Page 1

Modular I/O-System

ETHERNET TCP/IP

750-342

Manual

Technical description,

installation and

configuration

Version 2.1.1

Page 2

ii • General

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Copyright © 2007 by WAGO Kontakttechnik GmbH & Co. KG

All rights reserved.

WAGO Kontakttechnik GmbH & Co. KG

Hansastraße 27

D-32423 Minden

Phone: +49 (0) 571/8 87 – 0

Fax: +49 (0) 571/8 87 – 1 69

E-Mail: info@wago.com

Web: http://www.wago.com

Technical Support

Phone: +49 (0) 571/8 87 – 5 55

Fax: +49 (0) 571/8 87 – 85 55

E-Mail: support@wago.com

Every conceivable measure has been taken to ensure the correctness and

completeness of this documentation. However, as errors can never be fully

excluded we would appreciate any information or ideas at any time.

E-Mail: documentation@wago.com

We wish to point out that the software and hardware terms as well as the

trademarks of companies used and/or mentioned in the present manual are

generally trademark or patent protected.

This product includes software developed by the University of California,

Berkley and ist contributors.

Page 3

Table of Contents • iii

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

TABLE OF CONTENTS

1 Important Notes ..........................................................................................1

1.1 Legal Principles........................................................................................1

1.1.1 Copyright.............................................................................................1

1.1.2 Personnel Qualification .......................................................................1

1.1.3 Conforming Use of Series 750 ............................................................2

1.1.4 Technical Condition of the Devices ....................................................2

1.2 Standards and Regulations for Operating the 750 Series.........................2

1.3 Symbols....................................................................................................3

1.4 Safety Information....................................................................................4

1.5 Font Conventions .....................................................................................5

1.6 Number Notation......................................................................................5

1.7 Scope........................................................................................................1

1.8 Important Comments for Starting up........................................................5

1.9 Abbreviation.............................................................................................6

2 The WAGO-I/O-SYSTEM 750..................................................................7

2.1 System Description...................................................................................7

2.2 Technical Data..........................................................................................8

2.3 Manufacturing Number..........................................................................14

2.4 Component Update.................................................................................15

2.5 Storage, Assembly and Transport ..........................................................15

2.6 Mechanical Setup...................................................................................16

2.6.1 Installation Position...........................................................................16

2.6.2 Total Expansion.................................................................................16

2.6.3 Assembly onto Carrier Rail...............................................................17

2.6.3.1 Carrier rail properties....................................................................17

2.6.3.2 WAGO DIN Rail ..........................................................................18

2.6.4 Spacing ..............................................................................................18

2.6.5 Plugging and Removal of the Components.......................................19

2.6.6 Assembly Sequence...........................................................................20

2.6.7 Internal Bus/Data Contacts................................................................21

2.6.8 Power Contacts..................................................................................22

2.6.9 Wire connection.................................................................................23

2.7 Power Supply .........................................................................................24

2.7.1 Isolation.............................................................................................24

2.7.2 System Supply...................................................................................25

2.7.2.1 Connection....................................................................................25

2.7.2.2 Alignment .....................................................................................26

2.7.3 Field Supply.......................................................................................28

2.7.3.1 Connection....................................................................................28

2.7.3.2 Fusing............................................................................................29

2.7.4 Supplementary power supply regulations..........................................32

2.7.5 Supply example .................................................................................33

2.7.6 Power Supply Unit.............................................................................34

2.8 Grounding...............................................................................................35

2.8.1 Grounding the DIN Rail ....................................................................35

2.8.1.1 Framework Assembly...................................................................35

Page 4

iv • Table of Contents

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.8.1.2 Insulated Assembly.......................................................................35

2.8.2 Grounding Function...........................................................................36

2.8.3 Grounding Protection ........................................................................37

2.9 Shielding (Screening).............................................................................38

2.9.1 General...............................................................................................38

2.9.2 Bus Conductors..................................................................................38

2.9.3 Signal Conductors..............................................................................38

2.9.4 WAGO Shield (Screen) Connecting System.....................................39

2.10 Assembly Guidelines/Standards.............................................................39

3 Fieldbus Coupler.......................................................................................40

3.1 Fieldbus coupler 750-342.......................................................................40

3.1.1 Description.........................................................................................40

3.1.2 Hardware............................................................................................41

3.1.2.1 View..............................................................................................41

3.1.2.2 Device supply................................................................................42

3.1.2.3 Fieldbus connection......................................................................42

3.1.2.4 Display elements...........................................................................43

3.1.2.5 Configuration interface.................................................................43

3.1.2.6 Hardware address (MAC-ID) .......................................................44

3.1.3 Operating system...............................................................................44

3.1.4 Process image ....................................................................................45

3.1.4.1 Example of a process input image ................................................46

3.1.4.2 Example of a process output image ..............................................47

3.1.4.3 Process Data Architecture.............................................................48

3.1.5 Data Exchange...................................................................................48

3.1.5.1 Memory areas................................................................................49

3.1.5.2 Addressing ....................................................................................50

3.1.5.2.1 Addressing the I/O modules..........................................................50

3.1.5.3 Data exchange between MODBUS/TCP master and I/O modules51

3.1.6 Starting up a Fieldbus Node ..............................................................52

3.1.6.1 Note the MAC-ID and establish the fieldbus node.......................52

3.1.6.2 Connecting PC and fieldbus node.................................................52

3.1.6.3 Determining IP addresses .............................................................53

3.1.6.4 Allocating the IP address to the fieldbus node .............................53

3.1.6.5 Testing the function of the fieldbus node .....................................56

3.1.6.6 Reading out the information as HTML pages...............................57

3.1.7 LED Display......................................................................................58

3.1.7.1 Fieldbus status...............................................................................58

3.1.7.2 Node status – Blink code from the 'I/O' LED ...............................59

3.1.7.3 Supply voltage status ....................................................................66

3.1.8 Fault behavior....................................................................................66

3.1.8.1 Fieldbus failure .............................................................................66

3.1.8.2 Internal bus fault ...........................................................................66

3.1.9 Technical Data...................................................................................67

4 Fieldbus Communication..........................................................................69

4.1 ETHERNET ...........................................................................................69

4.1.1 General...............................................................................................69

Page 5

Table of Contents • v

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

4.1.2 Network Architecture – Principles and Regulations .........................70

4.1.2.1 Transmission Media......................................................................71

4.1.2.2 Network Topologies......................................................................73

4.1.2.3 Coupler Modules...........................................................................76

4.1.2.4 Important Terms............................................................................77

4.1.3 Network Communication...................................................................79

4.1.3.1 Protocol layer model.....................................................................79

4.1.3.2 Communication Protocols.............................................................81

4.1.3.2.1 ETHERNET..................................................................................82

4.1.3.3 Channel access method.................................................................82

4.1.3.3.1 IP-Protocol....................................................................................83

4.1.3.3.1.1 RAW IP.................................................................................... 87

4.1.3.3.1.2 IP Multicast..............................................................................87

4.1.3.3.2 TCP Protocol.................................................................................87

4.1.3.3.3 UDP...............................................................................................88

4.1.3.3.4 ARP...............................................................................................88

4.1.3.4 Administration and Diagnosis Protocols ......................................89

4.1.3.4.1 BootP (Bootstrap Protocol)...........................................................89

4.1.3.4.2 HTTP (HyperText Transfer Protocol)..........................................90

4.1.3.4.3 DHCP (Dynamic Host Configuration Protocol)...........................91

4.1.3.4.4 DNS (Domain Name Systems) .....................................................92

4.1.3.4.5 SNTP-Client (Simple Network Time Protocol)............................92

4.1.3.4.6 FTP-Server (File Transfer Protocol).............................................92

4.1.3.4.7 SMTP (Simple Mail Transfer Protocol) .......................................94

4.1.3.5 Application Protocols ...................................................................94

4.2 MODBUS Functions..............................................................................95

4.2.1 General...............................................................................................95

4.2.2 Use of the MODBUS Functions........................................................97

4.2.3 Description of the MODBUS Functions ...........................................98

4.2.3.1 Function Code FC1 (Read Coils)..................................................99

4.2.3.2 Function Code FC2 (Read Input Discretes)................................100

4.2.3.3 Function Code FC3 (Read multiple registers) ............................101

4.2.3.4 Function code FC4 (Read input registers) ..................................102

4.2.3.5 Function Code FC5 (Write Coil) ...............................................103

4.2.3.6 Function Code FC6 (Write single register)................................104

4.2.3.7 Function code FC7 (Read Exception Status)..............................105

4.2.3.8 Function Code FC11 (Get comm event counter)........................106

4.2.3.9 Function Code FC15 (Force Multiple Coils).............................107

4.2.3.10 Function Code FC16 (Write multiple registers) ........................108

4.2.3.11 Function Code FC23 (Read/Write multiple registers)................108

4.2.4 MODBUS Register Mapping ..........................................................110

4.2.5 Internal Variables ............................................................................111

4.2.5.1 Description of the internal variables...........................................113

4.2.5.1.1 Watchdog (Fieldbus failure) .......................................................113

4.2.5.1.2 Watchdog Register:.....................................................................113

4.2.5.2 Diagnostic Functions ..................................................................118

4.2.5.3 Configuration Functions .............................................................118

4.2.5.4 Firmware Information.................................................................120

4.2.5.5 Constant Registers .....................................................................122

Page 6

vi • Table of Contents

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

5 I/O Modules .............................................................................................124

5.1 Overview ..............................................................................................124

5.1.1 Digital Input Modules......................................................................124

5.1.2 Digital Output Modules...................................................................126

5.1.3 Analog Intput Modules....................................................................127

5.1.4 Analog Output Modules ..................................................................128

5.1.5 Special Modules ..............................................................................129

5.1.6 System Modules...............................................................................130

5.2 Process Data Architecture for MODBUS/TCP....................................131

5.2.1 Digital Input Modules......................................................................131

5.2.2 Digital Output Modules...................................................................133

5.2.3 Analog Input Modules.....................................................................137

5.2.4 Analog Output Modules ..................................................................138

5.2.5 Specialty Modules ...........................................................................139

5.2.6 System Modules...............................................................................151

6 Application Examples.............................................................................152

6.1 Test of MODBUS protocol and fieldbus nodes ...................................152

6.2 Visualization and control using SCADA software...............................152

7 Use in Hazardous Environments ...........................................................155

7.1 Foreword ..............................................................................................155

7.2 Protective measures..............................................................................155

7.3 Classification meeting CENELEC and IEC.........................................155

7.3.1 Divisions..........................................................................................155

7.3.2 Explosion protection group .............................................................156

7.3.3 Unit categories.................................................................................157

7.3.4 Temperature classes.........................................................................157

7.3.5 Types of ignition protection ............................................................158

7.4 Classifications meeting the NEC 500...................................................159

7.4.1 Divisions..........................................................................................159

7.4.2 Explosion protection groups............................................................159

7.4.3 Temperature classes.........................................................................160

7.5 Identification ........................................................................................161

7.5.1 For Europe.......................................................................................161

7.5.2 For America.....................................................................................162

7.6 Installation regulations.........................................................................163

8 Glossary....................................................................................................165

9 Literature List .........................................................................................177

10 Index.........................................................................................................178

Page 7

Important Notes • 1

Legal Principles

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

1 Important Notes

This section provides only a summary of the most important safety

requirements and notes which will be mentioned in the individual sections. To

protect your health and prevent damage to the devices, it is essential to read

and carefully follow the safety guidelines.

1.1 Legal Principles

1.1.1 Copyright

This manual including all figures and illustrations contained therein is subject

to copyright. Any use of this manual which infringes the copyright provisions

stipulated herein, is not permitted. Reproduction, translation and electronic

and phototechnical archiving and amendments require the written consent of

WAGO Kontakttechnik GmbH & Co. KG, Minden. Non-observance will

entail the right of claims for damages.

WAGO Kontakttechnik GmbH & Co. KG reserves the right of changes

serving technical progress.

All rights developing from the issue of a patent or the legal protection of

utility patents are reserved to WAGO Kontakttechnik GmbH & Co. KG.

Third-party products are always indicated without any notes concerning patent

rights. Thus, the existence of such rights must not be excluded.

