Page 1

Pos: 2 /Dokumentation allgemein/Einband/Einband Handbuch - Deckblatt oh ne V ari ant enfel d ( Sta ndar d) @ 9 \mod_1285229289866_0.docx @ 64941 @ @ 1

Manual

WAGO-I/O-SYSTEM 750

Pos: 3 /Alle Seri en (Allgemeine Module)/Hinweise zur Dokumentation/Impressum für Standardhandbücher - allg. Angaben, Anschr iften, Telef onnu mmern un d E-Mail- Adres sen @ 3\mod_1219151118203_21.docx @ 21060 @ @ 1

Bluetooth® RF-Transceiver

750-644

Version 2.0.0, valid from FW/HW Version 03/03

Page 2

2 WAGO-I/O-SYSTEM 750

750-644 Bluetooth

®

RF-Transceiver

© 2014 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

=== Ende der Li st e für Te xtm arke Ei nba nd_ vorn e ===

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-644 Bluetooth

Pos: 5 /Do kume ntati on allg em ein /Ver zeic hni sse /Inh alts ver z eich nis - Ü bers chrif t oG und Ver zeic hnis @ 3\ mod_1219151230875_21.docx @ 21063 @ @ 1

®

RF-Transceiver

Table of Contents

1 Notes about this Documentation ................................................................. 8

1.1 Validity of this Documentation ................................................................. 8

1.2 Revision History ........................................................................................ 8

1.3 Copyright ................................................................................................... 8

1.4 Symbols ..................................................................................................... 9

1.5 Number Notation ..................................................................................... 11

1.6 Font Conventions .................................................................................... 11

2 Important Notes ......................................................................................... 12

2.1 Legal Bases ............................................................................................. 12

2.1.1 Subject to Changes ............................................................................. 12

2.1.2 Personnel Qualifications ..................................................................... 12

2.1.3 Use of the 750 Series in Compliance with Underlying Provisions .... 12

2.1.4 Technical Condition of Specified Devices ......................................... 13

2.2 Safety Advice (Precautions) .................................................................... 14

3 Bluetooth® Technology............................................................................... 16

3.1 Piconet ..................................................................................................... 16

3.2 Profile and Identification ......................................................................... 16

3.3 Security ................................................................................................... 17

3.4 Definition of Terms ................................................................................. 17

4 Device Description ..................................................................................... 19

4.1 View ........................................................................................................ 22

4.2 Connectors ............................................................................................... 23

4.2.1 Data Contacts/Internal Bus ................................................................. 23

4.2.2 Power Jumper Contacts/Field Supply ................................................ 24

4.3 Antenna ................................................................................................... 26

4.4 Display Elements .................................................................................... 28

4.4.1 “Configuration” Mode ........................................................................ 28

4.4.2 “Real-Time Communication” Mode, Master ..................................... 28

4.4.3 “Real-Time Communication” Mode, Slave ....................................... 29

4.4.4 “Ad-hoc Communication” Mode ....................................................... 30

4.5 Schematic Diagram ................................................................................. 31

4.6 Technical Data ........................................................................................ 32

4.6.1 Device ................................................................................................. 32

4.6.2 Supply ................................................................................................. 32

4.6.3 Communication .................................................................................. 32

4.6.4 Configuration and Diagnostics ........................................................... 33

4.6.5 Climatic Environmental Conditions ................................................... 33

4.6.6 Connection Type ................................................................................ 33

4.7 Approvals ................................................................................................ 34

4.8 Standards and Guidelines ........................................................................ 35

5 Function Description ................................................................................. 36

5.1 Operating Modes ..................................................................................... 36

5.1.1 “Configuration” Mode ........................................................................ 37

5.1.2 “Real-Time Communication” Mode .................................................. 37

5.1.3 “Ad-hoc Communication” Mode ....................................................... 37

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-644 Bluetooth

®

RF-Transceiver

5.2 Radio Interface ........................................................................................ 37

5.2.1 Net Forming........................................................................................ 38

5.2.1.1 Slots, Slot Addresses ..................................................................... 38

5.2.1.2 Scan for Remote Devices ............................................................... 38

5.2.2 Operation as a Master in “Real-Time Communication” Mode .......... 39

5.2.3 Operation as a Slave in “Real-Time Communication” Mode ............ 40

5.2.4 Operation as a Master in “Ad-hoc Communication” Mode ............... 40

5.2.5 Operation as a Slave in “Ad-hoc Communication” Mode ................. 41

5.2.6 Visibility and Connectivity................................................................. 41

5.2.7 Encryption .......................................................................................... 42

5.2.8 Authentication .................................................................................... 42

5.2.9 Coexistence......................................................................................... 42

5.3 Startup Behavior ...................................................................................... 43

5.4 Factory Settings ....................................................................................... 43

5.5 Timing ..................................................................................................... 44

6 Process Image ............................................................................................. 45

6.1 Control/Status Byte (C/S Byte) ............................................................... 47

6.2 Prozess Data ............................................................................................ 47

6.2.1 “Real-Time Communication” Mode .................................................. 48

6.2.2 “Ad-hoc Communication” Mode ....................................................... 50

6.3 Higher-Level Configuration Protocols .................................................... 52

6.3.1 Mailbox............................................................................................... 54

6.3.2 Process Data Overlaid by Mailbox ..................................................... 58

6.3.3 Register Communication .................................................................... 60

6.3.4 Parameter Channel.............................................................................. 61

6.3.4.1 Parameter Data (Register 56) ......................................................... 62

6.3.4.2 Communication Control (Register 57) .......................................... 62

6.3.4.3 Parameter Sets ............................................................................... 63

6.3.4.4 Process of Parameter Transmission ............................................... 63

7 Mounting ..................................................................................................... 67

7.1 Mounting Sequence ................................................................................. 67

7.2 Inserting and Removing Devices ............................................................ 68

7.2.1 Inserting I/O Module .......................................................................... 68

7.2.2 Removing the I/O Module .................................................................. 69

7.3 Mount Antenna ........................................................................................ 70

7.3.1 Scope of Application .......................................................................... 71

7.3.2 Range in Open Area ........................................................................... 71

8 Commissioning ........................................................................................... 74

8.1 Configuration and Parameterization with WAGO-I/O-CHECK ............ 74

8.1.1 Title Bar .............................................................................................. 75

8.1.2 Toolbar ............................................................................................... 75

8.1.3 Navigation .......................................................................................... 76

8.1.4 Operating Mode and Role Assignment .............................................. 77

8.1.5 Parameterization Mode ....................................................................... 78

8.1.5.1 Settings .......................................................................................... 79

8.1.5.2 Net Forming ................................................................................... 80

8.1.5.3 PI Mapping .................................................................................... 82

8.1.5.4 Block Transfer ............................................................................... 85

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 5

WAGO-I/O-SYSTEM 750 Table of Contents 5

750-644 Bluetooth

®

RF-Transceiver

8.1.5.5 Diagnostics .................................................................................... 87

8.1.6 Status Display ..................................................................................... 90

8.2 Configuration and Parameterization via Process Image ......................... 90

9 Example Configuration ............................................................................. 91

9.1 Example Configurations via WAGO-I/O-CHECK ................................. 91

9.1.1 Startup with the Bluetooth® Parameterization Dialog ........................ 91

9.1.1.1 Network Configuration .................................................................. 91

9.1.1.2 Startup of the 750-644 I/O Modules .............................................. 92

9.1.1.2.1 Configuring Slaves via “Net Forming” ..................................... 92

9.1.1.2.2 Configuring the Master via “Net Forming” .............................. 95

9.1.1.2.3 Assigning Process Data ............................................................. 97

9.1.1.3 Testing Process Data Exchange ..................................................... 98

9.1.2 Startup via Mailbox Commands in the Process Data Dialog ............. 98

9.1.2.1 Network Configuration .................................................................. 99

9.1.2.2 Startup of the 750-644 I/O Modules .............................................. 99

9.1.2.2.1 Switching On the Mailbox ........................................................ 99

9.1.2.2.2 Resetting 750-644 I/O Modules to Factory Settings ............... 100

9.1.2.2.3 Specifying the Master ............................................................. 100

9.1.2.2.4 Querying MAC IDs ................................................................. 101

9.1.2.2.5 Loading the MAC IDs of the Slave in the Device List

of the Master ........................................................................... 101

9.1.2.2.6 Loading the MAC ID of the Master in the Device Lists

of the Slaves ............................................................................ 103

9.1.2.2.7 Binding Slaves ........................................................................ 103

9.1.2.2.8 Binding the Master .................................................................. 104

9.1.2.2.9 Setting “Communication” Mode for Master and Slaves ......... 105

9.2 Connecting with WAGO 757-801 ........................................................ 106

9.2.1 Preparing a 757-801 ......................................................................... 106

9.2.2 Preparing a 750-644 ......................................................................... 106

9.2.3 Exchanging Data .............................................................................. 106

9.3 Connecting to an Android Smartphone ................................................. 108

9.4 Connecting to Windows 7 PC ............................................................... 110

9.4.1 Preparing a PC .................................................................................. 110

9.4.2 Preparing a 750-644 I/O Module ...................................................... 110

9.4.3 Adding the 750-644 I/O Module to the PC Device List ................... 111

9.4.4 Starting Data Exchange via Terminal Program ................................ 112

10 Diagnostics ................................................................................................ 114

10.1 Diagnostics in WAGO-I/O-CHECK ..................................................... 114

10.2 Diagnostics via Process Image or LED Display ................................... 116

10.2.1 No Field Supply ................................................................................ 116

10.2.2 No Radio Connection ....................................................................... 117

10.2.3 Signal Status of the Radio Connections ........................................... 117

10.2.4 Validity of Process Data ................................................................... 118

10.2.5 Topicality of Process Data ................................................................ 119

10.2.5.1 Topicality Not Specified for Known Reasons ............................. 119

10.2.5.2 Topicality Not Specified for Other Reasons ................................ 119

10.2.6 Configuration Errors ......................................................................... 120

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 6

6 Table of Contents WAGO-I/O-SYSTEM 750

750-644 Bluetooth

®

RF-Transceiver

11 Use in Hazardous Environments ............................................................ 121

11.1 Marking Configuration Examples ......................................................... 121

11.1.1 Marking for Europe According to CENELEC and IEC ................... 121

11.1.2 Marking for America according to NEC 500 ................................... 125

11.2 Installation Regulations ......................................................................... 126

11.2.1 Special Conditions for Safe Operation of the ATEX and

IEC Ex (acc. DEMKO 08 ATEX 142851X and

IECEx PTB 07.0064)........................................................................ 126

11.2.2 Special conditions for safe use

(ATEX Certificate TÜV 07 ATEX 554086 X) ................................ 127

11.2.3 Special conditions for safe use

(IEC-Ex Certificate TUN 09.0001 X) .............................................. 128

11.2.4 ANSI/ISA 12.12.01 .......................................................................... 129

12 Appendix ................................................................................................... 130

12.1 Mailbox Commands .............................................................................. 130

12.1.1 Übersicht sortiert nach Gruppen und Opcodes ................................. 130

12.1.2 Overview Sorted According Mailbox Commands ........................... 134

12.2 Return Values of Mailbox Commands .................................................. 137

12.3 Reference for Mailbox Commands ....................................................... 138

12.3.1 General Commands .......................................................................... 139

12.3.1.1 No Task ........................................................................................ 139

12.3.2 Block Transfer .................................................................................. 139

12.3.2.1 Download Start of a Block .......................................................... 139

12.3.2.2 Continuing Block Download or Upload ...................................... 141

12.3.2.3 Stopping Block Download or Upload .......................................... 142

12.3.3 Maintenance and Firmware .............................................................. 144

12.3.3.1 Warm Booting the Bluetooth® Subsystem ................................... 144

12.3.3.2 Save Configuration with Subsequent Warm Boot ....................... 144

12.3.3.3 Reading the Host Firmware Version ........................................... 145

12.3.3.4 Reading the Firmware Version of the Baseband Controller ........ 146

12.3.4 Process Image (PI) ............................................................................ 147

12.3.4.1 Determining the Size of a Slot for Data Transfer in the

Master PI ...................................................................................... 147

12.3.4.2 Querying Remote Process Image Parameters within the

Master PI ...................................................................................... 148

