Page 1

Fieldbus Independent

I/O Modules

AS-Interface master module

750-655

Manual

Version 1.2.3

Page 2

ii • General

Copyright 2007 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded, we would appreciate any information or ideas at any time.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 3

Table of Contents • iii

Table of Contents

1 Important Comments ................................................................................. 6

1.1 Legal Principles........................................................................................6

1.1.1 Copyright ............................................................................................. 6

1.1.2 Personnel Qualification ....................................................................... 6

1.1.3 Intended Use ........................................................................................ 6

1.2 Symbols .................................................................................................... 7

1.3 Number Notation......................................................................................7

1.4 Safety Notes ............................................................................................. 8

1.5 Scope ........................................................................................................8

2 I/O Modules .................................................................................................9

2.1 Special Modules ....................................................................................... 9

2.1.1 750-655 [AS-Interface master module]...............................................9

2.1.1.1 View................................................................................................9

2.1.1.2 Description......................................................................................9

2.1.1.3 Indicating devices .........................................................................13

2.1.1.4 Schematic circuit diagram............................................................. 14

2.1.1.5 Technical data ............................................................................... 15

2.1.1.6 Functional description................................................................... 16

2.1.1.6.1 Start-up behavior......................................................................16

2.1.1.6.1.1 Offline phase ....................................................................... 16

2.1.1.6.1.2 Detection phase ................................................................... 16

2.1.1.6.1.3 Activation phase .................................................................. 17

2.1.1.6.1.4 Normal mode ....................................................................... 17

2.1.1.6.2 Slave lists ................................................................................. 17

2.1.1.6.3 Operating modes ...................................................................... 17

2.1.1.6.3.1 Set-up mode.........................................................................17

2.1.1.6.3.2 Protected operating mode.................................................... 18

2.1.1.6.4 Addressing in set-up mode.......................................................19

2.1.1.6.5 Addressing in the case of configuration errors ........................19

2.1.1.6.5.1 Automatic addressing .......................................................... 19

2.1.1.6.5.2 Manual addressing............................................................... 20

2.1.1.7 Process image................................................................................ 21

2.1.1.7.1 Overview .................................................................................. 21

2.1.1.7.2 Control and status byte.............................................................25

2.1.1.7.2.1 Assignment for process data communication...................... 25

2.1.1.7.2.2 Assignment for register communication .............................26

2.1.1.7.3 AS-Interface process data ........................................................27

2.1.1.7.3.1 AS-Interface flags................................................................ 28

2.1.1.7.4 Mailbox ....................................................................................28

2.1.1.7.4.1 Structure .............................................................................. 29

2.1.1.7.4.2 Access procedure.................................................................30

2.1.1.8 Mailbox commands....................................................................... 31

2.1.1.8.1 Overview of mailbox commands .............................................31

2.1.1.8.2 Result values of mailbox commands........................................ 33

2.1.1.8.3 Example of mailbox use...........................................................33

WAGO-I/O-SYSTEM 750

I/O Modules

Page 4

iv • Important Comments

Legal Principles

2.1.1.9 Data channel for parameter exchange...........................................36

2.1.1.9.1 Introduction .............................................................................. 36

2.1.1.9.2 Register structure ..................................................................... 36

2.1.1.9.2.1 Parameter data (Register 56) ............................................... 36

2.1.1.9.2.2 Communications control (Register 57) ...............................37

2.1.1.9.3 Parameter sets........................................................................... 38

2.1.1.9.3.1 General parameter data (system parameter range) .............. 38

2.1.1.9.3.2 Bus module-specific parameter data ...................................39

2.1.1.9.4 Parameter transmission process ...............................................39

2.1.1.9.4.1 Determining the maximum bus module parameter data

(system parameters).............................................................39

2.1.1.9.4.2 Setting the monitoring time (system parameters)................ 40

2.1.1.9.4.3 Restoring factory settings (system parameters)................... 40

2.1.1.9.4.4 Reading/writing parameters (module-specific) ................... 41

2.1.1.9.4.5 Example: Configuring AS-Interface process data and

mailbox ................................................................................ 42

2.1.1.10 Extended diagnostics of the AS-Interface master.........................43

2.1.1.10.1 List of AS-Interface slaves, which have initiated configuration

errors (LCS).............................................................................. 43

2.1.1.10.2 Protocol analysis: Counter for transmission errors for data

telegrams ..................................................................................43

2.1.1.10.3 Offline phase in the case of configuration errors.....................43

2.1.2 Node Design ......................................................................................45

2.1.2.1 Grouping of AS-Interface Master Modules ..................................45

3 Working with the AS-Interface master module 750-655....................... 46

3.1 Set up and configuration with WAGO-I/O-CHECK 2........................... 46

3.1.1 Setting up the AS-Interface process data and mailbox length........... 46

3.1.2 Setting up the operating mode for the AS-Interface master .............. 47

3.1.3 Including a new slave in the AS-Interface network ..........................47

3.1.4 Selecting an AS-Interface slave from the slave overview................. 48

3.1.5 Configuring an AS-Interface slave .................................................... 48

3.1.6 Observing and setting up AS-Interface process data......................... 49

3.1.7 AS-Interface diagnostics.................................................................... 49

4 Fieldbus-specific behavior........................................................................ 50

4.1 CANopen................................................................................................ 50

4.1.1 Accessing the process image ............................................................. 50

4.1.1.1 Example ........................................................................................ 53

4.2 DeviceNet............................................................................................... 55

4.2.1 Accessing the process image ............................................................. 55

4.2.1.1 Example ........................................................................................ 55

4.3 ETHERNET ........................................................................................... 57

4.3.1 Modbus protocol................................................................................ 57

4.3.1.1 Accessing the process image ........................................................ 57

4.3.1.1.1 Example.................................................................................... 57

4.3.2 ETHERNET IP protocol.................................................................... 59

4.3.2.1 Accessing the process image ........................................................ 59

4.3.2.1.1 Example.................................................................................... 59

WAGO-I/O-SYSTEM 750

I/O Modules

Page 5

Table of Contents • v

4.4 PROFIBUS DP....................................................................................... 61

4.4.1 Accessing the process image ............................................................. 61

4.4.1.1 Example ........................................................................................ 61

4.5 LON........................................................................................................ 64

5 Appendix .................................................................................................... 65

5.1 Overview of mailbox commands............................................................ 65

5.2 Overview of mailbox commands sorted by function ............................. 67

5.3 Overview of mailbox commands sorted by opcode ...............................69

5.4 Overview of mailbox commands sorted by value ..................................71

5.5 Mailbox command - Reference.............................................................. 73

5.5.1 Mailbox commands ........................................................................... 73

5.5.2 Functional profiles........................................................................... 126

WAGO-I/O-SYSTEM 750

I/O Modules

Page 6

6 • Important Comments Legal Principles

1 Important Comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanations are

carefully read and abided by.

1.1 Legal Principles

1.1.1 Copyright

This manual is copyrighted, together with all figures and illustrations

contained therein. Any use of this manual which infringes the copyright

provisions stipulated herein, is not permitted. Reproduction, translation and

electronic and photo-technical archiving and amendments require the written

consent of WAGO Kontakttechnik GmbH & Co. KG. Non-observance will

entail the right of claims for damages.

WAGO Kontakttechnik GmbH & Co. KG reserves the right to perform

modifications allowed by technical progress. In case of grant of a patent or

legal protection of utility patents all rights are reserved by WAGO

Kontakttechnik GmbH & Co. KG. Products of other manufacturers are always

named without referring to patent rights. The existence of such rights can

therefore not be ruled out.

1.1.2 Personnel Qualification

The use of the product detailed in this manual is exclusively geared to

specialists having qualifications in PLC programming, electrical specialists or

persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH & Co. KG declines all liability

resulting from improper action and damage to WAGO products and third party

products due to non-observance of the information contained in this manual.

1.1.3 Intended Use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only

permitted within the framework of the possibilities documented in the

manuals. All other changes to the hardware and/or software and the nonconforming use of the components entail the exclusion of liability on part of

WAGO Kontakttechnik GmbH & Co. KG.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH & Co.

KG.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 7

Important Comments • 7 Symbols

1.2 Symbols

Danger

Always abide by this information to protect persons from injury.

Warning

Always abide by this information to prevent damage to the device.

Attention

Marginal conditions must always be observed to ensure smooth operation.

ESD (Electrostatic Discharge)

Warning of damage to the components by electrostatic discharge. Observe

the precautionary measure for handling components at risk.

Note

Routines or advice for efficient use of the device and software optimization.

More information

References on additional literature, manuals, data sheets and INTERNET

pages

1.3 Number Notation

Number Code Example Note

Decimal 100 normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Within ',

Nibble separated with dots

WAGO-I/O-SYSTEM 750

I/O Modules

Page 8

8 • Important Comments

Safety Notes

1.4 Safety Notes

Warning

Switch off the system prior to working on bus modules!

In the event of deformed contacts, the module in question is to be replaced, as

its functionality can no longer be ensured on a long-term basis.

The components are not resistant against materials having seeping and

insulating properties. Belonging to this group of materials is: e.g. aerosols,

silicones, triglycerides (found in some hand creams).

If it cannot be ruled out that these materials appear in the component

environment, then additional measures are to be taken:

- installation of the components into an appropriate enclosure

- handling of the components only with clean tools and materials.

Attention

Cleaning of soiled contacts may only be done with ethyl alcohol and leather

cloths. Thereby, the ESD information is to be regarded.

1.5 Scope

Do not use any contact spray. The spray may impair the functioning of the

contact area.

The WAGO-I/O-SYSTEM 750 and its components are an open system. It

must only be assembled in housings, cabinets or in electrical operation

rooms. Access must only be given via a key or tool to authorized qualified

personnel.

The relevant valid and applicable standards and guidelines concerning the

installation of switch boxes are to be observed.

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the

environment (persons, workplace and packing) is well grounded. Avoid

touching conductive components, e.g. gold contacts.

This manual describes the Special Module 750-655

AS-Interface master module of the modular WAGO-I/O-SYSTEM 750.

Handling, assembly and start-up are described in the manual of the Fieldbus

Coupler. Therefore this documentation is valid only in the connection with the

appropriate manual.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 9

750-655 [AS-Interface master module] • 9 View

2 I/O Modules

2.1 Special Modules

2.1.1 750-655 [AS-Interface master module]

2.1.1.1 View

Fig. 2.1.1-1: View g065500e

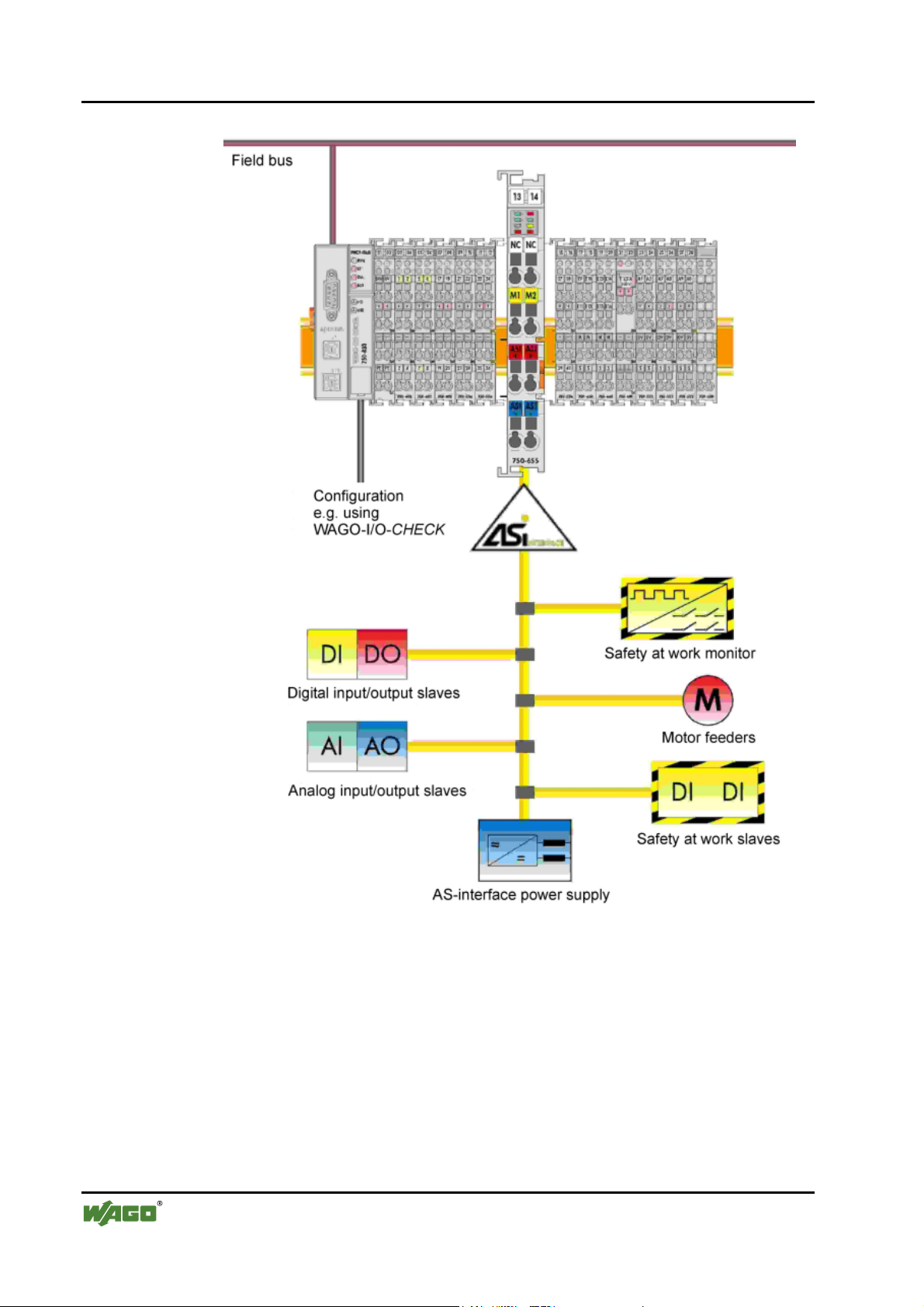

2.1.1.2 Description

The AS-Interface master module 750-655 is used to integrate the AS-Interface

network into the WAGO-I/O-SYSTEM 750. By this means, AS-Interface

slaves or subsystems, together with modules from the WAGO-I/O-SYSTEM

750, can be used in widely differing field bus systems.

The AS-Interface master module 750-655 behaves as a master for the ASInterface and as a slave for the field bus.

It already complies with the new AS-Interface specification 2.1. This means

that:

• up to 62 AS-Interface slaves can be connected to the master,

• the transmission of analog values is integrated within the masters and

• all other functions of the new specification, such as the evaluation of

peripheral errors, are also implemented.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 10

10 • 750-655 [AS-Interface master module]

Description

Fig. 2.1.1-2: Overview of the AS-Interface network p065501e

The AS-Interface functions are made available acyclically and the ASInterface process data are made available both cyclically and acyclically over

the field bus.

In cyclical data exchange, up to 32 bytes of I/O data (resettable) are

transmitted for the binary data of the AS-Interface strand.

In addition, analog values, and also all other commands of the new ASInterface specification, can be transmitted acyclically in a management

channel over the field bus.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 11

750-655 [AS-Interface master module] • 11

Description

Diagnostics functions, which go well beyond the AS-Interface specification,

enable intermittent configuration errors and sources of interference on the ASInterface communication to be easily localized. In this way, the downtimes of

systems can be minimized in the case of a fault and preventative maintenance

measures can be implemented.