1.1.2 Personnel Qualification

The use of the product described in this manual requires special qualifications,

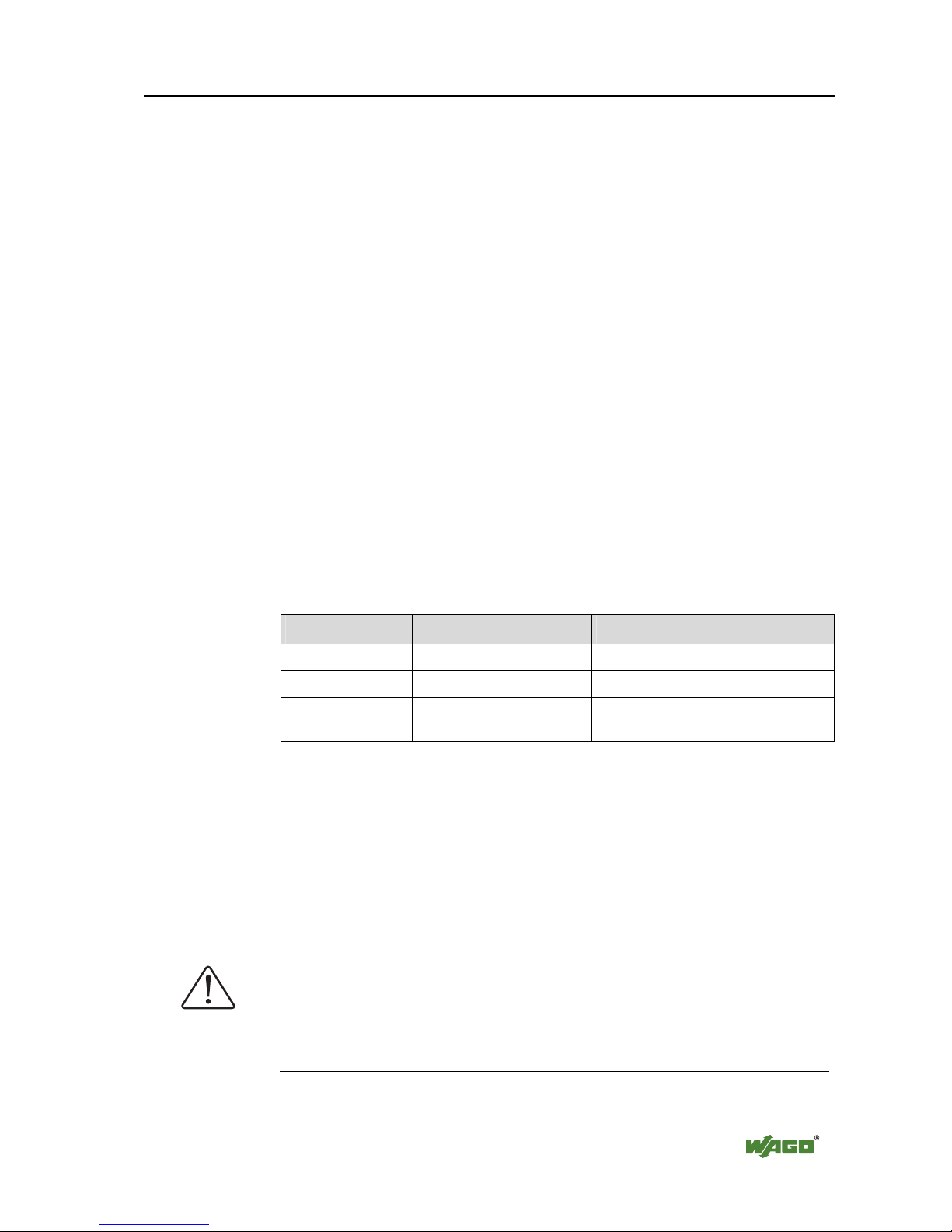

as shown in the following table:

Activity Electrical specialist

Instructed

personnel*)

Specialists**) having

qualifications in PLC

programming

Assembly

X X

Commissioning

X X

Programming

X

Maintenance

X X

Troubleshooting

X

Disassembly

X X

*) Instructed persons have been trained by qualified personnel or electrical specialists.

**) A specialist is someone who, through technical training, knowledge and experience,

demonstrates the ability to meet the relevant specifications and identify potential dangers in

the mentioned field of activity.

All personnel must be familiar with the applicable standards.

WAGO Kontakttechnik GmbH & Co. KG declines any liability resulting from

Page 8

2 • Important Notes

Standards and Regulations for Operating the 750 Series

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

improper action and damage to WAGO products and third party products due to

non-observance of the information contained in this manual.

1.1.3 Conforming Use of Series 750

The couplers and controllers of the modular I/O System 750 receive digital

and analog signals from the I/O modules and sensors and transmit them to the

actuators or higher level control systems. Using the WAGO controllers, the

signals can also be (pre-)processed.

The device is designed for IP20 protection class. It is protected against finger

touch and solid impurities up to 12.5mm diameter, but not against water

penetration. Unless otherwise specified, the device must not be operated in

wet and dusty environments.

1.1.4 Technical Condition of the Devices

For each individual application, the components are supplied from the factory

with a dedicated hardware and software configuration. Changes in hardware,

software and firmware are only admitted within the framework of the

possibilities documented in the manuals. All changes to the hardware or

software and the non-conforming use of the components entail the exclusion

of liability on the part of WAGO Kontakttechnik GmbH & Co. KG.

Please direct any requirements pertaining to a modified and/or new hardware

or software configuration directly to WAGO Kontakttechnik GmbH & Co.

KG.

1.2 Standards and Regulations for Operating the 750 Series

Please observe the standards and regulations that are relevant to your

installation:

• The data and power lines must be connected and installed in compliance

with the standards to avoid failures on your installation and eliminate any

danger to personnel.

• For installation, startup, maintenance and repair, please observe the

accident prevention regulations of your machine (e.g. BGV A 3,

"Electrical Installations and Equipment").

• Emergency stop functions and equipment must not be made ineffective.

See relevant standards (e.g. DIN EN 418).

• Your installation must be equipped in accordance to the EMC guidelines

so that electromagnetic interferences can be eliminated.

• Operating 750 Series components in home applications without further

measures is only permitted if they meet the emission limits (emissions of

interference) according to EN 61000-6-3. You will find the relevant

information in the section on "WAGO-I/O-SYSTEM 750" Æ "System

Description" Æ "Technical Data".

Page 9

Important Notes • 3

Symbols

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

• Please observe the safety measures against electrostatic discharge

according to DIN EN 61340-5-1/-3. When handling the modules, ensure

that the environment (persons, workplace and packing) is well grounded.

• The relevant valid and applicable standards and guidelines concerning the

installation of switch cabinets are to be observed.

1.3 Symbols

Danger

Always observe this information to protect persons from injury.

Warning

Always observe this information to prevent damage to the device.

Attention

Marginal conditions that must always be observed to ensure smooth and

efficient operation.

ESD (Electrostatic Discharge)

Warning of damage to the components through electrostatic discharge.

Observe the precautionary measure for handling components at risk of

electrostatic discharge.

Note

Make important notes that are to be complied with so that a trouble-free and

efficient device operation can be guaranteed.

Additional Information

References to additional literature, manuals, data sheets and INTERNET

pages.

Page 10

4 • Important Notes

Safety Information

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

1.4 Safety Information

When connecting the device to your installation and during operation, the

following safety notes must be observed:

Danger

The WAGO-I/O-SYSTEM 750 and its components are an open system. It

must only be assembled in housings, cabinets or in electrical operation

rooms. Access is only permitted via a key or tool to authorized qualified

personnel.

Danger

All power sources to the device must always be switched off before carrying

out any installation, repair or maintenance work.

Warning

Replace defective or damaged device/module (e.g. in the event of deformed

contacts), as the functionality of fieldbus station in question can no longer be

ensured on a long-term basis.

Warning

The components are not resistant against materials having seeping and

insulating properties. Belonging to this group of materials is: e.g. aerosols,

silicones, triglycerides (found in some hand creams). If it cannot be ruled out

that these materials appear in the component environment, then the

components must be installed in an enclosure that is resistant against the

above mentioned materials. Clean tools and materials are generally required

to operate the device/module.

Warning

Soiled contacts must be cleaned using oil-free compressed air or with ethyl

alcohol and leather cloths.

Warning

Do not use contact sprays, which could possibly impair the functioning of the

contact area.

Warning

Avoid reverse polarity of data and power lines, as this may damage the

devices.

ESD (Electrostatic Discharge)

The devices are equipped with electronic components that may be destroyed

by electrostatic discharge when touched.

Page 11

Important Notes • 5

Font Conventions

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

1.5 Font Conventions

italic

Names of paths and files are marked in italic.

e.g.: C:\Programs\WAGO-IO-CHECK

italic

Menu items are marked in bold italic.

e.g.: Save

\

A backslash between two names characterizes the

selection of a menu point from a menu.

e.g.: File \ New

END

Press buttons are marked as bold with small capitals

e.g.:

ENTER

< >

Keys are marked bold within angle brackets

e.g.: <F5>

Courier

The print font for program codes is Courier.

e.g.: END_VAR

1.6 Number Notation

Number code Example Note

Decimal 100 Normal notation

Hexadecimal 0x64 C notation

Binary '100'

'0110.0100'

Within ',

Nibble separated with dots

1.7 Scope

This manual describes the fieldbus coupler for ETHERNET 10/100 MBit/s of

the WAGO-I/O-SYSTEM 750.

1.8 Important Comments for Starting up

Attention

For the start-up of the coupler 750-341 important notes are to be considered,

because it strongly differentiates in some points of starting up the WAGO

ETHERNET coupler 750-342.

Read for this the chapter: “Starting up EHTERNET TCP/IP fieldbus nodes“.

Page 12

6 • Important Notes

Abbreviation

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

1.9 Abbreviation

AI

Analog Input

AO

Analog Output

DI

Digital Input

DO

Digital Output

I/O

Input/Output

ID

Identifier

Page 13

System Description • 7

Technical Condition of the Devices

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

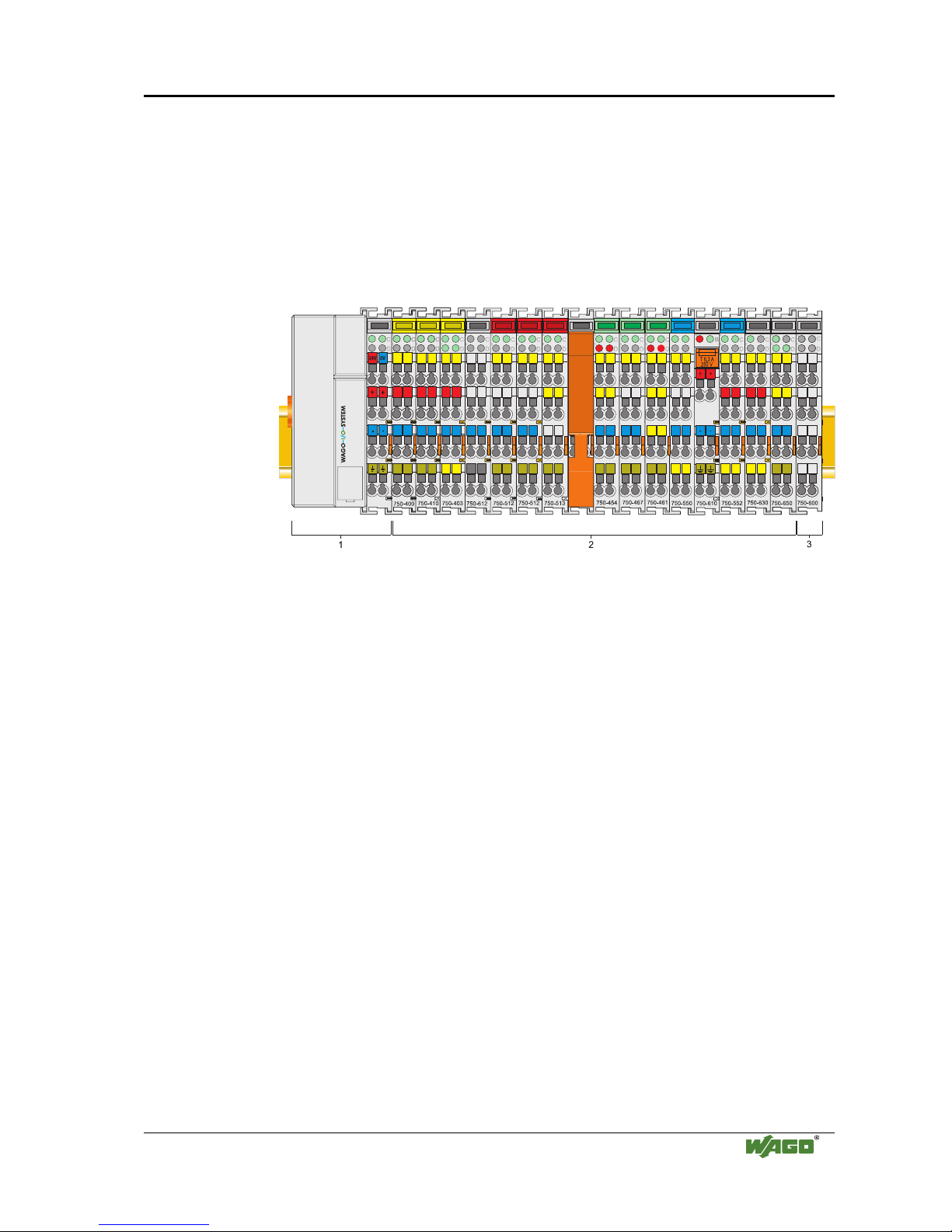

2 The WAGO-I/O-SYSTEM 750

2.1 System Description

The WAGO-I/O-SYSTEM 750 is a modular, fieldbus independent I/O system.

It is comprised of a fieldbus coupler/controller (1) and connected fieldbus

modules (2) for any type of signal. Together, these make up the fieldbus node.

The end module (3) completes the node.