12.3.5 Device Configuration ....................................................................... 149

12.3.5.1 Reading Local Device Names...................................................... 149

12.3.5.2 Wiriting Local Device Names ..................................................... 150

12.3.5.3 Reading Local MAC IDs ............................................................. 151

12.3.5.4 Reading a Local WAGO Device Class ........................................ 152

12.3.5.5 Writing a Local Device Class ...................................................... 153

12.3.5.6 Reading a Local Operating Mode ................................................ 153

12.3.5.7 Setting the Local Operating Mode ............................................... 154

12.3.5.8 Reading the Local Encryption Mode ........................................... 155

12.3.5.9 Setting the Local Encryption Mode ............................................. 156

12.3.5.10 Reading the Local Authentication Mode ..................................... 157

12.3.5.11 Setting Local Authentication Mode ............................................. 157

12.3.5.12 Reading the Local Bluetooth® Password ..................................... 159

12.3.5.13 Writing the Local Bluetooth® Password ...................................... 160

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 7

WAGO-I/O-SYSTEM 750 Table of Contents 7

750-644 Bluetooth

®

RF-Transceiver

12.3.5.14 Erasing Local Authorization ........................................................ 161

12.3.5.15 Reading the Length of the Flash Configuration .......................... 162

12.3.5.16 Reading the Roll of the Local Device .......................................... 162

12.3.5.17 Setting the Role of the Local Device ........................................... 163

12.3.5.18 Restoring Factory Settings ........................................................... 164

12.3.5.19 Reading the Maximum Transmission Power ............................... 164

12.3.5.20 Setting the Maximum Transmission Power ................................. 165

12.3.5.21 Reading the Default Transmission Power ................................... 166

12.3.5.22 Setting the Default Transmission Power ..................................... 166

12.3.6 Network ............................................................................................ 168

12.3.6.1 Scanning for a Remote Device in the Wireless Network ............ 168

12.3.6.2 Reading the MAC ID of a Remote Device .................................. 169

12.3.6.3 Reading the Device Names of a Remote Device ......................... 170

12.3.6.4 Entering a Device in the Table of Allowed Devices ................... 172

12.3.6.5 Reading a Remote Device from the Table of Allowed Devices .. 173

12.3.6.6 Granting Access Permission to a Device ..................................... 174

12.3.6.7 Deleting Access Permission for a Device .................................... 175

12.3.6.8 Reading Access Permission for Remote Devices ........................ 176

12.3.6.9 Reading QoS Settings .................................................................. 177

12.3.6.10 Setting QoS Settings .................................................................... 178

12.3.6.11 Reading Back the Time Setting – Between Two Attempts to

Establish a Connection ................................................................ 179

12.3.6.12 Setting the Time Setting – Between Two Attempts to Establish

a Connection ................................................................................ 180

12.3.6.13 Reading the User-Friendly Name of an Allowed Device ............ 181

12.3.6.14 Writing the User-Friendly Name of an Allowed Device ............. 182

12.3.7 Diagnostics ....................................................................................... 184

12.3.7.1 Reading the Status of the Local I/O Module ............................... 184

12.3.7.2 Reading the Status of the Wireless Network ............................... 185

12.3.7.3 Reading Diagnostic Information .................................................. 186

12.3.7.4 Establishment of the Object ID .................................................... 189

12.3.7.5 Reading the Connection Quality .................................................. 191

12.3.7.6 Reading the Signal Strength for a Connection ............................ 192

12.3.7.7 Reading Available Hopping Channels ......................................... 194

12.3.7.8 Setting an LED ............................................................................ 195

12.3.7.9 Mirroring a Mailbox for Test Purposes ....................................... 197

12.3.7.10 Reading the Operating Time of the I/O Module .......................... 197

12.4 Extended Register Structure (Configuration Block) ............................. 198

13 Glossary .................................................................................................... 201

List of Figures .................................................................................................... 213

List of Tables ...................................................................................................... 215

