Page 1

Pos: 2 /Dokumentation allgemein/Einband/Einband Handbuch - Frontseite 20 15 - mit D ocV ari abl en (S ta ndar d) @ 9\mod_1285229289866_0.docx @ 64941 @ @ 1

WAGO-I/O-SYSTEM 750 XTR

Manual

750-559/040-000

10V DC /XTR

10 VDC /XTR

Version 1.2.0

4-Channel Analog Output Module, 0-

Pos: 3 /Alle S erie n (Al lge mei ne M odul e) /Rec htli ch es, Allg emei n es/I mpre ssu m f ür St and ard han dbüc h er - al lg. Ang aben, A nschr iften, Telef onnu mmern un d E-Mail -Adr esse n @ 3\mod_1219151118203_21.docx @ 21060 @ @ 1

4AO 0-

Page 2

2 WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

© 2016 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

=== Ende der Li st e für Te xtm arke Ei nba nd_ vorn e ===

Manual

Version 1.2.0

Page 3

WAGO-I/O-SYSTEM 750 XTR Table of Contents 3

750-559/040-000 4AO 0-10V DC /XTR

Pos: 5 /Do kume ntati on allg em ein /Ver zeic hni sse /Inh alts ver z eich nis - Ü ber schrif t oG und Verzei chnis @ 3\mod_1219151230875_21.docx @ 21063 @ @ 1

Table of Contents

1 Notes about this Documentation ................................................................. 5

1.1 Validity of this Documentation ................................................................. 5

1.2 Copyright ................................................................................................... 5

1.3 Symbols ..................................................................................................... 6

1.4 Number Notation ....................................................................................... 8

1.5 Font Conventions ...................................................................................... 8

2 Important Notes ........................................................................................... 9

2.1 Legal Bases ............................................................................................... 9

2.1.1 Subject to Changes ............................................................................... 9

2.1.2 Personnel Qualifications ....................................................................... 9

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with

Underlying Provisions .......................................................................... 9

2.1.4 Technical Condition of Specified Devices ......................................... 10

2.2 Safety Advice (Precautions) .................................................................... 11

3 Device Description ..................................................................................... 13

3.1 View ........................................................................................................ 15

3.2 Connectors ............................................................................................... 16

3.2.1 Data Contacts/Internal Bus ................................................................. 16

3.2.2 Power Jumper Contacts/Field Supply ................................................ 17

3.2.3 CAGE CLAMP® Connectors ............................................................. 19

3.3 Display Elements .................................................................................... 20

3.4 Operating Elements ................................................................................. 20

3.5 Schematic Diagram ................................................................................. 21

3.6 Technical Data ........................................................................................ 22

3.6.1 Device ................................................................................................. 22

3.6.2 Supply ................................................................................................. 22

3.6.3 Communication .................................................................................. 22

3.6.4 Outputs ............................................................................................... 23

3.6.5 Connection Type ................................................................................ 23

3.6.6 Mechanical Conditions ....................................................................... 23

3.6.7 Climatic Environmental Conditions ................................................... 23

3.7 Approvals ................................................................................................ 24

3.8 Standards and Guidelines ........................................................................ 26

4 Process Image ............................................................................................. 30

5 Mounting ..................................................................................................... 31

5.1 Mounting Sequence ................................................................................. 31

5.2 Inserting and Removing Devices ............................................................ 32

5.2.1 Inserting the I/O Module .................................................................... 32

5.2.2 Removing the I/O Module .................................................................. 33

6 Connect Devices ......................................................................................... 34

6.1 Connecting a Conductor to the CAGE CLAMP® ................................... 34

6.2 Connection Example ............................................................................... 35

7 Use in Hazardous Environments .............................................................. 36

7.1 Marking Configuration Examples ........................................................... 37

Manual

Version 1.2.0

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

7.1.1 Marking for Europe According to ATEX and IEC-Ex ...................... 37

7.1.2 Marking for America According to NEC 500 .................................... 42

7.2 Installation Regulations ........................................................................... 43

7.2.1 Special Conditions for Safe Use

(TÜV 14 ATEX 148929 X) ................................................................ 44

7.2.2 Special Conditions for Safe Use

(ATEX Certificate TÜV 12 ATEX 106032 X) .................................. 45

7.2.3 Special Conditions for Safe Use

(IEC-Ex Certificate TUN 14.0035X) ................................................. 46

7.2.4 Special Conditions for Safe Use

(IEC-Ex Certificate IECEx TUN 12.0039 X) .................................... 47

7.2.5 Special Conditions for Safe Use according to ANSI/ISA 12.12.01 ... 48

List of Figures ...................................................................................................... 49

List of Tables ........................................................................................................ 50

=== Ende der Li st e für Te xtm arke Ver zeic hni s_v or ne == =

Manual

Version 1.2.0

Page 5

WAGO-I/O-SYSTEM 750 XTR Notes about this Documentation 5

750-559/040-000 4AO 0-10V DC /XTR

Pos: 7 /Alle Ser ie n (All ge mein e M odul e) /Üb ersc hri ften/ Ne ue Ü ber schr ift en/ Ebe ne 1Hin weis e z u di eser D okum ent atio n - Ü ber schri ft 1 @ 4\ mod_1237987661750_21.doc x @ 29029 @ 1 @ 1

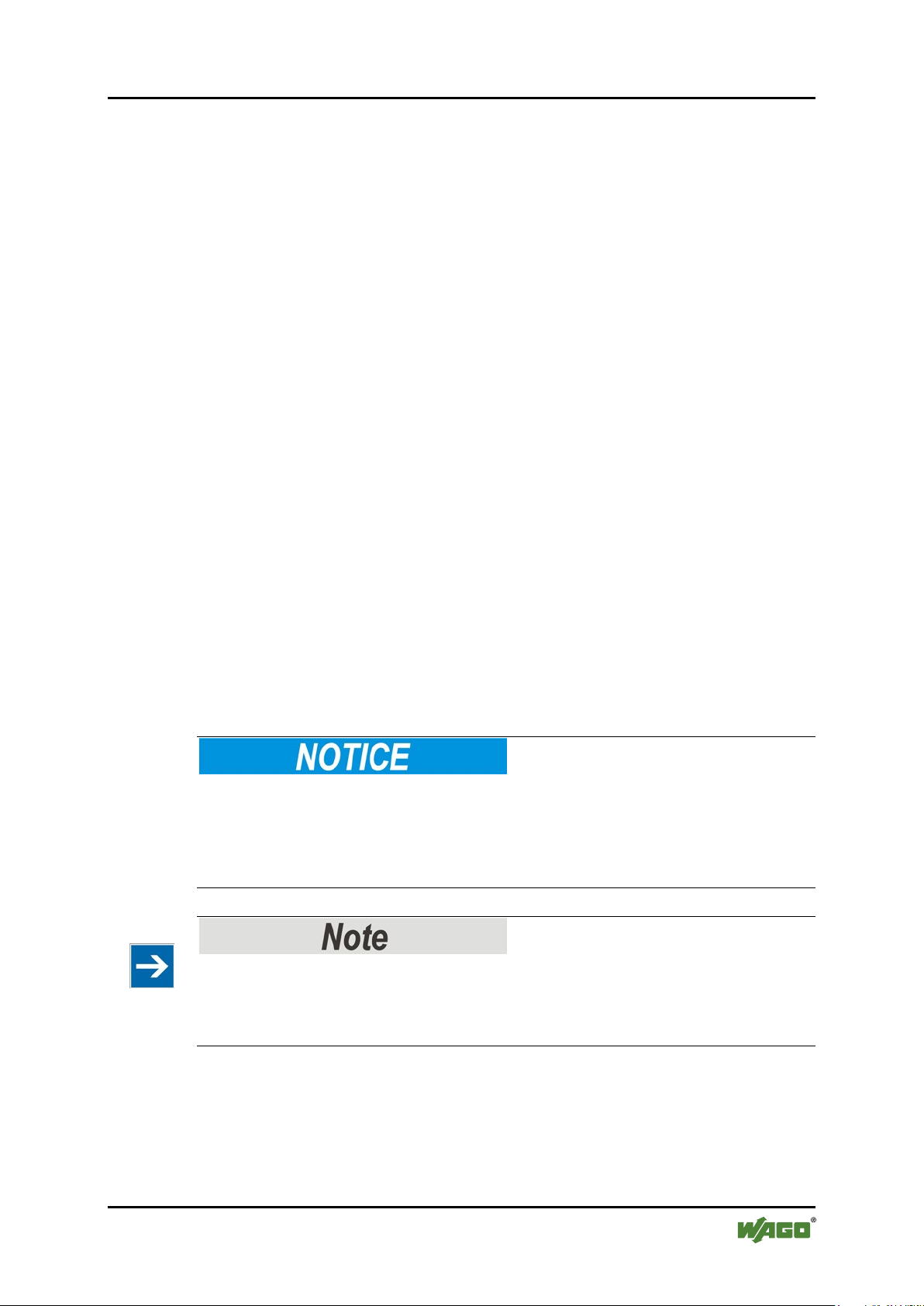

1 Notes about this Documentation

Pos: 8 /Alle S erie n (Al lge mei ne M odul e) /Sic her hei ts- und sonstige Hinweise/HinweisHinweis: Dokumentation aufbewahr en @ 4\mod_1237987339812_21.docx @ 29026 @ @ 1

Always retain this documentation!

This documentation is part of the product. Therefore, retain the documentation

during the entire service life of the product. Pass on the documentation to any

subsequent user. In addition, ensure that any supplement to this documentation is

included, if necessary.

Pos: 9 /Alle S erie n (Al lge mei ne M odul e) /Üb ersc hri ften/ Ne ue Ü ber sc hrift en /Ebe ne 2Gül tig keit sber eic h - Ü ber schr if t 2 @ 12\ mod_1338912448776_21.docx @ 9 6469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/ Gül tigk eits ber eic h/G ültig k eits ber eich Dok um enta tio n Bus kl emme 75 0-x xxx, o hne V aria nten ang abe @ 14\mod_1358944037947_21.docx @ 109346 @ @ 1

This documentation is only applicable to the I/O module 750-559/040-000

(4AO 0-10V DC /XTR).

