Page 1

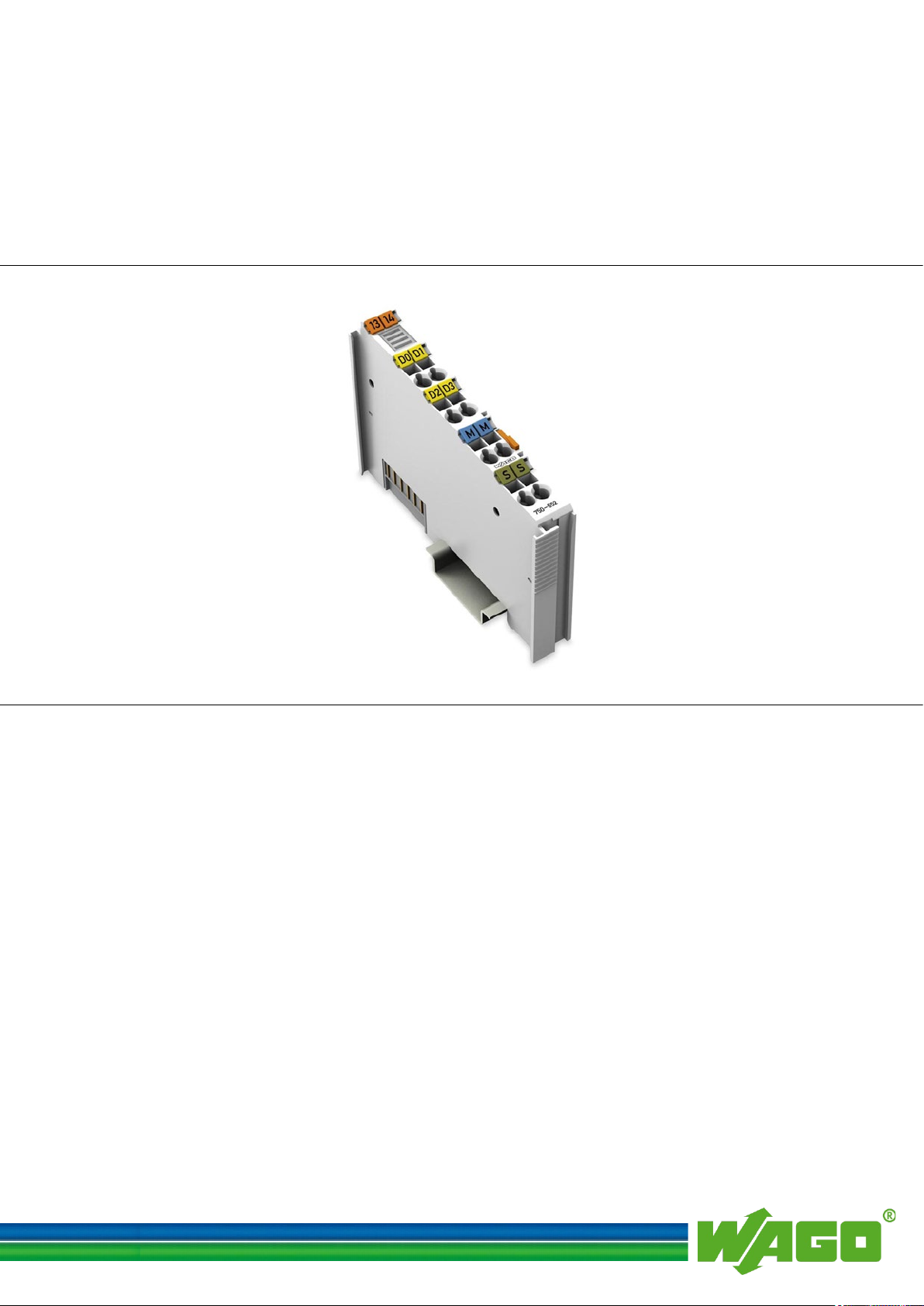

WAGO-I/O-SYSTEM 750

Manual

750-652

485

Configurable

Version 1.4.0

Serial Interface RS-232 / RS-

Page 2

2 WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

© 2015 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Manual

Version 1.4.0

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-652 Serial Interface RS-232 / RS-485

Table of Contents

1 Notes about this Documentation ................................................................. 6

1.1 Validity of this Documentation ................................................................. 6

1.2 Copyright ................................................................................................... 6

1.3 Symbols ..................................................................................................... 7

1.4 Number Notation ....................................................................................... 9

1.5 Font Conventions ...................................................................................... 9

2 Important Notes ......................................................................................... 10

2.1 Legal Bases ............................................................................................. 10

2.1.1 Subject to Changes ............................................................................. 10

2.1.2 Personnel Qualifications ..................................................................... 10

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying

Provisions ........................................................................................... 10

2.1.4 Technical Condition of Specified Devices ......................................... 11

2.2 Safety Advice (Precautions) .................................................................... 12

3 Device Description ..................................................................................... 14

3.1 View ........................................................................................................ 18

3.2 Connectors ............................................................................................... 19

3.2.1 Data Contacts/Internal Bus ................................................................. 19

3.2.2 Power Jumper Contacts/Field Supply ................................................ 20

3.2.3 CAGE CLAMP® Connectors ............................................................. 22

3.3 Display Elements .................................................................................... 23

3.4 Operating Elements ................................................................................. 24

3.5 Schematic Diagram ................................................................................. 24

3.6 Technical Data ........................................................................................ 25

3.6.1 Device Data ........................................................................................ 25

3.6.2 Supply ................................................................................................. 25

3.6.3 Communication .................................................................................. 25

3.6.4 Interface .............................................................................................. 26

3.6.5 Connection Type ................................................................................ 26

3.6.6 Climatic Environmental Conditions ................................................... 26

3.7 Approvals ................................................................................................ 27

3.8 Standards and Guidelines ........................................................................ 28

4 Process Image ............................................................................................. 29

4.1 Operating Modes for Serial Transmission .............................................. 29

4.2 Data Exchange Mode .............................................................................. 31

5 Function Description ................................................................................. 33

5.1 Operating Modes for Serial Transmission .............................................. 33

5.1.1 Transmit Data ..................................................................................... 33

5.1.1.1 Continuous Transmission .............................................................. 33

5.1.2 Receive Data ....................................................................................... 34

5.1.2.1 Continuous Receipt ........................................................................ 34

5.1.3 RS-232 Operating Mode..................................................................... 35

5.1.3.1 Flow Control Using XON-/XOFF Protocol .................................. 35

5.1.3.2 Flow Control Using RTS/CTS ....................................................... 35

5.1.3.3 Flow Control Using RTS/CTS, RTS with Lead/Follow-on Time . 35

Manual

Version 1.4.0

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

5.1.4 RS-485 Operating Mode..................................................................... 36

5.1.5 RS-422 Operating Mode..................................................................... 36

5.1.6 DMX Operating Mode ....................................................................... 36

5.2 Data Exchange Operating Mode ............................................................. 37

6 Mounting ..................................................................................................... 38

6.1 Mounting Sequence ................................................................................. 38

6.2 Inserting and Removing Devices ............................................................ 39

6.2.1 Inserting the I/O Module .................................................................... 39

6.2.2 Removing the I/O Module .................................................................. 40

7 Connect Devices ......................................................................................... 41

7.1 Connecting a Conductor to the CAGE CLAMP® ................................... 41

7.2 Connection Examples .............................................................................. 42

7.2.1 RS-232 Operating Mode..................................................................... 42

7.2.2 RS-485 Operating Mode..................................................................... 43

7.2.3 RS-422 Operating Mode..................................................................... 44

7.2.4 DMX Operating Mode ....................................................................... 45

7.2.5 Data Exchange Mode ......................................................................... 45

8 Commissioning ........................................................................................... 46

8.1 Configuration and Parameterization with WAGO-I/O-CHECK ............. 46

8.1.1 RS-232 / RS-485 Serial Interface (Configuration Dialog) ................. 46

8.1.2 Toolbar on the Configuration Dialog ................................................. 47

8.1.3 Process Image Size ............................................................................. 48

8.1.4 Parameter Range ................................................................................. 49

8.1.5 Setting the RS-232 / RS-485 Serial Interface ..................................... 50

8.2 Configuration and Parameterization via GSD for PROFIBUS DP and

PROFINET IO ........................................................................................ 51

8.3 Data Transfer ........................................................................................... 51

8.3.1 Example of Operating Modes for Serial Transmission ...................... 51

8.3.2 Initialization ........................................................................................ 52

8.3.3 Transmission of the Character String "Hello World!" ....................... 53

8.3.4 Receiving the Character String "WAGO" .......................................... 54

8.3.5 Operation with Continuous Send........................................................ 55

8.3.5.1 Transmission of a Block of One to 512 Bytes ............................... 55

8.3.5.2 Transmission of a Block of More than 512 Bytes ......................... 55

8.3.6 DMX Application Example ................................................................ 57

8.3.6.1 Operation with Deactivated Continuous Send ............................... 57

8.3.6.2 Operation with Activated Continuous Send .................................. 57

8.3.7 Data Exchange Operating Mode Application Example ..................... 58

9 Diagnostics .................................................................................................. 59

9.1 Serial Operating Modes ........................................................................... 59

9.2 Data Exchange Operating Mode ............................................................. 59

10 Use in Hazardous Environments .............................................................. 60

10.1 Marking Configuration Examples ........................................................... 61

10.1.1 Marking for Europe According to ATEX and IEC-Ex ...................... 61

10.1.2 Marking for America According to NEC 500 .................................... 66

10.2 Installation Regulations ........................................................................... 67

Manual

Version 1.4.0

Page 5

WAGO-I/O-SYSTEM 750 Table of Contents 5

750-652 Serial Interface RS-232 / RS-485

10.2.1 Special Conditions for Safe Use

(ATEX Certificate TÜV 07 ATEX 554086 X) .................................. 68

10.2.2 Special Conditions for Safe Use

(ATEX Certificate TÜV 12 ATEX 106032 X) .................................. 69

10.2.3 Special Conditions for Safe Use

(IEC-Ex Certificate TUN 09.0001 X) ................................................ 70

10.2.4 Special Conditions for Safe Use

(IEC-Ex Certificate IECEx TUN 12.0039 X) .................................... 71

10.2.5 Special Conditions for Safe Use

According to ANSI/ISA 12.12.01 ...................................................... 72

11 Appendix ..................................................................................................... 73

11.1 Configuration and Parameterization via GSD for PROFIBUS DP and

PROFINET IO ........................................................................................ 73

11.1.1 Configuration of the RS-232/RS-485 Interface .................................. 73

11.1.1.1 PROFIBUS DP (750-333, 750-343, 750-833) Fieldbus Coupler

PROFINET IO (750-370) Fieldbus Coupler ................................. 73

11.1.1.2 PROFINET IO (750-375, 750-377) Fieldbus Coupler .................. 73

11.1.2 Configuration of the RS-232/RS-485 Serial Interface ....................... 74

11.1.2.1 All PROFIBUS DP and PROFINET IO Fieldbus Couplers .......... 75

11.1.2.2 PROFIBUS DP (750-333, 750-343, 750-833) Fieldbus Coupler

PROFINET IO (750-370) Fieldbus Coupler ................................. 77

11.1.2.3 PROFINET IO (750-375, 750-377) Fieldbus Coupler .................. 77

List of Figures ...................................................................................................... 78

List of Tables ........................................................................................................ 79