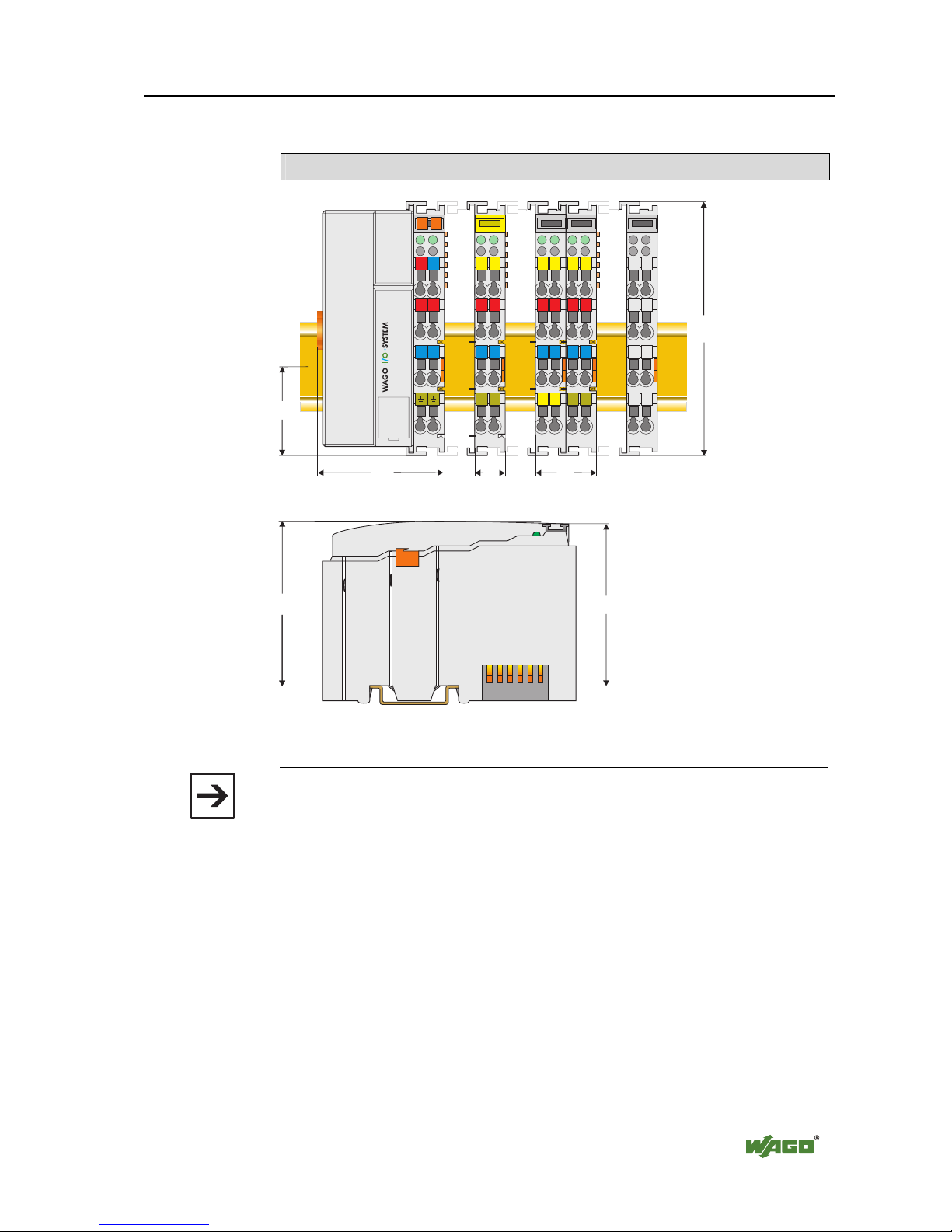

Fig. 2-1: Fieldbus node g0xxx00x

Couplers/controllers for fieldbus systems such as PROFIBUS, INTERBUS,

ETHERNET TCP/IP, CAN (CANopen, DeviceNet, CAL), MODBUS, LON

and others are available.

The coupler/controller contains the fieldbus interface, electronics and a power

supply terminal. The fieldbus interface forms the physical interface to the

relevant fieldbus. The electronics process the data of the bus modules and

make it available for the fieldbus communication. The 24 V system supply and

the 24 V field supply are fed in via the integrated power supply terminal.

The fieldbus coupler communicates via the relevant fieldbus. The

programmable fieldbus controller (PFC) enables the implementation of

additional PLC functions. Programming is done with the WAGO-I/O-PRO 32

in accordance with IEC 61131-3.

Bus modules for diverse digital and analog I/O functions as well as special

functions can be connected to the coupler/controller. The communication

between the coupler/controller and the bus modules is carried out via an

internal bus.

The WAGO-I/O-SYSTEM 750 has a clear port level with LEDs for status

indication, insertable mini WSB markers and pullout group marker carriers.

The 3-wire technology supplemented by a ground wire connection allows for

direct sensor/actuator wiring.

Page 14

8 • The WAGO-I/O-SYSTEM 750

Technical Data

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.2 Technical Data

Mechanic

Material Polycarbonate, Polyamide 6.6

Dimensions W x H* x L

* from upper edge of DIN 35 rail

- Coupler/Controller (Standard)

- Coupler/Controller (ECO)

- Coupler/Controller (FireWire)

- I/O module, single

- I/O module, double

- I/O module, fourfold

- 51 mm x 65 mm x 100 mm

- 50 mm x 65 mm x 100 mm

- 62 mm x 65 mm x 100 mm

- 12 mm x 64 mm x 100 mm

- 24 mm x 64 mm x 100 mm

- 48 mm x 64 mm x 100 mm

Installation on DIN 35 with interlock

modular by double featherkey-dovetail

Mounting position any position

Marking marking label type 247 and 248

paper marking label 8 x 47 mm

Connection

Connection type CAGE CLAMP®

Wire range 0.08 mm² ... 2.5 mm², AWG 28-14

Stripped length 8 – 9 mm,

9 – 10 mm for components with pluggable wiring

(753-xxx)

Contacts

Power jumpers contacts blade/spring contact

self-cleaning

Current via power contacts

max

10 A

Voltage drop at I

max

< 1 V/64 modules

Data contacts slide contact, hard gold plated

1.5 µm, self-cleaning

Climatic environmental conditions

Operating temperature 0 °C ... 55 °C,

-20 °C … +60 °C for components with extended

temperature range (750-xxx/025-xxx)

Storage temperature -20 °C ... +85 °C

Relative humidity 5 % to 95 % without condensation

Resistance to harmful substances acc. to IEC 60068-2-42 and IEC 60068-2-43

Maximum pollutant concentration at

relative humidity < 75%

SO

2

≤ 25 ppm

H

2

S ≤ 10 ppm

Special conditions Ensure that additional measures for components are

taken, which are used in an environment involving:

– dust, caustic vapors or gasses

– ionization radiation.

Page 15

Technical Data • 9

Technical Condition of the Devices

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

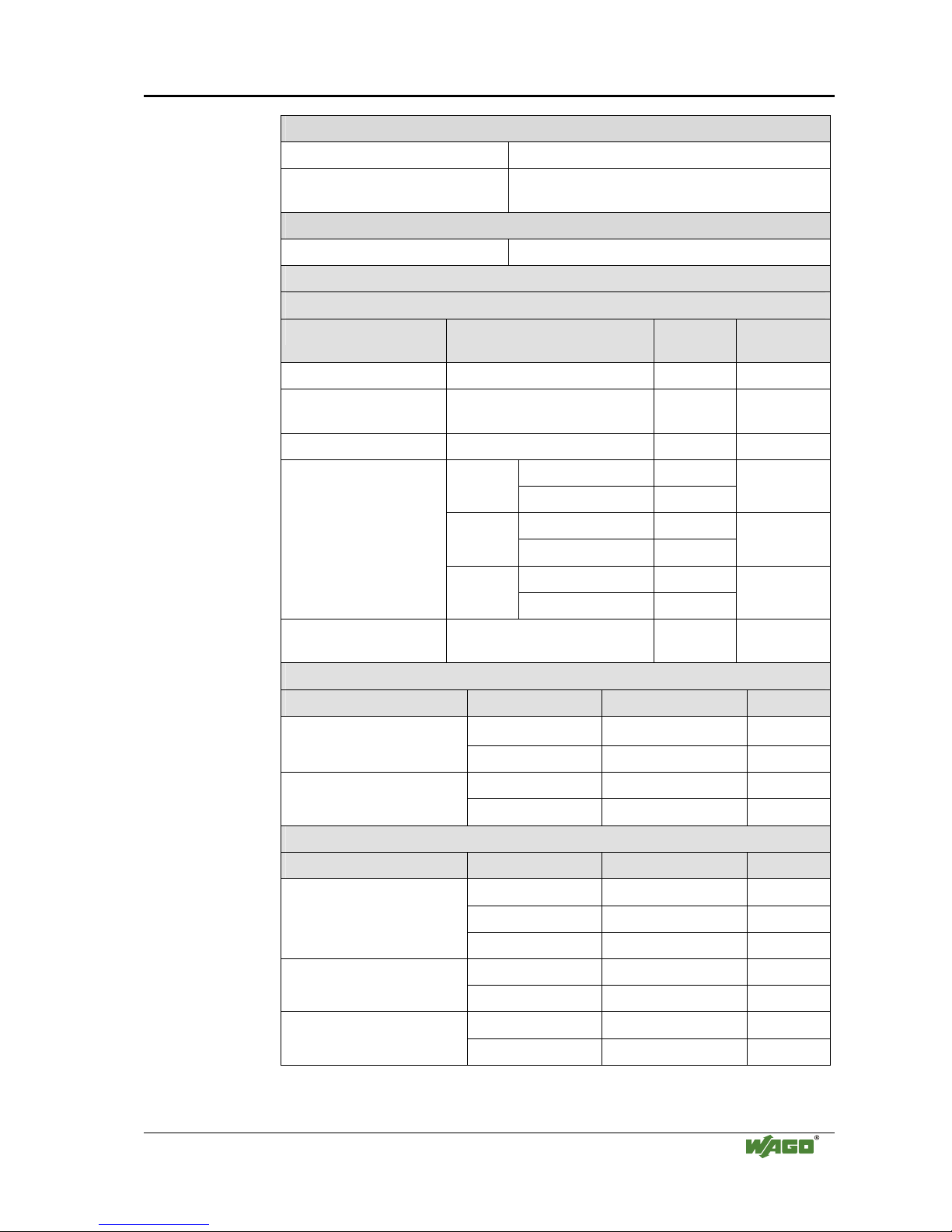

Safe electrical isolation

Air and creepage distance acc. to IEC 60664-1

Degree of pollution

acc. To IEC 61131-2

2

Degree of protection

Degree of protection IP 20

Electromagnetic compatibility

Immunity to interference for industrial areas acc. to EN 61000-6-2 (2001)

Test specification Test values Strength

class

Evaluation

criteria

EN 61000-4-2 ESD 4 kV/8 kV (contact/air) 2/3 B

EN 61000-4-3

electromagnetic fields

10 V/m 80 MHz ... 1 GHz 3 A

EN 61000-4-4 burst 1 kV/2 kV (data/supply) 2/3 B

-/- (line/line) Data:

1 kV (line/earth) 2

B

0.5 kV (line/line) 1 DC

supply:

0.5 kV (line/earth) 1

B

1 kV (line/line) 2

EN 61000-4-5 surge

AC

supply:

2 kV (line/earth) 3

B

EN 61000-4-6

RF disturbances

10 V/m 80 % AM (0.15 ... 80

MHz)

3 A

Emission of interference for industrial areas acc. to EN 61000-6-4 (2001)

Test specification Limit values/[QP]*) Frequency range Distance

79 dB (µV) 150 kHz ... 500 kHz EN 55011 (AC supply,

conducted)

73 dB (µV) 500 kHz ... 30 MHz

40 dB (µV/m) 30 MHz ... 230 MHz 10 m EN 55011 (radiated)

47 dB (µV/m) 230 MHz ... 1 GHz 10 m

Emission of interference for residential areas acc. to EN 61000-6-3 (2001)

Test specification Limit values/[QP]*) Frequency range Distance

66 ... 56 dB (µV) 150 kHz ... 500 kHz

56 dB (µV) 500 kHz ... 5 MHz

EN 55022 (AC supply,

conducted)

60 dB (µV) 5 MHz ... 30 MHz

40 ... 30 dB (µA) 150 kHz ... 500 kHz EN 55022 (DC supply/data,

conducted)

30 dB (µA) 500 kHz ... 30 MHz

30 dB (µV/m) 30 MHz ... 230 MHz 10 m EN 55022 (radiated)

37 dB (µV/m) 230 MHz ... 1 GHz 10 m

Page 16

10 • The WAGO-I/O-SYSTEM 750

Technical Data

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

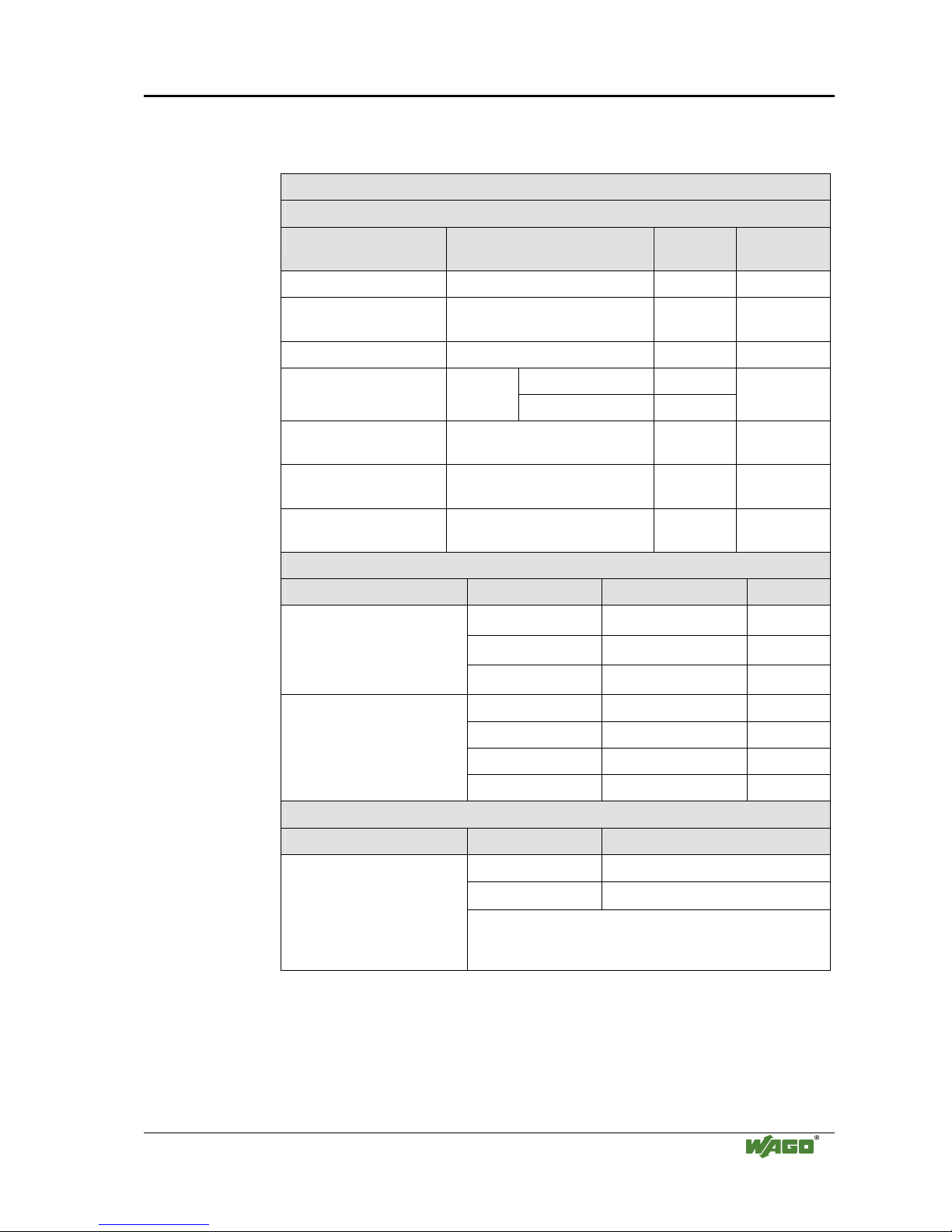

Mechanical strength acc. to IEC 61131-2

Test specification Frequency range Limit value

5 Hz ≤ f < 9 Hz

1.75 mm amplitude (permanent)