Pos: 11 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/H in weis e z ur D okum ent ati on/Hi n weis e/Ac ht ung : Hin wei s z ur D oku ment ati on B us kle mme n 75 0-xxxx @ 4\mod_1237986979656_21.docx @ 29023 @ @ 1

The I/O module 750-559/040-000 shall only be installed and operated according

to the instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos: 12.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Ur h ebers chut z - Ü ber schr ift 2 @ 2 3\mod_1435647042188_21.docx @ 184808 @ 2 @ 1

1.2 Copyright

Pos: 12.2 /Al le Seri en ( All ge meine Mo dul e)/R ec htli ches , Al lge mei nes /Ur heb ersc hut z au sf ührli ch @ 4\mod_1235565145234_21.docx @ 27691 @ @ 1

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Pos: 12.3 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Pos: 12.4 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2 Sy mbol e - Ü bersc hri ft 2 @ 13\ mod_1351068042408_21.docx @ 105270 @ 2 @ 1

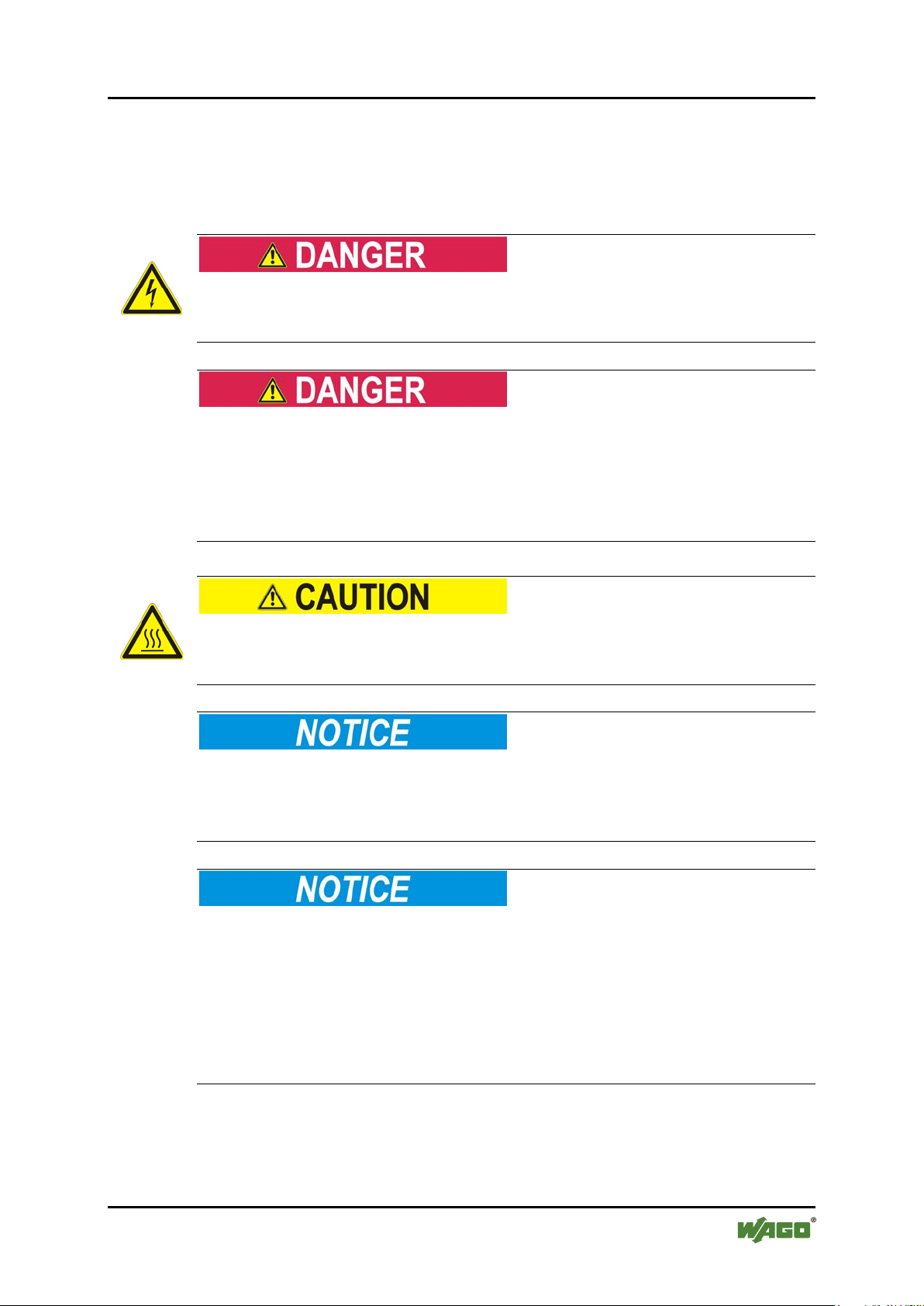

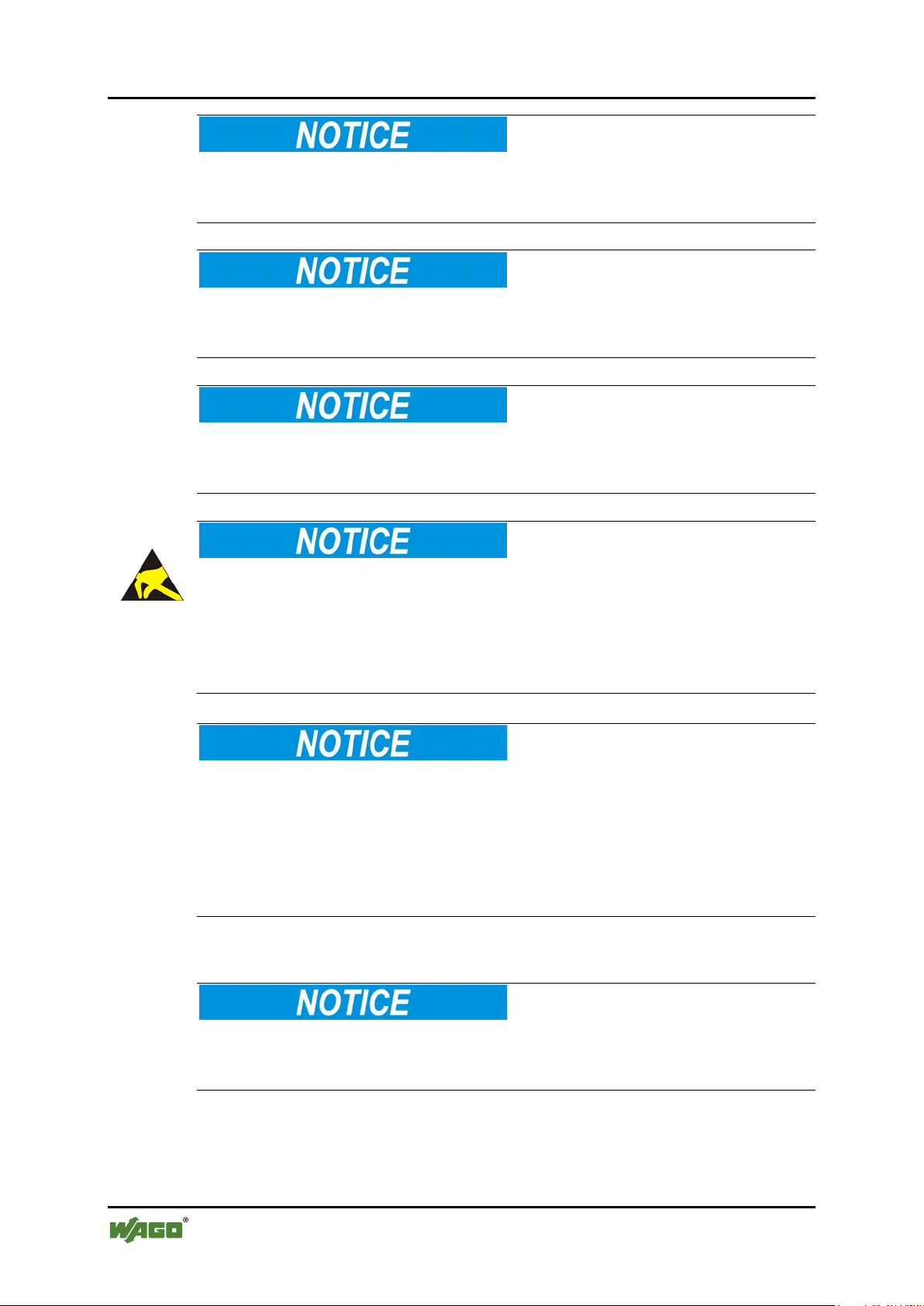

1.3 Symbols

Pos: 12.5.1 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Ge fahr /G efa hr: _War nu ng vor P ers onen sch äde n al lge mei n_ - Erläu ter ung @ 13 \mod_1343309450020_21.docx @ 101029 @ @ 1

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 12.5.2 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonsti ge Hin weise/ Gefahr /Gef ahr: _ Warnu ng vor Per sonen schä den dur ch ele ktrisc hen Stro m_ - Erläuterung @ 13\mod_1343309694914_21.docx @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 12.5.3 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/W arn ung/ War nung : _ Warn ung vor Perso nensc häde n allgem ein_ - Erläuterung @ 13\mod_1343309877041_21.docx @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 12.5.4 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonsti ge Hin weise/ Vorsic ht/V orsich t: _War nung v or Pers onens chäd en allge mein _ - Erläuterung @ 13\mod_1343310028762_21.docx @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 12.5.5 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Ac htu ng/ Ach tung : _ War nung vor Sac hsc häd en al lg emei n_ - Erläuterung @ 13\mod_1343310134623_21.docx @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 12.5.6 /All e Serie n ( All ge meine Mo dul e)/ Sich erh eits- und sonsti ge Hin weise/ Achtu ng/Ac htung : _War nung vor Sachsc häden durc h elektr ostatis che Au fladu ng_ - Erl äuter ung @ 13\ mod_1343310227702_21.docx @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 12.5.7 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Erläuterung @ 13\mod_1343310326906_21.docx @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 12.5.8 /All e Serie n (All gemei ne Mod ule)/ Sicher heits- und sons ti ge Hi n weis e/Inf or mati on/I nf orma tio n: _ Wei ter e Inf or mati on allg emei n_ - Erl äuter ung @ 13 \mod_1343310439814_21.docx @ 101051 @ @ 1

Manual

Version 1.2.0

Page 7

WAGO-I/O-SYSTEM 750 XTR Notes about this Documentation 7

750-559/040-000 4AO 0-10V DC /XTR

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 12.6 /Dokumentation allgemein/Gliederungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750 XTR

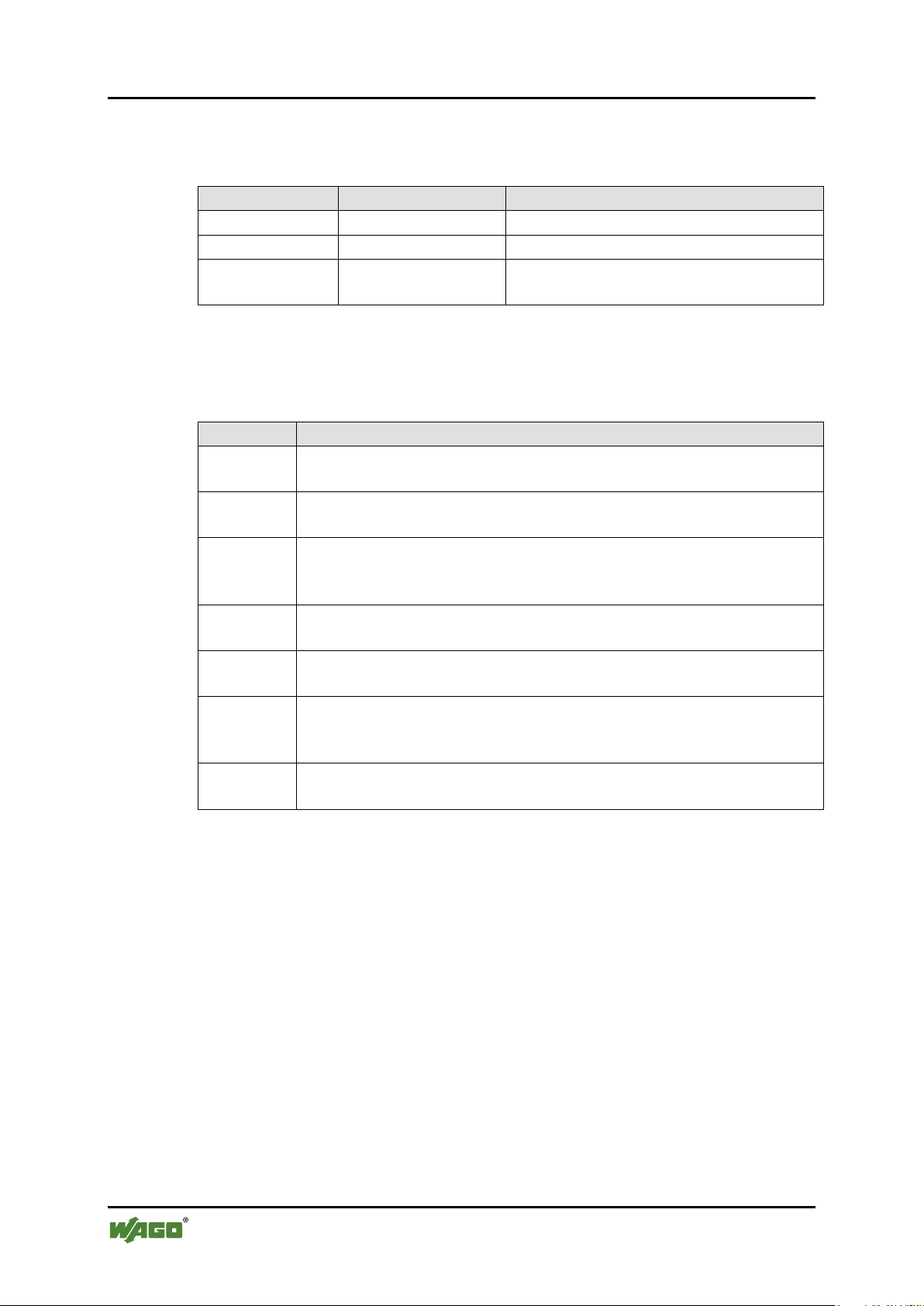

Table 1: Number Notation

Number Code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 2: Font Conventions