LEDs signal the readiness for operation and the fault-free module bus

communication as well as the status of the signal transmission.

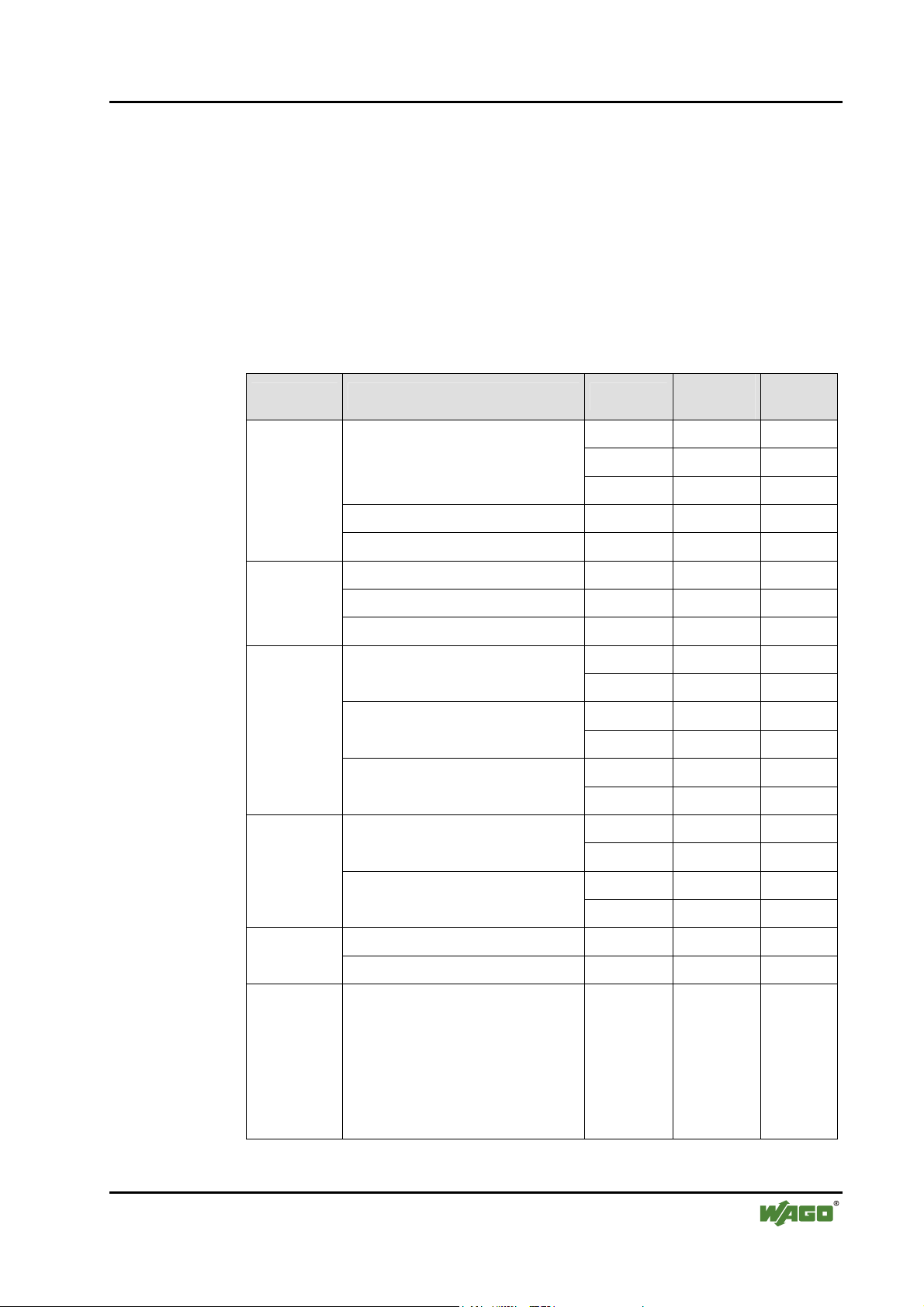

The AS-Interface master module 750-655 can be used with the following

WAGO-I/O-SYSTEM 750 couplers/controllers:

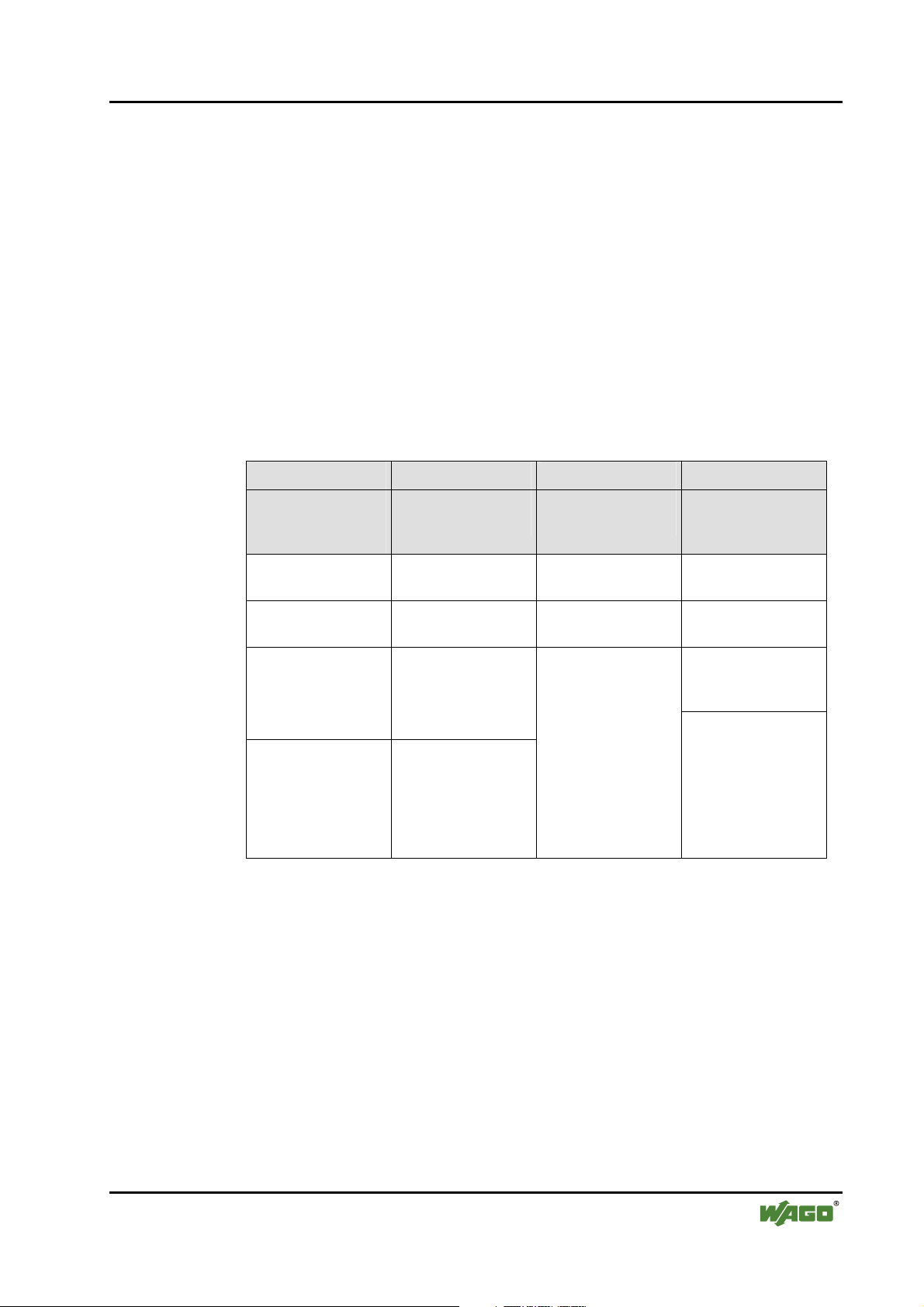

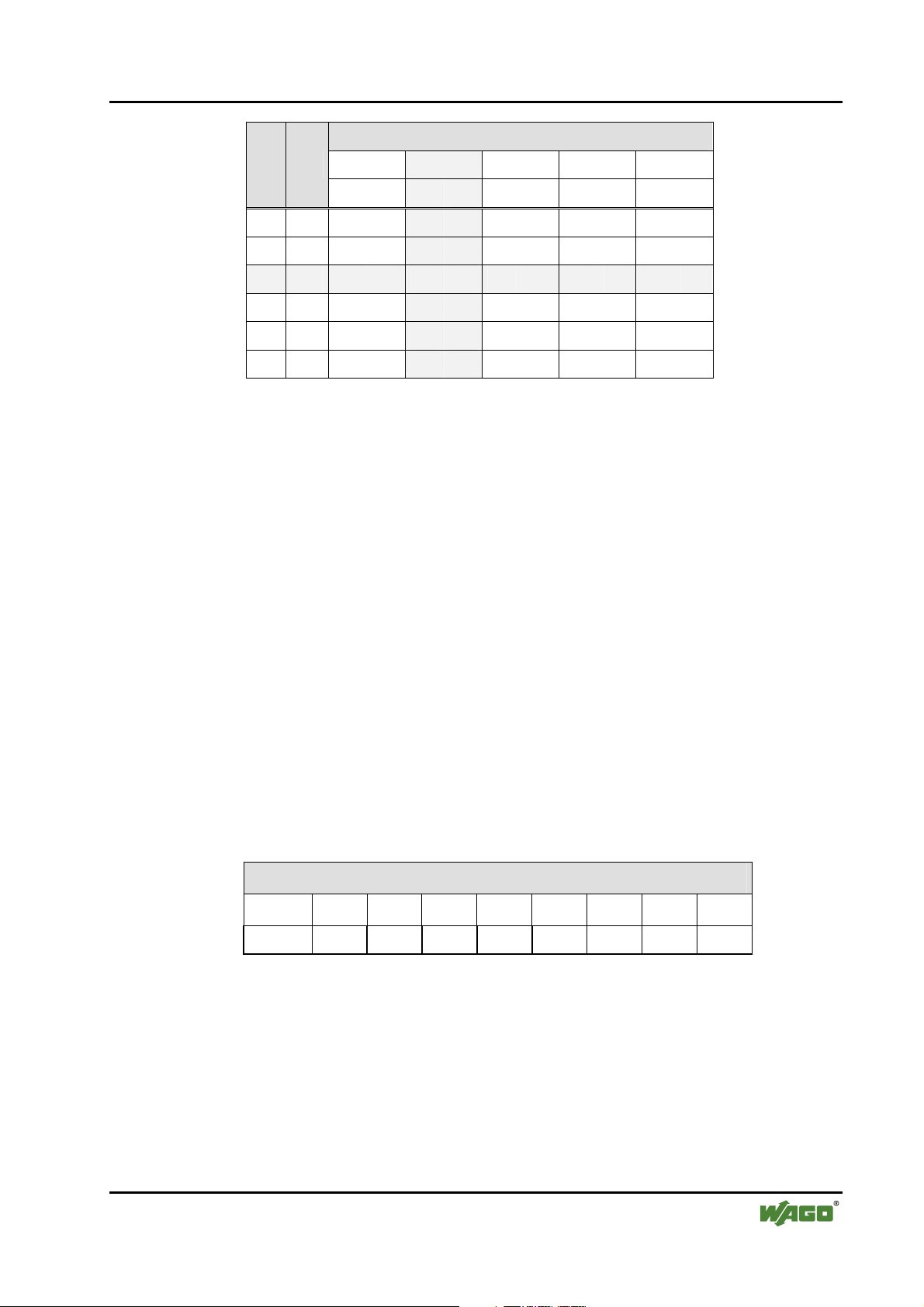

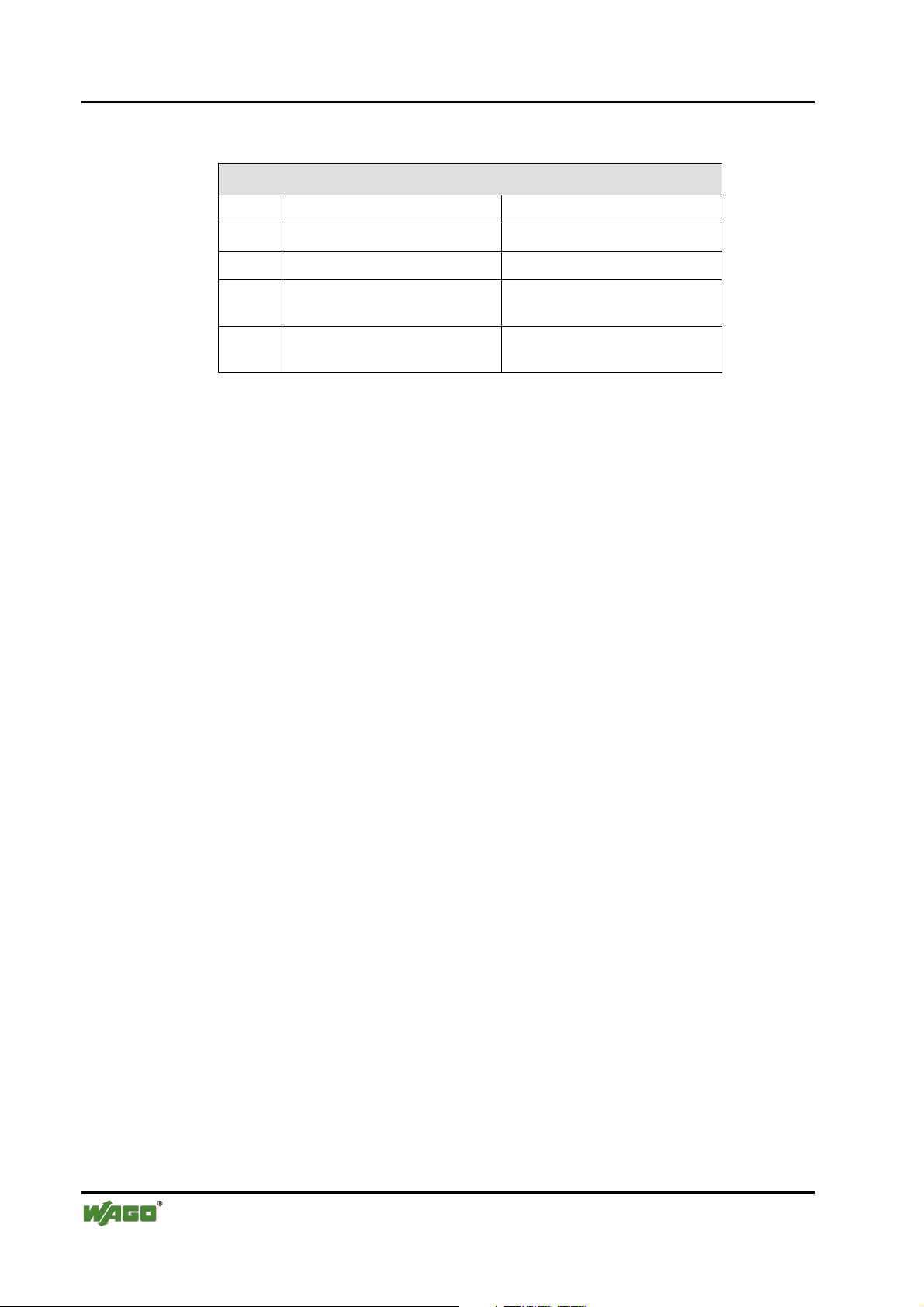

Bus system Coupler / Controller Item No.

