WAGO 750-402, 750-402/025-000, WAGO-I/O-SYSTEM 750 Series, 750-406, 750-430 User Manual

...Page 1

Pos: 2 /Dokumentation allgemein/Einband/Einband Han dbuch - Deckblatt ohne Varia ntenfeld (S tandard) @ 9\mod_1285229289866_0.docx @ 64941 @ @ 1

Manual

WAGO-I/O-SYSTEM 750

4-Channel Digital Input Module 24 V DC, 2- to 3-

Pos: 3 /Alle Serien (Al lgemein e Module)/H inweise z ur Dokumen tation/Im pressum für Standar dhandbüc her - allg. A ng a be n, A ns c hriften, Tel ef onnummer n und E-Mail-A dr es sen @ 3\mod_1219151118203_21.docx @ 21060 @ @ 1

4DI 24V DC 3.0ms

750-402(/xxx-xxx)

conductor conne ction; high-side switching

Version 1.1.0

Page 2

2 WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

© 2013 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

=== Ende der Liste für Textmar ke Einband _vorne ===

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the accuracy and

completeness of this documentation. However, as errors can never be fully

excluded, we always appreciate any information or suggestions for improving the

documentation.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally protected by trademark or patent.

Manual

Version 1.1.0

Page 3

WAGO-I/O-SYSTEM 750 Table of Contents 3

750-402 4DI 24V DC 3.0ms

Pos: 5 /Do kumentation allgemei n/Verzeic hnisse/Inh altsverz eichnis - Üb er s chr i f t oG und Verzei chnis @ 3\mod_1219151230875_21.docx @ 21063 @ @ 1

Table of Contents

Table of Contents ................................................................................................... 3

1 Notes about this Documentation ................................................................. 5

1.1 Validity of this Documentation ................................................................. 5

1.2 Copyright ................................................................................................... 5

1.3 Symbols ..................................................................................................... 6

1.4 Number Notation ....................................................................................... 8

1.5 Font Conventions ...................................................................................... 8

2 Important Notes ........................................................................................... 9

2.1 Legal Bases ............................................................................................... 9

2.1.1 Subject to Changes ............................................................................... 9

2.1.2 Personnel Qualifications ....................................................................... 9

2.1.3 Use of the 750 Series in Compliance with Underlying Provisions ...... 9

2.1.4 Technical Condition of Specified Devices ......................................... 10

2.2 Safety Advice (Precautions) .................................................................... 11

3 Device Description ..................................................................................... 13

3.1 View ........................................................................................................ 15

3.2 Connectors ............................................................................................... 16

3.2.1 Data Contacts/Internal Bus ................................................................. 16

3.2.2 Power Jumper Contacts/Field Supply ................................................ 17

3.2.3 CAGE CLAMP® Connectors ............................................................. 18

3.3 Display Elements .................................................................................... 19

3.4 Schematic Diagram ................................................................................. 20

3.5 Technical Data ........................................................................................ 21

3.5.1 Device data ......................................................................................... 21

3.5.2 Supply ................................................................................................. 21

3.5.3 Communication .................................................................................. 21

3.5.4 Inputs .................................................................................................. 21

3.5.5 Connection Type ................................................................................ 22

3.5.6 Climatic Environmental Conditions ................................................... 22

3.6 Approvals ................................................................................................ 23

3.7 Standards and Guidelines ........................................................................ 25

4 Process Image ............................................................................................. 26

5 Mounting ..................................................................................................... 27

5.1 Mounting Sequence ................................................................................. 27

5.2 Inserting and Removing Devices ............................................................ 28

5.2.1 Inserting I/O Module .......................................................................... 28

5.2.2 Removing the I/O Module .................................................................. 29

6 Connect Devices ......................................................................................... 30

6.1 Connecting a Conductor to the CAGE CLAMP® ................................... 30

6.2 Connection Examples .............................................................................. 31

6.2.1 2-Conductor Connection .................................................................... 31

6.2.2 3-Conductor Connection .................................................................... 31

7 Use in Hazardous Environments .............................................................. 32

Manual

Version 1.1.0

Page 4

4 Table of Contents WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

7.1 Marking Configuration Examples ........................................................... 33

7.1.1 Marking for Europe according to ATEX and IEC-Ex ........................ 33

7.1.2 Marking for America according to NEC 500 ..................................... 38

7.2 Installation Regulations ........................................................................... 39

7.2.1 Special conditions for safe use (ATEX Certificate TÜV 07 ATEX

554086 X) ........................................................................................... 40

7.2.2 Special conditions for safe use (ATEX Certificate TÜV 12 ATEX

106032 X) ........................................................................................... 41

7.2.3 Special conditions for safe use (IEC-Ex Certificate TUN 09.0001 X)42

7.2.4 Special conditions for safe use (IEC-Ex Certificate IECEx TUN

12.0039 X) .......................................................................................... 43

7.2.5 ANSI/ISA 12.12.01 ............................................................................ 44

List of Figures ...................................................................................................... 45

List of Tables ........................................................................................................ 46

=== Ende der Liste für Textmar ke Verzeich nis_vorne ===

Manual

Version 1.1.0

Page 5

WAGO-I/O-SYSTEM 750 Notes about this Documentation 5

Table 1: Variants

Item Number/Variant

Designation

750-402

4DI 24V DC 3.0ms

750-402/025-000

4DI 24V DC 3.0ms/T

750-402 4DI 24V DC 3.0ms

Pos: 7 /Alle Serien (Al lgemein e Module)/Ü berschri ften für all e Serien/Hi nweis z ur Dokumen tation/Hin weise zur D okument ation - Über schrift 1 @ 4\mod_1237987661750_21.doc x @ 29029 @ 1 @ 1

1 Notes about this Documentation

Pos: 8 /Alle Serien (Al lgemein e Module)/H inweise z ur Dokumen tation/Hi nweise/Hi nweis: Do kumentatio n aufbew ahren @ 4\mod_1237987339812_21.docx @ 29026 @ @ 1

Keep this documentation!

The operating instructions are part of the product and shall be kept for the entire

lifetime of the device. They shall be transferred to each subsequent owner or user

of the device. Care must also be taken to ensure that any supplement to these

instructions are included, if applicable.

Pos: 9 /Alle Serien (Al lgemein e Module)/Ü berschri ften für all e Serien/H inweis z ur Dokumen tation/Gül tigkeits bereich - Üb er s c hrift 2 @ 12\mod_1338912448776_21.docx @ 96469 @ 2 @ 1

1.1 Validity of this Documentation

Pos: 10 /Ser ie 750 ( WAGO-I/O-SYST EM)/Hin weise zur D okumentati on/Gültig keitsberei ch Dokum entation B usklemme 750-xxxx, St an d ardversio n un d a ufgelistet e V arianten @ 14 \ mod_1358944038682_21.docx @ 109354 @ @ 1

This documentation is only applicable to the I/O module 750-402 (4DI 24V DC

3.0ms) of the WAGO-I/O-SYSTEM 750 series and the variants listed in the table

below.

Pos: 11 /Ser ie 750 ( WAGO-I/O-SYST EM)/Hin weise zur D okumentat ion/Varia ntenliste n/Variant enliste - 750-xxx - St andardvers ion und V ariante /0 25-000 (erw eiterter T emperatur bereich) @ 9\mod_1281521920414_21. doc x @ 63093 @ @ 1

Pos: 12 /Ser ie 750 ( WAGO-I/O-SYST EM)/Hin weise zur D okumentati on/Hinwei se/Achtu ng: Hinweis zur Doku mentation Busklemme n 750-xxxx @ 4\mod_1237986979656_21.docx @ 29023 @ @ 1

The I/O module 750-402 shall only be installed and operated according to the

instructions in this manual and in the manual for the used fieldbus

coupler/controller.

Consider power layout of the WAGO-I/O-SYSTEM 750!

In addition to these operating instructions, you will also need the manual for the

used fieldbus coupler/controller, which can be downloaded at www.wago.com.

There, you can obtain important information including information on electrical

isolation, system power and supply specifications.

Pos: 13.1 /Al le Seri en (Allgemei ne Modul e)/Hinweis e zur Dok umentation /Urhebers chutz aus führlich @ 4\mod_1235565145234_21.docx @ 27691 @ 2 @ 1

1.2 Copyright

Pos: 13.2 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

This Manual, including all figures and illustrations, is copyright-protected. Any

further use of this Manual by third parties that violate pertinent copyright

provisions is prohibited. Reproduction, translation, electronic and phototechnical

filing/archiving (e.g., photocopying) as well as any amendments require the

written consent of WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany.

Non-observance will involve the right to assert damage claims.

Page 6

6 Notes about this Documentation WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 13.3 /Al le Seri en (Allgemei ne Modul e)/Überschr iften für alle Seri en/Hinweis zur Dok umentation /Symbole - Ü berschrif t 2 @ 13\mod_1351068042408_21.docx @ 105270 @ 2 @ 1

1.3 Symbols

Pos: 13.4.1 /Alle Ser ien (Allg emeine Mo dule)/Wic htige Erlä uterungen/ Sicherhei ts- und sonstige Hinweise/G efahr/Gefahr: _Warnung vor Personenschäden allgemein_ - Erläuterung @ 13\mod_1343309450020_21.doc x @ 101029 @ @ 1