=== Ende der Li st e für Te xtm arke Ver zeic hni s_v or ne == =

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

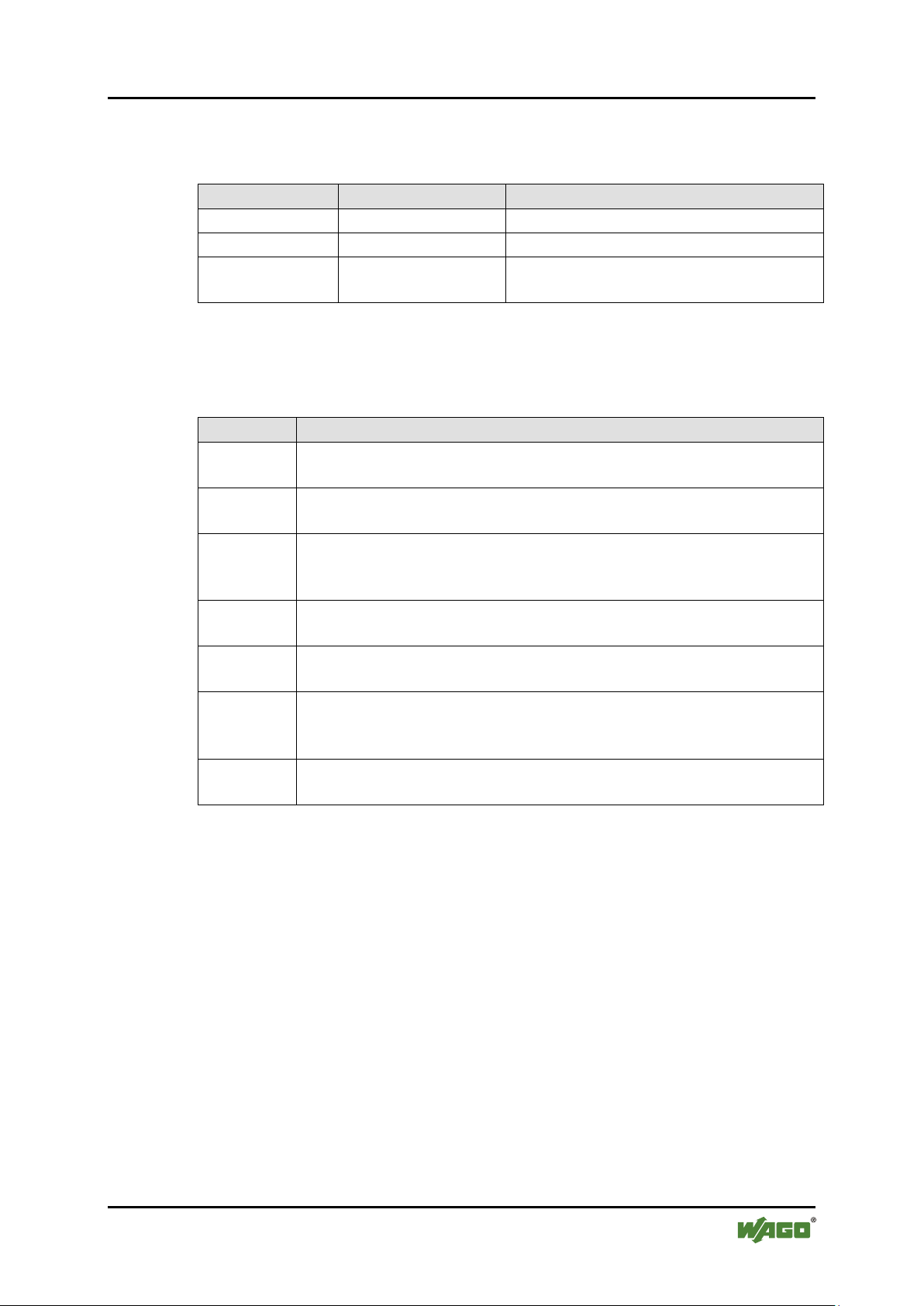

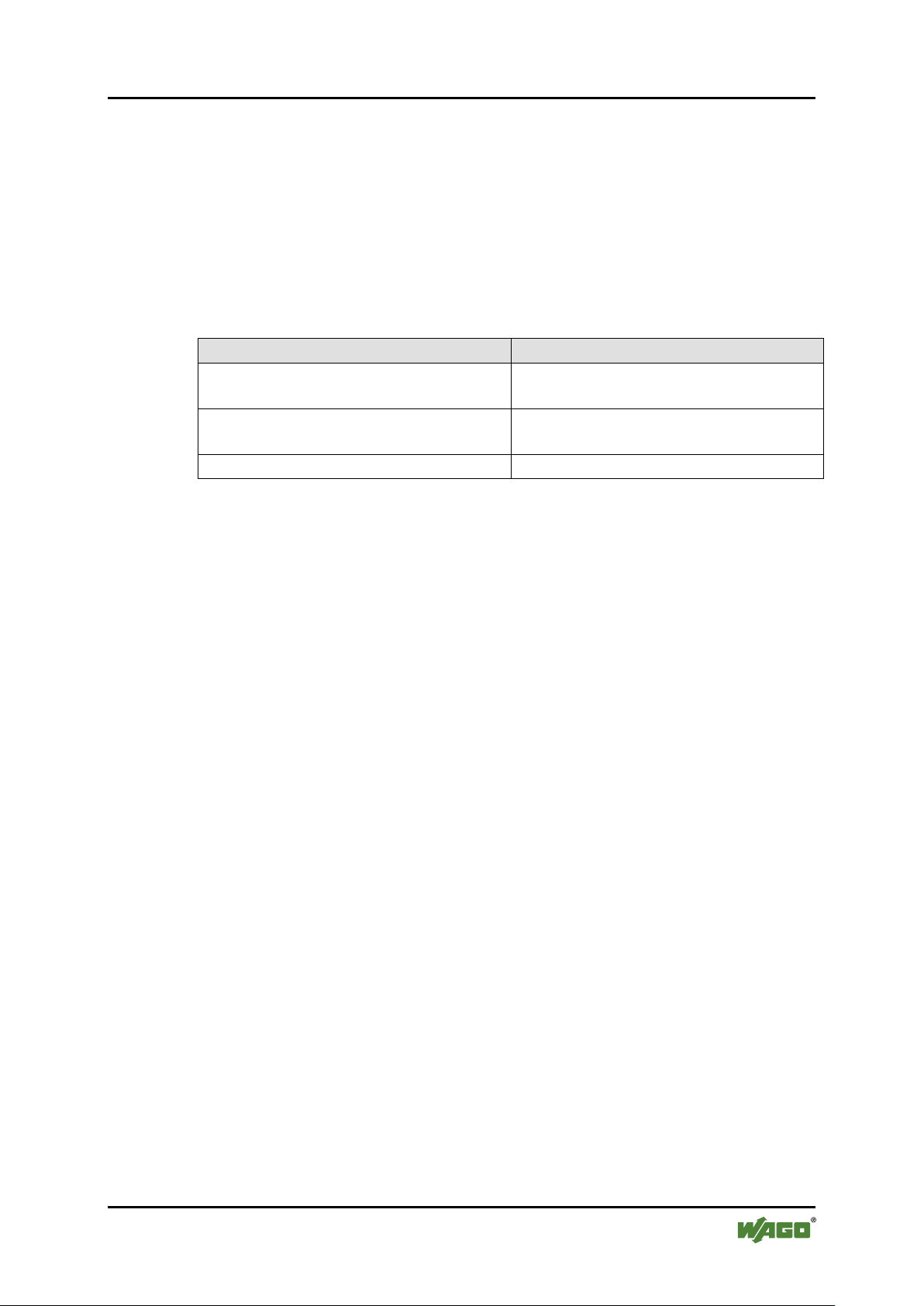

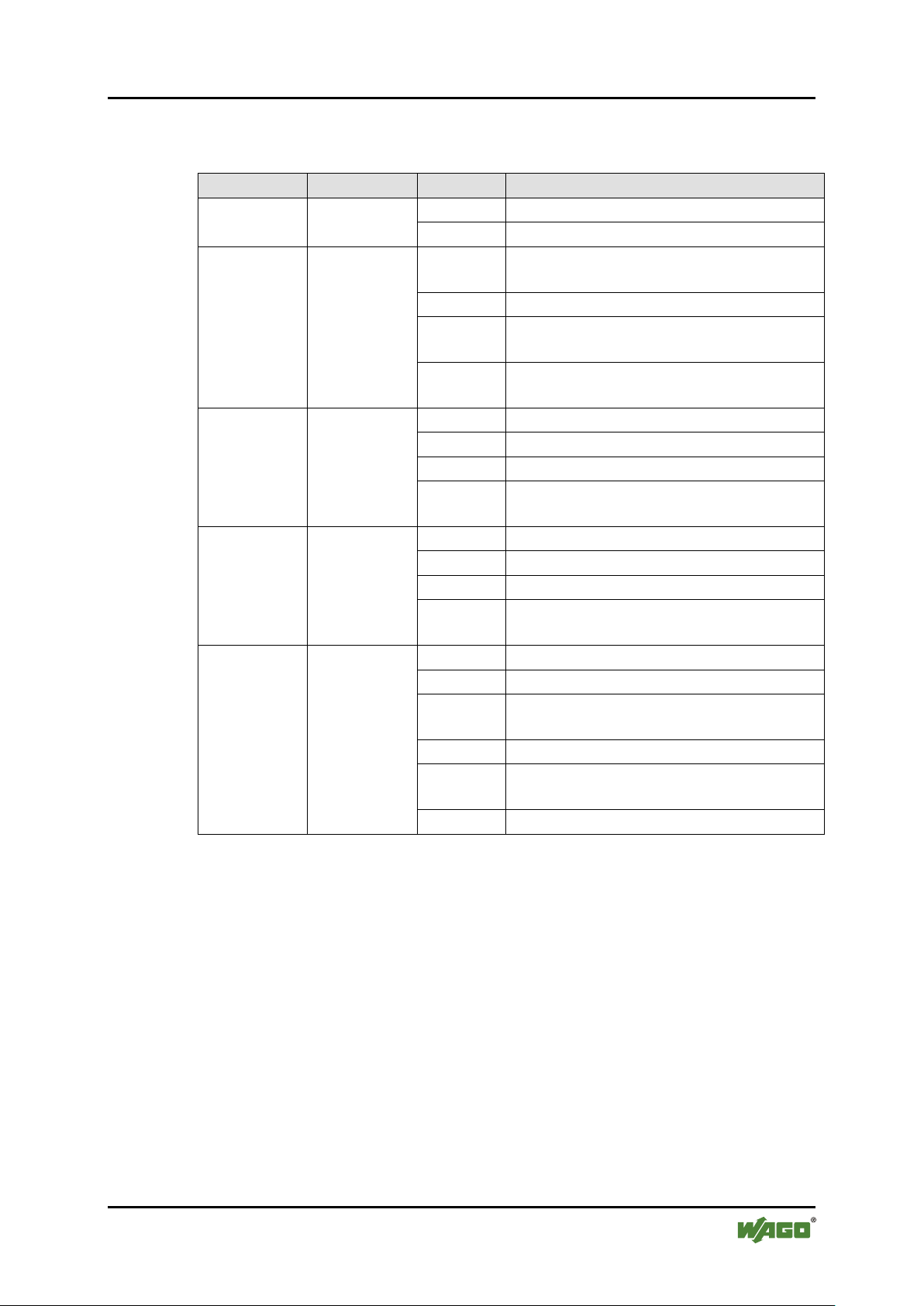

Table 1: Revision history

Document

Equipment version

Hardware

Software

1.0.0

01

01

Initial draft

2.0.0

03

03

Reorganization after functional expansion of the

“Ad-hoc communication ” mode

750-644 Bluetooth

Pos: 7 /Alle S erie n (Al lge mei ne M odul e) /Üb ersc hri ften für all e S erie n/Hi n weis zur Do kum enta tio n/Hin wei se z ur Do kume nt atio n - Üb ers chr ift 1 @ 4 \mod_1237987661750_21.docx @ 29029 @ 1 @ 1

®

RF-Transceiver

1 Notes about this Documentation

Pos: 8 /Alle S erie n (Al lge mei ne M odul e) /Hin wei se z ur Dok umen ta tio n/Hi nweis e/H in weis : D oku ment atio n a uf bewahr e n @ 4\mod_1237987339812_21.docx @ 29026 @ @ 1

Keep this documentation!

The operating instructions are part of the product and shall be kept for the entire

lifetime of the device. They shall be transferred to each subsequent owner or user

of the device. Care must also be taken to ensure that any supplement to these

instructions are included, if applicable.

Pos: 9 /Alle S erie n (Al lge mei ne M odul e) /Üb ersc hri ften für all e S erie n/Hi n weis zur Do kum enta tio n/Gül tig kei ts ber eich - Über schr ift 2 @ 12\mod_1338912448776_21.docx @ 96469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/ Gül tigk eits ber eic h/G ültig k eits ber eich Dok um entation Busklemme 750-xxxx, ohne V aria nten ang abe @ 14\mod_1358944037947_21.docx @ 109346 @ @ 1

This documentation is only applicable to the I/O module 750-644

(Bluetooth® RF-Transceiver).

Pos: 11 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/Hi n weis e/Ac ht ung : Hin wei s z ur D oku ment ati on B us kle mme n 75 0-xxxx @ 4\mod_1237986979656_21.docx @ 29023 @ @ 1

The I/O module 750-644 shall only be installed and operated according to the

instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos: 12 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n f ür al le Ser ien/ Hin weis zur D oku ment ati on/Ä nder ung shi st orie - Über sc hrift 2 @ 6\ mod_1255513312687_21.docx @ 42790 @ 2 @ 1

1.2 Revision History

Pos: 13 /D okum ent atio n al lge mein/ Test /Al ex/ 750- 644/ Änd erung shis tori e - 750-644 @ 15\mod_1371728027050_21.docx @ 123812 @ @ 1

version

Change

Pos: 14.1 /Al l e Ser ien ( Al lge mei ne M od ule)/H i nweis e z ur D ok ume ntati on /Urh eber sc hutz au sführ li ch @ 4\mod_1235565145234_21.docx @ 27691 @ 2 @ 1

1.3 Copyright

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Pos: 14.2 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 9

WAGO-I/O-SYSTEM 750 Notes about this Documentation 9

750-644 Bluetooth

Pos: 14.3 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n für all e S eri en/Hi nw eis z ur D o kume ntati on /Sy mb ole - Ü ber schr if t 2 @ 13\ mod_1351068042408_21.docx @ 105270 @ 2 @ 1

®

RF-Transceiver

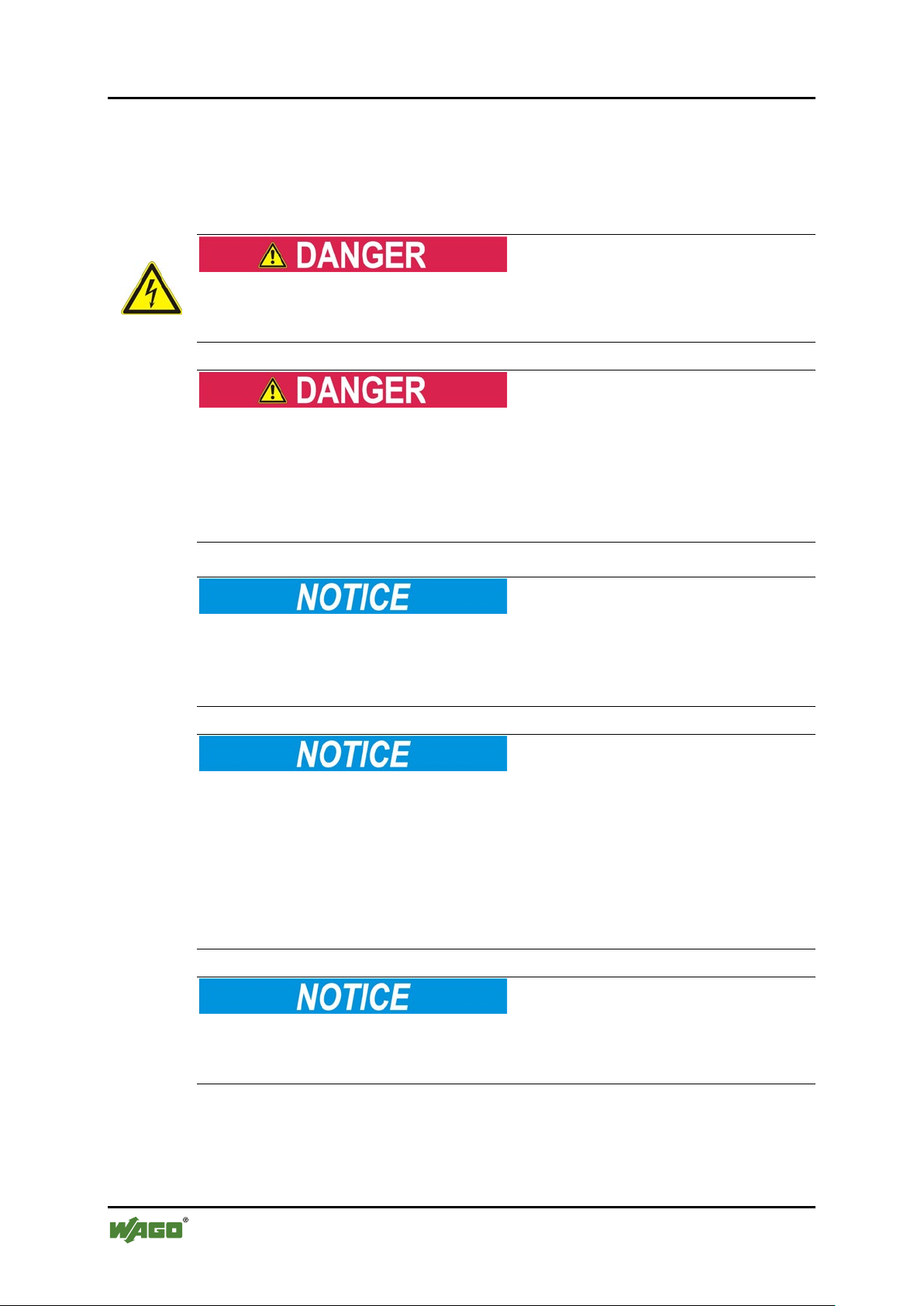

1.4 Symbols

Pos: 14.4.1 /All e Serie n (All gemei ne M od ule)/ Wic htig e E rlä uter ung en/ Sic herh eits - und sonstige Hinweise/Gefahr/Gefahr: _Warnung vor Personenschäden allgemein_ - Erläuterung @ 13\ mod_1343309450020_21.docx @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 14.4.2 /All e Serie n (All gemei ne Mod ule)/ Wichtig e Erlä uteru ngen/ Sich erheits - und sonsti ge Hinw eise/ Gefahr /Gef ahr: _ Warnu ng vor Per sonen schä den durc h elekt risc hen Stro m_ - Erläuterung @ 13\mod_1343309694914_21.docx @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 14.4.3 /All e Serie n (All gemei ne Mod ule)/ Wichtig e Erlä uteru ngen/ Sich erheits - und sons ti ge Hi nw eis e/W arn ung/ War nung : _ Warn ung vor P erso nensc h äde n allg em ei n_ - Erläuterung @ 13\mod_1343309877041_21.docx @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 14.4.4 /All e Serie n (All gemei ne Mod ule)/ Wichtig e Erlä uteru ngen/ Sich erheits - und sons ti ge Hi nw eis e/Vor sic ht /Vor sich t: _War nung v or Pers onensc häde n allge mein _ - Erläuterung @ 13\mod_1343310028762_21.docx @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 14.4.5 /All e Serie n ( All ge meine Mo dul e)/ Wic htige Erl äut eru nge n/Si ch erhei ts- und sonstige Hinweise/Achtung/Achtung: _Warnung vor Sachschäden allgemein_ - Erläuterung @ 13\mod_1343310134623_21.docx @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 14.4.6 /All e Serie n (All gemei ne Mod ule)/ Wichtig e Erlä uteru ngen/ Sich erheits - und sonstige Hinweise/Achtung/ Achtung: _Warnung vor Sachschäden durch elektrostatische Aufladung_ - Erlä uteru ng @ 13\mod_1343310227702_21.docx @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 14.4.7 /All e Serie n (All gemei ne Mod ule)/ Wichtig e Erlä uteru nge n/Si cher heits - und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Erläuterung @ 13\mod_1343310326906_21.docx @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 14.4.8 /All e Serie n (All gemei ne Mod ule)/ Wichtig e Erlä uteru ngen/ Sich erheits - und sons ti ge Hi nw eis e/Inf or mati on/I nf orma tio n: _ Wei ter e Inf or mati on allg emei n_ - Erl äuter ung @ 13\ mod_1343310439814_21.docx @ 101051 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 10

10 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-644 Bluetooth

®

RF-Transceiver

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 14.5 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 11

WAGO-I/O-SYSTEM 750 Notes about this Documentation 11

Table 2: Number notation

Number code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 3: Font conventions

Font type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Programme\WAGO-I/O-CHECK

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-644 Bluetooth

Pos: 14.6 /All e Serien ( Allge meine Module) /Hi nweise z ur Dok ument ation /Zahle nsys teme @ 3\ mod_1221059454015_21.docx @ 21711 @ 2 @ 1

®

RF-Transceiver

1.5 Number Notation

Pos: 14.7 /All e Serien ( Allge meine Module) /Hi nweise z ur Dok ument ation /Schri ftko nventi onen @ 3\mod_1221059521437_21.docx @ 21714 @ 2 @ 1

1.6 Font Conventions

menu item from a menu.

brackets.

Pos: 15 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-644 Bluetooth

Pos: 16 /Alle Seri en (Al lgemei ne Mod ule)/Ü ber schrif ten für al le Ser ien/ Wichtig e Erlä uteru ngen/ Wichtige Erläuterungen - Üb ersc hrift 1 @ 4\ mod_1241428899156_21.docx @ 32170 @ 1 @ 1

®

RF-Transceiver

2 Important Notes

Pos: 17.1 /Al l e Ser ien ( Al lge mei ne D oku men te) ( All ge mei ne Mo dul e)/ Wic htig e Er läut eru nge n/ Einl eit ung Wic htig e Er lä uter ung en @ 3\mod_1221059818031_21.docx @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 17.2 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n für all e S eri en/ Wich tig e Er läuter u ngenR ec htli che Gr undl ag en - Ü bersc hrift 2 @ 3\mod_1221060626343_21.docx @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 17.3 /Al l e Ser ien ( Al lge mei ne Dokumente) (Allgemeine Module)/Wichtige Erläuterungen/Änderungsvorbehalt - Überschrift 3 u nd I nhal t @ 3\mod_1221060036484_21.docx @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 17.4 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Person alqu alifi kationP ers onalqu alifi katio n 750-xxxx - Über schri ft 3 und I nhalt @ 3\ mod_1224061208046_21.docx @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on Series 750 devices may only be carried out by

electrical specialists with sufficient knowledge in automation. The specialists

must be familiar with the current norms and guidelines for the devices and

automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 17.5 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Bestim mung sgemäße VerwendungBestimmungsgemäße Verwendung 750-xxxx - Überschrift 3 un d In hal t @ 3 \mod_1224064151234_21.docx @ 24070 @ 3 @ 1

2.1.3 Use of the 750 Series in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The components have been developed for use in an environment that meets the

IP20 protection class criteria. Protection against finger injury and solid impurities

up to 12.5 mm diameter is assured; protection against water damage is not

ensured. Unless otherwise specified, operation of the components in wet and

dusty environments is prohibited.