3.5 mm amplitude (short term)

9 Hz ≤ f < 150 Hz

0.5 g (permanent)

1 g (short term)

IEC 60068-2-6 vibration

Note on vibration test:

a) Frequency change: max. 1 octave/minute

b) Vibration direction: 3 axes

15 g IEC 60068-2-27 shock

Note on shock test:

a) Type of shock: half sine

b) Shock duration: 11 ms

c) Shock direction: 3x in positive and 3x in negative

direction for each of the three mutually perpendicular axes

of the test specimen

IEC 60068-2-32 free fall 1 m

(module in original packing)

*) QP: Quasi Peak

Note:

If the technical data of components differ from the values described here, the

technical data shown in the manuals of the respective components shall be

valid.

Page 17

Technical Data • 11

Technical Condition of the Devices

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

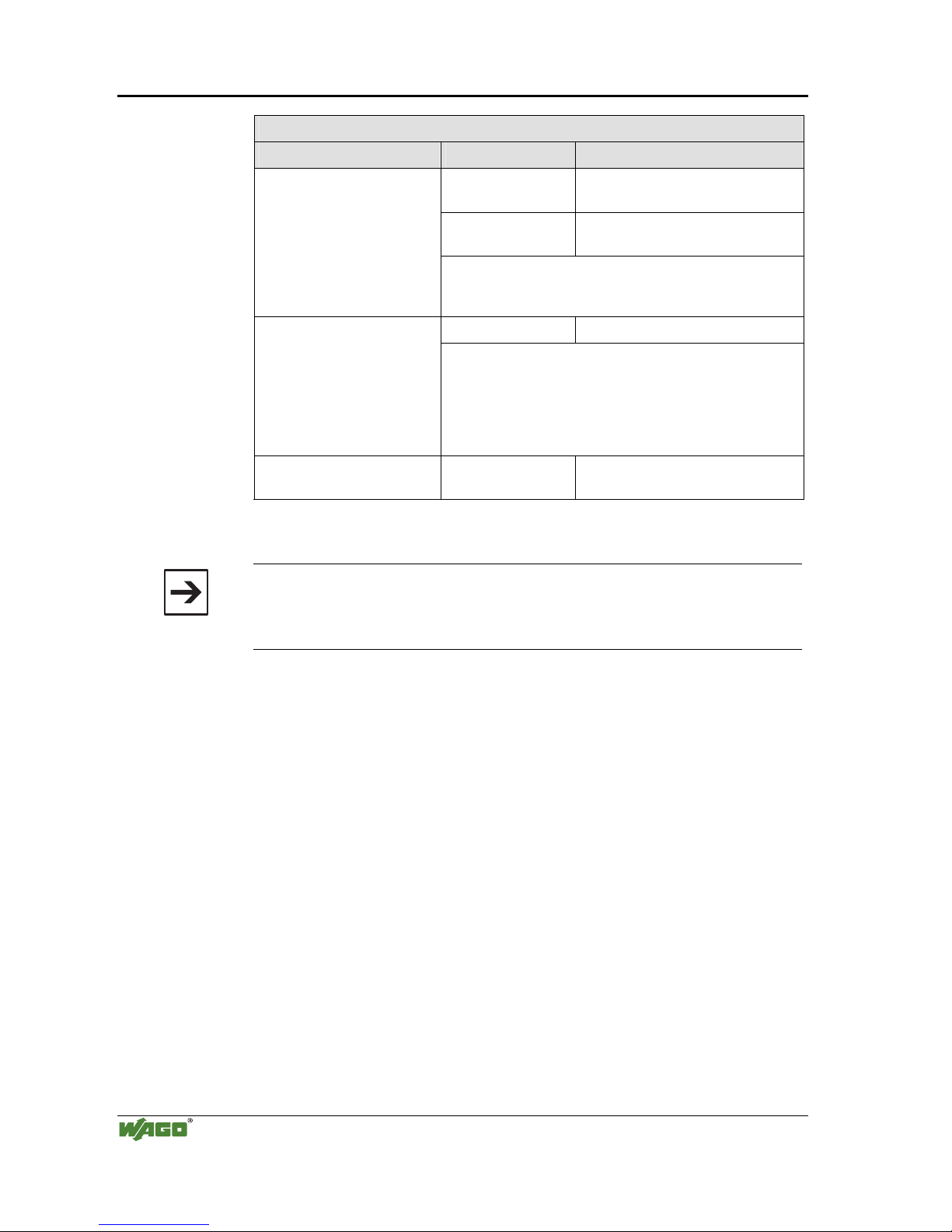

For Products of the WAGO-I/O-SYSTEM 750 with ship specific approvals,

supplementary guidelines are valid:

Electromagnetic compatibility

Immunity to interference acc. to Germanischer Lloyd (2003)

Test specification Test values Strength

class

Evaluation

criteria

IEC 61000-4-2 ESD 6 kV/8 kV (contact/air) 3/3 B

IEC 61000-4-3

electromagnetic fields

10 V/m 80 MHz ... 2 GHz 3 A

IEC 61000-4-4 burst 1 kV/2 kV (data/supply) 2/3 A

0.5 kV (line/line) 1 IEC 61000-4-5 surge AC/DC

Supply:

1 kV (line/earth) 2

A

IEC 61000-4-6

RF disturances

10 V/m 80 % AM (0.15 ... 80

MHz)

3 A

Type test AF disturbances

(harmonic waves)

3 V, 2 W - A

Type test high voltage 755 V DC

1500 V AC

- -

Emission of interference acc. to Germanischer Lloyd (2003)

Test specification Limit values Frequency range Distance

96 ... 50 dB (µV) 10 kHz ... 150 kHz

60 ... 50 dB (µV) 150 kHz ... 350 kHz

Type test

(EMC1, conducted)

allows for ship bridge control

applications

50 dB (µV) 350 kHz ... 30 MHz

80 ... 52 dB (µV/m) 150 kHz ... 300 kHz 3 m

52 ... 34 dB (µV/m) 300 kHz ... 30 MHz 3 m

Type test

(EMC1, radiated)

allows for ship bridge control

applications

54 dB (µV/m) 30 MHz ... 2 GHz 3 m

außer für: 24 dB (µV/m) 156 MHz ... 165 MHz 3 m

Mechanical strength acc. to Germanischer Lloyd (2003)

Test specification Frequency range Limit value

2 Hz ≤ f < 25 Hz

± 1.6 mm amplitude (permanent)

25 Hz ≤ f < 100 Hz

4 g (permanent)

IEC 60068-2-6 vibration

(category A – D)

Note on vibration test:

a) Frequency change: max. 1 octave/minute

b) Vibration direction: 3 axes

Page 18

12 • The WAGO-I/O-SYSTEM 750

Technical Data

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Range of

application

Required specification

emission of interference

Required specification

immunity to interference

Industrial areas EN 61000-6-4 (2001) EN 61000-6-2 (2001)

Residential areas EN 61000-6-3 (2001)*) EN 61000-6-1 (2001)

*)

The system meets the requirements on emission of interference in residential areas with

the fieldbus coupler/controller for:

ETHERNET

LonWorks

CANopen

DeviceNet

MODBUS

750-342/-841/-842/-860

750-319/-819

750-337/-837

750-306/-806

750-312/-314/ -315/ -316

750-812/-814/ -815/ -816

With a special permit, the system can also be implemented with other fieldbus

couplers/controllers in residential areas (housing, commercial and business areas, smallscale enterprises). The special permit can be obtained from an authority or inspection

office. In Germany, the Federal Office for Post and Telecommunications and its branch

offices issues the permit.

It is possible to use other field bus couplers/controllers under certain boundary

conditions. Please contact WAGO Kontakttechnik GmbH & Co. KG.

Maximum power dissipation of the components

Bus modules 0.8 W / bus terminal (total power dissipation,

system/field)

Fieldbus coupler/controller 2.0 W / coupler/controller

Warning

The power dissipation of all installed components must not exceed the

maximum conductible power of the housing (cabinet).

When dimensioning the housing, care is to be taken that even under high

external temperatures, the temperature inside the housing does not exceed the

permissible ambient temperature of 55 °C.

Page 19

Technical Data • 13

Technical Condition of the Devices

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Dimensions

51

24V 0V

+

+

-

-

01

02

C

D

B

A

C

D

B

A

C

D

B

A

C

D

B

A

C

D

B

A

100

12

24

64

35

65

Side view

Dimensions in mm

Fig. 2-2: Dimensions g01xx05e

Note:

The illustration shows a standard coupler. For detailed dimensions, please

refer to the technical data of the respective coupler/controller.

Page 20

14 • The WAGO-I/O-SYSTEM 750

Manufacturing Number

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.3 Manufacturing Number

The manufacturing number indicates the delivery status directly after

production.

This number is part of the lateral marking on the component.

In addition, starting from calender week 43/2000 the manufacturing number is

also printed on the cover of the configuration and programming interface of

the fieldbus coupler or controller.

Hansastr. 27

D-32423 Minden

ITEM-NO.:750-333

PROFIBUS DP 12 MBd /DPV1

0V

Power Supply

Electronic

PATENTS PENDING

II3GD

DEMKO 02 ATEX132273 X

EEx nA II T4

24V DC

AWG 28-14

55°C max ambient

LISTED 22ZA AND 22XM

72072

0103000203-B000000

Hansastr. 27

D-32423 Minden

ITEM-NO.:750-333

PROFIBUS DP 12 MBd /DPV1

0V

Power Supply

Electronic

PATENTS PENDING

II3GD

DEMKO 02 ATEX132273 X

EEx nA II T4

24V DC

AWG 28-14

55°C max ambient

LISTED 22ZA AND 22XM

72072

0103000203-B060606

1

0

3

0

0

0

2

0

0

3

DS

NO

SW

HW

GL

FWL

Power Supply

Field

24 V

+

-

-B060606

PROFIBUS

WAGO - I/O - SYSTEM

750-333

01030002

03-B

060606

72072

Manufacturing Number

Calendar

week

Year Software

version

Hardware

version

Firmware Loader

version

Internal

Number

Fig. 2-3: Example: Manufacturing Number of a PROFIBUS fieldbus coupler 750-333

g01xx15e

The manufacturing number consists of the production week and year, the

software version (if available), the hardware version of the component, the

firmware loader (if available) and further internal information for

WAGO Kontakttechnik GmbH.

Page 21

Component Update • 15

Technical Condition of the Devices

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.4 Component Update

For the case of an Update of one component, the lateral marking on each

component contains a prepared matrix.

This matrix makes columns available for altogether three updates to the entry

of the current update data, like production order number (NO; starting from

calendar week 13/2004), update date (DS), software version (SW), hardware

version (HW) and the firmware loader version (FWL, if available).