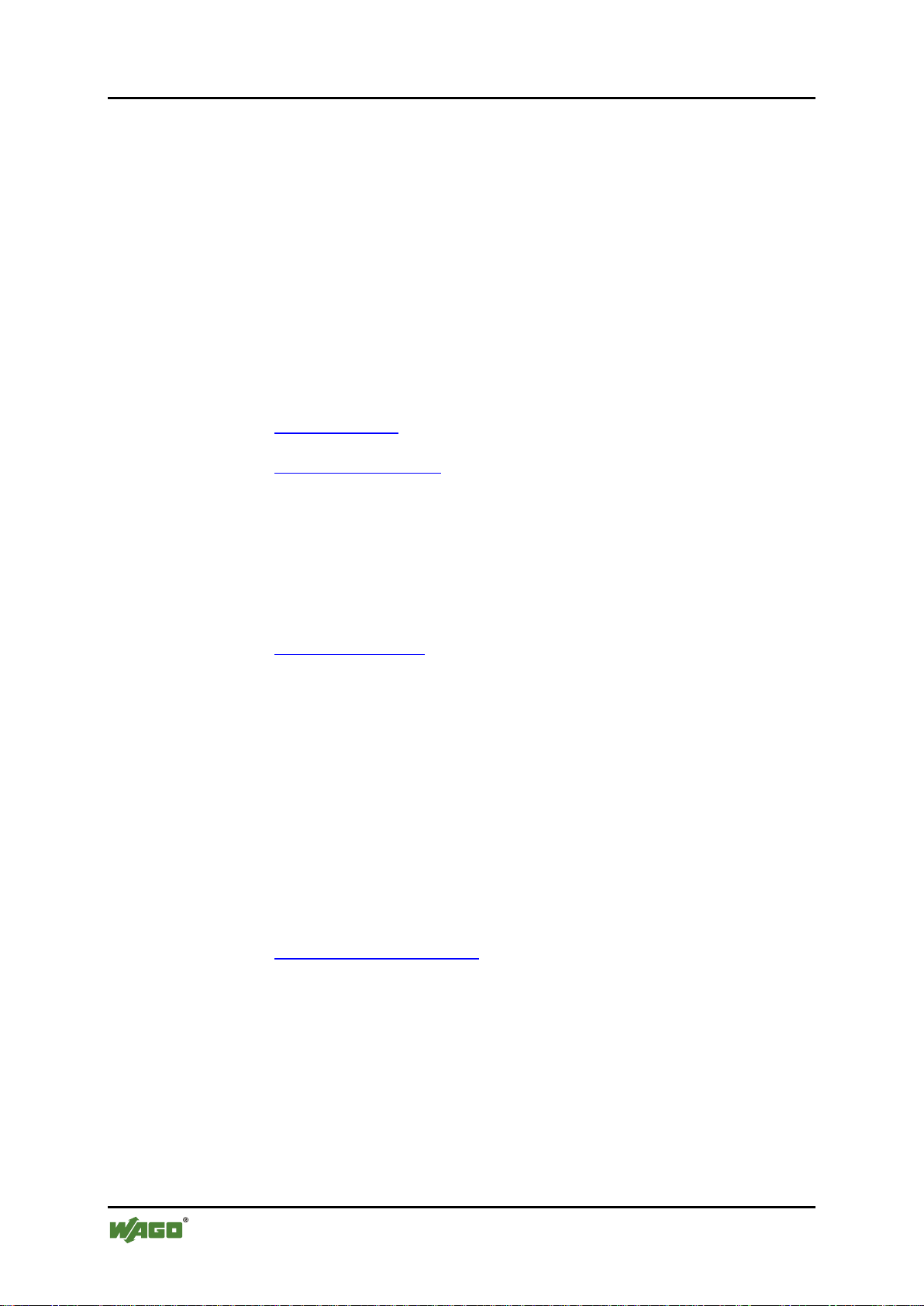

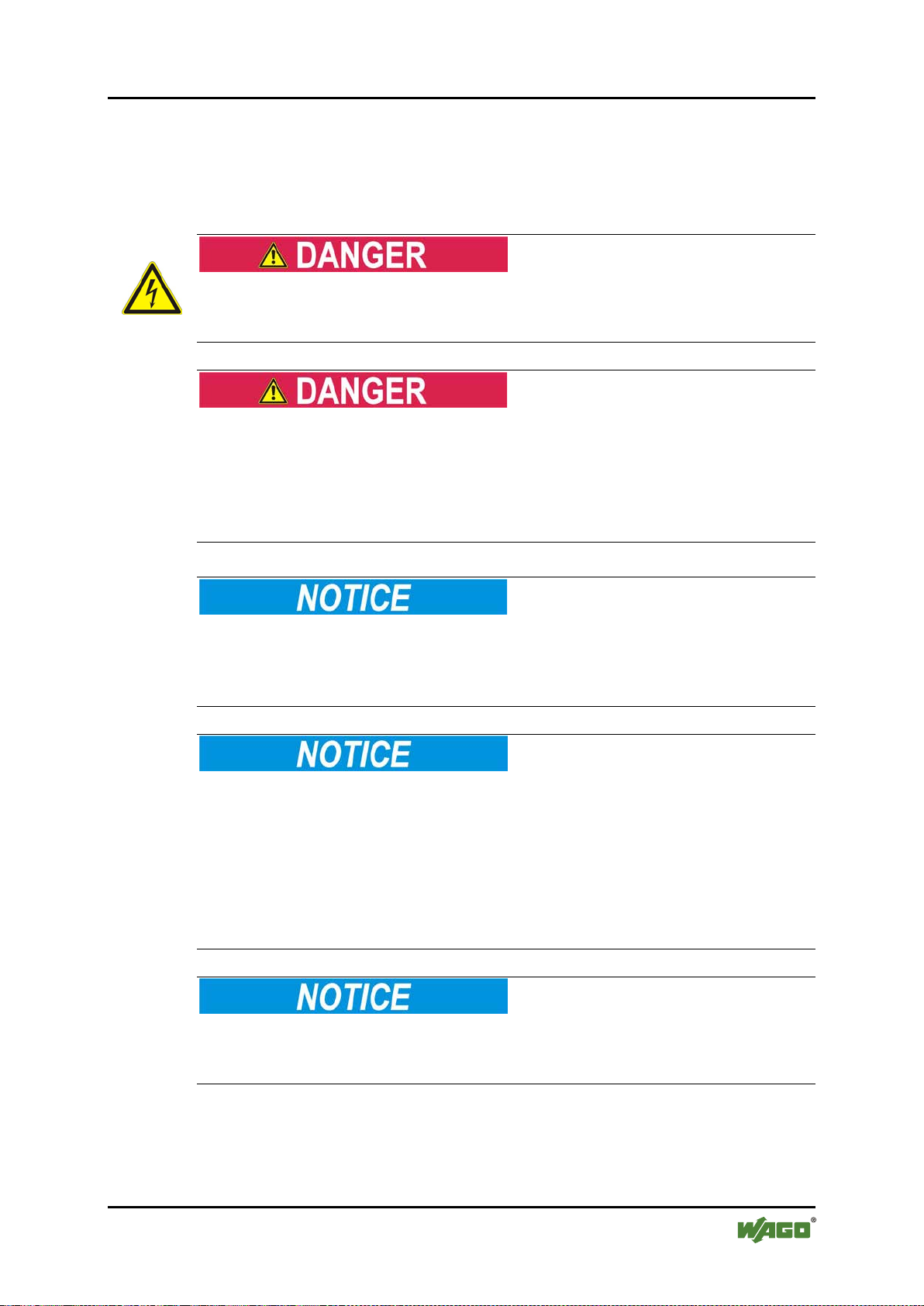

Personal Injury!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 13.4.2 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sonsti g e Hin weise/Ge f a hr /G efahr: _War nung vor Pers o n en schäden dur c h el e ktrische n Str o m_ - Erläuterung @ 13\mod_1343309694914_21.docx @ 101030 @ @ 1

Personal Injury Caused by Electric Current!

Indicates a high-risk, imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Pos: 13.4.3 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sons tige Hinwei se/Warnung /Warnung : _Warnu ng vor Per sonenschäd en allgem ein_ - Erläuterung @ 13\mod_1343309877041_21.docx @ 101035 @ @ 1

Personal Injury!

Indicates a moderate-risk, potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Pos: 13.4.4 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sons tige Hinwei se/Vorsic ht/Vorsic ht: _Warnu ng vor Per sonenschä den allge mein_ - Erl äuterung @ 13\mod_1343310028762_21.docx @ 101038 @ @ 1

Personal Injury!

Indicates a low-risk, potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Pos: 13.4.5 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sonstige Hinwei se/Achtung/Achtung: _Warnung vor Sachschäden allgemein_ - Erläuterung @ 13\mod_1343310134623_21.docx @ 101041 @ @ 1

Damage to Property!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 13.4.6 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sonstige Hinwei se/Achtung/Achtung: _Warnung vor Sachschäden durch elektr ostatische Aufladung_ - Erläuterung @ 13\mod_1343310227702_21.docx @ 101044 @ @ 1

Damage to Property Caused by Electrostatic Discharge (ESD)!

Indicates a potentially hazardous situation which, if not avoided, may result in

damage to property.

Pos: 13.4.7 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sonstige Hinweise/Hinweis/Hinweis: _Wichtiger Hinweis allgemein_ - Eräuterung @ 13\mod_1343310326906_21.docx @ 101047 @ @ 1

Important Note!

Indicates a potential malfunction which, if not avoided, however, will not result in

damage to property.

Pos: 13.4.8 /All e Serien (All g emeine Mod ul e) / Wichtige Er lä uterunge n/ Sicherheit s- und sons tige Hinwei se/Infor mation/Inf ormation: _Weitere I nformatio n allgemei n_ - Erläu ter ung @ 13\mod_1343310439814_21.do cx @ 101051 @ @ 1

Manual

Version 1.1.0

Page 7

WAGO-I/O-SYSTEM 750 Notes about this Documentation 7

750-402 4DI 24V DC 3.0ms

Additional Information:

Refers to additional information which is not an integral part of this

documentation (e.g., the Internet).

Pos: 13.5 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechs el--- @ 3\mod_1221108045078_0 .docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 8

8 Notes about this Documentation WAGO-I/O-SYSTEM 750

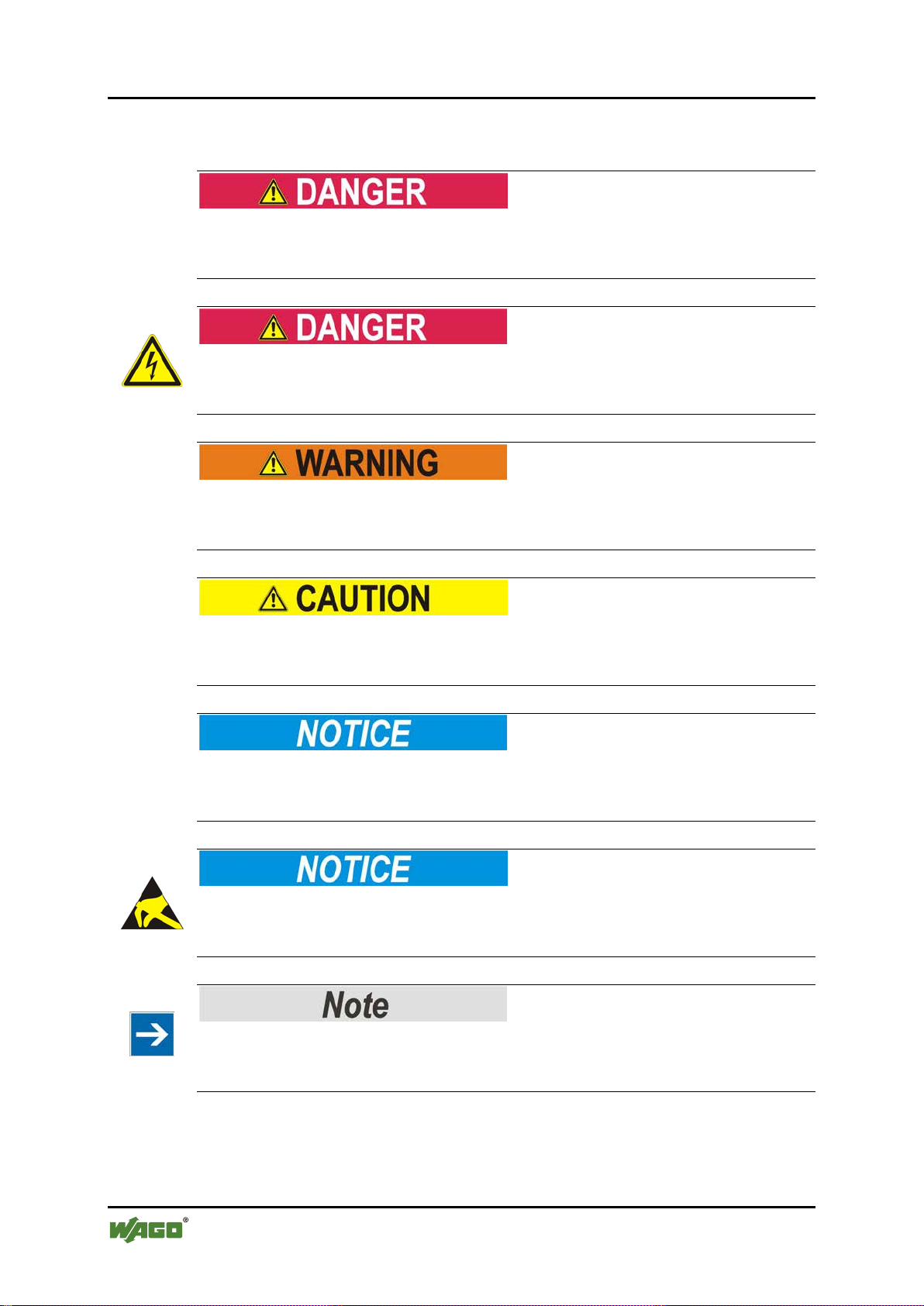

Table 2: Number notation

Number code

Example

Note

Decimal

100

Normal notation

Hexadecimal

0x64

C notation

Binary

'100'

'0110.0100'

In quotation marks, nibble separated with

dots (.)