Operating 750 Series components in home applications without further measures

is only permitted if they meet the emission limits (emissions of interference)

according to EN 61000-6-3. You will find the relevant information in the section

on “WAGO-I/O-SYSTEM 750” “System Description” “Technical Data” in

the manual for the used fieldbus coupler/controller.

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 13

WAGO-I/O-SYSTEM 750 Important Notes 13

750-644 Bluetooth

®

RF-Transceiver

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 17.6 /Al l e Ser ien ( Al lge mei ne D oku men te) ( All ge mei ne Mo dul e)/ Wic htig e Er läut eru nge n/T ec hnis cher Z ustan d d er G erä te - Über schri ft 3 und In halt @ 3\ mod_1221060446109_21.docx @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 17.7 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 14

14 Important Notes WAGO-I/O-SYSTEM 750

750-644 Bluetooth

Pos: 17.8 /All e Serien ( Allge meine Module) /Über schri fte n für alle S erie n/Wich tige Er läuter ungen Sicher hei tshin weise - Ü bersc hrift 2 @ 6\mod_1260180299987_21.docx @ 46724 @ 2 @ 1

®

RF-Transceiver

2.2 Safety Advice (Precautions)

Pos: 17.9 /Al l e Ser ien ( Al lge mei ne D oku men te) ( All ge mei ne Mo dul e)/ Wic htig e Er läut eru nge n/ Sich erh eits hi nweis e/ Einl eitu ng Sich erh eits hin weis e H ard war e @ 6\mod_1260180170493_21.docx @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 17.10. 1 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Nic ht an G erät en unter Sp ann ung ar beit en! @ 6\ mod_1260180365327_21.docx @ 46727 @ @ 1

Do not work on components while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 17.10. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Gef ahr/ Gefa hr: Ei nbau 07 50- xxxx nur in Geh äusen, Schrä nken oder ele ktrisc hen Betr iebsr äume n! @ 6\mod_1260180556692_21.docx @ 46731 @ @ 1

Installation only in appropriate housings, cabinets or in electrical operation

rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 17.10. 3 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Un fall verh üt ungs vors chr ift en b each te n! @ 6\mod_1260180657000_21.docx @ 46735 @ @ 1

Pos: 17.10. 4 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Auf nor mg erec hte n Ans chl uss ac hten! @ 6\mod_1260180753479_21.docx @ 46739 @ @ 1

Pos: 17.11.1 /Alle Serien (Allgemeine Dokumente) (Allgemeine Module)/Wichtig e Erläuter ung en/Sic her heits hinwei se/Ac htung /Acht ung: Defekt e oder besc hädig te Ger äte aus tausc hen! @ 6\mod_1260180857358_21.docx @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 17.11. 2 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: G erä te vor kriec he nde n u nd is olier e nden Sto ff en sch ützen! @ 6\mod_1260181036216_21.docx @ 46747 @ @ 1

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 17.11. 3 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: R eini gu ng n ur mit z ul ässig en M at eri alie n! @ 6\mod_1260181203293_21.docx @ 46751 @ @ 1

Cleaning only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 17.11. 4 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: K ei n Ko nta ktspr ay ver wend en! @ 6\mod_1260181290808_21.docx @ 46755 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 15

WAGO-I/O-SYSTEM 750 Important Notes 15

750-644 Bluetooth

®

RF-Transceiver

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 17.11. 5 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: V erp ol ung ver meide n! @ 6\ mod_1260184045744_21.docx @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 17.11. 6 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: El ektros tatisc he Entl adu ng verm eiden! @ 6\mod_1260181364729_21.docx @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that you may destroy by

electrostatic discharge when you touch. Pay attention while handling the devices

to good grounding of the environment (persons, job and packing).

Pos: 18 /Dokum entati on allg emei n/Gli ederung s elem ente /---Seit en wechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 16

16 Bluetooth® Technology WAGO-I/O-SYSTEM 750

750-644 Bluetooth

Pos: 19 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/F eld bus komm uni katio n/Bl uetooth®/Bluetooth®-Technologie @ 15\mod_1365146994039_21.docx @ 116621 @ 12222 @ 1

®

RF-Transceiver

3 Bluetooth® Technology

Bluetooth® technology is wireless communication method based on IEEE

802.15.1. It allows license-free wireless communication in the ISM-band

frequency range between 2.402 and 2.480 GHz worldwide.

This technology is primarily used for data exchange between wireless input

devices or smartphones, but has also established itself in industrial applications.

Compared to other wireless technologies, only relatively low data rates are

achieved, but connections are very robust. Industrial implementations also allow

connections with ranges well beyond the ranges of devices for private use.

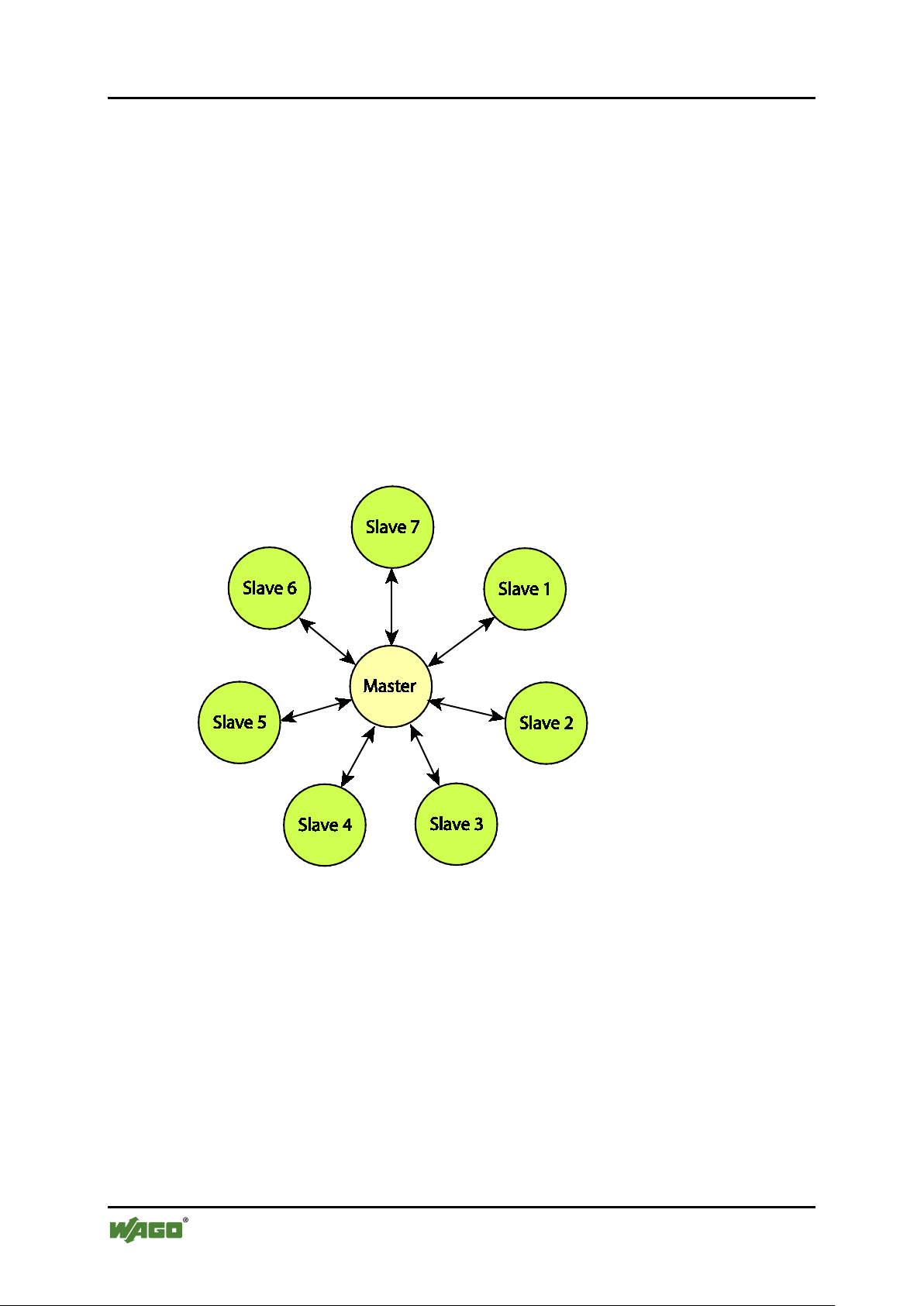

3.1 Piconet

Devices that use Bluetooth® technology to communicate form a so-called piconet.

One device assumes the master role and all others are slaves.

Figure 1: Piconet

Data is exchanged between the master and slave directly, but not between the

slaves themselves.

3.2 Profile and Identification

Bluetooth® technology can be used in many ways. Supported applications can

have very different requirements. For example, transmission of a business card or

audio signal requires different protocols. Bluetooth® devices normally support

only certain protocols. To make identification of suitable partners easier for

devices, profiles have been defined. Communication between devices is then

possible when both devices support the same profile.

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 17

WAGO-I/O-SYSTEM 750 Bluetooth® Technology 17

Table 4: Classes (CoD) of WAGO devices

WAGO Device

CoD (hexadezimal)

Bluetooth® RF Transceiver 750-644

(real-time profile)

0x0020f8

Bluetooth® Module 757-801 with

RS-232

0x1f00

Bluetooth® Adapter 750-921

0x1f00

750-644 Bluetooth

®

RF-Transceiver

A standardized profile is the “Serial Port Profile” (SPP). It is used for wireless

transmission of serial interface data such as RS-232 or RS-485.

The “Service Discovery Profile” (SDP) supported by all Bluetooth® devices

allows a device to discover which devices are in range and to identify supported

profiles. Devices can broadcast which functions are supported by encoding such

functions as a so-called “Class of Device” (CoD) and by sharing that with other

devices. The CoD then makes it possible to look for devices with specific

functionality.

In addition to the CoD, all devices have a MAC ID that is used to uniquely

identify the device. Many devices also allow you to choose and save a specific

name for the device. This name is then also be queried wirelessly.

In addition to standardized profiles, industrial devices sometimes also use

proprietary profiles to meet specific requirements, e.g. in terms of reliability.

3.3 Security

Compatibility, connectivity and the security of radio communication are high

priorities for Bluetooth® technology. Due to the wide variety of devices and

applications that the technology uses, configurations can arise where devices are

unable to communicate with each other because of the different security

mechanisms implemented. This can affect devices, for example, that have no

configuration options for reasons of cost or devices that do not allow direct user

interaction based on their design.

3.4 Definition of Terms

The following table contains explanations about the terms used in this documentation.