Manual

Version 1.4.0

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750

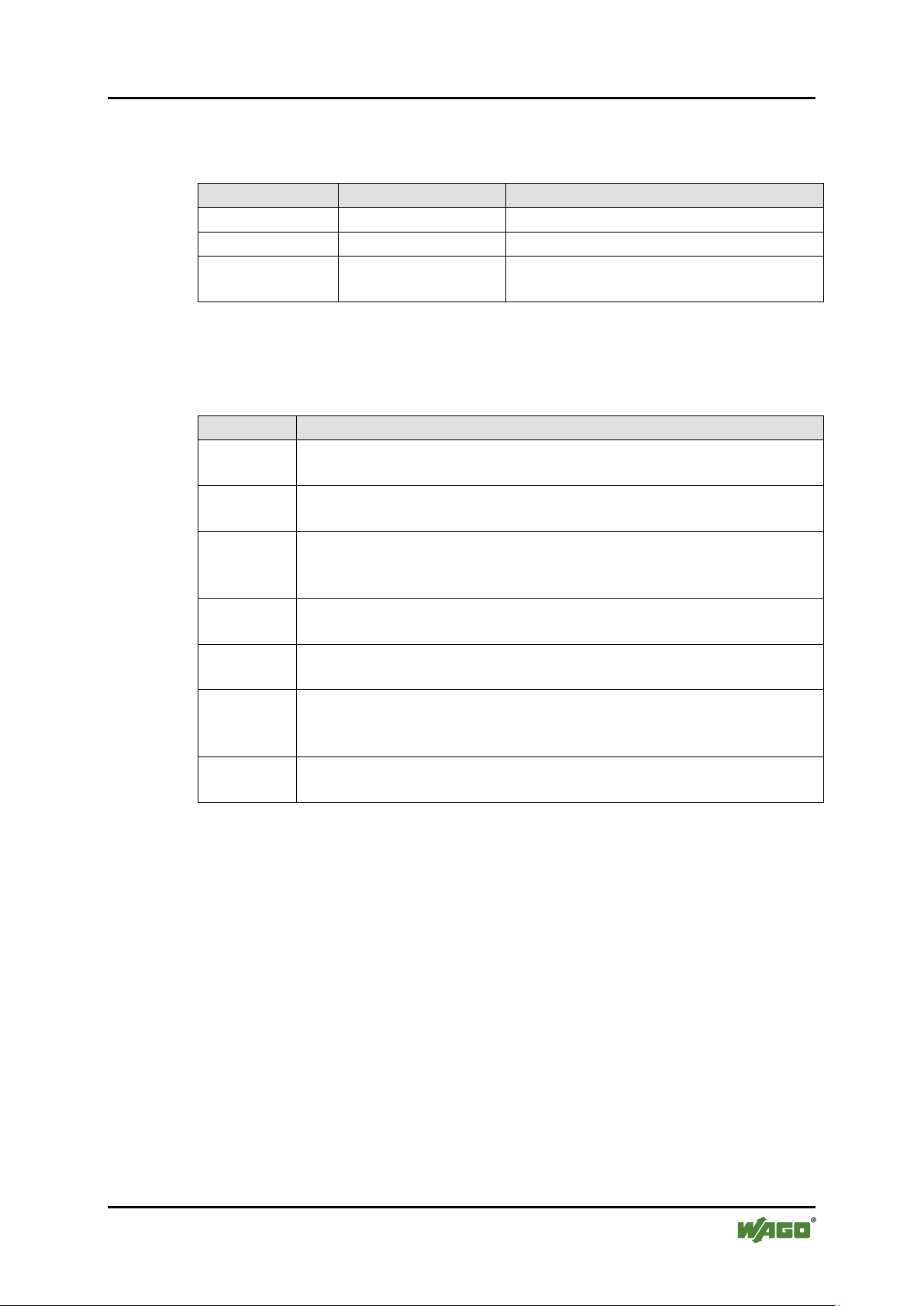

Table 1: Variants

Item Number/Variant

Designation

750-652

Serial Interface RS-232 / RS-485

750-652/025-000

Serial Interface RS-232 / RS-485/T

750-652 Serial Interface RS-232 / RS-485

1 Notes about this Documentation

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

1.1 Validity of this Documentation

This documentation is only applicable to the I/O module 750-652 (Serial Interface

RS-232 / RS-485) and the variants listed in the table below.

Documentation Validity for Variants

Unless otherwise indicated, the information given in this documentation applies to

listed variants.

The I/O module 750-652 shall only be installed and operated according to the

instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

1.2 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Manual

Version 1.4.0

Page 7

WAGO-I/O-SYSTEM 750 Notes about this Documentation 7

750-652 Serial Interface RS-232 / RS-485

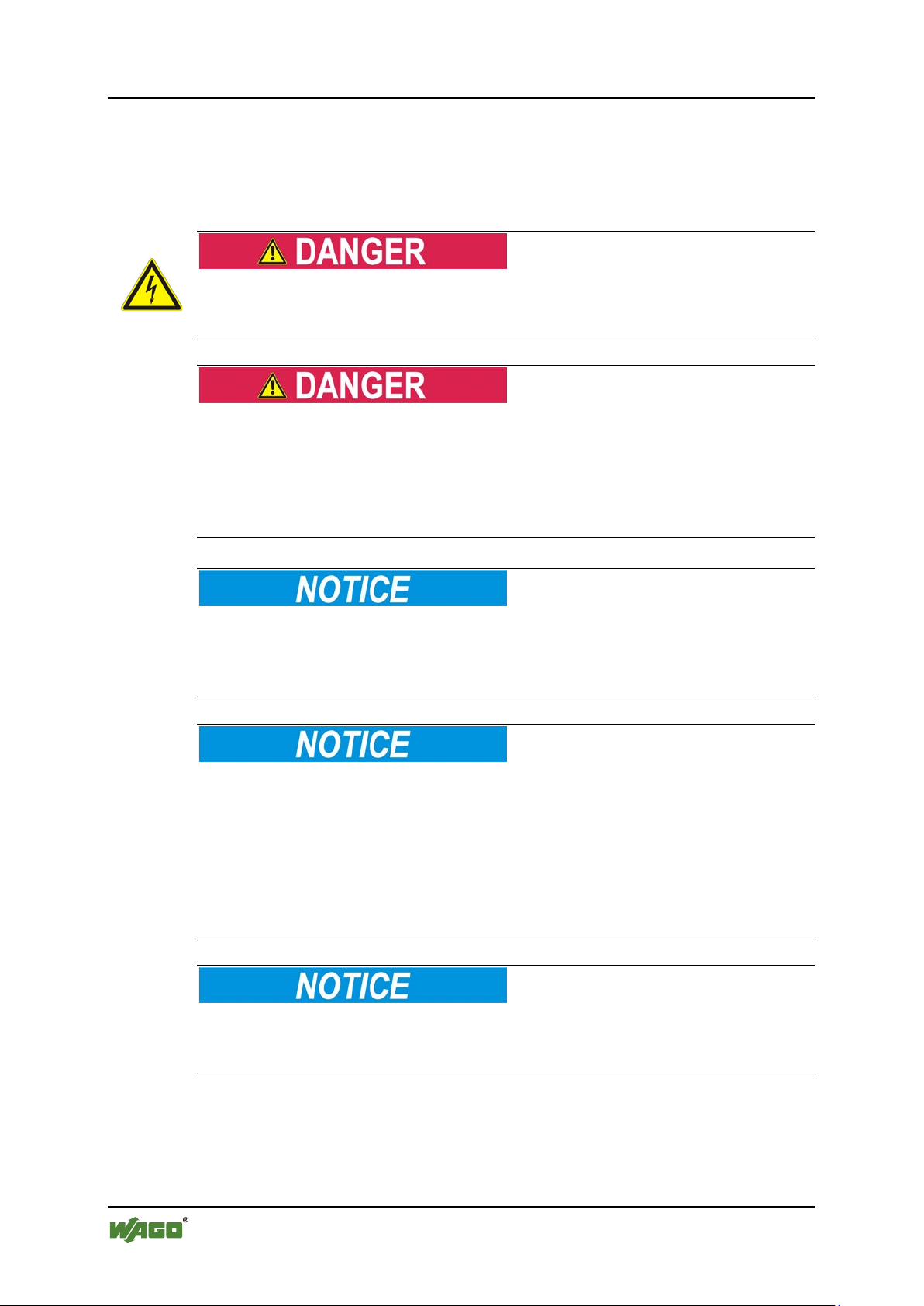

1.3 Symbols

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Manual

Version 1.4.0

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Manual

Version 1.4.0

Page 9

WAGO-I/O-SYSTEM 750 Notes about this Documentation 9

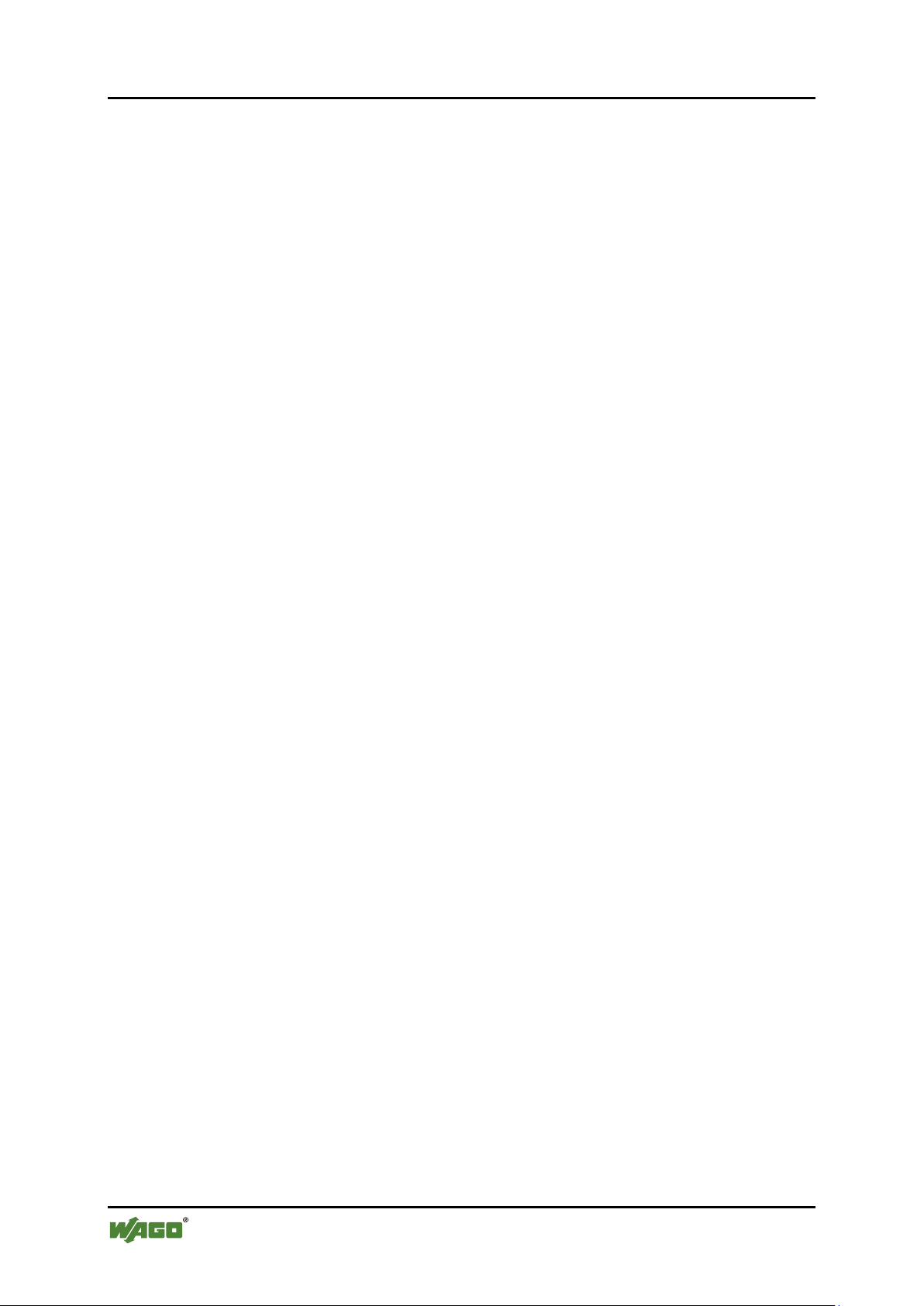

Table 2: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 3: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-652 Serial Interface RS-232 / RS-485

1.4 Number Notation

1.5 Font Conventions

menu item from a menu.

brackets.

Manual

Version 1.4.0

Page 10

10 Important Notes WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

2 Important Notes

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

2.1 Legal Bases

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 1.4.0

Page 11

WAGO-I/O-SYSTEM 750 Important Notes 11

750-652 Serial Interface RS-232 / RS-485

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Manual

Version 1.4.0

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

2.2 Safety Advice (Precautions)

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Manual

Version 1.4.0

Page 13

WAGO-I/O-SYSTEM 750 Important Notes 13

750-652 Serial Interface RS-232 / RS-485

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Manual

Version 1.4.0

Page 14

14 Device Description WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

3 Device Description

The I/O module 750-652 (Serial Interface RS-232 / RS-485) allows the optional

connection of devices with a RS-485, RS-422 or RS-232 interface.

It also provides gateways between the serial interface and the fieldbus systems

supported by the WAGO-I/O-SYSTEM 750.

No higher protocol level is required by the module. Communication to the

associated fieldbus master is completely transparent. This provides for a broader

application scope for the serial interface module. If required, communication

protocols can be configured via fieldbus master.

The 2560 byte input buffer provides for high data baud rates. At lower baud rates,

the data received in lower priority tasks is evaluated without data loss.

The 512-byte output buffer provides fast transmission of larger data strings.

The operating mode of the I/O module can be configured with the start-up tool

WAGO-I/O-CHECK 3.3 (firmware version 03 or higher requires WAGO-I/OCHECK version 3.5.3 or higher).