Table 3: Font conventions

Font type

Indicates

italic

Names of paths and data files are marked in italic-type.

e.g.: C:\Programme\WAGO-I/O-CHECK

Menu

Menu items are marked in bold letters.

e.g.: Save

>

A greater-than sign between two names means the selection of a

e.g.: File > New

Input

Designation of input or optional fields are marked in bold letters,

e.g.: Start of measurement range

“Value”

Input or selective values are marked in inverted commas.

e.g.: Enter the value “4 mA” under Start of measurement range.

[Button]

Pushbuttons in dialog boxes are marked with bold letters in square

e.g.: [Input]

[Key]

Keys are marked with bold letters in square brackets.

e.g.: [F5]

750-402 4DI 24V DC 3.0ms

Pos: 13.6 /Al le Seri en (Allgemei ne Modul e)/Hinweis e z ur D o k u me nt ation/Zahl e nsysteme @ 3\ mod_1221059454015_21.docx @ 21711 @ 2 @ 1

1.4 Number Notation

Pos: 13.7 /All e Ser i en (Allgemei ne Module)/ H i nweise zur D o ku mentation /Sc hriftko n vent i onen @ 3\mod_1221059521437_21.docx @ 21714 @ 2 @ 1

1.5 Font Conventions

menu item from a menu.

brackets.

Pos: 14 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 9

WAGO-I/O-SYSTEM 750 Important Notes 9

750-402 4DI 24V DC 3.0ms

Pos: 15 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serien/Wichtige Erläuterungen/Wichtige Erläuterungen - Überschrift 1 @ 4\mod_1241428899156_21.docx @ 32170 @ 1 @ 1

2 Important Notes

Pos: 16.1 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Wic htige Erlä uterunge n/Einleit ung Wichtig e Erläuter ungen @ 3\ mod_1221059818031_21.docx @ 21717 @ @ 1

This section includes an overall summary of the most important safety

requirements and notes that are mentioned in each individual section. To protect

your health and prevent damage to devices as well, it is imperative to read and

carefully follow the safety guidelines.

Pos: 16.2 /Al le Seri en (Allgemei ne Modul e)/Überschr iften für alle Seri en/Wichti ge Erläuter ungenRec htliche Gr undlagen - Überschri ft 2 @ 3\ mod_1221060626343_21.docx @ 21726 @ 2 @ 1

2.1 Legal Bases

Pos: 16.3 /Alle Se r ie n ( Allgemeine Dokumente) (Allgemeine Module)/Wichtige Erläuterungen/Änderungsvorbehalt - Überschri ft 3 und I nhalt @ 3\mod_1221060036484_21.docx @ 21720 @ 3 @ 1

2.1.1 Subject to Changes

WAGO Kontakttechnik GmbH & Co. KG reserves the right to provide for any

alterations or modifications that serve to increase the efficiency of technical

progress. WAGO Kontakttechnik GmbH & Co. KG owns all rights arising from

the granting of patents or from the legal protection of utility patents. Third-party

products are always mentioned without any reference to patent rights. Thus, the

existence of such rights cannot be excluded.

Pos: 16.4 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Pers onalquali fi kation 750- xxxx @ 3\mod_1224061208046_21.docx @ 24063 @ 3 @ 1

2.1.2 Personnel Qualifications

All sequences implemented on Series 750 devices may only be carried out by

electrical specialists with sufficient knowledge in automation. The specialists

must be familiar with the current norms and guidelines for the devices and

automated environments.

All changes to the coupler or controller should always be carried out by qualified

personnel with sufficient skills in PLC programming.

Pos: 16.5 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Bes ti m m u ng s g e mäß e Verwend ung 7 50- xxxx @ 3\mod_1224064151234_21.docx @ 24070 @ 3 @ 1

2.1.3 Use of the 750 Series in Complianc e wit h Unde rlying Provisions

Couplers, controllers and I/O modules found in the modular WAGO-I/OSYSTEM 750 receive digital and analog signals from sensors and transmit them

to the actuators or higher-level control systems. Using programmable controllers,

the signals can also be (pre-) processed.

The components have been developed for use in an environment that meets the

IP20 protection class criteria. Protection against finger injury and solid impurities

up to 12.5 mm diameter is assured; protection against water damage is not

ensured. Unless otherwise specified, operation of the components in wet and

dusty environments is prohibited.

Operating 750 Series components in home applications without further measures

is only permitted if they meet the emission limits (emissions of interference)

according to EN 61000-6-3. You will find the relevant information in the section

on "WAGO-I/O-SYSTEM 750" "System Description" "Technical Data" in

the manual for the used fieldbus coupler/controller.

Manual

Version 1.1.0

Page 10

10 Important Notes WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Appropriate housing (per 94/9/EG) is required when operating the WAGO-I/OSYSTEM 750 in hazardous environments. Please note that a prototype test

certificate must be obtained that confirms the correct installation of the system in

a housing or switch cabinet.

Pos: 16.6 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Wic htige Erlä uterunge n/Technis cher Zustan d der Ger äte - Übersc hrift 3 und Inh alt @ 3\mod_1221060446109_21.doc x @ 21723 @ 3 @ 1

2.1.4 Technical Condition of Spec ified Devices

The components to be supplied Ex Works, are equipped with hardware and

software configurations, which meet the individual application requirements.

WAGO Kontakttechnik GmbH & Co. KG will be exempted from any liability in

case of changes in hardware or software as well as to non-compliant usage of

components.

Please send your request for modified and new hardware or software

configurations directly to WAGO Kontakttechnik GmbH & Co. KG.

Pos: 16.7 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechs el--- @ 3\mod_1221108045078_0 .docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 11

WAGO-I/O-SYSTEM 750 Important Notes 11

750-402 4DI 24V DC 3.0ms

Pos: 16.8 /All e Ser i en (Allgemei ne Module)/ Ü berschrift en für alle Ser i e n/Wichtig e Er l ä ut er ungenSic her heitshi n weis e - Überschr i ft 2 @ 6\ mod_12601802999 87_21.docx @ 46724 @ 2 @ 1

2.2 Safety Advice (Precautions)

Pos: 16.9 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Wic htige Erlä uterunge n/Sicherhei tshinweis e/Einleit ung Sicher heitshin weise Hard ware @ 6\mod_1260180170493_21.docx @ 46720 @ @ 1

For installing and operating purposes of the relevant device to your system the

following safety precautions shall be observed:

Pos: 16.10. 1 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ngen/Sich erheitshin weise/Gef ahr/Gefahr : Nicht an Geräten unter Spann ung arbeit en! @ 6\mod_1260180365327_21.docx @ 46727 @ @ 1

Do not work on components while energized!

All power sources to the device shall be switched off prior to performing any

installation, repair or maintenance work.

Pos: 16.10. 2 /Serie 75 0 (WAGO-I/O- SYSTEM) /Wichtige Er läuterung en/Sicher heits- un d sonstige H inweise /Gefahr/Ge fahr: Einb au 0750-xx x x nur i n Ge häusen, Sc hr ä nken oder el e ktr is c hen Betrie bsr ä umen! @ 6\mod_1260180556692_21.docx @ 46731 @ @ 1

Installation only in appropriate housings, cabinets or in electrical operation

rooms!

The WAGO-I/O-SYSTEM 750 and its components are an open system. As such,

install the system and its components exclusively in appropriate housings,

cabinets or in electrical operation rooms. Allow access to such equipment and

fixtures to authorized, qualified staff only by means of specific keys or tools.

Pos: 16.10. 3 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ngen/Sich erheitshin weise/Gef ahr/Gefahr : Unfall verhütungs vorschrift en beachte n! @ 6\mod_1260180657000_21.docx @ 46735 @ @ 1

Pos: 16.10.4 / Alle Seri en (Allgem eine Doku mente) (All gemeine M odule)/ Wichtige Er läuterung en/Sicher heitshinw eise/Gefahr /Gefahr: Auf normg erechten A nschluss achten! @ 6\mod_1260180753479_21.docx @ 46739 @ @ 1

Pos: 16.11.1 /Al le Serien (Allgemei ne D okumente) (Allgemei n e M o dule)/Wich tige Erläut er ungen/Sic herheits hi n w ei s e /Ac htung/Ac ht ung: Defek t e od er beschädigt e Geräte aus ta us c hen! @ 6\mod_1260180857358_21.docx @ 46743 @ @ 1

Replace defective or damaged devices!

Replace defective or damaged device/module (e.g., in the event of deformed

contacts), since the long-term functionality of device/module involved can no

longer be ensured.

Pos: 16.11. 2 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ng en /Sicherh ei ts hinweise /Ac htung/Ac ht ung: Gerät e vor kr i ec he nden und isol i er enden Stof f en s ch ützen! @ 6\mod_1260181036216_21.docx @ 46747 @ @ 1

Protect the components against materials having seeping and insulating

properties!

The components are not resistant to materials having seeping and insulating

properties such as: aerosols, silicones and triglycerides (found in some hand

creams). If you cannot exclude that such materials will appear in the component

environment, then install the components in an enclosure being resistant to the

above-mentioned materials. Clean tools and materials are imperative for handling

devices/modules.

Pos: 16.11. 3 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ngen/Sich erheitshin weise/Acht ung/Acht ung: Reinig ung nur mit zulässig en Mater ialien! @ 6\mod_1260181203293_21.docx @ 46751 @ @ 1

Cleaning only with permitted materials!

Clean soiled contacts using oil-free compressed air or with ethyl alcohol and

leather cloths.

Pos: 16.11. 4 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ngen/Sich erheitshin weise/Acht ung/Acht ung: Kein K ontaktspr ay verwe nden! @ 6\mod_1260181290808_21.docx @ 46755 @ @ 1

Manual

Version 1.1.0

Page 12

12 Important Notes WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Do not use any contact spray!

Do not use any contact spray. The spray may impair contact area functionality in

connection with contamination.

Pos: 16.11. 5 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ngen/Sich erheitshin weise/Acht ung/Acht ung: Verpol ung ver meiden! @ 6\ mod_1260184045744_21.docx @ 46767 @ @ 1

Do not reverse the polarity of connection lines!