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 18

18 Bluetooth® Technology WAGO-I/O-SYSTEM 750

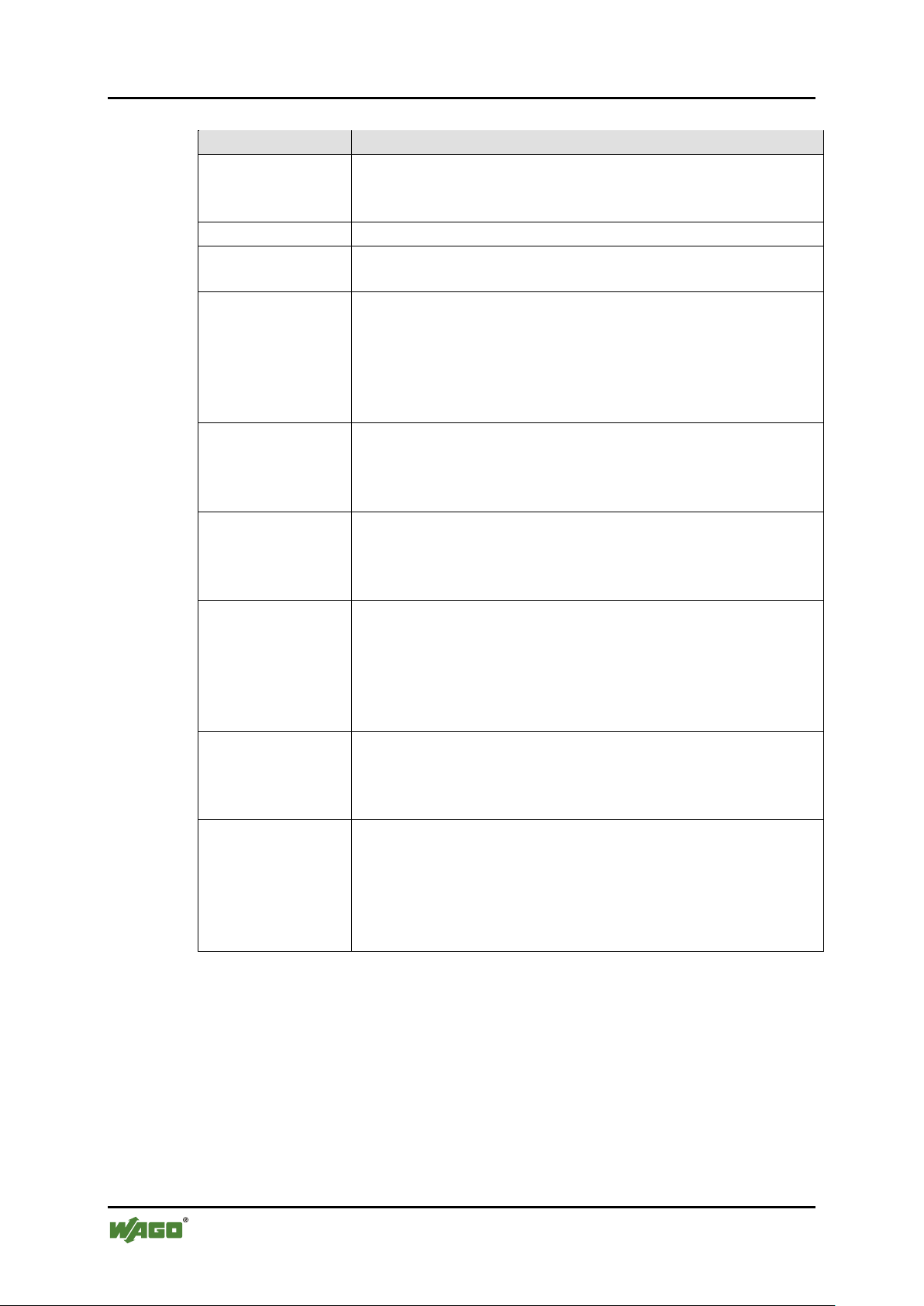

Table 5: Terms used

Term

Explanation

Local

A component or device to which there is a wired connection.

CHECK on the operator PC.

Remote

A component or device to which there is no wired connection.

Communication

partner

A remote device (from the perspective of the local device) or

the local device (from the perspective of a remote device).

In range

Devices or components are in range when transmitter and

settings are compatible.

Allowed

For secure connections, communication is only possible with

“authorized devices”, as well as “paired” or “coupled”.

Visible

Describes a Bluetooth® device that responds to scans from

come from authorized devices.

Connectable

Describes a Bluetooth® device to which connections can be

that number has already been reached.

Connected

Describes a state in which devices are able to exchange data

between authorized devices.

Authentication

Refers to the process of mutual verification of two Bluetooth®

not allowed.

750-644 Bluetooth

®

RF-Transceiver

Example: A 750-644 I/O module represented in WAGO-I/O-

receiver are mutually so strong or sensitive that

communication is technically possible. Whether

communication actually occurs depends on several other

factors, e.g. if radio connection is even wanted or if security

devices defined as “authorized devices”. Bluetooth®

technology designates devices that view each other as

Pos: 20 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

any other Bluetooth® device. A device that is not visible only

responds to scans or connection attempts when such attempts

established. Sometimes it may not be possible for authorized

devices to connect to a Bluetooth® device. This is the case,

for example, when the device is designed or configured to

allow only a certain number of simultaneous connections and

with each other. To do so, the devices must be in range. If the

devices have a secure connection, the connection must be

devices, where each device determines if the other is an

authorized device. Part of the process can be user interaction,

e.g. display of a dialog box on a smartphone or access to a

saved configuration that indicates which devices are and are

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 19

WAGO-I/O-SYSTEM 750 Device Description 19

750-644 Bluetooth

Pos: 21 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n f ür al le Ser ien/ Ger äte besc hrei bu ng/G erä te beschr ei bu ng - Ü bersc hrift 1 @ 3\mod_1233756084656_21.docx @ 27096 @ 1 @ 1

®

RF-Transceiver

4 Device Description

Pos: 22.1 /Serie 750 (WAGO-I/O-SYSTEM)/Gerätebeschreibung/Einleitung/Anwendung/SO/Anwendung 750- 0644 @ 15\mod_1365146295004_21.docx @ 116599 @ @ 1

The Bluetooth® RF Transceiver 750-644, hereafter referred to as the 750-644 I/O

module, is used to integrate a Bluetooth® network (Piconet) in the WAGO-I/OSYSTEM 750. 750-644 modules are installed and used jointly with other I/O

modules of the WAGO-I/O-SYSTEMs 750 in different fieldbus systems.

The 750-644 I/O module permits wireless exchange of data within the Bluetooth®

piconet. It can function as the coordinator (referred to in the following as the

“master”) or as the terminal (referred to in the following as the “slave”) depending

on the configuration. A maximum of seven slaves may communicate with one

master.

In piconets consisting of 750-644 I/O modules exclusively, the I/O modules can

use a specific proprietary profile for communication. If using the WAGO 758-912

antenna, ranges of up to 1000 meters can be achieved. In addition to particularly

robust, deterministic radio communication, expanded diagnostic functions are also

available.

The 750-644 I/O module can communication with devices from different

manufacturers that support the protocols of the SPP profile, i.e. the wireless

transmission of serial interface data. Apps are available that allow smartphones to

exchange data with the 750-644 I/O module.

The WAGO-I/O-CHECK software is used to configure the 750-644 I/O module

locally (network configuration, process image mapping). Eight 3-color LEDs

indicate the current status of the 750-644 I/O module.

Pos: 23 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Pos: 24 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/Ei nlei tu ng/E ins atz ber eich /Ei ns atzber ei ch 7 50- xxx x nur Koppl er/C ontrol ler a us Kompa tibili tätsli ste @ 4\ mod_1242389440265_21.docx @ 33262 @ @ 1

Pos: 25 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/Ei nlei tu ng/Ei ns atz berei ch/K om pati bilit ätsl isten /Kom patibi lität slist e 750-0644 @ 18\mod_1390827073962_21.docx @ 143418 @ @ 1

The 750-644 module can be used with the fieldbus couplers and controllers of the

WAGO-I/O-SYSTEM 750 of the specified version or higher listed in the

“Compatibility list” table.

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 20

20 Device Description WAGO-I/O-SYSTEM 750

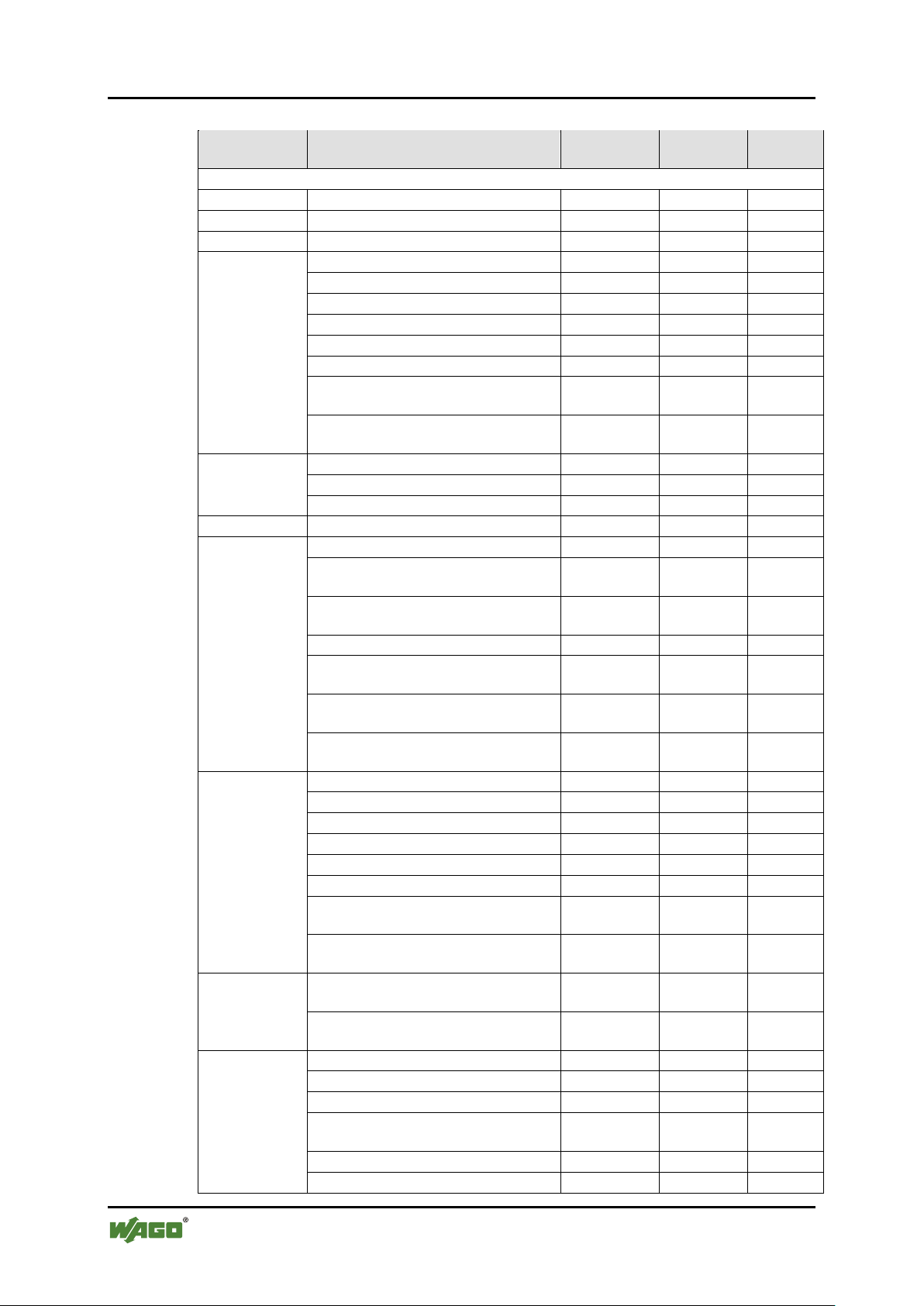

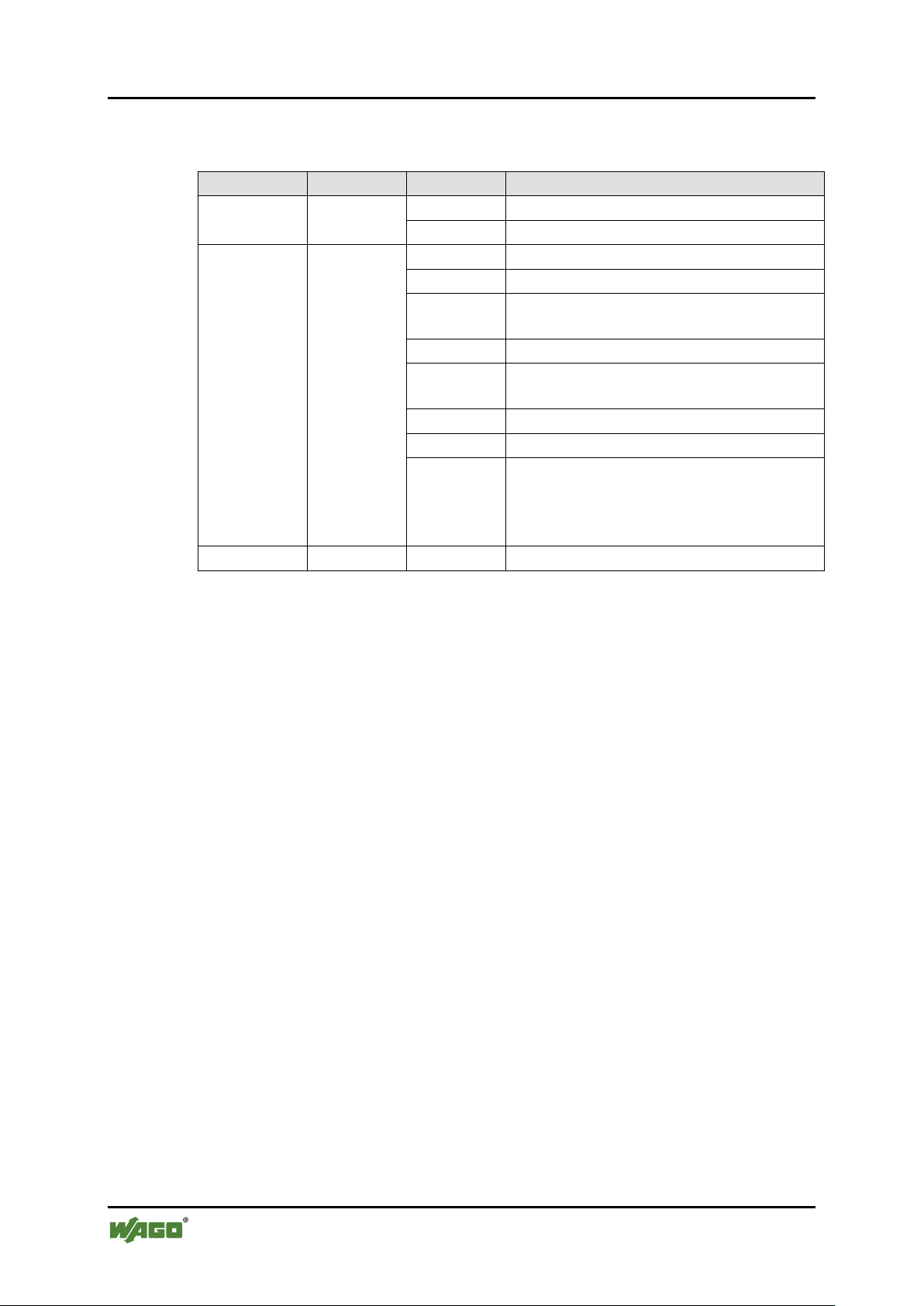

Table 6: Compatibility list

Bus system

Fieldbus couplers/controllers

Item no.