NOTE

The default operating mode is RS-485 half-duplex. The default data transmission

rate is 9600 baud. 1 start bit, 8 data bits and 1 stop bit are sent. There is no parity

generation and dataflow control.

Before starting operation, the connections of the I/O module must be cabled

appropriately (see section “Connect Devices” > … > “Connection Examples” ).

In RS-232 mode, the interface works in accordance with the TIA/EIA-232-F and

CCITT V.28/DIN 66259-1 standards.

In RS-485/RS-422 mode, the interface works in accordance with the TIA/EIA485-A, DIN 66259 standards.

The connected device can communicate directly with the control unit via the

fieldbus coupler/controller used.

The active communication channel works independent of the fieldbus system used

in full or half-duplex operation at up to 115200 baud.

In the data flow control through RTS/CTS in RS-232 mode, a lead time or followon time can be configured for the I/O module for the RTS signal. This function is

available with firmware version 03 or higher.

Direct data exchange between different fieldbus nodes of the 750 series is possible

in conjunction with a second I/O module. This function is available with firmware

version 03 or higher.

Manual

Version 1.4.0

Page 15

WAGO-I/O-SYSTEM 750 Device Description 15

750-652 Serial Interface RS-232 / RS-485

The I/O module can be configured as a DMX sender with a baud rate of

250 kBits/s. This function is available with firmware version 03 or higher.

The wiring to the communication partner takes place in RS-232 mode via the

TxD, RxD connections, if necessary RTS/CTS and ground and in the RS-485/

RS-422 mode via the connections A, B, X, Y, and ground.

The shield connection is fed directly to the carrier rail and contact is made

automatically by snapping the module onto the rail.

The assignment of the connections is described in the “Connectors” section.

Connection examples are shown in section “Connecting Devices” > … >

“Connection Example(s)”.

Multi-color LEDs indicate the operating status and the trouble-free internal bus

communication as well as the status of the signal transmission.

The meaning of the LEDs is described in the “Display Elements” section.

The I/O module 750-652 (Serial Interface RS-232 / RS-485) receives the 24 V

voltage supply for the field level from an upstream I/O module or from the

fieldbus coupler/controller via blade-formed power jumper contacts. It then

provides these potentials to subsequent I/O modules via spring-formed power

jumper contacts.

The field voltage and the system voltage are electrically isolated from each other.

With consideration of the power jumper contacts, the individual modules can be

arranged in any combination when configuring the fieldbus node. An arrangement

in groups within the group of potentials is not necessary.

Manual

Version 1.4.0

Page 16

16 Device Description WAGO-I/O-SYSTEM 750

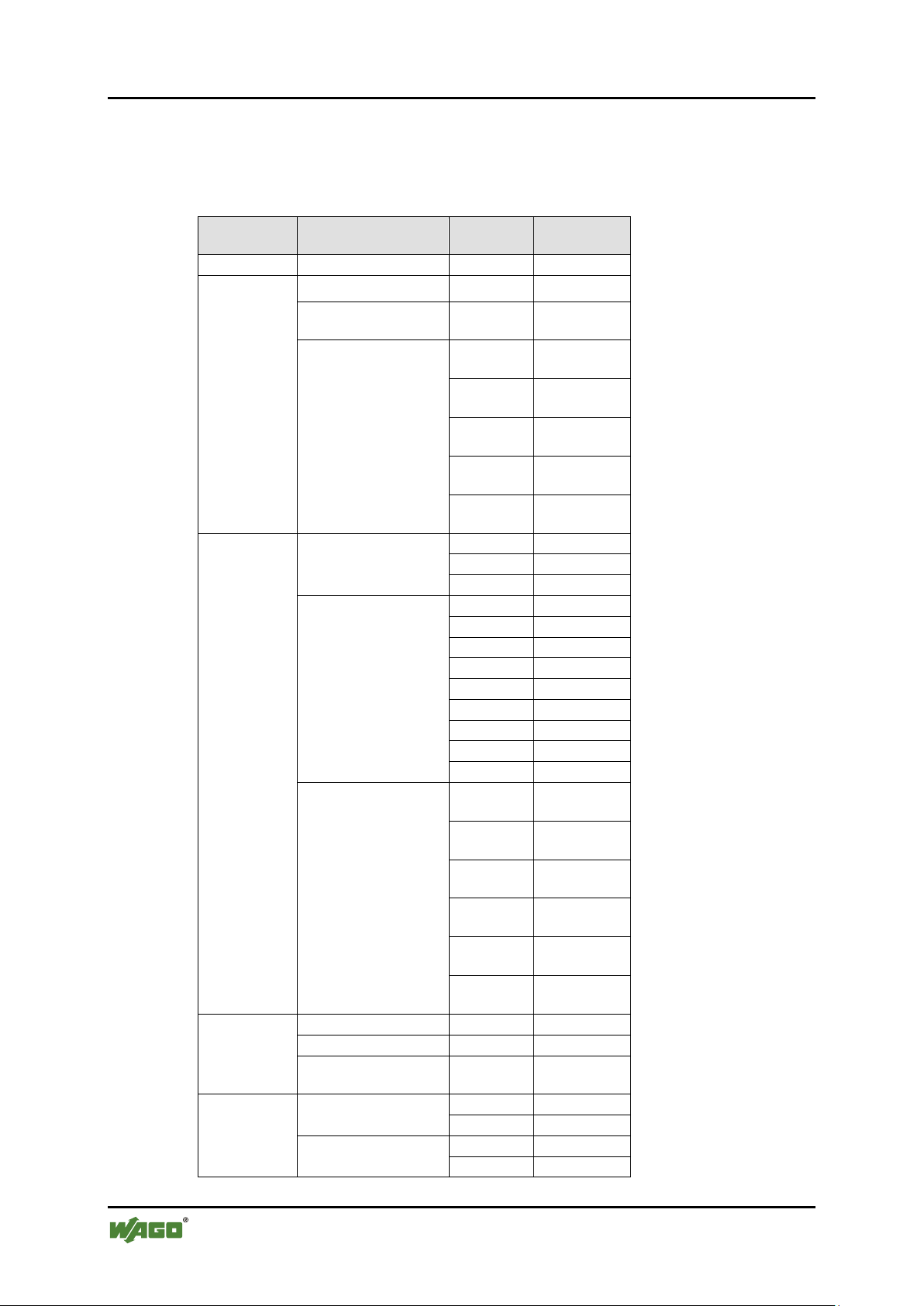

Table 4: Compatibility List 750-0652

Fieldbus

couplers/controllers

Firmware

status

PROFINET

Fieldbus couplers

750-370

02

Profibus

Fieldbus couplers

750-333

14

Programmable

fieldbus controller

750-833

14

I/O-IPC*

758-870/

000-111

05

758-870/

000-131

05

758-874/

000-111

05

758-875/

000-111

05

758-876/

000-111

05

ETHERNET

Fieldbus couplers

750-341

07

750-342

17

750-352

02

Programmable

750-841

18

750-842

18

750-843

02

750-871

07

750-872

03

750-873

03

750-880

02

750-881

02

750-882

01

I/O-IPC

758-870/

000-110

05

758-870/

000-130

05

758-874/

000-110

05

758-875/

000-110

05

758-875/

000-130

05

758-876/

000-110

05

DeviceNet

Fieldbus couplers

750-306

4K

ECO fieldbus coupler

750-346

10

Programmable

fieldbus controller

750-806

10

CANopen

Fieldbus couplers

750-337

19

750-338

19

ECO fieldbus coupler

750-347

08

750-348

08

750-652 Serial Interface RS-232 / RS-485

The 750-652 module can be used with the fieldbus couplers and controllers of the

WAGO-I/O-SYSTEM 750 of the specified version or higher listed in the

“Compatibility list” table.

Bus System

Item No.

fieldbus controller

Manual

Version 1.4.0

Page 17

WAGO-I/O-SYSTEM 750 Device Description 17

Table 4: Compatibility List 750-0652

Fieldbus

couplers/controllers

Firmware

status

Programmable

750-837

14

750-838

14

I/O-IPC*

758-870/

000-112

05

758-875/

000-112

05

KNX

Programmable

fieldbus controller

750-849

04

BACnet

Programmable

fieldbus controller

750-830

03

*

Also available via 2 ETHERNET interfaces

750-652 Serial Interface RS-232 / RS-485

Bus System

Other fieldbus couplers/controllers on request.

Item No.

fieldbus controller

Manual

Version 1.4.0

Page 18

18 Device Description WAGO-I/O-SYSTEM 750

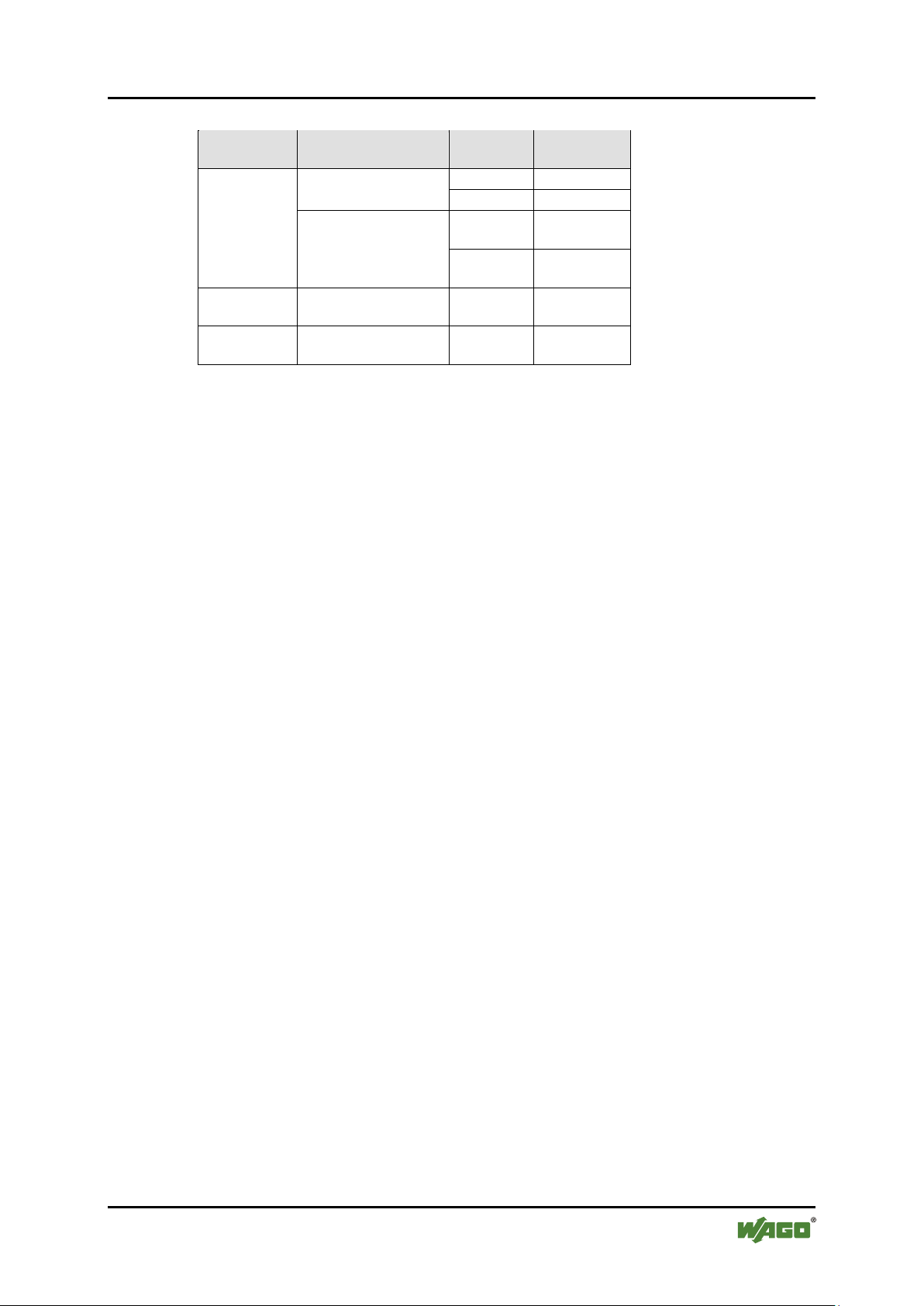

Table 5: Legend for Figure “View”

Pos.