Font Type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Program Files\WAGO Software

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-559/040-000 4AO 0-10V DC /XTR

Pos: 12.7 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/D arst ell ung der Z a hle nsys tem e - Ü bers chri ft 2 @ 23\mod_1435647128078_21.docx @ 184811 @ 2 @ 1

1.4 Number Notation

Pos: 12.8 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes /Za hle nsy st eme @ 3\mod_1221059454015_21.docx @ 21711 @ @ 1

Pos: 12.9 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/Eb ene 2/Sc hr ift kon venti one n - Ü bersc hr ift 2 @ 23\ mod_1435647186005_21.docx @ 18 481 4 @ 2 @ 1

1.5 Font Conventions

Pos: 12.10 / All e S erie n (Al lge mei ne M o dule) /Re cht lich es, All ge mein es/ Schr ift kon venti on en @ 3\mod_1221059521437_21.docx @ 21714 @ @ 1

Pos: 13 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0. docx @ 2 181 0 @ @ 1

menu item from a menu.

brackets.

Manual

Version 1.2.0

Page 9

WAGO-I/O-SYSTEM 750 XTR Important Notes 9

750-559/040-000 4AO 0-10V DC /XTR

Pos: 14 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 1Wic hti ge Erlä ut erung en - Üb ersc hrif t 1 @ 4 \mod_1241428899156_21.docx @ 32170 @ 1 @ 1

2 Important Notes

Pos: 15.1 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes Wic htig e E rlä uter ung en - Einl eitung @ 3\mod_1221059818031_21.docx @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 15.2 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2R ec htli che Gru ndl age n - Ü bers chri ft 2 @ 3\mo d_1221060626343_21.docx @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 15.3 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes Ä nderu ngs vor beh alt - Ü b erschr if t 3 und I n halt @ 3 \mod_1221060036484_21.docx @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 15.4 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Person alqu alifi kationPersonalqualifikation 750-xxxx - Überschrift 3 und Inh alt @ 3\mod_1224061208046_21.docx @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on WAGO-I/O-SYSTEM 750 devices may only be

carried out by electrical specialists with sufficient knowledge in automation. The

specialists must be familiar with the current norms and guidelines for the devices

and automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 15.5 /Serie 750 (WAGO-I/O-SYSTEM)/Wichtige Erläuterungen/Bestimmungsgemäße VerwendungBestimmungsgemäße Verwendung 750-xxxx - Überschrift 3 und I nhal t @ 3\ mod_1224064151234_21.doc x @ 24070 @ 3 @ 1

2.1.3 Use of the WAGO-I/O-SYSTEM 750 in Compliance with Underlying Provisions

Fieldbus couplers, fieldbus controllers and I/O modules found in the modular

WAGO-I/O-SYSTEM 750 receive digital and analog signals from sensors and

transmit them to actuators or higher-level control systems. Using programmable

controllers, the signals can also be (pre-) processed.

The devices have been developed for use in an environment that meets the IP20

protection class criteria. Protection against finger injury and solid impurities up to

12.5 mm diameter is assured; protection against water damage is not ensured.

Unless otherwise specified, operation of the devices in wet and dusty

environments is prohibited.

Operating the WAGO-I/O-SYSTEM 750 devices in home applications without

further measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant information

in the section “Device Description” > “Standards and Guidelines” in the manual

for the used fieldbus coupler/controller.

Manual

Version 1.2.0

Page 10

10 Important Notes WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Appropriate housing (per 2014/34/EU) is required when operating the WAGOI/O-SYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 15.6 /Al l e Ser ien ( Al lge mei ne M od ule)/R ec htli ches , Al lg emei nes Tec hnis ch er Z ust and der Ger äte - Üb ersc hrift 3 u nd Inhalt @ 3\mod_1221060446109_21.docx @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Specified Devices

The devices to be supplied ex works are equipped with hardware and software

configurations, which meet the individual application requirements. WAGO

Kontakttechnik GmbH & Co. KG will be exempted from any liability in case of

changes in hardware or software as well as to non-compliant usage of devices.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 15.7 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 11

WAGO-I/O-SYSTEM 750 XTR Important Notes 11

750-559/040-000 4AO 0-10V DC /XTR

Pos: 15.8 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2 Sich er heits hi nweis e - Ü b erschr if t 2 @ 6 \mod_1260180299987_21.docx @ 46724 @ 2 @ 1

2.2 Safety Advice (Precautions)

Pos: 15.9 /Al l e Ser ien ( Al lge mei ne M od ule)/ Sic herh eits - u nd s ons tig e Hi nweis e/ Einl eit ung Sic herh eits hin wei se H ar dwar e @ 6\mod_1260180170493_21.docx @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 15.10. 1 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Nic ht an G erät en unter Sp ann ung ar beit en! @ 6\ mod_1260180365327_21.docx @ 46727 @ @ 1

Do not work on devices while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 15.10. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Gef ahr/ Gefa hr: Ei nbau 07 50- xxxx nur in Geh äusen, Schrä nken oder ele ktrisc hen Betr iebsr äumen! @ 6\mod_1260180556692_21.docx @ 46731 @ @ 1

Install the device only in appropriate housings, cabinets or in electrical

operation rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 15.10. 3 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Un fall verh üt ungs vors chr ift en b each te n! @ 6\mod_1260180657000_21.docx @ 46735 @ @ 1

Pos: 15.10. 4 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/G efahr /G ef ahr: Auf nor mg erec hte n Ans chl uss ac hten! @ 6\mod_1260180753479_21.docx @ 46739 @ @ 1

Pos: 15.11 / All e S erie n (Al lge mei ne M o dule) /Sic h erhei ts- und sons tige Hi nwei s e/Vor sic ht/ Vorsi cht : H eiße O berfl äc he al lge mei n @ 6\mod_1264428115588_21.docx @ 48610 @ @ 1

Hot surface!

The surface of the housing can become hot during operation. If the device was

operated at high ambient temperatures, allow it to cool off before touching it.

Pos: 15.12. 1 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung/Ac htu ng: Defe kte od er besch ädigt e Gerät e austa usch en! @ 6\mod_1260180857358_21.docx @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 15.12.2 /Alle Serien (Allgemeine Dokumente) (Allgemeine Module)/Wich tige Er läuter ungen /Sic herh eitshi nweise /Acht ung/ Achtu ng: Ger äte vor krieche nden u nd isoli ere nden Sto ffen sch ütze n! @ 6\mod_1260181036216_21.docx @ 46747 @ @ 1

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 15.12. 3 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: R eini gu ng n ur mit z ul ässig en M at eri alie n! @ 6\mod_1260181203293_21.docx @ 46751 @ @ 1

Manual

Version 1.2.0

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Clean only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 15.12. 4 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: K ei n Ko nta ktspr ay ver wend en! @ 6\mod_1260181290808_21.docx @ 46755 @ @ 1

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 15.12. 5 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: V erp ol ung ver meide n! @ 6\ mod_1260184045744_21.docx @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 15.12. 6 /A lle Ser ien ( All ge mein e D oku ment e) ( Allg em ein e M odul e)/ Wich tig e Er lä uter ung en/Si ch erh eits hin weis e/Ac ht ung /Ac htu ng: El ektros tatisc he Entl adu ng verm eiden! @ 6\mod_1260181364729_21.docx @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge when touched. Please observe the safety precautions

against electrostatic discharge per DIN EN 61340-5-1/-3. When handling the

devices, please ensure that environmental factors (personnel, work space and

packaging) are properly grounded.

Pos: 15.13 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Ac htu ng/Ac ht ung: XTR - Is ola tio ns prüf ung en mit DC d urch führ en! @ 15\mod_1370843209441_21.docx @ 122210 @ @ 1

Perform insulation tests with direct current (DC)!

Both the supply voltage and control voltage side are capacitively coupled to the

DIN rail. If the modules are mounted on the DIN rail, application of an AC

voltage between the two potentials can lead to the destruction of the device.

Use only direct current (DC) for insulation testing.

To avoid destroying the device, discharge the device completely before applying

the test voltage again.

Pos: 16 /Alle Seri en (Al lge mei ne Mo dul e)/ Sich er heits- und s onst ige H i nweis e/ Acht ung/ Ac htung : Ni cht in Tel ek ommu ni kati ons netz en eins etze n! (Zus atz RJ- 45) @ 3\ mod_1224065187468_21.docx @ 24076 @ @ 1

Do not use in telecommunication circuits!

Only use devices equipped with ETHERNET or RJ-45 connectors in LANs.

Never connect these devices with telecommunication networks.

Pos: 17 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 13

WAGO-I/O-SYSTEM 750 XTR Device Description 13

750-559/040-000 4AO 0-10V DC /XTR

Pos: 18 /Alle Seri en (Al lge mei ne Mo dul e)/Ü b erschr if ten/ Neu e Ü ber schri ft en/ Ebe ne 1 Ger äteb esc hrei bung - Ü ber schr if t 1 @ 3\mod_1233756084656_21.docx @ 27096 @ 1 @ 1

3 Device Description

Pos: 19.1 /Serie 750 (WAGO-I/O-SYSTEM)/Gerätebeschreibung/Einleitung/Anwendung/AO/Anwendung 750- 05xx AO (0...10V) @ 5\mod_1247046851995_21.docx @ 36817 @ @ 1

The analog output module 750-559/040-000 (4AO 0-10V DC /XTR) generates a

standardized signal of 0 … 10 V for the field area.

Pos: 19.2 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nlei tung /I/ O-Besc hrei bu ng/ AO/I/ O-Beschreibung 750-05xx 4 AO 2-Leiter (AO1.. .AO4 u nd Mass e) @ 5\mod_1247053300854_21.docx @ 36880 @ @ 1

The I/O module has 4 output channels, making direct wiring of four 2-wire

actuators possible.