Hardware

status

Software

status

750 Series

BACnet/IP

Programmable fieldbus controller

750-830

03

03

Programmable fieldbus controller

750-831

01

01

CAL

Fieldbus coupler

750-305

CANopen

Fieldbus coupler

750-307

Programmable fieldbus controller

750-807

Fieldbus coupler

750-337

13

10

Fieldbus coupler, D-Sub

750-338

01

10

ECO fieldbus coupler

750-347

01

04

ECO fieldbus coupler, D-Sub

750-348

01

04

Programmable fieldbus controller,

MCS

750-837

06

11

Programmable fieldbus controller,

D-Sub

750-838

01

11

DeviceNet

Fieldbus coupler

750-306

15

4I

ECO fieldbus coupler

750-346

02

07

Programmable fieldbus controller

750-806

07

07

EtherCAT

Fieldbus coupler

750-354

01

01

ETHERNET

Programmable fieldbus controller

750-880

04

02

Programmable fieldbus controller,

TeleControl

750-880/

025-001

02

Programmable fieldbus controller,

TeleControl ECO

750-880/

025-002

02

Programmable fieldbus controller

750-881

02

03

Programmable media-redundant

fieldbus coupler

750-882

05

02

Programmable fieldbus controller,

Application Controller BA

750-884 02

Programmable media-redundant

fieldbus coupler

750-885

06

04

ETHERNET

TCP/IP fieldbus coupler

750-341

03

03

TCP/IP fieldbus coupler

750-342

04

14

Fieldbus coupler

750-352

02

02

Programmable fieldbus controller

750-841

11

07

Programmable fieldbus controller

750-842

13

12

Programmable fieldbus controller

750-843

Programmable fieldbus controller,

2 ports

750-871

05

07

Programmable fieldbus controller,

RS-232

750-873 03

IEC60870-5

Programmable fieldbus controller for

telecontrol applications

750-872

04

03

Programmable fieldbus controller for

telecontrol applications, TeleControl

750-872/

020-000

INTERBUS

Fieldbus coupler

750-304

Fieldbus coupler

750-324

Programmable fieldbus controller

750-804

Fieldbus coupler with fiber-optic

connection

750-334

ECO fieldbus coupler

750-344

ECO fieldbus coupler

750-345

750-644 Bluetooth

®

RF-Transceiver

TCP/IP

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 21

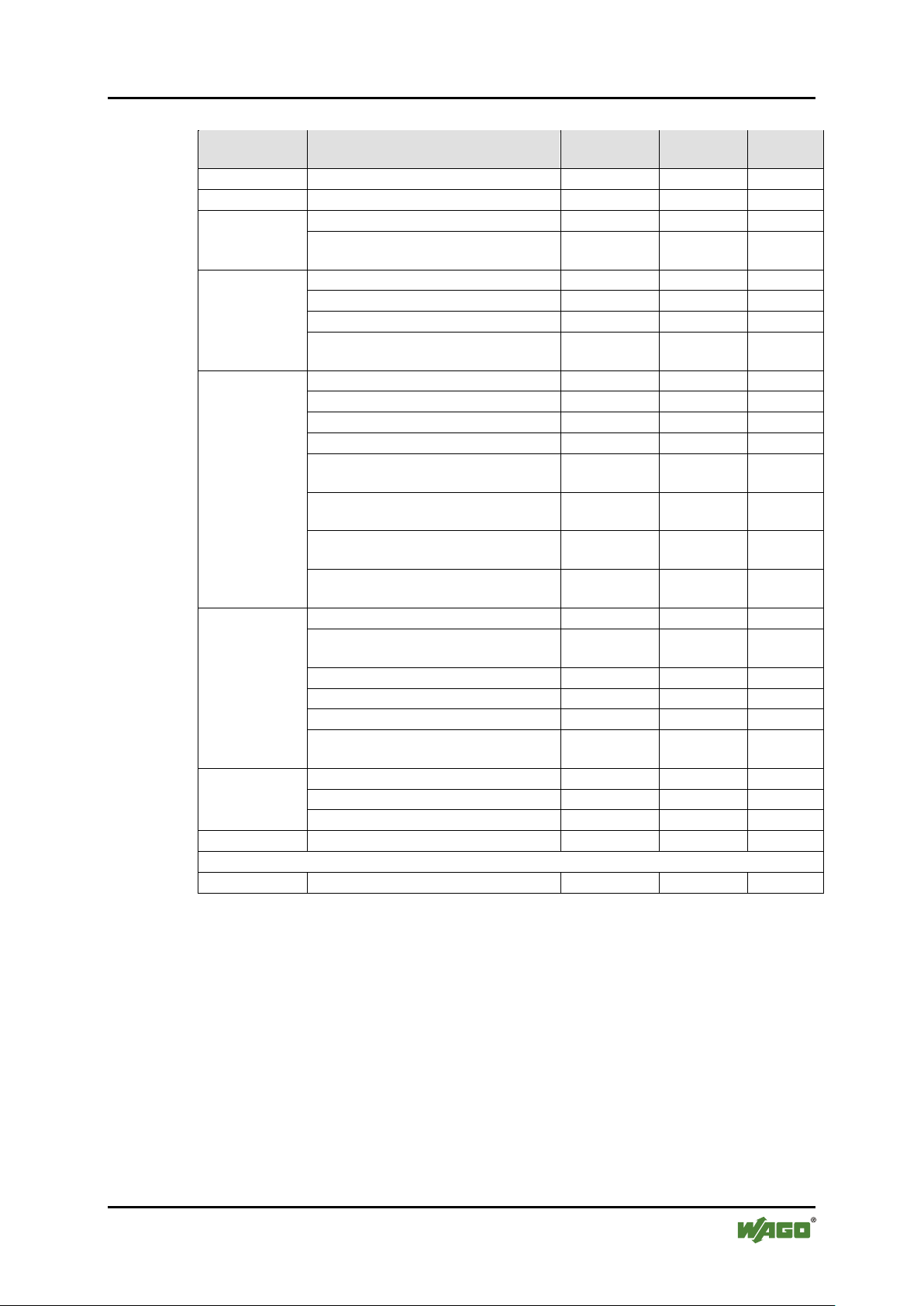

WAGO-I/O-SYSTEM 750 Device Description 21

Table 6: Compatibility list

Bus system

Fieldbus couplers/controllers

Item no.

Hardware

status

Software

status

KNX IP

Programmable fieldbus controller

750-849

03

03

KNX IP

KNX IP controller

750-889

Linux®

Programmable fieldbus controller

750-860

Programmable fieldbus controller,

RS-232

750-863

LonWorks®

Fieldbus coupler

750-309

Programmable fieldbus controller

750-819

08

07

Fieldbus coupler

750-319

07

05

Peer-to-peer fieldbus coupler

750-319/

004-000

MODBUS

Fieldbus coupler, RS-485

750-312

Fieldbus coupler, RS-232

750-314

Fieldbus coupler, RS-485

750-315

Fieldbus coupler, RS-232

750-316

Programmable fieldbus controller,

RS-485

750-812

Programmable fieldbus controller,

RS-232

750-814

Programmable fieldbus controller,

RS-485

750-815

Programmable fieldbus controller,

RS-232

750-816

PROFIBUS

DP/FMS fieldbus coupler

750-303

01

07

Fieldbus coupler with fiber-optic

connection

750-331

DP/V1 fieldbus coupler

750-333

16

07

DPECO fieldbus coupler

750-343

03

06

DP fieldbus coupler

750-323

Programmable fieldbus controller

DP/V1

750-833

20

07

PROFINET IO

Fieldbus coupler

750-340

Fieldbus coupler, 2 ports

750-370

04

05

Fieldbus coupler, 2 ports

750-375

01

01

sercos III

Fieldbus coupler, 2 ports

750-351

02

02

758 Series

WAGO-I/O-IPC

758-870 06

750-644 Bluetooth

®

RF-Transceiver

Pos: 26 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 22

22 Device Description WAGO-I/O-SYSTEM 750

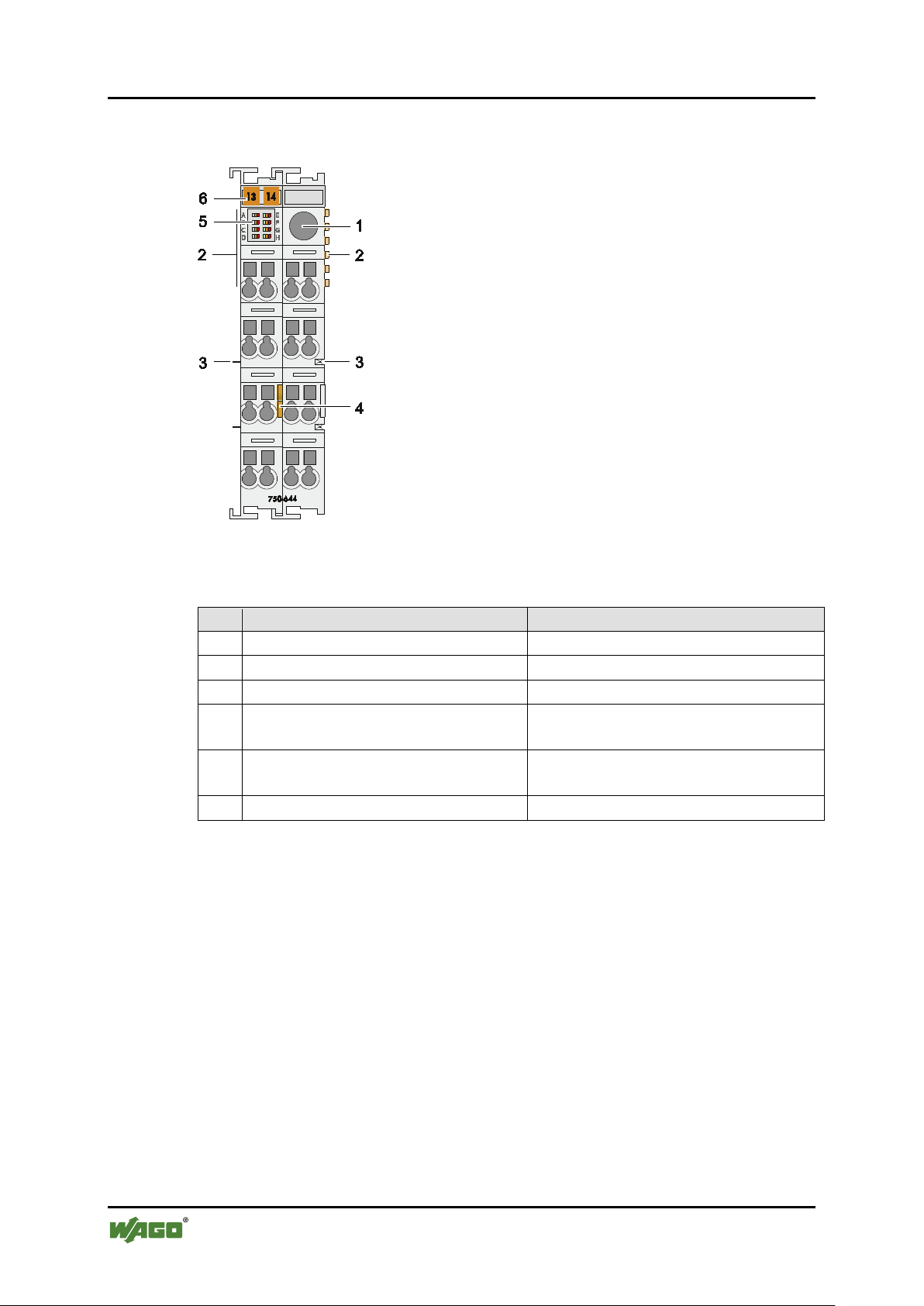

Table 7: Legend for the “View” figure

Pos.

