Fieldbus Independent

I/O Modules

4 AI DC ±10 V, Single-Ended

750-457

Manual

Version 1.0.2

ii • General

Copyright © 2006 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and completeness of this documentation. However, as errors can never be fully excluded, we would appreciate any information or ideas at any time.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

WAGO-I/O-SYSTEM 750

I/O Modules

Content • iii

Content

1 Important Comments .................................................................................4

1.1 Legal Principles........................................................................................4

1.1.1 Copyright............................................................................................. 4

1.1.2 Personnel Qualification ....................................................................... 4

1.1.3 Intended Use........................................................................................ 4

1.2 Symbols.................................................................................................... 5

1.3 Number Notation......................................................................................5

1.4 Safety Notes .............................................................................................6

1.5 Scope ........................................................................................................ 6

2 I/O Modules ................................................................................................. 7

2.1 Digital Output Modules............................................................................7

2.1.1 750-457 [4 AI DC ±10 V, Single-Ended]............................................ 7

2.1.1.1 View................................................................................................7

2.1.1.2 Description......................................................................................7

2.1.1.3 Display Elements ............................................................................8

2.1.1.4 Schematic Diagram.........................................................................9

2.1.1.5 Technical Data ................................................................................9

2.1.1.6 Process Image ............................................................................... 11

2.1.1.6.1 Standard Data Format ..............................................................12

WAGO-I/O-SYSTEM 750

I/O Modules

4 • Important Comments

Legal Principles

1 Important Comments

To ensure fast installation and start-up of the units described in this manual,

we strongly recommend that the following information and explanations are

carefully read and abided by.

1.1 Legal Principles

1.1.1 Copyright

This manual is copyrighted, together with all figures and illustrations

contained therein. Any use of this manual which infringes the copyright

provisions stipulated herein, is not permitted. Reproduction, translation and

electronic and photo-technical archiving and amendments require the written

consent of WAGO Kontakttechnik GmbH & Co. KG. Non-observance will

entail the right of claims for damages.

WAGO Kontakttechnik GmbH & Co. KG reserves the right to perform

modifications allowed by technical progress. In case of grant of a patent or

legal protection of utility patents all rights are reserved by WAGO

Kontakttechnik GmbH & Co. KG. Products of other manufacturers are always

named without referring to patent rights. The existence of such rights can

therefore not be ruled out.

1.1.2 Personnel Qualification

The use of the product detailed in this manual is exclusively geared to

specialists having qualifications in PLC programming, electrical specialists or

persons instructed by electrical specialists who are also familiar with the valid

standards. WAGO Kontakttechnik GmbH & Co. KG declines all liability

resulting from improper action and damage to WAGO products and third party

products due to non-observance of the information contained in this manual.

1.1.3 Intended Use

For each individual application, the components supplied are to work with a

dedicated hardware and software configuration. Modifications are only

permitted within the framework of the possibilities documented in the

manuals. All other changes to the hardware and/or software and the nonconforming use of the components entail the exclusion of liability on part of

WAGO Kontakttechnik GmbH & Co. KG.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH & Co.

KG.