The actuators are connected to CAGE CLAMP® connectors AO 1 and common

Pos: 19.3 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nlei tung /I/ O-Besc hrei bu ng/ AO/I/ O-Beschreibung 750-05xx AO Gemei nsam es M ass epo tent ial @ 5 \mod_1247050255026_21.docx @ 36870 @ @ 1

Pos: 19.4 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nlei tung /I/ O-Besc hr eibu ng/ All gem ein/ Ver weis auf K apit el " Ansc hl üsse" @ 8\mod_1276775378035_21.docx @ 57956 @ @ 1

Pos: 19.5 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nlei tung /I/ O-Besc hr eibu ng/ All gem ein/ Ver weis auf K apit el " Ger äte ans chli eß en" > "Ansc hlussb eispi el(e)" @ 5\mod_1246015203281_21.docx @ 36298 @ @ 1

Pos: 19.6 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nlei tung /LED -Anz eig e/LE D Z ust and B etrie b und Kle mmen bus-Ko mmuni katio n @ 5\mod_1247054901573_21.docx @ 36892 @ @ 1

Pos: 19.7 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Einl ei tung /LED- Anz eig e/LED Fe hl er K urzsc hl uss/ Über la st @ 5\ mod_1247118146009_21.docx @ 36939 @ @ 1

Pos: 19.8 /Serie 750 (WAGO-I/O-S YST EM)/ Geräte bes chr eibu ng/Ei nlei tu ng/L ED-A nzeig e/Ver weis au f Kapit el "Anz eige elemen te" @ 5\mod_1246010525000_21.docx @ 36194 @ @ 1

Pos: 19.9 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ei nleitung/Versorgung/Spannungsversorgung aus Systemspannung @ 5\mod_1247116433759_21.docx @ 36920 @ @ 1

Pos: 19.10 / Ser ie 750 ( WA GO-I/ O-SY STEM )/G erät ebe schr eibu ng/E inl eitung /V ersor gu ng/V ers orgung 24 V, 0 V über Leist ungs konta kte Stan dard @ 3\ mod_1226498974531_21.docx @ 25020 @ @ 1

Pos: 19.11 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s ons tig e Hi nw eise /Acht u ng/Ac ht ung: Ma xim aler Str om Leis tung s konta kte 10 A @ 3\mod_1226499143500_21.docx @ 25029 @ @ 1

(ground) or AO 2, AO 3, AO 4 and respective common (ground).

The channels have a common ground potential.

The assignment of the connections is described in the “Connectors” section.

Connection examples are shown in section “Connecting Devices” > … >

“Connection Example(s)”.

The operational readiness and the trouble-free internal data bus communication of

the channels are indicated via a green function LED.

A red error LED indicates a short circuit or overcurrent.

The meaning of the LEDs is described in the “Display Elements” section.

Power to the internal electronics is supplied via internal data bus.

The I/O module 750-559/040-000 (4AO 0-10V DC /XTR) receives the 24 V

voltage supply for the field level from an upstream I/O module or from the

fieldbus coupler/controller via blade-formed power jumper contacts. It then

provides these potentials to subsequent I/O modules via spring-formed power

jumper contacts.

Do not exceed maximum current via power jumper contacts!

The maximum current to flow through the power jumper contacts is 10 A.

Greater currents can damage the contacts.

When configuring your system, ensure that this current is not exceeded. If

exceeded, insert an additional supply module.

Pos: 19.12 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und sonstige Hinweise/Hinweis/Hinweis: Potenti al eins peis e klem me f ür E rde eins etz en! (k eine LK f ür E rde) @ 3\mod_1226499037468_21.docx @ 25023 @ @ 1

Use supply modules for ground (earth)!

The I/O module has no power jumper contacts for receiving and transmitting the

earth potential. Use a supply module when an earth potential is needed for the

subsequent I/O modules.

Pos: 19.13 / Ser ie 750 ( WA GO-I/ O-SYSTEM)/Gerätebeschreibung/Einleitung/Funktion/Galvanische Trennung Ausgangssignal/Systemebene (12 Bit) @ 5\mod_1247050641729_21.docx @ 36877 @ @ 1

The Output signal is electrically isolated and will be transmitted with a resolution

of 12 bits.

Pos: 19.14 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und sonstige Hinweise/Hinweis/Hinweis: XTR - Mischbetrieb XTR/Hinweis: XTR - Misch betri eb XTR/ Stan dard @ 15\mod_1367496420828_21.docx @ 118326 @ @ 1

Manual

Version 1.2.0

Page 14

14 Device Description WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Mixed operation

Mixed operation (standard/XTR modules) within a node is possible when groups

of modules are electrically isolated on the field side (i.e., electrically isolated

power supply).

Pos: 19.15 /S eri e 7 50 ( WAG O-I/O- SYST EM) /Wi chtig e Er l äuter ung en /Sic her hei ts- und so nstige Hinweise/Hinweis/Hinweis: XTR - Erhöht e St örf estig k eit @ 15\ mod_1367496424993_21.docx @ 118330 @ @ 1

Increased interference!

For standard-compliant application in substation instrumentation and control,

telecontrol systems, railway technology or shipbuilding certified operation,

field-side power supply filter 750-624/040-001 or power supply filter

750-626/040-000 are generally to be used for XTR module groups.

Pos: 19.16 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Gerät ebes chrei bung /Einlei tung/ Eins atzb ereich/ Eins atzb ereich 7 50-xxxx/ 040-000 al le XTR-K oppl er /Ei nsat zber ei ch 7 50- xxxx/040-00 0 al le XT R- Koppl er/- Contr oller ohne Ei nschr änku ng @ 15\mod_1368425919479_21.docx @ 119444 @ @ 1

The I/O module can be operated with all fieldbus couplers/controllers of the

WAGO-I/O-SYSTEM 750 XTR.

Observe the instructions for mixed operation when used in mixed operation

behind standard fieldbus couplers/controllers.

Pos: 20 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 15

WAGO-I/O-SYSTEM 750 XTR Device Description 15

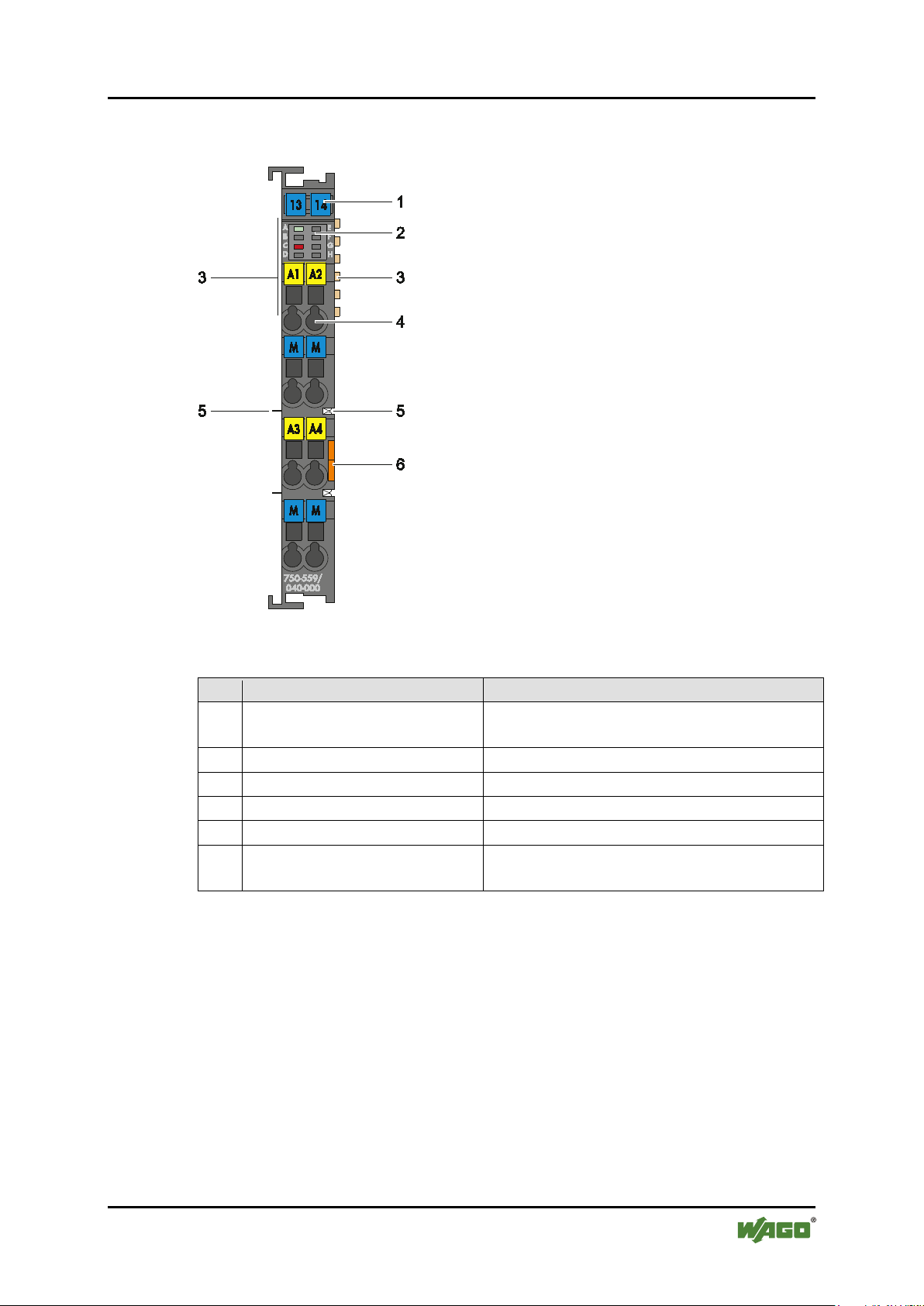

Table 3: Legend for Figure “View”

Pos.

Description

Details See Section

1

Marking possibility with MiniWSB

--2

Status LEDs

“Device Description” > “Display Elements”

3

Data contacts

“Device Description” > “Connectors”

4

CAGE CLAMP® connectors

“Device Description” > “Connectors”

5

Power jumper contacts

“Device Description” > “Connectors”

6

Release tab

“Mounting” > “Inserting and Removing

Devices”

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.1 /Al l e Ser ien ( Al lge mei ne M od ule)/Ü ber sc hrift e n/N eue Ü ber schr if ten/ Ebe ne 2 Ans ich t - Ü bersc hri ft 2 @ 4\mod_1240984217343_21.docx @ 31958 @ 2 @ 1

3.1 View

Pos: 21.2 /Serie 750 (WAGO-I/O-S YSTEM )/Ger äteb eschr eibu ng/Ans icht /Anal ogausg angs klem men/A nsicht 750-05 59/ 040- xxx @ 17\mod_1380708771349_21.docx @ 133580 @ @ 1

Figure 1: View

Pos: 21.3 /Serie 750 (WAGO-I/O-S YST EM) /Ger äte bes chr ei bung /Ans ic ht/A nsic ht C ag eCl amp® _Leg en de mit LEDs , mi t 1 Entr ieg el ung slasc h e @ 1 5\mod_1370867188922_21.docx @ 122225 @ @ 1

Pos: 21.4 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 16

16 Device Description WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.5 /All e Serien ( Allg emei ne Mo dule) /Ü bers chri ft en/N eu e Üb ersc hrif te n/Eb ene 2An schl üss e - Ü ber schr if t 2 @ 4\mod_1240984262656_21.docx @ 31961 @ 2 @ 1

3.2 Connectors

Pos: 21.6 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ans chl üsse /Da ten konta kt e/Kl emme nbus - Ü berschr ift 3 @ 6\ mod_1256294684083_21.docx @ 43660 @ 3 @ 1