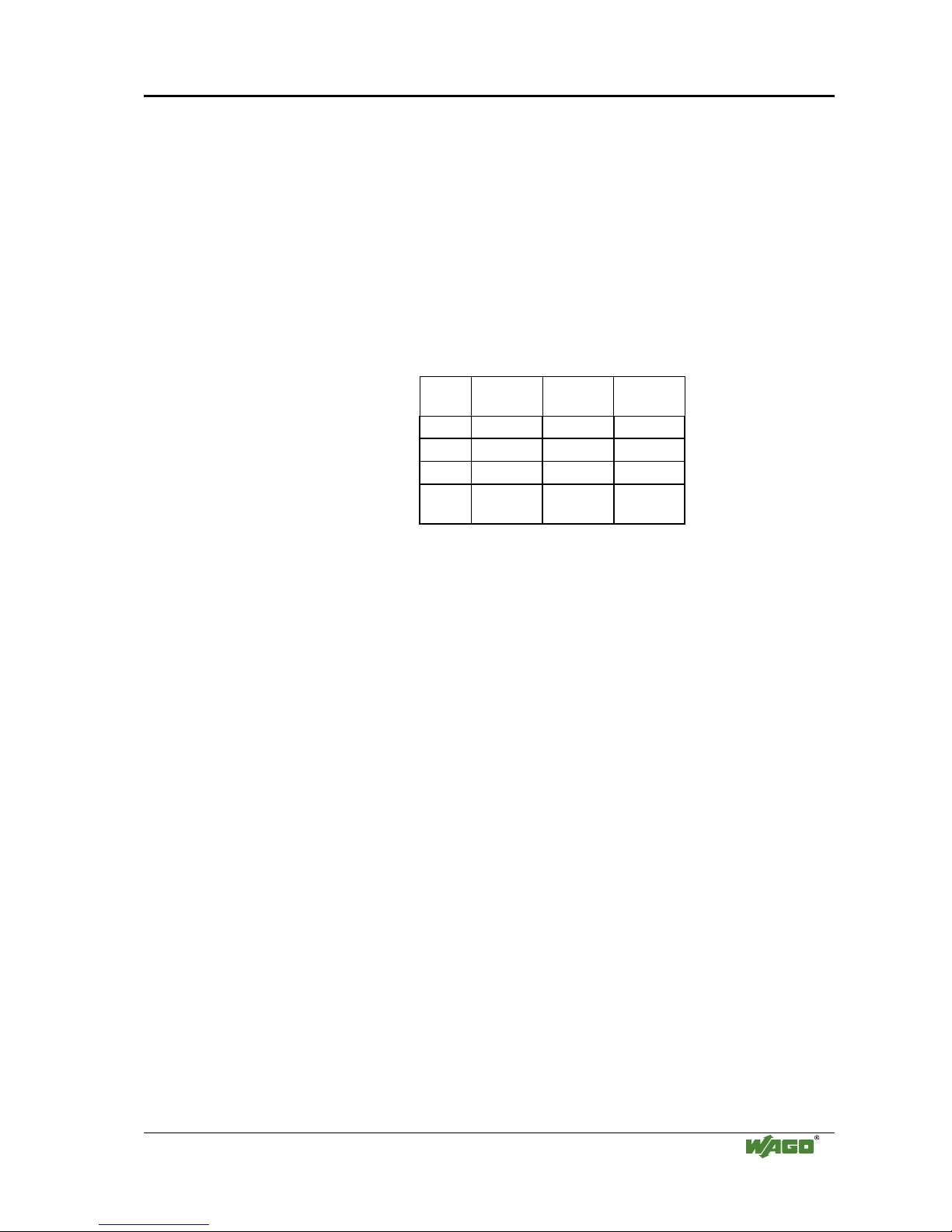

Update Matrix

Current Version data for: 1. Update 2. Update 3. Update

Production Order

Number

NO

Å Only starting from

calendar week 13/2004

Datestamp

DS

Software index

SW

Hardware index

HW

Firmware loader index

FWL

Å Only for coupler/

controller

If the update of a component took place, the current version data are registered

into the columns of the matrix.

Additionally with the update of a fieldbus coupler or controller also the cover

of the configuration and programming interface of the coupler or controller is

printed on with the current manufacturing and production order number.

The original manufacturing data on the housing of the component remain

thereby.

2.5 Storage, Assembly and Transport

Wherever possible, the components are to be stored in their original

packaging. Likewise, the original packaging provides optimal protection

during transport.

When assembling or repacking the components, the contacts must not be

soiled or damaged. The components must be stored and transported in

appropriate containers/packaging. Thereby, the ESD information is to be

regarded.

Statically shielded transport bags with metal coatings are to be used for the

transport of open components for which soiling with amine, amide and

silicone has been ruled out, e.g. 3M 1900E.

Page 22

16 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.6 Mechanical Setup

2.6.1 Installation Position

Along with horizontal and vertical installation, all other installation positions

are allowed.

Attention

In the case of vertical assembly, an end stop has to be mounted as an

additional safeguard against slipping.

WAGO item 249-116 End stop for DIN 35 rail, 6 mm wide

WAGO item 249-117 End stop for DIN 35 rail, 10 mm wide

2.6.2 Total Expansion

The length of the module assembly (including one end module of 12mm

width) that can be connected to the coupler/controller is 780mm. When

assembled, the I/O modules have a maximum length of 768mm.

Examples:

• 64 I/O modules of 12mm width can be connected to one coupler/controller.

• 32 I/O modules of 24mm width can be connected to one coupler/controller.

Exception:

The number of connected I/O modules also depends on which type of

coupler/controller is used. For example, the maximum number of I/O modules

that can be connected to a Profibus coupler/controller is 63 without end

module.The maximum total expansion of a node is calculated as follows:

Warning

The maximum total length of a node without coupler/controller must not

exceed 780mm. Furthermore, restrictions made on certain types of

couplers/controllers must be observed (e.g. for Profibus).

Page 23

Mechanical Setup • 17

Assembly onto Carrier Rail

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.6.3 Assembly onto Carrier Rail

2.6.3.1 Carrier rail properties

All system components can be snapped directly onto a carrier rail in

accordance with the European standard EN 50022 (DIN 35).

Warning

WAGO supplies standardized carrier rails that are optimal for use with the

I/O system. If other carrier rails are used, then a technical inspection and

approval of the rail by WAGO Kontakttechnik GmbH should take place.

Carrier rails have different mechanical and electrical properties. For the

optimal system setup on a carrier rail, certain guidelines must be observed:

• The material must be non-corrosive.

• Most components have a contact to the carrier rail to ground electro-

magnetic disturbances. In order to avoid corrosion, this tin-plated carrier

rail contact must not form a galvanic cell with the material of the carrier

rail which generates a differential voltage above 0.5 V (saline solution of

0.3% at 20°C) .

• The carrier rail must optimally support the EMC measures integrated into

the system and the shielding of the bus module connections.

• A sufficiently stable carrier rail should be selected and, if necessary,

several mounting points (every 20 cm) should be used in order to prevent

bending and twisting (torsion).

• The geometry of the carrier rail must not be altered in order to secure the

safe hold of the components. In particular, when shortening or mounting

the carrier rail, it must not be crushed or bent.

• The base of the I/O components extends into the profile of the carrier rail.

For carrier rails with a height of 7.5 mm, mounting points are to be riveted

under the node in the carrier rail (slotted head captive screws or blind

rivets).

Page 24

18 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.6.3.2 WAGO DIN Rail

WAGO carrier rails meet the electrical and mechanical requirements.

Item Number Description

210-113 /-112 35 x 7.5; 1 mm; steel yellow chromated; slotted/unslotted

210-114 /-197 35 x 15; 1.5 mm; steel yellow chromated; slotted/unslotted

210-118 35 x 15; 2.3 mm; steel yellow chromated; unslotted

210-198 35 x 15; 2.3 mm; copper; unslotted

210-196 35 x 7.5; 1 mm; aluminum; unslotted

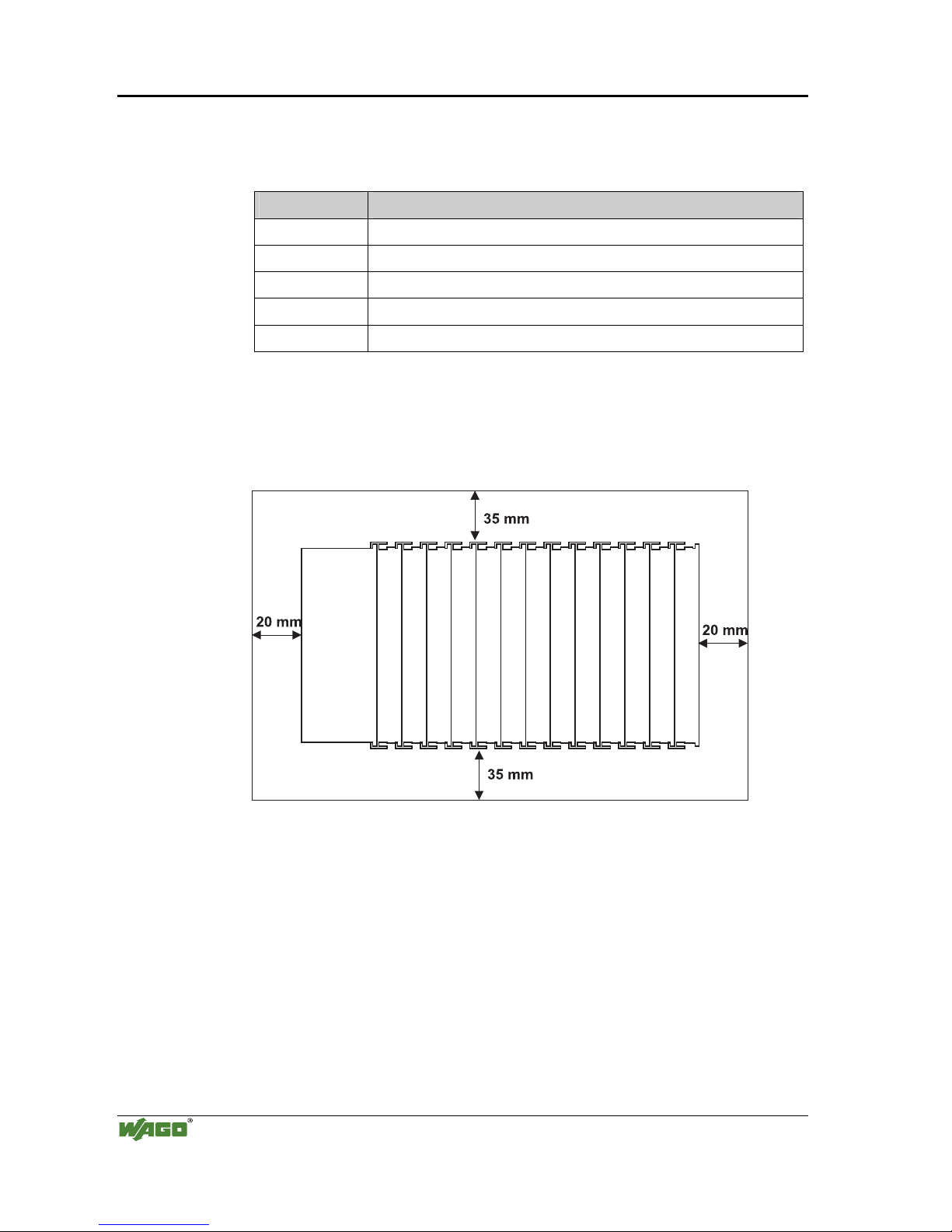

2.6.4 Spacing

The spacing between adjacent components, cable conduits, casing and frame

sides must be maintained for the complete field bus node.

Fig. 2-4: Spacing g01xx13x

The spacing creates room for heat transfer, installation or wiring. The spacing

to cable conduits also prevents conducted electromagnetic interferences from

influencing the operation.

Page 25

Mechanical Setup • 19

Plugging and Removal of the Components

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

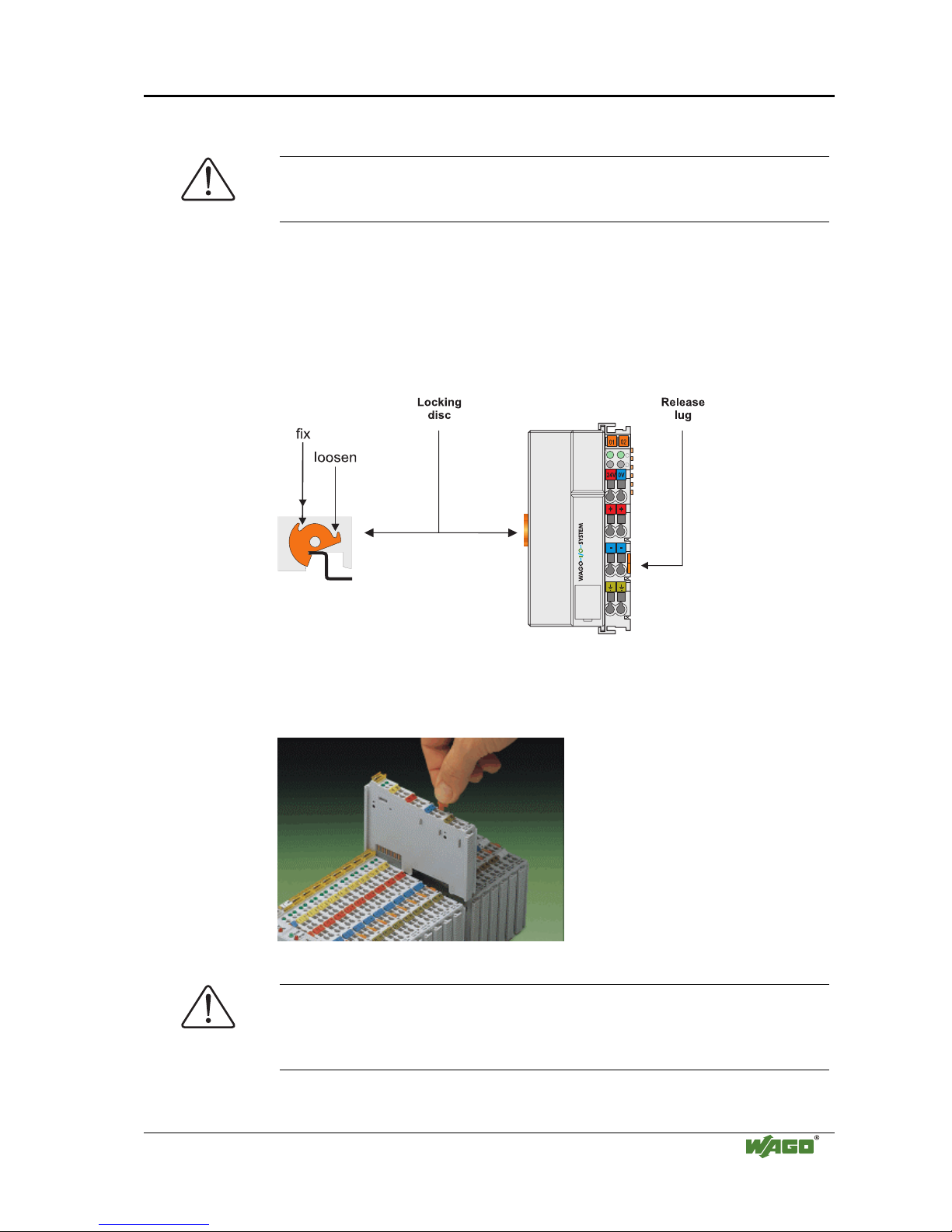

2.6.5 Plugging and Removal of the Components

Warning

Before work is done on the components, the voltage supply must be turned

off.