Avoid reverse polarity of data and power supply lines, as this may damage the

devices involved.

Pos: 16.11. 6 /Alle Ser ien (Allge meine Do kumente) (A llgemein e Module)/ Wichtige Erläuteru ngen/Sich erheitshin weise/Acht ung/Acht ung: Elektr ost atische Entl adung verm ei d en! @ 6\mod_1260181364729_21.docx @ 46759 @ @ 1

Avoid electrostatic discharge!

The devices are equipped with electronic components that you may destroy by

electrostatic discharge when you touch. Pay attention while handling the devices

to good grounding of the environment (persons, job and packing).

Pos: 17 /Dokum e nt ation allge mein/Glie derungsele mente/---Seit enwechsel--- @ 3\ mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 13

WAGO-I/O-SYSTEM 750 Device Description 13

750-402 4DI 24V DC 3.0ms

Pos: 18 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Gerätebe schreibu ng - Übersc hr i ft 1 @ 3\ mod_1233756084656_21.docx @ 27096 @ 1 @ 1

3 Device Description

Pos: 19.1 /Serie 750 (WAGO-I/O-S YSTEM)/ Ger ätebeschr ei bung/Einl ei tung/An w en d ung/DI/An w en dung 750-x4 xx DI @ 3\mod_1233762736718_21.docx @ 27108 @ @ 1

The digital input module 750-402 receives control signals from digital field (e.g.

of sensors, transmitters, switches or proximity switches).

Pos: 19.2 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/Ei nleitung /I/O-Besc hreibung/DI /I/O-Besc hreibung 7 50-04xx 4 DI 2-/3-Leiter (DI, 24 V und 0 V) @ 6\mod_1263895132463_21.docx @ 48086 @ @ 1

The I/O module has 4 input channels, providing a direct connection to two 2- or 3wire sensors. Two additional sensors may be connected via potential distributor.

The input signals are connected to the following CAGE CLAMP® terminals: DI 1

Pos: 19.3 /Dokumentation allgemein/Glieder ungselemente/------Leerzeile------ @ 3\mod_1224662755687_0.do cx @ 24460 @ @ 1

Pos: 19.4 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Sich er h eits- und s onstige Hi nweise/Hi nweis/Hin weis: DI P otential vervielfält igungsmod ule für Se nsorvers orgung eins etzen @ 3\ mod_1233762069125_21.docx @ 27105 @ @ 1

... DI 4, 24 V and 0 V.

Use field side connection modules!

Where required, use the appropriate field side connection modules for power

supply to the sensors.

Pos: 19.5 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/Ei nleitung /I/O-Besc hreibung/ Allgemein/V erweis auf Kapitel "Anschlüss e" @ 8\mod_1276775378035_21.docx @ 57956 @ @ 1

Pos: 19.6 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/Ei nleitung /I/O-Besc hreibung/ Allgemein/V erweis auf Kapitel "Geräte a nschließen" > "Ansc hlussbeis piel(e)" @ 5\mod_1246015203281_21.docx @ 36298 @ @ 1

The assignment of the connections is described in the "Connections" section.

Connection examples are shown in section "Connecting Devices" > "Connection

Example(s)".

Pos: 19.7 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/Ei nleitung /I/O-Besc hreibung/DI /I/O-Besc hreibung 7 50-x4xx DI RC-Fil t er 3, 0 ms @ 3\mod_1233755071062_21.docx @ 27080 @ @ 1

Each input channel has an RC noise rejection filter with a time constant of 3.0 ms.

Pos: 19.8 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/Ei nleitung /I/O-Besc hreibung/DI /I/O-Besc hreibung 7 50-x4xx DI HSS / posi tivschalt end (24 V) @ 3\mod_1233831724648_21.docx @ 27231 @ @ 1

The I/O module inputs provide high-side switching. If the 24V potential for field

power is switched to an input connection, the signal status for the corresponding

input channel is set to "high."

Pos: 19.9 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/Ei nleitung /LED-Anzei ge/LED Zu stand Sig nal @ 3\mod_1233755258578_21.docx @ 27087 @ @ 1

Pos: 19.10 / Serie 750 ( WAGO-I/O-S YSTEM)/G erätebeschr eibung/Ei nleitung/ LED-Anzeig e/Verweis auf Kapi tel "Anzeig eel emente" @ 5\ mod_1246010525000_21.docx @ 36194 @ @ 1

A green LED indicates the switched status of each channel.

The meaning of the LEDs is described in the “Display Elements” section.

Pos: 19.11 / Serie 750 ( WAGO-I/O-S YSTEM)/G erätebeschr eibung/Ei nleitung/ Versorgu ng/Versor gung 24 V, 0 V über L eistungs kontakte Stan d ar d @ 3\ mod_1226498974531_21.docx @ 25020 @ @ 1

The I/O module receives the 24 V voltage supply for the field level from an

upstream I/O module or from the fieldbus coupler/controller via the power

contacts used as blade contacts. It then provides this potential to subsequent I/O

modules via the power contacts used as spring contacts.

Pos: 19.12 / Serie 750 ( WAGO-I/O-S YSTEM)/ Wichtige Erl äuterung en/Sicher heits- und s onstige Hi nweise/Ac htung/Ac htung: Maxi maler Str om Leistu ngskontak te 10 A @ 3 \mod_1226499143500_21.docx @ 25029 @ @ 1

Do not exceed maximum current via power contacts!

The maximum current to flow through the power contacts is 10 A.

Greater currents can damage the power contacts.

When configuring the system, ensure that this current is not exceeded. If

exceeded, an additional potential feed module must be used.

Pos: 19.13 / Serie 750 ( WAGO-I/O-S YSTEM)/ Wichtige Erl äuterung en/Sicher heits- und s onstige Hi nweise/Hi nweis/Hi nweis: Pote ntialeins peiseklem me für Erd e einsetze n! @ 3\mod_1226499037468_21.docx @ 25023 @ @ 1

Use potential feed module for Ground (earth)!

The I/O module has no power contacts for PE intake and transfer. Use a potential

feed module when a PE feed is needed for the subsequent I/O modules.

Pos: 19.14 /Ser i e 7 50 ( WAGO-I/O-SYS TEM)/Gerät ebeschr eibung/Ei nleitung/V ersorgung /Galvanisc he Trennu ng Feld/S ystem @ 3\mod_1233756478750_21.docx @ 27102 @ @ 1

Manual

Version 1.1.0

Page 14

14 Device Description WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

The field voltage and the system voltage are electr ical l y isolated from each other.

Pos: 19.15 /Ser i e 7 50 ( WAGO-I/O-SYS T EM)/Gerät e be schreibu ng /Einleitung /Versorg u ng/Anord nu ng unt er Berücksi c htigung der L ei st ungskonta k t e bel i e big @ 3\mod_1233756233468_21.doc x @ 27099 @ @ 1

With consideration of the power jumper contacts, the individual modules can be

arranged in any combination when configuring the fieldbus node. An arrangement

in groups within the group of potentials is not necessary.

Pos: 19.16 / Serie 750 ( WAGO-I/O-S Y ST EM)/Gerät ebeschrei b ung/Einlei t ung/Einsa tzbereich/ Einsatzb er ei c h 750-xxxx al l e K op pl er / C ontroller ohne Eins chränkung @ 3\mod_1232541691906_21.docx @ 26522 @ @ 1

The I/O module 750-402 can be used with all fieldbus couplers/controllers of the

WAGO-I/O-SYSTEM 750.

Pos: 20 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seitenwechsel--- @ 3\mod_1221108 045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 15

WAGO-I/O-SYSTEM 750 Device Description 15

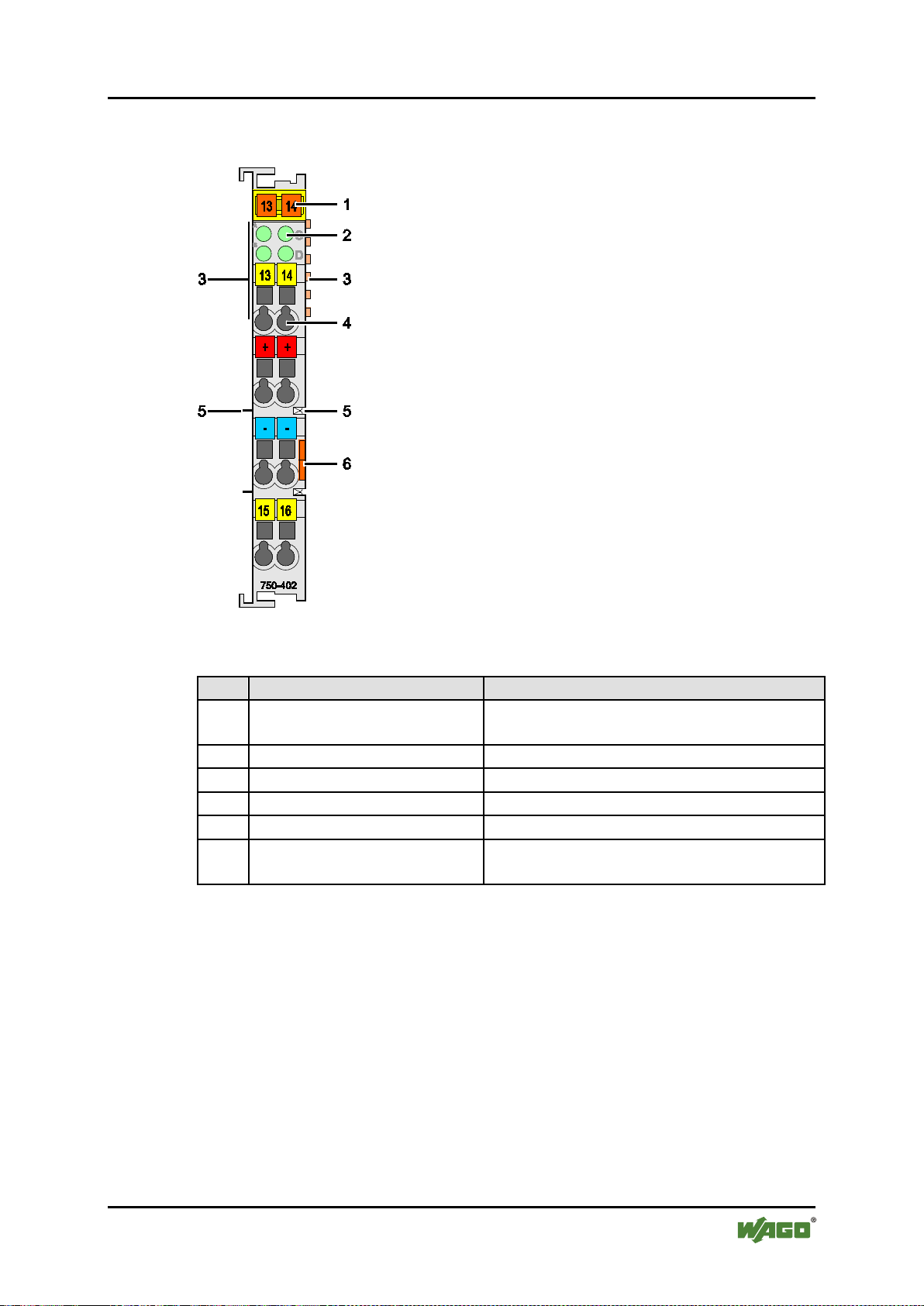

Table 1: Caption acc. to figure “View”

Pos.