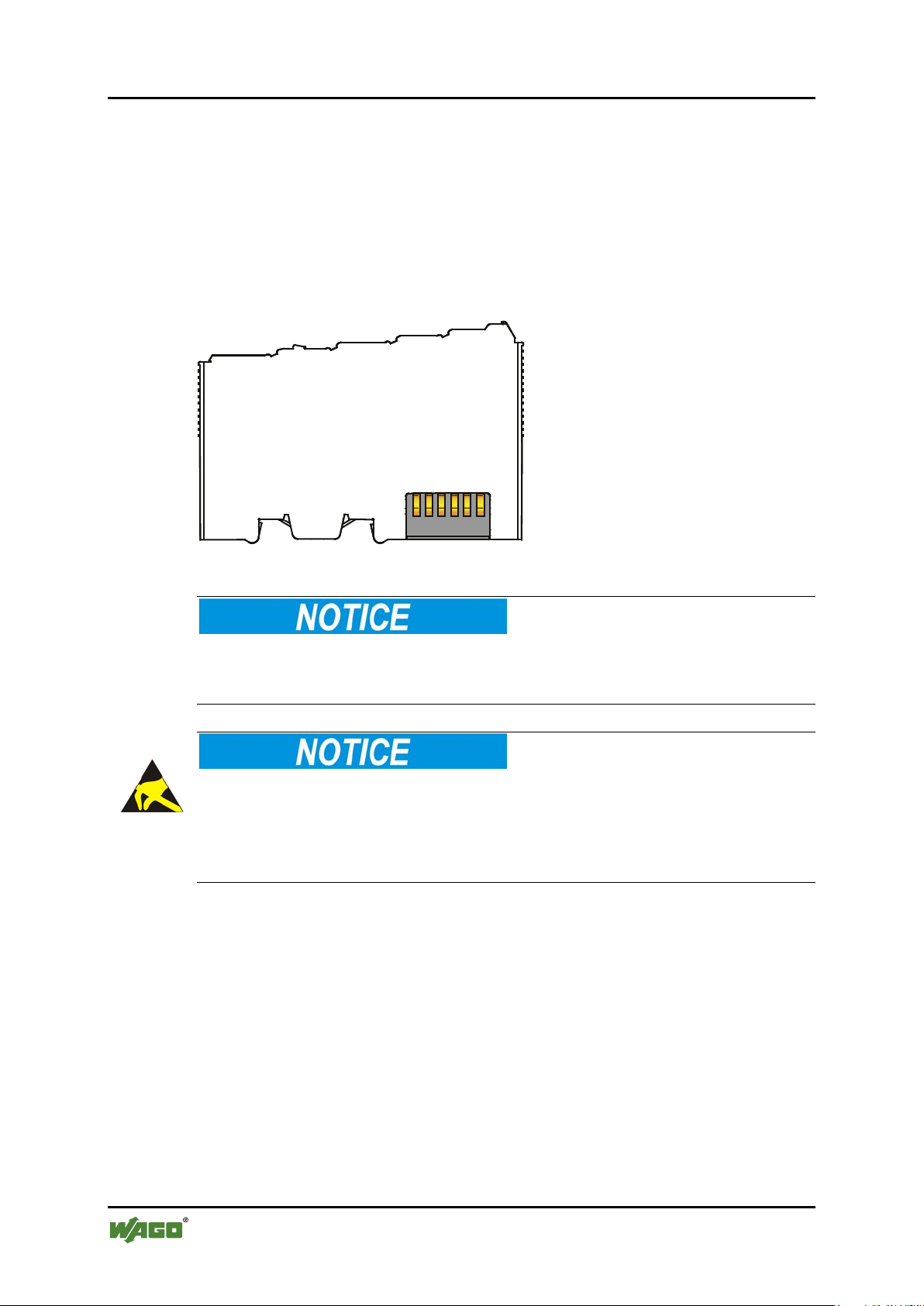

3.2.1 Data Contacts/Internal Bus

Pos: 21.7.1 /S erie 750 (W AGO- I/O-SYSTEM)/Gerätebeschreibung/Anschlüsse/Datenkontakte - Feldbuskoppler /-con trol ler , A bbil dung u nd B esc hrei bu ng @ 3\mod_1231771259187_21.docx @ 26002 @ @ 1

Communication between the fieldbus coupler/controller and the I/O modules as

well as the system supply of the I/O modules is carried out via the internal bus. It

is comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data Contacts

Pos: 21.7.2 /S erie 750 (W AGO- I/O-SYSTEM)/Wichtige Erläuterungen/Sicherheits- und sonstig e H in weis e/A chtu ng/ Ach tung : Buskl em men nic ht a uf G oldf eder k onta kte leg en! @ 7 \mod_1266318463636_21.docx @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 21.7.3 /S erie 750 (W AGO-I/ O-SYSTEM)/Wichtige Erläuterungen/Sicherheits- und sonstige Hinweise/Achtung/Achtung: ESD - A uf gut e Erdung der Umg ebung achte n! @ 7\mod_1266318538667_21.docx @ 50708 @ @ 1

Ensure that the environment is well grounded!

The devices are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the devices, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 21.8 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 17

WAGO-I/O-SYSTEM 750 XTR Device Description 17

Table 4: Legend for Figure “Power Jumper Contacts”

Contact

Type

Function

1

Spring contact

Potential transmission (Uv) for field supply

2

Spring contact

Potential transmission (0 V) for field supply

3

Blade contact

Potential feed-in (0 V) for field supply

4

Blade contact

Potential feed-in (Uv) for field supply

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.9 /Serie 750 (WAGO-I/O-S YST EM)/ Ger äteb esc hrei bung /Ans chl üsse /Lei stu ngs kont akt e/Fel dver sor gu ng - Üb ersc hri ft 3 @ 6\mod_1256294692864_21.docx @ 43664 @ 3 @ 1

3.2.2 Power Jumper Contacts/Field Supply

Pos: 21.10. 1 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Vors ich t/V orsic ht: V erlet zu ngsg efa hr d urc h sc har fka ntig e Mes ser kon ta kte! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Pos: 21.10. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Ans chl üss e/L eist ungs kon ta kte 2 LK ( M ess er/L eist ung s konta kte 2 LK (M esser /F eder ) - Einl eitu ng @ 15\ mod_1371721641099_21.docx @ 123714 @ @ 1

The I/O module 750-559/040-000 has 2 self-cleaning power jumper contacts that

supply and transmit power for the field side. The contacts on the left side of the

I/O module are designed as blade contacts and those on the right side as spring

contacts.

Pos: 21.10. 3 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Ger äte bes chr eib ung/ Ans chl üss e/L eist ungs kon tak te 2 LK ( M ess er/L eist ung sko nta kte 2 LK (Mes ser /F eder ) - Abbil dung , ei nf ache Br eite - St an dard @ 1 5\mod_1367500700037_21.docx @ 118396 @ @ 1

Figure 3: Power Jumper Contacts

Pos: 21.10. 4 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Ans chl üss e/L eist ungs kon ta kte 2 LK ( M ess er/L eist ung s konta kte 2 LK (M esser /F eder ) - Leg end e @ 1 5\mod_1371721352500_21.docx @ 123710 @ @ 1

Pos: 21.10. 5 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Acht ung /Ac htung : Maxi maler Stro m Leistu ngsko ntak te 10 A @ 3\mod_1226499143500_21.docx @ 25029 @ @ 1

Do not exceed maximum current via power jumper contacts!

The maximum current to flow through the power jumper contacts is 10 A.

Greater currents can damage the contacts.

When configuring your system, ensure that this current is not exceeded. If

exceeded, insert an additional supply module.

Pos: 21.10. 6 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Wic htig e Er l äuter ung en /Sic her hei ts- und s onst ige H i nwei se/ Hin weis /Hi nwei s: P ot enti alei nsp eis ekl emm e für Er de eins etz en! (kei ne LK f ür Er de) @ 3\mod_1226499037468_21.docx @ 25023 @ @ 1

Manual

Version 1.2.0

Page 18

18 Device Description WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Use supply modules for ground (earth)!

The I/O module has no power jumper contacts for receiving and transmitting the

earth potential. Use a supply module when an earth potential is needed for the

subsequent I/O modules.

Pos: 21.11 /D o kum entat io n all ge mei n/Gli ed eru ngsel e ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 19

WAGO-I/O-SYSTEM 750 XTR Device Description 19

Table 5: Legend for Figure “CAGE CLAMP® Connectors”

Channel

Designation

Connector

Function

AO 1

1

Analog output 1: Signal voltage

Common

(ground)

Analog output 1: Common (ground)

AO 2

5

Analog output 2: Signal voltage

Common

(ground)

Analog output 2: Common (ground)

AO 3

3

Analog output 3: Signal voltage

Common

(ground)

Analog output 3: Common (ground)

AO 4

7

Analog output 4: Signal voltage

Common

(ground)

Analog output 4: Common (ground)

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.12 / Ser ie 750 ( WA GO-I/ O-SY STEM )/G erät ebe schr ei bu ng/A nsc hlüss e/C AG E C LAM P-Anschlü sse - Über schr ift 3 @ 6\mod_1256296337770_21.docx @ 43674 @ 3 @ 1

3.2.3 CAGE CLAMP® Connectors

Pos: 21.13 / Ser ie 750 ( WA GO-I/ O-SY STEM )/G erät ebe schr ei bu ng/A nsc hlüss e/ Anal og ausg ang s klemm en/A nsc hlüs se 750- 055 7, -0559 @ 14\mod_1359705332140_21.docx @ 110715 @ @ 1

Figure 4: CAGE CLAMP

®

Connectors

1

2

3

4

Pos: 21.14 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Hi nwei s/Hi n weis : Ges chi r mte Sig nal lei tu nge n ver we nde n! @ 7\mod_1265723251019_21.docx @ 50140 @ @ 1

Use shielded signal lines!

Only use shielded signal lines for analog signals and I/O modules which are

equipped with shield clamps. Only then can you ensure that the accuracy and

interference immunity specified for the respective I/O module can be achieved

even in the presence of interference acting on the signal cable.

2

6

4

8

Pos: 21.15 / Ser ie 750 ( WA GO-I/ O-SY STEM )/A nsc hli eße n/Ver wei s a uf K api tel Sc hirm ung im S yst emh and buc h XTR @ 19\ mod_1399554643119_21.docx @ 153199 @ @ 1

For further information about shielding, see system manual WAGO-I/O-SYSTEM

750 XTR, section “Connect Devices” > … > “Shielding.”

Pos: 21.16 /D o kum entat io n all ge mei n/Gli ed eru ngsel e ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 20

20 Device Description WAGO-I/O-SYSTEM 750 XTR

Table 6: Legend for Figure “Display Elements”

Designation

LED

State

Function

No operational readiness or the internal data bus

communication is interrupted

Operational readiness and trouble-free internal

data bus communication

Off

No error

Overload or short circuit to ground in one of the

output channels

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.17 / Alle S erie n (Al lge mei ne M odul e) /Üb ersc hri ften /Ne ue Ü ber sc hrift e n/Eb ene 2Anz eig eel em ente - Üb erschr ift 2 @ 4\mod_1240984390875_21.docx @ 31964 @ 2 @ 1

3.3 Display Elements

Pos: 21.18 / Ser ie 750 ( WA GO-I/ O-SY STEM )/G erät ebe schr eibu ng/A nzeig eel e mente/ An alog ausgang skl emme n/Anzei geel eme nte 750-05xx/040-xxx 4AO ( Agn, Cr t) @ 17\ mod_1380641377218_21.docx @ 133466 @ @ 1

Figure 5: Display Elements

Function

A

Error C

Pos: 21.19 / All e S erie n (Al lge mei ne M o dule) /Üb ersc hri ft en/N eu e Über sc hrif te n/Eb ene 2Be die nel ement e - Über schr ift 2 @ 4\mod_1239191655456_21.docx @ 30439 @ 2 @ 1

3.4 Operating Elements

Pos: 21.20 / Ser ie 750 ( WA GO-I/ O-SYST EM) /Ger ätebe schr ei bu ng/B edi enel eme nte/ Be dien ele men te B us kle mme 7 50- xxxx nicht vorhanden @ 4\mod_1236322031125_21.docx @ 28063 @ @ 1

The I/O module 750-559/040-000 has no operating elements.