In order to safeguard the coupler/controller from jamming, it should be fixed

onto the carrier rail with the locking disc To do so, push on the upper groove

of the locking disc using a screwdriver.

To pull out the fieldbus coupler/controller, release the locking disc by pressing

on the bottom groove with a screwdriver and then pulling the orange colored

unlocking lug.

Fig. 2-5: Coupler/Controller and unlocking lug g01xx12e

It is also possible to release an individual I/O module from the unit by pulling

an unlocking lug.

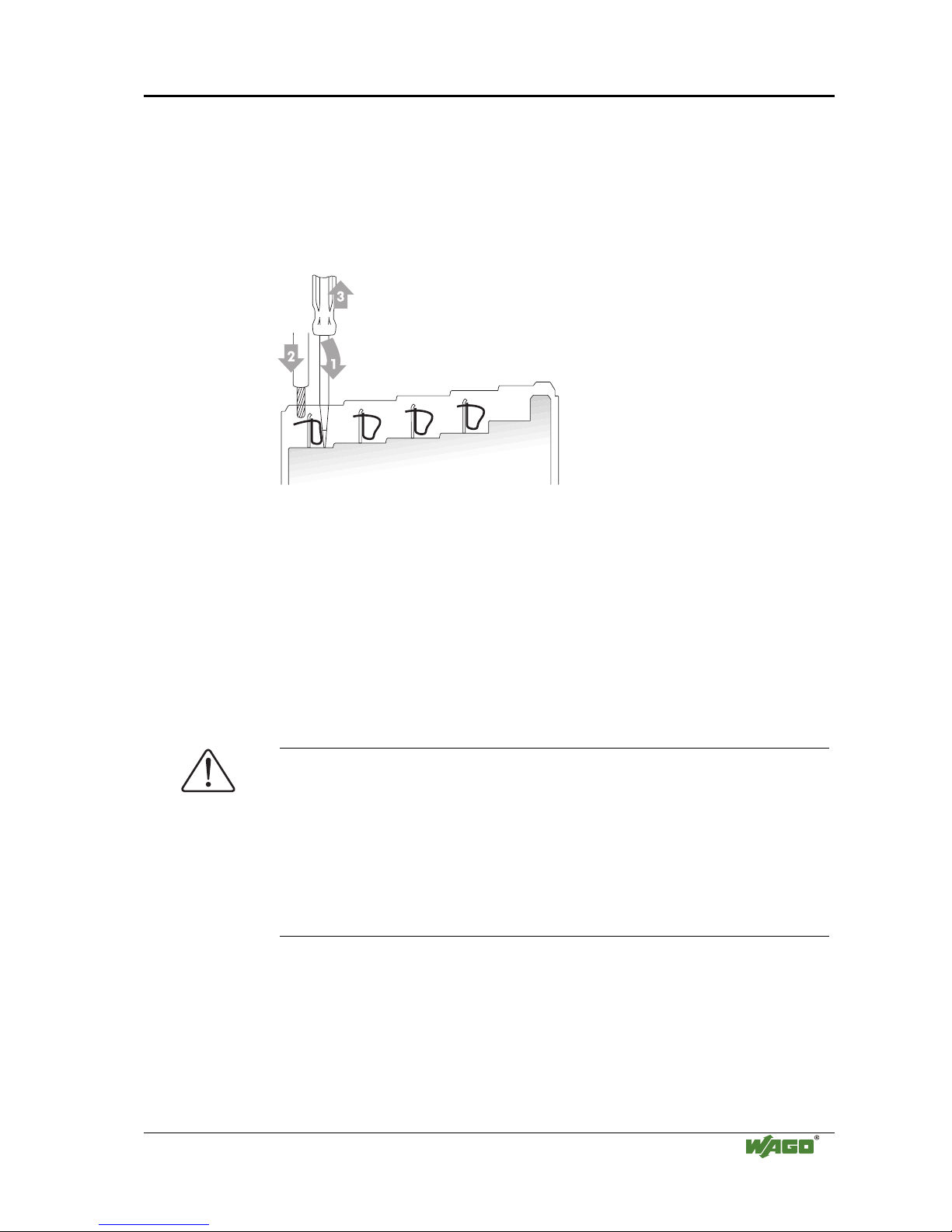

Fig. 2-6: removing bus terminal p0xxx01x

Danger

Ensure that an interruption of the PE will not result in a condition which

could endanger a person or equipment!

For planning the ring feeding of the ground wire, please see chapter 2.6.3.

Page 26

20 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.6.6 Assembly Sequence

All system components can be snapped directly on a carrier rail in accordance

with the European standard EN 50022 (DIN 35).

The reliable positioning and connection is made using a tongue and groove

system. Due to the automatic locking, the individual components are securely

seated on the rail after installing.

Starting with the coupler/controller, the bus modules are assembled adjacent

to each other according to the project planning. Errors in the planning of the

node in terms of the potential groups (connection via the power contacts) are

recognized, as the bus modules with power contacts (male contacts) cannot be

linked to bus modules with fewer power contacts.

Attention

Always link the bus modules with the coupler/controller, and always plug

from above.

Warning

Never plug bus modules from the direction of the end terminal. A ground

wire power contact, which is inserted into a terminal without contacts, e.g. a

4-channel digital input module, has a decreased air and creepage distance to

the neighboring contact in the example DI4.

Always terminate the fieldbus node with an end module (750-600).

Page 27

Mechanical Setup • 21

Internal Bus/Data Contacts

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

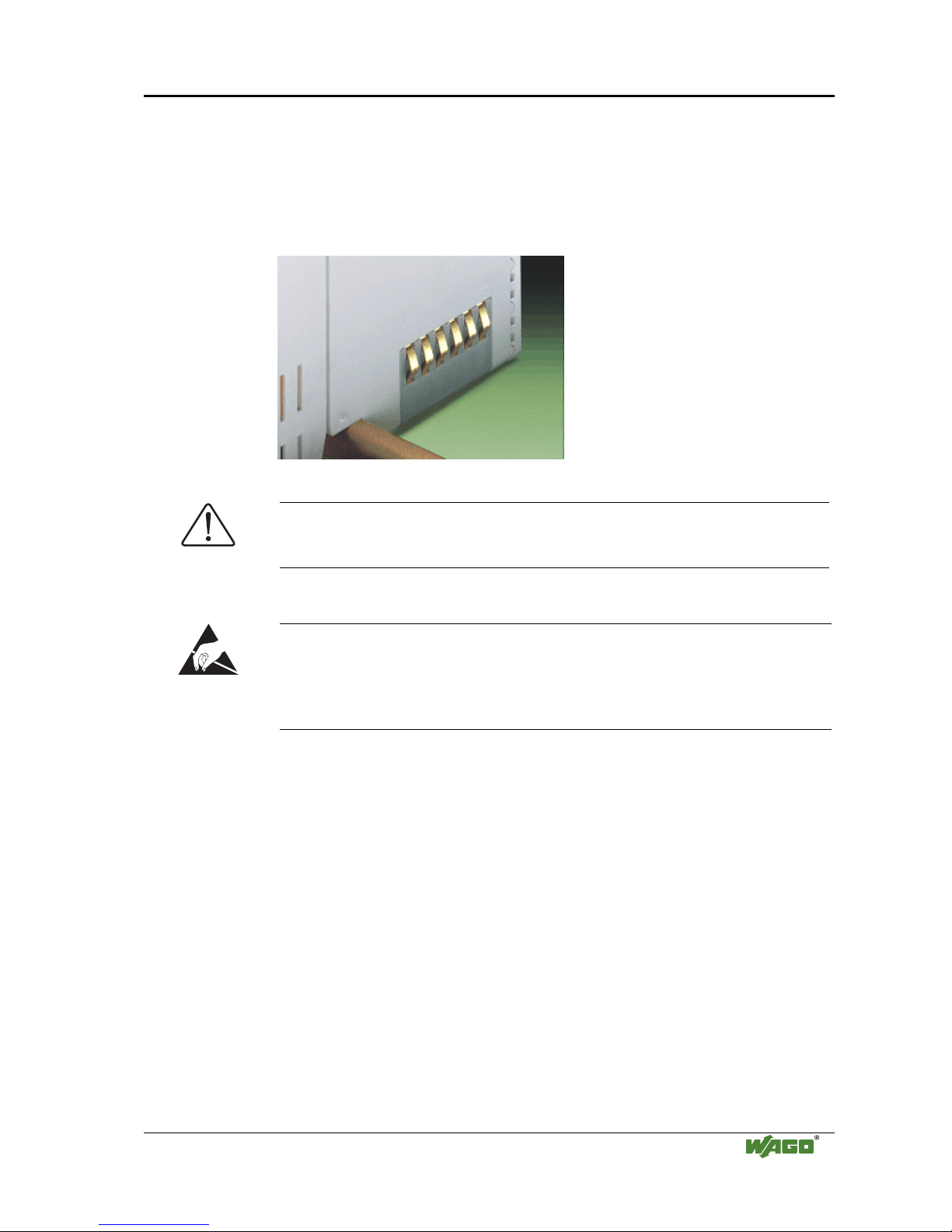

2.6.7 Internal Bus/Data Contacts

Communication between the coupler/controller and the bus modules as well as

the system supply of the bus modules is carried out via the internal bus. It is

comprised of 6 data contacts, which are available as self-cleaning gold spring

contacts.

Fig. 2-7: Data contacts p0xxx07x

Warning

Do not touch the gold spring contacts on the I/O modules in order to avoid

soiling or scratching!

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the

environment (persons, workplace and packing) is well grounded. Avoid

touching conductive components, e.g. gold contacts.

Page 28

22 • The WAGO-I/O-SYSTEM 750

Mechanical Setup

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

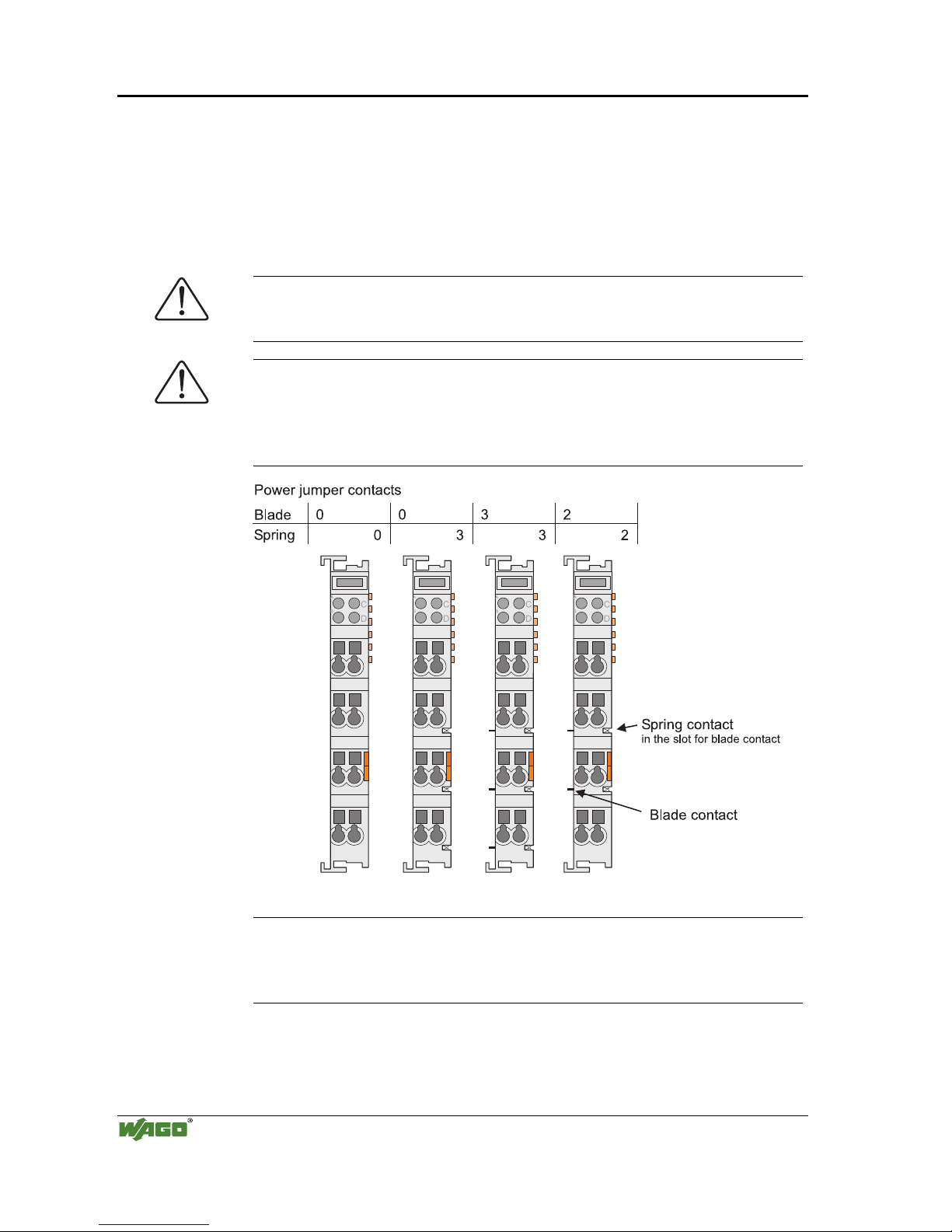

2.6.8 Power Contacts

Self-cleaning power contacts , are situated on the side of the components

which further conduct the supply voltage for the field side. These contacts

come as touchproof spring contacts on the right side of the coupler/controller

and the bus module. As fitting counterparts the module has male contacts on

the left side.

