251019_21.docx @ 50140 @ @ 1

Use shielded signal lines!

Only use shielded signal lines for analog signals and I/O modules which are

equipped with shield clamps. Only then can you ensure that the accuracy and

interference immunity specified for the respective I/O module can be achieved

even in the presence of interference acting on the signal cable.

Pos: 39 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 22

22 Device Description WAGO-I/O-SYSTEM 750

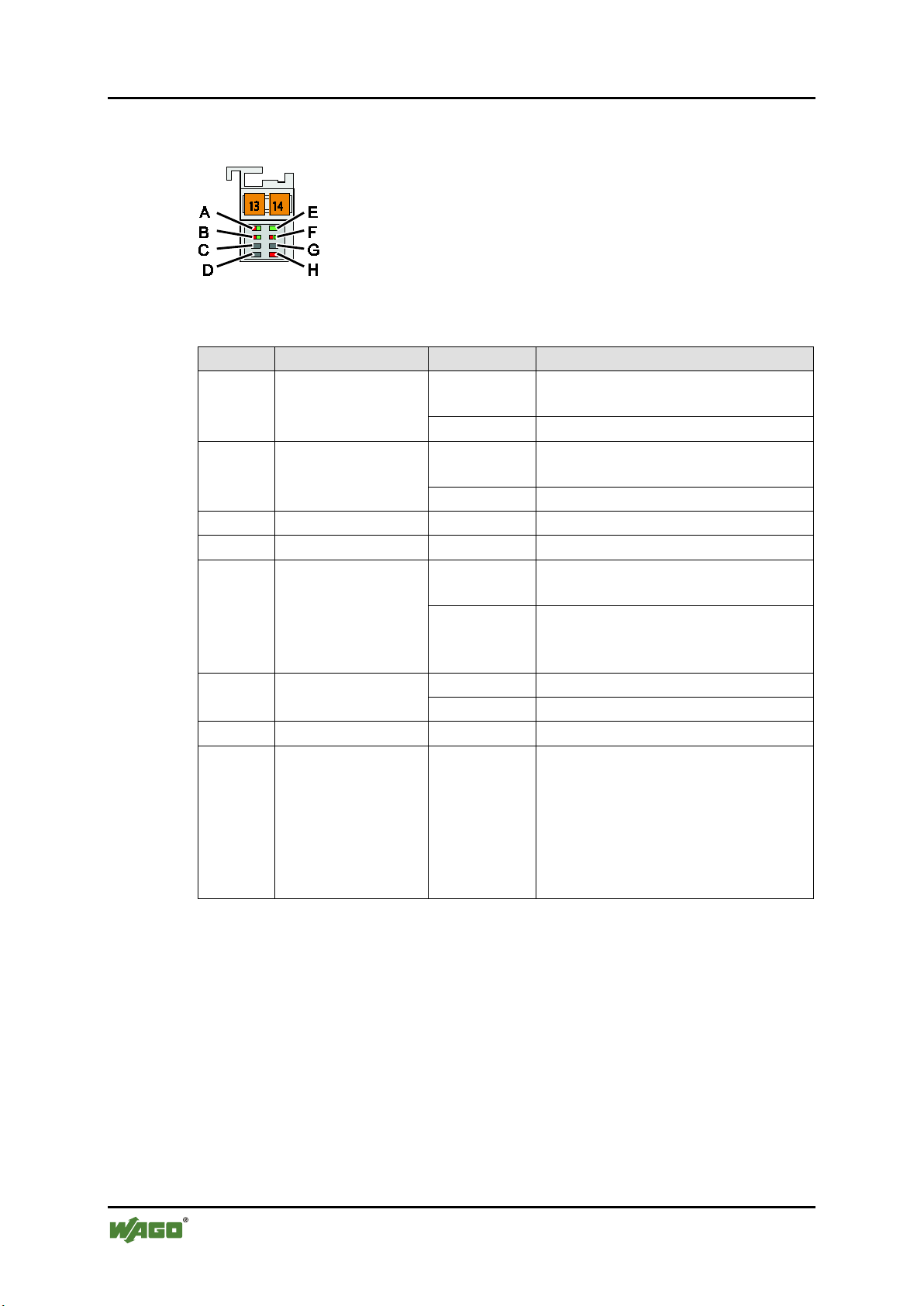

Table 8: Legend for Figure “Display Elements”

LED

Designation

Status

Function

Error on the CAN bus. CAN bus

not initialized.

green

CAN bus properly initialized.

CAN telegram could not be

received.

green

CAN telegram received.

C

not assigned - -

D

not assigned - -

Data exchange via mailbox or

register communication possible.

Data exchange via mailbox or

possible.

red

CAN telegram could not be sent.

green

CAN telegram sent.

G

not assigned - -

Internal error:

error

750-658 CAN Gateway

Pos: 40 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Anz eig eel eme nte - Ü b erschr if t 2 @ 4 \mod_1240984390875_21.docx @ 31964 @ 2 @ 1

4.3 Display Elements

Pos: 41 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/A nz eige elem ente /Son der kle mmen /Anz eigeel eme nte 750- 0658 @ 14\mod_1358501741773_21.docx @ 108920 @ @ 1

Figure 5: Display Elements

A CAN status

B CAN-Rx

red

red

green

E

Internal data bus

RUN

off

F CAN-Tx

H Int. ERROR red

register communication not

• Buffer overflow

• Error in mailbox

communication

• Parameter channel error

• Register communication

Pos: 42 /Dokum entati on allg emei n/Gli ederung sele mente/---Seiten wechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