Description

Details see section

1

Marking possibility with

Mini-WSB

--2

Status-LEDs

“Device Description” > “Display Elements”

3

Data contacts

“Device Description” > ”Connectors”

4

CAGE CLAMP® supplies

“Device Description” > ”Connectors”

5

Power jumper contacts

“Device Description” > ”Connectors”

6

Release tab

“Mounting” > ”Inserting and Removing

Devices”

750-402 4DI 24V DC 3.0ms

Pos: 21 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Ansicht - Ü berschrif t 2 @ 4\mod_1240984217343_21.docx @ 31958 @ 2 @ 1

3.1 View

Pos: 22 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ A ns i c ht /Digitalei ngangs kle m m en /Ansicht 7 50- 0402 @ 9\ mod_1295861125135_21.docx @ 68661 @ @ 1

Figure 1: View

Pos: 23 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ A ns i c ht /Ansicht C ag eC l amp®_Leg ende mit LED @ 1 5\ mod_1370867188922_21.docx @ 122225 @ @ 1

Pos: 24 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 16

16 Device Description WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 25 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al l e S erien/Gerä tebeschr ei b u ng /Anschlü ss e - Üb er s c hrift 2 @ 4\mod_1240984262656_21.docx @ 31961 @ 22 @ 1

3.2 Connectors

Pos: 26 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansc hlüsse/Da tenkontak te/Klemme nbus - Übers c hrift 3 @ 6\mod_1256294684083_21.docx @ 4 3660 @ 3 @ 1

3.2.1 Data Contacts/Interna l Bus

Pos: 27.1 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/A nschlüsse /Datenkon takte - Fel dbuskoppl er/-controll er, Abbil dung und B eschreibu ng @ 3\mod_1231771259187_21.docx @ 26002 @ @ 1

Communication between the coupler/controller and the I/O modules as well as the

system supply of the I/O modules is carried out via the internal bus. It is

comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Figure 2: Data contacts

Pos: 27.2 /Serie 750 (WAGO-I/O-SYSTEM)/Wichti g e Erläuteru ngen/Sich er h eits- und s onstige Hi nweise/Ac htung/Ach tung: Bus klemmen ni cht auf G oldfederk ontakte leg en! @ 7\mod_1266318463636_21.docx @ 50695 @ @ 1

Do not place the I/O modules on the gold spring contacts!

Do not place the I/O modules on the gold spring contacts in order to avoid soiling

or scratching!

Pos: 27.3 /Serie 750 (WAGO-I/ O-SYSTEM)/ Wi c htige Erläut erungen/ Si c h er h ei t s- und sonstige Hinwei se/Achtung/Achtung: ESD - Auf gute Erd ung der U mgebung ac hten! @ 7\ mod_1266318538667_21.docx @ 50708 @ @ 1

Ensure that the environment is well grounded!

The modules are equipped with electronic components that may be destroyed by

electrostatic discharge. When handling the modules, ensure that the environment

(persons, workplace and packing) is well grounded. Avoid touching conductive

components, e.g. data contacts.

Pos: 28 /D okumentatio n allgemei n/Glieder ungselem ente/---Seite nwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 17

WAGO-I/O-SYSTEM 750 Device Description 17

Table 4: Caption acc. to view “Power jumper contacts”

Contact

Type

Function

1

Spring contact

Potential transmission (Uv) for field supply

2

Spring contact

Potential transmission (0 V) for field supply

3

Blade contact

Potential feed-in (0 V) for field supply

4

Blade contact

Potential feed-in (Uv) for field supply

750-402 4DI 24V DC 3.0ms

Pos: 29 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansc hlüsse/Lei stungs kontakte/Fel dversorg ung - Übersc hrift 3 @ 6\mod_1256294692864_21.docx @ 43664 @ 3 @ 1

3.2.2 Power Jumper Contacts/Field Supply

Pos: 30.1 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Sich er h eits- und s onstige Hi nweise/Vor sicht/V orsicht: Ver letzungsg efahr durc h scharf kantige M esserkonta kte! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged male contacts!

The male contacts are sharp-edged. Handle the module carefully to prevent injury.

Pos: 30.2 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/A nschlüsse /Leistung skontakte 2 LK (Mess er/Leistu ngskonta kte 2 LK (Me sser/Fed er) - Einleit ung @ 15\mod_1371721641099_21.docx @ 123714 @ @ 1

The I/O module 750-402 has 2 self-cleaning power jumper contacts that supply

and transmit power for the field side. The contacts on the left side of the I/O

module are designed as male contacts and the contacts on the right side as spring

contacts.

Pos: 30.3 /Serie 750 (WAGO-I/O-S YSTEM)/G erätebesc hreibung/A nschlüsse /Leistung skontakte 2 LK (Mess er/Leistu ngskontak te 2 LK (Me sser/Fed er) - Abbil du ng (ei nfache Brei te) @ 15\mod_1367500700037_21.docx @ 118396 @ @ 1

Figure 3: Power jumper contacts

Pos: 30.4 /S erie 750 (WAGO-I/O-SYSTEM )/Geräte beschreibu ng/Anschl üsse/Leist ungskont akte 2 LK ( Messer/Lei stungsk ontakte 2 L K (Messer /Feder) - L eg e nd e @ 15\mod_1371721352500_21.docx @ 123710 @ @ 1

Pos: 30.5 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Sich er h eits- und so nst i g e Hinweise/ Achtung/A c h tu ng: Maximal er Strom Leis t ung skontakt e 10 A @ 3\mod_1226499143500_21.docx @ 25029 @ @ 1

Do not exceed maximum current via power contacts!

The maximum current to flow through the power contacts is 10 A.

Greater currents can damage the power contacts.

When configuring the system, ensure that this current is not exceeded. If

exceeded, an additional potential feed module must be used.

Pos: 30.6 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Sich er h eits- und so nst i g e Hinweise/ Hi n weis/Hin w ei s : Po t e nti aleinspei s eklemme für Er d e ei nsetzen! @ 3\mod_1226499037468_21.docx @ 25023 @ @ 1

Use potential feed module for Ground (earth)!

The I/O module has no power contacts for PE intake and transfer. Use a potential

feed module when a PE feed is needed for the subsequent I/O modules.

Pos: 31 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 18

18 Device Description WAGO-I/O-SYSTEM 750

Table 5: Caption acc. to figure “CAGE CLAMP® Connectors”

Channel

Designation

Connector

Function

1

DI 1

1

Input DI 1: Signal voltage

2

DI 2

5

Input DI 2: Signal voltage

3

DI 3

4

Input DI 3: Signal voltage

4

DI 4

8

Input DI 4: Signal voltage

-

+24 V

2

Sensor supply +24 V

-

+24 V

6

Sensor supply +24 V

-

0 V

3

Sensor supply 0 V

-

0 V

7

Sensor supply 0 V

750-402 4DI 24V DC 3.0ms

Pos: 32 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Ansc hlüsse/CA GE CLAMP- Anschlüss e - Überschri ft 3 @ 6\ mod_1256296337770_21.docx @ 43674 @ 3 @ 1

3.2.3 CAGE CLAMP® Connectors

Pos: 33 /Ser ie 750 ( WAGO-I/O-SYST EM)/Geräteb eschreibu ng /Anschl üss e/Digital eingangs kle m m e n/Anschl üss e 750-04xx 4 DI 3-Leiter (DIn, 24 V, 0 V) @ 9\mod_129586 1237712_21.docx @ 68665 @ @ 1

Figure 4: CAGE CLAMP

®

Connectors

Pos: 34 /Ser ie 750 ( WAGO-I/O-SYST EM )/Wichti g e Er l ä ut erungen/ Si c h er h ei ts - und sonstige Hi nweise/Hi nweis/Hin weis: DI P otential vervielfälti gungsmod ule für Se nsorversor gung einse tzen @ 3\ mod_1233762069125_21.docx @ 27105 @ @ 1

Use field side connection modules!

Where required, use the appropriate field side connection modules for power

supply to the sensors.

Pos: 35 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 19

WAGO-I/O-SYSTEM 750 Device Description 19

Table 6: Caption acc. to figure “Display elements”

Channel

Designation

LED

State

Function

out

Input DI 1: Signal voltage „0“

green

Input DI 1: Signal voltage „1“

out

Input DI 2: Signal voltage „0“

green

Input DI 2: Signal voltage „1“

out

Input DI 3: Signal voltage „0“

green

Input DI 3: Signal voltage „1“

out

Input DI 4: Signal voltage „0“

green

Input DI 4: Signal voltage „1“

750-402 4DI 24V DC 3.0ms

Pos: 36 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Anzeigeel emente - Überschri ft 2 @ 4\mod_1240984390875_21.docx @ 31964 @ 22 @ 1

3.3 Display Elements

Pos: 37 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ A nz eigeelem en te/Digital ei ngangs kle m m en /Anzeigeel emente 750- 04xx 4 DI (Agn, Bg n, Cgn, Dg n) @ 9\mod_1291641003036_21.do cx @ 67080 @ @ 1

Figure 5: Display elements

1 Status DI 1 A

2 Status DI 2 C

3 Status DI 3 B

4 Status DI 4 D

Pos: 38 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 20

20 Device Description WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 39 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Schemat isches Sc haltbild - Ü berschrift 2 @ 4\mod_1240984441312_21.docx @ 31967 @ 2 @ 1

3.4 Schematic Diagram

Pos: 40 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Sch ematische Schaltbil der/Digit aleingangs klemmen/Sc hematisc hes Schal tbild 750-0 40 2 @ 9\mod_1295863706202_21.docx @ 68711 @ @ 1

Figure 6: Schematic d iagram

Pos: 41 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 21

WAGO-I/O-SYSTEM 750 Device Description 21

Table 7: Technical data – device

Width

12 mm

Height (from upper edge of 35 DIN rail)

64 mm

Depth

100 mm

Weight

48,5 g

Table 2: Technical data – supply

Voltage supply

Via system voltage terminal bus

(5 V DC) and power contacts (24 V DC)

Current consumption

. (internal).

(5 V DC)

7.5 mA

Input current

. (Field).

(24 V DC)

Total input current + sensor supply

Voltage via power jumper contacts

24 VDC (-25 % … + 30 %)

Current via power jumper contacts

10 A

Isolation (Peak value)

500 V System/Field

Table 3: Technical data – communication

Internal bit width (Terminal bus)

4 bit in

Table 4: Technical data – inputs

No. of inputs

4

Signal voltage

- 3 V … + 30 V DC

Signal voltage (0)

- 3 V … + 5 V DC

Signal voltage (1)

+ 15 V … + 30 V DC

Input filter

3.0 ms

Input current

typ

.