Danger

The power contacts are sharp-edged. Handle the module carefully to prevent

injury.

Attention

Please take into consideration that some bus modules have no or only a few

power jumper contacts. The design of some modules does not allow them to

be physically assembled in rows, as the grooves for the male contacts are

closed at the top.

Fig. 2-8: Example for the arrangement of power contacts g0xxx05e

Recommendation

With the WAGO ProServe® Software smartDESIGNER, the assembly of a

fieldbus node can be configured. The configuration can be tested via the

integrated accuracy check.

Page 29

Mechanical Setup • 23

Wire connection

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.6.9 Wire connection

All components have CAGE CLAMP® connections.

The WAGO CAGE CLAMP® connection is appropriate for solid, stranded

and fine–stranded conductors. Each clamping unit accommodates one

conductor.

Fig. 2-9: CAGE CLAMP® Connection g0xxx08x

The operating tool is inserted into the opening above the connection. This

opens the CAGE CLAMP®. Subsequently the conductor can be inserted into

the opening. After removing the operating tool, the conductor is safely

clamped.

More than one conductor per connection is not permissible. If several

conductors have to be made at one connection point, then they should be made

away from the connection point using WAGO Terminal Blocks. The terminal

blocks may be jumpered together and a single wire brought back to the I/O

module connection point.

Attention

If it is unavoidable to jointly connect 2 conductors, then a ferrule must be

used to join the wires together.

Ferrule:

Length 8 mm

Nominal cross section

max.

1 mm2 for 2 conductors with 0.5 mm2

each

WAGO Product 216-103

or products with comparable properties

Page 30

24 • The WAGO-I/O-SYSTEM 750

Power Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.7 Power Supply

2.7.1 Isolation

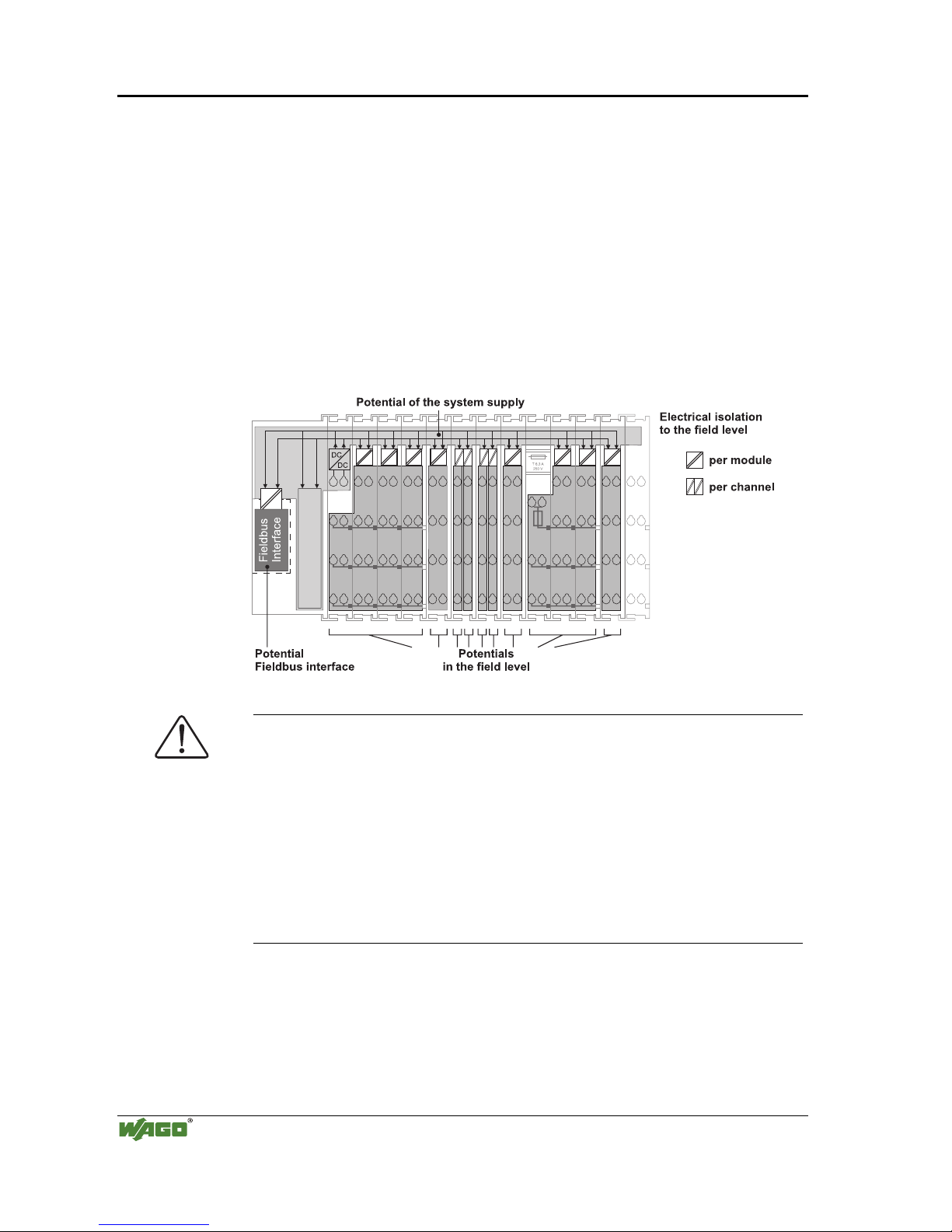

Within the fieldbus node, there are three electrically isolated potentials.

• Operational voltage for the fieldbus interface.

• Electronics of the couplers/controllers and the bus modules (internal bus).

• All bus modules have an electrical isolation between the electronics

(internal bus, logic) and the field electronics. Some digital and analog

input modules have each channel electrically isolated, please see catalog.

Fig. 2-10: Isolation g0xxx01e

Attention

The ground wire connection must be present in each group. In order that all

protective conductor functions are maintained under all circumstances, it is

recommended that a ground wire be connected at the beginning and end of a

potential group. (ring format, please see chapter "2.8.3"). Thus, if a bus

module comes loose from a composite during servicing, then the protective

conductor connection is still guaranteed for all connected field devices.

When using a joint power supply unit for the 24 V system supply and the

24 V field supply, the electrical isolation between the internal bus and the

field level is eliminated for the potential group.

Page 31

Power Supply • 25

System Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.7.2 System Supply

2.7.2.1 Connection

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply

(-15% or +20 %). The power supply is provided via the coupler/controller and,

if necessary, in addition via the internal system supply modules (750-613).

The voltage supply is reverse voltage protected.

Attention

The use of an incorrect supply voltage or frequency can cause severe damage

to the component.

Fig. 2-11: System Supply g0xxx02e

The direct current supplies all internal system components, e.g.

coupler/controller electronics, fieldbus interface and bus modules via the

internal bus (5 V system voltage). The 5 V system voltage is electrically

connected to the 24 V system supply.

Fig. 2-12: System Voltage g0xxx06e

Page 32

26 • The WAGO-I/O-SYSTEM 750

Power Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Attention

Resetting the system by switching on and off the system supply, must take

place simultaneously for all supply modules (coupler/controller and

750-613).

2.7.2.2 Alignment

Recommendation

A stable network supply cannot be taken for granted always and everywhere.

Therefore, regulated power supply units should be used in order to guarantee

the quality of the supply voltage.

The supply capacity of the coupler/controller or the internal system supply

module (750-613) can be taken from the technical data of the components.

Internal current consumption*)

Current consumption via system voltage:

5 V for electronics of the bus modules and

coupler/controller

Residual current for bus

terminals*)

Available current for the bus modules. Provided by

the bus power supply unit. See coupler/controller

and internal system supply module (750-613)

*) cf. catalogue W4 Volume 3, manuals or Internet

Example

Coupler 750-301:

internal current consumption:350 mA at 5V

residual current for

bus modules : 1650 mA at 5V

sum I(5V)

total

: 2000 mA at 5V

The internal current consumption is indicated in the technical data for each

bus terminal. In order to determine the overall requirement, add together the

values of all bus modules in the node.

Attention

If the sum of the internal current consumption exceeds the residual current

for bus modules, then an internal system supply module (750-613) must be

placed before the module where the permissible residual current was

exceeded.

Example:

A node with a PROFIBUS Coupler 750-333 consists of 20 relay

modules (750-517) and 10 digital input modules (750-405).

Current consumption:

20* 90 mA = 1800 mA

10* 2 mA = 20 mA

Sum 1820 mA

The coupler can provide 1650 mA for the bus modules. Consequently,

an internal system supply module (750-613), e.g. in the middle of the

node, should be added.

Page 33

Power Supply • 27

System Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Recommendation

With the WAGO ProServe® Software smartDESIGNER, the assembly of a

fieldbus node can be configured. The configuration can be tested via the

integrated accuracy check.

The maximum input current of the 24 V system supply is 500 mA. The exact

electrical consumption (I

(24 V)

) can be determined with the following formulas:

Coupler/Controller

I(5 V)

total

= Sum of all the internal current consumption of the connected

bus modules

+ internal current consumption coupler/controller

750-613

I(5 V)

total

= Sum of all the internal current consumption of the connected

bus modules

Input current I(24 V) =

5 V / 24 V * I(5 V)

total

/ η

η = 0.87 (at nominal load)

Note

If the electrical consumption of the power supply point for the 24 V-system

supply exceeds 500 mA, then the cause may be an improperly aligned node

or a defect.

During the test, all outputs, in particular those of the relay modules, must be

active.

Page 34

28 • The WAGO-I/O-SYSTEM 750

Power Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.7.3 Field Supply

2.7.3.1 Connection

Sensors and actuators can be directly connected to the relevant channel of the

bus module in 1-/4 conductor connection technology. The bus module supplies

power to the sensors and actuators. The input and output drivers of some bus

modules require the field side supply voltage.

The coupler/controller provides field side power (DC 24V). In this case it is a

passive power supply without protection equipment.

Power supply modules are available for other potentials, e.g. AC 230 V.

Likewise, with the aid of the power supply modules, various potentials can be

set up. The connections are linked in pairs with a power contact.

Fig. 2-13: Field Supply (Sensor/Actuator) g0xxx03e

The supply voltage for the field side is automatically passed to the next

module via the power jumper contacts when assembling the bus modules .

The current load of the power contacts must not exceed 10 A on a continual

basis. The current load capacity between two connection terminals is identical

to the load capacity of the connection wires.

By inserting an additional power supply module, the field supply via the

power contacts is disrupted. From there a new power supply occurs which

may also contain a new voltage potential.

Page 35

Power Supply • 29

Field Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Attention

Some bus modules have no or very few power contacts (depending on the I/O

function). Due to this, the passing through of the relevant potential is

disrupted. If a field supply is required for subsequent bus modules, then a

power supply module must be used.

Note the data sheets of the bus modules.

In the case of a node setup with different potentials, e.g. the alteration from

DC 24 V to AC 230V, a spacer module should be used. The optical

separation of the potentials acts as a warning to heed caution in the case of

wiring and maintenance works. Thus, the results of wiring errors can be

prevented.

2.7.3.2 Fusing

Internal fusing of the field supply is possible for various field voltages via an

appropriate power supply module.

750-601 24 V DC, Supply/Fuse

750-609 230 V AC, Supply/Fuse

750-615 120 V AC, Supply/Fuse

750-610 24 V DC, Supply/Fuse/Diagnosis

750-611 230 V AC, Supply/Fuse/Diagnosis

Fig. 2-14: Supply module with fuse carrier (Example 750-610) g0xxx09x

Page 36

30 • The WAGO-I/O-SYSTEM 750

Power Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Warning

In the case of power supply modules with fuse holders, only fuses with a

maximum dissipation of 1.6 W (IEC 127) must be used.

For UL approved systems only use UL approved fuses.

In order to insert or change a fuse, or to switch off the voltage in succeeding

bus modules, the fuse holder may be pulled out. In order to do this, use a

screwdriver for example, to reach into one of the slits (one on both sides) and

pull out the holder.

Fig. 2-15: Removing the fuse carrier p0xxx05x

Lifting the cover to the side opens the fuse carrier.

Fig. 2-16: Opening the fuse carrier p0xxx03x

Fig. 2-17: Change fuse p0xxx04x

After changing the fuse, the fuse carrier is pushed back into its original

position.

Page 37

Power Supply • 31

Field Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

Alternatively, fusing can be done externally. The fuse modules of the WAGO

series 281 and 282 are suitable for this purpose.

Fig. 2-18: Fuse modules for automotive fuses, Series 282 pf66800x

Fig. 2-19: Fuse modules with pivotable fuse carrier, Series 281 pe61100x

Fig. 2-20: Fuse modules, Series 282 pf12400x

Page 38

32 • The WAGO-I/O-SYSTEM 750

Power Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.7.4 Supplementary power supply regulations

The WAGO-I/O-SYSTEM 750 can also be used in shipbuilding or offshore

and onshore areas of work (e.g. working platforms, loading plants). This is

demonstrated by complying with the standards of influential classification

companies such as Germanischer Lloyd and Lloyds Register.