750-658 CAN Gateway

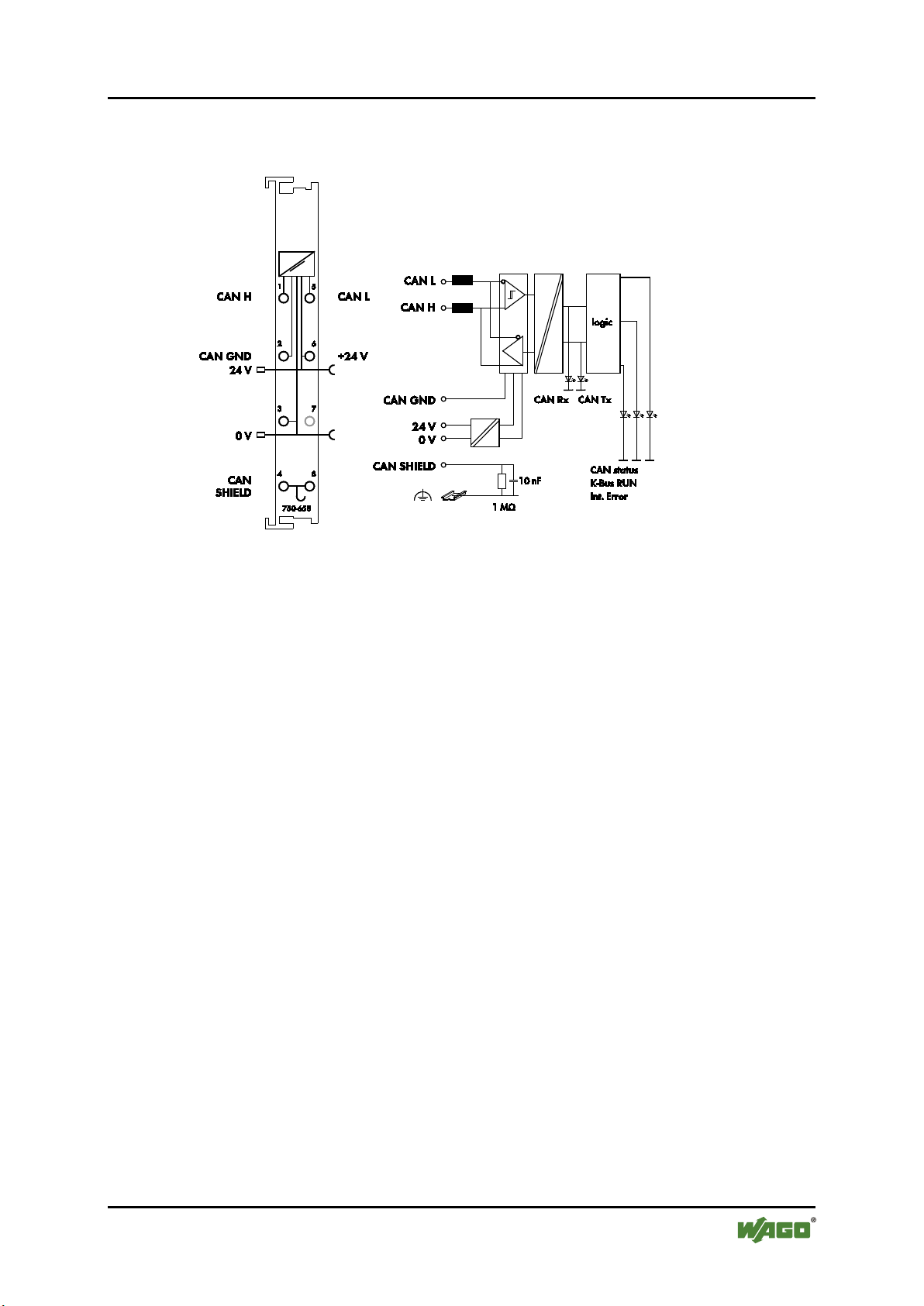

Pos: 43 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Sc hemat is ches Sc halt bild - Ü bersc hrift 2 @ 4\ mod_1240984441312_21.docx @ 31967 @ 2 @ 1

4.4 Schematic Diagram

Pos: 44 /Ser ie 750 (WAGO-I/O-SYSTEM )/ Ger äteb esc hrei bu ng/S ch emat isc he Sc h altbil der /S ond erkl em men/ Sche mati sc hes Sc halt bild 75 0-0 658 @ 14\ mod_1361883149925_21.doc x @ 112965 @ @ 1