Description

Details See Section

1

Marking possibility with MiniWSB

--2

Status LEDs

“Device Description” > “Display Elements”

3

Data contacts

“Device Description” > “Connectors”

4

CAGE CLAMP® connectors

“Device Description” > “Connectors”

5

Power jumper contacts

“Device Description” > “Connectors”

6

Release tab

“Mounting” > “Inserting and Removing

Devices”

750-652 Serial Interface RS-232 / RS-485

3.1 View

Figure 1: View

Manual

Version 1.4.0

Page 19

WAGO-I/O-SYSTEM 750 Device Description 19

750-652 Serial Interface RS-232 / RS-485

3.2 Connectors

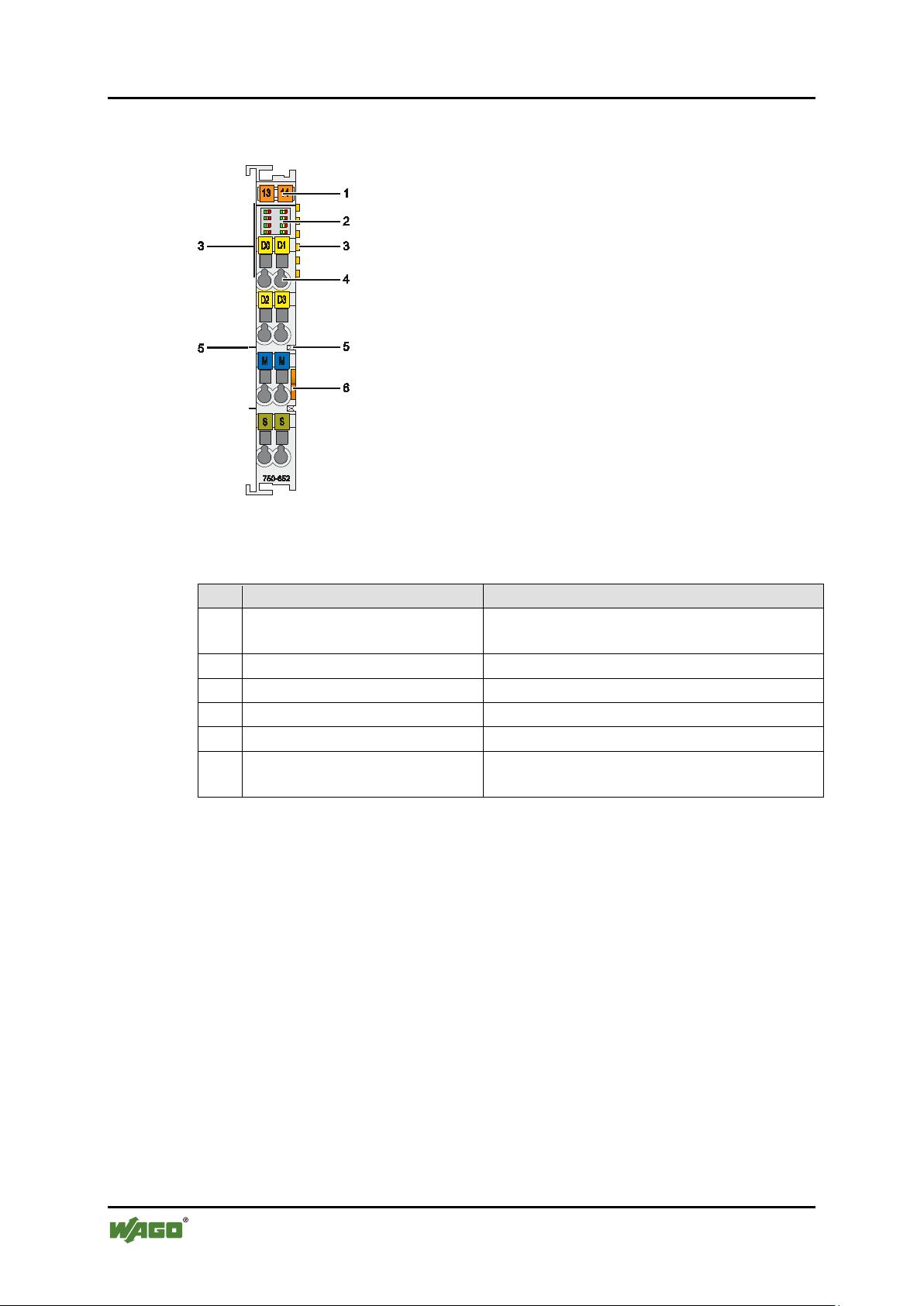

3.2.1 Data Contacts/Internal Bus

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data Contacts

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Manual

Version 1.4.0

Page 20

20 Device Description WAGO-I/O-SYSTEM 750

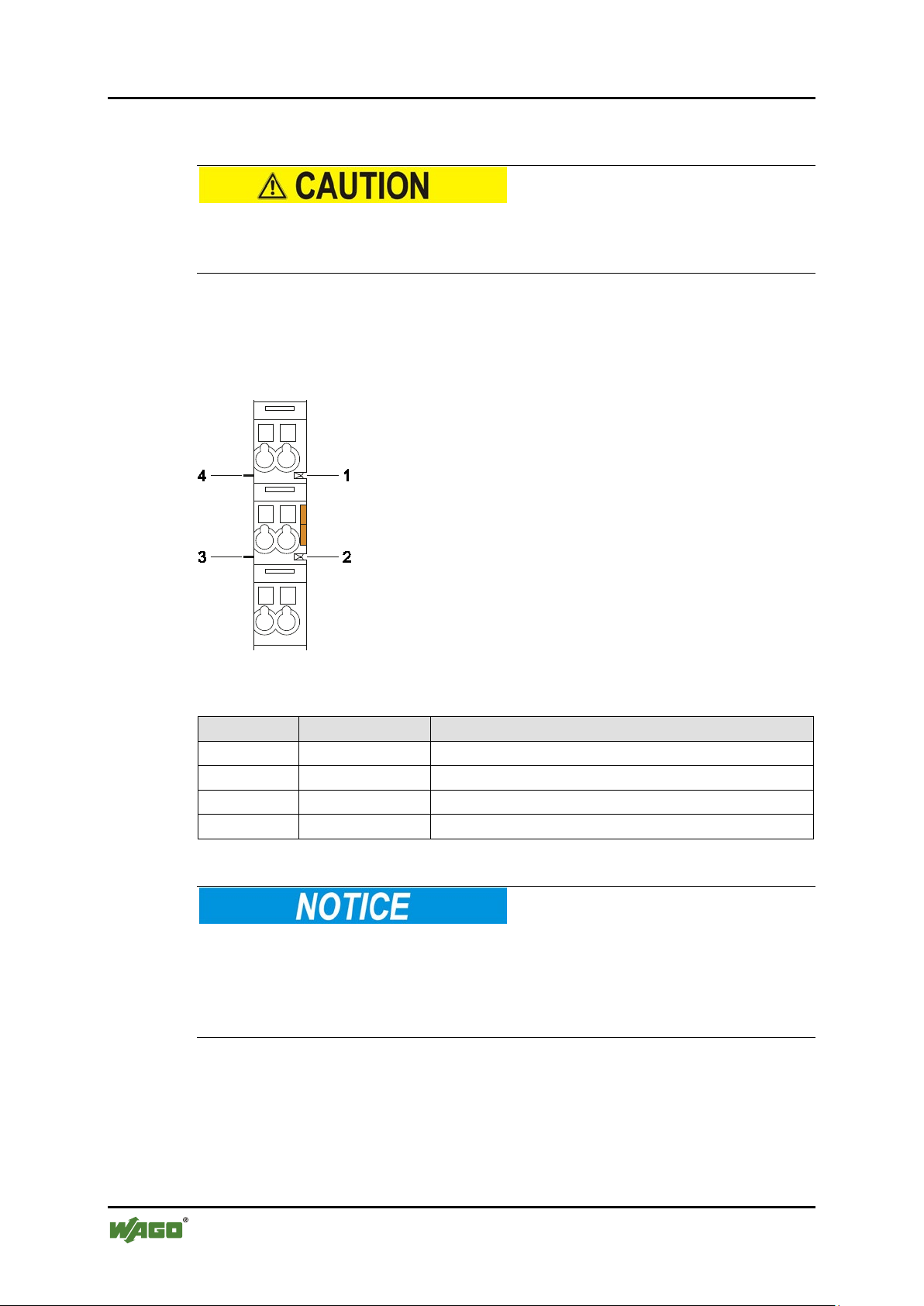

Table 6: Legend for Figure “Power Jumper Contacts”

Contact

Type

Function

1

Spring contact

Potential transmission (Uv) for field supply

2

Spring contact

Potential transmission (0 V) for field supply

3

Blade contact

Potential feed-in (0 V) for field supply

4

Blade contact

Potential feed-in (Uv) for field supply

750-652 Serial Interface RS-232 / RS-485

3.2.2 Power Jumper Contacts/Field Supply

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

The I/O module 750-652 has 2 self-cleaning power jumper contacts that supply

and transmit power for the field side. The contacts on the left side of the I/O

module are designed as blade contacts and those on the right side as spring

contacts.

Figure 3: Power Jumper Contacts

Do not exceed maximum current via power jumper contacts!

The maximum current to flow through the power jumper contacts is 10 A.

Greater currents can damage the contacts.

When configuring your system, ensure that this current is not exceeded. If

exceeded, insert an additional supply module.

Manual

Version 1.4.0

Page 21

WAGO-I/O-SYSTEM 750 Device Description 21

750-652 Serial Interface RS-232 / RS-485

Use supply modules for ground (earth)!

The I/O module has no power jumper contacts for receiving and transmitting the

earth potential. Use a supply module when an earth potential is needed for the

subsequent I/O modules.

Manual

Version 1.4.0

Page 22

22 Device Description WAGO-I/O-SYSTEM 750

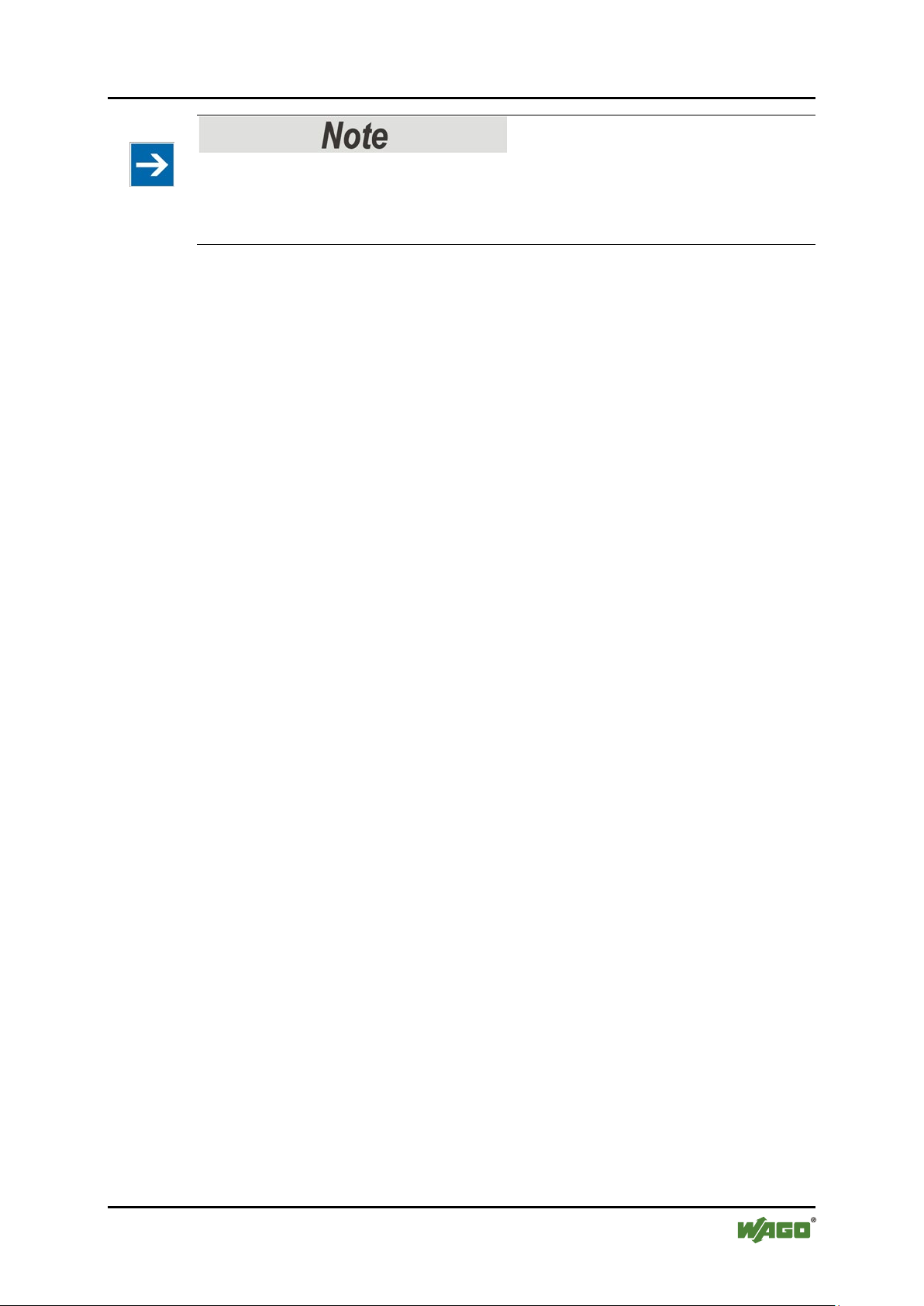

Table 7: Legend for Figure “CAGE CLAMP® Connectors”

Designation

Connector

Function

RTS (RS-232)

Z / TxD+ (RS-485/RS-422)

TxD (RS-232)

Y / TxD- (RS-485/RS-422)

CTS (RS-232)

B / RxD+ (RS-485/RS-422)

RxD (RS-232)

A / RxD- (RS-485/RS-422)

Common

(ground)

3

Common (ground)

7

Common (ground)

Shield

4

Shield (screen)

8

Shield (screen)

750-652 Serial Interface RS-232 / RS-485

3.2.3 CAGE CLAMP® Connectors

Use shielded signal lines!