Pos: 21.21 /D o kum entat io n all ge mei n/Gli ed eru ngsel e ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Off

Green

Red

Manual

Version 1.2.0

Page 21

WAGO-I/O-SYSTEM 750 XTR Device Description 21

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.22 / All e S erie n (Al lge mei ne M o dule) /Üb ersc hri ft en/N eu e Über sc hrif te n/Eb ene 2Sc he matis ches Sc hal tbi ld - Ü ber schr if t 2 @ 4\mod_1240984441312_21.docx @ 31967 @ 2 @ 1

3.5 Schematic Diagram

Pos: 21.23 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Gerät ebes chrei bung /Sche matis che Sc haltbil der/ Analog ausg angs klem men/Sc hemati sch es Schalt bild 750-055 9/04 0-xxx @ 17\mod_1380712534380_21.docx @ 133611 @ @ 1

Figure 6: Schematic Diagram

Pos: 21.24 /D o kum entat io n all ge mei n/Gli eder ung sel ement e/---S eiten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 22

22 Device Description WAGO-I/O-SYSTEM 750 XTR

Table 7: Technical Data – Device

Width

12 mm

Height (from upper edge of DIN 35 rail)

61 mm

Length

100 mm

Weight

53.5 g

Degree of protection

IP20

Table 8: Technical Data – Supply

Current consumption, system voltage

max.

(5 VDC)

125 mA

Current consumption, power jumper

contact

typ.

(24 VDC)

---

Voltage via power jumper contacts:

under laboratory conditions

+55 °C … +70 °C

24 VDC

Current via power jumper contacts

max.

10 A

Rated surge voltage

1 kV

1)

Including residual ripple of 15 %

Table 9: Technical Data – Communication

Bit width

4 × 16 bits data

4 × 8 bits control/status (optional)

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.25 / All e S erie n (Al lge mei ne M o dule) /Üb ersc hri ft en/N eu e Über sc hrif te n/Eb ene 2T echni sc he Da te n - Üb ers chrif t 2 @ 3 \mod_1232967587687_21.docx @ 26924 @ 2 @ 1

3.6 Technical Data

Pos: 21.26. 1 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Tec hni sch e D ate n/VS ( Var i ablen ste uer ung )/Tec h nisch e D ate n Ger ät ( VS) - XT R @ 15\ mod_1369311215011_21.doc x @ 120260 @ 3 @ 1

3.6.1 Device

Pos: 21.26. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Ger äte besc hrei bung /Tec h nisch e D ate n/V S (V ari abl enste uer ung )/T ech nisc he D at en Vers org ung ( VS) D C 24 V - XT R @ 15\ mod_1369311347965_21.docx @ 120278 @ 3 @ 1

3.6.2 Supply

for ambient operating temperature

for ambient operating temperature

Pos: 21.26. 3 /S eri e 75 0 ( WAG O-I/O- SYST EM) /Ger äte besc hrei bung /Tec hni sch e Dat en/V S ( Vari abl en steu eru ng) /Tec hni sch e Dat e n Ko mmuni kat ion (V S) @ 4\mod_1242119312796_21.docx @ 32970 @ 3 @ 1

3.6.3 Communication

+15 °C … +35 °C

−40 °C … +55 °C

18 V … 31.2 V (17.4 V … 31.2 V) 1)

18 V … 28.8 V (17.4 V … 28.8 V) 1)

18 V … 26.4 V (17.4 V … 26.4 V) 1)

Pos: 21.26.4 /S erie 75 0 (WAG O-I/O-SY ST EM) /Ger äte bes chr eibung / Tec hnis che D at en/A n alog ausg ang skl em men/T ec hnisc h e Dat en 7 50- 055 9/Tec hnis ch e D aten 75 0-0 559/ 040- xxx @ 17\mod_1380710481106_21.docx @ 133603 @ 3 @ 1

Manual

Version 1.2.0

Page 23

WAGO-I/O-SYSTEM 750 XTR Device Description 23

Table 10: Technical Data – Outputs

No. of outputs

4

Load impedance

> 5 kΩ

Signal voltage

0 V … 10 V

Resolution

12 bit

Conversion time

typ.

10 ms

Recovery time

typ.

100 ms

Measuring error at 25 °C

< ±0.1 % of upper range value

Temperature coefficient

< ±0.01 %/K of upper range value

Table 11: Technical Data – Field Wiring

Wire connection

CAGE CLAMP®

Cross section

0.25 mm² … 2.5 mm² / AWG 24 … 14

Stripped lengths

8 mm … 9 mm / 0.33 in

Table 12: Technical Data – Power Jumper Contacts

Power jumper contacts

blade/spring contact, self-cleaning, hard

gold plated

Voltage drop at I

max.

< 1 V at 64 I/O modules

Table 13: Technical Data – Data Contacts

Data contacts

slide contact, self-cleaning, hard gold

plated

Table 14: Technical Data – Mechanical Conditions

Vibration resistance

Max. 5g 1)

1)

Follow the installation instructions

Table 15: Technical Data – Climatic Environmental Conditions

Operating temperature range

−40 °C … +70 °C

Storage temperature range

−40 °C … +85 °C

Relative humidity

1)

95 %

Elevation above sea level

max.

5000 m

1)

Short-term condensation per Class 3K7/IEC EN 60721-3-3 and E DIN 40046-721-3 (except

wind-driven precipitation, water and ice formation)

750-559/040-000 4AO 0-10V DC /XTR

3.6.4 Outputs

Pos: 21.26. 5 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Tec hni sch e D ate n/VS ( Var i ablen ste uer ung )/Tec h nisch e D ate n Ans chl uss tec hni k (V S) @ 1 6\mod_1373273824961_21.docx @ 125714 @ 3 @ 1

3.6.5 Connection Type

Pos: 21.26. 6 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Tec hni sch e D ate n/VS ( Var i ablen ste uer ung )/Tec h nisch e D ate n M echa nisc he Bedi ng ung en ( VS) - XTR @ 1 5\mod_1369387569701_21.docx @ 120364 @ 3 @ 1

3.6.6 Mechanical Conditions

Pos: 21.26. 7 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Tec hni sch e D ate n/VS ( Var i ablen ste uer ung )/Tec h nisch e D ate n kli ma tisc he Umw elt bedi ngu nge n (V S) - X TR @ 15\mod_1369387559187_21.docx @ 120360 @ 3 @ 1

3.6.7 Climatic Environmental Conditions

without temperature derating

with temperature derating

Pos: 21.27 /D o kum entat io n all gem ei n/Gli eder ungs ele ment e/---Sei ten wec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

0 m … 2000 m

2000 m … 5000 m: 0.5 K per 100 m

Page 24

24 Device Description WAGO-I/O-SYSTEM 750 XTR

Conformity Marking

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

IECEx

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.28 / All e S erie n (Al lge mei ne M o dule) /Üb ersc hri ft en/N eu e Über sc hrif te n/Eb ene 2Z ulass ung en - Über schr ift 2 @ 3\mod_1224055364109_21.docx @ 24030 @ 2 @ 1

3.7 Approvals

Pos: 21.29. 1 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Zul ass ung en/ Infor m ati on: Weit ere I nf ormat io nen z u Z ula ssu nge n 7 50-xxxx @ 3\mod_1227190967156_21.docx @ 25221 @ @ 1

More information about approvals.

Detailed references to the approvals are listed in the document “Overview

Approvals WAGO-I/O-SYSTEM 750”, which you can find via the internet

under: www.wago.com > SERVICES > DOWNLOADS > Additional

documentation and information on automation products > WAGO-I/O-SYSTEM

750 > System Description.

Pos: 21.29. 2 /S eri e 75 0 ( WAGO-I/O-S YSTEM )/Ger ätebe schr eibung /Zul assung en/A llge mein/Z ulass unge n Buskle mme 7 50-xxxx Allgemein, ohne Variantenangabe - Einleitung @ 4 \mod_1237460656921_21.docx @ 28643 @ @ 1

The following approvals have been granted to 750-559/040-000 I/O modules:

Pos: 21.29. 3 /A lle Ser ien ( All ge mein e M odul e)/ Zul ass ung en/S tan dar dzul ass ung en/C E ( Kon for mit ätsk ennz eic hnu ng) @ 3\ mod_1224494777421_21.docx @ 24276 @ @ 1

Pos: 21.29. 4 /A lle Ser ien ( All ge mein e M odul e)/ Zul ass ung en/S tan dar dzul ass ung en/c ULus ( UL50 8) @ 3\ mod_1224055013140_0.docx @ 24020 @ @ 1

Pos: 21.29. 5 /A lle Ser ien ( All ge mein e M odul e)/ Zul ass ung en/S tan dar dzul ass ung enKC - K ore a C ertifi c ate - A O @ 20\mod_1406533092951_21.docx @ 160372 @ @ 1

Pos: 21.29. 6 /D ok ument ati on al lg em ein/G li eder ung sel eme nte/------Le erzei le------ @ 3\ mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 21.29. 7 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/ Zul ass ung en/ Ex/Z ul ass ung en B uskl emm e 7 50-xxxx Ex, ohne Variantenangabe - Einleitung @ 4\ mod_1237191218000_21.docx @ 28423 @ @ 1

The following Ex approvals have been granted to 750-559/040-000 I/O modules:

Pos: 21.29. 8 /A lle Ser ien ( All ge mein e M odul e)/Z ulas su nge n/Ex-Z ul ass unge n/cU Lus/ cU Lus ( AN SI/I SA 12. 12.0 1) C las s I, Di v2 A BCD T4 @ 3\ mod_1224054791812_0.docx @ 24014 @ @ 1

Pos: 21.29. 9 /D ok ument ati on al lg em ein/G li eder ung sel eme nte/------Le erzei le------ @ 3\ mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 21.29. 10 / Seri e 7 50 ( WA GO-I /O-SY STEM) /Ger ät ebesc hrei bu ng/Z ulas sung en/ Ex/Z ul. i n Vor bereit ung Bus klem me 750- xxxx Ex, ohne Variantenangabe - Einleitung @ 7\mod_1274259264803_21.docx @ 56610 @ @ 1

The following Ex approvals are pending for 750-559/040-000 I/O modules:

Pos: 21.29. 11.1 / Alle Seri en (All ge mein e M odul e)/Z ulas sung en/ Ex-Zulassungen/Sonstige/ATEX allgemein @ 16\mod_1373352135578_0.docx @ 125803 @ @ 1

Pos: 21.29. 11.2 / Alle Seri en (All ge mein e M odul e)/Z ul ass unge n/E x-Z ulass ung en/I ECE x ( TÜV Nor d)/ IEC Ex al lge mei n @ 16\ mod_1373353532946_0.docx @ 125807 @ @ 1

Pos: 21.29.12 /Dok ument ation all gem ein/Gli eder ungsel eme nte/------Leer zeil e------ @ 3\mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 21.29. 13 / Seri e 7 50 ( WA GO-I /O-SY STEM)/ Gerät ebesc hrei bung/Z ulas sunge n/Schi ff/ Einlei tungss ätzeZ ulas sung en Buskl emm e 750-xxxx Sc hiff , ohn e Var iant ena nga be - Einl eit ung @ 4\ mod_1237190918453_21.docx @ 28420 @ @ 1

The following ship approvals have been granted to 750-559/040-000 I/O modules:

Pos: 21.29. 14 / All e Ser ien (Al lg emei ne M od ule)/ Zul ass ung en/ Schi ffs zul ass ung en/G L (G er mani sc her Ll o yd) C at. A, B, C , D ( EMC 1) , H @ 15 \mod_1370521488638_0.docx @ 122022 @ @ 1