WAGO-I/O-SYSTEM 750

I/O Modules

Important Comments • 5 Symbols

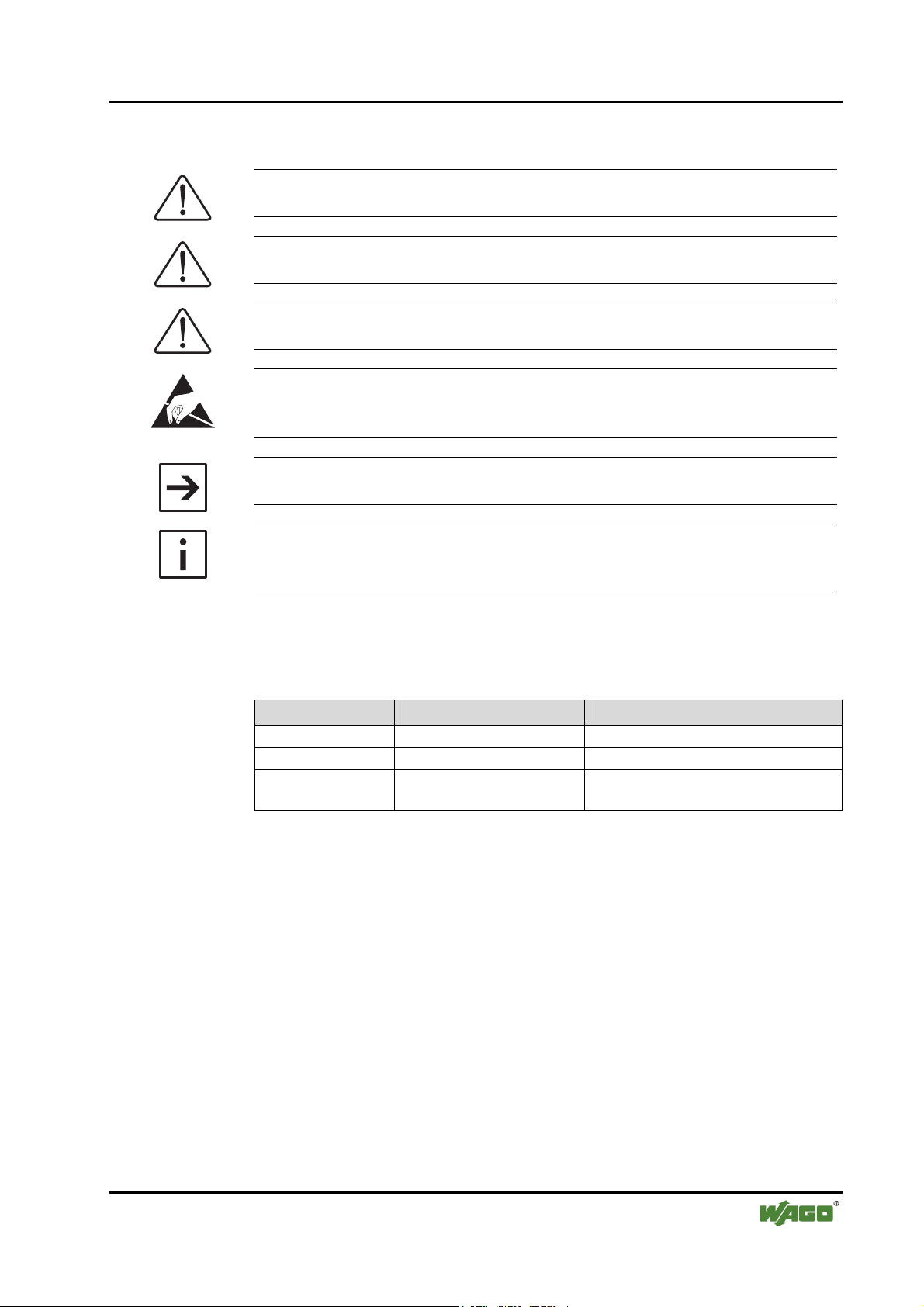

1.2 Symbols

Danger

Always abide by this information to protect persons from injury.

Warning

Always abide by this information to prevent damage to the device.

Attention

Marginal conditions must always be observed to ensure smooth operation.

ESD (Electrostatic Discharge)

Warning of damage to the components by electrostatic discharge. Observe

the precautionary measure for handling components at risk.

Note

Routines or advice for efficient use of the device and software optimization.

More information

References on additional literature, manuals, data sheets and INTERNET

pages

1.3 Number Notation

Number Code Example Note

Decimal 100 normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Within ',

Nibble separated with dots

WAGO-I/O-SYSTEM 750

I/O Modules

6 • Important Comments

Safety Notes

1.4 Safety Notes

Warning

Switch off the system prior to working on bus modules!

In the event of deformed contacts, the module in question is to be replaced, as

its functionality can no longer be ensured on a long-term basis.

The components are not resistant against materials having seeping and

insulating properties. Belonging to this group of materials is: e.g. aerosols,

silicones, triglycerides (found in some hand creams).

If it cannot be ruled out that these materials appear in the component

environment, then additional measures are to be taken:

- installation of the components into an appropriate enclosure

- handling of the components only with clean tools and materials.

Attention

Cleaning of soiled contacts may only be done with ethyl alcohol and leather

cloths. Thereby, the ESD information is to be regarded.

1.5 Scope

Do not use any contact spray. The spray may impair the functioning of the

contact area.

The WAGO-I/O-SYSTEM 750 and its components are an open system. It

must only be assembled in housings, cabinets or in electrical operation

rooms. Access must only be given via a key or tool to authorized qualified

personnel.

The relevant valid and applicable standards and guidelines concerning the

installation of switch boxes are to be observed.

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the

environment (persons, workplace and packing) is well grounded. Avoid

touching conductive components, e.g. gold contacts.

This manual describes the Analog Input Module 750-457

4 AI DC ±10 V, Single-Ended of the modular WAGO-I/O-SYSTEM 750.

Handling, assembly and start-up are described in the manual of the Fieldbus

Coupler. Therefore this documentation is valid only in the connection with the

appropriate manual.