Only use shielded signal lines for analog signals and I/O modules which are

equipped with shield clamps. Only then can you ensure that the accuracy and

interference immunity specified for the respective I/O module can be achieved

even in the presence of interference acting on the signal cable.

Figure 4: CAGE CLAMP

D0 1

D1 5

D2 2

D3 6

(screen)

®

Connectors

Manual

Version 1.4.0

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

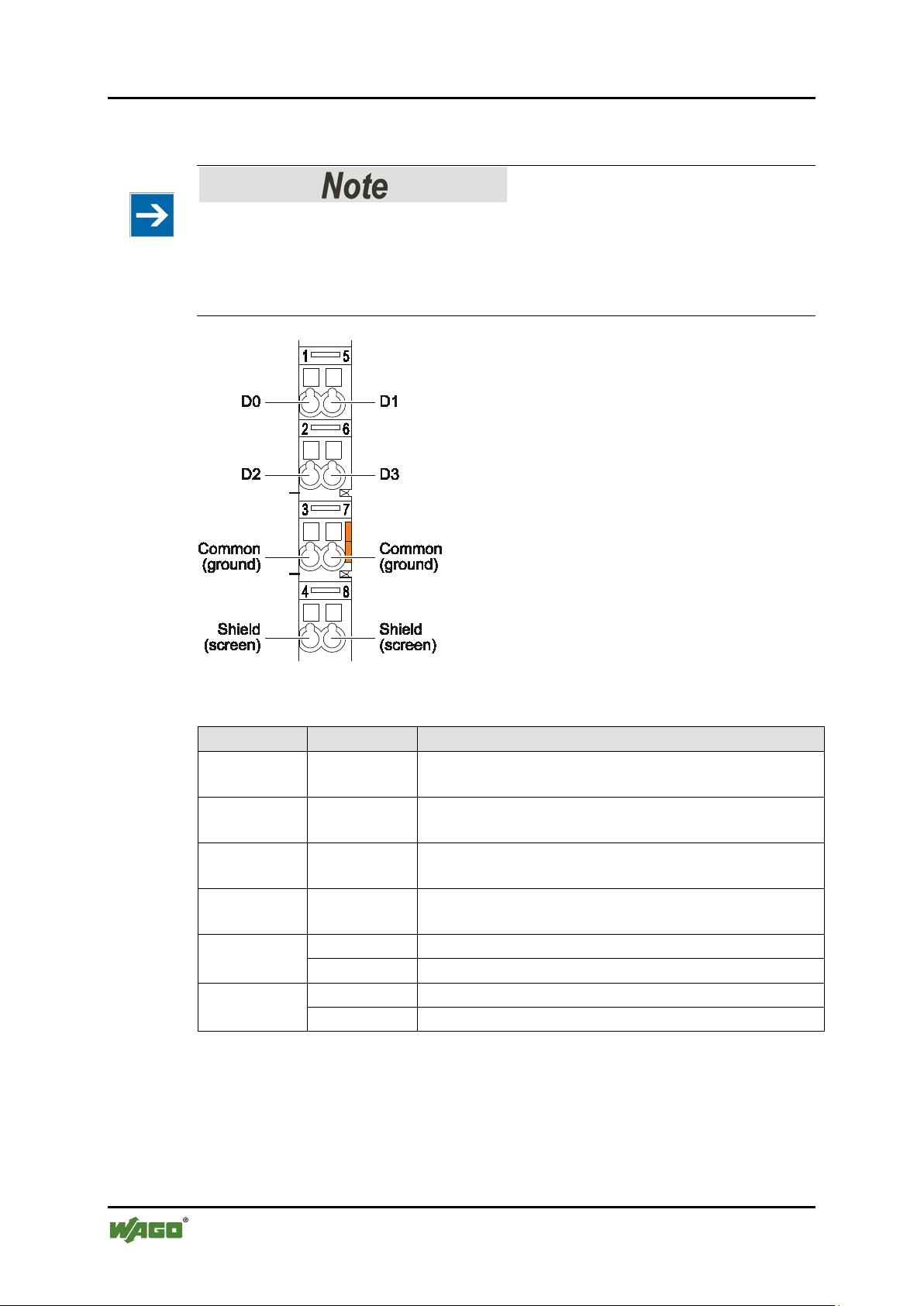

Table 8: Legend for Figure “Display Elements”

Ready for operation and undisturbed internal bus

communication

Not ready for operation or no or disturbed internal bus

communication

OFF

No signal transmission TxD

Green

Signal transmission TxD present 1)

I/O module has received XOFF character, the

CTS line has fallen, the transmission is inactive

OFF

No signal transmission RxD or input open

Green

Signal transmission RxD present 1)

Signal transmission RxD present 1), but some characters

error has occurred) 3)

OFF

No transmission error

Green

Output buffer is full

Input buffer is full (LED lights up if there are more than

buffer)

Green

RS-485 half-duplex, DMX

Yellow

RS-422 full-duplex, data exchange

Red

RS-232

OFF

No data flow control

Green

RTS/CTS data flow control active 4)

Yellow

XON/XOFF data flow control active 2)

Red

RTS with lead time and follow-on time is active 5)

OFF

Data exchange mode is OFF 5)

Yellow

Data exchange mode is initialized

Green

Data exchange mode is ON

Yellow

flashing

Data exchange mode is ON, but there is no

communication (timeout)

750-652 Serial Interface RS-232 / RS-485

3.3 Display Elements

Figure 5: Display Elements

LED Designation Status Function

Green

A Function

Red

B

C

D

TxD

(transmit)

RxD

(receive)

Transmission

status

E Mode

F Data flow control

Yellow

Red

Yellow

transmission is inactive

2)

4)

received are defective. (parity, data frame or overrun

2304 characters in the input buffer. LED does not light

up if there are fewer than 2176 characters in the input

Data exchange

G

mode

5)

Manual

Version 1.4.0

Page 24

24 Device Description WAGO-I/O-SYSTEM 750

Table 8: Legend for Figure “Display Elements”

H

OFF

DMX is OFF

Green

DMX is ON

1)

With high baud rates, the pulses are so short that the on state cannot or can hardly be detected

with the naked eye.

2)

XON/XOFF data flow control active

3)

Defective characters are not transmitted by the I/O module to the fieldbus coupler/controller.

4)

RTS/CTS data flow control active

5)

Firmware version 03 or higher

750-652 Serial Interface RS-232 / RS-485

LED Designation Status Function

DMX 5)

3.4 Operating Elements

The I/O module 750-652 has no operating elements.