Profibus

DeviceNet

CANopen

ETHERNET

Fieldbus coupler

ECO fieldbus coupler 750-343 03 from 06

Programmable fieldbus controller 750-833 12 from 07

Fieldbus coupler 750-306 11 4I

ECO fieldbus coupler 750-346 02 07

Programmable fieldbus controller 750-806 02 07

Programmable fieldbus controller

750-301 01 07

750-303 01 07

750-333 12 from 07

750-337 09 10 Fieldbus coupler

750-338 01 14

750-347 01 04 ECO fieldbus coupler

750-348 01 04

750-837 06 11

750-838 01 11

750-341 03 03 Fieldbus coupler

Hardware

version

Software

version

IPC WAGO-IPC 750-870 02 IPC-

Further couplers/controllers on request.

WAGO-I/O-SYSTEM 750

I/O Modules

750-342 04 14

Programmable fieldbus controller

Fieldbus coupler 750-319 07 05 LON

Programmable fieldbus controller 750-819 08 07

750-841 03 07

750-842 04 12

Firmware

02.04.

18/0200

KbusFirmware

01.02.

03(06)

Page 12

12 • 750-655 [AS-Interface master module]

Description

The version number is included in the fabrication number, which is printed on

the right-hand side of the bus module.

Note

A maximum of three AS-Interface master modules can be incorporated into

one fieldbus node. If it is intended to install two or three master modules in

direct vicinity to each other in one node, it is essential to observe the node

design acc. to chapter 2.1.2.1 „Grouping of AS-Interface Master Modules“.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 13

750-655 [AS-Interface master module] • 13

Indicating devices

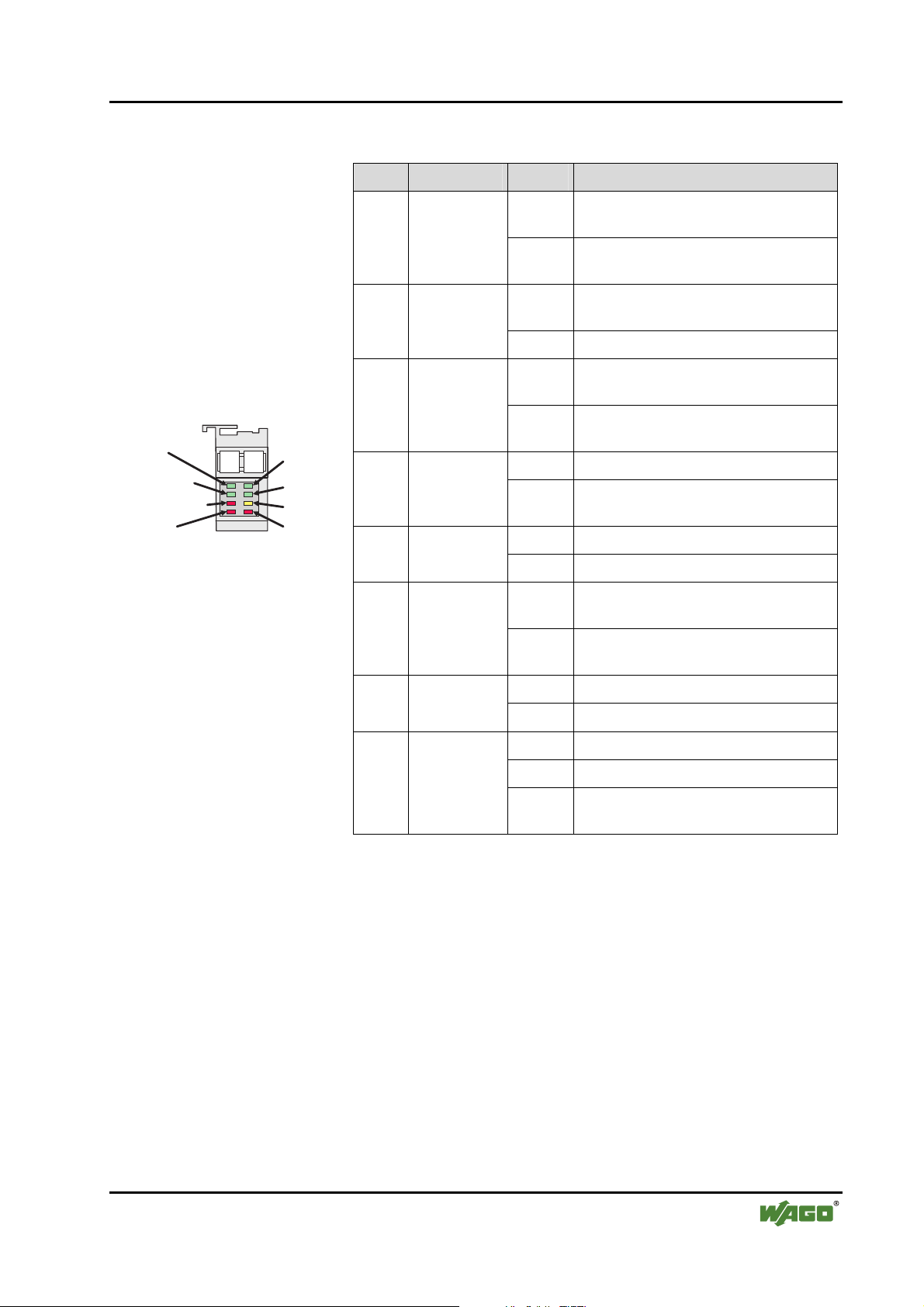

2.1.1.3 Indicating devices

LED Designation State Function

24 V - power

AS-interfacepower

Mapping

consistency

K-Bus timeout

overflow

Fig. 2.1.1-3: Indicating devices

13 14

AS-interface

active

prg enable

cfg mode

cfg error

g065502e

Power

green

AS-Interface

power

green

red

Mapping

consistency

Internal bus

timeout

red overflow

green

AS-Interface

active

green prg enable

off 24 V supply fault or

AS-Interface supply fault

on 24 V supply OK and

AS-Interface supply OK

off AS-Interface incomplete on internal bus

(mapping)

on AS-Interface complete on internal bus

off Communication to coupler/controller

OK

on Communication to coupler/controller

interrupted

off AS-Interface complete on internal bus

on AS-Interface incomplete on internal bus

(timing)

off AS-Interface not active

on AS-Interface active

off No automatic programming possible /

necessary

on A slave is missing and can be replaced

by automatic programming

yellow cfg mode

off Protected operating mode

on Set-up mode

off No fault

red general fault

flashing Peripheral fault

on Configuration error (Config Error Bit)

or at least one of the status bits 1 or 2

WAGO-I/O-SYSTEM 750

I/O Modules

Page 14

14 • 750-655 [AS-Interface master module]

Schematic circuit diagram

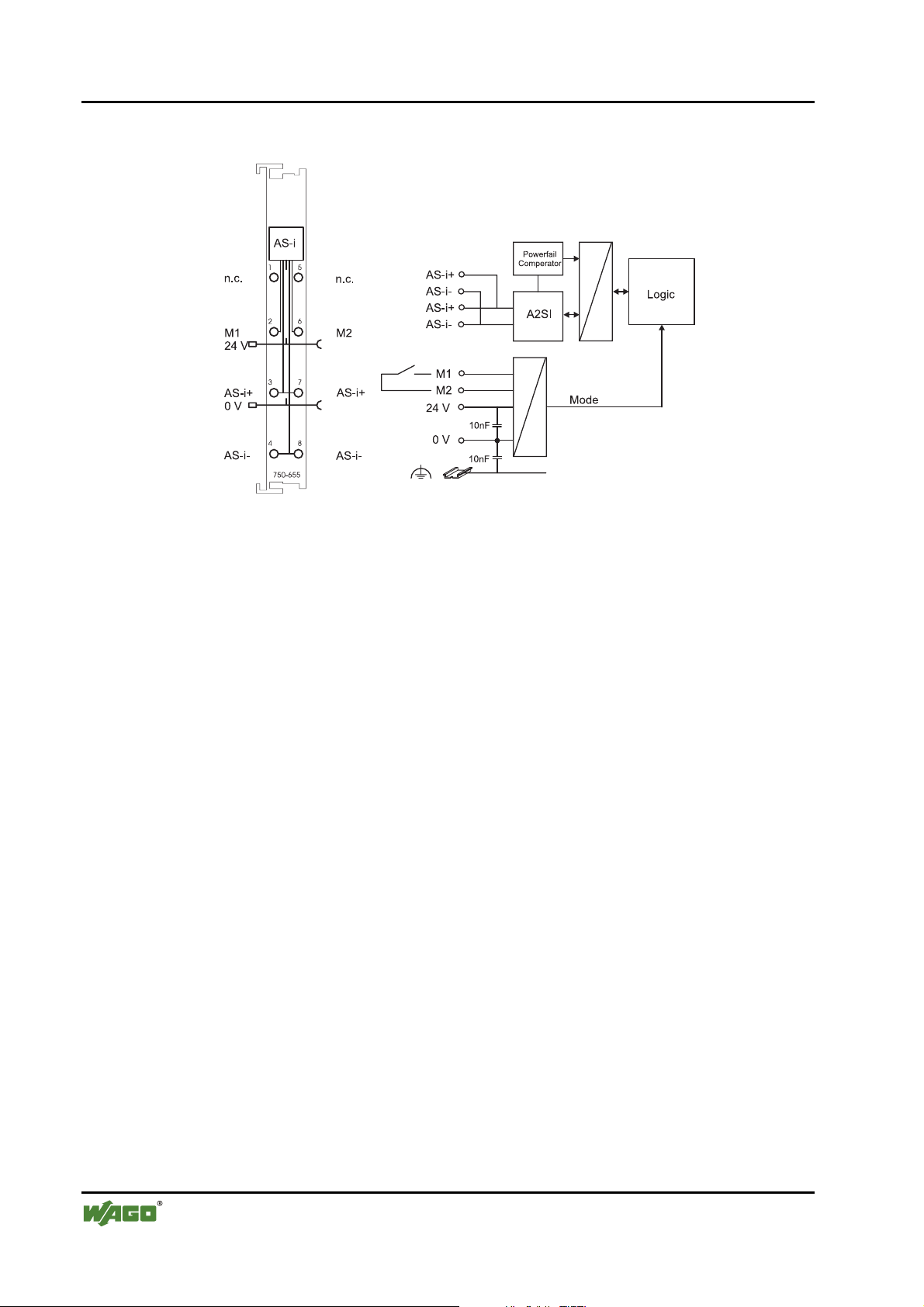

2.1.1.4 Schematic circuit diagram

Fig. 2.1.1-4: Schematic circuit diagram g065501e

WAGO-I/O-SYSTEM 750

I/O Modules

Page 15

750-655 [AS-Interface master module] • 15 Technical data

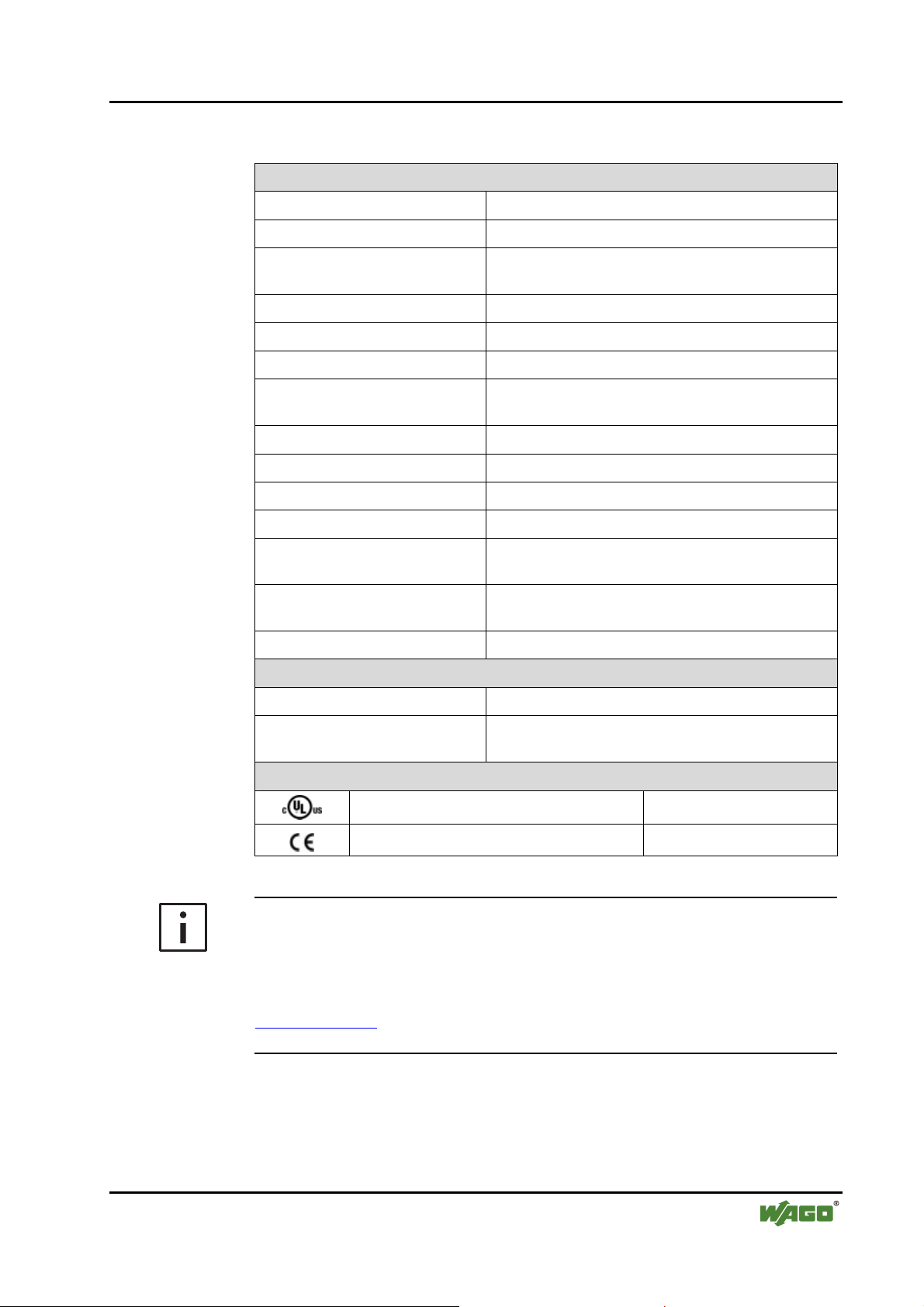

2.1.1.5 Technical data

Module-specific data

AS-Interface specification 2.1

Number of slaves up to 62

Current consumption (ASInterface)

Supply voltage (AS-Interface) 26.5 V ... 31.6 V

AS-Interface cable length max. 100 m, with repeater 300 m

Cycle time AS-Interface 0.3 ms ... 10 ms, depending on number of slaves

Configuration

Transmission channel 1

Current consumption max. (internal) 55 mA

Supply voltage DC 24 V via power contacts

Potential isolation 500 V system / supply / AS-Interface connection point

Data width 12 ... 48 bytes max. freely configurable,

Dimensions (mm) W x H x L 12 x 64* x 100

Weight ca. 70 g

Norms and Directives (cf. Chapter 2.2 in manual for coupler/controller)

EMC Immunity to interference CE according to EN 61000-6-2 (1996), EN 50295 (1999)

40 mA

via process image, WAGO-I/O-CHECK 2

or AS-Interface mode contacts

including 1 byte control / status

* from upper edge of mounting rail DIN 35

EMC Emissions of interference

CE

Approvals (cf. Chapter 2.2 in manual for coupler/controller)

(UL508)

CULUS

Conformity Marking

according to EN 61000-6-4 (2001)

More Information

Detailed references to the approvals are listed in the document "Overview

Approvals WAGO-I/O-SYSTEM 750", which you can find on the CD ROM

ELECTRONICC Tools and Docs (Item-No.: 0888-0412)

or in the internet under:

www.wago.com ! Documentation ! WAGO-I/O-SYSTEM 750 !