Filter modules for 24-volt supply are required for the certified operation of the

system.

Item No. Name Description

750-626 Supply filter Filter module for system supply and field supply (24 V,

0 V), i.e. for field bus coupler/controller and bus power

supply (750-613)

750-624 Supply filter Filter module for the 24 V- field supply

(750-602, 750-601, 750-610)

Therefore, the following power supply concept must be absolutely complied

with.

Fig. 2-21: Power supply concept g01xx11e

Note

Another potential power terminal 750-601/602/610 must only be used behind

the filter terminal 750-626 if the protective earth conductor is needed on the

lower power contact or if a fuse protection is required.

Page 39

Power Supply • 33

Supply example

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.7.5 Supply example

Note

The system supply and the field supply should be separated in order to ensure

bus operation in the event of a short-circuit on the actuator side.

750-630750-400 750-410 750-401

750-613

750-512 750-512750-616 750-513 750-610 750-552 750-600750-612 750-616

1)

a)

b)

c)

d)

1)

2) 2)

24V

24V

10 A

10 A

L1

L2

L3

N

PE

230V

230V

Main ground bus

Shield (screen) bus

System

Supply

Field

Supply

Field

Supply

1) Separation module

recommended

2) Ring-feeding

recommended

a) Power Supply

on coupler / controller

via external Supply

Module

b) Internal System

Supply Module

c) Supply Module

passive

d)

iagnostics

Supply Module

with fuse carrier/

d

Fig. 2-22: Supply example g0xxx04e

Page 40

34 • The WAGO-I/O-SYSTEM 750

Power Supply

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.7.6 Power Supply Unit

The WAGO-I/O-SYSTEM 750 requires a 24 V direct current system supply

with a maximum deviation of -15% or +20 %.

Recommendation

A stable network supply cannot be taken for granted always and everywhere.

Therefore, regulated power supply units should be used in order to guarantee

the quality of the supply voltage.

A buffer (200 µF per 1 A current load) should be provided for brief voltage

dips. The I/O system buffers for approx 1 ms.

The electrical requirement for the field supply is to be determined individually

for each power supply point. Thereby all loads through the field devices and

bus modules should be considered. The field supply as well influences the bus

modules, as the inputs and outputs of some bus modules require the voltage of

the field supply.

Note

The system supply and the field supply should be isolated from the power

supplies in order to ensure bus operation in the event of short circuits on the

actuator side.

WAGO products

Article No.

Description

787-903 Primary switched - mode, DC 24 V, 5 A

wide input voltage range AC 85-264 V

PFC (Power Factor Correction)

787-904 Primary switched - mode, DC 24 V, 10 A

wide input voltage range AC 85-264 V

PFC (Power Factor Correction)

787-912 Primary switched - mode, DC 24 V, 2 A

wide input voltage range AC 85-264 V

PFC (Power Factor Correction)

288-809

288-810

288-812

288-813

Rail-mounted modules with universal mounting carrier

AC 115 V / DC 24 V; 0,5 A

AC 230 V / DC 24 V; 0,5 A

AC 230 V / DC 24 V; 2 A

AC 115 V / DC 24 V; 2 A

Page 41

Grounding • 35

Grounding the DIN Rail

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.8 Grounding

2.8.1 Grounding the DIN Rail

2.8.1.1 Framework Assembly

When setting up the framework, the carrier rail must be screwed together with

the electrically conducting cabinet or housing frame. The framework or the

housing must be grounded. The electronic connection is established via the

screw. Thus, the carrier rail is grounded.

Attention

Care must be taken to ensure the flawless electrical connection between the

carrier rail and the frame or housing in order to guarantee sufficient

grounding.

2.8.1.2 Insulated Assembly

Insulated assembly has been achieved when there is constructively no direct

conduction connection between the cabinet frame or machine parts and the

carrier rail. Here the earth must be set up via an electrical conductor.

The connected grounding conductor should have a cross section of at least

4 mm2.

Recommendation

The optimal insulated setup is a metallic assembly plate with grounding

connection with an electrical conductive link with the carrier rail.

The separate grounding of the carrier rail can be easily set up with the aid of

the WAGO ground wire terminals.

Article No. Description

283-609 Single-conductor ground (earth) terminal block make an automatic

contact to the carrier rail; conductor cross section: 0.2 -16 mm2

Note: Also order the end and intermediate plate (283-320)

Page 42

36 • The WAGO-I/O-SYSTEM 750

Grounding

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.8.2 Grounding Function

The grounding function increases the resistance against disturbances from

electro-magnetic interferences. Some components in the I/O system have a

carrier rail contact that dissipates electro-magnetic disturbances to the carrier

rail.

Fig. 2-23: Carrier rail contact g0xxx10e

Attention

Care must be taken to ensure the direct electrical connection between the

carrier rail contact and the carrier rail.

The carrier rail must be grounded.

For information on carrier rail properties, please see chapter 2.6.3.2.

Page 43

Grounding • 37

Grounding Protection

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.8.3 Grounding Protection

For the field side, the ground wire is connected to the lowest connection

terminals of the power supply module. The ground connection is then

connected to the next module via the Power Jumper Contact (PJC). If the bus

module has the lower power jumper contact, then the ground wire connection

of the field devices can be directly connected to the lower connection

terminals of the bus module.

Attention

Should the ground conductor connection of the power jumper contacts within

the node become disrupted, e.g. due to a 4-channel bus terminal, the ground

connection will need to be re-established.

The ring feeding of the grounding potential will increase the system safety.

When one bus module is removed from the group, the grounding connection

will remain intact.

The ring feeding method has the grounding conductor connected to the

beginning and end of each potential group.

Fig. 2-24: Ring-feeding g0xxx07e

Attention

The regulations relating to the place of assembly as well as the national

regulations for maintenance and inspection of the grounding protection must

be observed.

Page 44

38 • The WAGO-I/O-SYSTEM 750

Shielding (Screening)

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.9 Shielding (Screening)

2.9.1 General

The shielding of the data and signal conductors reduces electromagnetic

interferences thereby increasing the signal quality. Measurement errors, data

transmission errors and even disturbances caused by overvoltage can be

avoided.

Attention

Constant shielding is absolutely required in order to ensure the technical

specifications in terms of the measurement accuracy.

The data and signal conductors should be separated from all high-voltage

cables.

The cable shield should be potential. With this, incoming disturbances can be

easily diverted.

The shielding should be placed over the entrance of the cabinet or housing in

order to already repel disturbances at the entrance.

2.9.2 Bus Conductors

The shielding of the bus conductor is described in the relevant assembly

guidelines and standards of the bus system.

2.9.3 Signal Conductors

Bus modules for most analog signals along with many of the interface bus

modules include a connection for the shield.

Note

For better shield performance, the shield should have previously been placed

over a large area. The WAGO shield connection system is suggested for such

an application.

This suggestion is especially applicable when the equipment can have even

current or high impulse formed currents running through it (for example

through atmospheric end loading).

Page 45

Assembly Guidelines/Standards • 39

WAGO Shield (Screen) Connecting System

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

2.9.4 WAGO Shield (Screen) Connecting System

The WAGO Shield Connecting system includes a shield clamping saddle, a

collection of rails and a variety of mounting feet. Together these allow many

dfferent possibilities. See catalog W4 volume 3 chapter 10.

Fig. 2-25: WAGO Shield (Screen) Connecting System p0xxx08x, p0xxx09x, and p0xxx10x

Fig. 2-26: Application of the WAGO Shield (Screen) Connecting System p0xxx11x

2.10 Assembly Guidelines/Standards

DIN 60204, Electrical equipping of machines

DIN EN 50178 Equipping of high-voltage systems with electronic

components (replacement for VDE 0160)

EN 60439 Low voltage – switch box combinations

Page 46

40 • Fieldbus coupler 750-342

Description

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

3 Fieldbus Coupler

3.1 Fieldbus coupler 750-342

3.1.1 Description

The fieldbus coupler 750-342 displays the peripheral data of all I/O modules

in the WAGO-I/O-SYSTEM 750 on ETHERNET.

All sensor input signals are grouped in the coupler (slave) and transferred to

the higher ranking controls (master) via the fieldbus. Process data linking is

performed in the higher ranking controls. The controls put out the resulting

data to the actuators via the bus and the node.

To be able to transmit process data via ETHERNET, the coupler supports a

series of network protocols. Process data are exchanged with the aid of the

MODBUS/TCP protocol.

Once the ETHERNET TCP/IP fieldbus coupler is connected, the coupler

detects all I/O modules connected to the node and creates a local process

image on this basis, which can be a mixed arrangement of analog (word-byword data exchange) and digital (bit-by-bit data exchange) modules.

The local process image is subdivided into an input and an output data area.

The data of the analog modules are mapped into the process image in the order

of their position downstream of the bus coupler.

The bits of the digital modules are grouped into words and also mapped into

the process image as soon as mapping of the analog modules is completed.

When the number of digital I/O’s exceeds 16 bits, the coupler automatically

starts the next word.

Also note that all process images start at WORD 0.

Information on configuration, status and the I/O data of the fieldbus node are

stored in the fieldbus coupler as HTML pages. These pages can be seen via a

standard WEB browser by typing the IP address, that you assigned the

coupler, into the Address field of your web browser.

Page 47

Fieldbus coupler 750-342 • 41

Hardware

WAGO-I/O-SYSTEM 750

ETHERNET TCP/IP

3.1.2 Hardware

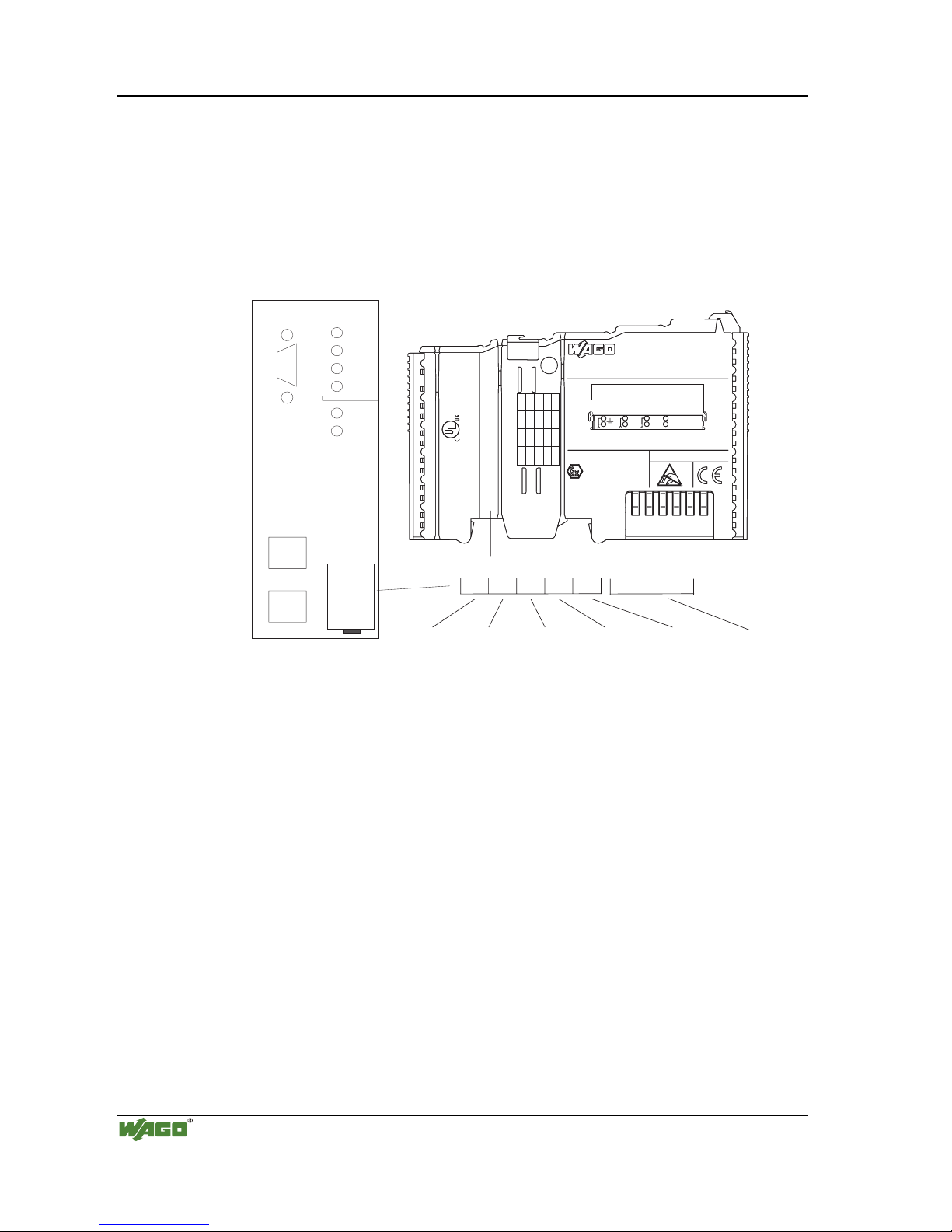

3.1.2.1 View

24V 0V

++

--

01 02

750-342

ON

LINK

TxD/RxD

I/O

ETHERNET

C

D

B

A

ERROR

0V

status

voltage supply

-power jumper contacts

-system

data contacts

supply

24V

0V

supply via

power jumper contacts

24V

0V

power jumper contacts

fieldbus

connection

RJ 45

configuration

interface

flap

open