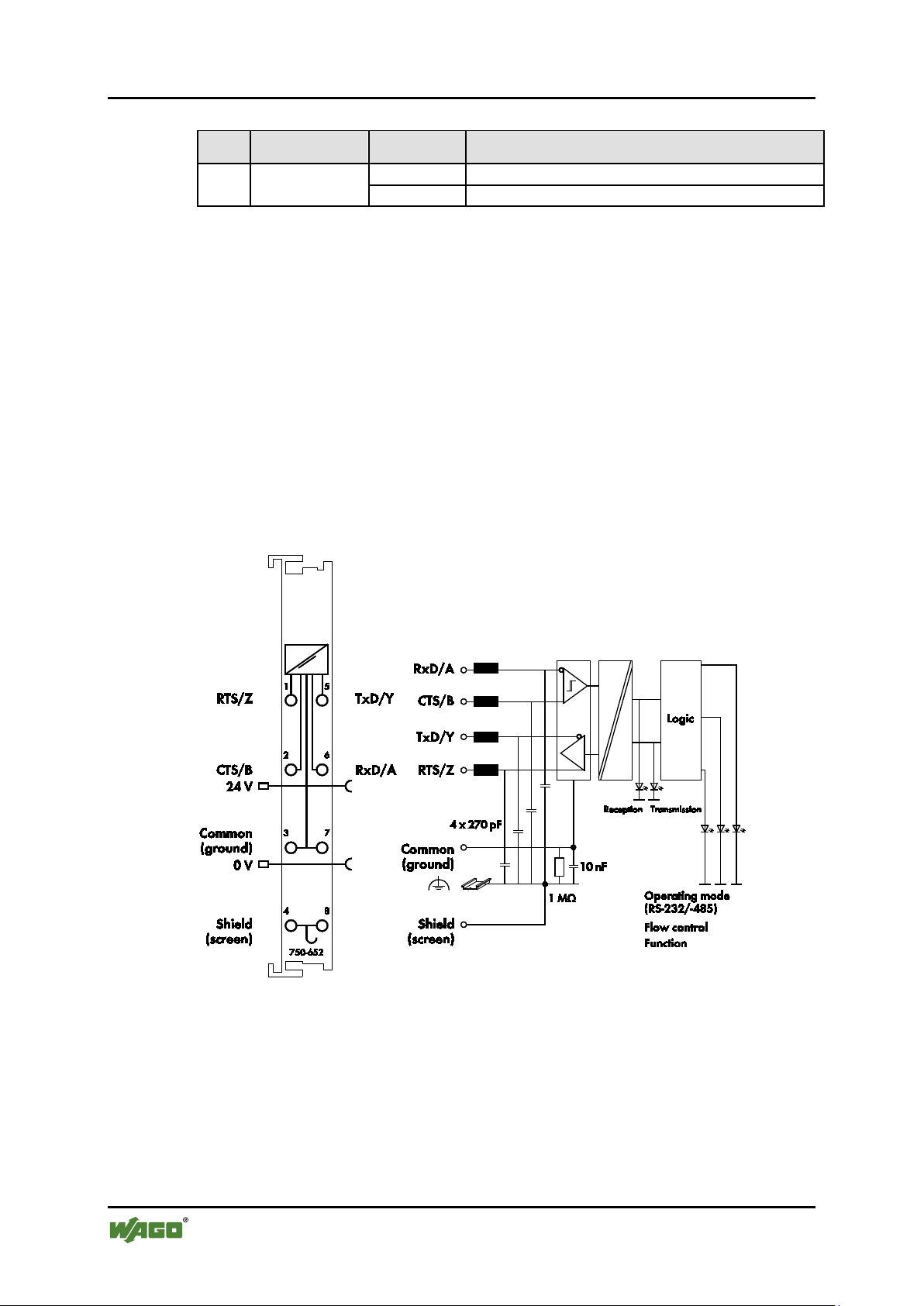

3.5 Schematic Diagram

Figure 6: Schematic Diagram

Manual

Version 1.4.0

Page 25

WAGO-I/O-SYSTEM 750 Device Description 25

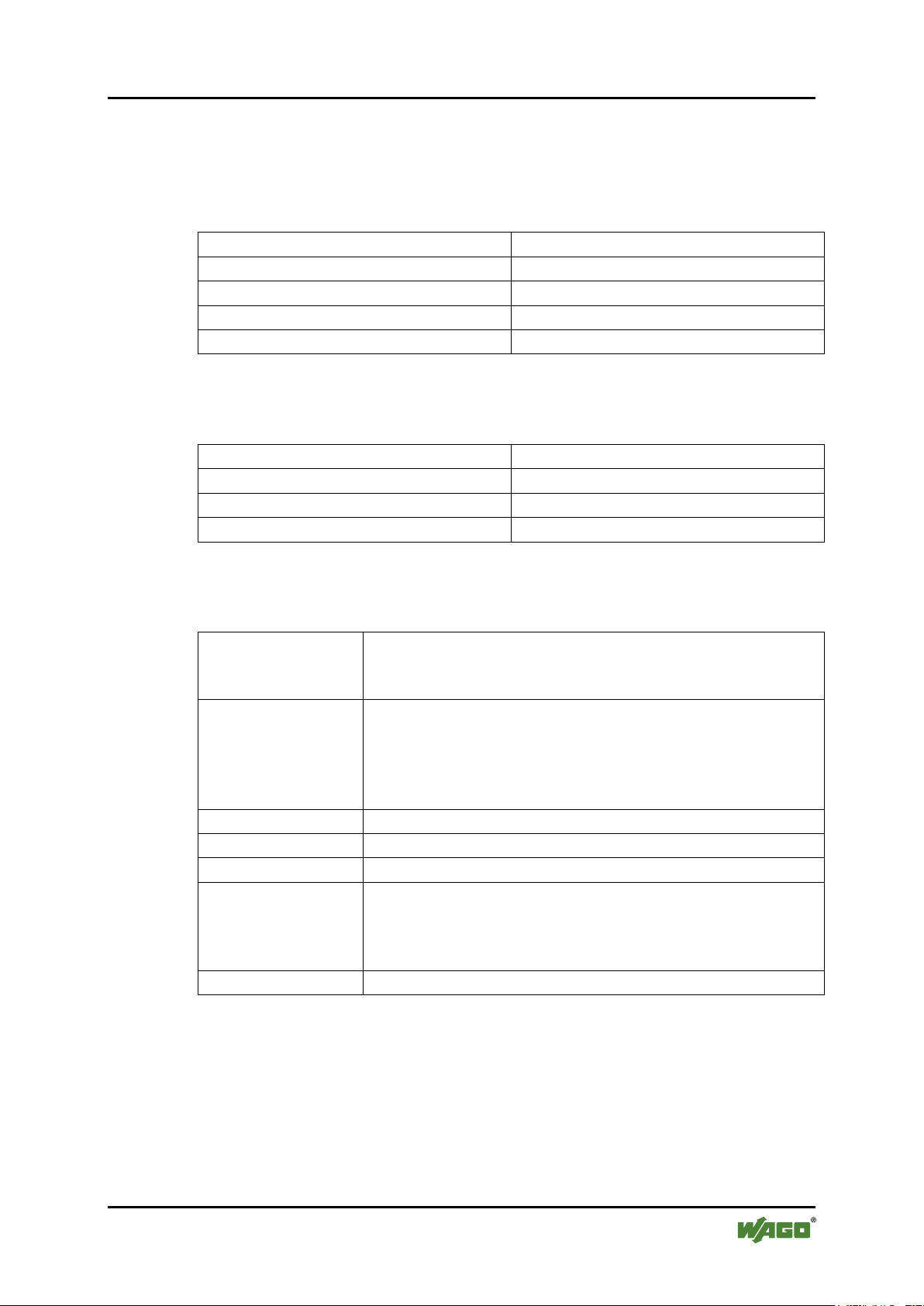

Table 9: Technical Data ‒ Device Data

Width

12 mm

Height (from upper edge of DIN 35 rail)

64 mm

Length

100 mm

Weight

approx. 50 g

Degree of protection

IP20

Table 10: Technical Data ‒ Supply

Power supply

via system voltage internal bus (5 VDC)

Current consumption (internal)

max. 85 mA

Current via power jumper contacts

max.

10 A

Isolation (peak value)

500 V system/supply

Table 11: Technical Data ‒ Communication

Transmission

1 TxD/1 RxD, full-duplex, half-duplex,

1 or 2 stop bits

Mode

• RS-232

• DMX half-duplex/250k1)

Data flow control

RTS/CTS

2)

depending on mode, XON/XOFF3)

Baud rate

300 ... 115200 baud

Data width, internal

8, 24*) or 48 bytes (configurable)

Line length

RS-485/RS-422: max. approx. 1000 m

4)

DMX: max. 100 m twisted pair cable

Buffer

2560 bytes for receive / 512 bytes for send5)

*)

Default setting

1)

Possible with firmware version 03 or higher

2)

Activation of flow control RTS/CTS is only possible for RS-232 mode

Flow control RTS/CTS with lead/follow-on time possible with firmware version 03 or higher

3)

Activation of flow control XON/XOFF is only possible for the RS-232 and RS-422 full-duplex

mode

4)

Depending on baud rate, bus system and cable type (use of a twisted-pair cable is recommended)

5)

RS-232, RS-485 half-duplex, RS-422 full-duplex modes

750-652 Serial Interface RS-232 / RS-485

3.6 Technical Data

3.6.1 Device Data

3.6.2 Supply

3.6.3 Communication

channels

(configurable)

7 or 8 bit data,

• RS-485 half-duplex

*)

• RS-422 full-duplex

• Data exchange RS-422

1)

RS-232: max. 40 m

Data exchange mode/

Manual

Version 1.4.0

Page 26

26 Device Description WAGO-I/O-SYSTEM 750

Table 12: Technical Data ‒ Interface

Number of interfaces

1

Input resistance of the receiver

24 kΩ (1/2 Unit Load)

(true fail-safe)

Isolation

500 V system/supply

Table 13: Technical Data – Field Wiring

Wire connection

CAGE CLAMP®

Cross section

0.08 mm² … 2.5 mm², AWG 28 … 14

Stripped lengths

8 mm … 9 mm / 0.33 in

Table 14: Technical Data – Power Jumper Contacts

Power jumper contacts

Blade/spring contact, self-cleaning

Voltage drop at I

max.

< 1 V/64 modules

Table 15: Technical Data – Data Contacts

Data contacts

Slide contact, hard gold plated, selfcleaning

Table 16: Technical Data – Climatic Environmental Conditions

Operating temperature range

0 °C … 55 °C

Operating temperature range for

temperature range (750-xxx/025-xxx)

−20 °C … +60 °C

Storage temperature range

−25 °C … +85 °C

Storage temperature range for

temperature range (750-xxx/025-xxx)

−40 °C … +85 °C

Relative humidity

Max. 5 % … 95 % without condensation

Resistance to harmful substances

Acc. to IEC 60068-2-42 and

IEC 60068-2-43

Maximum pollutant concentration at

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

Ensure that additional measures for

– ionizing radiation

750-652 Serial Interface RS-232 / RS-485

3.6.4 Interface

RS-485/RS-422

Defined receiver state with shortcircuited or isolated inputs

3.6.5 Connection Type

3.6.6 Climatic Environmental Conditions

components with extended

components with extended

relative humidity < 75 %

Manual

Version 1.4.0

components are taken, which are used in

an environment involving:

– dust, caustic vapors or gases

Page 27

WAGO-I/O-SYSTEM 750 Device Description 27

Conformity Marking

TÜV 07 ATEX 554086 X

I M2 Ex d I Mb

II 3 D Ex tc IIIC T135°C Dc

IECEx TUN 09.0001 X

Ex d I Mb

Ex tc IIIC T135°C Dc

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

750-652 Serial Interface RS-232 / RS-485

3.7 Approvals

The following approvals have been granted to the basic version and all variants of

750-652 I/O modules:

CULUS

UL508

Korea Certification MSIP-REM-W43-SIM750

The following Ex approvals have been granted to the basic version and all

variants of 750-652 I/O modules:

II 3 G Ex nA IIC T4 Gc

Ex nA IIC T4 Gc

The following ship approvals have been granted to 750-652 I/O modules:

ABS (American Bureau of Shipping)

Federal Maritime and Hydrographic Agency

BV (Bureau Veritas)

DNV (Det Norske Veritas) Class B

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1)

KR (Korean Register of Shipping)

Manual

Version 1.4.0

Page 28

28 Device Description WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

LR (Lloyd’s Register) Env. 1, 2, 3, 4

NKK (Nippon Kaiji Kyokai)

RINA (Registro Italiano Navale)

The following ship approvals have been granted to 750-652/025-000 I/O module

variations:

Federal Maritime and Hydrographic Agency

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1)

3.8 Standards and Guidelines

All variations of 750-652 I/O modules meet the following requirements on

emission and immunity of interference:

EMC CE-Immunity to interference acc. to EN 61131-2

EMC CE-Immunity to interference acc. to EN 61000-6-2

EMC CE-Emission of interference acc. to EN 61000-6-3

EMC marine applications-Emission

of interference acc. to Germanischer Lloyd

EMC marine applications-Immunity

to interference acc. to Germanischer Lloyd

Manual

Version 1.4.0

Page 29

WAGO-I/O-SYSTEM 750 Process Image 29

Table 17: Process Data for Serial Transmission

Process

Length

Input Data

Output Data

8 bytes

S0

Status byte 0

C0

Control byte 0

S1

Status byte 1

C1

Control byte 1

D0

Data byte 0

D0

Data byte 0

D1

Data byte 1

D1

Data byte 1

D2

Data byte 2

D2

Data byte 2

… … D5

Data byte 5

D5

Data byte 5

24 bytes

D6

Data byte 6

D6

Data byte 6

… … D21

Data byte 21

D21

Data byte 21

48 bytes

D22

Data byte 22

D22

Data byte 22

… … D45

Data byte 45

D45

Data byte 45

750-652 Serial Interface RS-232 / RS-485

4 Process Image

Mapping of process data in the process image of fieldbus systems

The representation of the I/O modules’ process data in the process image depends

on the fieldbus coupler/controller used. Please take this information as well as the

particular design of the respective control/status bytes from the section “Fieldbus

Specific Design of the Process Data” included in the description concerning the

process image of the fieldbus coupler/controller used.

4.1 Operating Modes for Serial Transmission

The data to be sent and received will be stored in up to 46 input and output bytes

(D0 ... D45). Data flow is controlled with control and status bytes C0 and S0 or

C1 and S1. The input bytes form the memory area for up to 46 characters, which

were received by the interface. The characters to be transmitted are sent via the

output bytes.

Image

The structure of the control and status bytes is described in the tables below.

Manual

Version 1.4.0

Page 30

30 Process Image WAGO-I/O-SYSTEM 750

Table 18: Control Byte C0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

RC

OL2

OL1

OL0

SC

IR

RA

TR

TR

Transmit request

RA

Receive acknowledge

IR

Initialization request

SC

Send continuous (of data from the FIFO)

OL 0

Output length (number of characters to be sent that were stored in the output

data, bit 0)

OL1

Output length (number of characters to be sent that were stored in the output

data, bit 1)

OL2

Output length (number of characters to be sent that were stored in the output

data, bit 2)

RC

Reserved for internal communication

Table 19: Status Byte S0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

RC

BUF_F

IL2

IL1

IL0

IA

RR

TA

TA

Transmit acknowledge

RR

Receive request

IA

Initialization acknowledge

IL0

Input length (number of characters received that are available in the input data,

bit 0)

IL1

Input length (number of characters received that are available in the input data,

bit 1)

IL2

Input length (number of characters received that are available in the input data,

bit 2)

BUF_F

Buffer full (message: input buffer is full)

RC

Reserved for internal communication

Table 20: Control Byte C1

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

0 0 0

OL5

OL4

OL3

OL3

Output length (number of characters to be sent that were stored in the output

data, bit 3)

OL4

Output length (number of characters to be sent that were stored in the output

data, bit 4)

OL5

Output length (number of characters to be sent that were stored in the output

data, bit 5)

0

This constant must be set to 0.

750-652 Serial Interface RS-232 / RS-485

Manual

Version 1.4.0

Page 31

WAGO-I/O-SYSTEM 750 Process Image 31

Table 21: Status Byte S1

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

EOV

EFR

EPR

CTS

BUF_E

IL5

IL4

IL3

IL3

Input length (number of characters received that are available in the input data,

bit 3)

IL4

Input length (number of characters received that are available in the input data,

bit 4)

IL5

Input length (number of characters received that are available in the input data,

bit 5)

BUF_E

Buffer empty (message: transmit inactive)

CTS

This value is always 01).

EPR

Error parity (message: error during the parity check)

EFR

Error framing (message: data frame is defective)

EOV

Error overrun (message: a character was lost during receipt)

1)

Only applies to flow control "RTS with lead/follow-on time":

Bit 4 is 1: CTS inactive

Table 22: Process Data in Data Exchange Mode

Process

Length

Input Data

Output Data

8 bytes

S0

Status byte 0

C0

Control byte 0

D0

Data byte 0

D0

Data byte 0

D1

Data byte 1

D1

Data byte 1

D2

Data byte 2

D2

Data byte 2

… … D6

Data byte 6

D6

Data byte 6

24 bytes

D7

Data byte 7

D7

Data byte 7

… … D22

Data byte 22

D22

Data byte 22

48 bytes

D23

Data byte 23

D23

Data byte 23

… … D46

Data byte 46

D46

Data byte 46

750-652 Serial Interface RS-232 / RS-485

Status of the CTS input:

Bit 4 is 0: CTS active

For evaluation of the bits of the status byte that signal errors, see chapter

"Diagnostics".