Description

Details see section

1

Antenna socket SMA

“Device Description” > “Connectors”

2

Data contacts

“Device Description” > “Connectors”

3

Power jumper contacts

“Device Description” > “Connectors”

4

Release tab

“Mounting” > “Inserting and

Removing Devices”

5

Status LEDs

“Device Description” > “Display

Elements”

6

Marking possibility with Mini-WSB

---

750-644 Bluetooth

Pos: 27 /All e S eri en ( Allg emei n e Mod ule)/Ü ber schrif ten für al le Ser ien/G eräte besc hreibu ng/Ans icht - Ü ber schri ft 2 @ 4\ mod_1240984217343_21.doc x @ 31958 @ 2 @ 1

®

RF-Transceiver

4.1 View

Pos: 28 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Ger ätebes chrei bung /Ansic ht/S onder klem men/A nsicht 750-0644 @ 15\mod_1365148663923_21.docx @ 116624 @ @ 1

Figure 2: View

Pos: 29 /D okum ent atio n al lge mein/ Gli eder ungs ele me nte/---Sei te nwec hsel--- @ 3\ mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

750-644 Bluetooth

Pos: 30 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n f ür al le Ser ien/ Ger äte besc hrei bu ng/A nsc hlü sse - Üb erschr ift 2 @ 4\mod_1240984262656_21.docx @ 31961 @ 2 @ 1

®

RF-Transceiver

4.2 Connectors

Pos: 31 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/A nsc hlüs se/D ate nko ntak te/Kl e mmen bus - Ü bersc hrift 3 @ 6\mod_1256294684083_21.docx @ 43660 @ 3 @ 1

4.2.1 Data Contacts/Internal Bus

Pos: 32.1 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Anschlüsse/Datenkontakte - Feldbuskoppler/-c ontr oll er, A bbi ldung u nd B esc hrei bu ng @ 3\mod_1231771259187_21.docx @ 26002 @ @ 1

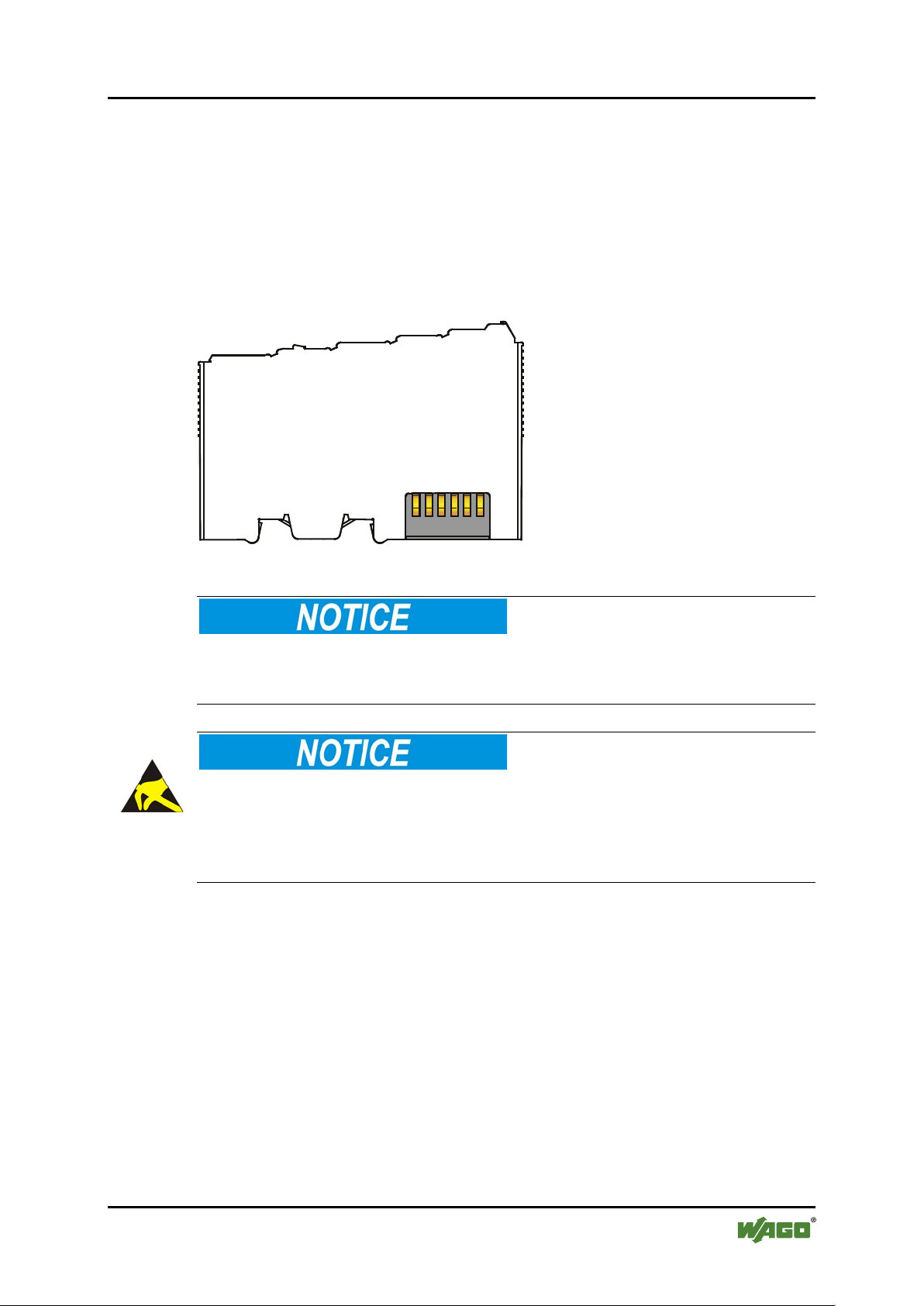

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 3: Data contacts

Pos: 32.2 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Ac htu ng/A ch tung : Bus kl em men nic ht a uf G oldf eder kon ta kte l eg en! @ 7 \mod_1266318463636_21.docx @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 32.3 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Achtung/Achtung: ESD - Auf gute Erdung der U mg ebu ng ac ht en! @ 7\ mod_1266318538667_21.docx @ 50708 @ @ 1

Ensure that the environment is well grounded!

The modules are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the modules, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 33 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 24

24 Device Description WAGO-I/O-SYSTEM 750

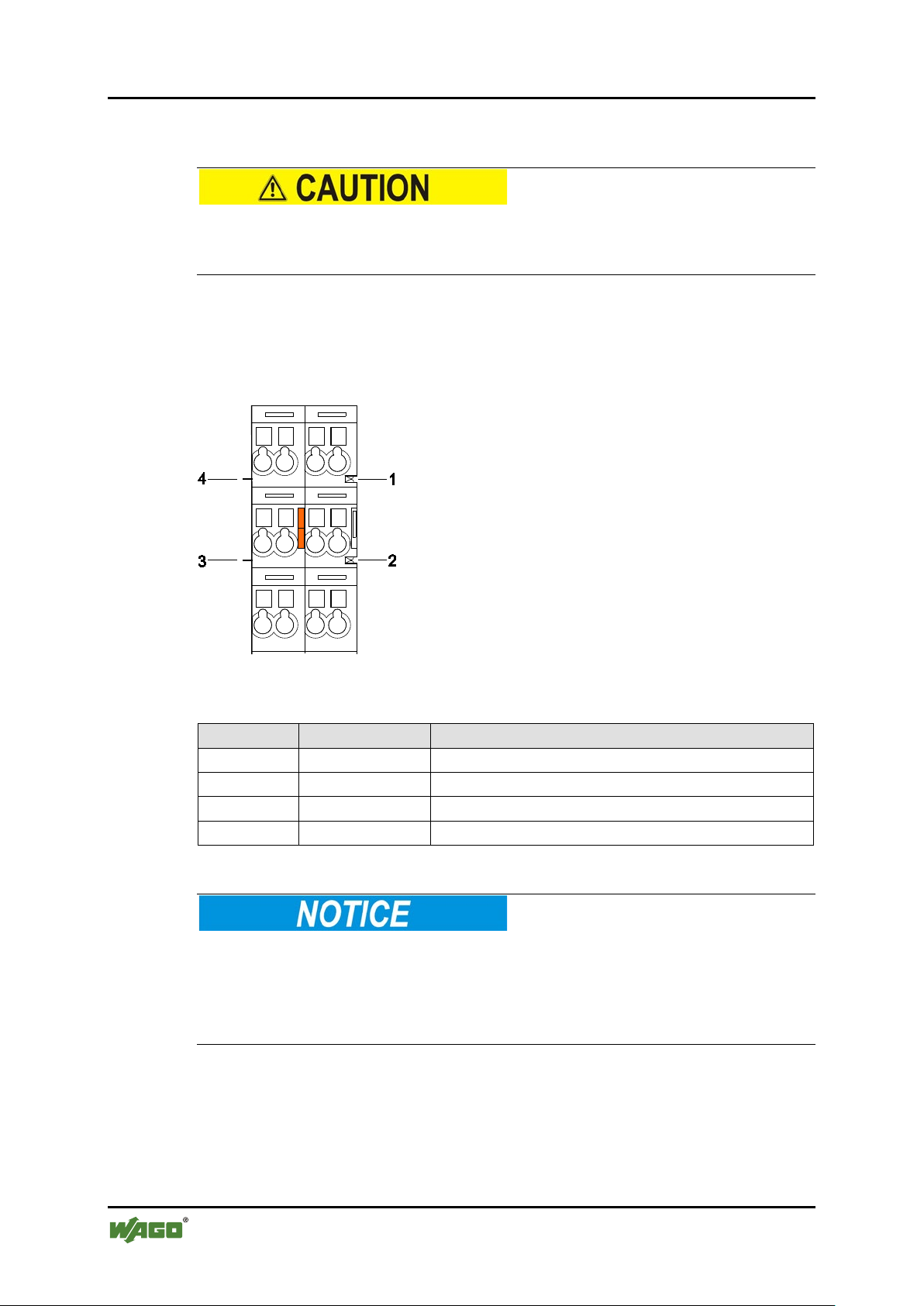

Table 8: Legend for the “Power jumper contacts” figure

Contact

Type

Function

1

Spring contact

Potential transmission (Uv) for field supply

2

Spring contact

Potential transmission (0 V) for field supply

3

Blade contact

Potential feed-in (0 V) for field supply

4

Blade contact

Potential feed-in (Uv) for field supply

750-644 Bluetooth

Pos: 34 /Ser ie 75 0 (WA GO-I/ O-S YSTEM )/ Ger äteb eschr ei bung/ Ansc hl üsse/ Leis tu ngs konta kte/F el dvers org ung - Über schr ift 3 @ 6\mod_1256294692864_21.docx @ 43664 @ 3 @ 1

®

RF-Transceiver

4.2.2 Power Jumper Contacts/Field Supply

Pos: 35.1 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Vor sic ht/ Vor sic ht: Verl etz ungs ge fahr dur ch s ch arf kant ige M ess er kont akt e! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Pos: 35.2 /Serie 750 (WAGO-I/O-S YST EM) /Ger äte bes chr ei bung /Ans chl üss e/L eist ung s konta kte 2 LK (M esser /Lei s tung sk onta kte 2 L K (Me sser /F ed er) - Einl eitung @ 15\mod_1371721641099_21.docx @ 123714 @ @ 1

The I/O module 750-644 has 2 self-cleaning power jumper contacts that supply

and transmit power for the field side. The contacts on the left side of the I/O

module are designed as blade contacts and those on the right side as spring

contacts.

Pos: 35.3 /S eri e 7 50 ( WA GO-I/O- SYST EM) /Ger äte bes chr ei bung /Ans chl üss e/L eist ung s konta kte 2 LK (M ess er/ Leis tung sk onta kte 2 L K (Me sser /F ed er) - Abbil du ng ( do ppelt e Br eit e) @ 15\ mod_1371721756578_21.docx @ 123718 @ @ 1

Figure 4: Power jumper contacts

Pos: 35.4 /Serie 750 (WAGO-I/O-SYSTEM)/Geräte bes chr ei bung /Ans chl üss e/L eist ung s konta kte 2 LK (M ess er/ Leis tung sk onta kte 2 L K (Me sser /F ed er) - Lege nde @ 15 \mod_1371721352500_21.doc x @ 123710 @ @ 1

Pos: 35.5 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstig e Hinw eise/ Achtu ng/Ac htung : Maxi maler S trom Lei stung skon takte 10 A @ 3\mod_1226499143500_21.docx @ 25029 @ @ 1

Do not exceed maximum current via power contacts!

The maximum current to flow through the power contacts is 10 A.

Greater currents can damage the power contacts.

When configuring the system, ensure that this current is not exceeded. If

exceeded, an additional potential feed module must be used.