System Description

WAGO-I/O-SYSTEM 750

I/O Modules

Page 16

16 • 750-655 [AS-Interface master module]

Functional description

2.1.1.6 Functional description

2.1.1.6.1 Start-up behavior

After switching on, all LEDs illuminate as part of a self test. Following this,

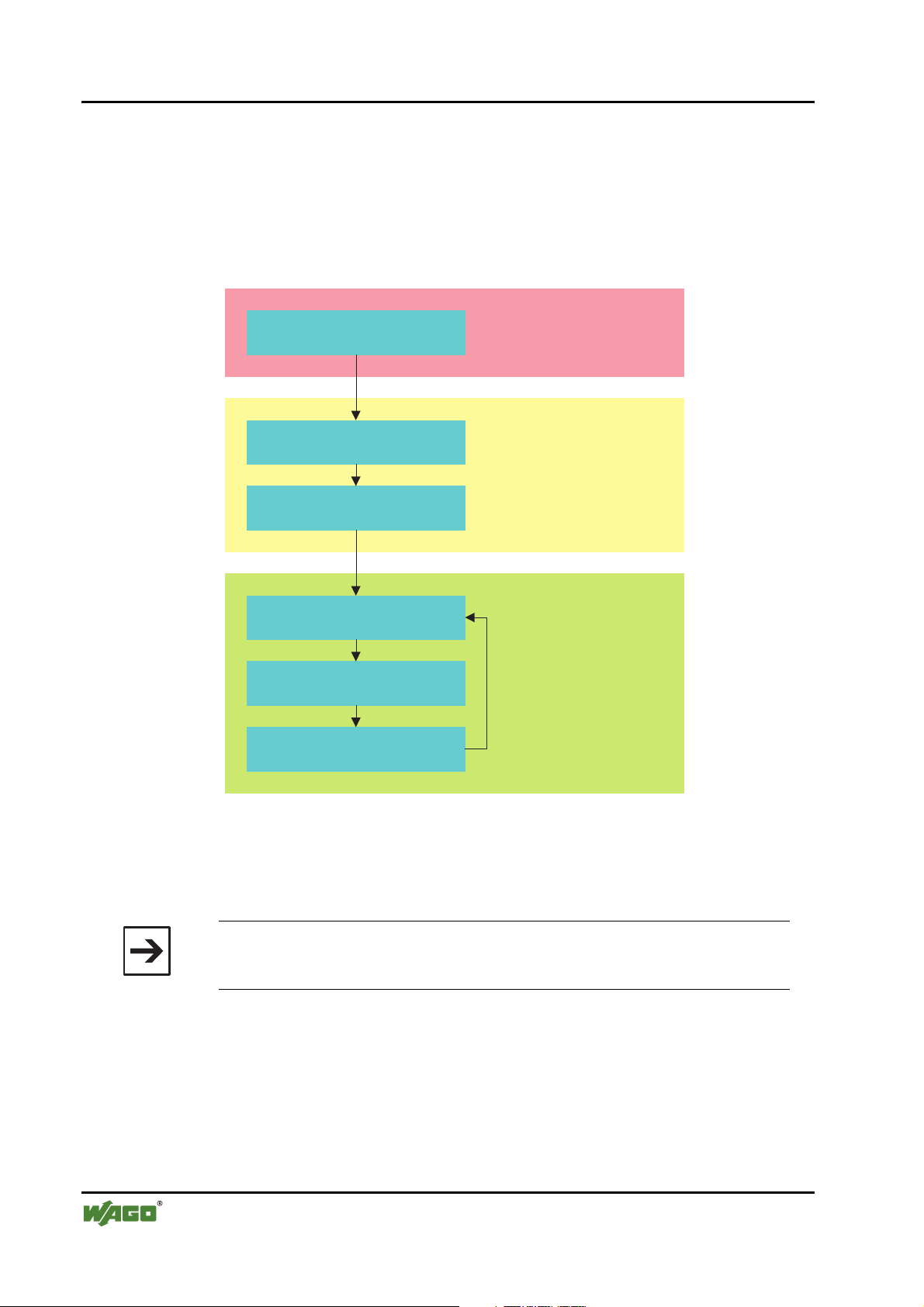

the LEDs indicate the status of the respective flags. On start-up, the ASInterface master module runs through the following phases:

Offline phase

Detection phase

Activation phase

Data exchange phase

Management phase

Acquisition phase

Initialisation

Start-up mode

Normal mode

Fig. 2.1.1-5: Start-up behavior g065503e

2.1.1.6.1.1 Offline phase

The master module is initialized; there is no exchange of data with the slaves.

Note

The master module will remain in the offline phase if the AS-Interface

circuit is not adequately supplied with power (U AS-I does not come on).

The offline phase can be exited in start-up mode or when the WAGO-I/O-

CHECK 2 commissioning tool starts automatically.

2.1.1.6.1.2 Detection phase

Beginning of start-up operation, in which a search is carried out for slaves

present on the AS-Interface. The master module remains in the detection

phase until at least one slave has been detected.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 17

750-655 [AS-Interface master module] • 17

Functional description

2.1.1.6.1.3 Activation phase

State at the end of the start-up mode, in which the parameters of all the

connected and detected slaves are transmitted. At this point, access is enabled

to the data connections in the slaves.

Depending on the operating mode, either all detected and set-up slaves are

activated (protected mode of operation) or all detected slaves are activated

(set-up mode).

2.1.1.6.1.4 Normal mode

In the normal mode, the master module exchanges data with all active slaves

(data exchange phase), transmits management telegrams (telegrams from and

to the host, management phase) and searches for and activates newly

connected slaves (acquisition phase).

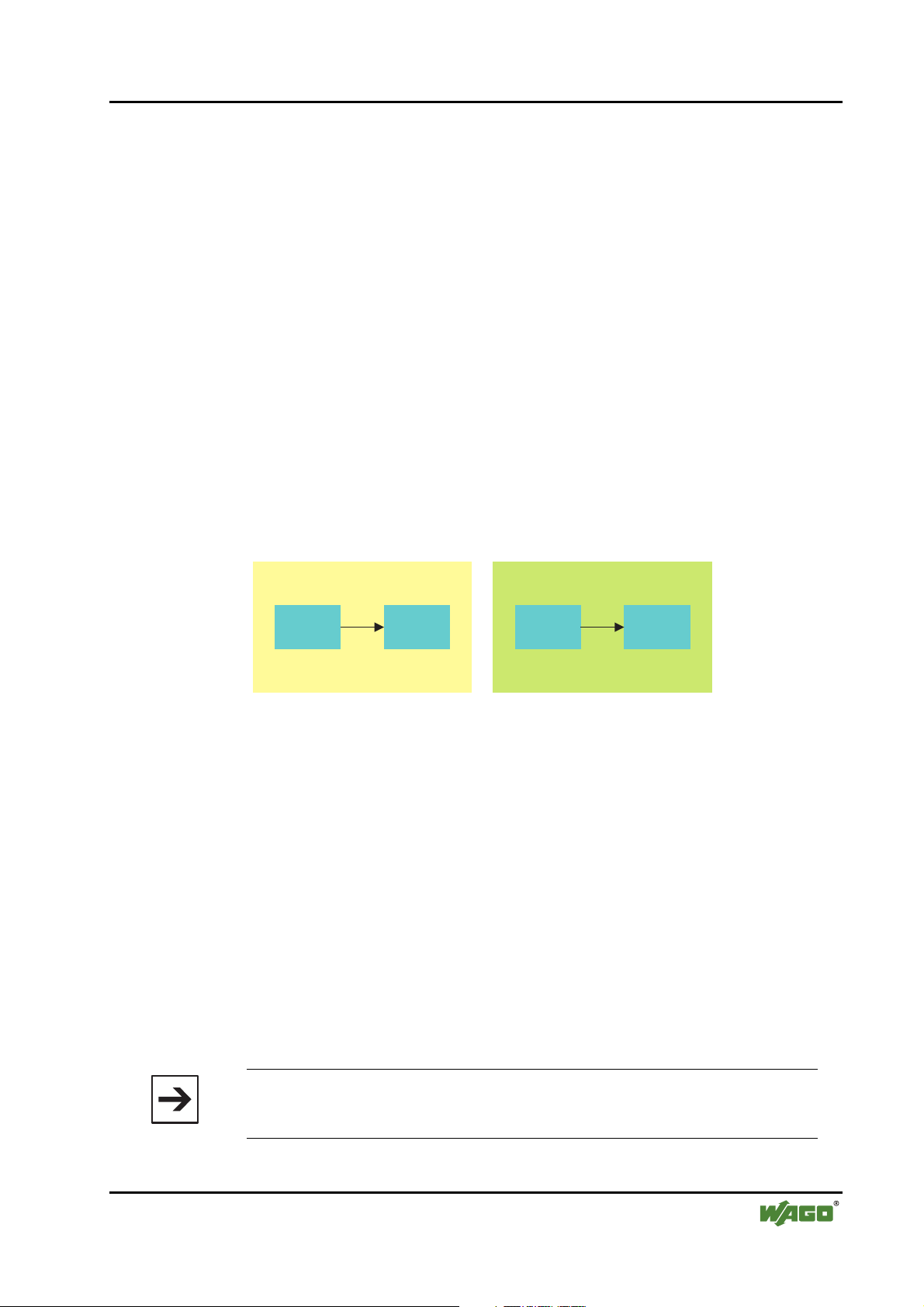

2.1.1.6.2 Slave lists

Information on available or set-up slaves is stored in the master in the form of

lists.

Set-up mode

LDS LAS

detected active projected active

Fig. 2.1.1-6: Slave lists g065504e

The list of detected slaves (LDS) includes all slaves, which the master detects

in the AS-Interface circuit and which have a valid address.

The list of projected slaves (LPS) includes all slaves, which the master expects

in the AS-Interface circuit as a result of the set-up.

The list of active slaves (LAS) includes all slaves with which the master

exchanges data. In the set-up mode, this list corresponds to the LDS list and,

in protected mode, it corresponds to the LPS list.

2.1.1.6.3 Operating modes

2.1.1.6.3.1 Set-up mode

Protected mode

LPS

LAS

The set-up mode is used for configuring the AS-Interface circuit.

Note

In the set-up mode, all detected slaves are activated even when there are

WAGO-I/O-SYSTEM 750

I/O Modules

differences between the required and actual configuration.

Page 18

18 • 750-655 [AS-Interface master module]

Functional description

The master module is switched to set-up mode by short-circuiting the mode

contacts M1 and M2 for at least five seconds. The yellow "prj mode" LED

illuminates in set-up mode. In set-up mode, all detected slaves, with the

exception of slave zero, are activated. The master module is in normal mode.

Data is exchanged between the master module and all detected slaves

regardless of whether the detected slaves have already been set up.

Note

The AS-Interface master module is supplied from the factory in set-up

mode.

2.1.1.6.3.2 Protected operating mode

The master module is switched from set-up mode to protected mode by shortcircuiting the mode contacts M1 and M2.

Brief short-circuit:

The master module switches from set-up mode to protected mode without

setting up the current actual configuration as a required configuration.

Short-circuiting for longer than five seconds:

The master module switches from set-up mode to protected mode. At the same

time, the actual configuration is stored in the module as a required

configuration.

Note

If a slave with the address zero is detected on the AS-Interface, it will not

be possible to exit the set-up mode.

Note

In protected mode, only those slaves are activated, which have been set up

and the required configuration of which matches the actual values.

Note

In contrast to the set-up mode, in protected mode, data is only exchanged

between the master module and the slaves that have been set-up.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 19

750-655 [AS-Interface master module] • 19

Functional description

2.1.1.6.4 Addressing in set-up mode

AS-Interface systems on the master module can be commissioned with the

WAGO-I/O-CHECK 2 commissioning tool.

The procedure is described in Chapter Fehler! Verweisquelle konnte nicht

gefunden werden. "Fehler! Verweisquelle konnte nicht gefunden

werden.".

Commissioning can also be carried out using an addressing unit.

2.1.1.6.5 Addressing in the case of configuration errors

2.1.1.6.5.1 Automatic addressing

One of the great advantages of the AS-Interface is the automatic address

programming. If a slave fails due to a defect, it can be replaced by a physically

identical slave with the address zero. The master module detects this and

automatically addresses the new slave with the address of the defective slave.

The following requirements must be satisfied for automatic programming:

• The master module must be in protected mode.

• The enable flag "Auto_prog" must be set.

• Only one of the set-up slaves must be undetected.

• The new slave must have the same configuration data as the missing slave.

When these conditions are satisfied, the master module indicates this with the

"prg enable" LED. If a slave is then detected with the address zero, it will

automatically be reprogrammed with the address of the missing slave.

The "Auto_prog" flag for automatic programming can be switched on and off

with the WAGO-I/O-CHECK 2 commissioning tool.

Note

Only slaves with the address zero can be re-addressed by the master

module.

Note

Automatic address programming is not carried out if the two slaves have

different configuration data, i.e. are not physically identical from the ASInterface side.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 20

20 • 750-655 [AS-Interface master module]

Functional description

2.1.1.6.5.2 Manual addressing

If several slaves have failed, the addresses of the new slaves must be set

manually. This can be carried out with the WAGO-I/O-CHECK 2

commissioning tool or an addressing unit.