4.2 Data Exchange Mode

The data to be sent and received will be stored in up to 47 input and output bytes

(D0 ... D46). Data flow is controlled with control and status bytes C0 and S0.

Image

The structure of the control and status bytes is described in the tables below.

Manual

Version 1.4.0

Page 32

32 Process Image WAGO-I/O-SYSTEM 750

Table 23: Control Byte C0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

RC X X X X

IR X X

IR

Initialization/reset (If the bit is set, the module is in the reset state.

Communication is started only after resetting the bit).

RC

Reserved for internal communication

X

Not used

Table 24: Status Byte S0

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

RC X X

X

RCVT

CHK

0

LGT

LGT

The length of the telegram last received does not match the PI size.

CHK

Wrong checksum received.

RCVT

No error-free transmission of the opposite side was received for >= 200 ms

communication partner, the RCVT bit is reset.

X

Not used

0

This value is always 0.

RC

Reserved for internal communication

750-652 Serial Interface RS-232 / RS-485

(timeout).

After the timeout has elapsed, an attempt is made to reestablish communication

between the I/O modules. If a valid telegram is received from the

For evaluation of the bits of the status byte, see chapter "Diagnostics".

Manual

Version 1.4.0

Page 33

WAGO-I/O-SYSTEM 750 Function Description 33

750-652 Serial Interface RS-232 / RS-485

5 Function Description

5.1 Operating Modes for Serial Transmission

In den

In the operating modes for serial transmission, the I/O module allows

communication with serial devices via RS-232, RS-485, RS-422 or DMX.

The I/O module operates in these modes as a link between one of these

standardized interfaces to the one side and the application or controller to the

other side.

Data transmission between the I/O module and serial devices is determined by the

respective interface parameters, e.g. baud rate.

Data transmission between the application and I/O module is controlled by the

control and status bytes.

5.1.1 Transmit Data

If data is transmitted via the I/O module to an RS-232, RS-485, RS-422 interface

or in DMX mode, the application writes to the data bytes of the process image

(output) per each part of the data. The application modifies the control bytes, so

that they signal to the I/O module that new data has arrived. The I/O module

receives the data sent to the output buffer and modifies the status bytes. Based on

these modified status bytes, the application can again recognize that the data

transfer was successful. Only when this feedback is present can the application

transmit the next part of the data.

The data transmission rates between the application and I/O module and between

the I/O module and serial interface are normally not identical.

If data transmission between the application and I/O module is faster than

between the I/O module and serial interface, the output buffer in the I/O module

fills up faster than it clears. If the application transmits continuously, the output

buffer queue even rises when data is continuously transmitted on the serial

interface. If the output buffer is full, the application has to wait for space to be

available in the output buffer by transmitting to the serial interface.

If data transmission between application and I/O module is slower than between

I/O module and serial interface, the output buffer in the I/O module fills up faster

than it clears. Transmission of data on the serial interface is repeatedly interrupted

even if the application continuously transmits.

5.1.1.1 Continuous Transmission

The I/O module can be set either to transmit data in the output buffer to the serial

interface immediately or to start the transmission process only after released by

the application. The latter is useful when data has to be transmitted on the serial

Manual

Version 1.4.0

Page 34

34 Function Description WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

interface according to time criteria, but data transmission between the application

and I/O module is slower than between the I/O module and serial interface.

If continuous transmission is activated, the I/O module evaluates the bit SC in

control byte 0. Only when SC takes the value 1 does the I/O module transmit the

data contained in the output buffer to the serial interface. The application can set

SC to 0 to prompt the I/O module to accumulate data in the output buffer.

5.1.2 Receive Data

If the I/O module receives data via an RS-232, RS-485 or RS-422 interface, the

data is written to the input buffer of the I/O module. The I/O module transfers data

to the application consecutively long as there is data in the input buffer. The I/O

module writes the respective part of the data to the data bytes of the process

image. The I/O module modifies the status bytes. Based on these modified status

bytes, the application can recognize that new data has been received, which it can

then evaluate. The application modifies the control bytes, so that they signal to the

I/O module that the data transfer was successful. Only when this feedback is

present can the I/O module transmit the next part of the data received.

5.1.2.1 Continuous Receipt

If there is data in the input buffer, the I/O module can be set either to begin

transmitting data to the application immediately or to wait to receive additional

data.

If the I/O module begins to transmit data to the application immediately, only part

of a contiguous message may have been received by that point. Whether a

message has been transmitted on the serial interface according to time criteria is

then no longer evident for the application.

Example: A serial device transmits 20 bytes. After the I/O module has received

1 byte, it begins to transmit the date to the application. The I/O module transmits

the remaining 19 bytes received in the meantime only after the application has

confirmed receipt of the first byte.

If continuous receipt is activated, the I/O module begins transmitting data to the

application only if no additional data has been received on the serial interface for

a specific period of time. In the example above, the I/O module would only start

transmitting data to the application when all 20 bytes have been received.

The time period after which the I/O module starts data transmission can be

defined using the "Continuous Receive Timeout" parameter. Because the duration

of the transfer of any amount of data depends on the baud rate setting, number of

data and stop bits and the parity, an absolute time specification is not feasible.

Therefore, the time required to transmit exactly one character to the serial

interface in the current interface parameter setting is used as the unit of

measurement.

Manual

Version 1.4.0

Page 35

WAGO-I/O-SYSTEM 750 Function Description 35

750-652 Serial Interface RS-232 / RS-485

5.1.3 RS-232 Operating Mode

The RS-232 operating mode in full-duplex is realized in a 2-wire or 4-wire pointto-point connection. Simultaneous transmission and receiving is possible.

In this mode, the I/O module supports flow control for the serial interface. The I/O

module can be set, so that flow control occurs using of one of the following

methods:

• XON-/XOFF protocol

• RTS/CTS

• RTS/CTS, RTS with lead / follow-on time (firmware version 03 or higher)

5.1.3.1 Flow Control Using XON-/XOFF Protocol

If flow control is activated using XON-/XOFF protocol, the I/O modules stops

transmitting data to the serial interface when it receives the XOFF character

(DC3==0x13) from the serial device. The I/O module continues transmitting data

when it receives the XON character (DC1==0x11). When data is received, the I/O

module monitors input buffer usage. It transmits the XOFF control character to

the serial device when the number of characters in the input buffer exceeds 2304.

If the number of characters in the input buffer is below 2176, it transmits XON.

5.1.3.2 Flow Control Using RTS/CTS

If flow control is activated using RTS/CTS, the I/O module stops transmitting

data to the serial interface when CTS is set. The I/O module continues

transmitting data when CTS is reset. When data is received, the I/O module

monitors input buffer usage. It sets RTS when the number of characters in the

input buffer exceeds 2304. If the number of characters in the input buffer is below

2176, the I/O module resets RTS.

5.1.3.3 Flow Control Using RTS/CTS, RTS with Lead/Follow-on Time

With firmware version 03 or higher, the I/O module allows RTS/CTS for

communication with serial devices that only support a half-duplex connection.

This is important, for example, for communication with some telecontrol

modems.

If this type of flow control is activated, the I/O module sets RTS while it transmits

data to the serial interface. This allows the serial device to switch between receive

and transmit depending on RTS. Depending on the technology of the serial

device, the switch can take some time. Therefore, the I/O module can be

configured to set RTS already some time before transmission of the first character

(RTS lead time) or RTS resets only some time after transmission of the last

character (RTS follow-on time).

The RTS lead time and RTS follow-on time can be configured independent of

each other within the valid rage of 0 to 1000 ms.

If RTS is activated with lead time, the current state of the CTS input is

represented by the CTS bit changing in status byte 1.

Manual

Version 1.4.0

Page 36

36 Function Description WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

5.1.4 RS-485 Operating Mode

The RS-485 operating mode in half-duplex is realized in a 2-wire multi-endpoint

(bus) connection. Simultaneous transmission and receiving is not possible with

2-wire connections. The I/O module switches to receive mode after transmitting

the content of the input buffer to the serial interface completely.

The the "RS-485 switching time" parameter can be used to configure the time

frame when the I/O module should switch after transmitting the last character can

be configured.

Possible settings are:

• 100 µs (default setting)

• Duration of the transfer of two characters with the current configuration

• Duration of the transfer of four characters at the current configuration

5.1.5 RS-422 Operating Mode

The RS-422 operating mode in full-duplex is realized in a 4-wire point-to-point

connection. Simultaneous transmission and receiving is thus possible.

In this mode, the I/O module supports flow control for the serial interface using

the XON/XOFF protocol (see chapter "Flow Control Using XON-/XOFF

Protocol").

5.1.6 DMX Operating Mode

The DMX operating mode is also available with firmware version 03 or higher.

In this mode, the I/O module functions as a DMX sender and allows up to 31

nodes to be connected.

The transmission channel is based on RS-485 physics with a transmission rate of

250 kBaud, as well as 1 start and 2 stop bits. In this mode, no further settings are

possible.

The structure of the transmitted telegram corresponds to the DMX 512/1990 (DIN

96530-2) specification.

The I/O module can transmit up to 255 bytes of data in this mode. Every

transmission of a DMX telegram begins with the transmission of the DMX start

byte. DMX channels 1 to 254 can be operated.

The possible refresh rate of DMX data depends on the number of channels

operated. By limiting the maximum channel number to 5, 21 or 45 (at a set

process image size of the I/O module of 8, 24 or 48 bytes), refresh rates of up to

200, 125 or 80 Hz are possible (see chapter "DMX Application Example").

Manual

Version 1.4.0

Page 37

WAGO-I/O-SYSTEM 750 Function Description 37

750-652 Serial Interface RS-232 / RS-485

5.2 Data Exchange Operating Mode

The Data Exchange operating mode is also available with firmware version 03 or

higher.

In this mode, the I/O module allows cyclic data exchange with another 750-652

I/O module configured in the same operating mode. Process data between

different fieldbus nodes can also be exchanged when integrated in different

fieldbus systems.

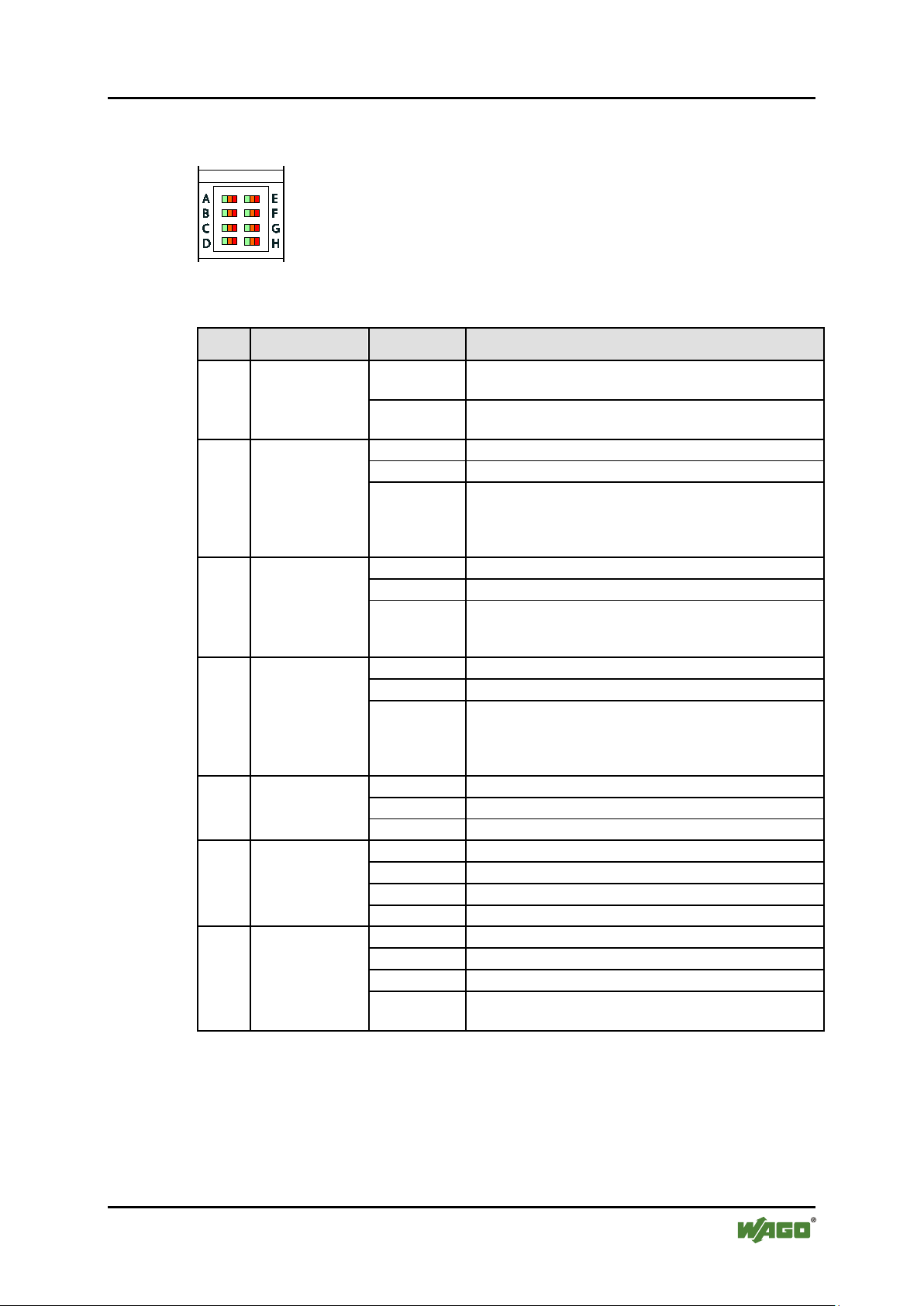

Figure 7: Internal Structure

If two I/O modules are connected together in this mode, each I/O module

transmits the data bytes of the process output image cyclically to the I/O module

on the opposite side. Received data bytes of the process output image on the

opposite side are again represented as data bytes in the process image of the local

I/O module. The sequence of data bytes remains unchanged during transmission.