CULUS

UL508

Korea Certification MSIP-REM-W43-AOM750

ATEX

Pos: 21.29.15 /Dok ument ation all gem ein/Gli eder ungsel eme nte/------Leer zeil e------ @ 3\mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 21.29. 16 / Seri e 7 50 ( WA GO-I /O-SY STEM) /G erät eb esc hrei bung /Z ulas sung en/ Schi ff/ Einl ei tung ss ätzeZ ul . i n Vor ber eitu ng Bus kle mme 7 50- xxx x Sc hiff , oh ne V ari ant ena nga be - Ei nl eitu ng @ 7\ mod_1274259318897_21.docx @ 56614 @ @ 1

Pos: 21.29. 17.1 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /ABS (A meri ca n Bur ea u of Shi ppi ng) @ 3\mod_1224055151062_0.docx @ 24023 @ @ 1

Pos: 21.29. 17.2 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /BSH (B und esa mt f ür S eesc hif ff ahrt und Hy drog raphi e) @ 5 \mod_1246341825156_21.docx @ 36334 @ @ 1

Manual

Version 1.2.0

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1), H

The following ship approvals are pending for 750-559/040-000 I/O modules:

ABS (American Bureau of Shipping)

Page 25

WAGO-I/O-SYSTEM 750 XTR Device Description 25

750-559/040-000 4AO 0-10V DC /XTR

Federal Maritime and Hydrographic Agency

Pos: 21.29. 17.3 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /BV ( Bur ea u Ver it as) @ 3\ mod_1224492116171_0.docx @ 24220 @ @ 1

BV (Bureau Veritas)

Pos: 21.29. 17.4 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /DNV (D et N ors ke Verit as) Cl ass B @ 3\mod_1224492540562_0.docx @ 24224 @ @ 1

DNV (Det Norske Veritas) Class B

Pos: 21.29.17 .5 /All e Seri en (Allg em eine D o kume nte) (Al lge mei ne M od ule)/Z ul ass ung en/ Schi ffs zul ass ung en/KR ( Kor ean R egi st er of Shi ppi ng) @ 3\ mod_1224492806109_0.docx @ 24232 @ @ 1

KR (Korean Register of Shipping)

Pos: 21.29. 17.6 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /LR (Llo yd’s R egis ter ) E nv. 1, 2, 3, 4 @ 3\ mod_1224492890453_0.docx @ 24236 @ @ 1

LR (Lloyd’s Register) Env. 1, 2, 3, 4

Pos: 21.29. 17.7 /Al le Seri en ( Allg em ein e D okum ent e) ( Allg em ein e Mod ule) /Z ulas sung en/ Sc hiffs zul ass ung en/ NKK (Ni pp on K aiji Kyo kai) @ 3\mod_1224493002656_0.docx @ 24240 @ @ 1

NKK (Nippon Kaiji Kyokai)

Pos: 21.29. 17.8 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /PR S (P ols ki R eje str Sta tk ów) @ 3\mod_1224497273250_0.docx @ 24295 @ @ 1

PRS (Polski Rejestr Statków)

Pos: 21.29. 17.9 / Alle Seri en (All ge mein e D okum ent e) ( Allg em ein e M odule) /Z ul ass unge n/Sc hiffs zul ass ung en /RIN A ( Regi str o I tali ano N a vale) @ 3\mod_1224493078359_0.docx @ 24244 @ @ 1

RINA (Registro Italiano Navale)

Pos: 21.29.17.10 /Dokumentation allgemei n/Gli eder ungsel emen te/------Leerz eile------ @ 3 \mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 21.29.18 /Dok ument ation all gem ein/Gli eder ungsel eme nte/---Sei ten wech sel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 26

26 Device Description WAGO-I/O-SYSTEM 750 XTR

Table 16: Climatic and Mechanical Environmental Conditions

Standard

Test Value

Transport

EN 60870-2-2

Ct2(2k4) (except precipitation / water /

moisture)

Mechanical Environmental Conditions

EN 60870-2-2

Bm

EN 60721-3-1

1M3

EN 60721-3-3

3M5

EN 60068-2-6

Acceleration 5g

IEC 60068-2-27 Shock

15g, 11 ms, 1000 shocks per axis and

direction, half-sine

25g, 6 ms, 1000 shocks per axis and direction,

half-sine

EN 50155

Random vibration:

Category 1, classes A and B

Shock 5g, 30 ms:

Category 1, classes A and B

Shipbuilding*)

Ambient categories A … D, H

(5g, 25 Hz … 150 Hz)

Climatic Environmental Conditions

EN 60721-3-1

1K5 (except precipitation and ice formation)

EN 60721-3-3

3K7 (except wind-driven precipitation, water

and ice formation)

EN 60870-2-2

C3 (except wind-driven precipitation and ice

formation)

Shipbuilding*)

Ambient categories A … D, H

(−40 °C … +70 °C)

*)

The list of ship certifications issued is available in the section “Approvals”.

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.30 / All e S erie n (Al lge mei ne M o dule) /Üb ersc hri ft en/N eu e Über sc hrif te n/Eb ene 2N orme n un d Ri chtl ini en - Über schri ft 2 @ 4\mod_1242804031875_21.docx @ 33646 @ 2 @ 1

3.8 Standards and Guidelines

Pos: 21.31. 1 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/N or me n u nd Ri cht lini en/N or men und Richtl inien B uskle mme 750- xxxx, ohne Variantenangabe - Einleitung @ 7\mod_1274278887584_21.docx @ 56645 @ @ 1

750-559/040-000 I/O modules meet the following standards and guidelines:

Pos: 21.31. 2 /S eri e 75 0 ( WAG O-I/O- SYST EM)/G erät ebesc hreib ung/N orme n und Ric htlini en/N ormen u nd Rich tlinie n XTR - Mechanik und Klima Komponenten-HB @ 18\mod_1394633219581_21.docx @ 147751 @ @ 1

EN 61373

Pos: 21.31. 3 /D ok ument ati on al lg em ein/G li eder ung sel eme nte/---S eit enwec hs el--- @ 3\ mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 27

WAGO-I/O-SYSTEM 750 XTR Device Description 27

Table 17: EMC – Immunity to Interference

Standard

Test Value

Electrostatic Discharge

• EN 61000-4-2

• IEEE C37.90.3

8 kV (contact discharge)

High-frequency Electromagnetic Fields

• EN 61000-4-3 + A1: + A2

• IEEE C37.90.2

20 V/m (80 MHz … 1 GHz)

Fast Electrical Transient Disturbances / Burst

• EN 61000-4-4

• IEEE C37.90.1

4 kV

Surge Voltage / Surge

• EN 61000-4-5

• EN 60255-22-5

1 kV (conductor/conductor)

2 kV (conductor/ground)

Conducted Disturbances, Induced by High-frequency Fields

• EN 61000-4-6

• EN 60255-22-6

10 V (150 kHz … 80 MHz)

Magnetic Fields With Electrical Frequencies

• EN 61000-4-8

300 A/m continuous / 1000 A/m for 1 s

Pulse-shaped Magnetic Fields

• EN 61000-4-9 + A1

300 A/m

Damped Oscillatory Magnetic Fields

• EN 61000-4-10 + A1

100 A/m

Voltage Dips, Short-term Interruptions and Voltage Fluctuations

• EN 61000-4-11

Standard not applicable

Damped Sinusoidal Oscillations

• EN 61000-4-12

1 kV (conductor/conductor)

2 kV (conductor/ground)

Harmonics and Interharmonics

• EN 61000-4-13 + A1

Standard not applicable

Conducted Asymmetric Disturbances

• EN 61000-4-16 + A1 + A2

30 V continuous

300 V for 1 s

Line Frequency Disturbances

• EN 60255-22-7

Standard not applicable

Alternating Components of the Voltage to DC Line Connections

• EN 61000-4-17+A2

15 %

750-559/040-000 4AO 0-10V DC /XTR

Pos: 21.31. 4 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/N or me n u nd Ri cht lini en/ EMV-N or men C on trol ler 75 0-xxxx/EMV-N orm en Buskl emm e 750-xxxx/004 0-0000 , nur St andard versi on - Ei nleitung XTR @ 18 \mod_1395909426189_21.docx @ 149708 @ @ 1

The I/O module 750-559/040-000 meets the following EMC standards as these

Pos: 21.31. 5 /S eri e 75 0 ( WAG O-I/O- SYST EM) /G erät ebe schr eib ung/N or me n u nd Ri cht lini en/N or men Stör fes tig kei t XTR @ 18\mod_1394030613258_21.docx @ 147348 @ @ 1

standards relate to the I/O module:

• EN 60255-22-2

• EN 60255-22-3

• EN 60255-22-4

8 kV (air discharge)

10 V/m (1 GHz … 3 GHz)

Manual

Version 1.2.0

Page 28

28 Device Description WAGO-I/O-SYSTEM 750 XTR

Table 17: EMC – Immunity to Interference

Standard

Test Value

Damped Oscillatory Waves

• EN 61000-4-18 + A1

• IEEE C37.90.1

1.25 kV conductor/conductor

Voltage Dips, Short-term Interruptions and Voltage Fluctuations to DC Supply

Inputs

• EN 61000-4-29

• EN 60255-11

Standard not applicable

Harmonics

• Shipbuilding*)

Standard not applicable

*)

The list of ship certifications issued is available in the section “Approvals”.

Table 18: EMC – Emission of Interference

Standard

Test Value *)

Enclosure Emission of Interference

• EN 61000-6-3 + A1

30 dB(µV/m), QP, 30 MHz … 230 MHz

54 dB(µV/m), AV, 3 GHz … 6 GHz

• EN 61000-6-4 + A1

40 dB(µV/m), QP, 30 MHz … 230 MHz

60 dB(µV/m), AV, 3 GHz … 6 GHz

• Shipbuilding

**)

(EMC 1)

80 dB(µV/m) …50 dB(µV/m), QP,

24 dB(µV/m), QP, 156 MHz … 165 MHz

• Shipbuilding

**)

(EMC 2)

80 dB(µV/m) … 50 dB(µV/m), QP,

24 dB(µV/m), QP, 156 MHz … 165 MHz

750-559/040-000 4AO 0-10V DC /XTR

• EN 60255-22-1

Pos: 21.31. 6 /S eri e 75 0 ( WAG O-I/O- SYST EM)/G erät ebesc hreib ung/N orme n und Rich tlini en/Nor men St öraus send ung XTR @ 18\mod_1394087664442_21.docx @ 147358 @ @ 1

• EN 55022 Class B

2.5 kV conductor/ground

37 dB(µV/m), QP, 230 MHz … 1 GHz

70 dB(µV/m), Peak, 1 GHz … 3 GHz

50 dB(µV/m), AV, 1 GHz … 3 GHz

74 dB(µV/m), Peak, 3 GHz … 6 GHz

• EN 60255-26

• EN 55011 + A1 Class A

• EN 55022 Class A

47 dB(µV/m), QP, 230 MHz … 1 GHz

76 dB(µV/m), Peak, 1 GHz … 3 GHz

56 dB(µV/m), AV, 1 GHz … 3 GHz

80 dB(µV/m), Peak, 3 GHz … 6 GHz

150 kHz … 300 kHz

50 dB(µV/m) … 34 dB(µV/m), QP,

0.3 MHz … 30 MHz

54 dB(µV/m), QP, 30 MHz … 2 GHz

150 kHz … 30 MHz

60 dB(µV/m) … 54 dB(µV/m), QP,

30 MHz … 100 MHz

54 dB(µV/m), QP, 100 MHz … 2 GHz

Manual

Version 1.2.0

Page 29

WAGO-I/O-SYSTEM 750 XTR Device Description 29

Table 18: EMC – Emission of Interference

Standard

Test Value *)

Conducted Emission of Interference – Line Connection AC Voltage

• EN 61000-6-3 + A1

• EN 55022 Class B

Standard not applicable

• EN 61000-6-4 + A1

• EN 55011 + A1 Class A

Standard not applicable

Conducted Emission of Interference – Line Connection

• Shipbuilding

**)

(EMC 1)

96 dB(µV) … 50 dB(µV), 10 kHz … 150 kHz

50 dB(µV), 0.35 MHz … 30 MHz

• Shipbuilding

**)

(EMC 2)

120 dB(µV) … 69 dB(µV),

73 dB(µV), 0.5 MHz … 30 MHz

Conducted Emission of Interference – Line Connection DC Voltage

• EN 61000-6-3 + A1

79 dB(µV) QP, 0.15 MHz … 0.5 MHz

60 dB(µV) AV, 0.5 MHz … 30 MHz

*)

QP = Quasi Peak Detector; AV = Average Detector

or EMC 2).