4.5 mA

750-402 4DI 24V DC 3.0ms

Pos: 42 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Technisc he Daten - Ü berschrif t 2 @ 3\mod_1232967587687_21.docx @ 26924 @ 2 @ 1

3.5 Technical Data

Pos: 43 /Ser ie 750 ( WAGO-I/O-SYST EM)/Ger ätebeschrei bung/Tec hnische Da ten/Digit aleingang sklemmen /Technisch e Daten 75 0-0402 @ 9\mod_1295863611535_21.docx @ 68707 @ 3333 @ 1

3.5.1 Device data

3.5.2 Supply

typ

typ

3.5.3 Communication

3.5.4 Inputs

Pos: 44 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 22

22 Device Description WAGO-I/O-SYSTEM 750

Table 8: Technical Data – Field Wiring

Wire connection

CAGE CLAMP®

Cross section

0.08 mm² … 2.5 mm², AWG 28 … 14

Stripped lengths

8 mm … 9 mm / 0.33 in

Table 9: Technical Data – Power Jumper Contacts

Power jumper contacts

blade/spring contact, self-cleaning

Voltage drop at I

max.

< 1 V/64 modules

Table 10: Technical Data – Internal Bus

Data contacts

slide contact, hard gold plated 1.5 µm,

self-cleaning

Table 11: Technical Data – Climatic environmental conditions

Operating temperature range

0 °C … 55 °C

Operating temperature r a nge for

temperature range (750-xxx/025-xxx)

-20 °C … +60 °C

Storage temperature range

-25 °C … +85 °C

Storage temperature range for

temperature range (750-xxx/025-xxx)

-40 °C … +85 °C

Relative humidity

max. 5 % … 95 % without condensation

Resistance to harmful substances

Acc. to IEC 60068-2-42 and

IEC 60068-2-43

Maximum pollutant concentration at

SO2 ≤ 25 ppm

H2S ≤ 10 ppm

Special conditions

Ensure that additional measures for

– ionizing radiation

750-402 4DI 24V DC 3.0ms

Pos: 45.1 /Al le Seri en (Allgemei ne Modul e)/Überschr iften für alle Seri en/Geräte beschreib ung/Anschl usstechni k - Überschr ift 3 @ 17\mod_1380123271324_21.docx @ 132788 @ 3 @ 1

3.5.5 Connection Type

Pos: 45.2 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/T echnische Daten/Tec hnische D aten Verdr ahtungs ebene CC - 0,08 bis 2,5mm2 @ 17\mod_1380121238809_21.docx @ 132780 @ @ 1

Pos: 45.3 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/T echnische Daten/A nschlusstec hnik/Tec hnische D aten Leist ungskonta kte (Messer/ Feder) @ 17\mod_1380123464149_21.docx @ 132791 @ @ 1

Pos: 45.4 /Serie 750 (WAGO-I/O-S YSTEM)/ Gerätebesc hreibung/T echnische Daten/A nschlusstec hnik/Tec hnische D aten Klemm enbus @ 1 7\mod_1380123495844_21.docx @ 132794 @ @ 1

Pos: 46 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Tech nische Da ten/Tech nische Dat en Klimatis che Umwel tbedingu ngen m. er w. Tempber eich; 0... 55°C/-20.. .+60°C/-25...+ 85°C @ 5\mod_1247658089120_21.docx @ 37606 @ 3 @ 1

3.5.6 Climatic Environmental Conditions

components with extended

components with extended

relative humidity < 75%

Pos: 47 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

components are

taken, which are used in an environment

involving:

– dust, caustic vapors or gases

Page 23

WAGO-I/O-SYSTEM 750 Device Description 23

Conformity Marking

TÜV 07 ATEX 554086 X

I M2 Ex d I Mb

II 3 D Ex tc IIIC T135°C Dc

Permissible ambient temperature range:

• Standard:

0 °C ≤ T

a

≤ +60 °C

• Variants with extended temperature

range (750-xxx/025-xxx):

-20 °C ≤ Ta ≤ +60 °C

IECEx TUN 09.0001 X

Ex d I Mb

Ex tc IIIC T135°C Dc

Permissible ambient temperature range:

• Standard:

0 °C ≤ T

a

≤ +60 °C

• Variants with extended temperature

range (750-xxx/025-xxx):

-20 °C ≤ Ta ≤ +60 °C

CULUS

ANSI/ISA 12.12.01

Class I, Div2 ABCD T4

750-402 4DI 24V DC 3.0ms

Pos: 48 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Zulassu ngen - Übers c hrift 2 @ 3\mod_1224055364109_21.docx @ 24030 @ 2 @ 1

3.6 Approvals

Pos: 49 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ Z ulassunge n/Informa ti o n: Weitere In for mationen zu Zulassungen 750-xxxx @ 3\mod_1227190967156_21.docx @ 25221 @ @ 1

More Information about Approvals

Detailed references to the approvals are listed in the document "Overview

Approvals WAGO-I/O-SYSTEM 750", which you can find via the internet

under: www.wago.com Documentation WAGO-I/O-SYSTEM 750

System Description.

Pos: 50 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Zulas sungen/ Allgemein/Z ulassung en Buskle mme 750-xxxx Allge mein, Stand ardversi on und alle Variante n - Einleitung @ 3\mod_1233911570312_21. docx @ 27390 @ @ 1

The following approvals have been granted to the basic version and all variations

of 750-402 I/O modules:

Pos: 51.1 /All e Serien ( Allgemei ne Dokumen te) (Allge meine Mod ule)/Zulas sungen/St andardzul assungen/C E (Konf ormitätske nnzeichnu ng) @ 3\mod_1224494777421_21.docx @ 24276 @ @ 1

Pos: 51.2 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Standardz ulassunge n/cULus (U L508) @ 3\ mod_122405501314 0_0. docx @ 24020 @ @ 1

Pos: 51.3 /Dokumentation allgemein/Glieder ungselemente/------Leerzeile------ @ 3\mod_1224662755687_0.do cx @ 24460 @ @ 1

Pos: 52 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ Z ulassunge n/Ex/Zulas sungen Bus kl e mme 750-xxxx Ex, S tandardversion und alle V arianten - Ei nleitung @ 4\ mod_1239099781531_21.docx @ 30158 @ @ 1

The following Ex approvals have been granted to the basic version and all

variations of 750-402 I/O modules:

Pos: 53.1 /Al le Seri en (Allgemei ne Modul e)/Zulassungen/Ex-Zulass ungen/TÜV ATEX/TÜ V 07 ATEX 554086 X: I M2 Ex d I Mb II 3 G E x nA IIC T 4 Gc II 3 D Ex tc IIIC T135°C Dc @ 14\mod_1361949753233_0.docx @ 113015 @ @ 1

Pos: 53.2 /Al le Seri en (Allgemei ne Module)/Zulassungen/Ex- Zulassung en/Ergänz ung Zuläss iger Umge bungstem peraturber eich 0 °C/- 20 °C <= Ta <= +60 °C , erw.Te mp.bereich @ 16\mod_1373889943656_21.doc x @ 126164 @ @ 1

CULUS

II 3 G Ex nA IIC T4 Gc

UL508

Pos: 53.3 /Al le Seri en (Allgemei ne Modul e)/Zulassu ngen/Ex-Zul assungen /IECEx (T ÜV Nord)/I ECEx TUN 09.0001 X: Ex d I Mb Ex nA IIC T4 Gc Ex tc IIIC T13 5°C @ 14\mod_1361950034299_0.docx @ 113019 @ @ 1

Ex nA IIC T4 Gc

Pos: 53.4 /Al le Seri en (Allgemei ne Modul e)/Zulassu ngen/Ex-Zul assungen /Ergänzung Zulässig er Umgeb ungstemper aturberei ch 0 °C/-20 °C <= Ta <= +60 °C, er w.Temp.b er ei c h @ 16\mod_1373889943656_21.docx @ 126164 @ @ 1

Pos: 53.5 /Dokumentation allgemein/Gli ederungsel emente/------Leerz eile------ @ 3\mod_1224662755687_0.docx @ 24460 @ @ 1

Pos: 54 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ Z ulassunge n/Ex/Zulas sungen Bus kl e mme 750-xxxx Ex, nur Standardversio n - Ei nl eitung @ 9\mod_1281526321376_21.docx @ 63104 @ @ 1

The following Ex approvals have been granted to the basic version of 750-402 I/O

modules:

Pos: 55 /All e Serien ( Allgemei ne Module)/Z ulassung en/Ex-Zul assungen/c ULus/cU Lus (ANSI/ ISA 12.12. 01) Class I , Div2 ABC D T4 @ 3\ mod_1224054791812_0.docx @ 24014 @ @ 1

Pos: 56 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 24

24 Device Description WAGO-I/O-SYSTEM 750

750-402

x x x x x x x x x

x

750-402

/025-000

750-402 4DI 24V DC 3.0ms

Pos: 57 /Ser ie 750 ( WAGO-I/O-SYST EM )/Gerät eb es c hreibung/ Z ulassunge n/Schiff/Z ulassunge n Busklemm e 75 0-xxxx Schiff , nur aufgeli s t et e V arianten - Einleitung @ 14 \ mod_1364210936228_21.docx @ 115844 @ @ 1

The following ship approvals have been granted to the variations 750-402 listed

below:

Pos: 58 /Ser ie 750 ( WAGO-I/O-SYST EM)/Gerät ebeschrei bung/Zulas sungen/ Schiff/Zulas sungen Bus klemme 750- 0400/-430 Schiff, T abellarisc he Übersic ht @ 16\mod_1379574156154_0.docx @ 132010 @ @ 1

Pos: 59.1 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ ABS (Amer i c an Bureau of Shi ppi ng) @ 3\mod_1224055151062_0.docx @ 24023 @ @ 1

Pos: 59.2 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ BSH (Bun desamt für Seeschiff fahrt und Hydrogra phie) @ 5\mod_1246341825156_21.docx @ 36334 @ @ 1

Pos: 59.3 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ BV (Bure au Veritas) @ 3\mod_1224492116171_0.docx @ 24220 @ @ 1

Pos: 59.4 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/D NV (Det N orske Verit as) Class B @ 3\ mod_1224492540562_0.docx @ 24224 @ @ 1

Pos: 59.5 /All e Ser i en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ GL (Germ anischer Ll oyd) Cat . A, B, C, D (EMC 1) @ 3\mod_1224492724484_0.docx @ 24228 @ @ 1

Pos: 59.6 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ KR (Korea n Regist er of Shippi ng) @ 3\mod_1224492806109_0.docx @ 24232 @ @ 1

Pos: 59.7 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ LR (Lloyd’ s Regist er) Env. 1, 2, 3, 4 @ 3\mod_1224492890453_0.docx @ 24236 @ @ 1

x x

ABS (American Bureau of Shipping)

Federal Maritime and Hydrographic Agency

BV (Bureau Veritas)

DNV (Det Norske Veritas) Class B

GL (Germanischer Lloyd) Cat. A, B, C, D (EMC 1)

KR (Korean Register of Shipping)

LR (Lloyd’s Register) Env. 1, 2, 3, 4

Pos: 59.8 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/N KK (Nip pon Kaiji K yokai) @ 3\mod_1224493002656_0.docx @ 24240 @ @ 1

NKK (Nippon Kaiji Kyokai)

Pos: 59.9 /Al le Seri en (Allgemei ne Dokum ente) (All gemeine Mo dule)/Zul assungen/ Schiffszul assungen/ PRS (Pols ki Rejestr Statkó w) @ 3\mod_1224497273250_0.doc x @ 24295 @ @ 1

PRS (Polski Rejestr Statków)