Note

If several slaves fail, they can no longer be automatically replaced by the

master.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 21

750-655 [AS-Interface master module] • 21 Process image

2.1.1.7 Process image

2.1.1.7.1 Overview

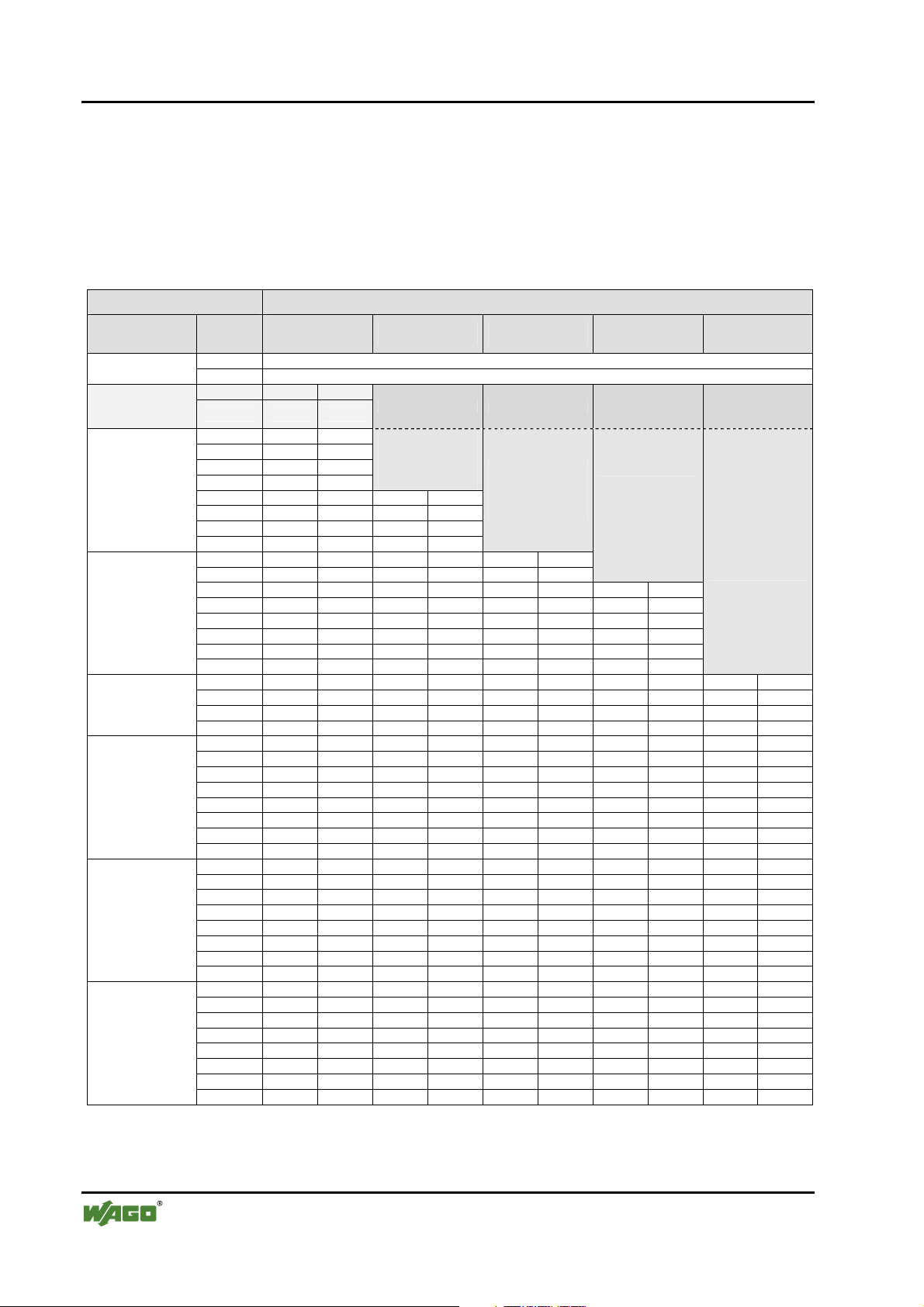

The length of the process image of the AS-Interface master module can be set

to fixed sizes of 12, 20, 24, 32, 40 or 48 bytes.

It consists of a control or status byte, a mailbox with a size of 0, 6, 10, 12 or

18 bytes and the AS-Interface process data, which can range from 0 to 32

bytes (Mode 1).

Alternatively, the mailbox can be set up to overlap, i.e. the mailbox is

temporarily superimposed on the AS-Interface process data with a length of 6,

10, 12 or 18 bytes depending on the total length of the process image that has

been configured (Mode 2).

Register communication is used to set up the module via the parameter

channel (Mode 3).

Mode 1 Mode 2.1 Mode 2.2 Mode 3

permanently

configured mailbox

(normal mode)

Control/Status

(1 byte, byte 0)

Internal use

(1 byte, byte 1)

Mailbox

(acyclical data,

0-18 bytes long,

bytes 2 to n)

Process data

(cyclical data,

0-32 bytes long,

bytes n+1 to m)

overlapping mailbox

activated

Control/Status

(1 byte, byte 0)

Internal use

(1 byte, byte 1)

Mailbox

(acyclical data,

6-18 bytes long,

bytes 2 to n)

Process data

(cyclical data,

0-32 bytes long,

bytes n+1 to m)

(take validity of data

into account!)

overlapping mailbox

deactivated

Control/Status

(1 byte, byte 0)

Internal use

(1 byte, byte 1)

Process data

(cyclical data,

0-32 bytes long,

bytes 2 to m)

register

communication

Control/Status

(1 byte, byte 0)

Internal use

(1 byte, byte 1)

Register data

(2 bytes, bytes 2 to

3)

Invalid data

(bytes 4 to m)

Changing between Mode 1 (permanently configured mailbox) and Mode 2

(overlapping mailbox) as well as the setting up of the mailbox and process

image sizes is carried out with the WAGO-I/O-CHECK 2 commissioning

tool or by means of the parameter channel via address 0. The values set are

mirrored in Register 33.

Mode 3 (register communication) is switched on and off with bit 27 of the

control byte. As this mode has a superimposed function, the previously

activated Mode 1 or 2 remains active after switching off.

All possible settings relating to the total process image length and mailbox

length are listed in the following tables.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 22

22 • 750-655 [AS-Interface master module]

Process image

In Mode 1, the control/status byte, the mailbox and the cyclical process data

are mapped. This is the default setting.

When the difference between the process image length and the mailbox length

is less than 34 bytes, only the first part of the AS-Interface process data is

transmitted; the data for the slaves with the higher addresses are then omitted.

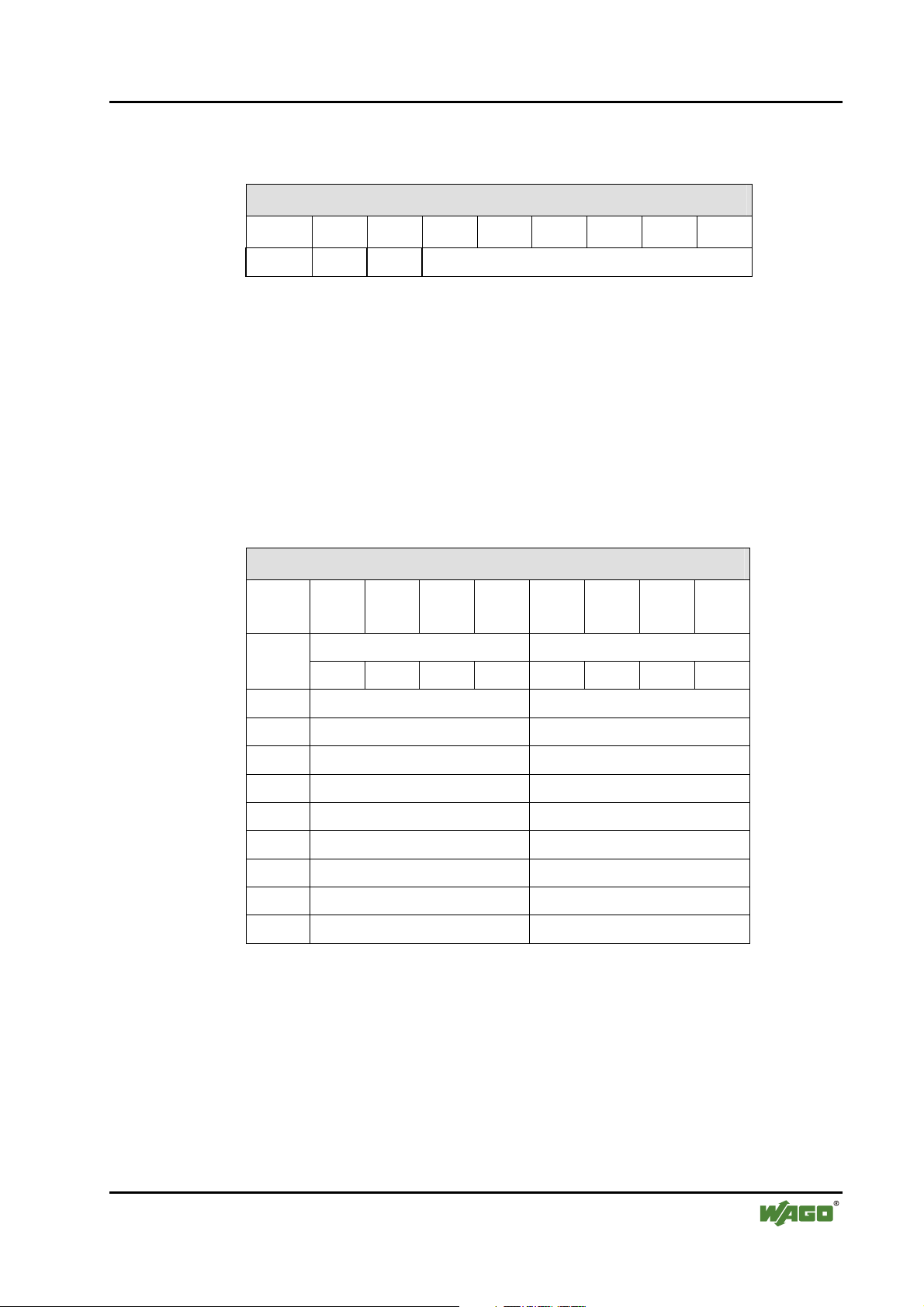

Mode 1 Mailbox length (permanently configured)

Process image

length

in control byte =

TRUE)

12 byte

20 byte

24 byte

32 byte

40 byte

48 byte

PI offset

in bytes

0 Control or status byte

1 Internal use

2 Flags 1/1A Register data (bit 27

3 2/2A 3/3A

4 4/4A 5/5A

5 6/6A 7/7A

6 8/8A 9/9A

7 10/10A 11/11A

8 12/12A 13/13A Flags 1/1A

9 14/14A 15/15A 2/2A 3/3A

10 16/16A 17/17A 4/4A 5/5A

11 18/18A 19/19A 6/6A 7/7A

12 20/20A 21/21A 8/8A 9/9A Flags 1/1A

13 22/22A 23/23A 10/10A 11/11A 2/2A 3/3A

14 24/24A 25/25A 12/12A 13/13A 4/4A 5/5A Flags 1/1A

15 26/26A 27/27A 14/14A 15/15A 6/6A 7/7A 2/2A 3/3A

16 28/28A 29/29A 16/16A 17/17A 8/8A 9/9A 4/4A 5/5A

17 30/30A 31/31A 18/18A 19/19A 10/10A 11/11A 6/6A 7/7A

18 Flags 1B 20/20A 21/21A 12/12A 13/13A 8/8A 9/9A

19 2B 3B 22/22A 23/23A 14/14A 15/15A 10/10A 11/11A

20 4B 5B 24/24A 25/25A 16/16A 17/17A 12/12A 13/13A Flags 1/1A

21 6B 7B 26/26A 27/27A 18/18A 19/19A 14/14A 15/15A 2/2A 3/3A

22 8B 9B 28/28A 29/29A 20/20A 21/21A 16/16A 17/17A 4/4A 5/5A

23 10B 11B 30/30A 31/31A 22/22A 23/23A 18/18A 19/19A 6/6A 7/7A

24 12B 13B Flags 1B 24/24A 25/25A 20/20A 21/21A 8/8A 9/9A

25 14B 15B 2B 3B 26/26A 27/27A 22/22A 23/23A 10/10A 11/11A

26 16B 17B 4B 5B 28/28A 29/29A 24/24A 25/25A 12/12A 13/13A

27 18B 19B 6B 7B 30/30A 31/31A 26/26A 27/27A 14/14A 15/15A

28 20B 21B 8B 9B Flags 1B 28/28A 29/29A 16/16A 17/17A

29 22B 23B 10B 11B 2B 3B 30/30A 31/31A 18/18A 19/19A

30 24B 25B 12B 13B 4B 5B Flags 1B 20/20A 21/21A

31 26B 27B 14B 15B 6B 7B 2B 3B 22/22A 23/23A

32 28B 29B 16B 17B 8B 9B 4B 5B 24/24A 25/25A

33 30B 31B 18B 19B 10B 11B 6B 7B 26/26A 27/27A

34 - - 20B 21B 12B 13B 8B 9B 28/28A 29/29A

35 - - 22B 23B 14B 15B 10B 11B 30/30A 31/31A

36 - - 24B 25B 16B 17B 12B 13B Flags 1B

37 - - 26B 27B 18B 19B 14B 15B 2B 3B

38 - - 28B 29B 20B 21B 16B 17B 4B 5B

39 - - 30B 31B 22B 23B 18B 19B 6B 7B

40 - - - - 24B 25B 20B 21B 8B 9B

41 - - - - 26B 27B 22B 23B 10B 11B

42 - - - - 28B 29B 24B 25B 12B 13B

43 - - - - 30B 31B 26B 27B 14B 15B

44 - - - - - - 28B 29B 16B 17B

45 - - - - - - 30B 31B 18B 19B

46 - - - - - - - - 20B 21B

47 - - - - - - - - 22B 23B

0 byte 6 byte 10 byte 12 byte 18 byte

Mailbox

Mailbox

Mailbox

Mailbox

WAGO-I/O-SYSTEM 750

I/O Modules

Page 23

750-655 [AS-Interface master module] • 23

Process image

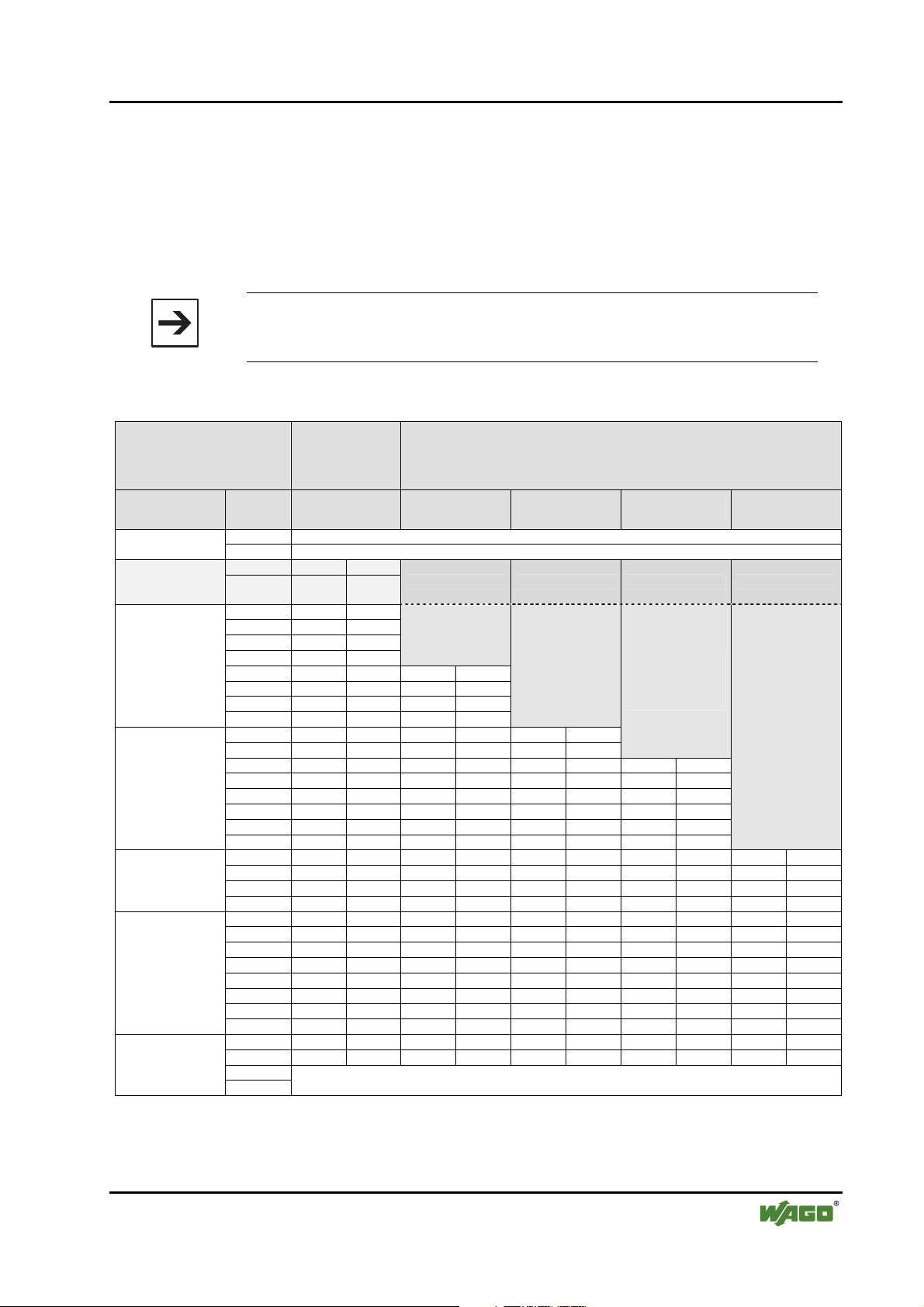

Mode 2 describes the operating mode with suppressible mailbox.