WAGO-I/O-SYSTEM 750

I/O Modules

750-457 [4 AI DC ±10 V, Single-Ended] • 7 View

2 I/O Modules

2.1 Digital Output Modules

2.1.1 750-457 [4 AI DC ±10 V, Single-Ended]

4-Channel Analog Input Module (± 10 V, Single-Ended)

2.1.1.1 View

14

13

Error AI 1

Error AI 3

AI 1

A

C

B

D

E1

E2

MM

Error AI 2

Error AI 4

Datacontacts

AI 2

Common

(ground)

AI 3

Common

(ground)

Fig. 2.1.1-1: 4-Channel Analog Input Module 750-457 g045700e

2.1.1.2 Description

This analog input module receives signals with standardized values of ±10 V.

The module has four input channels. The fieldside signals may be received via

the connections AI 1 and Common (ground) or AI 2, AI 3, AI 4 and Common

(ground). The common (ground) contacts of all four channels have one

common 0 V ground potential.

The input signal of each channel is electrically isolated and will be transmitted

with a resolution of 12 bits.

E3 E4

MM

750-457

Common

(ground)

AI 4

Common

(ground)

Power jumper

contacts

Overrange or underflow of the measuring range is indicated via a red error

LED.

Any configuration of the input modules is possible when designing the

fieldbus node. Grouping of module types is not necessary

The voltage supply is done via system voltage.

WAGO-I/O-SYSTEM 750

I/O Modules

8 • 750-457 [4 AI DC ±10 V, Single-Ended]

Display Elements

The field side supply voltage of 24 V and 0 V for the input module is derived

from adjacent I/O modules or from a supply module. The field supply voltage

is passed on separately galvanically to following modules without own use.

The supply voltage for the field side is made automatically through the

individual I/O modules by means of power jumper contacts.

Warning

The maximum current of the internal power jumper contacts is 10 A. When

configuring the system it is important not to exceed the maximum/sum

current. However, if such a case should occur, another supply module must be

added.

The analog input module 750-457 can be used with all couplers/controllers of

the WAGO-I/O-SYSTEM 750 (except for the economy types 750-320, -323,

-324 and -327).

2.1.1.3 Display Elements

13 14

A

A

B

Fig. 2.1.1-2: Display

Elements

B

g045302x

C

D

LED Channel Meaning State Function

off Normal operation

on

off Normal operation

on

off Normal operation

on

off Normal operation

on

C

D

A

red

C

red

B

red

D

red

1

2

3

4

Error

AI 1

Error

AI 2

Error

AI 3

Error

AI 4

Overrange/underflow of the

admissible measuring range

Overrange/underflow of the

admissible measuring range

Overrange/underflow of the

admissible measuring range

Overrange/underflow of the

admissible measuring range

WAGO-I/O-SYSTEM 750

I/O Modules

750-457 [4 AI DC ±10 V, Single-Ended] • 9

Schematic Diagram

2.1.1.4 Schematic Diagram

5

AI 1

1

AI 2

AI

A

D

Logic

Common

(ground)

24V

AI 3

0V

Common

(ground)

2

3

4

750-457750-457

6

7

8

Fig. 2.1.1-3: 4-Channel Analog Input Module 750-457 g045701e

2.1.1.5 Technical Data

Module Specific Data

Number of inputs 4

Voltage supply via system voltage DC /DC

Current consumption

Input voltage

Signal current

max.

AI 4

(internal) 65 mA

typ.

Common

(ground)

270pF

± 40 V

± 10 V

Error

10nF

Input resistance

Resolution 12 bits

Conversion time

Measuring error

Temperature coefficient

Isolation 500 V (Field/System)

Bit width 4 x 16 bits data

Dimensions (mm) W x H x L 12 x 64* x 100

Weight ca. 55 g

WAGO-I/O-SYSTEM 750

I/O Modules

typ.

10 ms

typ.