Figure 6: Schematic Diagram

Pos: 45 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 24

24 Device Description WAGO-I/O-SYSTEM 750

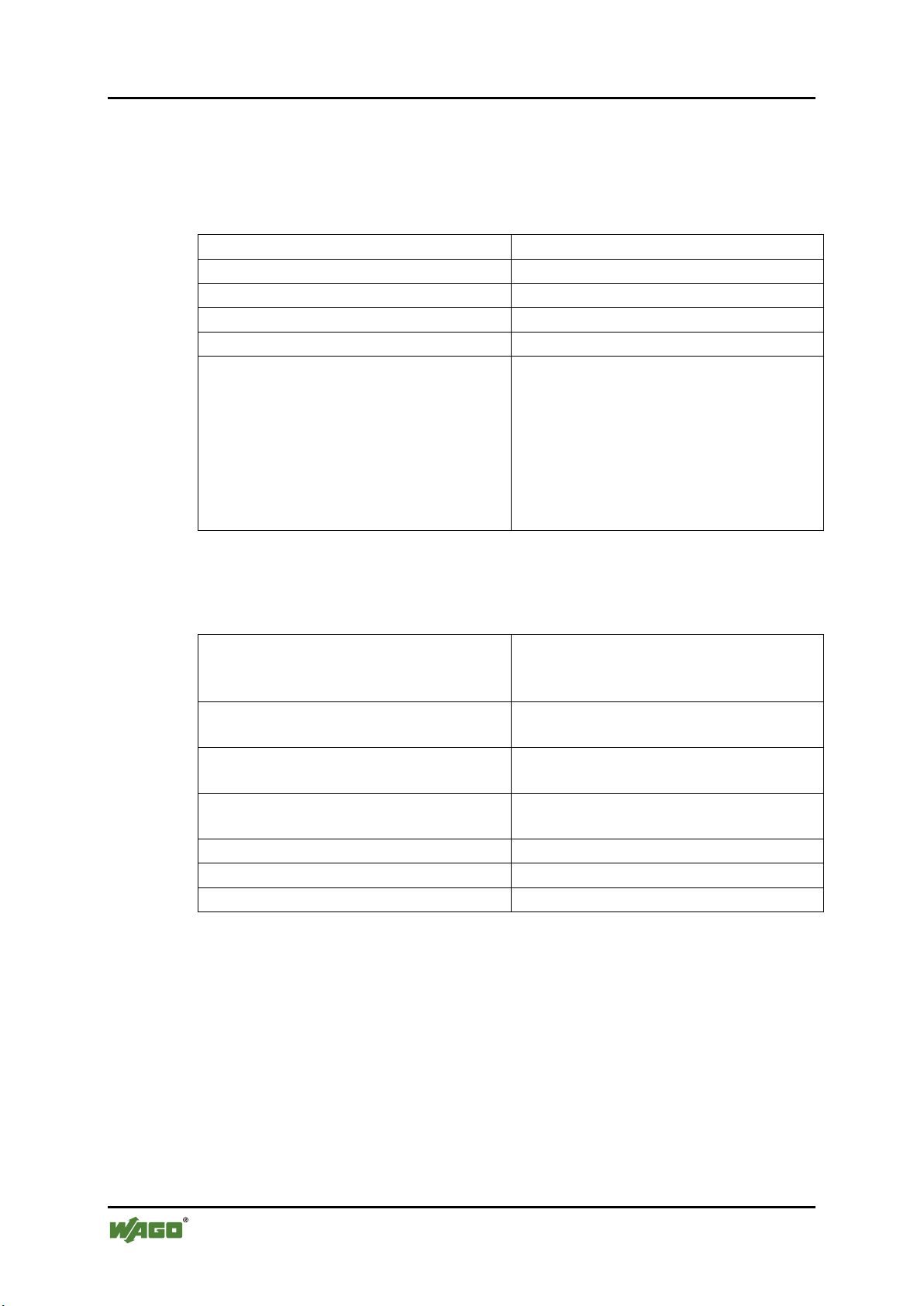

Table 9: Technical Data – Device

Width

12 mm/0.472 in.

Height (from upper edge of DIN 35 rail)

64 mm

Length

100 mm

Weight

approx. 55 g

Degree of protection

IP20

Data width, internal

8 bytes

48 bytes

Table 10: Technical Data ‒ Supply

Power supply

Via system voltage internal bus (5 V

DC)

Current consumption, system voltage

(5 V DC)

50 mA

Current consumption

(24 V DC)

12 mA

Voltage via power jumper contacts

24 V DC

(supply via e.g. 750-625)

Current via power jumper contacts

max.

10 A

Power consumption P

max.

circa 0.5 W

Isolation (peak value)

500 V DC system / supply

750-658 CAN Gateway

Pos: 46 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Tec hni sch e Dat en - Über sc hrift 2 @ 3\ mod_1232967587687_21.docx @ 26924 @ 2 @ 1

4.5 Technical Data

Pos: 47 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/T ech nisc he D ate n/ Son derkl e mmen/T ec hni sch e D ate n 75 0-065 8 @ 14\mod_1358511761305_21.docx @ 108951 @ 333 @ 1

4.5.1 Device Data

12 bytes

16 bytes

20 bytes

24 bytes

32 bytes

40 bytes

4.5.2 Supply

DC) and power jumper contacts (24 V

typ.

max.

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 25

WAGO-I/O-SYSTEM 750 Device Description 25

Table 11: Technical Data – CAN Communication

Baud rate CAN

10 kBit/s

Auto baud rate

Diagnostic information

Internal bus status via status byte,

event codes via the mailbox

Table 12: Technical Data – Field Wiring

Wire connection

CAGE CLAMP®

Cross section

0.08 mm² … 2.5 mm², AWG 28 … 14

Stripped lengths

8 mm … 9 mm / 0.33 in

Table 13: Technical Data – Power Jumper Contacts

Power jumper contacts

Blade/spring contact, self-cleaning

Table 14: Technical Data – Data Contacts

Data contacts

Slide contact, hard gold plated, selfcleaning

Table 15: Technical Data – Climatic Environmental Conditions

Operating temperature range

0 °C … 55 °C

Storage temperature range

−25 °C … +85 °C

Relative humidity without condensation

Max. 95 %

Resistance to harmful substances

Acc. to IEC 60068-2-42 and

IEC 60068-2-43

Maximum pollutant concentration at

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

Ensure that additional measures for

– ionizing radiation

750-658 CAN Gateway

4.5.3 CAN Communication

20 kBit/s

50 kBit/s

125 kBit/s

250 kBit/s

500 kBit/s

800 kBit/s

1000 kBit/s

Pos: 48.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 3/A nsc hluss te chni k - Überschrift 3 @ 17\mod_1380123271324_21.docx @ 132788 @ 3 @ 1

4.5.4 Connection Type

Pos: 48.2 /Serie 750 (WAGO-I/O-S YST EM) /Ger äte bes chr ei bung /T echni sc he Da ten/ A nsc hluss tec hni k/T echni sc he D at en V erdr aht ung sebe ne C C - 0,0 8 bis 2,5 mm2 @ 17\ mod_1380121238809_21.docx @ 132780 @ @ 1

Pos: 48.3 /Serie 750 (WAGO-I/O-S YST EM) /Ger äte bes chr ei bung /T echni sc he Da ten/ A nsc hluss tec hni k/T echni sc he D at en L eist ungs ko nta kte ( Mes ser/ Fe der) @ 19\ mod_1400241643293_21.docx @ 153921 @ @ 1

Pos: 48.4 /Serie 750 (WAGO-I/O-S YST EM) /Ger äte bes chr ei bung /T echni sc he Da ten/ A nsc hluss tec hni k/T echni sc he D at en Da te nkon tak te @ 17\ mod_1380123495844_21.docx @ 132 794 @ @ 1

Pos: 49 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/T ech nisc he D ate n/ Kli mati sch e Umg eb ungs bedi ng ung en/T ech nisc he Da ten Klim at. Umg ebung sbed. ohne er w. Tem p. 0... 55°C/-2 5... +85° C @ 5\ mod_1247657968368_21.docx @ 37603 @ 3 @ 1

4.5.5 Climatic Environmental Conditions

Pos: 50 /Dokum entati on allg emei n/Gli ederung sele mente /---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

relative humidity < 75 %

components are taken, which are used in

an environment involving:

– dust, caustic vapors or gases

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 26

26 Device Description WAGO-I/O-SYSTEM 750

Conformity Marking

TÜV 14 ATEX 148929 X

II 3 G Ex nA IIC T4 Gc

IECEx TUN 14.0035 X

Ex nA IIC T4 Gc

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

750-658 CAN Gateway

Pos: 51 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Zul ass ung en - Ü bersc hrift 2 @ 3\mod_1224055364109_21.docx @ 24030 @ 2 @ 1