Pos: 35.6 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstig e Hinw eise/H inwei s/Hi nweis : Potent ialei nspei sekl emme für Erde ei nsetz en! @ 3\mod_1226499037468_21.docx @ 25023 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 25

WAGO-I/O-SYSTEM 750 Device Description 25

750-644 Bluetooth

®

RF-Transceiver

Use potential feed module for Ground (earth)!

The I/O module has no power contacts for earth intake and transfer. Use a

potential feed module when an earth feed is needed for the subsequent I/O

modules.

Pos: 36 /Dokum entati on allg emei n/Gli ederung sele mente /---Seite nwe chsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 26

26 Device Description WAGO-I/O-SYSTEM 750

750-644 Bluetooth

Pos: 37 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr eibu ng/A nsc hlüs se/A nte nne - Ü b ersc hrif t 2 @ 1 6\mod_1374051031775_21.docx @ 126410 @ 2 @ 1

®

RF-Transceiver

4.3 Antenna

Pos: 38 /Ser ie 75 0 (WA GO-I/ O-S YSTE M)/Z ub ehör /Zu beh ör f ür 750- 644 Antenne @ 16\mod_1376481596445_21.docx @ 128799 @ @ 1

The 750-644 I/O module has an SMA socket for attaching an external antenna.

Figure 5: SMA socket

The 750-644 I/O module can also be used without an external antenna, but the

achievable range of the radio connection is then significantly smaller.

In countries where use of radio products are regulated by the R&TTE directive,

any antenna with radio gain of 0 dBi or less can be used. For use in all other

countries where the I/O module can be operated, only the WAGO 758-912

magnetic base antenna can be used.

Figure 6: Accessory – WAGO 758-912 antenna

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 27

WAGO-I/O-SYSTEM 750 Device Description 27

750-644 Bluetooth

®

RF-Transceiver

No operating license when antenna configuration is not approved!

Use of an unapproved antenna configuration can void your operating license. This

applies in particular when the equivalent isotropic radiated power (EIRP) of the

structure is higher when using the antenna configuration than is permitted

according to the regional or national specifications applicable to the location.

The composite function of the 750-644 I/O module and WAGO 758-912 antenna

is not intended for use outside of buildings.

Pos: 39 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 28

28 Device Description WAGO-I/O-SYSTEM 750

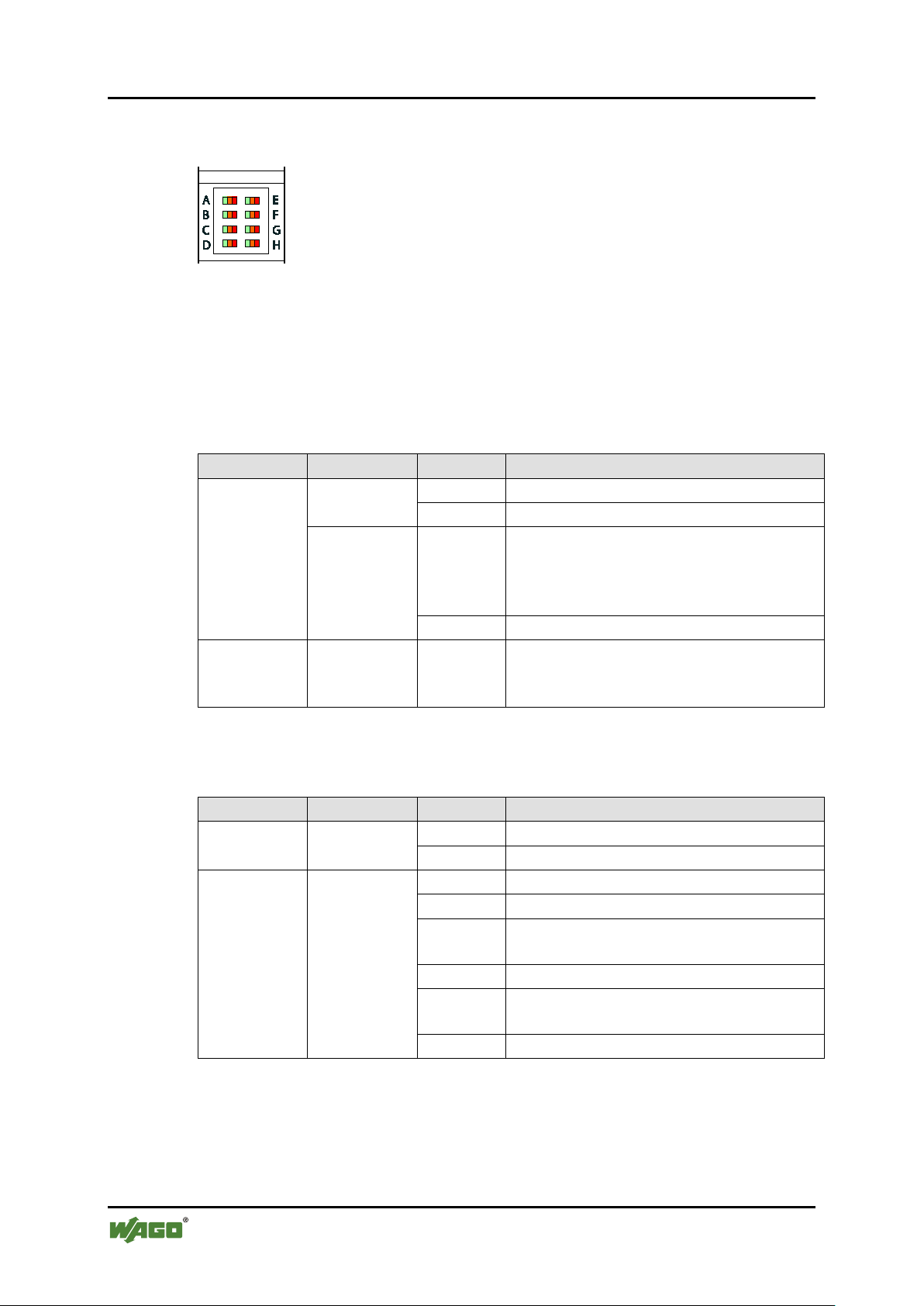

Designation

LED

State

Function

green

I/O module ready for operation

red

I/O module note ready for operation

System is configured (in “Configuration”

nication” mode only).

off

I/O module note ready for operation

B, C,

G, H

Designation

LED

State

Function

Status

indicator

green

I/O module ready for operation

red

I/O module note ready for operation

off

Slave not connected

yellow

Wait for connection

yellow

flashing

green

Connection established

green

flashing

red

Connection error

750-644 Bluetooth

Pos: 40 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n f ür al le Ser ien/ Ger äte besc hrei bu ng/A nz eig eele ment e - Über schri ft 2 @ 4\mod_1240984390875_21.docx @ 31964 @ 2 @ 1

®

RF-Transceiver

4.4 Display Elements

Pos: 41 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Ger ätebes chrei bung /Anzei geel emen te/Son der klemm en/Anz eigeel ement e 750- 0644 @ 15\mod_1365149418098_21.docx @ 116650 @ 3333 @ 1

Figure 7: Display elements

8 LEDs indicate status. Depending on the operating mode

(configuration/communication) and role (master/slave), the LEDs display the

colors green, yellow or red as continuous illumination or flashing.

4.4.1 “Configuration” Mode

Table 9: Legend for the “Display elements” figure – “Configuration” mode

A

Status

indicator

E

-

D, F,

yellow

off -

mode only) or no connection to the first

slave could be established (in “Commu-

4.4.2 “Real-Time Communication” Mode, Master

Table 10: Legend for the “Display elements” figure – “Real-Time Communication” mode, master

A

Status of the

slave in slot

0x20, 0x21,

0x22, 0x23,

0x24, 0x25,

0x26

E, B, F, C,

G, D, H

Connection is being established

Data transfer

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 29

WAGO-I/O-SYSTEM 750 Device Description 29

Designation

LED

State

Function

Status

indicator

green

I/O module ready for operation

red

I/O module note ready for operation

> 53 channels free (no or negligible

external activity in the frequency range)

yellow

39 … 53 uninterrupted channels

< 39 only marked as free (massive

external activity in the frequency range)

There is no connection or only for a few

seconds

green

Signal quality optimal

yellow

Signal quality moderate

red

Signal quality low

There is no connection or only for a few

seconds

green

Signal strength optimal

yellow

Signal strength high

red

Signal strength low

There is no connection or only for a few

seconds

off

Master not connected

yellow

Wait for connection

yellow

flashing

green

Connection established

green

flashing

red

Connection error

750-644 Bluetooth

®

RF-Transceiver

4.4.3 “Real-Time Communication” Mode, Slave

Table 11: Legend for the “Display elements” figure – “Real-Time Communication” mode, slave

A

green

Interference D, H

Signal

quality

Signal

strength

C, G

B, F

Status of the

master in

E

slow 0x20

red

off

off

off

Connection is being established

Data transfer

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 30

30 Device Description WAGO-I/O-SYSTEM 750

Designation

LED

State

Function

Status

indicator

green

I/O module ready for operation

red

I/O module note ready for operation

off

No connection configured

yellow

Connection terminated

yellow

flashing

green

Connection established

green

flashing

red

Connection failed

red flashing

Connection terminated

flashing

green

- H off

-

750-644 Bluetooth

®

RF-Transceiver

4.4.4 “Ad-hoc Communication” Mode

Table 12: Legend for the “Display elements” figure – “Ad-hoc Communication” mode

A

Connection is being established

Status for

slot

0x10, 0x11,

0x12, 0x13,

0x14, 0x15

E, B, F, C,

G, D

Data transfer

Pos: 42 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

alternately

yellow and

Input buffer is full

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 31

WAGO-I/O-SYSTEM 750 Device Description 31

750-644 Bluetooth

Pos: 43 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n f ür al le Ser ien/ Ger äte besc hrei bu ng/Sc h ema tisch es Sch altbi l d - Ü bersc hri ft 2 @ 4\ mod_1240984441312_21.docx @ 31967 @ 2 @ 1

®

RF-Transceiver

4.5 Schematic Diagram

Pos: 44 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Gerät ebes chr ei bung /Sch ema tis che Sc halt bil der/ Son der kle mmen/ Sc hem atisc h es Sc halt bil d 7 50-0 644 @ 15 \mod_1365150212938_21.doc x @ 116653 @ @ 1

Figure 8: Schematic diagram

Pos: 45 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 32

32 Device Description WAGO-I/O-SYSTEM 750

Table 13: Technical Data – Device

Width

24 mm

Height (from upper edge of DIN 35 rail)

64 mm

approx. 6.5 mm

Length

100 mm

Weight

85 g

Table 14: Technical Data – Supply

Bluetooth® power supply

via 24 V DC field supply

Current consumption, field supply

approx. 8 mA, max. 35 mA

Power supply, system

via system voltage (DC/DC)

Current consumption, system

approx. 20 mA

Isolation

500 V antenna/system

Table 15: Technical Data – Communication

Data width (internal)

Configurable to 12, 24, 48 bytes,

including 1 control/status byte

Wireless technology

Bluetooth® 2.0 + EDR

Frequency band

License-free ISM band, 2402-2480

MHz

Transmitter power

up to 20 dBm (Bluetooth® Class 1)

Receiver sensitivity

-94 dBm

Transmission range

Max. 1000 m open area, 100 m in

WAGO, item no. 758-912)

Topology

Piconet (1 master, max. 7 slaves)

Coexistence

AFH and adaptive transmission power

Profile, standard

Serial Port Profile (SPP)

Profile, proprietary

Real-time

750-644 Bluetooth

Pos: 46 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n f ür al le Serien/Gerätebeschreibung/Technische Daten - Üb ersc hrif t 2 @ 3 \mod_1232967587687_21.docx @ 26924 @ 2 @ 1

®

RF-Transceiver

4.6 Technical Data

Pos: 47 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Ger äteb esc hrei bu ng/T ech nisc he D ate n/ Son derkl e mmen/T ec hni sch e D ate n 75 0-064 4 @ 15\mod_1365150321151_21.docx @ 116656 @ 3333 @ 1

4.6.1 Device

+ excess length of the SMA socket

4.6.2 Supply

4.6.3 Communication

building

(using the magnetic base antenna from

Manual

Version 2.0.0, valid from FW/HW Version 03/03

Page 33

WAGO-I/O-SYSTEM 750 Device Description 33

Table 16: Technical Data – Configuration and Diagnostics

Diagnostics, statuses

Device status, connection status, signal

strength, signal quality, interference

Diagnostics, interfaces

LED indication, process image,

WAGO-I/O-CHECK

Configuration

WAGO-I/O-CHECK, WAGO-I/O-PRO

CAA

Table 17: Technical data – Climatic environmental conditions

Operating temperature range

0 °C … 55 °C

Storage temperature range

-25 °C … +85 °C

Relative humidity without condensation

max. 95 %

Resistance to harmful substances

Acc. to IEC 60068-2-42 and

IEC 60068-2-43

Maximum pollutant concentration at

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

Ensure that additional measures for

– ionizing radiation