750-559/040-000 4AO 0-10V DC /XTR

60 dB(µV) … 50 dB(µV),

150 kHz … 350 kHz

10 kHz … 150 kHz

79 dB(µV), 150 kHz … 500 kHz

• EN 60255-26

• EN 55022 Class A

**)

If necessary, please find different data in the section “Approval” (regarding approval for EMC 1

Pos: 22 /Dokum entati on allg emei n/Gli ederung sele mente /---Seit enwe chs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

66 dB(µV) AV, 0.15 MHz … 0.5 MHz

73 dB(µV) QP, 0.5 MHz … 30 MHz

Manual

Version 1.2.0

Page 30

30 Process Image WAGO-I/O-SYSTEM 750 XTR

Table 19: Process Image

Binary

Output Value

0.00

'0000.0000.0000.0000'

0x0000 0 0x00

1.25

'0001.0000.0000.0000'

0x1000

4096

0x00

2.50

'0010.0000.0000.0000'

0x2000

8192

0x00

3.75

'0011.0000.0000.0000'

0x3000

12288

0x00

5.00

'0100.0000.0000.0000'

0x4000

16384

0x00

6.25

'0101.0000.0000.0000'

0x5000

20480

0x00

7.50

'0110.0000.0000.0000'

0x6000

24576

0x00

8.75

'0111.0000.0000.0000'

0x7000

28672

0x00

10.00

'0111.1111.1111.1111'

0x7FFF

32767

0x00

750-559/040-000 4AO 0-10V DC /XTR

Pos: 23 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 1Pr ozess a bbil d - Über sc hrift 1 @ 4\ mod_1240983067828_21.docx @ 31942 @ 1 @ 1

4 Process Image

Pos: 24 /Ser ie 75 0 (WA GO-I/ O-SYS TEM) /Proz essab bild Klemme nbus/ Hinw eis: Pro zessa bbil dmappi ng abh ängig von FBK/ PFC, o hne Stat us-/C ontr olb yte XT R @ 1 8\mod_1396511070508_21.docx @ 150 676 @ @ 1

Mapping of process data in the process image of fieldbus systems

The representation of the process data of some I/O modules or their variations in

the process image depends on the fieldbus coupler/controller used. Please take

this information from the section “I/O Modules” included in the description

concerning the process image of the corresponding coupler/controller.

Pos: 25 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Proz ess abbi ld Kle mme nbus /A nalog aus ga ngs klem me n/Pr oz essab bil d 7 50-0 559/ 040-000 @ 18\mod_1392290197027_21.docx @ 145382 @ @ 1

The analog output module 750-559/040-000 provides 16 bits of data and 8 status

bits per channel.

The digitalized output value is output in a data word (16 bit) via the process image

of the fieldbus coupler/controller as output byte 0 (low) and output byte 1 (high).

This value is mapped with a resolution of 12 bit to bit B3 … B14.

The three least significant bits (B0 … B2) are not evaluated.

With analog output module 750-559/040-000, the numerical value range of

0x0000 to 0x7FFF is scaled to the output voltage range of 0 V to 10 V.

Output Value

0 V … 10 V

Pos: 26 /Ser ie 75 0 (WA GO-I/ O-SYS TEM )/ Proz ess abbi ld Kle mme nbus /Hi nw eis: Stat us byt e-Aus wer tung ni cht mögl ic h @ 6 \mod_1256127653548_21.docx @ 43347 @ @ 1

No Status Byte to evaluate!

Some fieldbus systems can process the status information of process values using

by means of a status byte.

As the returned status byte of this I/O module is always zero, it will not be parsed.

Pos: 27 /Dokum entati on allg emei n/Gli eder ungs ele ment e/---Seit en wechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Numerical Value

Hex. Dec.

Status Byte

Hex.

Manual

Version 1.2.0

Page 31

WAGO-I/O-SYSTEM 750 XTR Mounting 31

750-559/040-000 4AO 0-10V DC /XTR

Pos: 28 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 1M onti eren - Üb ersc hrift 1 @ 3\ mod_1225446744750_21.docx @ 24900 @ 1 @ 1

5 Mounting

Pos: 29.1 /Serie 750 (WAGO-I/O-SYSTEM)/Monti eren/D emon tiere n/Mo ntager eihe nfolg e @ 3\mod_1231770210031_21.docx @ 25992 @ 2 @ 1

5.1 Mounting Sequence

Fieldbus couplers/controllers and I/O modules of the WAGO-I/O-SYSTEM

750/753 are snapped directly on a carrier rail in accordance with the European

standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual devices are securely seated

on the rail after installation.

Starting with the fieldbus coupler/controller, the I/O modules are mounted

adjacent to each other according to the project design. Errors in the design of the

node in terms of the potential groups (connection via the power contacts) are

recognized, as the I/O modules with power contacts (blade contacts) cannot be

linked to I/O modules with fewer power contacts.

Pos: 29.2 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und so nstig e H inw eis e/Vor sic ht/ Vor sic ht: Verl etz ungs ge fahr dur ch s ch arf kant ige M ess er kont akt e! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged blade contacts!

The blade contacts are sharp-edged. Handle the I/O module carefully to prevent

injury.

Pos: 29.3 /Serie 750 (WAGO-I/O-S YSTEM) /Wic htige Erlä uteru nge n/Si cher heit s- und sonstige Hinweise/Achtung/Achtung: Busklemmen nur in vorgesehener Reihenfolge stecken! @ 6\mod_1256194177073_21.docx @ 43429 @ @ 1

Insert I/O modules only from the proper direction!

All I/O modules feature grooves for power jumper contacts on the right side. For

some I/O modules, the grooves are closed on the top. Therefore, I/O modules

featuring a power jumper contact on the left side cannot be snapped from the top.

This mechanical coding helps to avoid configuration errors, which may destroy

the I/O modules. Therefore, insert I/O modules only from the right and from the

top.

Pos: 29.4 /Serie 750 (WAGO-I/O-S YSTEM )/Wi chtig e Erlä uteru ngen/ Sicher heits- und sonstige Hinweise/Hinweis/Hinweis: Bu sabsc hlus s XTR nic ht verg essen! @ 15\mod_1368426836647_21.docx @ 119458 @ @ 1

Don't forget the bus end module!

Always plug a bus end module 750-600/040-000 onto the end of the fieldbus

node! You must always use this bus end module at all fieldbus nodes with the

WAGO I/O System 750 XTR fieldbus couplers/controllers to guarantee proper

data transfer.

Pos: 29.5 /Serie 750 (WAGO-I/O-SYSTEM)/Montieren/Demontieren/Busklemmen 750xxxx/0040xxxx 4g-5g @ 15\mod_1367558844291_21.docx @ 118470 @ @ 1

For vibration loads > 4g, observe the following installation instructions:

• Use pan-head screws or blind rivets at least every 60 mm (12 mm pin

spacing) to secure the DIN rail.

• Make the open conductor length between strain relief and wire connection

as short as possible.

Pos: 29.6 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

• Use the reinforced end stop 249-197.

Manual

Version 1.2.0

Page 32

32 Mounting WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Pos: 29.7 /Serie 750 (WAGO-I/O-S YST EM)/ Mon tier en/D em onti eren/ Ger äte ein füg en u nd e nt fer nen - Ü ber schr if t 2 @ 3\ mod_1231768483250_21.doc x @ 25950 @ 2 @ 1

5.2 Inserting and Removing Devices

Pos: 29.8 /Al l e Ser ien ( Al lge mei ne M od ule)/ Sic herh eits - u nd s ons tig e Hi nweis e/ Vorsi cht /V orsi cht : Hei ß e Ob erfl äch e al lge mei n @ 6 \mod_1264428115588_21.docx @ 48610 @ @ 1

Hot surface!

The surface of the housing can become hot during operation. If the device was

operated at high ambient temperatures, allow it to cool off before touching it.

Pos: 29.9 /Al l e Ser ien ( Al lge mei ne M od ule)/ Sic herh eits - u nd s ons tig e Hi nweis e/ Ac htung /Ac htu ng: Arb eit en a n Ger ät en n ur s pan nung sfr ei d urc hf ühr en! @ 6\ mod_1256193963573_21.doc x @ 43426 @ @ 1

Perform work on devices only if they are de-energized!

Working on energized devices can damage them. Therefore, turn off the power

supply before working on the devices.

Pos: 29.10 / Ser ie 750 ( WA GO-I/ O-SY STEM )/ Wichti g e Erl äu ter ung en/Si cher hei ts- und s o nstig e H inw eise /Ac htu ng/Ac ht ung: XTR nic ht unt er -2 0 °C ver draht en oder u mstec ken @ 15\ mod_1367559895186_21.docx @ 118480 @ @ 1

Observe operating temperature!

XTR I/O modules may be operated below −20 °C, but not wired and/or

reconnected.

Pos: 29.11 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Monti ere n/De montier en/Bus kle mme einf ügen @ 3\mod_1231769726703_21.docx @ 25989 @ 3 @ 1

5.2.1 Inserting the I/O Module

1. Position the I/O module so that the tongue and groove joints to the fieldbus

coupler/controller or to the previous or possibly subsequent I/O module are

engaged.

Figure 7: Insert I/O Module (Example)

2. Press the I/O module into the assembly until the I/O module snaps into the

carrier rail.

Manual

Version 1.2.0

Page 33

WAGO-I/O-SYSTEM 750 XTR Mounting 33

750-559/040-000 4AO 0-10V DC /XTR

Figure 8: Snap the I/O Module into Place (Example)

With the I/O module snapped in place, the electrical connections for the data

contacts and power jumper contacts (if any) to the fieldbus coupler/controller or to

the previous or possibly subsequent I/O module are established.

Pos: 29.12 / Ser ie 750 ( WA GO-I/ O-SY STEM) /Monti ere n/De montier en/Bus kle mme ent ferne n @ 4\mod_1239169375203_21.docx @ 30334 @ 3 @ 1

5.2.2 Removing the I/O Module

1. Remove the I/O module from the assembly by pulling the release tab.

Figure 9: Removing the I/O Module (Example)

Electrical connections for data or power jumper contacts are disconnected when

removing the I/O module.

Pos: 30 /D okum ent atio n allge mein/ Glie derungs elem ente/ ---Seite nwec hsel --- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.2.0

Page 34

34 Connect Devices WAGO-I/O-SYSTEM 750 XTR

750-559/040-000 4AO 0-10V DC /XTR

Pos: 31 /All e S eri en ( Allg emei n e Mod ule) /Ü ber schri fte n/N eue Ü b ersc hrif te n/Eb ene 1Ger ät e an schl ieß en - Ü b erschr if t 1 @ 3 \mod_1234172889468_21.docx @ 27460 @ 1 @ 1

6 Connect Devices