4.6 Approvals

Pos: 52 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/Z ulas su nge n/ Allg emei n/Z ulass u nge n Bus kl emme 75 0-x xxx Allg emein, ohne Var iant enang abe - Einl eit ung @ 4\mod_1237460656921_21.docx @ 28643 @ @ 1

The following approvals have been granted to 750-658 I/O modules:

Pos: 53 /Alle Serien (Allgemeine Module)/Zulassungen/Standardz ulassungen/CE (Konformitätskennzeichnung) @ 3\mod_1224494777421_21.docx @ 24276 @ @ 1

Pos: 54 /All e S eri en ( Allg emei n e Mod ule) /Z ulas sung en/ St and ardz ula ssu nge n/cU Lus ( U L50 8) @ 3\mod_1224055013140_0.docx @ 24020 @ @ 1

Pos: 55 /All e S eri en ( Allg emei n e Mod ule) /Z ulas sung en/ St and ardz ula ssu nge n/KC - Kor ea Cer tifi cat e - MSM @ 23\mod_1435133798551_21.docx @ 184462 @ @ 1

Pos: 56 /Dokum entati on allg emei n/Gli ederung sele mente /---Leera bs atz-( 2Z)--- @ 3 \mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 57 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/Z ulass unge n/Ex/Z ulass unge n Buskle mme 75 0-xxxx Ex, ohne Variantenangabe - Einleitung @ 4\mod_1237191218000_21.docx @ 28423 @ @ 1

The following Ex approvals have been granted to 750-658 I/O modules:

Pos: 58.1 /All e Serien ( Al lge mei ne M od ule)/Z ul assu nge n/ Ex-Zulassungen/TÜV ATEX/TÜV 14 ATEX 148929 X: II 3 G Ex nA IIC T4 Gc @ 21\mod_1416987498312_0.docx @ 169048 @ @ 1

Pos: 58.2 /Al l e Ser ien ( Al lge mei ne M od ule)/Z ul assu nge n/ Ex-Zul ass u ngen /IEC Ex (TÜ V Nor d) /IEC Ex TUN 14 .003 5 X: Ex nA IIC T 4 Gc @ 21 \mod_1416987779897_0.docx @ 169052 @ @ 1

Pos: 58.3 /Al l e Ser ien ( Al lge mei ne M od ule)/Z ul assu nge n/ Ex-Zul ass u ngen /cU Lus /cU Lus ( AN SI/I SA 12.1 2.01) Cl ass I, Di v2 A BCD T 4 @ 3\ mod_1224054791812_0.docx @ 24014 @ @ 1

Pos: 58.4 /Dokumentation allgemein/Glieder ungselemente/----Leerzeile-(1Z)---- @ 28\mod_1485262995837_0.docx @ 404006 @ @ 1

Pos: 59 /Dokum entati on allg emei n/ Glie derung s elem ente /---Leer abs atz-( 2Z) --- @ 3\mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 60 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Ger ätebes chrei bung /Zulass ung en/Sc hiff/ Einl eitungs sätz e/Zulas sung en Bus klem me 750- xxxx Sc hiff, oh ne Vari ante nanga be - Einl eitung @ 4\mod_1237190918453_21.docx @ 28420 @ @ 1

The following ship approvals have been granted to 750-658 I/O modules:

Pos: 61 /All e S eri en ( Allg emei n e Mod ule) /Z ulas sung en/ Sc hiffs zul ass ung en/ BSH (B und esam t für Se esc hiff fahr t u nd H ydr ogr aphi e) @ 5\ mod_1246341825156_21.docx @ 36334 @ @ 1

CULUS

UL508

Korea Certification MSIP-REM-W43-MSM750

Federal Maritime and Hydrographic Agency

Pos: 62 /All e S eri en ( Allg emei n e Mod ule) /Z ulas sung en/ Sc hiffs zul ass ung en/ GL ( Ger ma nisc her Llo yd) C at . A, B, C , D ( EM C 1) @ 3\mod_1224492724484_0.docx @ 24228 @ @ 1

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1)

Pos: 63 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 27

WAGO-I/O-SYSTEM 750 Device Description 27

750-658 CAN Gateway

Pos: 64 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/ Ebe ne 2/ Nor men und Ri chtl inie n - Ü bersc hrift 2 @ 4\mod_1242804031875_21.docx @ 33646 @ 2 @ 1

4.7 Standards and Guidelines

Pos: 65 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/N orm en u nd R ic htlini e n/EM V-Nor m en B uskl e mme 7 50-x xxx, ohn e Vari anten angab e - Einl eitung @ 4\mod_1242803944015_21.docx @ 33642 @ @ 1

750-658 I/O modules meet the following requirements on emission and immunity

of interference:

Pos: 66 /All e S eri en ( Allg emei n e Mod ule) /N or men un d Ri chtl i nien/ EM V-N orme n - St andar d/ EMV CE- Stör fest igk eit EN 61000-6-2 @ 4\mod_1242797655625_21.docx @ 33591 @ @ 1

EMC CE-Immunity to interference EN 61000-6-2

Pos: 67 /All e S eri en ( Allg emei n e Mod ule) /N or men un d Ri chtl i nien/ EM V-N orme n - St andar d/ EMV CE- Stör festi gkeit EN 6113 1-2 @ 5\mod_1245337216375_21.docx @ 35650 @ @ 1

EMC CE-Immunity to interference EN 61131-2

Pos: 68 /All e S eri en ( Allg emei n e Mod ule) /N or men un d Ri chtl i nien/ EM V-N orme n - St andar d/ EMV CE- Störaussendung EN 61000-6-3 + A1 @ 27\mod_1467095722426_21.docx @ 214858 @ @ 1

EMC CE-Emission of interference EN 61000-6-3 + A1

Pos: 69 /All e S eri en ( Allg emei n e Mod ule) /N or men un d Ri chtl i nien/ EM V-N orme n - St andar d/ EMV CE- Störaussendung EN 61131-2 @ 6\mod_1259753022195_21.docx @ 46410 @ @ 1