Pos: 59.10 / Alle Seri en (Allgem eine Doku mente) (All gemeine M odule)/Z ulassunge n/Schiffsz ulassunge n/RINA (R egistro It aliano Nav ale) @ 3\mod_1224493078359_0.docx @ 24244 @ @ 1

RINA (Registro Italiano Navale)

Pos: 60 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 25

WAGO-I/O-SYSTEM 750 Device Description 25

750-402 4DI 24V DC 3.0ms

Pos: 61 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Geräteb eschreibung /Normen u nd Richtli nien - Über sc hrift 2 @ 4\mod_1242804031875_21.docx @ 33646 @ 2 @ 1

3.7 Standards and Guidelines

Pos: 62 /Ser ie 750 ( WAGO-I/O-SYST EM)/Ger ätebeschrei bung/Nor men und Ri chtlinie n/EMV-Norm en Buskle mme 750-xxx x, St a ndardversi on und alle Var i a nt e n - Einleitung @ 6\mod_1263981980650_21.docx @ 48120 @ @ 1

All variations of 750-402 I/O modules meet the following requirements on

emission and immunity of interference:

Pos: 63 /All e Serien ( Allgemei ne Module)/N ormen un d Richtli nien/EMV C E-Störfest i g kei t EN 6 10 00- 6-2: 2005 @ 4\mod_1242797655625_21.docx @ 33591 @ @ 1

EMC CE-Immunity to interference acc. to EN 61000-6-2: 2005

Pos: 64 /All e Serien ( Allgemei ne Module)/N ormen un d Richtli nien/EMV C E-Störaussendung EN 61000-6- 4: 2007 @ 4\mod_1242798273984_21.docx @ 33602 @ @ 1

EMC CE-Emission of interference acc. to EN 61000-6-4: 2007

Pos: 65 /Alle Seri en (Allge meine Modul e)/Norme n und Richtl inien/EM V Schiffb au-Störfest igkeit Ger manischer Lloyd (2 003) @ 4\mod_1242798409640_21.docx @ 33610 @ @ 1

EMC marine applications-Immunity

to interference acc. to Germanischer Lloyd (2003)

Pos: 66 /All e Serien ( Allgemei ne Module)/N ormen un d Richtli nien/EMV Sc hiffbau- Störaussen d ung Germanisc h er Lloyd (20 03) @ 4\ mod_1242798400546_21.docx @ 33606 @ @ 1

EMC marine applications-Emission

of interference acc. to Germanischer Lloyd (2003)

Pos: 67 /Dokum e nt ation allge mein/Glie derungsele mente/---Seit enwechsel--- @ 3\ mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 26

26 Process Image WAGO-I/O-SYSTEM 750

Table 12: Input bits

Bit 3

Bit 2

Bit 1

Bit 0

DI 4

DI 3

DI 2

DI 1

DI 1

Signal state DI 1 – Digital input channel 1

DI 2

Signal state DI 2 – Digital input channel 2

DI 3

Signal state DI 3 – Digital input channel 3

DI 4

Signal state DI 4 – Digital input channel 4

750-402 4DI 24V DC 3.0ms

Pos: 68 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Prozess abbild - Über s c hrift 1 @ 4\mod_1240983067828_21.docx @ 31942 @ 11 @ 1

4 Process Image

Pos: 69 /Ser ie 750 ( WAGO-I/O-SYST EM)/Proz essabbild K lemmenbus /Digitalei ngangs klemmen/Pr ozessabbil d 750-x4xx 04 D I @ 4\mod_1236259579218_21.docx @ 28028 @ @ 1

Pos: 70 /D okumentatio n allgemei n/Glieder ungselem ente/---Seite nwechsel--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 27

WAGO-I/O-SYSTEM 750 Mounting 27

750-402 4DI 24V DC 3.0ms

Pos: 71 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Montiere n - Demonti eren/Monti eren - Übers c hrift 1 @ 3\mod_1225446744750_21.docx @ 24900 @ 11 @ 1

5 Mounting

Pos: 72.1 /Serie 750 (WAGO-I/O-S YSTEM)/M ontieren/D emontiere n/ M ontagerei henfolge @ 3\ mod_1231770210031_21.docx @ 25992 @ 2 @ 1

5.1 Mounting Sequence

All system components can be snapped directly on a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual components are securely

seated on the rail after installation.

Starting with the coupler/controller, the I/O modules are mounted adjacent to each

other according to the project design. Errors in the design of the node in terms of

the potential groups (connection via the power contacts) are recognized, as the I/O

modules with power contacts (male contacts) cannot be linked to I/O modules

with fewer power contacts.

Pos: 72.2 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Sich er h eits- und s onstige Hi nweise/Vor sicht/V orsicht: Ver letzungsg efahr durc h scharf kantige Mes serkonta kte! @ 6\mod_1256193279401_21.docx @ 43414 @ @ 1

Risk of injury due to sharp-edged male contacts!

The male contacts are sharp-edged. Handle the module carefully to prevent injury.

Pos: 72.3 /Serie 750 (WAGO-I/O-S YSTEM)/Wic htige Erläuter ungen/Si cherheits- und sonstige Hinweise/Achtung/Achtung: Busklemmen nu r i n vorgesehener Reihenfolge stecken! @ 6\mod_1256194177073_21.docx @ 43429 @ @ 1

Insert I/O modules only from the proper directions!

All I/O modules feature grooves for power jumper contacts on the right side. For

some I/O modules, the grooves are closed on the top. Therefore, I/O modules

featuring a power jumper contact on the left side cannot be snapped from the top.

This mechanical coding helps to avoid configuration errors, which may destroy

the components. Therefore, insert I/O modules only from the right and from the

top.

Pos: 72.4 /Serie 750 (WAGO-I/O-S YSTEM)/ Wic htige Erlä ut er u ngen/Sich er h eits- und s onstige Hi nweise/Hi nweis/Hin weis: Busa bschluss nicht verg essen! @ 6 \mod_1256194225557_21.docx @ 43432 @ @ 1

Don't forget the bus end module!

Always plug a bus end module 750-600 onto the end of the fieldbus node! You

must always use a bus end module at all fieldbus nodes with the WAGO I/O

System 750 fieldbus couplers/controllers to guarantee proper data transfer.

Pos: 72.5 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechs el--- @ 3\mod_1221108045078_0 .docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 28

28 Mounting WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 72.6 /Serie 750 (WAGO-I/O-S YSTEM)/M ontieren/D emontiere n/Geräte einfügen u nd entfer nen - Übersc hrift 2 @ 3\mod_1231768483250_21.docx @ 25950 @ 22 @ 1

5.2 Ins erting and Removing Devices

Pos: 72.7 /Al le Seri en (Allgemei ne Modul e)/Wichtig e Erläuter ungen/Sic herheits- u nd sonsti ge Hinweis e/Achtung /Achtung: Arbeiten a n Geräten nur span nungsfrei d urchführ en! @ 6\mod_1256193963573_21.docx @ 43426 @ @ 1

Perform work on devices only if the system is de-energized!

Working on devices when the system is energized can damage the devices.

Therefore, turn off the power supply before working on the devices.

Pos: 72.8 /Serie 750 (WAGO-I/O-S YSTEM)/M ontieren/D emontiere n/ Busklem m e ein fügen @ 3\mod_1231769726703_21.docx @ 25989 @ 3 @ 1

5.2.1 Inserting I/O Module

1. Position the I/O module so that the tongue and groove joints to the fieldbus

coupler/controller or to the previous or possibly subsequent I/O module are

engaged.

Figure 7: Insert I/O module (sample)

2. Press the I/O module into the assembly until the I/O module snaps into the

carrier rail.

Figure 8: Snap the I/O mo dule into place (sample)

With the I/O module snapped in place, the electrical connections for the data

contacts and power contacts (if any) to the fieldbus coupler/controller or to the

previous or possibly subsequent I/O module are established.

Pos: 72.9 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechs el--- @ 3\mod_1221108045078_0 .docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 29

WAGO-I/O-SYSTEM 750 Mounting 29

750-402 4DI 24V DC 3.0ms

Pos: 72.10 / Serie 750 ( WAGO-I/O-S Y ST EM)/Monti eren/De mo nti eren/Bus kl emme entfer nen @ 4\mod_1239169375203_21.docx @ 30334 @ 3 @ 1

5.2.2 Removing the I/O Module

1. Remove the I/O module from the assembly by pulling the release tab.

Figure 9: Removing the I/O module (sample)

Electrical connections for data or power contacts are disconnected when removing

the I/O module.

Pos: 73 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 30

30 Connect Devices WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 74 /Alle Seri en (Allge meine Modul e)/Übersc hriften für alle Ser ien/Anschl ießen/Ger äte anschl ießen - Über schrift 1 @ 3\mod_1234172889468_21.doc x @ 27460 @ 11 @ 1

6 Connect Devices

Pos: 75 /Ser ie 750 ( WAGO-I/O-SYST EM)/Anschl ießen/L eiter an C AGE CLAMP anschließ en - Überschr ift 2 und Text @ 3\mod_1225448660171_21.docx @ 24928 @ 2 @ 1

6.1 Con ne cti ng a Conductor to the CAGE CLAMP®

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded and

finely stranded conductors.

Only connect one conductor to each CAGE CLAMP® connection!

Only one conductor may be connected to each CAGE CLAMP® connection.

Do not connect more than one conductor at one single connection!

If more than one conductor must be routed to one connection, these must be

connected in an up-circuit wiring assembly, for example using WAGO feedthrough terminals.

Exception:

If it is unavoidable to jointly connect 2 conductors, then you must use a ferrule to

join the wires together. The following ferrules can be used:

Length 8 mm

Nominal cross section

WAGO Product 216-103 or products with comparable properties.

1. To open the CAGE CLAMP® insert the actuating tool into the opening

above the connection.

1 mm2 for 2 conductors with 0.5 mm2 each

max.

2. Insert the conductor into the corresponding connection opening.

3. To close the CAGE CLAMP® simply remove the tool - the conductor is

then clamped firmly in place.

Figure 10: Connecting a conductor to a CAGE CLAMP

Pos: 76 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

®

Manual

Version 1.1.0

Page 31

WAGO-I/O-SYSTEM 750 Connect Devices 31

750-402 4DI 24V DC 3.0ms

Pos: 77 /All e Serien ( Allgemei ne Module)/Ü berschri ften für al le Serie n/Anschließ en/Anschl ussbeispi ele - Übers chrift 2 @ 4\mod_1240996036328_21.docx @ 32010 @ 22 @ 1

6.2 Connection Examples

Pos: 78 /Ser ie 750 ( WAGO-I/O-SYST EM)/Anschl ießen/An schlussb eispiele/Dig italeing angsklem men/Anschl ussbeispi ele 750-04xx_4DI_2L_3L @ 11\mod_132255478 9647_21.docx @ 84038 @ 33 @ 1

6.2.1 2-Conductor Connection

Figure 11: Conne cting diagrams – 2-conductor connection

6.2.2 3-Conductor Connection

Figure 12: Conne cting diagrams – 3-conductor connection

Pos: 79 /Dokum e nt ation allge mei n/Glieder ungselem e nte/---Seiten wechsel--- @ 3\mod_1221108045078_0.docx @ 218 10 @ @ 1

Manual

Version 1.1.0

Page 32

32 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 80.1 /Al le Seri en (Allgemei ne Modul e)/Einsatz in Ex-Ber eichen/Eins atz in ex plosionsgef ährdeten Bereich en - Überschr i f t 1 @ 3\ mod_1224075191281_21.docx @ 24084 @ 1 @ 1

7 Use in Hazardou s E nvironments

Pos: 80.2 /Serie 750 (WAGO-I/O-S YSTEM)/Eins atz in Ex-Ber eichen/Ei nsatzber eich Serie 750 @ 3\mod_1234272230203_21.docx @ 27500 @ @ 1

The WAGO-I/O-SYSTEM 750 (electrical equipment) is designed for use in

Zone 2 hazardous areas.