If the mailbox flag (bit 25 in the control byte) is set, then the mailbox is

imposed over the cyclical data range. The covered range is then no longer

valid (the range not covered continues to be updated, however, and can

therefore be used). If the mailbox flag is not set, then the mailbox is

suppressed and the cyclical data range becomes valid. The required setting is

acknowledged by mirroring in bit 25 of the status byte.

Note

The application program must take into account the validity of the data

ranges.

Mailbox

Mode 2

Process image

length

in control byte =

TRUE)

12 byte

20 byte

24 byte

32 byte

40 byte

suppressed (bit 25

in control byte =

FALSE)

PI offset

in bytes

0 Control or status byte

1 Internal use

2 Flags 1/1A Register data (bit 27

3 2/2A 3/3A

4 4/4A 5/5A

5 6/6A 7/7A

6 8/8A 9/9A

7 10/10A 11/11A

8 12/12A 13/13A 12/12A 13/13A

9 14/14A 15/15A 14/14A 15/15A

10 16/16A 17/17A 16/16A 17/17A

11 18/18A 19/19A 18/18A 19/19A

12 20/20A 21/21A 20/20A 21/21A 20/20A 21/21A

13 22/22A 23/23A 22/22A 23/23A 22/22A 23/23A

14 24/24A 25/25A 24/24A 25/25A 24/24A 25/25A 24/24A 25/25A

15 26/26A 27/27A 26/26A 27/27A 26/26A 27/27A 26/26A 27/27A

16 28/28A 29/29A 28/28A 29/29A 28/28A 29/29A 28/28A 29/29A

17 30/30A 31/31A 30/30A 31/31A 30/30A 31/31A 30/30A 31/31A

18 Flags 1B Flags 1B Flags 1B Flags 1B

19 2B 3B 2B 3B 2B 3B 2B 3B

20 4B 5B 4B 5B 4B 5B 4B 5B 4B 5B

21 6B 7B 6B 7B 6B 7B 6B 7B 6B 7B

22 8B 9B 8B 9B 8B 9B 8B 9B 8B 9B

23 10B 11B 10B 11B 10B 11B 10B 11B 10B 11B

24 12B 13B 12B 13B 12B 13B 12B 13B 12B 13B

25 14B 15B 14B 15B 14B 15B 14B 15B 14B 15B

26 16B 17B 16B 17B 16B 17B 16B 17B 16B 17B

27 18B 19B 18B 19B 18B 19B 18B 19B 18B 19B

28 20B 21B 20B 21B 20B 21B 20B 21B 20B 21B

29 22B 23B 22B 23B 22B 23B 22B 23B 22B 23B

30 24B 25B 24B 25B 24B 25B 24B 25B 24B 25B

31 26B 27B 26B 27B 26B 27B 26B 27B 26B 27B

32 28B 29B 28B 29B 28B 29B 28B 29B 28B 29B

33 30B 31B 30B 31B 30B 31B 30B 31B 30B 31B

...

39

n byte mailbox 6 byte mailbox 10 byte mailbox 12 byte mailbox 18 byte mailbox

Empty

Mailbox imposed

(bit 25 in control byte = TRUE)

Mailbox

Mailbox

Mailbox

Mailbox

WAGO-I/O-SYSTEM 750

I/O Modules

Page 24

24 • 750-655 [AS-Interface master module]

Process image

Mode 3 is reserved for register communication. Bit 27 in the control byte is set

to activate register communication. Resetting this bit switches register

communication off again. The selected setting is mirrored in bit 27 of the

status byte. The register data are superimposed on the PI offset byte 2 and byte

3 over the respective cyclical or acyclical memory range depending on the

selected mode.

Note

In Mode 3, the mailbox and the process data are basically no longer valid.

Process image length and mailbox length:

The process image length and the mailbox length can be freely set within fixed

limits with the limitation that the process image length is greater than the

mailbox length plus two control/status bytes.

The size of the process image can be set to 12 bytes, 20 bytes, 24 bytes, 32

bytes, 40 bytes or 48 bytes.

The mailbox length can be set to 0 bytes, 6 bytes, 10 bytes, 12 bytes or 18

bytes.

Note

If a mailbox length of 0 bytes is set, it will only be possible to access the

process data of digital slaves.

AS-Interface process data:

The length of the AS-Interface data and thus the number of transferable slaves

is given by the combination of the above-mentioned process image and

mailbox settings.

AS-Interface process data length = (Process image length – Mailbox length – 2)

The following table shows a summary of the permissible configurations of

process image and mailbox:

WAGO-I/O-SYSTEM 750

I/O Modules

Page 25

750-655 [AS-Interface master module] • 25

Process image

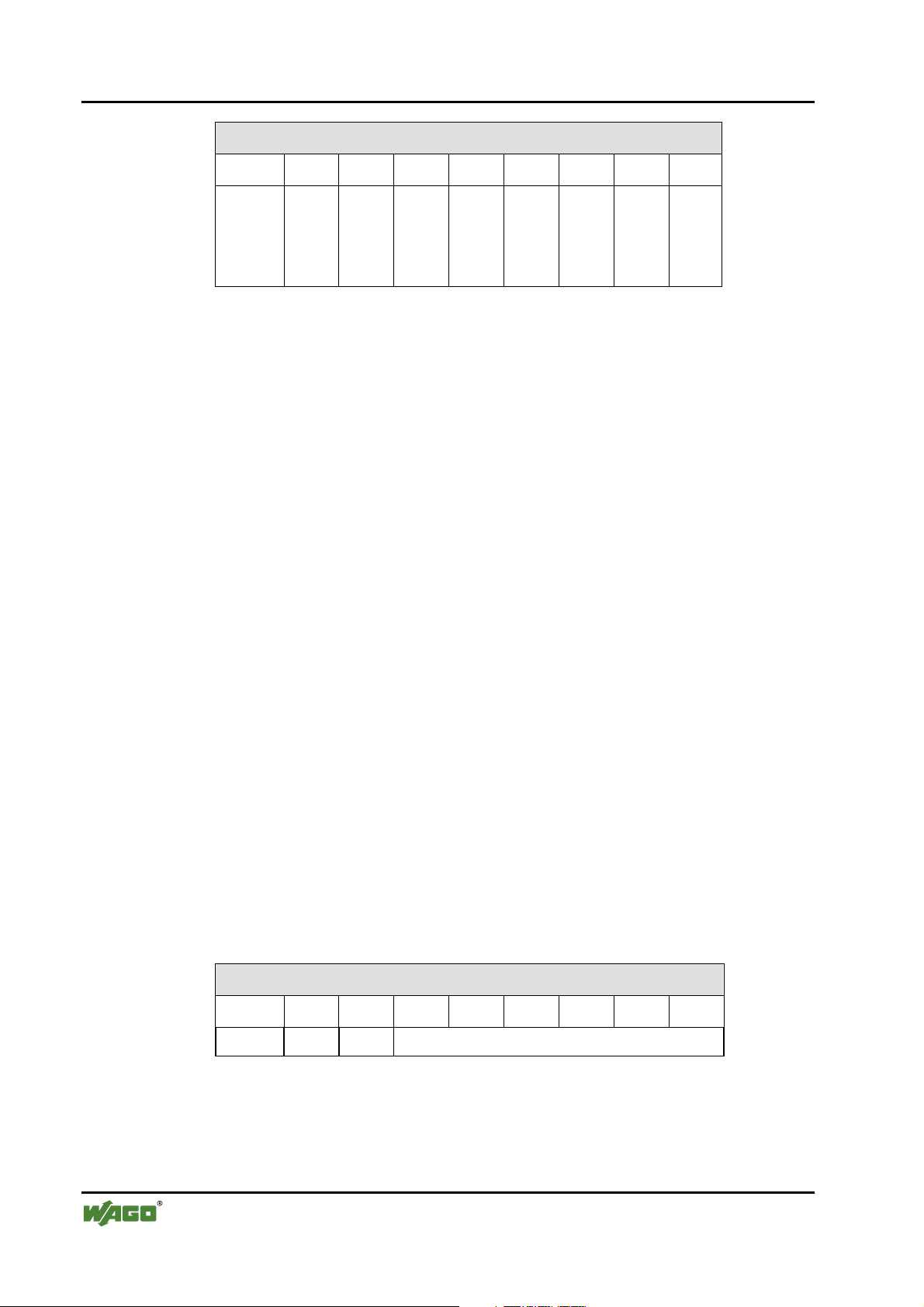

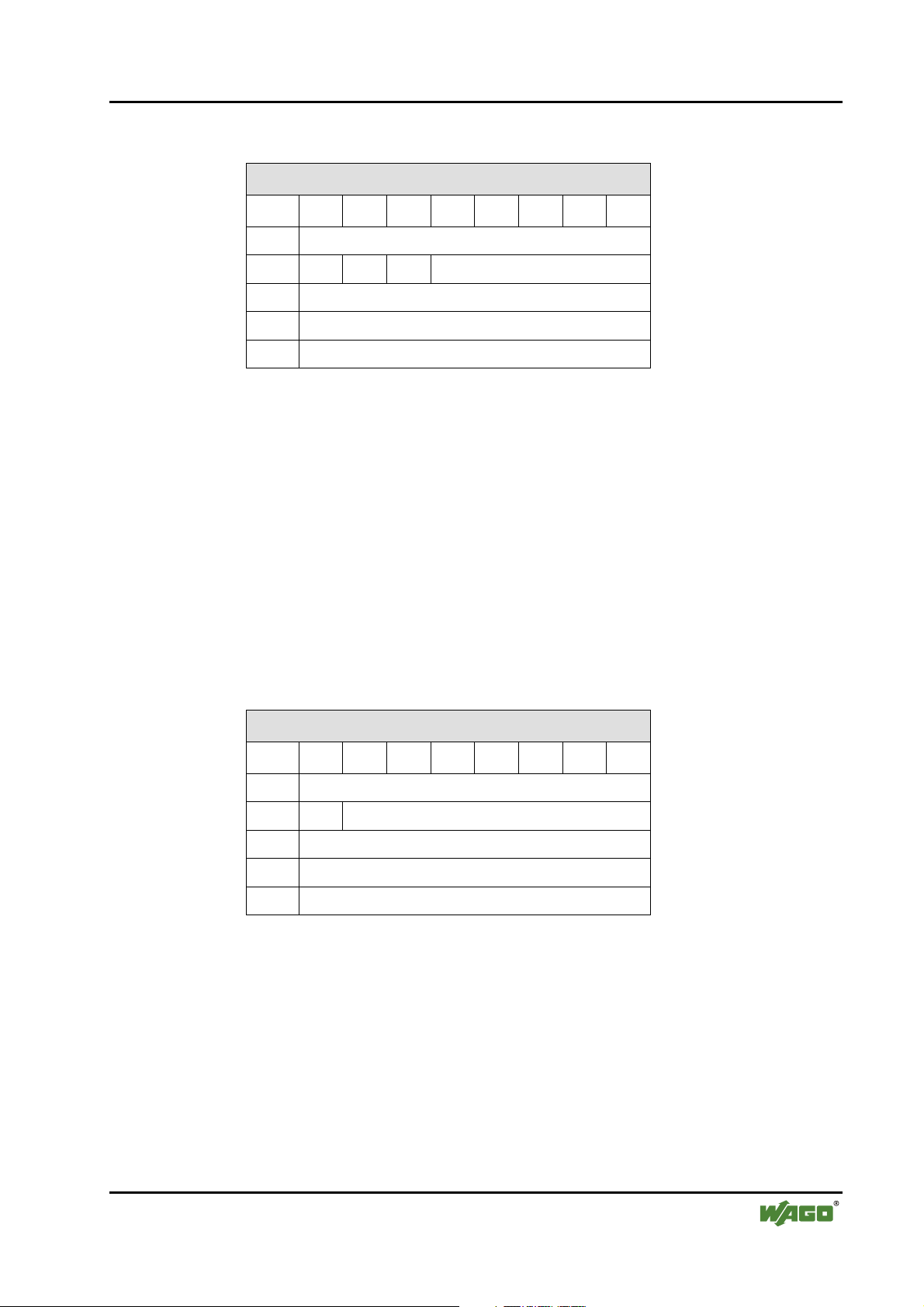

Mailbox length

PI C/S

12 2 10 19 4 7 0 0 - - - -

20 2 18 34 12 23 8 15 6 11 0 0

24 2

32 2 30 58 24 46 20 38 18 34 12 23

40 2 38 62 32 62 28 54 26 50 18 38

48 2 46 62 40 62 36 62 34 62 28 54

PI Length of process image that can be set

C/S Number of status and control bytes (incl. filler bytes)

PD Length of AS-Interface process data

SL Number of transferable slaves

0 byte 6 byte 10 byte 12 byte 18 byte

PD SL PD SL PD SL PD SL PD SL

22 42

16 31

12 23 10 19 4 7

The standard setting is a process image length of 24 bytes and a mailbox

length of 6 bytes. This results in an AS-Interface process data length of 16

bytes, i.e. 31 slaves can be read out.

2.1.1.7.2 Control and status byte

The bus master switches between process data communication and register

communication with bit 27 in the control byte.

The changeover is acknowledged by the bus module with bit 27 in the status

byte.

2.1.1.7.2.1 Assignment for process data communication

With process data communication, the control and status bytes are assigned as

follows:

Control byte

Byte 27 26 25 24 23 22 21 20

1 0 0 mbx 0 0 0 0 0

0 Mailbox suppressed mbx

1 Mailbox superimposed

The superimposition of the mailbox is activated and deactivated with bit 25 in

the control byte.

With process data communication, bit 27 in the control byte is always reset.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 26

26 • 750-655 [AS-Interface master module]

Process image

Status byte

Byte 27 26 25 24 23 22 21 20

1 0 gen.

fault

0 AS-Interface complete on internal bus Overflow

1 AS-Interface incomplete on internal bus (timing)

0 AS-Interface active AS-I

1 AS-Interface not active

0 AS-Interface supply OK and 24 V supply OK AS-Interface

power

consistency

(config error)

1 AS-Interface supply fault or 24 V supply fault

0 AS-Interface complete on internal bus Mapping

1 AS-Interface incomplete on internal bus (mapping)

0 Protected operating mode cnf mode

1 Set-up mode

0 Mailbox suppressed mbx

1 Mailbox superimposed

0 No fault General fault

1 Configuration error or at least one of the status bits 1 or 2

mbx cnf

mode

Map-

ping

consist-

ency

AS-

inter-

face -

power

AS-I Over-

flow

The status of the AS-Interface master module is indicated by the bits 20 to 24

and 26 in the status byte.