EMC CE-Emission of interference EN 61131-2

Pos: 70 /Dokumentation allgemein/Gl ieder ung sele me nte/---Sei te nwec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 28

28 Function Description WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Pos: 71.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 1/F un ktion sb eschr ei bung - Ü bersc hri ft 1 @ 4\mod_1239025975389_21.docx @ 30003 @ 1 @ 1

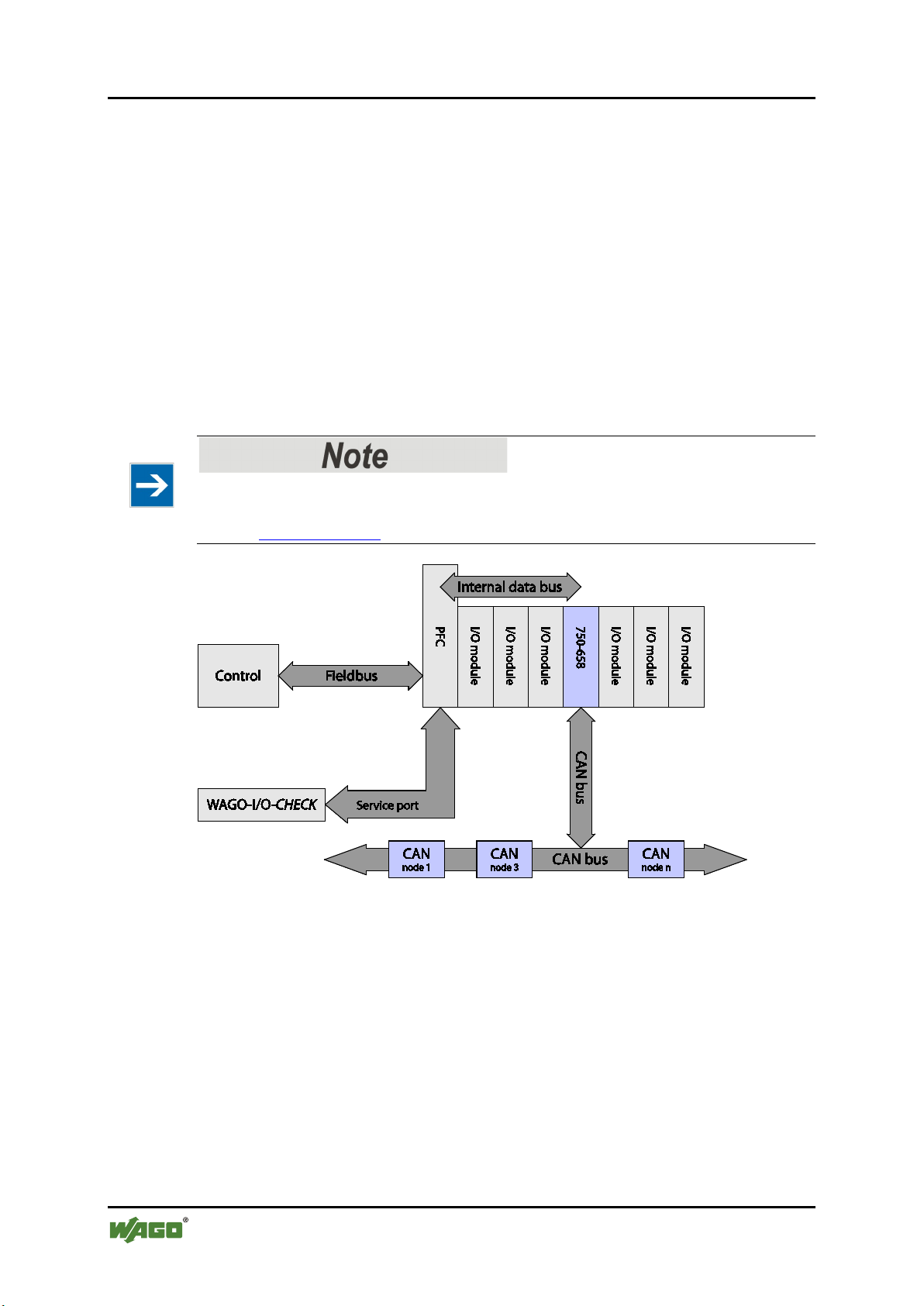

5 Function Description

Pos: 71.2 /Serie 750 (WAGO-I/O-S YSTEM )/F unktio nsbes chrei bung /Fun ktionsb eschr eibu ng 750-0658 - Ei nleit ung @ 13\mod_1355737974549_21.docx @ 107690 @ @ 1

The I/O module has the following functions:

• CAN telegrams that contain user data can be copied to the process image of

the input.

• Received CAN telegrams can be transferred to the controller.

• CAN telegrams can be sent to other CAN nodes.

• Specific CAN bus diagnostics can be displayed.

The data can be transferred by the "Mailbox 2.0" protocol among others.

Use Mailbox 2.0!

Use IEC-61131 compliant function blocks to use Mailbox 2.0. You can download

them at www.wago.com.