25°C

>100 kΩ

<± 0.1 % of full scale value

<± 0.01 % /K of full scale value

4 x 8 bits control/status (option)

* from upper edge of 35 DIN rail

10 • 750-457 [4 AI DC ±10 V, Single-Ended]

Technical Data

Standards and Regulations (cf. Chapter 2.2 of the Coupler/Controller Manual)

EMC-Immunity to interference (CE) acc. to EN 50082-2 (96)

EMC-Emission of interference (CE) acc. to EN 50081-1 (93)

EMC-Immunity to interference

(Ship building)

EMC-Emission of interference

(Ship building)

Approvals (cf. Chapter 2.2 of the Coupler/Controller Manual)

(UL508)

CULUS

ABS (American Bureau of Shipping)

BV (Bureau Veritas) (applied for)

DNV (Det Norske Veritas) Cl. B

GL (Germanischer Lloyd) Cat. A, B, C, D

KR (Korean Register of Shipping)

LR (Lloyd's Register) (applied for) Env. 1, 2, 3, 4

NKK (Nippon Kaiji Kyokai)

(UL1604) Class I Div2 ABCD T4A

CULUS

KEMA II 3 G EEx nA II T4

acc. to Germanischer Lloyd (01)

acc. to Germanischer Lloyd (01)

Conformity Marking

More Information

Detailed references to the approvals are listed in the document "Overview

Approvals WAGO-I/O-SYSTEM 750", which you can find on the CD ROM

ELECTRONICC Tools and Docs (Item-No.: 0888-0412)

or in the internet under:

www.wago.com ! Documentation ! WAGO-I/O-SYSTEM 750 !

System Description

WAGO-I/O-SYSTEM 750

I/O Modules

750-457 [4 AI DC ±10 V, Single-Ended] • 11 Process Image

2.1.1.6 Process Image

The analog input module 750-457 transmits 16-bit measured values and

8 optional status bits per channel.

The digitalized measured value is transmitted in a data word (16 bits) as input

byte 0 (low) and input byte 1 (high) into the process image of the coupler /

controller.

This value is represented with a 12 bit resolution on bit B3 ... B14.

The status information included in the three least significant bits (B0 ... B2)

can be parsed in the event of an error. Bit B0 and B1 = 1 are set when the

range of measurement is overranged or underflow. Bit B2 is not defined and

not evaluated. Therefore, they are represented with a ‘X‘ in the table.

Some fieldbus systems can process input channel status information by means

of a status byte.

This status byte can be displayed using the starting tool WAGO-I/O-CHECK

2. However, the coupler / controller process operation is optional, which

means that accessing or parsing the status information depends on the fieldbus

system.

Attention

The representation of the process data of some fieldbus modules or their

variations in the process image depends on the fieldbus coupler/-controller

used. Please take this information as well as the particular design of the

respective control/status bytes from the section "Fieldbus specific design of

the process data" included in the description of the process image of the

corresponding coupler/controller.

WAGO-I/O-SYSTEM 750

I/O Modules

12 • 750-457 [4 AI DC ±10 V, Single-Ended]

Process Image

2.1.1.6.1 Standard Data Format

For the standard module 750-457 , the input voltage ranging from –10 V to

+10 V is scaled on the numerical values ranging from 0x8000 to 0x7FFF.

Process values of module 750-457

voltage

± 10 V

<-10 '1000.0000.0000.0 X11' 0x8003 -32765 0x41 on

-10 '1000.0000.0000.0 X00' 0x8000 -32768 0x00 off

-8 '1001.1001.1001.1 X00' 0x9998 -26214 0x00 off

-6 '1011.0011.0011.0 X00' 0xB334 -19660 0x00 off

-4 '1100.1100.1100.1 X00' 0xCCCC -13107 0x00 off

-2 '1110.0110.0110.0 X00' 0xE664 -6553 0x00 off

0 '0000.0000.0000.0 X00' 0x0000 0 0x00 off

2 '0001.1001.1001.1 X00' 0x1998 6553 0x00 off

4 '0011.0011.0011.0 X00' 0x3330 13107 0x00 off

6 '0100.1100.1100.1 X00' 0x4CCC 19660 0x00 off

8 '0110.0110.0110.0 X00' 0x6664 26214 0x00 off

10 '0111.1111.1111.1 X00' 0x7FFC 32764 0x00 off

>10 '0111.1111.1111.1 X11' 0x7FFF 32767 0x42 on

*) status bits: X = not used, F = short-circuit, Ü = oversize

Measured value *) X F Ü

binary

Numerical value Input

hex. dec.

Status-

byte

hex. AI 1-4

LED

Error

WAGO-I/O-SYSTEM 750

I/O Modules

750-457 [4 AI DC ±10 V, Single-Ended] • 13

Process Image

WAGO-I/O-SYSTEM 750

I/O Modules

WAGO Kontakttechnik GmbH & Co. KG

Postfach 2880 • D-32385 Minden

Hansastraße 27 • D-32423 Minden

Phone: 05 71/8 87 – 0

Fax: 05 71/8 87 – 1 69

E-Mail: info@wago.com

Internet: http://www.wago.com

Loading...

Loading...