The superimposition of the mailbox is acknowledged by the bus module with

5

in the status byte.

bit 2

Process data communication is acknowledged by the bus module with bit 2

the status byte.

2.1.1.7.2.2 Assignment for register communication

With register communication, the control and status bytes are assigned as

follows:

Control byte

Byte 27 26 25 24 23 22 21 20

1 1 R/W Register number

0 Read access R/W

1 Write access

7

in

WAGO-I/O-SYSTEM 750

I/O Modules

Page 27

750-655 [AS-Interface master module] • 27

Process image

Bit 26 (R/W) in the control byte determines the register read or write access.

With register communication, bit 27 in the control byte is always set.

Status byte

Byte 27 26 25 24 23 22 21 20

1 1 — Register number

Register communication is acknowledged by the bus module with bit 27 in the

status byte.

2.1.1.7.3 AS-Interface process data

In the data field of the AS-Interface process data, the data for (or from) 2

slaves are transmitted with each byte. In doing so, the data for the slave with

the higher address are located in the lower value nibble.

The main EC (Execution Control) flags or control bits are transmitted in place

of slave 0, with which the master does not exchange any process data.

AS-Interface process data

Byte

offset

0

1 Slave 2/2A Slave 3/3A

… … …

14 Slave 28/28A Slave 29/29A

15 Slave 30/30A Slave 31/31A

16 Reserved Slave 1B

17 Slave 2B Slave 3B

… … …

30 Slave 28B Slave 29B

31 Slave 30B Slave 31B

27 26 25 24 23 22 21 20

Flags Slave 1/1A

F3 F2 F1 F0 D3 D2 D1 D0

Depending on the process image length, mailbox length and mailbox mode, it

may be that not all AS-Interface process data are transmitted (cf. Chapter

2.1.1.7.1 "Overview process image").

WAGO-I/O-SYSTEM 750

I/O Modules

Page 28

28 • 750-655 [AS-Interface master module]

Process image

2.1.1.7.3.1 AS-Interface flags

Flags

Input data Output data

F0 ConfigError Offline

F1 APF LOS master bit

F2 PeripheryFault A rising edge switches the

master to the set-up mode

F3 ConfigurationActive A rising edge switches the

master to the protected mode

0 Config OK ConfigError:

1 Config error

0 AS-Interface power OK APF:

1 AS-Interface power failed

0 Periphery OK PeripheryFault:

All bits in the LOS are set with a rising edge of the LOS master bit. All bits in

the LOS are reset with a falling edge of the LOS master bit.

2.1.1.7.4 Mailbox

As well as the 32 bytes of input and output data, an AS-Interface master

manages a large amount of configuration and parameter data. These data are

only required for setting up the AS-Interface circuit and for diagnostics and

therefore only have to be read or written occasionally.

In addition, the master supports slaves according to profile S-7.3 and S-7.4

and other multiplexing slaves, whereby large amounts of data can also occur.

1 Periphery fault

0 Configuration inactive, master in protected mode ConfigurationActive:

1 Configuration active, master in set-up mode

0 Online Offline:

1 Offline

0 Offline with ConfigError deactivated LOS master bit:

1 Offline with ConfigError activated

Access is made to these non-time-critical data via the mailbox.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 29

750-655 [AS-Interface master module] • 29

Process image

2.1.1.7.4.1 Structure

Mailbox request

Byte 27 26 25 24 23 22 21 20

1 Opcode

2 T O A/B -

3 Request parameter byte 1

… …

36 Request parameter byte 34

Opcode Command code for the mailbox order

T Toggle flag A mailbox order is started when a change occurs.

O Order flag

(for mailbox orders

with bit information)

A/B

(for 6-byte mailbox

orders with bit

information)

Channel changeover

(for 6-byte mailbox

orders with word

information)

0 Bits are stored in parameter bytes in ascending order

(default value).

1 Bits are stored in parameter bytes in descending order.

0 A-slave data are transmitted before B-slave data. Slave changeover

1 B-slave data are transmitted before A-slave data.

0 Analog values are transmitted in the order Channel 1,

Channel 2, Channel 3, Channel 4.

1 Analog values are transmitted in the order Channel 3,

Channel 4, Channel 1, Channel 2.

Mailbox response

Byte 27 26 25 24 23 22 21 20

1 Opcode (mirrored)

2 T Result

3 Response parameter byte 1

… …

34 Response parameter byte 32

Opcode Mirrored command code for the mailbox order

T Toggle flag A mailbox order is acknowledged when a change occurs.

Result Status / error in the mailbox order

In most cases, the mailbox will not have the full length in order to provide

space for the AS-Interface process data.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 30

30 • 750-655 [AS-Interface master module]

Process image

2.1.1.7.4.2 Access procedure

The user first writes the request parameter and then the opcode and toggle

flag. As soon as the opcode or toggle flag changes, the master interprets the

mailbox range of the module bus output data as a complete mailbox command

and executes it. In doing so, the response parameters are stored in the mailbox

range of the internal bus input data.

When the command has been processed, the master mirrors the opcode and the

toggle flag. From this, the user recognizes that his request has been dealt with

and the result is available in the internal bus input data.

The toggle flag is required so that two mailbox commands with the same

opcode (but possibly different parameters) can be executed directly after one

another.

The execution of a mailbox command is declined if the number of request

parameter bytes transmitted (in the output data direction) is too small, i.e. if

the mailbox length has been set too low.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 31

750-655 [AS-Interface master module] • 31

Mailbox commands

2.1.1.8 Mailbox commands

2.1.1.8.1 Overview of mailbox commands

Opcode

IDLE 0x00 No order 2 2 ● ● ● ● 73

Configuration

GET_LDS_A/B 0x46 Get_List_of_Detected_Slaves 2 10 A/B ● ● ● 89

READ_CDI 0x28 Read_Actual_Configuration 3 4 ● ● ● ● 82

STORE_CDI 0x07 Store_Actual_Configuration 2 2 ● ● ● ● 81

SET_PCD 0x25 Set_Permanent_Configuration 5 2 ● ● ● ● 79

GET_PCD 0x26 Get_Permanent_Configuration 3 4 ● ● ● ● 80

GET_LPS_A/B 0x44 Get_List_of_Projected_Slaves 2 10 A/B ● ● ● 85

SET_LPS_A/B 0x6B Set_List_of_Projected_Slaves 10 2 A/B ● ● ● 83

GET_LAS_A/B 0x45 Get_List_of_Activated_Slaves 2 10 A/B ● ● ● 87

Parameters

GET_PP 0x01 Get_Permanent_Parameter 3 3 ● ● ● ● 75

SET_PP 0x43 Set_Permanent_Parameter 4 2 ● ● ● ● 74

READ_PI 0x03 Read_Parameter_from_Image 3 3 ● ● ● ● 77

Valu

e

Meaning

Req

Len

Executable with

Res

mailbox

Len

Page

6 10 12 18

WRITE_P 0x02 Write_Parameter 4 3 ● ● ● ● 76

STORE_PI 0x04 Store_Actual_Parameter_Image 2 2 ● ● ● ● 78

GET_DELTA_A/B*) 0x57 Get list of config. diff. 2 10 A/B ● ● ● 110

SLAVE_ADDR 0x0D Change_Slave_Address 4 2 ● ● ● ● 96

Diagnosis

GET_FLAGS 0x47 Get_Flags 2 5 ● ● ● ● 91

GET_LPF_A/B 0x3E Get_List_of_Peripheral_Failure 2 10 A/B ● ● ● 99

GET_LCS_A/B*) 0x6C Get_List_of_Corrupted_Slaves 2 10 A/B ● ● ● 116

GET_TEC_X*) 0x66 Get transm.err.counters X-Slaves 4

Operation Modes

SET_OP_MODE 0x0C Set_Operation_Mode 3 2 ● ● ● ● 93

SET_OFFLINE 0x0A Set_Off-Line_Mode 3 2 ● ● ● ● 94

SET_DATA_EX 0x48 Set_Data_Exchange_Active 3 2 ● ● ● ● 95

SET_AAE 0x0B Set_Auto_Adress_Enable 3 2 ● ● ● ● 97

GET_LOS_A/B*) 0x61 GET_LOS 2 10 A/B ● ● ● 118

SET_LOS_A/B*) 0x6D SET_LOS 10 2 A/B ● ● ● 120

≥5

● ● ● ● 122

Special Functions

WRITE_XID1 0x3F Write_Extended_ID-Code_1 3 2 ● ● ● ● 101

WAGO-I/O-SYSTEM 750

I/O Modules

Page 32

32 • 750-655 [AS-Interface master module]

Mailbox commands

Opcode

EXEC_CMD 0x49 Execute_Command 4 3 ● ● ● ● 98

FP_PARAM*) 0x7D „Functional Profile“ Param.

FP_DATA*) 0x7E „Functional Profile“ Data

Digital Slaves

RD_SLV_DATA*) 0x5E Read_Slave_Data 3 6 ● ● ● ● 102

WR_SLV_DATA*) 0x5F Write_Slave_Data 4 2 ● ● ● ● 103

16 Bit Slaves

RD_7X_IN_A/B 0x50 Read 1 7.3-slave in.data 3 10 A/B ● ● ● 104

WR_16BIT_OUT_S 0x6F WR_16BIT_OUT_S 6 2 ● ● ● ● 107

WR_7X_OUT 0x51 Write 1 7.3-slave out.data 11 2 - - ● ● 106

RD_7X_OUT_A/B 0x52 Read 1 7.3-slave out.data 3 10 A/B ● ● ● 108

Extended 16 Bit Slaves

WR_74_PARAM 0x5A Write S-7.4-slave parameter

RD_74_PARAM 0x5B Read S-7.4-slave parameter 4

Valu

e

Meaning

Req

Len

≥3 ≥2

≥3 ≥2

≥6

Executable with

Res

mailbox

Len

6 10 12 18

● ● ● ● 124

● ● ● ● 125

2 ● ● ● ● 112

● ● ● ● 113

≥3

Page

RD_74_ID 0x5C Read S-7.4-slave ID string 4

RD_74_DIAG 0x5D Read S-7.4-slave diagnosis string 4

Housekeeping

BUTTONS*) 0x75 Disable Pushbuttons 3 2 ● ● ● ● 123

*) Command in addition to AS-Interface specification

● Command is executable

- Command is not executable

A/B Command is executable with changeover between A/B slaves or channels

● ● ● ● 114

≥3

● ● ● ● 115

≥3

WAGO-I/O-SYSTEM 750

I/O Modules

Page 33

750-655 [AS-Interface master module] • 33

Mailbox commands

2.1.1.8.2 Result values of mailbox commands

Result Value Location Meaning

OK 0x00 – Fault-free execution

HI_NG 0x11 HI General fault (host interface "not good")

HI_OPCODE 0x12 HI Invalid value in opcode

HI_LENGTH 0x13 HI Length of mailbox in I/O data range or length of the

DP V1 request is too small

HI_ACCESS 0x14 HI No access right

EC_NG 0x21 EC General fault (AS-I execution control "not good")

EC_SND 0x22 EC "Slave (source addr) not detected"

EC_SD0 0x23 EC "Slave 0 detected"

EC_SD2 0x24 EC "Slave (target addr) not detected"

EC_DE 0x25 EC "Delete error"

EC_SE 0x26 EC "Set error"

EC_AT 0x27 EC "Address temporary"

EC_ET 0x28 EC "Extended ID1 temporary"

EC_RE 0x29 EC "Read (extended ID1) error"

HI Host Interface of the module

EC Execution Control (part specific to AS-Interface)

2.1.1.8.3 Example of mailbox use

The command for reading-in the four 16-bit channels of an AS-Interface input

slave, which is set up according to slave profile 7.3, is shown by way of an

example (RD_7X_IN).

When processing process image:

Mailbox size: 6 bytes

WAGO-I/O-SYSTEM 750

I/O Modules

Page 34

34 • 750-655 [AS-Interface master module]

Mailbox commands

Selection of channels 1 and 2 (A/B flag = 0):

Request: RD_7X_IN

Byte 1 0x50 (RD_7X_IN)

Byte 2 0x00 (Toggle flag = 0, A/B flag = 0)

Byte 3 0x1D (Slave address 29)

Byte 4 0x00

… …

Byte 6 0x00

Response

Byte 1 0x00

… …

Byte 6 0x00

The mailbox call is not answered with the current analog values, as the toggle

flag has not been set.

Setting the toggle flag:

Request

Byte 1 0x50

Byte 2 0x80 (Toggle flag = 1, A/B flag = 0)

Byte 3 0x1D (Slave address 29)

Byte 4 0x00

… …

Byte 6 0x00

Response

Byte 1 0x50

Byte 2 0x80 (Toggle flag = 1, no error)

Byte 3 Analog channel 1 high byte, hex

Byte 4 Analog channel 1 low byte, hex

Byte 5 Analog channel 2 high byte, hex

Byte 6 Analog channel 2 low byte, hex

The values for channels 1 and 2 appear in the response.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 35

750-655 [AS-Interface master module] • 35

Mailbox commands

Selection of channels 3 and 4 (A/B flag = 1):

Request

Byte 1 0x50

Byte 2 0xA0 (Toggle flag = 1, A/B flag = 1)

Byte 3 0x1D (Slave address 29)

Byte 4 0x00

… …

Byte 6 0x00

Response

Byte 1 0x00

… …

Byte 6 0x00

The mailbox call is not answered with the current analog values, as the toggle

flag has not been reset.

Resetting the toggle flag:

Request

Byte 1 0x50

Byte 2 0x20 (Toggle flag = 0, A/B flag = 1)

Byte 3 0x1D (Slave address 29)

Byte 4 0x00

… …

Byte 6 0x00

Response

Byte 1 0x50

Byte 2 0x00 (Toggle flag = 0, no error)

Byte 3 Analog channel 3 high byte, hex

Byte 4 Analog channel 3 low byte, hex

Byte 5 Analog channel 4 high byte, hex

Byte 6 Analog channel 4 low byte, hex

The values for channels 3 and 4 appear in the response.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 36

36 • 750-655 [AS-Interface master module]

Data channel for parameter exchange

2.1.1.9 Data channel for parameter exchange

2.1.1.9.1 Introduction

A general data channel between application and bus module is used for the

acyclical exchange of parameter sets and for their checking by the complex

bus module. In order to obtain access via all available interfaces of a bus

coupler or bus controller, the parameter channel is mapped onto the existing

register model. The parameter channel can therefore currently be controlled

via the following interfaces:

• via the control/status byte in the process data exchange

• via the 2-byte process data interface (PLC interface)

• via the exchange of parameters in the case of the respective field bus

systems (e.g. PROFIBUS-DP/DP-V1)

• via the asynchronous serial interface of the bus coupler/bus controller (e.g.

for 750-101, WAGO-I/O-CHECK 2, WAGO-I/O-PRO 32 and BKService)

The mapping of the parameter channel takes place via registers 56 and 57 of

the appropriate table or the appropriate channel of the complex bus module.

The parameter data are stored word by word in register 56 and the

communication is controlled via register 57. The structure of registers 56 and

57 is described in the following chapters.