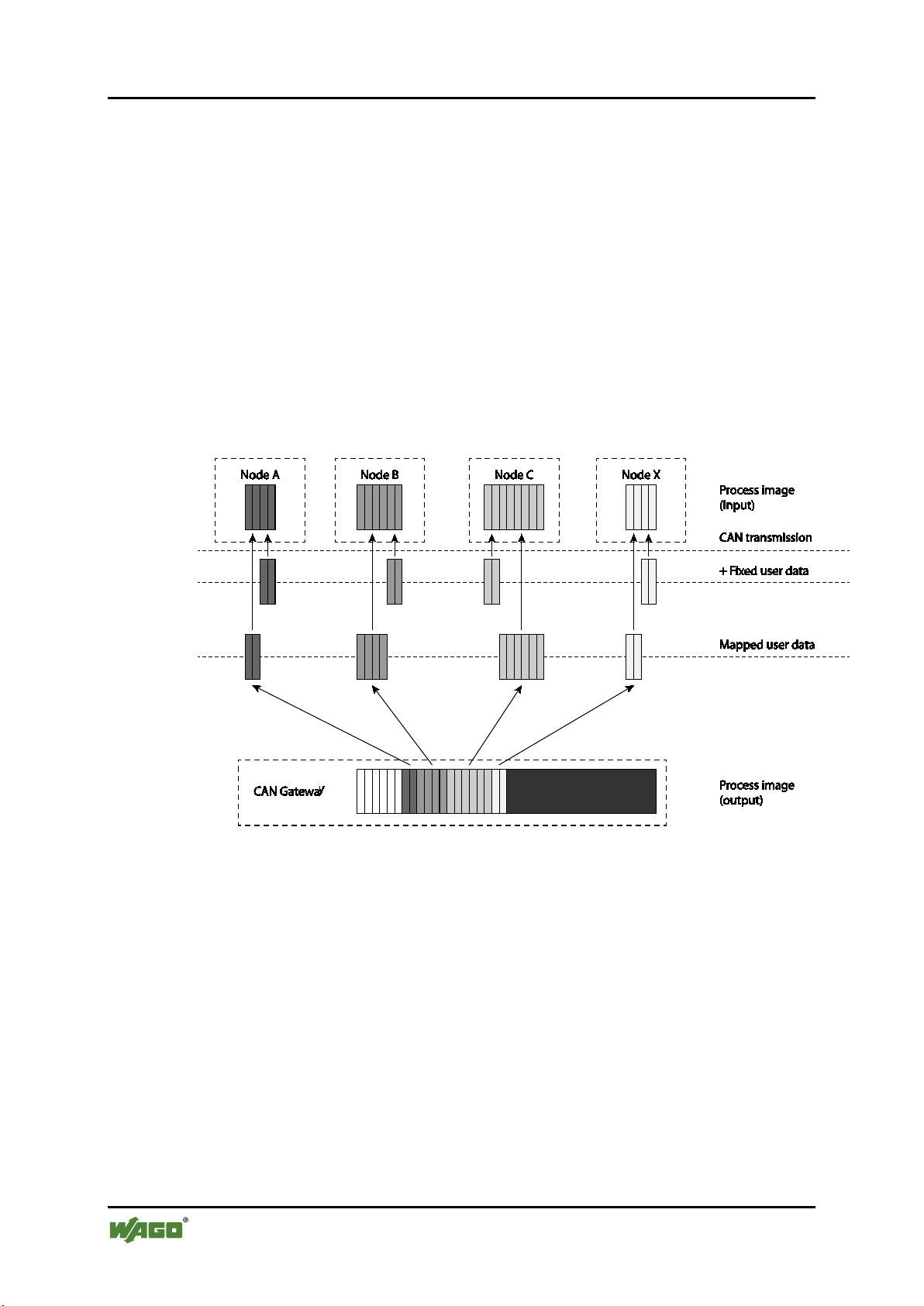

Figure 7: Functional Description 750-658

Pos: 71.3 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/B etri ebs arte n - Ü ber schr if t 2 @ 13\ mod_1355740360138_21.docx @ 107697 @ 2 @ 1

5.1 Operating Modes

Pos: 71.4 /Serie 750 (WAGO-I/O-S YSTEM )/F unktio nsbes chrei bung /Fun ktionsb eschr eibu ng 750-0658 - Üb ersic ht der Betr iebs arten @ 14\mod_1360311385982_21.docx @ 111210 @ @ 1

The I/O module can be operated in the following three modes:

• Sniffer mode

• Transparent mode

• Mapped mode

Pos: 71.5 /Serie 750 (WAGO-I/O-S YSTEM )/F unktio nsbes chrei bung /Fun ktionsb eschr eibu ng 750-0658 - Betr ie bsar ten @ 13\mod_1355758147324_21.docx @ 107750 @ 3334455554 @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 29

WAGO-I/O-SYSTEM 750 Function Description 29

750-658 CAN Gateway

5.1.1 Sniffer Mode

In "Sniffer mode", the I/O module is a passive node in the bus network. That

means that the transmitter is deactivated from the hardware side. In this operating

mode telegrams can only be sent and not sent in principle.

If CAN telegrams are received, no confirmation is sent to the sender.

Confirmation must be handled by a third node. At least two other CAN nodes

must be available. Received telegrams are transferred to the higher-level

controller via the "Mailbox 2.0" transmission protocol.

5.1.2 Transparent Mode

In "Transparent mode", the I/O module is an active node in the bus network. That

means that the transmitter is activated from the hardware side. In this operating

mode, telegrams can be received and sent.

If CAN telegrams are received, confirmation is sent to the sender. Received

telegrams are transferred to the higher-level controller via that "Mailbox 2.0"

transmission protocol.