The following sections include both the general identification of components

(devices) and the installation regulations to be observed. The individual

subsections of the "Installation Regulations" section must be taken into account if

the I/O module has the required approval or is subject to the range of application

of the ATEX directive.

Pos: 80.3 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechsel--- @ 3\mod_122110804507 8_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 33

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 33

750-402 4DI 24V DC 3.0ms

Pos: 80.4 /Serie 750 (WAGO-I/O-S YSTEM)/Eins atz in Ex-Ber eichen/B eispielha fter Aufba u der Kennz eichnung - Überschr i ft 2 @ 3\ mod_1224157499140_21.docx @ 24182 @ 22 @ 1

7.1 Marking Configuration Examples

Pos: 80.5 /Serie 750 (WAGO-I/O-SYSTEM)/Einsatz in Ex-Berei chen/Kennz eichnung für Europ a gemäß AT EX und IEC- EX - Übersc hrift 3 @ 3\mod_1224157620203_21.docx @ 24185 @ 3 @ 1

7.1.1 Marking for Europe according to ATEX and IEC-Ex

Pos: 80.6 /Serie 750 ( WAGO-I/O-SYST EM)/Einsatz in Ex-Ber eic h en /Beispiel bedrucku ng der AT E X- und IEC-Ex-zugel assenen B usklemmen gemäß CE NELEC un d IEC_2013 @ 14\mod_1360569228625_21.doc x @ 111294 @ @ 1

Figure 13: Side marking example for approved I/O modules according to ATEX and IECEx

Figure 14: Printing Text d e ta il – Marking example for approved I/O modules according to ATEX

and IECEx.

Manual

Version 1.1.0

Page 34

34 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

Table 13: Description of marking example for approved I/O modules according to ATEX and

IECEx

Printing on Text

Description

TÜV 07 ATEX 554086 X

IECEx TUN 09.0001 X

Approving authority and certificate numbers

Dust

II

Equipment group: All except mining

3D

Category 3 (Zone 22)

Ex

Explosion protection mark

tc Dc

Type of protection and equipment protection

level (EPL):protection by enclosure

IIIC

Explosion group of dust

T 135°C

Max. surface temperature of the enclosure

(without a dust layer)

Mining

I

Equipment group: Mining

M2

Category: High level of protection

Ex

Explosion protection mark

d Mb

Type of protection and equipment protection

level (EPL): Flameproof enclosure

I

Explosion group for electrical equipment for

mines susceptible to firedamp

Gases

II

Equipment group: All except mining

3G

Category 3 (Zone 2)

Ex

Explosion protection mark

nA Gc

Type of protection and equipment protection

level (EPL): Non-sparking equipment

nC Gc

Type of protection and equipment protection

interior

IIC

Explosion group of gas and vapours

T4

Temperature class: Max. surface temperature

135°C

750-402 4DI 24V DC 3.0ms

Pos: 80.7 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechs el--- @ 3\mod_1221108045078_0 .docx @ 21810 @ @ 1

Manual

Version 1.1.0

level (EPL): Sparking apparatus with protected

contacts. A device which is so constructed that

the external atmosphere cannot gain access to the

Page 35

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 35

750-402 4DI 24V DC 3.0ms

Pos: 80.8 /Serie 750 (WAGO-I/O-S YSTEM)/Eins atz in Ex-Berei c h en /B eispielbe druckung der E x-i- und IEC-Ex-i-zugel assenen B usklemme n gemäß CEN ELEC und I EC_2013 @ 14\mod_1360569320118_21.d ocx @ 111298 @ @ 1

Figure 15: Side marking example for approved Ex i I/O modules according to ATEX and IECEx.

Figure 16: Text de ta il – Marking example for approved Ex i I/O modules according to ATEX and

IECEx.

Manual

Version 1.1.0

Page 36

36 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

Table 14: Description of marking example for approved Ex i I/O modules according to ATEX and

IECEx

Inscription text

Description

TÜV 07 ATEX 554086 X

IECEx TUN 12.0039 X

Approving authority and certificate numbers

Dust

II

Equipment group: All except mining

3(1)D

Category 3 (Zone 22) equipment containing a safety

device for a category 1 (Zone 20) equipment

3(2)D

Category 3 (Zone 22) equipment containing a safety

device for a category 2 (Zone 21) equipment

Ex

Explosion protection mark

tc Dc

Type of protection and equipment protection level

(EPL): protection by enclosure

[ia Da]

Type of protection and equipment protection level

circuits for use in Zone 20

[ib Db]

Type of protection and equipment protection level

circuits for use in Zone 21

IIIC

Explosion group of dust

T 135°C

Max. surface temperature of the enclosure (without a

dust layer)

Mining

I

Equipment Group: Mining

M2 (M1)

Category: High level of protection with electrical

circuits which present a very high level of protection

Ex d Mb

Explosion protection mark with Type of protection

enclosure

[ia Ma]

Type of protection and equipment protection level

electrical circuits

I Explosion group for electrical equipment for mines

susceptible to firedamp

750-402 4DI 24V DC 3.0ms

IECEx TUN 09.0001X

TÜV 12 ATEX 106032 X

(EPL): associated apparatus with intrinsic safety

(EPL): associated apparatus with intrinsic safety

and equipment protection level (EPL): Flameproof

(EPL): associated apparatus with intrinsic safety

Manual

Version 1.1.0

Page 37

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 37

Table 14: Description of marking example for approved Ex i I/O modules according to ATEX and

IECEx

Gases

II

Equipment group: All except mining

3(1)G

Category 3 (Zone 2) equipment containing a safety

device for a category 1 (Zone 0) equipment

3(2)G

Category 3 (Zone 2) equipment containing a safety

device for a category 2 (Zone 1) equipment

Ex

Explosion protection mark

nA Gc

Type of protection and equipment protection level

(EPL): Non-sparking equipment

[ia Ga]

Type of protection and equipment protection level

circuits for use in Zone 0

[ia Gb]

Type of protection and equipment protection level

circuits for use in Zone 1

IIC

Explosion group of gas and vapours

T4

Temperature class: Max. surface temperature 135°C

750-402 4DI 24V DC 3.0ms

(EPL): associated apparatus with intrinsic safety

(EPL): associated apparatus with intrinsic safety

Pos: 80.9 /Dokumentation allgemein/Glieder ungselemente/---Seitenwechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 38

38 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

Table 15: Description of marking example for approved I/O modules according to NEC 500

Printing on Text

Description

CL I

Explosion protection group (condition of use

category)

DIV 2

Area of application

Grp. ABCD

Explosion group (gas group)

Op temp code T4

Temperature class

750-402 4DI 24V DC 3.0ms

Pos: 80.10 / Serie 750 ( WAGO-I/O-SY STEM)/Eins atz in Ex-B er eic hen/Ken nz eichnung für A mer i ka gemäß NEC 5 00 - Üb er s c hrift 3 @ 3\mod_1224158423187_21.docx @ 24188 @ 3 @ 1

7.1.2 Marking for America according to NEC 500

Pos: 80.11 / Serie 750 ( WAGO-I/O-SY STEM)/Eins atz in Ex-B ereichen/B eispielbe druckung g emäß NEC 5 00_2013 @ 14\mod_1360580302684_21. doc x @ 111353 @ @ 1

Figure 17: Side marking example for I/O modules according to NEC 500

Figure 18: Text de ta il – Marking example for approved I/O modules according to NEC 500

Pos: 80.12 /D okument ation allge mein/Gli ederungsel emente/---Sei tenwechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 39

WAGO-I/O-SYSTEM 750 Use in Hazardous Environments 39

750-402 4DI 24V DC 3.0ms

Pos: 80.13 /All e Serien (A llgemein e Module)/ Einsatz i n Ex-Bereichen/Errichtun gsbestimmungen @ 3\mod_1232453624234_21.docx @ 26370 @ 2 @ 1

7.2 Installation Regulations

Pos: 80.14 / Alle Seri en (Allgem eine Modul e)/Einsatz in Ex-Bereichen/Errichtungsbest i m m ungen Einleitung_2013 @ 14\mod_1360582328318_21.docx @ 111371 @ @ 1

For the installation and operation of electrical equipment in hazardous areas, the

valid national and international rules and regulations which are applicable at the

installation location must be carefully followed.

Pos: 80.15 /D okument ation allge mein/Gli ederungsel emente/---Sei tenwechs el--- @ 3\mod_1221108045078_0.docx @ 21810 @ @ 1

Manual

Version 1.1.0

Page 40

40 Use in Hazardous Environments WAGO-I/O-SYSTEM 750

750-402 4DI 24V DC 3.0ms

Pos: 80.16 / Serie 750 ( WAGO-I/O-SY STEM)/Eins atz in Ex-B ereichen/B esondere Bedingung en für den sicheren E x-Betrieb g em. ATEX-Zertifikat TÜV 07 ATEX 554086_X_2013_2 @ 15\mod_1368620071975_21.docx @ 119778 @ 3 @ 1

7.2.1 Special conditions for safe use (ATEX Certificate TÜV 07 ATEX 554086 X)

1. For use as Gc- or Dc-apparatus (in zone 2 or 22) the Field bus Independent

I/O Modules WAGO-I/O-SYSTEM 750-*** shall be erected in an

enclosure that fulfils the requirements of the applicable standards (see the

marking) EN 60079-0, EN 60079-11, EN 60079-15 and EN 60079-31.

For use as group I electrical apparatus M2 the apparatus shall be erected in

an enclosure that ensures a sufficient protection according to EN 60079-0

and EN 60079-1 and the degree of protection IP64.

The compliance of these requirements and the correct installation into an

enclosure or a control cabinet of the devices shall be certified by an ExNB.

2. Measures have to be taken outside of the device that the rating voltage is not

being exceeded of more than 40 % because of transient disturbances.

3. Dip-switches, binary-switches and potentiometers, connected to the module

may only be actuated when explosive atmosphere can be excluded.

4. The connecting and disconnecting of the non-intrinsically safe circuits is

only permitted during installation, for maintenance or for repair purposes.

The temporal coincidence of explosion hazardous atmosphere and

installation, maintenance resp. repair purposes shall be excluded.

This is although and in particular valid for the interfaces “Memory-Card”,

“USB”, “Fieldbus connection”, “Configuration and programming interface”,

“antenna socket”, “D-Sub”, “DVI-port” and the “Ethernet interface”. These

interfaces are not energy limited or intrinsically safe circuits. An operating

of those circuits is in the behalf of the operator.

5. For the types 750-606, 750-625/000-001, 750-487/003-000, 750-484 and