2.1.1.9.2 Register structure

2.1.1.9.2.1 Parameter data (Register 56)

Register 56 is used for holding the parameter data that are to be read or

written. Depending on access, the register is written by the bus module (read

parameters) or by the bus coupler (write parameters).

Register 56 parameter channel register 0

Bit 27 26 25 24 23 22 21 20

Parameter

Bit 215 214 213 212 211 210 29 28

Parameter

PRM0 ...

PRM15

PRM7 PRM6 PRM5 PRM4 PRM3 PRM2 PRM1 PRM0

PRM15 PRM14 PRM13 PRM12 PRM11 PRM10 PRM9 PRM8

Parameter data bit 20 to bit 215

WAGO-I/O-SYSTEM 750

I/O Modules

Page 37

750-655 [AS-Interface master module] • 37

Data channel for parameter exchange

2.1.1.9.2.2 Communications control (Register 57)

Register 57 is used for the control and diagnostics of the parameter channel.

Register 57 parameter channel register 1

Bit 27 26 25 24 23 22 21 20

Request

parameter

Response

parameter

Bit 215 214 213 212 211 210 29 28

Request

parameter

Response

parameter

Request

parameter

Response

parameter

A7 A6 A5 A4 A3 A2 A1 A0

A7 A6 A5 A4 A3 A2 A1 A0

TGL_

MS

TGL_

SM

Information is written by the application and read by the module

Information is written by the module and read by the application

PRM_

RW

TIME

OUT

MORE_

PRM

BUF_

OVF

RES RES RES RES RES

PRM_

ERR

RES RES RES RES

Parameter Value range Meaning

A0 … A7 0 ... 255 Word address of the parameter to be currently

written/read.

TGL_MS FALSE,

TRUE

Toggle bit for transmitting new orders from the

application to the module. If TGL_SM and TGL_MS

have the same status, a new order has not yet been

initiated. If the flags have different statuses, a new order

has been initiated and is currently being processed.

TGL_SM FALSE,

TIMEOUT

WAGO-I/O-SYSTEM 750

I/O Modules

FALSE Parameter data are being read from A7 ... A0 PRM_RW

TRUE Parameter data are being written to A7 ... A0

FALSE Parameter transmission is complete. MORE_PRM

TRUE Further parameter data are to follow

Toggle bit for signaling the acceptance of a transmitted

TRUE

FALSE The transmission of the parameters has been completed in

TRUE The maximum transmission time for the parameters

parameter on the part of the module. If the status of

TGL_SM is not the same as that of TGL_MS, then the

respective order is being processed by the module. If both

flags have the same status, then the order for the

previously sent or requested parameter has been

completed.

the agreed time (parameter address 0).

previously negotiated between the module and the

application has been exceeded.

Page 38

38 • 750-655 [AS-Interface master module]

Data channel for parameter exchange

Parameter Value range Meaning

BUF_OVF

PRM_ERR

RES FALSE Reserved for expansion

FALSE Access was allowed to the write or read buffer

respectively of the module.

TRUE Access was made to parameters outside the write or read

buffer.

FALSE The previously transmitted parameter or all transmitted

parameters was/were valid.

TRUE At least one parameter was faulty on transmission. The

flag can be set either after each parameter received or on

completion of the parameter transmission.

2.1.1.9.3 Parameter sets

Parameter sets, which are indexed via parameter addresses (A7 ... A0), are

defined for using the parameter channel. Differentiation is made between

general (system parameter) and module-specific parameter addresses.

2.1.1.9.3.1 General parameter data (system parameter range)

The following addresses are defined for access to bus module system

parameters:

Address Mode

250 ...

253

254 R/W TIMEOUT This parameter contains the maximum

255

R/W RESERVED Reserved for expansion

R NO_OF_PRMS Number of bus module parameters in

W SET_DEFAULT_PRMS The bus module is reset to the factory

Parameter Description

permissible time in milliseconds that may

elapse when transferring the parameter

set. When TIMEOUT = 0, the monitoring

time is infinite.

words

settings.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 39

750-655 [AS-Interface master module] • 39

Data channel for parameter exchange

2.1.1.9.3.2 Bus module-specific parameter data

The following addresses are defined for access to the specific parameter data

of the AS-Interface master module:

Address Mode Parameter Description

0 R/W

1 R/W

2 …

249

*)

see Chapter 2.1.1.7.1 "Overview process image"

R/W RESERVED Reserved for expansion

LB 20...27 ASI_DATA_

LEN

HB

28...214MBX_LEN Length of the mailbox to be set in bytes

15

2

MBX_

MODE

20 DS_EN Internal use LB

1

...27 RES Reserved for expansion

2

8

HB 2

...215RES Reserved for expansion

*)

AS-Interface data length in bytes

FALSE No superimposition of mailbox

and AS-Interface process data

TRUE Mailbox can be superimposed

on the AS-Interface process

data (by setting bit 2

control byte)

5

in the

The contents of address 0 are also entered by the module in register 33 with

the read-only attribute.

2.1.1.9.4 Parameter transmission process

Parameter data are exchanged between application and bus modules by means

of the Request-Response process. The application initiates an order with the

help of the toggle bit (TGL_MS != TGL_SM). The communications control

register (R57) then polls the module until the latter acknowledges the

execution of the order (TGL_SM == TGL_MS).

The possible orders to the parameterizing interface of the bus module are

listed in the following.

2.1.1.9.4.1 Determining the maximum bus module parameter data (system parameters)

Request (Application)

Parameter Value Meaning

TGL_MS != TGL_SM Initiate order

PRM_RW = FALSE Read access

A0 ... A7 255 Address of parameter data length

WAGO-I/O-SYSTEM 750

I/O Modules

Page 40

40 • 750-655 [AS-Interface master module]

Data channel for parameter exchange

Response (Bus module)

Parameter Value Meaning

TGL_SM == TGL_MS Order executed

A0 ... A7 255 Address of parameter data length mirrored

PRM0 ...

PRM15

N Number of parameters in the address range 0 ... (n-1),

n ∈ {N < 250}

2.1.1.9.4.2 Setting the monitoring time (system parameters)

Request (Application)

Parameter Value Meaning

TGL_MS != TGL_SM Enter order

PRM_RW = TRUE Write access

A0 ... A7 254 Address TIMEOUT

PRM0 ...

PRM15

0 ... 65535 Monitoring time in milliseconds. The entry 0 means no

monitoring of the parameterization.

Response (Bus module)

Parameter Value Meaning

TGL_SM == TGL_MS Order executed

A0 ... A7 254 Address TIMEOUT mirrored

The module monitors the time for the transfer of the parameter data. The

monitoring of the time is started on the first occasion that the parameter range

specific to the module is accessed. It finishes with the receipt of the last

parameter word, which is identified by MORE_PRM = FALSE.

2.1.1.9.4.3 Restoring factory settings (system parameters)

Request (Application)

Parameter Value Meaning

TGL_MS != TGL_SM Enter order

PRM_RW = TRUE Write access

A0 ... A7 255 Address of factory settings

WAGO-I/O-SYSTEM 750

I/O Modules

Page 41

750-655 [AS-Interface master module] • 41

Data channel for parameter exchange

Response (Bus module)

Parameter Value Meaning

TGL_SM == TGL_MS Order executed

A0 ... A7 255 Address of factory settings mirrored

2.1.1.9.4.4 Reading/writing parameters (module-specific)

Request (Application)

Parameter Value Meaning

TGL_MS != TGL_SM Initiate order

= FALSE Read access PRM_RW

= TRUE Write access

MORE_PRM

A0 ... A7 0 ... (n-1) Address of parameter data

PRM0 ...

PRM15

= FALSE The transmission of the parameter data is terminated with

the currently transmitted parameter.

= TRUE Further parameter data are to follow.

0 ... 65535 Parameter data for write access

Response (Bus module)

Parameter Value Meaning

TGL_SM == TGL_MS Order executed

A0 ... A7 0 ... (n-1) Address of parameter data mirrored

TIMEOUT FALSE, TRUE Monitoring time expired

BUF_OFL FALSE, TRUE Access outside the module parameter range

PRM_ERR FALSE, TRUE Parameter/parameter set error

PRM0 ...

PRM15

0 ... 65535 Parameter data for read access

Errors when exchanging parameter data are reported by the module in the

error flags TIMEOUT, BUF_OV and PRM_ERR.

When the last parameter has been transferred to the module (MORE_PRM =

FALSE), the entire parameter set is checked by the module and accepted if

correct. Otherwise, the module returns a parameterizing error (PRM_ERR =

TRUE).

WAGO-I/O-SYSTEM 750

I/O Modules

Page 42

42 • 750-655 [AS-Interface master module]

Data channel for parameter exchange

2.1.1.9.4.5 Example: Configuring AS-Interface process data and mailbox

Request (Application)

Parameter Value Meaning

TGL_MS != TGL_SM Initiate order

PRM_RW = TRUE Write access

MORE_PRM = FALSE The transmission of the parameter data is terminated with

the currently transmitted parameter.

A0 ... A7 0 Address of parameter data

PRM0 ...

PRM7

PRM8 ...

PRM14

PRM15 MBX_MODE

ASI_DATA_

LEN

MBX_LEN Mailbox length in bytes

AS-Interface data length in bytes

FALSE No superimposition of mailbox and AS-

Interface process data

TRUE Mailbox can be superimposed on the AS-

Interface process data (by setting bit 2

control byte)

Response (Bus module)

Parameter Value Meaning

TGL_SM == TGL_MS Order executed

A0 ... A7 0 Address of parameter data mirrored

TIMEOUT FALSE, TRUE Monitoring time expired

BUF_OFL FALSE, TRUE Access outside the module parameter range

PRM_ERR FALSE, TRUE Parameter/parameter set error

5

in the

WAGO-I/O-SYSTEM 750

I/O Modules

Page 43

750-655 [AS-Interface master module] • 43 Extended diagnostics of the AS-Interface master

2.1.1.10 Extended diagnostics of the AS-Interface master

The extended diagnostics can be used to localize intermittent configuration

errors as well as assessing the quality of the data transmission on the ASInterface bus.

2.1.1.10.1 List of AS-Interface slaves, which have initiated configuration errors

(LCS)

In order to diagnose the causes, which are responsible for short-term

configuration errors on the AS-Interface network, along with the list of

projected slaves (LPS), the list of detected slaves (LDS) and the list of active

slaves (LAS), AS-Interface masters with extended diagnostics functionality

also manage an additional list of slaves, which have initiated a configuration

error (LCS, List of Corrupted Slaves). In this list appear all slaves, which

have caused at least one short-term configuration error since the last time the

list was read or since the master was switched on. Furthermore, short-term

voltage dips on the AS-Interface network are also displayed in the LCS in

place of slave 0.

Note

The LCS is deleted again each time a read process is carried out.

2.1.1.10.2 Protocol analysis: Counter for transmission errors for data telegrams

Masters with extended diagnostics provide a counter for each slave for

telegram repeats, which is incremented for every transmission error in the case

of data telegrams. By this means, the quality of the transmission can be

assessed even when only individual telegrams are faulty and the slave would

therefore never initiate a configuration error.

Note

The status of the counters is read out via the appropriate host interface and

reset with each read access. The highest valid instantaneous status of the

counter is 254. A count of 255 indicates a counter overflow.

2.1.1.10.3 Offline phase in the case of configuration errors

Masters with extended diagnostics provide the option of placing themselves in

the offline state in the case of a configuration error, hence placing the ASInterface network in a safe operating state. It is thus possible to respond more

quickly to configuration errors and the host is relieved of this task. If problems

occur on the AS-Interface, the masters can automatically switch the ASInterface network into a safe state.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 44

44 • 750-655 [AS-Interface master module]

Extended diagnostics of the AS-Interface master

There are two ways of parameterizing the master for this function:

• Every configuration error that occurs on the AS-Interface switches the

master from normal operation in protected mode into the offline phase.

• A list of slave addresses is defined, which can cause the offline phase to be

initiated when configuration errors occur (List of Offline Slaves LOS).

Here, the user himself can decide how the master is to respond to a

configuration error on the AS-Interface. Hence, with critical slaves, the

master can be switched directly into the offline phase while, with less

critical slaves, the error message "configuration error" is sent to the host,

but the AS-Interface network is not switched offline.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 45

Node Design • 45 Grouping of AS-Interface Master Modules

2.1.2 Node Design

2.1.2.1 Grouping of AS-Interface Master Modules

Note

A maximum of three AS-Interface master modules can be incorporated

into one fieldbus node!

A single AS-Interface master module 750-655 can be placed at any position in

the node. However, if two or three modules are to be placed in direct vicinity

to each other in one node, they must be placed at the end of the node since in

that case power for the field supply should not be derived from the power

jumper contacts of the AS-Interface master modules. Also, the power for the

AS-Interface module must not be supplied via the CAGE CLAMP®

connections of the modules but must be fed in either between AS-Interface

master module and the slaves or between the slaves.

AS-interface Circuit 1

13 14

NC

NC

15

NC

NC

16

A

C

B

D

AS-interface

Power Supply

--

++

M1 M2

750-XXX 750-XXX

ASI+

ASI-

750-655

ASI+

ASI-

M1 M2

ASI+

ASI-

750-655

ASI+

ASI-

750-600

Slave Slave Slave Slave

AS-interface

Power Supply

--

++

AS-interface Circuit 2

Slave Slave Slave Slave

Fig. 2.1.2-7: Node design with 2 AS-Interface modules

g065510e

WAGO-I/O-SYSTEM 750

I/O Modules

Page 46

46 • Set up and configuration with WAGO-I/O-CHECK 2

Setting up the AS-Interface process data and mailbox length

3 Working with the AS-Interface master module

750-655

3.1 Set up and configuration with WAGO-I/O-CHECK 2

In order to work with the AS-Interface master module 750-655, first set up the

communication connection to your node. Then read out the node configuration

and select the required module in the navigation screen or node view.

Next set the required process data and mailbox length in the parameter setting

dialog.

After this, you can set up the required operating mode for the master in the

process data dialog or select a slave for further processing from the list of

slave addresses.

Use the diagnostics function in order to correct configuration errors.

3.1.1 Setting up the AS-Interface process data and mailbox length

Open the parameter dialog for the selected bus module. To do this, click on

the Settings command in the context menu for the module (node view or

navigation).

The size of the internal bus process image is specified with the Process Image

Length selection box. You can choose values of 12, 20, 24, 32, 40 or 48 bytes.

The size of the mailbox is specified with the Mailbox Length selection box.

You can set values of 0, 6, 10, 12 or 18 bytes.

Note:

If a mailbox length of 0 bytes is selected, it will only be possible to display

process data for digital slaves in monitor mode. Process data cannot then be

displayed or set up in control mode.

The Overlapped Mailbox selection box is used to determine whether the

mailbox data are overlapped with the AS-Interface process data (selection box

activated) or whether the AS-Interface process data are transmitted after the

mailbox data (selection box not activated).

The available combinations of options correspond to the configurations that

can be set up using the Profibus or CANopen type files.

To display the default values for this module, click on DEFAULT. The

displayed values can then be further modified.

Transfer the set values to the non-volatile memory of the module by clicking

ACCEPT and exit the dialog box by pressing CLOSE.

WAGO-I/O-SYSTEM 750

I/O Modules

Page 47

Set up and configuration with WAGO-I/O-CHECK 2 • 47 Setting up the operating mode for the AS-Interface master

3.1.2 Setting up the operating mode for the AS-Interface master

Open the process data dialog for the selected bus module. To do this, click on

the Process data command in the context menu for the module (node view or

navigation).