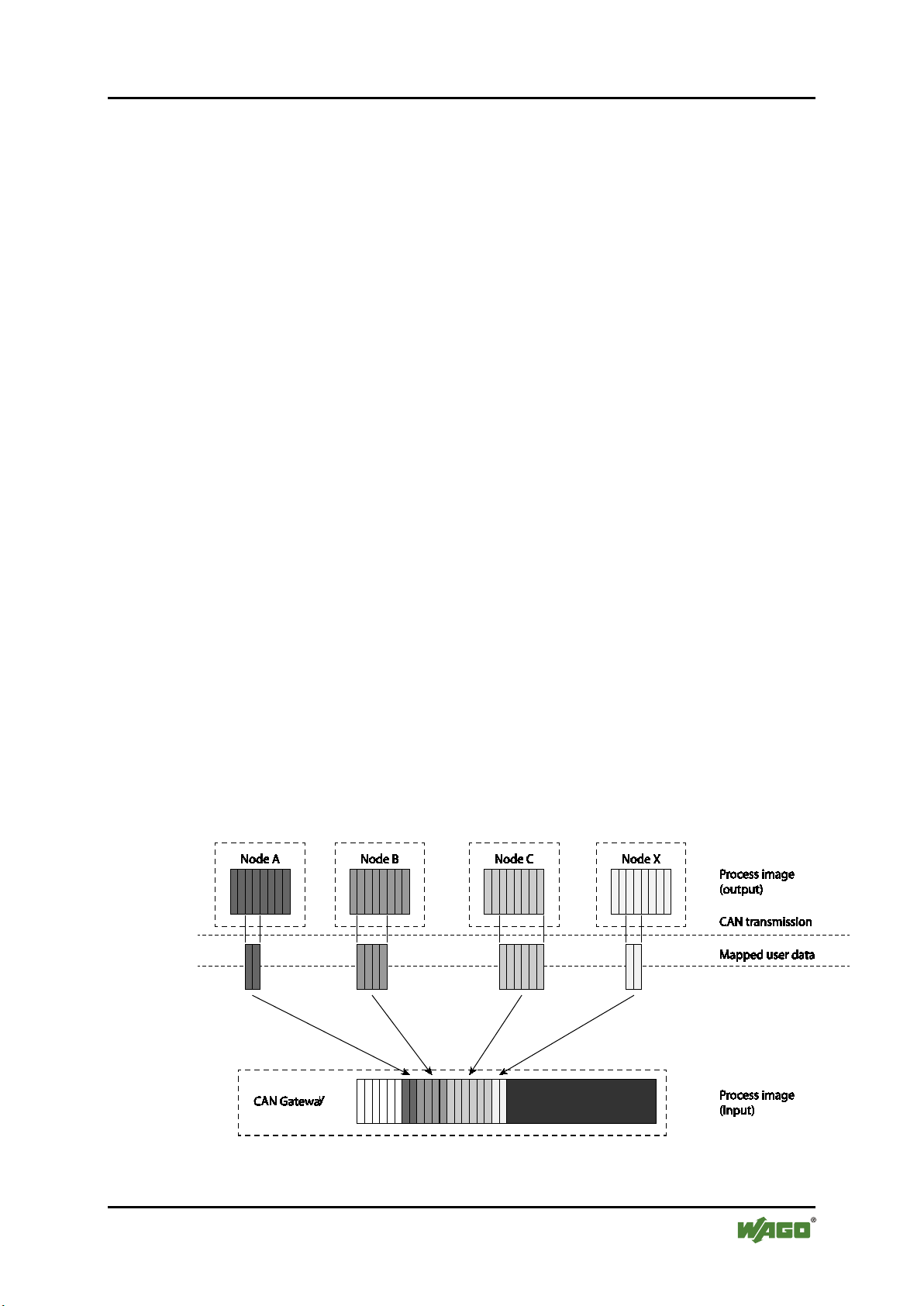

5.1.3 Mapped Mode

The "Mapped mode" is fundamentally different from the other two modes. In this

operating mode, incoming and outgoing CAN telegrams can be mapped to the

process image without any protocol. Only user data and no control data is

mapped.

5.1.3.1 Map CAN Telegrams in Input Direction

Up to 44 bytes can be configured in the process image of the input. During

configuration, CAN telegrams can be selected from which a user data byte should

be mapped. A more detailed description is available in the "Process Image"

section.

Figure 8: Map CAN Telegrams in Input Direction

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 30

30 Function Description WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

Once a CAN telegram is received, the bytes in question are updated in the process

image of the input with the respective data.

5.1.3.2 Map CAN Telegrams in Output Direction

CAN telegrams can also be mapped in the output direction. However, it is

somewhat more complex because individual settings are required for each

telegram before it can be sent. When a configured CAN telegram is sent also

depends on the trigger configuration. The following settings are possible:

• Send on request

• Send on change

• Cycle time

Figure 9: Map CAN Telegrams in Output Direction

5.1.3.2.1 "Content of the CAN telegram" Setting

The content of the CAN telegram to send can be set in addition to the trigger. The

following settings are possible:

"Identifier extension bit" (IDE) Setting

The "Identifier extension bit" (IDE) can be used to set whether the output

telegram should be one of the following:

• "2.0A Standard Frame"

• "2.0B Extended Frame"

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 31

WAGO-I/O-SYSTEM 750 Function Description 31

Table 16: Toggle Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Toggle byte

Group 8

Group 7

Group 6

Group 5

Group 4

Group 3

Group 2

Group 1

750-658 CAN Gateway

For a "2.0A Standard Frame", 211 (7FFh) is the largest possible CAN ID and for

"2.0B Extended Frame", 229 (1FFFFFFF) is the largest.

"Remote Transmission Request" (RTR) Setting

The "Remote Transmission Request" bit can used to set whether the mapped CAN

output frame involves a so-called "remote request" or a data frame.

"Data Length Code" (DLC) Setting

The "Data Length Code" (DLC) can be used to specify how many user data bytes

there should be in the CAN telegram.

The user data bytes do not have to match the mapped bytes on the process image

in terms of quantity. A fixed value can be specified for all non-mapped data bytes.

Fixed values can be specified for data storage areas that have been defined in the

DLC, but not mapped variably in the process image. These values are then

automatically copied to the user data when a telegram in the output direction is

generated.

5.1.3.2.2 "Send on request" Setting

In this setting, CAN telegrams are send via the so-called "toggle byte" in the

process image. Send groups can be assigned to telegrams to be sent.

If one or more bits are inverted in the toggle byte, the respective send groups are

affected. All assigned telegrams are created and sent.

The I/O module then confirms transmission by inverting the associated bit of the

toggle byte in the process image of the input.

If several send groups are selected, they are sent one after the other: Group 1 has

the highest send priority, Group 8 has the lowest.

5.1.3.2.3 "Send on change" Setting

If this setting is enabled, the CAN telegram is sent when a mapped byte has been

sent. The mapped and fixed values are applied.

5.1.3.2.4 "Cycle Time" Setting

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

A cycle time can be set for each CAN telegram to sent. The telegram is then

created and sent repeatedly by the I/O module. The time interval between two

transmissions is the cycle time. It can also be a telegram that contained no data

from the process image of the output, rather fixed values only.

Page 32

32 Function Description WAGO-I/O-SYSTEM 750

750-658 CAN Gateway

5.1.3.3 Access CAN Telegrams via the Mailbox

CAN telegrams of a defined range can also be received and sent via the mailbox.

The data format is identical to the data formats of the "Sniffer" and "Transparent"

operating modes.

Note modified access times!

Communication via the mailbox is slower, but it is possible in this option to

access selected CAN telegrams acyclically (e.g. comparable to "SDO" and

"EMCY" functionalities).