The cycle, in which process data is exchanged between I/O modules, is event

driven. The I/O module only starts the next transmission after assessing the

transmission of the opposite side as error-free. The I/O module then also begins a

new transmission if no error-free transmission has been received from the

opposite side for a period of at least 200 ms. This ensures that data exchange is

automatically resumed in the event of simultaneous operation or temporary

disturbance of the transmission.

The I/O module monitors the process data received from the opposite side for

actuality. If no error-free transmission was received from the opposite side for a

period of at least 200 ms, the I/O module sets all data bytes of the process image

(input) to zero.

Manual

Version 1.4.0

Page 38

38 Mounting WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

6 Mounting

6.1 Mounting Sequence

Fieldbus couplers/controllers and I/O modules of the WAGO-I/O-SYSTEM

750/753 are snapped directly on a carrier rail in accordance with the European

standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual devices are securely seated

on the rail after installation.

Starting with the fieldbus coupler/controller, the I/O modules are mounted

adjacent to each other according to the project design. Errors in the design of the

node in terms of the potential groups (connection via the power contacts) are

recognized, as the I/O modules with power contacts (blade contacts) cannot be

linked to I/O modules with fewer power contacts.

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Insert I/O modules only from the proper direction!

All I/O modules feature grooves for power jumper contacts on the right side. For

some I/O modules, the grooves are closed on the top. Therefore, I/O modules

featuring a power jumper contact on the left side cannot be snapped from the top.

This mechanical coding helps to avoid configuration errors, which may destroy

the I/O modules. Therefore, insert I/O modules only from the right and from the

top.

Don't forget the bus end module!

Always plug a bus end module 750-600 onto the end of the fieldbus node! You

must always use a bus end module at all fieldbus nodes with WAGO-I/OSYSTEM 750 fieldbus couplers/controllers to guarantee proper data transfer.

Manual

Version 1.4.0

Page 39

WAGO-I/O-SYSTEM 750 Mounting 39

750-652 Serial Interface RS-232 / RS-485

6.2 Inserting and Removing Devices

Perform work on devices only if they are de-energized!

Working on energized devices can damage them. Therefore, turn off the power

supply before working on the devices.

6.2.1 Inserting the I/O Module

1. Position the I/O module so that the tongue and groove joints to the fieldbus

coupler/controller or to the previous or possibly subsequent I/O module are

engaged.

Figure 8: Insert I/O Module (Example)

2. Press the I/O module into the assembly until the I/O module snaps into the

carrier rail.

Figure 9: Snap the I/O Module into Place (Example)

With the I/O module snapped in place, the electrical connections for the data

contacts and power jumper contacts (if any) to the fieldbus coupler/controller or to

the previous or possibly subsequent I/O module are established.

Manual

Version 1.4.0

Page 40

40 Mounting WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

6.2.2 Removing the I/O Module

1. Remove the I/O module from the assembly by pulling the release tab.

Figure 10: Removing the I/O Module (Example)

Electrical connections for data or power jumper contacts are disconnected when

removing the I/O module.

Manual

Version 1.4.0

Page 41

WAGO-I/O-SYSTEM 750 Connect Devices 41

750-652 Serial Interface RS-232 / RS-485

7 Connect Devices

Use shielded signal lines!

Only use shielded signal lines for analog signals and I/O modules which are

equipped with shield clamps. Only then can you ensure that the accuracy and

interference immunity specified for the respective I/O module can be achieved

even in the presence of interference acting on the signal cable.

7.1 Connecting a Conductor to the CAGE CLAMP®

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded and

finely stranded conductors.

Only connect one conductor to each CAGE CLAMP®!

Only one conductor may be connected to each CAGE CLAMP®.

Do not connect more than one conductor at one single connection!

If more than one conductor must be routed to one connection, these must be

connected in an up-circuit wiring assembly, for example using WAGO feedthrough terminals.

Exception:

If it is unavoidable to jointly connect 2 conductors, then you must use a ferrule to

join the wires together. The following ferrules can be used:

Length: 8 mm

Nominal cross section

: 1 mm2 for 2 conductors with 0.5 mm2 each

max.

WAGO product: 216-103 or products with comparable properties

1. For opening the CAGE CLAMP® insert the actuating tool into the opening

above the connection.

2. Insert the conductor into the corresponding connection opening.

3. For closing the CAGE CLAMP® simply remove the tool. The conductor is

now clamped firmly in place.

Manual

Version 1.4.0

Page 42

42 Connect Devices WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

Figure 11: Connecting a Conductor to a CAGE CLAMP

®

7.2 Connection Examples

7.2.1 RS-232 Operating Mode

Figure 12: Point-to-point Connection Operating Mode RS-232 with RTS/CTS Data Flow Control

In the RS-232 operating mode (point-to-point connection), terminal resistors are

not necessary.

The cable length can be up to 40 m due to the maximum allowable cable

capacitance of 1500 pF.

By using the data flow control software (XON/XOFF), as well as complete

renunciation of flow control, the RTS-to-CTS line is not necessary.

Manual

Version 1.4.0

Page 43

WAGO-I/O-SYSTEM 750 Connect Devices 43

750-652 Serial Interface RS-232 / RS-485

7.2.2 RS-485 Operating Mode

Figure 13: Bus Connection RS-485 Operating Mode, Half-Duplex

In the RS-485 operating mode (bus connection), a twisted-pair cable should be

used at least for larger cable lengths or higher transmission rates. The ends of the

cable should be terminated with a terminal resistor.

Generally, a passive resistance is used by connecting the signal lines via one

100 … 120 Ω resistor apiece to both bus ends.

For communication between 2 or more 750-652interface modules at low baud

rates or with shorter line lengths, it is not necessary to use the terminal resistors.

The receiver built into the I/O module has a defined output state if both inputs are

not connected and the data line has a short circuit or no transmitter is active (idle

line).

If the 750-652 serial interface module works on a network with other

communication partners, the wiring of a resistance-biasing network (known as a

fail-safe network) to one line end can be necessary.

Figure 14: Bus Connection RS-485 Operating Mode with Biasing Network, Half-Duplex

With the use of the biasing resistors, it is guaranteed in this case that all receiver

inputs A have the voltage difference of more than 200 mV to the inputs B if no

transmitter is active. The oscillations of the receiver that can cause defective

reception are thus prevented.

Manual

Version 1.4.0

Page 44

44 Connect Devices WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

Biasing network

Check the necessity of an external biasing network before start-up.

In modern devices with RS-485/RS-422 interface, this network is either already

integrated or the devices have an improved RS-485/RS-422 receiver. The output

of this receiver is in a defined state if the data line is short-circuited or not active.

7.2.3 RS-422 Operating Mode

Figure 15: Bus Connection RS-422 Operating Mode

For the RS-422 operating mode (point-to-point connection), the bus ends (at least

for longer line lengths and greater baud rates) should be terminated with a

terminal resistor.

Generally a passive resistance is used by connecting the signal lines via one

100 ... 120 Ω resistor apiece to both bus ends.

For communication between 2 or several 750-652 interface modules at low baud

rates or with shorter line lengths, it is not necessary to use the terminal resistors.

If the 750-652 serial interface module works on a network with other

communication partners, the wiring of a resistance-biasing network (known as a

fail-safe network) to one line end can be necessary.

Biasing network

Check the necessity of an external biasing network before start-up.

In modern devices with RS-485/RS-422 interface, this network is either already

integrated or the devices have an improved RS-485/RS-422 receiver. The output

of this receiver is in a defined state if the data line is short-circuited or not active.

Manual

Version 1.4.0

Page 45

WAGO-I/O-SYSTEM 750 Connect Devices 45

750-652 Serial Interface RS-232 / RS-485

7.2.4 DMX Operating Mode

In the DMX operating mode, the wiring is based on the RS-485 operating mode.

7.2.5 Data Exchange Mode

Figure 16: Point-to-point Connection Between Two Nodes

In this mode, the contacts of the I/O modules to connect are connected to each

other crosswise.

In the Data Exchange operating mode (point-to-point connection), a twisted-pair

cable should be used at least for larger cable lengths. Two wire pairs and one

ground wire are required. The ends of the cable should be terminated with a

terminal resistor.

Generally, a passive resistance is used by connecting the signal lines via one

100 … 120 Ω resistor apiece to the ends of the of the cable (A-B).

Manual

Version 1.4.0

Page 46

46 Commissioning WAGO-I/O-SYSTEM 750

750-652 Serial Interface RS-232 / RS-485

8 Commissioning

8.1 Configuration and Parameterization with WAGO-I/O-CHECK

The serial interface module is configured with the WAGO-I/O-CHECK software

(version 3.3 or higher, WAGO-I/O-CHECK version 3.5.3 is required for firmware

version 03 or higher). The software's basic functionality is described separately in

the WAGO-I/O-CHECK documentation.

Component damage due to incorrect voltage level!

Incorrectly selected voltage levels can destroy the device!

Note when switching between operating modes that RS-232 and RS-485 use

different voltage levels.

Switch off connected devices before changing operating modes!

Make sure that devices you connect support the voltage level of the current

operating mode!

8.1.1 RS-232 / RS-485 Serial Interface (Configuration Dialog)

Figure 17: Parameter Dialog

Manual

Version 1.4.0

Page 47

WAGO-I/O-SYSTEM 750 Commissioning 47

Table 25: Toolbar

Button

Function

Description

Closes the active window. If you have changed

the I/O module.

750-652 Serial Interface RS-232 / RS-485

The parameter dialog is divided into the following areas:

• Title bar with item and item number of the selected I/O module, info area

with item number, designation, and version number and version date of the

I/O module,

• Toolbar (1),

• Parameter range (2) and

• Status bar (3).

Status reports are output in the status display in the lower area of the configuration

dialog.

8.1.2 Toolbar on the Configuration Dialog

The toolbar contains the following buttons:

Figure 18: Toolbar

Exit

Open

Save

Read

Write

settings, you will be asked to save these values in

Opens a file with saved parameters. WAGO-I/OCHECK shows the Open File dialog.

Saves the current parameters in a file. WAGO-I/OCHECK shows the Save File dialog.

Reads the current settings from the connected I/O

module.

Writes the current parameters to the selected I/O

module.

settings

Manual

Version 1.4.0

Factory

Overwrites the locally-saved configuration and

parameterization with factory settings.

Page 48

48 Commissioning WAGO-I/O-SYSTEM 750

Table 25: Toolbar

Button

Function

Description

Table 26: PI Size

Selection box

Settings

Process image size

8 bytes, 24 bytes*, 48 bytes

*)

Default setting

750-652 Serial Interface RS-232 / RS-485

Configuration Sets the process image size.

Help Opens the WAGO-I/O-CHECK online help.

8.1.3 Process Image Size

To make settings on the "PI Mapping" (process image mapping) page, the process

image size of the master must be set first.

Use the [Configuration] button on the toolbar to open the dialog for entering the

process image size.

Figure 19: Process Image Size

Changes to the process image size!

Note that with changes to the process data length, the structure of the process

image changes, and if necessary, changes to the configuration of the superior

controller may be necessary.

The following selection box is displayed:

With the [Apply] button, you transfer the changed parameters to the non-volatile