Pos: 71.6 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 33

WAGO-I/O-SYSTEM 750 Function Description 33

750-658 CAN Gateway

Pos: 71.7 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/F ilter ei nstel l unge n - Ü bersc hrift 2 @ 14\ mod_1358176336838_21.docx @ 108633 @ 2 @ 1

5.2 Filter Settings

Pos: 71.8 /Serie 750 (WAGO-I/O-S YSTEM )/F unktio nsbes chrei bung /Fun ktionsb eschr eibu ng 750-0658 - Fil ter eins tell ung en @ 1 4\mod_1358176214506_21.docx @ 108630 @ 33 @ 1

With 6 configurable pass-through filters, the bandwidth of the CAN telegrams for

the user transmitted to the controller can be limited to specific ranges. This saves

resources on the control level and in the I/O module.

A CAN ID can be specified for the upper and lower limits per filter. The value of

the upper limit must be greater than or equal to the value of the lower limit.

Otherwise, the I/O module will output an error message. Only the telegrams are

transmitted that fall within the filter limits.

Transmission of CAN telegrams from the I/O module to the controller can take

more time than receiving these telegrams on the CAN bus. Thus, several CAN

telegram of the same CAN ID may be cached in the I/O module. The following

settings can be made:

1. "Overwrite"

2. "Keep All"

5.2.1 "Overwrite" Setting

If this setting is selected, newly received telegrams are overwritten when

telegrams of the same CAN ID are received. This requires that the received

telegram has not yet been forwarded to the controller. The system workload can

be reduced significantly.

Do not select "Overwrite" for protocol data!

The "Overwrite" setting should not be selected when protocol data of higher

layers (e.g. SDOs, etc.) is transmitted. It may be unusable because all data of a

CAN ID is required in general. Select the "Keep All" setting here.

5.2.2 "Keep All" Setting

If this setting is selected, received telegrams are not overwritten, rather forwarded

to the controller sequentially. Only use this setting when data usage of received

CAN telegrams is low.

Pos: 72 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 34

34 Process Image WAGO-I/O-SYSTEM 750

Table 17: Control Byte

Control byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

res.*

res.*

res.*

res.*

res.*

res.*

res.*

0 = Read register

1 = Write register

* Reserved

Table 18: Status Byte

Status byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0

GEN_

ERR

CAN_

ERR

TX_

OVF

RX_

OVF

INT_

ERR

1

Res.

Register number

(Bit 7)

0

Mailbox 0 active

1

Register communication enabled

GEN_ERR

0

No error on the CAN Bus.

1

Error on the CAN bus. Set when one of the bits 0…5 = 1.

CAN_ERR

0

No error on the CAN Bus.

1

Error on the CAN bus.

TX_OVF

0

Send buffer OK.

1

Send buffer overflow (downstream). No data can be received by the I/O module.

RX_OVF

0

Receive buffer OK.

1

Receive buffer overflow (upstream). No data can be received by the I/O module.

INT_ERR

0

No internal error.

1

Internal error. Possible causes:

• Faulty register request

750-658 CAN Gateway

Pos: 73 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Proz ess abbi ld Kle mme nbus /S ond er klemm en/P roz ess ab bild 750- 0658 @ 14\mod_1358254522792_21.docx @ 108700 @ 12332332333 @ 1

6 Process Image

The first byte of the internal bus process image is:

• The control byte in the process output direction

• The status byte in the process input direction

The mailbox is static in the process image and is cross-faded when register

communication is on.

During register communication, the register query response is contained in the

status byte followed by 2 bytes of register data.

If the mailbox is active, status information of the I/O module is displayed

cyclically via the status byte.

Control byte

1

Register number

Status byte

• 24V field supply missing

• Communication via mailbox and process data faulty

• Faulty parameterization request

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 35

WAGO-I/O-SYSTEM 750 Process Image 35

750-658 CAN Gateway

6.1 Process Image in "Sniffer" Operating Mode

The CAN user data range on the process image is symmetrical for both data

directions.

Figure 10: Process Image in "Sniffer" Mode

6.1.1 Mailbox

Modules with mailbox functionality have an acyclic communication channel

(mailbox) in the process image. The "Mailbox 2.0" (referred to below as

"mailbox") transmission method is the basis.

If the Mailbox is active (control byte, bit 7 = 0), it is used to transfer

configuration, parameterization and diagnostic data. Byte 1 to byte 6 of the

internal process image are used by default. Additional information about the

"Mailbox 2.0 Transmission Method" is available in the respective chapter in the

appendix.

6.1.2 CAN User Data Range

The CAN user data range is a fixed component of the "Sniffer" and "Transparent"

operating modes (see respective chapter). CAN telegrams are transmitted via the

"Mailbox 2.0" communication mechanism. The mechanism supports the

following two types of telegrams:

• "2.0A Standard Frame"

• "2.0B Extended Frame"

Manual

Version 1.2.0, valid from FW/HW-Version 01/01

Page 36

36 Process Image WAGO-I/O-SYSTEM 750

Table 19: Structure of CAN Telegrams with the "2.0A Standard Frame" Setting

Byte

Name

Bits

Identifier

byte 1

Identifier

byte 2

2

Data

TR/RX Data Byte 1

3

Data

TR/RX Data Byte 2

4

Data

TR/RX Data Byte 3

5

Data

TR/RX Data Byte 4

6

Data

TR/RX Data Byte 5

7

Data

TR/RX Data Byte 6

8

Data

TR/RX Data Byte 7

9

Data

TR/RX Data Byte 8

Table 20: Structure of CAN Telegrams with the "2.0B Extended Frame" Setting

Byte

Name

Bits

Identifier

byte 1

Identifier

byte 2

Identifier

byte 3

Identifier

byte 4

Identifier

byte 5

5

Data

TR/RX Data Byte 1

6

Data

TR/RX Data Byte 2

7

Data

TR/RX Data Byte 3

8

Data

TR/RX Data Byte 4

9

Data

TR/RX Data Byte 5

10

Data

TR/RX Data Byte 6

11

Data

TR/RX Data Byte 7

12

Data

TR/RX Data Byte 8

750-658 CAN Gateway

If the "2.0A Standard Frame" is activated, CAN telegrams have the following

structure:

0

1

ID.10 ID.9 ID.8 ID.7 ID.6 ID.5 ID.4 ID.3

ID.2 ID.1 ID.0 RTR DLC.3 DLC.2 DLC.1 DLC.0